Professional Documents

Culture Documents

Customer Responsibilities: "Agilent GC, GC/MS, and Automatic Liquid Sampler (ALS) Site Preparation Guide"

Customer Responsibilities: "Agilent GC, GC/MS, and Automatic Liquid Sampler (ALS) Site Preparation Guide"

Uploaded by

محمد محمودOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Customer Responsibilities: "Agilent GC, GC/MS, and Automatic Liquid Sampler (ALS) Site Preparation Guide"

Customer Responsibilities: "Agilent GC, GC/MS, and Automatic Liquid Sampler (ALS) Site Preparation Guide"

Uploaded by

محمد محمودCopyright:

Available Formats

7890 Series GC Site Preparation Checklist

Thank you for purchasing an Agilent Instrument. To get you started and to assure a successful and

timely installation of your 7890 GC, please refer to this site prep checklist.

Correct site preparation is the key first step in ensuring that your instruments and software systems

operate reliably over an extended lifetime. This document is a checklist prepared for you that outlines

the space, utilities, supplies and consumable requirements for your equipment for your site.

For more detailed site preparation information, refer to the

"Agilent GC, GC/MS, and Automatic Liquid Sampler (ALS) Site Preparation Guide" :

http://www.agilent.com/cs/library/usermanuals/public/7890B_SitePrepGuide.pdf

Customer Responsibilities

0B

Make sure your site meets the following specifications before the installation date. For

5B

details, see specific sections within this checklist, including:

The necessary laboratory bench space is available

The environmental conditions for the lab and gas venting

Laboratory gases and plumbing

The power requirements related to the product

The required operating supplies necessary for the product at installation

Please consult the "Other Requirements" section for other product-specific information.

If Agilent is delivering installation and familiarization services, users of the instrument

6B

should be present throughout these services; otherwise, they will miss important

operational, maintenance and safety information.

Important Customer Information

1B

1. If you have questions or problems in providing anything described under "Customer

Responsibilities" above, please contact your local Agilent or partner support/service organization

for assistance prior to delivery. In addition, Agilent and/or its partners reserve the right to

reschedule the installation dependent upon the readiness of your laboratory.

2. Should your site not be ready for whatever reasons, please contact Agilent as soon as possible to

re-arrange any services that have been purchased.

3. Other optional services such as additional training, operational qualification (OQ) and

consultation for user-specific applications may also be provided at the time of installation when

ordered with the system, but should be contracted separately.

Issued: 09-Dec-2015, Revision: 1.8 Copyright1 2013 Agilent Technologies

Page 1 of 15

7890 Series GC Site Preparation Checklist

Laboratory Bench Space - Dimensions and Weight

19B

18B

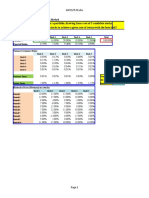

Identify the laboratory bench space before your system arrives based on the table below.

Pay special attention to the total height and total weight requirements for all system components you

have ordered and avoid bench space with overhanging shelves. Also pay special attention to the total

weight of the modules you have ordered to ensure your laboratory bench can support this weight.

Special Notes

7B

1. Allow at least 25 cm clearance between back of GC and wall to dissipate heated air. See picture

below. A simple system that includes a GC and a computer requires about 86 cm of bench space.

2. Avoid bench space with overhanging shelves. A 7683 or 7693 automatic liquid sampler will add to

the height of the instrument as shown below.

3. G1888A Headspace, 5977 GCMS and QQQ MS are installed to the left of the 7890 and the 7697

Headspace and 220/240 Ion Trap MS are installed to the right. Refer to the "Dimensions and

Weight" section of the "Agilent GC, GC/MS, and ALS Site Preparation Guide" for more detail.

Instrument Dimensions

Component Height (cm) Width (cm) Depth (cm) Weight (kg)

G3440A Agilent 7890 GC 50 to 58 59 54 50

G3440A with 3rd detector 50 to 58 68 54 57

G2913A 7683 Auto-injector 42 above GC 3.1

G2614A 7683 Tray 30 Left of GC 3.0

G4513A 7693 Auto-injector 50 above GC 3.9

2 cm in front of

G4514A 7693 Tray 45 Left of GC 6.8

GC

7890 GC with 7683 ALS System 7890 GC with 7693 ALS System

Conversions: 1 kg = 2.2 pounds; 1 cm = 0.39 inches.

Issued: 09-Dec-2015, Revision: 1.8 Copyright2 2013 Agilent Technologies

Page 2 of 15

7890 Series GC Site Preparation Checklist

Environmental Conditions

21B

20B

Operating your instrument within the recommended temperature ranges insures optimum instrument

performance and lifetime.

Special Notes

8B

1. Performance can be affected by sources of heat & cold e.g. direct sunlight, heating/cooling from

air conditioning outlets, drafts and/or vibrations.

