Professional Documents

Culture Documents

Closed Cell Physically Crosslinked Polyolefin Foam Insulation

Closed Cell Physically Crosslinked Polyolefin Foam Insulation

Uploaded by

zackii90Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Closed Cell Physically Crosslinked Polyolefin Foam Insulation

Closed Cell Physically Crosslinked Polyolefin Foam Insulation

Uploaded by

zackii90Copyright:

Available Formats

Thermal Insulation

Closed Cell Physically crosslinked

polyolefin foam PHYSICALLY

insulation

C R O S S L I N K E D

SEKISUI TECHNOLOGY

PHYSICALLY

C R O S S L I N K E D

SEKISUI TECHNOLOGY

SPC011_Thermobreak 8pp_concept_FA.indd 1 28/04/14 3:24 PM

Si

M

M

M

Setting the Standard

Thermobreak® is the leading and most innovative polyolefin foam thermal insulation available to the HVAC and Building industry

worldwide. Thermobreak’s performance is unsurpassed.

Thermobreak® thermal insulation is an all-in-one closed cell physically crosslinked polyolefin foam that is manufactured in

compliance to ASTM C1427 Standard.

Thermobreak® was developed in Australia and has sold worldwide for over 20 years. The revolutionary insulation product has a

factory applied reinforced foil facing and adhesive backing. Thermobreak® enables much faster installation and eliminates many

errors and limitations encountered when using older insulation technology.

Thermobreak® is manufactured using our proprietary physically crosslinked polyolefin foam technology, invented and

commercialised by the Sekisui Chemical group in Japan. The technology allows crosslinking of the polyolefin without the use of

chemical agents. Instead the Sekisui process utilises clean and precise crosslinking through irradiation (physical) means.

Sekisui has been manufacturing crosslinked polyolefin foams since 1967. Today Sekisui Foam division is the largest and leading

crosslinked polyolefin foam manufacturer in the world operating 10 foam factories located in Europe, USA, Thailand, Japan, Korea,

and Australia. PHYSICALLY

C R O S S L I N K E D

SEKISUI TECHNOLOGY

Our commitment to quality and the protection of the environment is embodied by our operations all being certified to both the ISO

9001 Quality Assurance and ISO 14001 Environmental standards.

PHYSICALLY

C R O S S L I N K E D

SEKISUI TECHNOLOGY

SPC011_Thermobreak 8pp_concept_FA.indd 2 28/04/14 3:24 PM SPC

Sidra Hospital Doha, Qatar

M&E Consultant KEO International

Marriott Hotel Abu Dhabi, UAE Sama Beirut, Lebanon

M&E Consultant Herberger Engineers M&E Consultant ERGA Group

3:24 PM SPC011_Thermobreak 8pp_concept_FA.indd 3 28/04/14 3:24 PM

Bu

M

Technically Superior

Our unique physically crosslinked technology results in a smaller and more evenly distributed cell structure. Cell structure

directly affects thermal conductivity and vapour permeability. Both are key factors in insulation performance.

AREA Thermal Conductivity: 0.032 W/mK (230C) is the lowest

(m 2) THICKNESS

(m)

of any flexible insulation material. On equivalent thickness

THERMAL

CONDUCTIVITY

RATE

basis, Thermobreak® provides up to 18% better insulation

THERMAL ENERGY

than elastomeric and chemically crosslinked foams.

(W-K-m)

(W)

TEMPERATURE1 TEMPERATURE2

(K) (K)

TEMPERATURE DIFFERENCE

△T=T1-T2

(K)

Vapour Permeability of almost zero ensures our thermal

conductivity remains relatively constant for a period of 10

years thus significantly contributing to building sustainability

and energy cost reduction.

Vapour Permeability = 2.3 x 10-15 Kg/Pa.s.m

Permeability Resistance Factor: µ > 80,000

Third Party Certification & Testing

Thermobreak® is third party certified ensuring that our stated technical specifications and test results are third party verified

through factory inspection, audit and sample preparation. All our product testing is performed with ISO 17025 Certified

laboratories ensuring testing integrity and verification.

