Professional Documents

Culture Documents

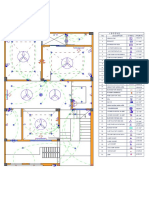

Plot Stamp - A1 - Adv 20-01-20-Electrical.

Plot Stamp - A1 - Adv 20-01-20-Electrical.

Uploaded by

nadeem UddinOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Plot Stamp - A1 - Adv 20-01-20-Electrical.

Plot Stamp - A1 - Adv 20-01-20-Electrical.

Uploaded by

nadeem UddinCopyright:

Available Formats

lista e indekseve / INDEX LIST

IND. OF DESCRIPTION OF CHANGES

00 04.03.19 revision (interior work - gypsum walls, doors, finishes in levels)

LEGEND

GENERAL NOTES:

1. PVC conduits shall be used concealed.

2. Where conduits are surface run in ceiling voids, shaft spaces, plant rooms etc, Galvanized EMT or RSC shall

be used. Adaptation between PVC and metal conduits shall be through metal bboxes.

3. Metal conduits either RSC or Electrical Metallic Tubings (EMT) shall be installed in exposed location as

required.

ELECTRICAL S/S 4. Type and size of the cables should be as per approved loads of the equipments and exposed location as

FAC1 - MET. PROC COMPOSITE INSUL F. TOILETTE & LOCKER GREY WATER T.P. required.

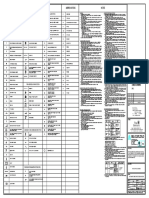

G.I.S. METERED RING MAIN UNIT 5. Contractor is responsible for any component requirement in DBs, based on the final approval of the

15.2 kV, 400 A, 60 Hz, 25 kA/1sec, G.I.S. DB DB DB DB equipments, meeting the safety requirements, without extra time and cost impact.

6. This drawing should be read in conjunction with the requirement of actual Lux of the light fixtures, approved

CC EC CC EC CC EC CC EC loads of mechanical equipments.

400 A 400 A 7. This drawing is to be coordinated with the actual location of the equipments, other services.

400 A

25kA/1s 25kA/1s 8. The lighting and power distribution boards are to be installed with top ends at 1800 mm AFF, unless

25kA/1s otherwise indicated and coordinated on the site.

9. All electrical installation, wiring accessories in mechanical rooms are to be of weather proof type.

400 A 10. Conduits, either PVC or EMT/RSC show in this drawing are indicative only. Actual routing shall be as per site

M 33/0.22kV 400 A condition, considering the minimum bends.

25kA 200 VA, cl.1 25 kA

11. All the wires shall be color coded as Red, Yellow, Blue, Black and Yellow/Green for Phase A, B, C, Neutral

400-200/5/5a and Earth.

3

15 VA, 5p10 2 2 2 2 12. Mounting height of the wiring accessories shall be coordinated with the requirements by equipment and

appliances suppliers,

33 kV 10 V, Cl. 0.5 33 kV

XLPE XLPE NOTE:

a. RATING OF THE EQUIPEMENT ARE

2

TENTATIVE, ACTUAL RATING WILL BE AS

400 A PER FINAL LOAD SCHEDULE AND

25kA/1s DG SET

SCHEMATIC DIAGRAM.

0.4/0.231kV 230/250 kVA b. PANEL ARRANGEMENT IN MDB ROOM IS

(OPTIONAL) TENTATIVE, SHALL BE RE-ARRANGED

17.5kV 60 Hz

220 VAC ONCE EQUIPEMENT SELECTION DONE.

P.F. 0.8

CABLE XLPE

13.8kV ~ 60 Hz

UPS

~

50 Ah

2500 kVA

Dyn 11 400 A

=

0.4 kV

COMMOM OFFICE BUILDING MAIN DB & GROUND FLOOR

LV CABLE LV CABLE LV CABLE

LV DISTRIBUTION BOARD

ESSENTIAL CONSUM (EC) COMMON CONSUM (CC)

0.4/0.11 kV 2000 A M 0.4/0.11 kV

M

400 A

100 VA, Cl.1.0 50 kA 100 VA,

0.4/0.231, 400 A, 60 Hz, 50 kA/1sec 0.4/0.231, 400 A, 60 Hz, 50 kA/1sec Cl.1.0

400 A

50kA

M

FAC2. TEST LAB

GALVANIZING PLANT

CONNECTION POINT

METAL PROCESS P.

