Professional Documents

Culture Documents

SANDVIK - Steel Designation and Markings - STA-02-030E

SANDVIK - Steel Designation and Markings - STA-02-030E

Uploaded by

Petr HavelCopyright:

Available Formats

You might also like

- Rothe Erde Slewing BearingDocument194 pagesRothe Erde Slewing BearingRafael FurquimNo ratings yet

- Materials Used in ShipbuildingDocument6 pagesMaterials Used in Shipbuildingagknair100% (1)

- Nippon Steel & Sumitomo Metal Seamless Steel Line PipeDocument8 pagesNippon Steel & Sumitomo Metal Seamless Steel Line Pipeharan2000No ratings yet

- The Essentials of Material Science and Technology for EngineersFrom EverandThe Essentials of Material Science and Technology for EngineersRating: 5 out of 5 stars5/5 (1)

- Table of Material Properties For Structural Steel S235, S275, S355, S420Document4 pagesTable of Material Properties For Structural Steel S235, S275, S355, S420vodounnou0% (1)

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Astm - Mag. PropertiesDocument2 pagesAstm - Mag. PropertiesPetr HavelNo ratings yet

- Technical Information: Radial Play (Internal Clearance) in Ball BearingsDocument4 pagesTechnical Information: Radial Play (Internal Clearance) in Ball Bearingsluisbmwm6No ratings yet

- Multi-Purpose Fenders: Trelleborg Marine SystemsDocument7 pagesMulti-Purpose Fenders: Trelleborg Marine SystemssivakumarNo ratings yet

- SKF Pillow Block HousingsDocument64 pagesSKF Pillow Block HousingsJulio Deyvis Ayala Gutierrez100% (1)

- External Internal: Major Dia Pitch Dia Minor DiaDocument5 pagesExternal Internal: Major Dia Pitch Dia Minor DiaDenis StruggleNo ratings yet

- Vdocuments - MX - Din 332 2 Gauri de Centrare PDFDocument1 pageVdocuments - MX - Din 332 2 Gauri de Centrare PDFMikeNo ratings yet

- Unc Unf Metric Thread Chart Northwest FastenerDocument1 pageUnc Unf Metric Thread Chart Northwest FastenerthailanNo ratings yet

- Is-5372-Taper Washer For ChannelDocument2 pagesIs-5372-Taper Washer For ChannelSurendra Kumar ChordiaNo ratings yet

- Westermann Table 8Document1 pageWestermann Table 8muhd.qasimNo ratings yet

- 1.0038 Steel S235JR Material Equivalent, Composition, Properties - World Steel GradesDocument4 pages1.0038 Steel S235JR Material Equivalent, Composition, Properties - World Steel GradesAdebanjo TomisinNo ratings yet

- Aar603 StructureDocument9 pagesAar603 StructureMUHAMMAD AQIL BIN RAMLINo ratings yet

- Alloy 6022 Sheet: Higher Strength With Improved FormabilityDocument6 pagesAlloy 6022 Sheet: Higher Strength With Improved Formabilitywulfgang66No ratings yet

- En 10025 2004 BDocument10 pagesEn 10025 2004 BPrasanna RajaNo ratings yet

- Structural Steel Design L 03A-19.11.2021Document74 pagesStructural Steel Design L 03A-19.11.2021LUGHANO NGAJILONo ratings yet

- Fracture Toughness and Fracture Behavior of SA508-III Steel at Different TemperaturesDocument9 pagesFracture Toughness and Fracture Behavior of SA508-III Steel at Different TemperaturesFajar Sri Lestari PangukirNo ratings yet

- High Strength SteelDocument2 pagesHigh Strength SteelTargetRockNo ratings yet

- brochures__DX51D - DX52D ENDocument2 pagesbrochures__DX51D - DX52D ENSuttisak SuriyachanhomNo ratings yet

- SE P5r1Document18 pagesSE P5r1BQ HeNo ratings yet

- Materials and Cold Work of Forming: 2.1 Steel StandardsDocument23 pagesMaterials and Cold Work of Forming: 2.1 Steel Standardshunter8080No ratings yet

- Steel Properties (Notes)Document27 pagesSteel Properties (Notes)ellesor macalamNo ratings yet

- Set 8-3 PDFDocument56 pagesSet 8-3 PDFAek JayNo ratings yet

- Table of Design Material Properties For Structural Steel: Eurocode 3Document5 pagesTable of Design Material Properties For Structural Steel: Eurocode 3Erikas AbepaNo ratings yet

- Structural Steels Equivalent ChartDocument2 pagesStructural Steels Equivalent ChartHamdan PkNo ratings yet

- EN10025 - Steel Grades SpecificationsDocument6 pagesEN10025 - Steel Grades SpecificationsFYNo ratings yet

