Professional Documents

Culture Documents

QC Flow Chart

QC Flow Chart

Uploaded by

Felix Loo Ter YinnOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

QC Flow Chart

QC Flow Chart

Uploaded by

Felix Loo Ter YinnCopyright:

Available Formats

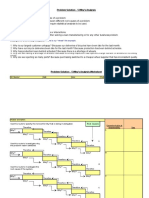

u QC Program:

Quality Assurance Flow Chart

Item Customer Sales R&D Q.A Manufactu Product Purchase Inventory

ring control control

Info. Survey

Marketing Request Inquiry Design evaluation

&

Design Quote

Contract

Design check

Sample

Approval Sample test

Sample approval

Pilot Pilot run & Reliability test

Run

& Specification preparation

Mass

Product Mass production

Inspection

Ship Shipment

Out

Ship out

Info. Claim

Failure analysis

Sales

Service Analysis report

Corrective action

Tracking

1. TQM Activities 2.TPM Activities 3.Process improvement proposal

Q.A

Activity 1. ISO 9002 Maintenance Activities 5.Education And Training Activities

6. Standardization Management 7.Equipment calibration

Reliability Conditions

NO Item Test Condition Applicable

Standard

Storage At 60±2 96~100 hrs MIL-202E

High Temperature

Surrounding Temperature Then Storage At

1 Storage Normal Condition 4hrs

Storage At –20±2 96~100 hrs

Low Temperature MIL-202E

Surrounding Temperature, Then Storage At

2 Storage Normal Condition 4hrs

1.Storage 96~100 hrs 60±2 , 90%RH MIL-202E

High Temperature

Surrounding Temperature, Then Storage At

/Humidity Storage Normal Condition 4hrs .(Polarizer may fail

in this environment).

Or

3 2.Storage 96~100 hrs 40±2 , 90%RH

Surrounding Temperature, Then

Storage At

Normal Condition 4 hrs.

-20 25 60 25

4 Temperature Cycling (30Mins) (5Mins) (30Mins) (5Mins) MIL-202E

10 Cycle

10~55Hz ( 1 Minute ) 1.5mm MIL-202E

5 Vibration X,Y And Z Direction (Each 2hrs)

Packing Weight (Kg) Drop High (Cm)

0 ~ 45.4 122

6.

Drop Test MIL-810E

45.4 ~ 90.8 76

90.8 ~ 454 61

Over 454 46

You might also like

- Scrum Master Interview QuestionsDocument93 pagesScrum Master Interview QuestionsTanmoy Das100% (11)

- Certified Quality Technician PDFDocument4 pagesCertified Quality Technician PDFSon of RizqNo ratings yet

- Excel Bill of Materials Bom TemplateDocument8 pagesExcel Bill of Materials Bom TemplateRavi ChhawdiNo ratings yet

- Jabilization 2010Document20 pagesJabilization 2010Star GazerNo ratings yet

- ISO 9001 Required Documentation and StepsDocument3 pagesISO 9001 Required Documentation and StepsganandmailNo ratings yet

- 5 Whys Analysis SheetDocument3 pages5 Whys Analysis SheetbhushansalunkeNo ratings yet

- Supplier Audits and SurveysDocument13 pagesSupplier Audits and SurveysBighneswar PatraNo ratings yet

- Corrective Action: Organization Details JustificationDocument1 pageCorrective Action: Organization Details JustificationaezacsNo ratings yet

- Deliverables in ConstructionDocument26 pagesDeliverables in ConstructionAnonymous xFCmP2K0D550% (2)

- Acceptance Sampling: Dr. Syed Amir IqbalDocument30 pagesAcceptance Sampling: Dr. Syed Amir IqbalSyedAneelMussawerNo ratings yet

- Cost of Quality Worksheet: Classification Examples # Totals Prevention CostsDocument2 pagesCost of Quality Worksheet: Classification Examples # Totals Prevention CostsvitortavaresNo ratings yet

- CPA Compliance ChecklistDocument25 pagesCPA Compliance ChecklistFizz FirdausNo ratings yet

- TS Auditor CourseDocument159 pagesTS Auditor CourseSally Ahmed100% (1)

- Project Review Check ListDocument12 pagesProject Review Check ListAjay Kumar KhattarNo ratings yet

- LRQA Management System Audit 2011Document18 pagesLRQA Management System Audit 2011ServosteelNo ratings yet

- Cost of Quality: Prepared By-Prashant TripathiDocument41 pagesCost of Quality: Prepared By-Prashant TripathiManoj PachariyaNo ratings yet

- Employee Training LogDocument6 pagesEmployee Training LogRoosy RoosyNo ratings yet

- Lab Audit Checklist (Battery Lab) - Lead AcidDocument1 pageLab Audit Checklist (Battery Lab) - Lead AcidpuneiatmanishNo ratings yet