METAL PROCESS F.

NON FERROUS F.P.

TREATMENT PLANT

TREATMENT PLANT

NON FERROUS F.F.

INSULATORS FACT.

INSULATORS FACT.

200 kVA (FUTURE)

SECURITY ROOMS

COMMON OFFICE

COMMON OFFICE

TOILETTE BLOCK

TOILETTE BLOCK

GALVANIZING P.

FIREFIGHTING

LNG STATION

WATER TANK

LOCK. ROOM

LOCK. ROOM

GREY WATER

COMPOSITE

COMPOSITE

GREY WATR

CAP. BANK

BUILDING

BUILDING

TEST LAB

WATER

SPARE

SPARE

SPARE

SPARE

SPARE

FAC 1.

FAC 2.

FAC 2.

FAC 2.

FAC2.

FAC2.

FAC1.

2 2 2 2 2

2

EC

DB

CC EC

DB

CC EC

DB

CC

A-1 FORMAT

COMMON OFFICE COMMON OFFICE COMMON OFFICE

FIRST FLOOR SECOND FLOOR ROOF Factory for Manufactoring

Building

Fittings&Accessories in KSA

NOTE:

AUTOMATIC TRANSFER SWITCH WITH OTHER ACCESSORIES

SHALL BE PLACED IN DG SET CONTROL PANEL MAS-ADEA

Investor

ARABIA CO

LEGEND:

1 - CONTACTOR

2 - POWER LV CABLES

Consultant AD VISION

2 2 2 2 2 2 2 EC - ESSENTIAL CONSUMERS

ENGINEERING

CC - COMMON CONSUMERS

DESIGN TEAM SIGNATURE

ARCHITECTURE, LANDSCAPE DESIGN:

1. Arch. Edlira Braja Lic ...............

2. Arch. Elio Shala Lic ...............

CC EC CC EC CC EC CC EC CC EC CC EC CC EC 3. Arch. Erald Dervishi Lic ...............

DB DB DB DB DB DB DB 4. Arch. Andrea Rapo Lic ...............

FAC2 - TEST LAB. FAC2 - NON FERR. FAC2 - GALVAN. SECURITY ROOM 1&2 FIRE FIGHT WATER LDG STATION WATER RESERV

STRUCTURAL DESIGN:

TANK 1. Eng. Arben Ahmati Lic................

ELT, ITT DESIGN:

1. Eng. Jorgo Harizi Lic ...............

MEP,FF, INFRASTRUCTURE DESIGN:

1. Eng. Avni Dervishi Lic ...............

1. Eng. Fatjon Shaha Lic ...............

1. Eng. Sofia Rubati Lic ...............

1. Eng. Fogert Cuku Lic ...............

DRAWING: FILE NAME

SINGLE LINE DIAGRAM B1-ELT-100.00[SLD].dwg

SCALE DATE

- 11.01.2020

You might also like

- Fire Alarm Sys Nec 760Document10 pagesFire Alarm Sys Nec 760nadeem Uddin100% (1)

- EE-17 Grounding System Riser Diagram and Grounding System LayoutDocument1 pageEE-17 Grounding System Riser Diagram and Grounding System LayoutLarry Nel L. DungoNo ratings yet

- BOM Electrical ComponentsDocument3 pagesBOM Electrical Componentslinkin_slayerNo ratings yet

- J-Head Operations and Maintenance Manual P/N 315-4110-901 Rev. KDocument92 pagesJ-Head Operations and Maintenance Manual P/N 315-4110-901 Rev. KNickel de la CruzNo ratings yet