- Tubos Huecos Seccion Cuadrada - PROTUBSADocument56 pagesTubos Huecos Seccion Cuadrada - PROTUBSACarlos Di Perna AriniNo ratings yet

- Structural Steel Plate, Beams, Columns, Channels, Angles - S275, S355Document2 pagesStructural Steel Plate, Beams, Columns, Channels, Angles - S275, S355توفيق عبداللهNo ratings yet

- Longitudinalbeam Production by Controlled Rolling at MMKDocument3 pagesLongitudinalbeam Production by Controlled Rolling at MMKjuan carlosNo ratings yet

- SECTION 05 40 00 Cold-Formed Metal FramingDocument10 pagesSECTION 05 40 00 Cold-Formed Metal FramingJuanPaoloYbañezNo ratings yet

- Steel Construction Products PDFDocument20 pagesSteel Construction Products PDFMohammed ShamilNo ratings yet

- JIS G3101 SS 400 Steel Plate StandardDocument6 pagesJIS G3101 SS 400 Steel Plate StandardArun kumarNo ratings yet

- Adi Design DataDocument14 pagesAdi Design DatalucianoNo ratings yet

- MATERIAL - S235JR (1.0038) - DatasheetDocument4 pagesMATERIAL - S235JR (1.0038) - DatasheetcorbesNo ratings yet

- Introduction of Steel SectionDocument44 pagesIntroduction of Steel SectionAmirul Asyraf Bin Mohd BekeriNo ratings yet

- HPDC Crack Line Issue PDFDocument6 pagesHPDC Crack Line Issue PDFpurushothaman1234566No ratings yet

- Macsteel VRN: Material Datasheet Edition: March 2019Document1 pageMacsteel VRN: Material Datasheet Edition: March 2019sorin robertNo ratings yet

- Böhler Fox CN 29/9-A: DescriptionDocument1 pageBöhler Fox CN 29/9-A: DescriptionKadir Koray BozyelNo ratings yet

- Acroni PDFDocument15 pagesAcroni PDFIgor GrujićNo ratings yet

- Structural Steel Standard SANS 50025 / EN 10025:2004: Macsteel Trading Macsteel VRN Tel: 011-871-4600 Tel: 011-861-5200Document11 pagesStructural Steel Standard SANS 50025 / EN 10025:2004: Macsteel Trading Macsteel VRN Tel: 011-871-4600 Tel: 011-861-5200JakesNo ratings yet

- En 10025 - 2004Document11 pagesEn 10025 - 2004Abhishek GoelNo ratings yet

- Cerjak Enzinger Pudar 39735Document18 pagesCerjak Enzinger Pudar 39735alok987No ratings yet

- Structural Steel Sub-Grades JR, J0 and J2 Does It Matter PDFDocument1 pageStructural Steel Sub-Grades JR, J0 and J2 Does It Matter PDFJafarNo ratings yet

- Structural Steel Sub-Grades JR, J0 and J2 Does It MatterDocument1 pageStructural Steel Sub-Grades JR, J0 and J2 Does It MatterJafarNo ratings yet

- Structural Steel Sub-Grades JR, J0 and J2 PDFDocument1 pageStructural Steel Sub-Grades JR, J0 and J2 PDFJafarNo ratings yet

- Weldeability Offshore SteelDocument12 pagesWeldeability Offshore Steelcarrotiron100% (1)

- SSAB Product and Delivery Information Oxelosund - Site PDFDocument14 pagesSSAB Product and Delivery Information Oxelosund - Site PDFAslam ShaikhNo ratings yet

- En 10025Document4 pagesEn 10025Jayesh83% (6)

- Introd-Steel Struc.Document4 pagesIntrod-Steel Struc.Fuad AhmedinNo ratings yet

- Ncma Tek: Steel Reinforcement For Concrete Masonry TEK 12-4DDocument4 pagesNcma Tek: Steel Reinforcement For Concrete Masonry TEK 12-4DReinaldo Andrei SalazarNo ratings yet

- The Impact of 500 MPA Reinforcement On The DuctilityDocument7 pagesThe Impact of 500 MPA Reinforcement On The Ductilitymehdi_hoseineeNo ratings yet

- EA Risk Society 2015-10-27 - Steel Standards FinalDocument84 pagesEA Risk Society 2015-10-27 - Steel Standards FinalChien KsNo ratings yet

- Stainless Steel Grade 2205 Duplex (UNS S32205)Document7 pagesStainless Steel Grade 2205 Duplex (UNS S32205)ingegnere1234No ratings yet

- 115-How To Specify SteelDocument2 pages115-How To Specify SteelTimmy VoNo ratings yet

- Structural Steel Sub-Grades JR, J0 and J2 Does It MatterDocument1 pageStructural Steel Sub-Grades JR, J0 and J2 Does It MatterJafarNo ratings yet

- Sheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkFrom EverandSheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkNo ratings yet