130546 SAI-CM20068 E193277

143961

Energy Efficiency & Building Sustainability

Building Sustainability, Energy Efficiency, Indoor Air Quality and Health & Safety, are all key

elements embodied in the Green Building concept.

Green buildings are designed to reduce the overall impact of the built environment on human Pa

health and the natural environment through energy efficiency, protecting occupant health, M

improving employee productivity, and reducing waste, pollution and environmental degradation.

Central to the green building concept is thermal insulation. Thermobreak® insulation is

manufactured to support and comply with such initiatives and enables credit point accumulation

through various building accreditation systems such as LEED and Estidama.

> Green Star Compliant (VOC) > Relatively constant thermal conductivity over a 10 year period

> No CFCs or HCFCs > Zero PVC, Zero Formaldehyde

> Zero Ozone Depletion Potential > Compliance to RoHS Directive

(Montreal Protocol) > Compliance to REACH Directive

> Low GWP > Resistance to Mould Growth

> Superior thermal insulation > Non-Allergenic Properties

SPC011_Thermobreak 8pp_concept_FA.indd 4 28/04/14 3:24 PM SPC

Burj Residences Dubai, UAE

M&E Consultant Holfrord Associates

Palm Twin Towers Doha, QATAR Zuellig Building Manila, Philippines Lim Binh

TowerTuong

HCMC,Political

VietnamCentre, Vietnam

M&E Consultant MZ & Partners First LEED Platinum building in the Philippines M&EM&E

Consultant

Consultant : CPG

CASA Vietnam

(HK)

M&E Consultant Meinhardt Philippines

SPC011_Thermobreak 8pp_concept_FA.indd 5 28/04/14 3:24 PM

Dubai Marriott Hotel Al Jaddaf, Dubai, UAE Royal Adelaide Hospital Adelaide, South Australia Movenpick Hotel Bangalore, India

M&E Consultant CKR Consulting Engineers M&E Consultant Lehr Consultants Intl. M&E Consultant Sankalpa Tech

Qatar Petroleum (QP) Plaza Doha, Qatar

M&E Consultant KEO International

SPC011_Thermobreak 8pp_concept_FA.indd 6 28/04/14 3:24 PM SPC

Compliance to International Fire & Smoke Standards

Thermobreak® has been tested and complies to International Fire and Smoke Standards including

> BRITISH (BS)

> ASTM

> AUSTRALIAN (AS)

> European (EN)

> ISO

Our testing regime includes various thicknesses in the range to ensure safety across all thickness used in projects. It is the only

polyolefin foam based sheet insulation to achieve FM Approval to FM4924, a demanding large scale room corner fire test.

Quality Materials Engineered to Last

Thermobreak® is supplied with factory applied reinforced aluminium foil facing and

repositionable acrylic tissue adhesive system. Our materials are of the highest quality.

Our aluminium foil facing is reinforced providing additional physical protection to

the insulation and at the same time reducing heat flow.

Thermobreak® is the only material that uses tissue interlayer based adhesive

system. Unlike conventional direct coated adhesives, our system ensures that the

adhesive provides 100% coverage on the duct surface and on the foam insulation.

This feature also provides the additional benefit of repositionability, an essential

requirement during installation. The insulation can be lifted off the duct numerous

times during alignment without tearing the insulation.

In keeping with current green building trends and demands such as indoor air quality,

our adhesive system is low VOC (Green Star) compliant and offers credit points for

building ratings systems such as LEED and Estidama.

Proven Reliability for Over 20 Years

With Thermobreak® installed in over 600 projects worldwide, our experience and results speak for themselves.

Tested and proven and in a variety of climatic conditions Thermobreak® has established an enviable reputation as a quality,

reliable, closed cell insulation performing flawlessly and delivering significant energy savings to building owners and operators.

Technical Support & Distribution Network

Backed by the technical expertise of Sekisui, a global multinational, our commitment and technical support to our customers

is unrivalled. Our office locations throughout Asia Pacific, India and the Middle East provide technical support to our customers

and distributors.