- KKMC WS5 Elec PresentationDocument52 pagesKKMC WS5 Elec PresentationHuynh Ngoc NghiaNo ratings yet

- Career Objective: Academic QualificationDocument1 pageCareer Objective: Academic QualificationMUBASHIRNo ratings yet

- 4Cx25mm AL/XLPE/SWA/PVC + 1Cx16mm CU/PVC ECC: Uncontrolled If PrintedDocument1 page4Cx25mm AL/XLPE/SWA/PVC + 1Cx16mm CU/PVC ECC: Uncontrolled If PrintedWael AlmassriNo ratings yet

- Architectural As Built ModelDocument1 pageArchitectural As Built ModelPATRICK JOHN EMERSON VISAYANo ratings yet

- Ibusway AECOMDocument25 pagesIbusway AECOMSargurusivaNo ratings yet

- Combined DrawingDocument1 pageCombined DrawingWael AlmassriNo ratings yet

- LDN Approved Drawings1Document3 pagesLDN Approved Drawings1shaikhsajid242No ratings yet

- NMP Guidelines - WWDocument66 pagesNMP Guidelines - WWOmerNo ratings yet

- Street Lighting Technology ComparisonDocument7 pagesStreet Lighting Technology ComparisonManoj KavediaNo ratings yet

- Key Single Line Diagram: Earth Pits Secondary Earth Bar Cable Sealing End 33kV Isolator CTDocument1 pageKey Single Line Diagram: Earth Pits Secondary Earth Bar Cable Sealing End 33kV Isolator CTVipinraj KrishnanNo ratings yet

- Saudi Arabian Oil Company: TY P AX 9 0 0Document1 pageSaudi Arabian Oil Company: TY P AX 9 0 0billNo ratings yet

- Central Battery System Schematic DiagramDocument1 pageCentral Battery System Schematic DiagramPeter K PaulNo ratings yet

- Street LightingDocument15 pagesStreet Lightingpolita1No ratings yet

- 10 - 02 - 16 - Temporary Single Line DiagramDocument1 page10 - 02 - 16 - Temporary Single Line Diagrammudassir mNo ratings yet

- EnergyCalculator AspxDocument2 pagesEnergyCalculator AspxWael AlmassriNo ratings yet

- 03 - BRIA FLATS - Electrical Works Technical SpecsDocument83 pages03 - BRIA FLATS - Electrical Works Technical SpecsChristian PechaNo ratings yet

- D-AAA-CIV-LIGHT (Rev.0-2019) Data SheetDocument12 pagesD-AAA-CIV-LIGHT (Rev.0-2019) Data SheetWael AlmassriNo ratings yet

- 2020 149-Feb-Schematic For Fire Pump ConnectionDocument1 page2020 149-Feb-Schematic For Fire Pump Connectionbhima irabattiNo ratings yet

- ADDC HV Permanent Connection ProcedureDocument6 pagesADDC HV Permanent Connection ProcedureAyman ShwalyNo ratings yet

- Electrical Specs KsaDocument75 pagesElectrical Specs KsaMEP299 MAPUANo ratings yet

- One-Line Diagram - TANJUNG TABALONG ... 66kV Line 1 & 2 (Short-Circuit Analysis)Document1 pageOne-Line Diagram - TANJUNG TABALONG ... 66kV Line 1 & 2 (Short-Circuit Analysis)Zaini DalimusNo ratings yet

- Single Line Diagram 2Document1 pageSingle Line Diagram 2Ronel Jasen BiriNo ratings yet

- Wa0641437 0004 0000Document1 pageWa0641437 0004 0000BenjaminNo ratings yet

- EmiratesGBC Energy and Water Benchmarking For UAE Hotels 2016 ReportDocument27 pagesEmiratesGBC Energy and Water Benchmarking For UAE Hotels 2016 ReportdharmaNo ratings yet

- Site Visit - N-17725 Dated 24.11.2020 PDFDocument17 pagesSite Visit - N-17725 Dated 24.11.2020 PDFAntaryami Singh GoondiNo ratings yet