- ASTM A786 - Rozměry ReliéfuDocument1 pageASTM A786 - Rozměry ReliéfuPetr HavelNo ratings yet

- One-Dimensional Consolidation Properties of Soils Using ... : Uploads 2020/01Document2 pagesOne-Dimensional Consolidation Properties of Soils Using ... : Uploads 2020/01Petr HavelNo ratings yet

- Ductile Cast Iron ASTM A536Document1 pageDuctile Cast Iron ASTM A536Petr HavelNo ratings yet

- L11a Weld - DesignDocument36 pagesL11a Weld - Designtan zhiyuNo ratings yet

- Cellulosic ElectrodeDocument12 pagesCellulosic Electrodecisar0007No ratings yet

- Electrode Equivalaent NumbersDocument2 pagesElectrode Equivalaent NumbersRamdas100% (2)

- Ch-19 Gas Welding, Gas Cutting & Arc WeldingDocument184 pagesCh-19 Gas Welding, Gas Cutting & Arc WeldingDivya Soni0% (1)

- Tin Plate Latas PDFDocument27 pagesTin Plate Latas PDFGustavo BarreraNo ratings yet

- Classifications: Austenitic Stainless Welding Wire (Low C, 18%Cr-8%Ni)Document1 pageClassifications: Austenitic Stainless Welding Wire (Low C, 18%Cr-8%Ni)Joni HartonoNo ratings yet

- High Strength Low Alloy Steels in Naval Construction PDFDocument18 pagesHigh Strength Low Alloy Steels in Naval Construction PDFbiancogallazzi100% (1)

- Electrode Material SelectionDocument1 pageElectrode Material SelectionJoel BrasilBorgesNo ratings yet

- Avesta Welding ManualDocument300 pagesAvesta Welding Manual66apenlullenNo ratings yet

- Weld AbilityDocument34 pagesWeld AbilityGauthamSarangNo ratings yet

- Budownictwo Zeszyt 4 B (12) 2014 7Document20 pagesBudownictwo Zeszyt 4 B (12) 2014 7Kamille Santana KriegerNo ratings yet

- Welding of 5083 Aluminum AlloyDocument6 pagesWelding of 5083 Aluminum AlloyMario MirićNo ratings yet

- European Steel and Alloy GradesDocument3 pagesEuropean Steel and Alloy Gradesfarshid KarpasandNo ratings yet

- Evolution of Advanced High-Strength Steels in Automotive ApplicationsDocument27 pagesEvolution of Advanced High-Strength Steels in Automotive ApplicationsJoao daokNo ratings yet

- I.S - 2062-2021Document13 pagesI.S - 2062-2021Gajendrasingh Rajput100% (1)

- Design and Planning Manual For Cost-Effective WeldingDocument132 pagesDesign and Planning Manual For Cost-Effective WeldingCak Nhass100% (2)

- Selection of Materials For Prototype Fast Breeder Reactor S.L.Mannan, S.C.Chetal, Baldev Raj and S.B.BhojeDocument35 pagesSelection of Materials For Prototype Fast Breeder Reactor S.L.Mannan, S.C.Chetal, Baldev Raj and S.B.BhojeSatish Kumar GautamNo ratings yet

- Datasheet BOHLER AWS E7018-1 Stick ElectrodeDocument1 pageDatasheet BOHLER AWS E7018-1 Stick ElectrodeArhamNo ratings yet

- Effect of Heat Treatments On Mechanical Properties of Hsla-X70 WeldsDocument2 pagesEffect of Heat Treatments On Mechanical Properties of Hsla-X70 WeldsÄness BŝŁm Řm EverNo ratings yet

- LTTDocument7 pagesLTTvasek28No ratings yet

- Mild Steel Welding Handbook Vol 4Document2 pagesMild Steel Welding Handbook Vol 4Fasil ParuvanathNo ratings yet

- Metals: A Short Review On Welding and Joining of High Entropy AlloysDocument21 pagesMetals: A Short Review On Welding and Joining of High Entropy AlloysErimiyas Liyew AbebeNo ratings yet

- B. Tech.: Printed Pages: 3Document3 pagesB. Tech.: Printed Pages: 3arugeetNo ratings yet

- Nas 64 (Uns s32506) - Improved 329j1Document4 pagesNas 64 (Uns s32506) - Improved 329j1Afronie Cepoz D'nextNo ratings yet

- Optim 500 ML Structural SteelsDocument5 pagesOptim 500 ML Structural SteelsgreelmindNo ratings yet

- NBM RWMA Booklet PDFDocument48 pagesNBM RWMA Booklet PDFSebastian MolinaNo ratings yet

- British Standard 5289: 1976: Visual InspectionDocument10 pagesBritish Standard 5289: 1976: Visual InspectionMarcelo Rodriguez FujimotoNo ratings yet