This includes our ThermaCalc® thickness selection software, heat flow and temperature profile analysis software, a series of

Technical Information Bulletins for M&E professionals, detailed Installation Instructions and full set of third party certificates.

Our extensive distribution network ensures that materials are locally available at all times.

For your nearest distributor please consult our website.

Complete Range for your HVAC Insulation Needs

Thermobreak® is available in a complete range to cover typical HVAC requirements:

> Thermobreak® Sheet (duct and large pipes, underslab)

> Thermobreak® Tube (preformed tube up to 10’ IPS (273mm ID) and 50mm wall thickness

> Thermobreak ® NO CLAD - Sheet and pipe insulation for external applications and heavy duty traffic areas

> Thermobreak® Acoustiplus- Fibre free acoustic liner with factory applied acrylic adhesive

:24 PM SPC011_Thermobreak 8pp_concept_FA.indd 7 28/04/14 3:24 PM

Technical Specifications

TECHNICAL

PHySiCAL PRoPERTiES

SPECIFICATIONS

FiRE AND SMoKE BEHAvioUR

Material: Physically (irradiation) crosslinked closed BS476 Parts 6 & 7: CLASS 0

Physical Properties cell polyolefin foam with factory applied Fire and Smoke Behaviour

reinforced aluminium foil and acrylic AS1530 PartParts

BS476 3 Ignitability Index:

6 & 7: CLASS 0 0

Material: Physically (irradiation) crosslinked

adhesive backing Spread of Flame Index: 0

closed cell polyolefin foam with AS1530 Part 3 Ignitability Index: 0

Density: factory

25 kg/m 3

(foamapplied reinforced

core only)

Heat Evolved Index:

Spread of Flame Index:

0

0

aluminium foil and acrylic Smoke

Heat Evolved Index: 0-1

Developed Index: 0

Thermal Conductivity: 0.032 adhesive

W/m/°K (@backing

23°C mean temp.) Smoke Developed Index: 0-1

(ASTM C518) 0.036 W/m/°K (@ ASTM E84: COMPLIES (NFPA 90A & B)

3 36°C mean temp.)

Density: 25 kg/m (foam core only) ASTM E84: COMPLIES

Flame Spread (NFPA

Index: 90A<25

& B)

Water vapour

Thermal Permeability:

Conductivity: 8.19 x0.032

10-15 kg/Pa.s.m

W/mK (@ 23°C mean temp.) FlameDeveloped

Smoke Spread Index:

Index: <50<25

(ASTM E96)

(ASTM C518) (0.0290.036

mg.m/N.h)

W/mK (@ 36°C mean temp.) Smoke Developed Index: <50

ASTM C411: COMPLIES (NFPA 90A & B)

Water

Water Vapour

vapour Permeability: 3.3 x 10

Permeance: 2.3-4 x 10-15 kg/Pa.s.m

g/MN.s ASTM C411: COMPLIES (NFPA 90A & B)

(ASTM E96) FM 4924

FM 4924: Thermobreak

ThermobreakSheet

Sheet APPROVED

APPROVED (143961)

Water absorption by volume: <0.1% v/v

Water

(JIS Vapour Permeance:

K6767) 0.000195

(0.00038 g/cm2) μg/N.s

Up

Uptoto25mm thickness

25mm thickness

12mm thickness EN ISO 11925 Reaction to Fire Complies (Euroclass E)

Permeability Resistance Factor: μ > 20,000

Water absorption by volume: <0.1% v/v AS 3837: BCAGroup

Group Number: 1 1

(JIS K6767) (0.00038 g/cm2) AS 3837 BCA Number:

Resistance to fungi: Zero Growth Smoke Index: ≤250

Smoke Index: ≤250

(ASTM G21)

Permeability Resistance Factor: μ > 80,000 BS 6853 Annex B: Smoke Toxicity COMPLIES (R < 1.0)

