Professional Documents

Culture Documents

BackDrop Details

BackDrop Details

Uploaded by

Andy LeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BackDrop Details

BackDrop Details

Uploaded by

Andy LeCopyright:

Available Formats

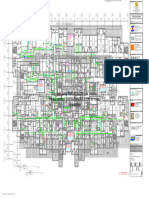

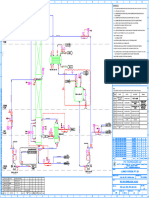

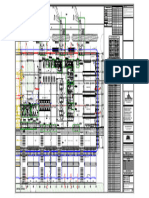

PIPES

ALL FOUL AND SURFACE WATER SEWERS (NOT HIGHWAY DRAINS), All pipes up to 300 dia. to be Hepseal, Hepsleve or

Supersleve extra strength or other approved flexibly

ARE TO BE CONSTRUCTED IN ACCORDANCE WITH "SEWERS FOR jointed vitrified clay type to BS EN295. Class S bed

and surround shall be used for all pipework in

accordance with IGN 4-08-01 and WIS 4-08-02

ADOPTION" 6th EDITION, AND AS AMENDED BY THIS DRAWING. Channels in manholes to be formed using approved

VC. or concrete channels as appropriate.

All pipes with a diameter of 300mm or greater are to

be flexibly jointed Class 120 concrete pipes to

BS 5911-1:2002 with Class S bed and surround.

All adoptable pipe runs with less than 1200mm of

cover to Soffit are to have a C20 reinforced 175mm

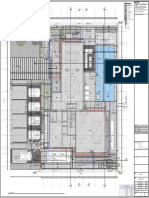

PIPE BEDDING DETAILS DESIGNATED TREE PIT STRUCTURE ACCESS TO INVERT thick concrete slab placed over the pipe and extend

the full width of the trench, and a further minimum of

Note: steeper gradients are preferred CLASS S BEDDING FOR

CLASS S BEDDING WITH 600mm dia pipes or greater 300mm on either side and positioned 150mm

REINFORCED CONCRETE Where work is required to be carried out within or adjacent to any above the crown. The slab will include a layer of

RIGID PIPES A393 mesh but must have expansion joints at 6m

to the use of backdrops PROTECTION SLAB sewer, there shall be regard of the relevant provisions of

700mm centres.

"The classification and management and confined space entries"

published by Water UK (Grade 316) Safety chains are required in manholes where the

PC concrete Stainless Steel diameter of the downstream sewer is 600mm or

chamber sections.

See JBA Consultancy Services LTD A Handrailing as required. greater than.

Drawings for further details

See specification

Clause 5.6.6.2 for (Grade 316) Stainless Steel

MANHOLE COVERS & FRAMES

rocker pipe detail. 300mm 300mm Chains or Polypropylene safety

150 min

All covers and frames are to be GRADE A, Ductile

ropes.

clearance Iron, Class D400 to BS EN124, badged 'FW' or 'SW'

Splash guard/pipe stopper as appropriate, non rocking without cushion inserts.

in rodding eye if requested 150mm The manufacturer / factory shall have quality

by the undertaker

accreditation (ISO 9002 or equivalent) from a UKAS

x Z H&Z not less registered company measured against EN45001,

than 100mm or 45011 and 45012. The manufacturer and the

250mm greater than

accreditation companies mark shall be cast on the

Invert of rodding eye to be 250mm.

100 150mm cover so that it is publicly visible. The covers should

not greater than 1.5m mm FLOW

250mm (Grade 316) preferably bear the AW logo. All manhole covers

above top of benching. GRANULAR 25mm dia.

Minimum 175mm thick reinforced shall be the non-ventilating type and shall have

CARE SHOULD BE TAKEN TO x = Outside Diameter MATERIAL AS concrete protection slab (will include a Stainless Steel

MAINTAIN FLEXIBLE JOINTS.

250mm rungs. closed keyways.

TABLE 3. layer of A393 mesh but must have

expansion joints at 6m centres). Details

subject to pipe size and site conditions 400mm

H

D400 COVER AND FRAMES

min 150 in-situ Where adoptable manholes are to be located in block

paved areas, the 150mm deep D400 cover and frames

MANHOLE concrete to be Grade

C20 (designed to BRE

min. 225mm

should be used.