2. The site’s ambient temperature conditions must be stable for optimum performance.

3. For storage or shipping, the allowable temperature range is -40 to 70C and the allowable

humidity range is 5-95%, non-condensing. After exposing the GC to extremes of temperature or

humidity, allow 2 hours for it to return to the recommended ranges.

4. Refer to the "Environmental Conditions" section of the "Agilent GC, GC/MS, and ALS Site

Preparation Guide" for more detail.

Operating temp Operating humidity Maximum altitude

Instrument Description range C range (%) (m)

Agilent 7890 GC, Standard Oven 15 to 35 5 - 95% 4,615

Agilent 7890 GC, Fast Oven

15 to 35 5 - 95% 4,615

(Options 002 and 003)

Agilent 7890 GC, Storage -40 to 70 5 - 95% 4,615

Conversions: 1 meter = 3.28 feet

1 BTU = 1055 Joules

Issued: 09-Dec-2015, Revision: 1.8 Copyright3 2013 Agilent Technologies

Page 3 of 15

7890 Series GC Site Preparation Checklist

Heat Dissipation

22B

Your facilities manager may wish to know the amount of heat that the system generates in order to

establish its contribution to the overall room ventilation requirements.

The following table may help you calculate the additional BTU’s of heat dissipation from this new

equipment. Maximums represent the heat given off when heated zones are set for maximum

temperatures.

Refer to the "Heat Dissipation" section of the "Agilent GC, GC/MS, and ALS Site Preparation Guide" for

more detail.

Oven type Heat dissipation

Standard oven ramp 7681 BTU / hour maximum

Fast oven ramp (options 002 and 003) 10,071 BTU / hour maximum

Venting the Oven - Oven Heat Deflector Option 306 or Part Number G1530-80650

10B

Below is a picture that shows the back view of an installed 7890 GC - with the Oven Heat Deflector

installed. The exhaust duct is 10 cm (4 inches) in diameter and adds 14 cm (5.5 inches) to the back of the

GC.

The connecting duct should provide unrestricted flow for the oven air and be as short and straight as

possible.

With the exhaust deflector installed the exhaust is about 65 CFM (ft3/min /1.840 m3/min). Without the

deflector, the exhaust rate is about 99 CFM (ft3/min /2.8 m3/min).

Refer to the "Exhaust Venting" section of the "Agilent GC, GC/MS, and ALS Site Preparation Guide" for

more detail.

Issued: 09-Dec-2015, Revision: 1.8 Copyright4 2013 Agilent Technologies

Page 4 of 15

7890 Series GC Site Preparation Checklist

Venting the uECD, TCD or Split-Splitless Inlet Vent gas flows to a Fume Hood or venting

manifold

If using a micro Electron Capture Detector, or if using hydrogen carrier gas that will be uncombusted,

you must either safely vent the exhaust gas, or operate the GC inside a fume hood.

For example, if using hydrogen carrier gas with a thermal conductivity detector (TCD) the GC would

vent uncombusted hydrogen from the detector and from the inlet split and septum purge vents.

The uECD exhaust vents through a stainless steel tube, connected to a length of large I.D. tubing that

exits the back panel. This should be routed to a fume hood or appropriate venting system. Agilent

Technologies recommends a vent line internal diameter of 6 mm (1/4-inch) or greater. With a line of this

diameter, the length is not critical. Make sure that the venting system does not put a direct negative

pressure on the vent tube from the GC.

Below is a picture that shows the back view of a 7890 GC with the micro Electron Capture Detector vent

tube exiting the back of the instrument.

Vent Line

from the

GC

Back

Panel

Issued: 09-Dec-2015, Revision: 1.8 Copyright5 2013 Agilent Technologies

Page 5 of 15

7890 Series GC Site Preparation Checklist

Power Consumption

24B

23B

The GC power consumption and requirements depend on the type of oven that you ordered and the

country the unit is shipping to.

The following table Lists the AC Power requirements for various 7890 GC configurations:

Oven Type Line Voltage (VAC) Frequency Maximum Current Rating Power Outlet

(Hz) Continuous (Amps) Rating

+/- 10%

Power (VA)

Standard Americas 120 48-63 2250 18.8 20 Amp

Single Phase Dedicated

Fast 220/230/240 Single 48-63 2950 13.4/12.8/12.3 15 Amp

or Split Phase Dedicated

Standard 220/230/240 Single 48-63 2250 10.2/9.8/9.4 10 Amp

or Split Phase Dedicated

Fast 200 Japan 48-63 2950 14.8 15 Amp

Split Phase Dedicated

Notes

1. The number and type of electrical outlets depends on the size and complexity of your system. For

example, a GC system with a computer, monitor, printer, and HUB/Switch requires 5 outlets.

2. The outlet for the GC must be dedicated to the GC with a dedicated ground.

3. The GC will have a label next to the power cord connector that lists the line voltage requirements.

Special Notes:

1. Option 003 is for any Country with standard 120/240 VAC to accommodate 208 VAC Power.

2. Power line conditioners that contribute any power line distortion should not be used with the

Agilent 7890 GC.