Resistance to fungi: Zero Growth BS 6853 Annex B Smoke Toxicity COMPLIES (R < 1.0)

ozone Resistance: Excellent IMO MSC 61(67) Part 2: Smoke Toxicity COMPLIES

(ASTM G21)

iMo MSC 61(67) Part 2 Smoke Toxicity COMPLIES

Uv Resistance: Excellent ISO 5659 Part 2 Smoke Density COMPLIES (IMO MSC 61(67) Part 2)

Ozone Resistance: Excellent Dm < 200

iSo 5659 Part 2 Smoke Density COMPLIES (IMO MSC 61(67) Part 2)

Noise Reduction Coefficient:

UV Resistance: 0.20 (12mm foam thickness)

Excellent Satisfies max allowable

(ISO 354) 0.30 (25mm foam thickness) Dm < 200

concentrations for the

Noise Reduction Coefficient: 0.20 (12mm foam thickness) Satisfies max allowable

following combustion gases:

(AS 1045)

operating

Temperature Range: -80 °C0.30 (25mm

~ +100 °C (nofoam thickness)

adhesive) concentrations for the

CO, HCl, HBr, HF, HCN, NOx, SO2

following combustion gases:

Operating

GreenStar Temperature Range:Low

Rating: VOC

-80Emitting

°C ~ +100 °C (no adhesive)

UL 94 Horizontal Burn APPROVED

CO, HCl, HBr, HF, HCN, (HF-1)

NOx, SO

2

(ASTM D5116)

GreenStar Rating: Low VOC Emitting (E193277)

(ASTM D5116) UL 94 Horizontal Burn APPROVED (HF-1)

Physical Property Requirements: COMPLIES (Type II - Sheet)

(ASTM C1427)

Physical Property Requirements: COMPLIES (Type II - Sheet) Size Availability

(ASTM C1427) SiZE AvAiLABiLiTy

REACH Directives: COMPLIES • 8mm: 50m x 1200mm rolls

REACH Directives:

(1907/2006/EC) COMPLIES

•

8-mm 10mm: 20m50m

x 1200mm

X 1200 mmrolls

rolls

(1907/2006/EC)

Product Certification may be plant specific. Please consult with your local representative. • 12mm: 20m x 1200mm rolls

Product Certification may be plant specific. Please consult with your local representative. 10-mm 20m X 1200 mm rolls

• 15mm: 20m x 1200mm rolls

Distributed by 12-mm

Distributed by • 20mm: 20m20m X 1200 mmrolls

x 1200mm rolls

© Sekisui Pilon May 2015 INTL

•

15-mm 25-50mm: 2300mm x 1200mm

20m X 1200 mm rolls sheets

Other sizes available on request

20-mm 20m X 1200 mm rolls

25~50-mm 2300mm X 1200mm sheets

Thermobreak is a registered trademark of Sekisui Chemical Co. Ltd. or its subsidiaries. Other sizes available on request.

AustralianPlant

Australian Plant Thailand Plant

Thailand Plant

1-5Parraweena

1-5 ParraweenaRd,

Rd,POPOBOX

Box 2898,

2898, 700/329 Moo

700/329 Moo6,6,Amata

AmataNakorn

NakornIndustrial

IndustrialEstate,

Estate,

TarenPoint

Taren PointNSW

NSW2229

2229Australia

Australia Tumbol Donhua-Ioh,

Tumbol Donhua-loh,Amphur

Amphur Muang

Muang Chonburi

Chonburi 20000

20000

Tel: +61

Tel: +61 2 9525

2 9525 9880

9880 Tel: +66

Tel: +663838213219-26

213219~26

Email: info@sekisuifoam.com.au

Email: info@sekisuifoam.com.au Email: info@thaisekisui.co.th

Email: info@thaisekisui.co.th

Web: www.sekisuifoam.com.au

Web: www.sekisuifoam.com.au Web: www.thaisekisui.co.th

Web: www.thaisekisui.co.th

SPC011_Thermobreak 8pp_concept_FA.indd 8 28/04/14 3:24 PM

You might also like

- Review of Data On Gas Migration Through Polymer EncapsulantsDocument50 pagesReview of Data On Gas Migration Through Polymer Encapsulantsapbeese3178No ratings yet