CHAMBER Special Digest 1

concrete in Aggressive A

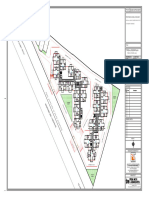

Ground). To be used where sewers are to be constructed beneath TEMPORARY LATERAL CAPPING

canopies of existing trees. PLAN ON RUNG

RECESS All temporary termination points of laterals and

Backdrop notes: *To be read in conjunction with pipe bedding details

200mm junctions are to be securely capped and painted

Extent of trench Extent of trench FW or SW or colour coded, as appropriate.

Construction joint 75 mm

100 mm 1) Steeper gradients to sewer are

preferred to the use of backdrops. CLASS S BEDDING SHALLOW PIPELINE USING A min. 1100mm

Double

CROSS LATERAL TRENCHES

400mm

2) A backdrop rodding eye is not FOR RIGID PIPES REINFORCED CONCRETE step rung

Special attention should be paid to the compaction

PROTECTION SLAB

permitted within an access shaft. of all cross lateral trenches to ensure that

subsidence does not occur in the upper trench.

225 mm 3) External Vertical backdrops are still

200mm

min

minimum diameter permitted where other methods SULPHATE RESISTING CEMENT

Grade C20 mass

concrete surround

of connection are inappropriate.

(sulphate resisting).

All concrete & concrete products used in the

construction of foul sewers, or in contact with the

D/3

D

150mm Polypropylene safety sewerage or sewerage vapour are to be Sulphate

ropes or Polypropylene resisting to Class 4, BRE digest 363, using Sulphate

covered chains fitted

D/3

downstream to all pipes resisting cement.

500mm 600mm dia

or greater All concrete & concrete products used in the

Terram root guard construction of surface water sewers, not in contact

with sewerage or with sewerage vapour, should be

geotextile or similar to line Neither Chains to be secured by

Re-root 2000 high strength root-barrier dimension to M12 Stainless Steel Sulphate resisting to Class 4, BRE digest 363, using

trench interior Roots to grow down eyebolts, fixed with Epoxy

or similar material. Fabric to line exceed 500mm Sulphate resisting cement, UNLESS DETAILED

grout.

750mm SOIL ANALYSIS PROVES OTHERWISE.

(for larger species) 500mm deep from

tree grille.

PRIVATE CONNECTIONS

Private connections to the adoptable sewers are a

minimum 100mm diameter vitrified clay and laid soffit to

soffit.

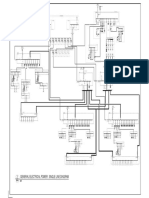

SW MANHOLE S28

To be constructed to accept a 101 SXH NOTE

Hydro-Brake Flow Control or similar approved ALL ONSITE & OFFSITE SEWER/ HIGHWAY

WORKS CARRIED OUT PRIOR TO FULL

device set to 5.5l/s @ 0.9m head TECHNICAL APPROVAL FROM ANGLIAN

WATER SERVICES AND/OR THE RELEVANT

HIGHWAYS AUTHORITY SHALL BE CARRIED

OUT AT THE RISK OF THE CONTRACTOR

Cover & frame to be GRADE A AND/OR CLIENT.

Eye bracket ductile Iron class D400 to BS EN124

Pull handle

for opening rope badged FW or SW as appropriate.

Approved packing material may be

Heavy duty reinforced concrete CL 25.225 used if required.

cover slab to BS EN752-3 with 750

x 600mm access hole.

Class B engineering brickwork

4 courses (max)

TABLE 3. GRANULAR BEDDING AND SIDEFILL

2 courses (min)

or PCC cover frame seating rings

MATERIALS

Type 1 Cover Frame Seating Ring

Suitable Materials S104 AGREEMENT

with 600 x 600mm eccentric access Pipe Maximum

Pivoting by-pass Class of

hole (BS752-3) bedded on Nominal Particle Size Maximum CF value

door operating Bedding Imported granular materials (Note a)

150mm of Grade C20 Concrete approved mortar. Bore (DN) (mm) for as-dug granular CONTRACTORS HEALTH & SAFETY ASSESSMENT

steel rope

surround(sulphate resisting), see Single Sized (mm) Graded (mm) materials (Note b) SCHEME - ACCREDITED CONTRACTOR

note

2100dia S 0.15

Precast concrete rings 100 to 125 10 10 -

B 0.30 (Note c)

Stainless Steel (Grade 316S31 S 0.15

BS970) or Polypropylene 150 to 200 14 10 or 14 14 to 5

B 0.30 (Note c) A SW Storage details added. 25.07.14

Encapsulated mild steel, Stainless

Steel or low Carbon Steel (Grade S 0.15 B SW Storage details removed. 29.07.14

225 to 300 20 10, 14 or 20 14 to 5 or 20 to 5

316S31) all to BS EN 13101:2002 B 0.30 (Note c)