3. Refer to the "Power Consumption" section of the "Agilent GC, GC/MS, and ALS Site Preparation

Guide" for more detail.

4. It is important to measure the line voltage at the receptacle for the GC to insure compatibility

with the power configuration of the GC.

25B

Issued: 09-Dec-2015, Revision: 1.8 Copyright6 2013 Agilent Technologies

Page 6 of 15

7890 Series GC Site Preparation Checklist

7890 Power Cords

Refer to the "Power Consumption" section - "Common Instrument Power Cord Plugs" - of the

"Agilent GC, GC/MS, and ALS Site Preparation Guide" for more detail.

Country Voltage/Amps Wall Termination Length Plug

Australia 240 Volts - 16 Amps AS3112 2.5m

China 220 Volts - 15 Amps GB 1002 4.5m

Europe, Korea 220/230/240 - 10 Amps CEE/7/V11 2.5m

Denmark, SWISS/DENMARK

Switzerland 230 Volts - 16 Amps 1302 2.5m

India,

South Africa 240 Volts - 15 Amps AS3112 4.5m

Israel 230 Volts - 16 Amps, 16 AWG ISRAELI SI32 2.5m

Japan 200 Volts - 20 Amps NEMA L6-20P 4.5m

United

Kingdom,

Hong Kong,

Singapore,

Malaysia 240 Volts - 13 Amps BS89/13 2.5m

United States 120 Volts - 20 Amps, 12 AWG NEMA 5-20P 4.5m

240 Volts - 15 Amps (Standard)

14 AWG

United States 208 Volts - 15 Amps (Opt 003) NEMA L6-15P 2.5m

Taiwan,

South America 120 Volts - 20 Amps, 12 AWG NEMA 5-20P 2.5m

Issued: 09-Dec-2015, Revision: 1.8 Copyright7 2013 Agilent Technologies

Page 7 of 15

7890 Series GC Site Preparation Checklist

Gas Selection

27B

26B

Special Notes

12B

1. Refer to the "Gas and Reagent Selection" section in the "Agilent GC, GC/MS and ALS Site

Preparation Guide" for more detail.

2. Agilent recommends a carrier and detector gas purity of 99.9995% or better. Air for flame

detectors should be zero grade. Agilent also recommends using traps to remove hydrocarbons,

water, and oxygen.

3. When used with capillary columns, GC detectors require a separate makeup gas for optimum

sensitivity. This table lists gas recommendations for capillary columns and the preferred makeup

gas types.

4. The inlet electronic pressure control (EPC) modules are calibrated for up to 4 carrier gases:

Split/Splitless capillary (SS), Purged packed (PP), Programmable temperature vaporization

(PTV), Multi-Mode (MM), and cool on-column (COC) are calibrated for Helium, Hydrogen,

Nitrogen, and Argon methane 5%.

Volatiles inlet VI is calibrated for only Helium and Hydrogen.

5. For GC/MS requirements, refer to the "GC/MS Gas and Reagent Requirements" section in the

"Agilent GC, GC/MS and ALS Site Preparation Guide"

Make up Make up

Detector Carrier gas 1st choice 2nd choice Purge or reference

Hydrogen* Argon/methane 5% Nitrogen Note: ArMe makeup provides

Electron Helium Argon/methane 5% Nitrogen maximum Dynamic Range

capture Nitrogen Nitrogen Argon/methane 5% Nitrogen makeup provides

Argon/methane Argon/methane 5% Nitrogen maximum Sensitivity

Hydrogen Nitrogen Helium

Flame

Helium Nitrogen Helium Hydrogen* and air for detector

ionization

Nitrogen Nitrogen Helium

Hydrogen* Nitrogen

Flame Helium Nitrogen

Nitrogen None Hydrogen* and air for detector

photometric Nitrogen

Argon Nitrogen

Nitrogen Helium Nitrogen Helium

Hydrogen* and air for detector

phosphorous Nitrogen Nitrogen Helium

Hydrogen* Must be same as

Thermal Must be same as Reference must be same as

Helium carrier and

conductivity carrier and reference carrier and makeup

Nitrogen reference

* See "Considerations For Hydrogen Carrier Gas" in this document.

Issued: 09-Dec-2015, Revision: 1.8 Copyright8 2013 Agilent Technologies

Page 8 of 15

7890 Series GC Site Preparation Checklist

Gas Supply Pressures

29B

28B

Special Notes

13B

1. Refer to the "General Requirements" section under "Gas Supplies" in the "Agilent GC, GC/MS and

ALS Site Preparation Guide" for more detail.

2. The following tables list minimum and maximum pressures in psi for each electronic pneumatic

control module (EPC). These requirements are for the input to the EPC module located at the

back of the gas chromatograph. Conversions: 1 psi = 6.8947 kPa = 0.068947 Bar = 0.068 ATM.