- Technical Catalogue For Submarine Installations of Polyethylene PipesDocument84 pagesTechnical Catalogue For Submarine Installations of Polyethylene Pipesvictor salvadorNo ratings yet

- Thermobreak Brochure (New) PDFDocument8 pagesThermobreak Brochure (New) PDFFranz CanonizadoNo ratings yet

- Thermal Isolation of AccelerometersDocument4 pagesThermal Isolation of AccelerometersLake HouseNo ratings yet

- Sekisui Thermobreak LS - Brochure 090516 INTL LOW RESDocument4 pagesSekisui Thermobreak LS - Brochure 090516 INTL LOW RESTuyen NguyenNo ratings yet

- PeekDocument23 pagesPeekwamikshahidrizviNo ratings yet

- PolyetheretherkeytoneDocument4 pagesPolyetheretherkeytoneGriffin BeemillerNo ratings yet

- The Effect of Sintering and Soaking Temperature On The Dye-SensitizedDocument6 pagesThe Effect of Sintering and Soaking Temperature On The Dye-SensitizedasadNo ratings yet

- Thermobreak Solarblock Brochure - Email - 18012021Document4 pagesThermobreak Solarblock Brochure - Email - 18012021Trương Tấn KhoaNo ratings yet

- Final Presentation Thermal CoatingDocument16 pagesFinal Presentation Thermal CoatingKarimMattaNo ratings yet

- Ball On Disk PTFEDocument9 pagesBall On Disk PTFEmarangoiaNo ratings yet

- Sin 2023 J. Phys. - Conf. Ser. 2523 012023Document15 pagesSin 2023 J. Phys. - Conf. Ser. 2523 012023Junaid AliNo ratings yet

- Contrast Joints of Glass-Fibre With Carbon-Fibre Reinforced Polystyrene Composite Bonded by Microwave IrradiationDocument33 pagesContrast Joints of Glass-Fibre With Carbon-Fibre Reinforced Polystyrene Composite Bonded by Microwave IrradiationBuyandalai KhuurchNo ratings yet

- PTFE SiO2ThinFilmsDocument7 pagesPTFE SiO2ThinFilms陳信辰No ratings yet

- Physically Crosslinked Closed Cell Polyolefin Foam Insulation For DuctsDocument8 pagesPhysically Crosslinked Closed Cell Polyolefin Foam Insulation For DuctsĐặng Văn SiêuNo ratings yet

- Teflon & K-12 Composite For Microwave Propagation - Version4.0Document4 pagesTeflon & K-12 Composite For Microwave Propagation - Version4.0Surendra KumarNo ratings yet

- Thermobreak SolarblockDocument4 pagesThermobreak SolarblockChristian Dominic Dela CruzNo ratings yet

- Why You Need To Consider The PTFE Dielectric Constant in Your ApplicationDocument10 pagesWhy You Need To Consider The PTFE Dielectric Constant in Your ApplicationjackNo ratings yet

- 08 Polymer Composites Applications - Part 2Document37 pages08 Polymer Composites Applications - Part 2Cyme CymeNo ratings yet

- Brosur Trocellen ROOFINGINSULATIONDocument6 pagesBrosur Trocellen ROOFINGINSULATIONTita Puspita SariNo ratings yet

- TMP 3189Document9 pagesTMP 3189FrontiersNo ratings yet

- Thermal EvaporationDocument22 pagesThermal EvaporationSMIT CHRISTIANNo ratings yet

- Surface CoatingDocument7 pagesSurface CoatingRessa FaelashofaNo ratings yet

- Characterization of Bolometers Based On Polycrystalline Silicon Germanium AlloysDocument4 pagesCharacterization of Bolometers Based On Polycrystalline Silicon Germanium Alloyslolopopo28No ratings yet

- Po IysthyreneDocument14 pagesPo IysthyreneEdward UyNo ratings yet

- Composites: Part A: Evon Foo, Mariatti Jaafar, Azizan Aziz, Lim Chong SimDocument6 pagesComposites: Part A: Evon Foo, Mariatti Jaafar, Azizan Aziz, Lim Chong Simeid elsayedNo ratings yet