- Techncial Submittal For Lighting Fixtures - 1ST Ring RoadDocument546 pagesTechncial Submittal For Lighting Fixtures - 1ST Ring Roadwsiim5718No ratings yet

- Judul: Disusun Oleh: Diperiksa:: Rd. Luthfan Sentani Ir. Kholiq Hernawan, MT One Line DiagramDocument1 pageJudul: Disusun Oleh: Diperiksa:: Rd. Luthfan Sentani Ir. Kholiq Hernawan, MT One Line DiagramLuthfanNo ratings yet

- Tender Document-Volume 2 Drawing List & Specifications: Establishment of A Digital Early Warning SystemDocument7 pagesTender Document-Volume 2 Drawing List & Specifications: Establishment of A Digital Early Warning SystemLove ChoudharyNo ratings yet

- Dfe-b00-Ele-dwg-sld-006 - Single Line Diagram For Process PCC Panel - 2a & 2b (Wet End)Document1 pageDfe-b00-Ele-dwg-sld-006 - Single Line Diagram For Process PCC Panel - 2a & 2b (Wet End)Electrical PCBL TeamNo ratings yet

- NMSU Electrical Master Plan Final Report 2014-09-05Document430 pagesNMSU Electrical Master Plan Final Report 2014-09-05Aubrey Yzabella Dumali AguilarNo ratings yet

- p2 Khos Visco BGM Shop Drawings 21sept19Document59 pagesp2 Khos Visco BGM Shop Drawings 21sept19tontranNo ratings yet

- Legend: Symbol Description NO From FFLDocument1 pageLegend: Symbol Description NO From FFLmeraj rizviNo ratings yet

- 09-Emergency Lighting Panel (F)Document4 pages09-Emergency Lighting Panel (F)Balasundaram iNo ratings yet

- Vdocuments - MX Mohamed Diab Electrical Engineer CVDocument12 pagesVdocuments - MX Mohamed Diab Electrical Engineer CVMelNo ratings yet

- SDCS0218 Rev00Document24 pagesSDCS0218 Rev00coolamruth.arunNo ratings yet

- ZBP v3 Alsaad HQ DWG SD Ar 0257 Rev01 Headquarter 10th Floor Ceiling LayoutDocument10 pagesZBP v3 Alsaad HQ DWG SD Ar 0257 Rev01 Headquarter 10th Floor Ceiling LayoutThe Saudi TamizhanNo ratings yet

- Load CalculationDocument22 pagesLoad CalculationAhmedMaherNo ratings yet

- EX00-CCTV-GN-XX0001-004005 REV-00-layoutDocument1 pageEX00-CCTV-GN-XX0001-004005 REV-00-layoutengrabbas75No ratings yet

- Goodyear: 69KV, 3 Ø, 3 Wire 60 HZ, SupplyDocument1 pageGoodyear: 69KV, 3 Ø, 3 Wire 60 HZ, SupplyTonyrey DelacuestaNo ratings yet

- Zbp-V3-Alsaad-Cc-Dwg-Sd-Ar-0020-Rev03 - Community Center Overall and Partial Ground Floor Reflected Ceiling Plan (1) KaosDocument15 pagesZbp-V3-Alsaad-Cc-Dwg-Sd-Ar-0020-Rev03 - Community Center Overall and Partial Ground Floor Reflected Ceiling Plan (1) KaosThe Saudi TamizhanNo ratings yet

- SLD MVDocument1 pageSLD MVAhmed AboelgoodNo ratings yet

- 4-4 - Electrical Works SpecsDocument41 pages4-4 - Electrical Works SpecsF Insomni AkNo ratings yet

- Project:: Tra Vinh Wind Farm ProjectDocument19 pagesProject:: Tra Vinh Wind Farm ProjectcanNo ratings yet

- MCC Schematics - Highlighted StartersDocument8 pagesMCC Schematics - Highlighted Startersshrikanth5singhNo ratings yet