Detectors

30B

FID NPD TCD ECD FPD

Hydrogen 35-100 35-100 45-100

Air 55-100 55-100 100-120

Make up 55-100 55-100 55-100 55-100 55-100

Reference 55-100

Auxiliary EPC and Pneumatic Control channels

31B

The minimum supply pressure for AUX and PCM modules is 20 psi greater than pressure used in your

method. For example, if you need a pressure of 20 psi for the method, the supply pressure must be at

least 40 psi.

AUX EPC PCM 1 PCM 2 or PCM Aux

Maximum 120 with Forward pressure control

120 120

pressure 50 with Back pressure control

Inlets

32B

The minimum supply pressure for inlet modules is 20 psi greater than pressure used in your method.

For example, if you need a pressure of 40 psi for the method, the supply pressure must be at least 60 psi.

SSL 150 SSL 100 MMI PPIP PCOC PTV

Carrier max 170 120 170 120 120 120

Issued: 09-Dec-2015, Revision: 1.8 Copyright9 2013 Agilent Technologies

Page 9 of 15

7890 Series GC Site Preparation Checklist

Gas Plumbing and Supplies

33B

Plumbing Considerations

1. Refer to the "Gas Plumbing" section in the "Agilent GC, GC/MS and ALS Site Preparation Guide"

for more detail.

2. Gases are supplied by tanks, internal distribution system, or gas generators. Tank supplies

require two stage, pressure regulation. To connect tubing to the supply, it must have one 1/8-inch

Swagelok female connector for each gas. Make sure that your regulator has the appropriate

sized adapter to end with a 1/8-inch Swagelok female connector.

3. If your order did NOT include parts to connect the gas supply to your 7890 GC, you must supply

pre-cleaned, 1/8-inch copper tubing and a variety of 1/8-inch Swagelok fittings to connect the

gas supply(s). Refer to the "GC Installation Kits" and "GC Plumbing" sections of this checklist for

Part Numbers.

4. Never use liquid thread sealer to connect fittings. Never use chlorinated solvents to clean

tubing or fittings.

5. Agilent also recommends using traps to remove water, hydrocarbons, and oxygen or a

combination trap such as the "Gas Clean" Filter System that removes all three.

Tank

Regulators

must

terminate

in a 1/8"

Swagelok

fitting

Special Notes

1. Shutoff Valves are recommended at both front and back Inlet Carrier Connections

2. FID, FPD and NPD need dedicated detector air supply

3. For Gas supply runs longer than 15 feet, use 1/4 inch tubing to prevent pressure drop

4. Do not reuse old copper tubing which can become brittle and break

Gas Clean Filter Configurations

Refer to the "Gas Plumbing/Filters and Traps" section of the "Agilent GC, GC/MS, and ALS Site

Preparation Guide" for more detail. Another good resource is the "Agilent Gas Clean Filter System User

Manual" - http://www.chem.agilent.com/Library/usermanuals/Public/GasCleanFilter_5973-1528.pdf

Issued: 09-Dec-2015, Revision: 1.8 Copyright10 2013 Agilent Technologies

Page 10 of 15

7890 Series GC Site Preparation Checklist

Tank Regulator Table

All Agilent regulators are supplied with the 1/8-inch Swagelok female connector.

Gas Type CGA Number Pressure Range Part Number

Air 346 0-125 PSIG (8.6 Bar) 5183-4641

Hydrogen, Argon/Methane 350 0-125 PSIG (8.6 Bar) 5183-4642

Oxygen 540 0-125 PSIG (8.6 Bar) 5183-4643

Helium, Argon, Nitrogen 580 0-125 PSIG (8.6 Bar) 5183-4644

Air 590 0-125 PSIG (8.6 Bar) 5183-4645

Common Plumbing Supplies

Recommended Supplies to make the GC system installation go smoother.

Description Part number

1/8 inch Copper Tubing - pre-washed - 50 feet 5180-4196

1/8 inch thick wall Stainless Steel Tubing - 20 Feet 7157-0210

1/8 inch Ball Shutoff Valve for Carrier Gas Supplies (order 1 for each inlet system) 0100-2144

PTFE tape (Never use liquid thread sealer to connect fittings.) 0460-1266

Miscellaneous Gas Plumbing Information

1. Cryogenic cooling with Liquid N2 requires 1/4-inch insulated copper tubing – 25-30 PSI supply.

2. Cryogenic cooling with Liquid CO2 requires 1/8-inch heavy-walled, stainless steel tubing –

750-1000 PSI supply – tank with dip (syphon) tube.

3. Cryogenic Liquid CO2 coolant must be free of particulate material, oil, and other contaminants -

A 2 micron particulate filter is provided with the Liquid CO2 Cryogenic cooling accessories.

4. Internal Valco rotary Valve actuation requires a separate pressurized, dry air at 55 psi.

5. If you have not requested option 305 (pre-plumbed GC), you must supply pre-cleaned, 1/8-inch

copper tubing and a variety of 1/8-inch Swagelok fittings to connect the GC to inlet and detector

gas supplies.