- Interaction of ProcessesDocument1 pageInteraction of ProcessesBharath100% (1)

- 4.1a - 4.1d Process PlanningDocument2 pages4.1a - 4.1d Process PlanningFendiNo ratings yet

- Project PlaningDocument64 pagesProject Planingsalipm100% (1)

- Customer Complaints LogDocument3 pagesCustomer Complaints LogSama NthaNo ratings yet

- RBA - Awareness Briefing - Suppliers - ASEMA 2018 PDFDocument27 pagesRBA - Awareness Briefing - Suppliers - ASEMA 2018 PDFcheri kokNo ratings yet

- Induction TrainingDocument6 pagesInduction Trainingsowmiya245No ratings yet

- Failure Modes and Effects Analysis (FMEA) Quad Torc 23/05/2015Document3 pagesFailure Modes and Effects Analysis (FMEA) Quad Torc 23/05/2015Vishnu RoyNo ratings yet

- Controlled Documents' Masterlist of EPSA CentralDocument85 pagesControlled Documents' Masterlist of EPSA CentralGetahunNo ratings yet

- Quality Management System Checklist Iso 9001Document13 pagesQuality Management System Checklist Iso 9001Ayman Hamed MalahNo ratings yet

- 03 - Design Development Documents (DBB)Document7 pages03 - Design Development Documents (DBB)budok23No ratings yet

- Advanced Planning and Scheduling APS Complete Self-Assessment GuideFrom EverandAdvanced Planning and Scheduling APS Complete Self-Assessment GuideNo ratings yet

- Environmental AuditingDocument334 pagesEnvironmental AuditingMKPashaPashaNo ratings yet

- MAI 07 - Control of Insp Measuring and Testing Equipment - DJ - v1Document9 pagesMAI 07 - Control of Insp Measuring and Testing Equipment - DJ - v1IT Support - FernanNo ratings yet

- Jed 588Document5 pagesJed 588sateeshkoriNo ratings yet

- QMPP Compliance Evaluation. Jan 09Document6 pagesQMPP Compliance Evaluation. Jan 09Alejandro100% (3)

- Process Audit Plan ScheduleDocument4 pagesProcess Audit Plan ScheduleTravisNo ratings yet

- Work Instruction Template PDFDocument2 pagesWork Instruction Template PDFdrg. Bobet Evih Hedi I.R., MMRNo ratings yet

- 2014 06 23 FMEA SlidesDocument19 pages2014 06 23 FMEA SlidesMadhan RajNo ratings yet

- M3 Corrective Action Form TemplateDocument1 pageM3 Corrective Action Form Templateyohanes wilasaNo ratings yet

- Check List para Revision de PpapDocument8 pagesCheck List para Revision de PpapCaleb CalderónNo ratings yet

- Awareness Posters - ISODocument17 pagesAwareness Posters - ISOrahim80abNo ratings yet

- Audit ProgrammeDocument3 pagesAudit Programmezahrahassan78No ratings yet

- Failure Analysis ReportDocument6 pagesFailure Analysis ReportAyaz BhattiNo ratings yet

- FMEADocument5 pagesFMEAmz007No ratings yet

- Structural Inspection Checklist For FactoryDocument1 pageStructural Inspection Checklist For FactoryAnonymous FD64zqL6S100% (1)

- Fmea Process TemplateDocument20 pagesFmea Process TemplateLazarasBenny IsprithiyoneNo ratings yet

- Pitfalls of Testing and CommissioningDocument43 pagesPitfalls of Testing and CommissioningSCottNo ratings yet

- ISO 9001-2015 Implementation TimelineDocument1 pageISO 9001-2015 Implementation TimelineGiovanniNo ratings yet

- Processaudit VDA 6.3 2010 enDocument37 pagesProcessaudit VDA 6.3 2010 enAdilson DoboszNo ratings yet

- HACCPDocument6 pagesHACCPnataliatirtaNo ratings yet

- Weekly Safety Inspection Report: SampleDocument3 pagesWeekly Safety Inspection Report: SampleAviects Avie JaroNo ratings yet

- 4.3 Scope of QMSDocument8 pages4.3 Scope of QMSVijayendran VijayNo ratings yet

- What: Where (Location) : When (Date) : Who (Name) : HowDocument3 pagesWhat: Where (Location) : When (Date) : Who (Name) : HowDaniswara Krisna PrabathaNo ratings yet

- PMF-project Quality ManagementDocument41 pagesPMF-project Quality Managementabdella.whateverNo ratings yet

- 5S-Lean Audit Checklist - Manufacturing: Comments On # 1Document1 page5S-Lean Audit Checklist - Manufacturing: Comments On # 1Chin Kok SoonNo ratings yet

- Session-2 & 3 Quality - Evolution of QualityDocument20 pagesSession-2 & 3 Quality - Evolution of Qualitymatten yahyaNo ratings yet