Double step rungs (280mm min. S 0.15

incoming width at 250mm centres max). 375 to 500 20 14 or 20 14 to 5 or 20 to 5

150dia pipe Max distance from cover level to B 0.30 (Note c)

first step 675mm. Over 500 S 14 to 5, 20 to 5 or 40 0.15

40 14, 20 or 40

1050mm 101 SXH Hydro-brake (Note d) B to 5 0.30 (Note c)

flow control device

INCOMING PIPE

NOTES:

(a) Imported granular material to include aggregates to BS 882,

air-cooled blast furnace slag to BS 1047 and sintered

300mm OUT pulverized-fuel ash to BS 3797.

IL 22.239 GOING PIPE (b) Compaction fraction value, to IGN 4-08-01 issue 4 February TABLE 2.

1994.

305mm

(c) The higher the CF value for as-dug bedding and side hill

Outlet spigot materials the greater the required effort for adequate compaction.

Dia. of largest pipe in Chamber section

(d) Angular materials should be chosen to ensure sufficient manhole (mm) dia. (mm)

225mm

Concrete slab

Intake support is provided to these heavier pipes. Crushed rock

aggregates to BS 882 are recommended. Air-cooled blast furnace

slag to BS 3797 or other granular materials may be used if they

205mm Sump

Concrete benching show a similar degree of angularity.

Less than 375mm 1200

SECTION A-A NOTE:

375-700 1500

In wet soils the migration of fine soil particles with ground water

into voids of the bedding and sidefill material, may be mimized by 750-900 1800

surrounding the granular material with filter fabric. Alternatively, the Greater than 900mm Consult Undertaker

grading of the material may be selected so that it is self filtering

with respect to the surrounding soil provided the other required

properties are not impaired. the Sulphate content of bedding and

sidefill materials for use with cementitous pipe should not be

greater than 0.3% as Sulphur trioxide.

Fixing lugs with masonry stud

anchor fixing bolts

Neoprene rubber

gasket All personnel should be trained and certificated to work

WORKING ON SEWERS. in confined spaces and should have access on site to all

All adoptable drainage shall conform to the design and the appropriate safety equipment.

A A construction guide for developers, "Sewers For Adoption All the workforce should be certified in accordance with

6th Edition" published by the WRC plc. the NEW ROAD & STREETWORKS ACT 1991.

Should only be carried out by suitably qualified and Connections and working on live sewers should be in

experienced personnel. accordance with Sections 106 and 108 of the WATER

Concrete mounting block

INDUSTRY ACT 1991, concerning builders making their

The works should be carried out only with the consent of own connections to the public sewer.

ANGLIAN WATER SERVICES and in accordance with the

requirements of the HEALTH AND SAFETY AT WORK All work should be carried out as laid down in the

ACT 1974. NATIONAL JOINT COMMITTEE for the water services,

' SAFE WORKING IN SEWERS AND AT SEWERAGE

WORKS ' publication.

ASD Engineering is part of the ASD Consultants group

ASD Consultants

PLAN 16A Bridge Street

01 Oct 2014 Halesworth

Tel: 01986 872250

Fax: 01986 872228

Suffolk DX 51201 Halesworth

20141155 ADD IP19 8AQ E-mail: enquiries@ ASD-consultants.co.uk

Anglia Survey & Design

1994 - 2014.

You might also like

- Cat 3508-B Electr - DiagramDocument2 pagesCat 3508-B Electr - DiagramCésar Pérez88% (8)

- Desjoyaux Pool MaintenanceDocument6 pagesDesjoyaux Pool MaintenanceSaikumar Sela50% (2)

- Max Liboiron - Pollution Is Colonialism (2021, Duke University Press) - Libgen - LiDocument217 pagesMax Liboiron - Pollution Is Colonialism (2021, Duke University Press) - Libgen - LiIsadora67% (3)

- Rainsoft Am 744Document5 pagesRainsoft Am 744Greg ReynekeNo ratings yet

- Attic Access - TguDocument5 pagesAttic Access - TgujhamiralexNo ratings yet

- 2-Hydraulic Diagram - WW LineDocument1 page2-Hydraulic Diagram - WW Linedilarasen334No ratings yet

- Second Floor Reflected Ceiling Plan: LegendDocument1 pageSecond Floor Reflected Ceiling Plan: Legendaceboy_17No ratings yet