Issued: 09-Dec-2015, Revision: 1.8 Copyright11 2013 Agilent Technologies

Page 11 of 15

7890 Series GC Site Preparation Checklist

Considerations for Hydrogen Carrier Gas

If planning to use hydrogen carrier gas, note that special considerations apply due to hydrogen’s

flammability and chromatographic properties. Refer to the to the "Gas Supplies/Requirements for

Hydrogen as a Carrier Gas" section in the "Agilent GC, GC/MS and ALS Site Preparation Guide" for more

detail.

Hydrogen Safety

When using hydrogen as the carrier gas or fuel gas, be aware that hydrogen gas can flow into the GC

oven and create an explosion hazard. Therefore, be sure that the Hydrogen gas supply is turned off until

all connections are made and ensure the inlet and detector column fittings are either connected to a

column or capped at all times when hydrogen gas is supplied to the instrument.

In any application using hydrogen, leak test all connections, lines, and valves before operating the

instrument.

Agilent highly recommends the G3388B Leak Detector or equivalent to safely check for leaks.

Supply tubing for Hydrogen Gas

Agilent recommends using NEW, chromatographic quality copper or stainless steel tubing and fittings

when using hydrogen.

Do not re-use old tubing when installing or switching to hydrogen carrier gas. Hydrogen gas tends to

remove contaminants left on old tubing by previous gases (by helium, for example).

These contaminants can appear in detector output as high background noise or hydrocarbon

contamination for several weeks.

Do not use old copper tubing with hydrogen gas. Old copper tubing can become brittle and create a

safety hazard.

Hydrogen Gas Supplies

Hydrogen can be supplied from a gas generator or from a cylinder.

Agilent recommends use of a high-quality hydrogen gas generator. A high-quality generator can

consistently produce purity > 99.9999%, and the generator can include built-in safety features such as

limited flow rates, and auto-shutdown.

If using a hydrogen gas cylinder, Agilent recommends use of Gas Clean Filters to purify the gas.

Consider additional safety equipment as recommended by your company safety personnel.

Issued: 09-Dec-2015, Revision: 1.8 Copyright12 2013 Agilent Technologies

Page 12 of 15

7890 Series GC Site Preparation Checklist

GC Installation Kits

Pre-configured kits to make the GC system installation go smoother.

All kits include two Shutoff valves - one for each inlet carrier supply.

Description Part number

Installation Kit for FID/NPD/FPD (Includes Gas Clean Filter Kit CP736538) for Moisture, O2 and

Hydrocarbon removal.

19199N

Installation Kit for TCD/ECD/MSD - no Gas Filters Included - order separately for ECD - Gas

Clean Filter is included with MSD.

19199M

Issued: 09-Dec-2015, Revision: 1.8 Copyright13 2013 Agilent Technologies

Page 13 of 15

7890 Series GC Site Preparation Checklist

Other Requirements

38B

37B

Your Agilent 7890 GC comes with an analytical column: 19091J-413 (HP5, 30 meter, 0.32mm x 0.25µm).

Our checkout standards are designed to work with this column. In many cases, you will need to select a

different column for your application. For information on GC Column Selection, refer to:

http://www.agilent.com/cs/library/catalogs/Public/5990-9867EN_GC_CSG.pdf

Tools and Consumables Supplied with your GC

Tool or consumable Used for

Inlet wrench for Turn Top - Split/Splitless

Replacing inlet septa and liners

and Multimode Inlets only.

¼-inch nut driver - FID Only FID/NPD jet replacement

¼-inch X 5/16 inch wrenches Column Installation

FID flow measuring insert FID troubleshooting

Ceramic wafer column cutter Column installation

1/8-inch nuts & ferrules, Swagelok, brass Connect gas supplies

Inlet septa appropriate for type Injection port seal

Inlet insert or liner Injection port

Capillary Column Ferrules - Graphite Column installation

2 Capillary Column Nuts Column installation

2 Column Hangers Column installation

Gas ID Labels For Labeling Gas Supply Tubing to Inlets and Detectors

LAN Cable Communication to the GC

Recommended Tools for GC Maintenance

Tool Used for

Basic Tools in a zipper tool bag

GC Tool Kit - 5182-3456

(Included with the Installation Kit Part Number 19199M)

ECD/TCD Detector plug, 5060-9055 Inlet pressure decay test.

Digital flow meter 220-1170 Verifying flows, checking for leaks and plugs.

Electronic gas leak detector - G3388B Pin pointing gas leaks. Safety checks when using Hydrogen.

T10 Torx driver - 5182- 3466 Remove FID Collector. Remove covers to access EPC modules, traps.

T20 Torx driver - 5182- 3465 Replace NPD Bead.

Tubing cutter for 1/8-inch Copper and 1/16

Cut gas supply tubing

inch Stainless Steel. - 5190-1442

Assorted wrenches: ¼, 3/8, 7/16, 9/16 inch Gas supply and plumbing fittings.