- Thermo Electric CoolingDocument17 pagesThermo Electric CoolingDebashish MohantyNo ratings yet

- Physically Crosslinked Polyolefin Foam Pipe InsulationDocument4 pagesPhysically Crosslinked Polyolefin Foam Pipe InsulationĐặng Văn SiêuNo ratings yet

- Chandramika BoraDocument7 pagesChandramika BoraMahalingam SNo ratings yet

- Evaluation of Different Light-Curing Lamps HalogenDocument7 pagesEvaluation of Different Light-Curing Lamps HalogenKenny Rafael Iglesias AlvarezNo ratings yet

- Polyether Ether Ketone - Wikipedia PDFDocument3 pagesPolyether Ether Ketone - Wikipedia PDFhafiNo ratings yet

- European Polymer Journal: Gérard Calleja, Alex Jourdan, Bruno Ameduri, Jean-Pierre HabasDocument9 pagesEuropean Polymer Journal: Gérard Calleja, Alex Jourdan, Bruno Ameduri, Jean-Pierre HabasGamini SureshNo ratings yet

- E3sconf Iccsre21 01006Document7 pagesE3sconf Iccsre21 01006HoudaNo ratings yet

- Composites: Part A: Ping Zhang, Qiang Li, Yimin XuanDocument7 pagesComposites: Part A: Ping Zhang, Qiang Li, Yimin Xuaneid elsayedNo ratings yet

- (Asia) PERLIFOC HP ECO + Structural Steel Spray Fire Protection 2Document6 pages(Asia) PERLIFOC HP ECO + Structural Steel Spray Fire Protection 2roslin.arif.pfpNo ratings yet

- Brochure ThermobreakDocument6 pagesBrochure Thermobreakptdacosa2No ratings yet

- Alumina Particle size-KPMDocument7 pagesAlumina Particle size-KPMrajeshayrNo ratings yet

- Thermochromic VO2 Films For Smart Windows ApplicationDocument3 pagesThermochromic VO2 Films For Smart Windows Applicationmasum.sNo ratings yet

- Thermo-Mechanical Analysis of Thermal Barrier Coating System Using Finite Element MethodDocument8 pagesThermo-Mechanical Analysis of Thermal Barrier Coating System Using Finite Element MethoderpublicationNo ratings yet

- (2014) (Longtin Et Al) Sensors For Harsh Enviroments by Direct Write Thermal SprayDocument4 pages(2014) (Longtin Et Al) Sensors For Harsh Enviroments by Direct Write Thermal SprayRenkuReNo ratings yet

- наполнители PTFEDocument4 pagesнаполнители PTFEAndreyNo ratings yet

- Leaflet Ekoprodurpm2233j enDocument12 pagesLeaflet Ekoprodurpm2233j enThao NguyenNo ratings yet

- Glass Bead Filled Polyetherketone (PEK) Composite PDFDocument7 pagesGlass Bead Filled Polyetherketone (PEK) Composite PDFjhaider20009No ratings yet

- Term o PlasticDocument15 pagesTerm o PlasticChristopher IbarraNo ratings yet

- Applied Thermal Engineering: Maksims Babenko, John Sweeney, Petko Petkov, Franck Lacan, Samuel Bigot, Ben WhitesideDocument12 pagesApplied Thermal Engineering: Maksims Babenko, John Sweeney, Petko Petkov, Franck Lacan, Samuel Bigot, Ben WhitesideAfredo Putra MintoNo ratings yet

- THERMOTEC AUST Thermal Pipe 4 Zero A4 4pp PDFDocument4 pagesTHERMOTEC AUST Thermal Pipe 4 Zero A4 4pp PDFGeorge_Wabag_2014No ratings yet

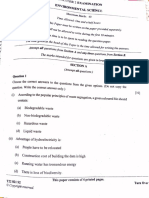

- Universiti Teknologi Mara Odl Exam 1: Confidential EM/ JUNE 2020/MEC551Document6 pagesUniversiti Teknologi Mara Odl Exam 1: Confidential EM/ JUNE 2020/MEC551Mohd HaniffNo ratings yet

