Professional Documents

Culture Documents

Preliminary - Welding Procedure Specification (WPS)

Preliminary - Welding Procedure Specification (WPS)

Uploaded by

Rudi DaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Preliminary - Welding Procedure Specification (WPS)

Preliminary - Welding Procedure Specification (WPS)

Uploaded by

Rudi DaCopyright:

Available Formats

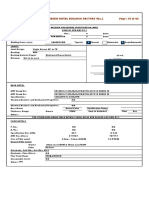

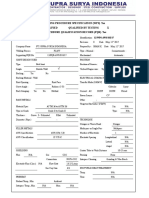

Preliminary - WELDING PROCEDURE SPECIFICATION (WPS)

MAIN PROCEDURE

Company Name : PT. KALIRAYA SARI Page : 1 of 1

WPS No. : 149/WPS/AWS/KRS/2011 Date : July. 10' 2012

Supporting PQR No. : 149/PQR/AWS/KRS/2011 Revision :0

Welding Process (es) : SMAW Type(s) : Manual

Applicable Code/Spec. : AWS D 1.1-(2006) and GS EP STR 301 (Rev. 11)

JOINT DETAIL

20 mm

Type : T Joint - Double Bevel

ASTM A.36

Backing : Yes No

Backing Material : N/A

Back Gouging : Yes No

Method : N/A

S.235

45° ± 5°

12 mm

BASE METALS POSITION

Material Spec. : ASTM A.36 TO S.235 Position of groove :3G

Base metal group : II TO I Vertical Progression :- Fillet : N/A

Thick. Range, Groove : actual will be recorded

Fillet : N/A PREHEAT

Diameter Range (Pipe) : Plate / O ≥ 24" Preheat Temp. Min : 20 ° ( Ambient temp )

Carbon content : actual will be recorded Interpass Temp. Max : 250 °C (actual will be recorded )

Other : -

FILLER METAL POSTWELD HEAT TREATMENT

AWS Specification : A5.1 & A 5.5 Temperature : N/A

AWS Classification : E.7016-1 & E.7018-G Time : N/A

AWS Groups : F4

Size of Filler Metal : 3,2 mm & 4 mm SHIELDING

Trade Name : ESAB OK 53.68 & ESAB OK 48.08 Flux : N/A Gas N/A

Composition N/A

ELECTRICAL CHARACTERISTICS Flow rate N/A

Transfer Mode(GMAW) : Short Circuiting Spray Electrode-Flux (Class) : N/A Gas Cup Size N/A

Globular Pulsed

Current : AC DCSP DCRP TECHNIQUE

Tungsten Electrode (GTAW) Stringer or Weave bead : String & Weave Bead

Size : N/A Multi Pass or Single Pass (per side) : Multi Pass or Single Pass

Type : N/A Number of Electrode : Multiple or Single

Other : - Contact Tube to Work Distance : N/A

Peening : N/A

Interpass Cleaning : Grind, Brush & Chipping

WELDING PARAMETER

Filler Metal Current Travel

Weld Pass Heat Input

Process Position Dia. Type & Amp. (A) Volt (V) Speed Remarks

(es) AWS Class (KJ/mm)

( mm ) Polarity Range Range (mm/min)

ROOT SMAW 3G E.7016 - 1 3.2 mm DCRP 80 - 130 20 - 30 80 - 125 0.77 - 2.93 -

HOT SMAW 3G E.7016 - 1 3.2 mm DCRP 80 - 130 20 - 35 95 - 150 0.64 - 2.87 -

FILL SMAW 3G E.7018 - G 4 mm DCRP 150 - 200 20 - 35 120 - 150 1.20 - 3.50 -

CAPPING SMAW 3G E.7018 - G 4 mm DCRP 150 - 200 20 - 35 120 - 150 1.20 - 3.50 -

Prepared by, Approved by, Reviewed by, Verified by,

PT. KALIRAYA SARI PT. KALIRAYA SARI PJ. TEK MANDIRI PT. TOTAL INDONESIE

Sintong W Hutahaean Rudy Wahyudi Afid M

Welding Engineer QA/QC Manager FO/INS/OPS

You might also like

- Bridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, OdishaDocument5 pagesBridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, Odishaniraj mouryaNo ratings yet

- Wps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxDocument5 pagesWps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxjobert100% (1)

- Welding Process: Mma/Smaw TYPES: Manual: Preliminary Welding Procedure Specification (PWPS) Nama: Shah Nadzri Bin JasmirDocument3 pagesWelding Process: Mma/Smaw TYPES: Manual: Preliminary Welding Procedure Specification (PWPS) Nama: Shah Nadzri Bin Jasmirshahaljawaie87100% (3)