Assure consistently air tight vial closure no matter who does the

Electric vial crimper - 5190-3188-P

crimping.

Issued: 09-Dec-2015, Revision: 1.8 Copyright14 2013 Agilent Technologies

Page 14 of 15

7890 Series GC Site Preparation Checklist

Recommended Supplies for GC Maintenance

First time GC users should consider stocking the following supplies to maintain their system. Please

refer to the Agilent Consumables and Supplies Catalog for part numbers and recommended maintenance

periods or visit http://www.chem.agilent.com/en-US/Promotions/pages/catalog.aspx

Supply Used for

Inlet supplies Septa, O-rings, liners, adapter, and seals

Inlet PM kits Kits with individual parts needed to maintain an inlet.

Column supplies Nuts, ferrules, adapters, guard columns, retention gaps

Detector supplies Jets, beads, liners, adapters, cleaning kits

Application supplies Standards, columns, syringes

Sampler supplies Vials, caps, electronic crimpers, and syringes.

Autosampler Hardware from Older Systems

2B

If you previously purchased samplers and would like to use these on your new GC, the samplers may

need firmware updates. Sampler models that are compatible include: 7683A and 7693A ALS;

and 7694B and 7697A Headspace Samplers.

This information is subject to change. For more details on software and hardware compatibility, please

contact your sales representative.

Important Customer Web Links

3B

For additional information about our solutions, please visit our web site at:

http://www.agilent.com/home

Customer Education – http://www.agilent.com/crosslab/university/

Detailed Site Preparation Manual:

http://www.agilent.com/cs/library/usermanuals/public/7890B_SitePrepGuide.pdf

Need supplies? – http://www.agilent.com/chem/supplies

HU U

Document part number: G3430-90001

Issued: 09-Dec-2015, Revision: 1.8 Copyright15 2013 Agilent Technologies

Page 15 of 15

You might also like

- Wipro Technologies Sal Slip AprDocument1 pageWipro Technologies Sal Slip Aprssvishal50% (10)

- Mental Math Number Talk Strategies PDFDocument26 pagesMental Math Number Talk Strategies PDFwargoNo ratings yet

- StartupOperating&MaintSTD - RFG1 Fuel Gas SkidDocument14 pagesStartupOperating&MaintSTD - RFG1 Fuel Gas Skidczekjo100% (1)

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- Automotive Air Conditioning and Climate Control SystemsFrom EverandAutomotive Air Conditioning and Climate Control SystemsRating: 4 out of 5 stars4/5 (6)

- Fast RGA ManualDocument28 pagesFast RGA ManualhopkhtnNo ratings yet

- 7890 Series GC Preventive Maintenance ChecklistDocument7 pages7890 Series GC Preventive Maintenance Checklistمحمد محمود100% (1)

- Owner & Operator's Manual: ModelsDocument16 pagesOwner & Operator's Manual: ModelskmpoulosNo ratings yet

- 7890 Series GC Preventive Maintenance ChecklistDocument7 pages7890 Series GC Preventive Maintenance Checklistمحمد محمود100% (1)

- Engineering Graphics Class XI BookDocument312 pagesEngineering Graphics Class XI Bookpranavvarma182% (11)

- Agilent GC 8890 Site Preparation ChecklistDocument19 pagesAgilent GC 8890 Site Preparation ChecklistZia HaqNo ratings yet

- 5977 Series MSD Site Preparation ChecklistDocument11 pages5977 Series MSD Site Preparation ChecklistLorentzNo ratings yet

- Agilent 6890n DatasheetDocument5 pagesAgilent 6890n DatasheetMayar SayedNo ratings yet

- G6400 LCMS Site Preparation ChecklistDocument10 pagesG6400 LCMS Site Preparation ChecklistAtul SharmaNo ratings yet

- 1260 Infinity II SFC SIPCh en SD 29001835Document9 pages1260 Infinity II SFC SIPCh en SD 29001835Lucero MarinNo ratings yet

- Agilent 7890A Gas ChromatographDocument16 pagesAgilent 7890A Gas ChromatographDuodo NguyenNo ratings yet

- Buck 210 211 Users ManualDocument103 pagesBuck 210 211 Users ManualjfmflNo ratings yet

- The Agilent 7890A Gas Chromatograph: All The Elements For Perfect ChemistryDocument16 pagesThe Agilent 7890A Gas Chromatograph: All The Elements For Perfect ChemistrykholisenangNo ratings yet

- 5100-5110 ICP-OES Site PreparationChecklistDocument6 pages5100-5110 ICP-OES Site PreparationChecklistahmedNo ratings yet

- Kti Agilent 3000 Manual v1.8Document10 pagesKti Agilent 3000 Manual v1.8Zakir BashaNo ratings yet