- Tio2 Thin Film Thesis PDFDocument7 pagesTio2 Thin Film Thesis PDFValerie Felton100% (2)

- Fracture Load and Failure Types of Different Veneered Polyetheretherketone Fixed Dental ProsthesesDocument8 pagesFracture Load and Failure Types of Different Veneered Polyetheretherketone Fixed Dental ProsthesesNelson BarakatNo ratings yet

- Ceramics International: Y. Al-Hadeethi, M.I. Sayyed, M.S. Al-BuriahiDocument12 pagesCeramics International: Y. Al-Hadeethi, M.I. Sayyed, M.S. Al-BuriahiJOHAN SEBASTIAN SANTANA GILNo ratings yet

- Modified Thick Thermal Barrier CoatingsDocument86 pagesModified Thick Thermal Barrier CoatingsAnonymous p0mg44xNo ratings yet

- Wire Insulation Types and Purposes ExplainedDocument5 pagesWire Insulation Types and Purposes ExplainedJose CupatitzioNo ratings yet

- Micro Injection Molding of A Micro-Fluidic PlaDocument5 pagesMicro Injection Molding of A Micro-Fluidic PlaTrần Long VũNo ratings yet

- Zeus FocusPTFEDocument6 pagesZeus FocusPTFESelva BabuNo ratings yet

- Study On Preparation and Properties of Silane-Crosslinked Polyethylene/ Magnesium Hydroxide/ Montmorillonite NanocompositesDocument15 pagesStudy On Preparation and Properties of Silane-Crosslinked Polyethylene/ Magnesium Hydroxide/ Montmorillonite NanocompositesAmirhosein FazilatiNo ratings yet

- NBR Vs EPDM 0616Document4 pagesNBR Vs EPDM 0616ammarashraf91No ratings yet

- Polymer Quenching and DSC HandoutDocument2 pagesPolymer Quenching and DSC HandoutSarbajitMannaNo ratings yet

- Sensors and Actuators B: Chemical: Azhar Ali Haidry, Andrea Ebach-Stahl, Bilge SaruhanDocument12 pagesSensors and Actuators B: Chemical: Azhar Ali Haidry, Andrea Ebach-Stahl, Bilge SaruhanAlexander Santos SolanoNo ratings yet

- Pip 1140Document12 pagesPip 1140tungbk9No ratings yet

- Thermal Conductivity Measurements in Atomically Thin Materials and DevicesFrom EverandThermal Conductivity Measurements in Atomically Thin Materials and DevicesNo ratings yet

- Engineering Design Guidelines Distillation Column Rev4Document24 pagesEngineering Design Guidelines Distillation Column Rev4zackii90No ratings yet

- Bai Tap Luu Hoang Tri 9A - 01Document22 pagesBai Tap Luu Hoang Tri 9A - 01zackii90No ratings yet

- ED45-974 (Floor Standing & Duct Connection Type) R410aDocument174 pagesED45-974 (Floor Standing & Duct Connection Type) R410aIpan April75% (8)

- Internal Floating RoofDocument7 pagesInternal Floating Roofzackii90No ratings yet

- Screw Conveyors PDFDocument121 pagesScrew Conveyors PDFzackii90No ratings yet

- Pure Oil Mist PresentationDocument20 pagesPure Oil Mist Presentationzackii90No ratings yet

- Elevation Design GuidlinesDocument124 pagesElevation Design Guidlinesarif khanNo ratings yet

- Đề thi vào lớp 10 môn Tiếng Anh đề 17Document9 pagesĐề thi vào lớp 10 môn Tiếng Anh đề 17Nguyễn MaiNo ratings yet

- 7 Eleven PDFDocument12 pages7 Eleven PDFEkin RokmanNo ratings yet

- CSIR-NEERI - Schedule - Ecology and Biodiversity Training - January 11-13,2022Document1 pageCSIR-NEERI - Schedule - Ecology and Biodiversity Training - January 11-13,2022Helly DesaiNo ratings yet