- Aws D1.6 - SS316 WPSDocument1 pageAws D1.6 - SS316 WPSBoby Thomas0% (1)

- Welding Procedure Specification Krishna Steel Industries: Electrical Characterstics (Qw-409)Document2 pagesWelding Procedure Specification Krishna Steel Industries: Electrical Characterstics (Qw-409)Harshit AdwaniNo ratings yet

- Welding Procedure Specification (WPS) : Section IX, ASME Boiler and Pressure Vessel CodeDocument1 pageWelding Procedure Specification (WPS) : Section IX, ASME Boiler and Pressure Vessel CodeKishan ChauhanNo ratings yet

- WPSDocument6 pagesWPSYASH BARDHAN SinghNo ratings yet

- Aic Asf PQR 0121Document2 pagesAic Asf PQR 0121AHMED MEDANYNo ratings yet

- PIPING WPS and PQRDocument5 pagesPIPING WPS and PQRshibaprasad0115No ratings yet

- Astm 537 CL.1 WPSDocument2 pagesAstm 537 CL.1 WPSaudiihussain67% (3)

- WPS NMB 001Document6 pagesWPS NMB 001mohamed nasserNo ratings yet

- Draf WPSDocument2 pagesDraf WPSMj EdinNo ratings yet

- WDI-WPS-072 Rev.00 SMAW 2Document4 pagesWDI-WPS-072 Rev.00 SMAW 2MohamedNo ratings yet

- WPS (Welding of Hub To Blade)Document2 pagesWPS (Welding of Hub To Blade)workshop13.asaNo ratings yet

- Welding Procedure Specification: ST NDDocument1 pageWelding Procedure Specification: ST NDMaung SleeperNo ratings yet

- Aic Asf PQR 0120Document2 pagesAic Asf PQR 0120AHMED MEDANYNo ratings yet

- SPL - PQR-WPS-SWPS SmawDocument7 pagesSPL - PQR-WPS-SWPS Smawgopuvinu4uNo ratings yet

- HRP Ii WPS LGP 50aDocument2 pagesHRP Ii WPS LGP 50aRohiNo ratings yet

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewDocument4 pages(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewBIIS QAQC Babu SivaNo ratings yet

- Afcons Infrastructure Limited: Procedure Qualification Record (PQR)Document21 pagesAfcons Infrastructure Limited: Procedure Qualification Record (PQR)GaapchuNo ratings yet

- QW 482 WPSDocument2 pagesQW 482 WPSsmit patelNo ratings yet

- Draft WPSDocument3 pagesDraft WPSWale OyeludeNo ratings yet

- Weld in G P Ro Cedu Re SP Ecifica Tio N (WP S)Document2 pagesWeld in G P Ro Cedu Re SP Ecifica Tio N (WP S)almasrizalNo ratings yet

- Welding Proposed Pwps For Our Jubail WorkDocument2 pagesWelding Proposed Pwps For Our Jubail WorkAlam MD Sazid100% (1)

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04Document9 pages(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04BIIS QAQC Babu SivaNo ratings yet

- WPS - 600 MW ChampaDocument7 pagesWPS - 600 MW ChampaAmjad PathanNo ratings yet

- WQTDocument1 pageWQTRamkunwar YadavNo ratings yet

- WpsDocument2 pagesWpssamer8saifNo ratings yet

- PhuBia-WPS-AWS D1.1-8-6-2011Document3 pagesPhuBia-WPS-AWS D1.1-8-6-2011poulmack100% (1)

- Note: For CJP Grove Details Will Be Based From AWS D1.1 2015 Figure 3.3 Prequalified CJP Grove WeldDocument2 pagesNote: For CJP Grove Details Will Be Based From AWS D1.1 2015 Figure 3.3 Prequalified CJP Grove WeldTadaya KasaharaNo ratings yet

- PQR Format PDFDocument2 pagesPQR Format PDFHarshit Adwani100% (2)

- Piping WPS SMAWDocument2 pagesPiping WPS SMAWJk KarthikNo ratings yet

- Preliminary Welding Procedure Specification (PWPS) : South Pars Gas Field Development Phase 14Document2 pagesPreliminary Welding Procedure Specification (PWPS) : South Pars Gas Field Development Phase 14Vijaya Barani100% (1)

- Annex M AWS D1.1/D1.1M:2015: Sample WPS Form (GMAW & FCAW) Welding Procedure Specification (WPS)Document2 pagesAnnex M AWS D1.1/D1.1M:2015: Sample WPS Form (GMAW & FCAW) Welding Procedure Specification (WPS)Daniel ZapataNo ratings yet