- Resource Breakdown Structure TemplateDocument5 pagesResource Breakdown Structure TemplateUmair BaigNo ratings yet

- Siemens' Motor HandbookDocument20 pagesSiemens' Motor HandbookJerome BaesNo ratings yet

- FMEA Memory JoggerDocument33 pagesFMEA Memory JoggeripatoffNo ratings yet

- RBC Options Strategies - SeagullsDocument2 pagesRBC Options Strategies - Seagullsalypaty100% (1)

- BEGIM Perfume Product LaunchDocument37 pagesBEGIM Perfume Product LaunchMuhammad Yoosuf ShahNo ratings yet

- Cost Accounting: Pricing PolicyDocument10 pagesCost Accounting: Pricing Policy9986212378No ratings yet

- Motorola: Making Quality A PriorityDocument19 pagesMotorola: Making Quality A PriorityKatya Avdieienko100% (1)

- ACCT 302 Financial Reporting II Tutorial Set 4-1Document8 pagesACCT 302 Financial Reporting II Tutorial Set 4-1Ohenewaa AppiahNo ratings yet

- Overall NSA - ICANDocument33 pagesOverall NSA - ICANDristi SaudNo ratings yet

- Dominos ProjectDocument59 pagesDominos ProjectLakhan Singh RajputNo ratings yet

- Clearsight Monitor - Professional Services Industry UpdateDocument9 pagesClearsight Monitor - Professional Services Industry UpdateClearsight AdvisorsNo ratings yet

- Internal Table Operations - Internal Tables and Work Areas - SapnutsDocument4 pagesInternal Table Operations - Internal Tables and Work Areas - SapnutsDeepakNo ratings yet

- Preliminary Engagement ActivitiesDocument6 pagesPreliminary Engagement ActivitiesJennelyn CapenditNo ratings yet

- Jigjiga University ResearchDocument41 pagesJigjiga University ResearchShalle said AdenNo ratings yet

- Placement Opportunity - Aditya Birla Capital (ABC) - BCA, BBA & MBA - Batch 2023Document2 pagesPlacement Opportunity - Aditya Birla Capital (ABC) - BCA, BBA & MBA - Batch 2023Shikhar chauhanNo ratings yet

- Air-Space-Cyberspace: This Application Is Due Back To Your Recruiter byDocument19 pagesAir-Space-Cyberspace: This Application Is Due Back To Your Recruiter byHuy ThânNo ratings yet

- Modified Schedule For Class Test - II Session 2020-21 ODD SemesterDocument3 pagesModified Schedule For Class Test - II Session 2020-21 ODD SemesterGobhiNo ratings yet

- Mini Project - Docx - 5 - 6 - 920230228112814Document3 pagesMini Project - Docx - 5 - 6 - 920230228112814RAHUL DUTTANo ratings yet

- FAR2 Chapter 6Document92 pagesFAR2 Chapter 6EmestaNo ratings yet

- MCQ - Question Bank On Industrial RelationsDocument6 pagesMCQ - Question Bank On Industrial RelationsAfad KhanNo ratings yet

- Developing Service Concepts: Core and Supplementary ElementsDocument41 pagesDeveloping Service Concepts: Core and Supplementary ElementsThịnh NguyễnNo ratings yet

- Cipla AFM...Document22 pagesCipla AFM...Saoni MitraNo ratings yet

- Performance Governance System: PNP P.A.T.R.O.L. Plan 2030Document158 pagesPerformance Governance System: PNP P.A.T.R.O.L. Plan 2030arnelmartin120689No ratings yet

- Alya Atina - Forum 3 - English For AccountingDocument8 pagesAlya Atina - Forum 3 - English For AccountingMuhammad PrasNo ratings yet

- CrowdStrike Investor Briefing - April 2022Document63 pagesCrowdStrike Investor Briefing - April 2022surupaNo ratings yet

- PSA-706 Emphasis On Matter Paragraphs & Other Matter Paragraphs in The Independent Auditor's ReportDocument14 pagesPSA-706 Emphasis On Matter Paragraphs & Other Matter Paragraphs in The Independent Auditor's ReportcolleenyuNo ratings yet

- Project Excution and Control FourDocument40 pagesProject Excution and Control FourMohammad AbdullahNo ratings yet

- Dissertation ExamplesDocument31 pagesDissertation Examplesbree0% (1)

- Final ProjectDocument58 pagesFinal ProjectAhmed FayazNo ratings yet

- HDMF Citizens CharterDocument24 pagesHDMF Citizens CharterEarl Russell S PaulicanNo ratings yet

- RiseSmart Career Transition Services - For Responsability PDFDocument14 pagesRiseSmart Career Transition Services - For Responsability PDFAlaksamNo ratings yet

- Sustainable Marketing SyllabusDocument17 pagesSustainable Marketing Syllabusnanda1101No ratings yet