- J Eti 2017 08 002Document38 pagesJ Eti 2017 08 002Gabriel SantiagoNo ratings yet

- Export RoHS 20220621 22243924Document2 pagesExport RoHS 20220621 22243924Andrzej RogalaNo ratings yet

- 24 ArticleText 279 1 10 20190204Document11 pages24 ArticleText 279 1 10 20190204DedipyaNo ratings yet

- Watershed Co-Management Approach - PPTX (Autosaved)Document32 pagesWatershed Co-Management Approach - PPTX (Autosaved)Mark Adrian TagabanNo ratings yet

- Water Code of The PhilippinesDocument91 pagesWater Code of The Philippineskyla victoria gagasaNo ratings yet

- The Earth System: Connections Among The Great SpheresDocument24 pagesThe Earth System: Connections Among The Great SpheresJe-ann AcuNo ratings yet

- Evs Question Paper Class 10 Sem 2, 2022-2023Document4 pagesEvs Question Paper Class 10 Sem 2, 2022-2023Bidisha DeyNo ratings yet

- Clean Air ActDocument52 pagesClean Air ActDongzKieTVNo ratings yet

- MSDS - D.col - FG21 FenugreekDocument2 pagesMSDS - D.col - FG21 FenugreekDeepak CharanNo ratings yet

- Natural Resources: - Himani GangakhedkarDocument33 pagesNatural Resources: - Himani GangakhedkarNavjivan ThoratNo ratings yet

- PPT-7 - Ethics in Global Business and Managing For SustainabilityDocument26 pagesPPT-7 - Ethics in Global Business and Managing For SustainabilityMuhammad Ali AdnanNo ratings yet

- (En) SHC107-84 PART B (Ver.7.3)Document8 pages(En) SHC107-84 PART B (Ver.7.3)Minh BảoNo ratings yet

- Astm F 402Document2 pagesAstm F 402frengki jm100% (1)

- Spatial Planning and Sustainable DevelopmentDocument462 pagesSpatial Planning and Sustainable DevelopmentMaria MilitaruNo ratings yet

- YORK - Double Effect Steam Fired ABS Chiller - YHAU-CW CatalogeDocument68 pagesYORK - Double Effect Steam Fired ABS Chiller - YHAU-CW CatalogeQuốc Nguyễn MinhNo ratings yet

- Pfizer ESG Report 2022Document83 pagesPfizer ESG Report 2022Thuong NguyenNo ratings yet

- Q1 Philosophy Lesson 6Document9 pagesQ1 Philosophy Lesson 6Cheena Francesca LucianoNo ratings yet

- Toilets: CST940DV / CST940DPVDocument2 pagesToilets: CST940DV / CST940DPVHtoo AungNo ratings yet

- Latvia-Univ-Agriculture Landscape Architecture Art VOL4 2014 PDFDocument84 pagesLatvia-Univ-Agriculture Landscape Architecture Art VOL4 2014 PDFsufiyanmd bhusnurNo ratings yet

- 6.1 Construction Materials ExtractionDocument13 pages6.1 Construction Materials ExtractionGang QiaoNo ratings yet

- Incineration of Sewage Sludge and Recovery of Residue Ash As Building Material A Valuable Option As A Consequence of The COVID-19Document8 pagesIncineration of Sewage Sludge and Recovery of Residue Ash As Building Material A Valuable Option As A Consequence of The COVID-19Poliana MartinsNo ratings yet

- Urban Spaces, Aesthetics and PatternsDocument14 pagesUrban Spaces, Aesthetics and PatternsKathleen Denise Doria MacaraegNo ratings yet

- Global Environmental IssuesDocument4 pagesGlobal Environmental IssuesKoshika ChawlaNo ratings yet

- TDS PDF Intercept - 7000Document4 pagesTDS PDF Intercept - 7000PastiDjadi PastiDjadiNo ratings yet

- Proposal For Development of LandDocument3 pagesProposal For Development of LandB.venkat AdityaNo ratings yet