- Pump Foundation Plan Pump Foundation Plan: NotesDocument1 pagePump Foundation Plan Pump Foundation Plan: NotesamitNo ratings yet

- 3512B & 3516B Engines With Premium Power Electrical System Wiring Harness For Marine AuxilaryDocument2 pages3512B & 3516B Engines With Premium Power Electrical System Wiring Harness For Marine AuxilaryGeorge GuoNo ratings yet

- Rapid Tower 08-05-2019 -DwDocument2 pagesRapid Tower 08-05-2019 -DwFrancis BautistaNo ratings yet

- Legends: Plumbing Layout P: Service AreaDocument1 pageLegends: Plumbing Layout P: Service AreaSherwin Jann ChavezNo ratings yet

- P1142 HM BSS Adf SD 05 - L5Document1 pageP1142 HM BSS Adf SD 05 - L5Polycarp Danson SigaiNo ratings yet

- PRA SITEPLAN JABONG VILLAGE-2022 07 04lDocument1 pagePRA SITEPLAN JABONG VILLAGE-2022 07 04lPebriansyah BSNo ratings yet

- Deepak Filling Point-ModelDocument1 pageDeepak Filling Point-ModelPRUTHWIRAJ DAS [पृथ्वीराज दास]No ratings yet

- 0815stfrancissch3pln50v4-0815 3 1304 GF LayoutDocument1 page0815stfrancissch3pln50v4-0815 3 1304 GF LayoutPhilip MelemuriyilNo ratings yet

- Toberas_ClackCorporation1Document12 pagesToberas_ClackCorporation1degrsacNo ratings yet

- Tunnel Ventilation LayoutDocument1 pageTunnel Ventilation LayoutPrivate PersonNo ratings yet

- 1113 Pipe Lay PosterDocument1 page1113 Pipe Lay PosterATQNo ratings yet

- Capitol Heights Typical Floor PlanDocument1 pageCapitol Heights Typical Floor PlanKaval HoraNo ratings yet

- Structural Drawing (Sleeves in Raft)Document3 pagesStructural Drawing (Sleeves in Raft)Omer HayatNo ratings yet

- 2) 2023.12.14 - SSB - MODIFIED Ground T FLOOR PLANS-FLOOR PLANSDocument1 page2) 2023.12.14 - SSB - MODIFIED Ground T FLOOR PLANS-FLOOR PLANSchan.bujjiNo ratings yet

- 6starmhroof-005 (Sheet 1 of 6)Document1 page6starmhroof-005 (Sheet 1 of 6)Jacob FryeNo ratings yet

- 6starmhconcourse-003 (Sheet 1 of 6)Document1 page6starmhconcourse-003 (Sheet 1 of 6)Jacob FryeNo ratings yet

- B974832002P00-480V 462-MCC-005Document1 pageB974832002P00-480V 462-MCC-005te2.esNo ratings yet

- Osp 401 Boat Deck 0.3Document1 pageOsp 401 Boat Deck 0.3erikacheuqueman80No ratings yet

- Blasting Quantities Long SectionDocument1 pageBlasting Quantities Long Sectiontapiwanaishe maunduNo ratings yet

- 5076-Al Wasl-Plot 38 1000 Series PlanDocument6 pages5076-Al Wasl-Plot 38 1000 Series Plandubai eyeNo ratings yet

- fgdrgMA UNIFILAR GENERALDocument1 pagefgdrgMA UNIFILAR GENERALcarlosNo ratings yet

- 7 2 PDFDocument20 pages7 2 PDFservisNo ratings yet

- Mount 1Document1 pageMount 1njizbentulan88No ratings yet

- Pipelay Capabilities WorldwideDocument1 pagePipelay Capabilities WorldwideJamesNo ratings yet

- PHJ Alc PRC Pid Dis - R10 - 25.11.2023Document37 pagesPHJ Alc PRC Pid Dis - R10 - 25.11.2023Guddus J AmeenNo ratings yet

- Legends: 120 kVA UPS-1 120 kVA UPS-2 120 kVA UPS-3Document1 pageLegends: 120 kVA UPS-1 120 kVA UPS-2 120 kVA UPS-3kajale.shrikantNo ratings yet

- Electrical Circuit - R55W9Document19 pagesElectrical Circuit - R55W9namvinhNo ratings yet

- Group 2 Electrical CircuitDocument2 pagesGroup 2 Electrical CircuitLuciano SantosNo ratings yet