- HVAC ManualDocument50 pagesHVAC ManualsdgdsdaNo ratings yet

- 1220Infinity-Infinity2-LC Site Preparation ChecklistDocument5 pages1220Infinity-Infinity2-LC Site Preparation ChecklistYudi - PT. Laborindo SaranaNo ratings yet

- t7000 6cng50 ManualDocument49 pagest7000 6cng50 ManualAlsheikh875No ratings yet

- AMC Final - IKEA WORLIDocument10 pagesAMC Final - IKEA WORLIAmanNo ratings yet

- 6890 GC Site Preparation ChecklistDocument4 pages6890 GC Site Preparation Checklistigor_239934024No ratings yet

- Convenient Functions of GC-2014: Gas ChromatographyDocument2 pagesConvenient Functions of GC-2014: Gas ChromatographyShashank ChoudharyNo ratings yet

- 6850 BrochureDocument8 pages6850 BrochureThanh Thanh Hai LeNo ratings yet

- Service Literature 80Mgf Series Units: Corp. 9801 L2 Revised 08 2004Document46 pagesService Literature 80Mgf Series Units: Corp. 9801 L2 Revised 08 2004askew9103No ratings yet

- 7697A Headspace Samplers Site Preparation ChecklistDocument7 pages7697A Headspace Samplers Site Preparation ChecklistnileshdhamorikarNo ratings yet

- Almacen Sunarp - B - GCM - 01Document17 pagesAlmacen Sunarp - B - GCM - 01Sicologo CimeNo ratings yet

- g3620 Sgoas Brochure 2012Document4 pagesg3620 Sgoas Brochure 2012Khasin FuadiNo ratings yet

- 7890A Series GC G3440A PM Checklist G3430-90004Document3 pages7890A Series GC G3440A PM Checklist G3430-90004Yony Jhontan Guerreros IñigoNo ratings yet

- 01200-90600 HW1200SitePreparationDocument11 pages01200-90600 HW1200SitePreparationManickam EllampoorananNo ratings yet

- Back Groung CorrectorDocument10 pagesBack Groung Correctorttv12linttNo ratings yet

- Agilent 6850 Site Prep PDFDocument4 pagesAgilent 6850 Site Prep PDFFrancesco MoriscoNo ratings yet

- Carrier 2trDocument15 pagesCarrier 2trfernandoreyes893No ratings yet

- 4000 GC/MS: Pre-Installation InstructionsDocument9 pages4000 GC/MS: Pre-Installation InstructionsZia HaqNo ratings yet

- 22 1739 04 - 02012010XXDocument16 pages22 1739 04 - 02012010XXMartinez MarNo ratings yet

- Catalogohce090 150Document18 pagesCatalogohce090 150Xol DiaMa GarciaNo ratings yet

- G61MPV - 09 01 2007Document104 pagesG61MPV - 09 01 2007Baryonyx Troodon100% (1)

- Lennox G21 and GSR21Document99 pagesLennox G21 and GSR21schrieberdieses100% (1)

- Trane AnalisisDocument13 pagesTrane AnalisisHendri PoerbaNo ratings yet

- T0220 PDFDocument35 pagesT0220 PDFChristian Andres PantojaNo ratings yet

- Bosch Greenstar ZWBR 7-25 A23 Gcno.46-311-44 Boiler Installation and Service ManualDocument36 pagesBosch Greenstar ZWBR 7-25 A23 Gcno.46-311-44 Boiler Installation and Service ManualMerlin1950No ratings yet

- 38hdt PDDocument12 pages38hdt PDDoan Tien Do100% (1)

- Gas Transmitter: AKO-575xxxDocument28 pagesGas Transmitter: AKO-575xxxAmic BanatNo ratings yet

- Potterton Suprima 30-100LDocument64 pagesPotterton Suprima 30-100LMartin Lee SmithNo ratings yet

- 0405Document27 pages0405miguelin226No ratings yet

- Xr8-G and Xr8-E: Mini Rack Oven Installation - Operation - MaintenanceDocument24 pagesXr8-G and Xr8-E: Mini Rack Oven Installation - Operation - Maintenancefranklin nicolaldeNo ratings yet

- GC, MS, ALS Installation Checklist - G7000-90033Document8 pagesGC, MS, ALS Installation Checklist - G7000-90033bert_avitia_1No ratings yet

- Agilent 7890B Gas ChromatographDocument24 pagesAgilent 7890B Gas ChromatographFernando González FloresNo ratings yet

- Quantidade Líquido ArrefecedorDocument2 pagesQuantidade Líquido Arrefecedorwagner_guimarães_1No ratings yet

- J1415 Omm R0 PDFDocument34 pagesJ1415 Omm R0 PDFCarlos MagNo ratings yet

- Agilent G1316 90011 TCC A B C EbookDocument126 pagesAgilent G1316 90011 TCC A B C EbookTimor ForexNo ratings yet

- Screw Compressor Controller PDFDocument28 pagesScrew Compressor Controller PDFMohan Raj100% (1)