- Welding Procedure SpecificationDocument4 pagesWelding Procedure SpecificationBhargav BbvsNo ratings yet

- Welding Procedure Welding Procedure Specification SpecificationDocument2 pagesWelding Procedure Welding Procedure Specification SpecificationHamid MansouriNo ratings yet

- Welding Procedure Specification Structural 3G PDFDocument3 pagesWelding Procedure Specification Structural 3G PDFsebincherian100% (1)

- WPS 7018+70S2Document8 pagesWPS 7018+70S2rajuNo ratings yet

- PQR A106 HAL-1Document1 pagePQR A106 HAL-1Budi Setia RahmanNo ratings yet

- Welding Procedure Specification (WPS) : Owner: (As Per QW 482 of ASME Section IX)Document2 pagesWelding Procedure Specification (WPS) : Owner: (As Per QW 482 of ASME Section IX)Saravanan Palanisamy Lakshmi100% (1)

- Aic Asf PQR 0122Document2 pagesAic Asf PQR 0122AHMED MEDANYNo ratings yet

- Wps For Steel RodsDocument5 pagesWps For Steel RodsHamid MansouriNo ratings yet

- WPS CuNiDocument1 pageWPS CuNiDieter Huaman ToscanoNo ratings yet

- WPS-035 - (Pno.15e To Pno.7) - 2Document2 pagesWPS-035 - (Pno.15e To Pno.7) - 2Allahyar YekkalamNo ratings yet

- Welding Procedure Specifications (WPS) : AWS D1.1Document2 pagesWelding Procedure Specifications (WPS) : AWS D1.1BS AhnNo ratings yet

- WPSDocument2 pagesWPSAlam MD Sazid100% (1)

- Negemco For Engineering & Contracting Processing Equipment Welding Procedure Spcifications (Qw-482)Document3 pagesNegemco For Engineering & Contracting Processing Equipment Welding Procedure Spcifications (Qw-482)Khaled GamalNo ratings yet

- Welding Procedure Specification SampleDocument2 pagesWelding Procedure Specification SampleBrown's P LikoNo ratings yet

- PQR FC-12-22Document2 pagesPQR FC-12-22cycsi02No ratings yet

- Arl-Al - WPS-001 PDFDocument2 pagesArl-Al - WPS-001 PDFrajuajiNo ratings yet

- PQR DT Macro 60mm Smaw Astm A 516 Gr60Document4 pagesPQR DT Macro 60mm Smaw Astm A 516 Gr60Boran YelkenciogluNo ratings yet

- WPS-PQR RepairDocument16 pagesWPS-PQR RepairmohammedetaNo ratings yet

- PQR - Gmaw BCCDocument2 pagesPQR - Gmaw BCCBasel MohammadNo ratings yet

- PQR FC-19-23Document2 pagesPQR FC-19-23cycsi02No ratings yet

- PQR FC-19-23.1Document2 pagesPQR FC-19-23.1cycsi02No ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- A Guide to Vintage Audio Equipment for the Hobbyist and AudiophileFrom EverandA Guide to Vintage Audio Equipment for the Hobbyist and AudiophileNo ratings yet

- In Service Welding Calculation (Confidential)Document1 pageIn Service Welding Calculation (Confidential)Rudi DaNo ratings yet

- International Standard: Specification and Qualification of Welding Procedures For Metallic Materials - General RulesDocument8 pagesInternational Standard: Specification and Qualification of Welding Procedures For Metallic Materials - General RulesRudi DaNo ratings yet

- Salisbury University Welding Safety: Page 1 of 22Document22 pagesSalisbury University Welding Safety: Page 1 of 22Rudi DaNo ratings yet

- Lecture Notes: Welding Introduction: Handout PPT - On Website Higgins - Ch. 17, Section 4 WeldingDocument3 pagesLecture Notes: Welding Introduction: Handout PPT - On Website Higgins - Ch. 17, Section 4 WeldingRudi DaNo ratings yet

- Introduction To Welding Health and SafetyDocument7 pagesIntroduction To Welding Health and SafetyRudi DaNo ratings yet

- "Downsizing" in The World of Resistance WeldingDocument15 pages"Downsizing" in The World of Resistance WeldingRudi DaNo ratings yet

- Memoryspectrum: Never Stop ThinkingDocument29 pagesMemoryspectrum: Never Stop ThinkingAlberto JimenezNo ratings yet

- John Highter ResumeDocument1 pageJohn Highter Resumeapi-284455343No ratings yet