- Ee423 Primary Distribution OverviewDocument41 pagesEe423 Primary Distribution OverviewCathryn FriasNo ratings yet

- RN 02 00001 01 11 EL NPC MI 000066 (01) M.sub For DMS RTU For Electrical Network (C)Document440 pagesRN 02 00001 01 11 EL NPC MI 000066 (01) M.sub For DMS RTU For Electrical Network (C)Cheap TrickNo ratings yet

- Government Berths: Limit of Work IP1 IP4Document1 pageGovernment Berths: Limit of Work IP1 IP4Sid BlankNo ratings yet

- Installation Instructions EPLAN Education 2023 enDocument16 pagesInstallation Instructions EPLAN Education 2023 enSachin ShikotraNo ratings yet

- 04 - ElectricalDocument220 pages04 - ElectricalwegNo ratings yet

- Legends Abbreviations Notes: Tender DrawingDocument14 pagesLegends Abbreviations Notes: Tender DrawingSuper HNo ratings yet

- J910-YQ01-P0ANA-145013 - 2 - Lighting System Installation Notes & Details (Approved)Document14 pagesJ910-YQ01-P0ANA-145013 - 2 - Lighting System Installation Notes & Details (Approved)Devy MangimbaNo ratings yet

- 21q34 On TemplateDocument74 pages21q34 On TemplatedhinuNo ratings yet

- 20167.MV MotorsDocument10 pages20167.MV Motorsmohammad kassarNo ratings yet

- Layout Earthing SsDocument0 pagesLayout Earthing Sscherif yahyaoui100% (1)

- E02 - Single Line Diagram-E2.1Document1 pageE02 - Single Line Diagram-E2.1RUEL RABANDABANNo ratings yet

- (Mixed Use Development) Feb Tower at BFH: Lower Ground Floor Lighting LayoutDocument1 page(Mixed Use Development) Feb Tower at BFH: Lower Ground Floor Lighting LayoutSujaniNo ratings yet

- Floor Layout PlanDocument1 pageFloor Layout PlanDereck W MarieNo ratings yet

- Water SupplyDocument1 pageWater SupplyZiyadawaliNo ratings yet

- Name REF RemarkDocument2 pagesName REF Remarknadeem UddinNo ratings yet

- Pages From ECBC-CodeDocument16 pagesPages From ECBC-Codenadeem UddinNo ratings yet

- Active Doc ListDocument405 pagesActive Doc Listnadeem UddinNo ratings yet

- Deep Breathing TechniquesDocument1 pageDeep Breathing Techniquesnadeem UddinNo ratings yet

- Fire Alarm Sys - Installation ChecklistDocument1 pageFire Alarm Sys - Installation Checklistnadeem UddinNo ratings yet

- Opt Vs IonDocument2 pagesOpt Vs Ionnadeem UddinNo ratings yet

- Data Center Tier RequirementsDocument1 pageData Center Tier Requirementsnadeem UddinNo ratings yet

- SLD of DBDocument1 pageSLD of DBnadeem UddinNo ratings yet

- Comparison Sheet of Fusion ModelDocument3 pagesComparison Sheet of Fusion Modelnadeem UddinNo ratings yet

- Data Center RequirementsDocument3 pagesData Center Requirementsnadeem Uddin100% (1)

- Ms Glanding & Termination of LV CablesDocument18 pagesMs Glanding & Termination of LV Cablesnadeem UddinNo ratings yet

- Cable Sizing Rev.3Document13 pagesCable Sizing Rev.3nadeem UddinNo ratings yet

- Boxes Raceways SpecificationDocument21 pagesBoxes Raceways Specificationnadeem UddinNo ratings yet

- Electronic Transformer For 12 V Halogen LampDocument15 pagesElectronic Transformer For 12 V Halogen LampWin KyiNo ratings yet

- Manual Inglês Encoder SinCos PG E3 PDFDocument33 pagesManual Inglês Encoder SinCos PG E3 PDFvicenteunicoNo ratings yet