- 210 VGP PDFDocument100 pages210 VGP PDFKim Uyên VõNo ratings yet

- Smart Charge Ii Gas Handling System: P/N 861-018 Rev. EDocument33 pagesSmart Charge Ii Gas Handling System: P/N 861-018 Rev. Ee3965No ratings yet

- CAT C175-16 2.5eMW Tier 4i QuoteDocument13 pagesCAT C175-16 2.5eMW Tier 4i Quoteraybugler100% (1)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsFrom EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsNo ratings yet

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- Structure Selection: Flexible Coupling - Slit - TypeDocument4 pagesStructure Selection: Flexible Coupling - Slit - Typeمحمد محمودNo ratings yet

- MSX 41 Various Part Numbers by Concentration 20TOL40HEX40ISO SdsDocument6 pagesMSX 41 Various Part Numbers by Concentration 20TOL40HEX40ISO Sdsمحمد محمودNo ratings yet

- 5991-hplc 1260 Mid DistDocument6 pages5991-hplc 1260 Mid Distمحمد محمودNo ratings yet

- 5991-hplc in Jet FuelDocument4 pages5991-hplc in Jet Fuelمحمد محمودNo ratings yet

- PHYS 3616E Chap91Document15 pagesPHYS 3616E Chap91johnNo ratings yet

- Kinetics QPDocument22 pagesKinetics QPdovidNo ratings yet

- Concrete Mix Design, Form Design, and Engineering: Pdhonline Course C291 (4 PDH)Document65 pagesConcrete Mix Design, Form Design, and Engineering: Pdhonline Course C291 (4 PDH)Mahsa Janati100% (1)

- Serviceability Limit StateDocument12 pagesServiceability Limit StateMohamad Salleh YassinNo ratings yet

- HDG Kla Gard enDocument2 pagesHDG Kla Gard enVictor ManuelNo ratings yet

- OverheadsDocument22 pagesOverheadsOlha LNo ratings yet

- Devore Ch. 1 Navidi Ch. 1Document16 pagesDevore Ch. 1 Navidi Ch. 1chinchouNo ratings yet

- SIM SAMPLE Distance Between Two PointsDocument14 pagesSIM SAMPLE Distance Between Two PointsDIOSDADO MADRONIONo ratings yet

- Excel SolverDocument10 pagesExcel SolverSumant SharmaNo ratings yet

- Latex ManualDocument160 pagesLatex Manualcd_levyNo ratings yet

- Iocl 5Document4 pagesIocl 5Knowledge AddaNo ratings yet

- EZ Voice User ManualDocument23 pagesEZ Voice User ManualmagalyNo ratings yet

- How AI Can Pump New Life Into Oilfields: Fueling Oil and Gas Industry PerformanceDocument12 pagesHow AI Can Pump New Life Into Oilfields: Fueling Oil and Gas Industry PerformancesaeedNo ratings yet

- Lab 7Document14 pagesLab 7stiviNo ratings yet

- Lecture 16Document36 pagesLecture 16Elsayed ElazazyNo ratings yet

- Basic Procedures at Outcrops PDFDocument29 pagesBasic Procedures at Outcrops PDFGian0% (1)

- Appendix C: Cocol Grammar For The Clang Compiler/interpreterDocument14 pagesAppendix C: Cocol Grammar For The Clang Compiler/interpreterKui MangusNo ratings yet

- DE+MPLAB AssignmentDocument8 pagesDE+MPLAB AssignmentBeena ShettyNo ratings yet

- ABB Technical Application Papers - Vol. 2 MVLV Transformer SubstationsDocument42 pagesABB Technical Application Papers - Vol. 2 MVLV Transformer SubstationsASM_213No ratings yet

- MATH G4 IDEALEQ4 W3 MELC56-58 Lesson ExemplarDocument6 pagesMATH G4 IDEALEQ4 W3 MELC56-58 Lesson ExemplarJEFFREY SORIANONo ratings yet

- Chapter 6 TestDocument7 pagesChapter 6 TestBrianNo ratings yet

- 12 Rules For Good Cursive HandwritingDocument2 pages12 Rules For Good Cursive HandwritingMagdNo ratings yet

- Final 2020 SolutionDocument12 pagesFinal 2020 SolutionShokhrud SafarovNo ratings yet

- On AstrologyDocument9,640 pagesOn Astrologyshridhar joshiNo ratings yet

- XSharp Cahors (2.13.2.2)Document882 pagesXSharp Cahors (2.13.2.2)hobec52288100% (1)

- Modeling Thermal Expansion in Ansys: 6/24/2017 Alex Grishin, PHDDocument24 pagesModeling Thermal Expansion in Ansys: 6/24/2017 Alex Grishin, PHDAchmad Nur HusainiNo ratings yet

- Emona DATEx Vol1 LabManual E2 Student v3Document400 pagesEmona DATEx Vol1 LabManual E2 Student v3Tom Kigezi0% (1)