- Rish DPM HZ: 72mm X 144mmDocument18 pagesRish DPM HZ: 72mm X 144mmSrinivasan SriniNo ratings yet

- Wa0010Document33 pagesWa001020bcs3236 ayush pratap singhNo ratings yet

- System Administrator ResumeDocument4 pagesSystem Administrator Resumewiznu46No ratings yet

- White Collor UnionDocument33 pagesWhite Collor Uniondeepa makhijaNo ratings yet

- Fatigue Analysis of 6300 Liters Pressure Vessel by Using Cyclic ServiceDocument7 pagesFatigue Analysis of 6300 Liters Pressure Vessel by Using Cyclic ServiceFisul RahumanNo ratings yet

- Tla ch03Document2 pagesTla ch03api-334420312No ratings yet

- Gantt ChartsDocument5 pagesGantt ChartsedchellemNo ratings yet

- Company Profile Monjil PrivateDocument2 pagesCompany Profile Monjil PrivateYousuf MunniNo ratings yet

- Employers Federation of IndiaDocument11 pagesEmployers Federation of Indiabiju100% (2)

- Introduction To Neural NetworksDocument51 pagesIntroduction To Neural NetworkssuryaNo ratings yet

- For Questions 1-12, Read The Text Below and Decide Which Answer Best Each GapDocument2 pagesFor Questions 1-12, Read The Text Below and Decide Which Answer Best Each Gapjaszmina hosszuNo ratings yet

- Bgy. Sindalan Vs CA - DigestDocument2 pagesBgy. Sindalan Vs CA - Digestremoveignorance100% (1)

- R02 IND246 IM ML WebDocument349 pagesR02 IND246 IM ML WebRich Vidal Apza SiñaniNo ratings yet

- Promoting The ProtegeDocument9 pagesPromoting The Protegebhavikcdoshi_88100% (1)

- Sonus Faber Olympica III Loudspeakers Review Test LoresDocument6 pagesSonus Faber Olympica III Loudspeakers Review Test LoresMilan TrengovskiNo ratings yet

- Of Its Modern Innovation.: BecauseDocument2 pagesOf Its Modern Innovation.: BecauseAlie GurreaNo ratings yet

- The Bilderberg GroupDocument35 pagesThe Bilderberg GroupTimothy100% (2)

- Final Constant Maturity Swap CappedDocument2 pagesFinal Constant Maturity Swap CappedLeo YamauchiNo ratings yet

- Lecture 1 - IntroductionDocument22 pagesLecture 1 - IntroductionNick jamesNo ratings yet

- Private Label Sourcing For: Lessons, Mistakes and StrategiesDocument15 pagesPrivate Label Sourcing For: Lessons, Mistakes and StrategiesДенис АкуляковNo ratings yet

- 175 010210Document2 pages175 010210Abu Anas M.SalaheldinNo ratings yet

- CEO and Executive Director - CV HICHAM FRAOUIDocument4 pagesCEO and Executive Director - CV HICHAM FRAOUIHicham FraouiNo ratings yet

- Green Revolution in Pakistan by Umair Alam 1817143Document4 pagesGreen Revolution in Pakistan by Umair Alam 1817143Umair RehmanNo ratings yet

- Surgical Treatment of Severe Osteoporosis Includin-DikonversiDocument6 pagesSurgical Treatment of Severe Osteoporosis Includin-DikonversikhairaniNo ratings yet

- Cuckoo Search (CS) Algorithm - Matlab CodeDocument4 pagesCuckoo Search (CS) Algorithm - Matlab CodeGogyNo ratings yet

- Dokumen - Pub Intelligent Systems in Digital Transformation Theory and Applications 9783031165979 9783031165986Document626 pagesDokumen - Pub Intelligent Systems in Digital Transformation Theory and Applications 9783031165979 9783031165986mohamednoorNo ratings yet

- Calophyllum Inophyllum L. - A Prospective Non-Edible Biodiesel Feedstock. Study of Biodiesel Production, Properties, Fatty Acid Composition, Blending and Engine PerformanceDocument12 pagesCalophyllum Inophyllum L. - A Prospective Non-Edible Biodiesel Feedstock. Study of Biodiesel Production, Properties, Fatty Acid Composition, Blending and Engine PerformanceDr. Abdelaziz AtabaniNo ratings yet

- Development of QR-code Based Interactive Dynamic Billboard System With Motion DetectionDocument10 pagesDevelopment of QR-code Based Interactive Dynamic Billboard System With Motion DetectionEditor IjasreNo ratings yet