- MR Regis N MRS Dorcas Taruvinga - 050209Document1 pageMR Regis N MRS Dorcas Taruvinga - 050209pzarchitectural99No ratings yet

- Alghanim International: General Trading & Contracting Co. LTDDocument1 pageAlghanim International: General Trading & Contracting Co. LTDahmadtaiyabiNo ratings yet

- DRAINAGE LAYOUT-ModelDocument1 pageDRAINAGE LAYOUT-ModelAya EzzNo ratings yet

- Somaa Bay Pool Reef Town - Emw 3 (1) - Pool PlanDocument1 pageSomaa Bay Pool Reef Town - Emw 3 (1) - Pool PlanAhmed NaserNo ratings yet

- Key Plan DC: Kone Internal Reference XDocument4 pagesKey Plan DC: Kone Internal Reference XAslamNo ratings yet

- 6starmhplatform-004 (Sheet 1 of 6)Document1 page6starmhplatform-004 (Sheet 1 of 6)Jacob FryeNo ratings yet

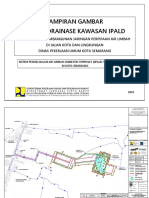

- L2 E. Desain Drainase Cover v4Document17 pagesL2 E. Desain Drainase Cover v4Muhammad WafidNo ratings yet

- Construction Drawing: LegendDocument1 pageConstruction Drawing: LegendrajavelNo ratings yet

- Group 3 Electrical Circuit (1/3)Document3 pagesGroup 3 Electrical Circuit (1/3)Vu HoiNo ratings yet

- All FloorsDocument6 pagesAll Floorsakashmaurya134No ratings yet

- Pid General Rev.b1-Pid GeneralDocument1 pagePid General Rev.b1-Pid GeneralDaniel GomezNo ratings yet

- TEC Series CatalogueDocument9 pagesTEC Series CatalogueAshutosh VishwakarmaNo ratings yet

- Ta 193115 001Document1 pageTa 193115 001Rene HebaNo ratings yet

- ASME-B36-19M-Stainless-Steel-PipeDocument4 pagesASME-B36-19M-Stainless-Steel-Pipemax salazarNo ratings yet

- Dhem Arca Pa191 E2 DR 20lg02 c2Document1 pageDhem Arca Pa191 E2 DR 20lg02 c2michael esoNo ratings yet

- Baylink Dwg.27.8.23pdfDocument12 pagesBaylink Dwg.27.8.23pdfshohugNo ratings yet

- Pra Saa NTB A 101Document1 pagePra Saa NTB A 101sbt.abhishekNo ratings yet

- Sector 230Document1 pageSector 230Mohit SinghNo ratings yet

- AADHYA 1194 0065 B PERAVALI Malleswaram 2022Document1 pageAADHYA 1194 0065 B PERAVALI Malleswaram 2022Usha Hasini VelagapudiNo ratings yet

- De Hyc 1901 P10 SP4Document1 pageDe Hyc 1901 P10 SP4williamNo ratings yet

- G3516B Generator Set Electrical System: Instrument Panel LayoutDocument4 pagesG3516B Generator Set Electrical System: Instrument Panel LayoutЮрий ШариковNo ratings yet

- UNDP - SZ - Environment - Doors-Windows Schedule PDFDocument1 pageUNDP - SZ - Environment - Doors-Windows Schedule PDFA MNo ratings yet

- FS0654-DOD-ZZ-XX-DR-M-2013 - Domestic Water Distribution Schematic - Construction - C01 - 0Document1 pageFS0654-DOD-ZZ-XX-DR-M-2013 - Domestic Water Distribution Schematic - Construction - C01 - 0mvrisleyNo ratings yet

- 02 - House Hugo - Rev 2 - 12.03.2024-Elev + SectionsDocument1 page02 - House Hugo - Rev 2 - 12.03.2024-Elev + SectionsD HOLNo ratings yet

- Public Market PDFDocument1 pagePublic Market PDFjefNo ratings yet

- 55-19007-DR-0037 C01 - Pool Section Slab Reinforcement SHT 1 of 2Document1 page55-19007-DR-0037 C01 - Pool Section Slab Reinforcement SHT 1 of 2Salam AlaikumNo ratings yet

- 0100-A-100-Layout-Basement Floor - 1Document1 page0100-A-100-Layout-Basement Floor - 1miraclechigozirimfestusNo ratings yet

- What Squirt Teaches Me about Jesus: Kids Learning about Jesus while Playing with FidoFrom EverandWhat Squirt Teaches Me about Jesus: Kids Learning about Jesus while Playing with FidoNo ratings yet