- JEBO Catalog 2017 (Web)Document73 pagesJEBO Catalog 2017 (Web)azra18No ratings yet

- Manual de Servicio Lavadora Maytag Neptune h3000Document157 pagesManual de Servicio Lavadora Maytag Neptune h3000JOSE CAMPOSNo ratings yet

- Clarification On Canopy Lightign BOQDocument2 pagesClarification On Canopy Lightign BOQImaginearc InfrastructureNo ratings yet

- Cable, Tray, Earthing WT CalculationDocument46 pagesCable, Tray, Earthing WT CalculationSadique Shaikh100% (1)

- Datasheet - EvaporatorDocument1 pageDatasheet - Evaporatorjknaveen001No ratings yet

- 2 P 2010 Newcatalog P 2010 CatalogDocument5 pages2 P 2010 Newcatalog P 2010 CatalogNoe Carlos Liviapoma GironNo ratings yet

- 160 88-CL1Document4 pages160 88-CL1vanthe140591No ratings yet

- Bright Source LED T5 Tube Data SheetDocument2 pagesBright Source LED T5 Tube Data SheetnabatiestNo ratings yet

- Xlpe CableDocument18 pagesXlpe Cablesopan saNo ratings yet

- Dishwasher Evo3: Service ManualDocument54 pagesDishwasher Evo3: Service ManualGaborNo ratings yet

- 3DN5 Knee Type Disconnectors enDocument2 pages3DN5 Knee Type Disconnectors enCristopher Antonio Páez CortésNo ratings yet

- Shut Off Fisher 634Document4 pagesShut Off Fisher 634Rolando PradaNo ratings yet

- Harmony XB5Document124 pagesHarmony XB5cnrk777No ratings yet

- PRINTER Datamax Parts Catalog - I-Class MK I (92-2506-01 Rev G)Document24 pagesPRINTER Datamax Parts Catalog - I-Class MK I (92-2506-01 Rev G)Anonymous FJO8CO97No ratings yet

- Sick - WT34 - R220Document7 pagesSick - WT34 - R220M MNo ratings yet

- 1446 - Thaneakea Srov Machine ListDocument5 pages1446 - Thaneakea Srov Machine ListKao SophearakNo ratings yet

- Specifications of Hermetic Scroll Compressor Approval SheetDocument13 pagesSpecifications of Hermetic Scroll Compressor Approval Sheetdavid salazarNo ratings yet

- MedLinket Catalogue - Attn-Jack 2018.6.15Document158 pagesMedLinket Catalogue - Attn-Jack 2018.6.15ecarrera1975No ratings yet

- Unwinding Unit - BG01Document30 pagesUnwinding Unit - BG01DeniMestiWidiantoNo ratings yet

- COMPARISON M&e Smm2 and NKR 2 UkDocument1 pageCOMPARISON M&e Smm2 and NKR 2 UkRasmen ABD. HALUNNo ratings yet

- Stock PH 1-8-2022Document66 pagesStock PH 1-8-2022ariniNo ratings yet

- Instruction Manual Codes 273S.A/3-/4 - /5: Technical CharacteristicsDocument4 pagesInstruction Manual Codes 273S.A/3-/4 - /5: Technical Characteristicsamskroud brahimNo ratings yet

- VTF - Mini Chiller PDFDocument4 pagesVTF - Mini Chiller PDFhoang nguyenNo ratings yet

- 29596-97 YSX40E en r0Document235 pages29596-97 YSX40E en r0darmaalikhwan7470% (1)

- Implementos y ServiciosDocument12 pagesImplementos y ServiciosIMPLEMENTOS CAJAMARCANo ratings yet

- Mankenberg dm662 enDocument2 pagesMankenberg dm662 enashwinmalooNo ratings yet

- 6.1a Chiller Installation, Operation and Maintenance ManualDocument83 pages6.1a Chiller Installation, Operation and Maintenance ManualNg Soon LeeNo ratings yet