- 3 FullDocument9 pages3 FullVijay KumarNo ratings yet

- PROSIDING - SUNARNO - 2019 - J. - Phys. - Conf. - Ser. - 1295 - 012043Document8 pagesPROSIDING - SUNARNO - 2019 - J. - Phys. - Conf. - Ser. - 1295 - 012043Sunarno UnnesNo ratings yet

- Nagpur City Profile PDFDocument9 pagesNagpur City Profile PDFpradeepNo ratings yet

- Technical Economic Analysis of A HybridDocument10 pagesTechnical Economic Analysis of A HybridVajoi OctavianNo ratings yet

- Bergen Port Shore ConnectionDocument2 pagesBergen Port Shore ConnectionJavier EverestNo ratings yet

- Bulacan Agricultural State College: Republic of The PhilippinesDocument10 pagesBulacan Agricultural State College: Republic of The PhilippinesAlbert UlacNo ratings yet

- Crossrail at Canary WharfDocument8 pagesCrossrail at Canary WharfAli AlizadehNo ratings yet

- La Mesa Eco Park Swot AnalysisDocument4 pagesLa Mesa Eco Park Swot AnalysisDaynalou Gaille PeñeraNo ratings yet

- Don't Scrap The Waste - The Need For Broader System Boundaries in Bioplastic Food Packaging Life-Cycle Assessment - A Critical ReviewDocument14 pagesDon't Scrap The Waste - The Need For Broader System Boundaries in Bioplastic Food Packaging Life-Cycle Assessment - A Critical ReviewCanarieNo ratings yet

- Diagnostic PhiloDocument4 pagesDiagnostic PhiloQueen MoneringNo ratings yet

- CO2 & SelexolDocument18 pagesCO2 & Selexolmihaileditoiu2010No ratings yet

- Material Safety Data Sheet: 1. Identification of The Substance/preparation and The CompanyDocument5 pagesMaterial Safety Data Sheet: 1. Identification of The Substance/preparation and The CompanySonia CaruntuNo ratings yet

- Shell Rimula R5 E 10W-40Document2 pagesShell Rimula R5 E 10W-40MUHAMMAD LUTHFINo ratings yet

- Pan Granulator For Fertilizer, Disc Granulator Machine For Granulating FertilizerDocument2 pagesPan Granulator For Fertilizer, Disc Granulator Machine For Granulating Fertilizervaratharajan g rNo ratings yet

- AQI - CalculatorDocument2 pagesAQI - CalculatorAnik KumarNo ratings yet

- Feasibility Study of A Low Cost Saltwater Lamp ForDocument11 pagesFeasibility Study of A Low Cost Saltwater Lamp ForGail TorrefielNo ratings yet

- Research ProposalDocument4 pagesResearch Proposalapi-703354548No ratings yet

- Instruction Manual: Each Bag Contains 50 KG of Compost Provided That The Submitted Information Is CompleteDocument21 pagesInstruction Manual: Each Bag Contains 50 KG of Compost Provided That The Submitted Information Is CompleteavieNo ratings yet

- MAKING VALUE JUDGMENT ON CRITICAL ISSUES-activity SheetDocument1 pageMAKING VALUE JUDGMENT ON CRITICAL ISSUES-activity SheetAudrey Ann Tugad PinasNo ratings yet

- PEECO-FINAL Clint E. MosenabreDocument36 pagesPEECO-FINAL Clint E. MosenabreJea MosenabreNo ratings yet

- MNGT622 ModuleHandbook 22-23Document18 pagesMNGT622 ModuleHandbook 22-23AcolyteNo ratings yet

- Change ManagementDocument11 pagesChange ManagementSam BrownsNo ratings yet

- The Rio Declaration On Environment and DevelopmentDocument4 pagesThe Rio Declaration On Environment and Developmentanshul0714No ratings yet

- Supplier Risk Assessment: 3 - Leading Questions 0 Poor 1 Average 2 - GoodDocument2 pagesSupplier Risk Assessment: 3 - Leading Questions 0 Poor 1 Average 2 - GoodAnthonyNo ratings yet

- 63 0301-0721 PDFDocument4 pages63 0301-0721 PDFRichardNo ratings yet

- Monitoring-Tool-Home-Likas (1) (Malitlit Es)Document6 pagesMonitoring-Tool-Home-Likas (1) (Malitlit Es)Juvilyn MorenNo ratings yet

- 11, EngDocument7 pages11, EngArbin HoqueNo ratings yet