- The Effect of An Aluminum Tip in Arc Stud Welding On The Properties of The Welded JointDocument9 pagesThe Effect of An Aluminum Tip in Arc Stud Welding On The Properties of The Welded JointMiguelNo ratings yet

SANDVIK - Steel Designation and Markings - STA-02-030E

SANDVIK - Steel Designation and Markings - STA-02-030E

Uploaded by

Petr HavelOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SANDVIK - Steel Designation and Markings - STA-02-030E

SANDVIK - Steel Designation and Markings - STA-02-030E

Uploaded by

Petr HavelCopyright:

Available Formats

STA-02-030E

STEEL DESIGNATIONS AND MARKINGS

Page 1/4

1. Purpose of the instruction

These instructions present Sandvik Mining and Construction’s global steel specifications for commonly

used steel materials. In addition, included are standards defining steel designations and steels which are

used when the material deviates from the SMC specifications.

2. General

The primarily used steel materials are SMC steel specifications, which are defined according to steel

applications. In need of other steel qualities, e.g. for higher strength, the designations in the standards

presented in these instructions are used.

3. Sandvik SMC specification

SMC steel specifications are defined in the table below.

Impact z-quality

Marking Quality (1 properties(2 Applications

value (3

(SMC demand)

Critical plate structures with high fatique

S355K2+N (4 40 J, -20˚C resistance and weldability; high surface and

S001 25

S355N (5 (100 J, -20˚C) shape demands. E.g. heavily loaded frames,

booms and their supports.

Plate structures with high fatique resistance and

S355J2+N 27 J, -20˚C weldability; high surface and shape demands.

S002 15

S355N (5 (60 J, -20˚C) E.g. frames and other structures bearing varying

loads.

Steel plates complying with K2 of the standard,

(6

40 J, -20˚C (7 high fatique resistance not guaranteed. E.g.

S003 S355K2+N (40 J, -20˚C tai -

27 J, -30˚C)

frames, supports, tanks, and other parts bearing

moderate load.

Steel plates complying with J2 of the standard,

27 J, 20˚C high strength properties not guaranteed. E.g.

S004 S355J2+N (6 -(7

(27 J, 20˚C) frames, supports, tanks, and other parts bearing

minor load.

Wear resistance steel with moderate weldability

S005 400 HB (30 J, -40°C) and formability in addition to high wear

resistance. E.g. dump boxes

Wear resistance steel with extra high wear

S006 500 HB (25 J, -40°C) resistance. E.g. Loader buckets

Note. Weldability is lower than for S005.

27 J, 0˚C Sheet metals (s=8 max), e.g. tanks and covers

S007 S355J0C+N (8 -

(27 J, 0˚C) with low strength requirements.

27 J, -20˚C Weldable hollow bars with high strength. E.g.

S008 E470 (9 -

(27 J, -20˚C) shafts and sleeves.

27 J, 20°C Steel plates complying with the standard. No

S009 S235JR+N (10 -

(27 J, 20°C) strength guarantees. E.g. counterweights

Revision Date Revised by Accepted by

25.11.2009 Arto Vento A. Huhmarkangas, J. Uotila, P. Julkunen

Original Date Created by Accepted by

STA-02-030E

STEEL DESIGNATIONS AND MARKINGS

Page 2/4

1) Quality designation, according to e.g. EN 10027-1, includes two parts: the principal symbol

(numerical) displays minimum yield strength with the nominal thickness ≤ 16 mm, and the

additional symbol displays impact properties or other special properties. For wear resistance

steels the marking provides minimum degree of hardness.

2) Impact properties values provide the minimum operating temperature where the material is

safe to use without a risk of brittle failure. Values in brackets are the SMC requirement for

approval. These are only meant to ensure the steel quality.

3) Properties perpendicular to the surface (reduction of area) is defined according to EN 10164,

having quality classes (z values): Z15, Z25 and Z35. Probability of lamellar tearing is

exceedingly unusual with the value Z25 and possible with the value Z15 in welds loaded

heavily and perpendicularly to the surface. The requirements are principally for thicknesses 60

mm or more, otherwise the verification is made by ultrasonography, if needed.

4) The designation equates the hot-rolled non-alloy structural steel EN 10025-2, as normalized

rolled, designation with the symbol +N.

5) EN 10025-3 – S355N, that is normalized and normalized rolled weldable fine grain steel is a

recommended alternative for the steel qualities of S001 and S002.

6) S003 and S004 requirements correspond with the normalized rolled fine grain steels defined in

EN 10025-2: qualities S355K2+N and S355J2+N, respectively. They are meant for weldable

structures where a risk of fatigue failure or lamellar tearing is low.

7) Thick plates, with the thickness of 60 mm or more, may be inspected with ultrasonography due

to the risk of lamellar tearing.

8) S355JR +N (impact energy value 27 J, 20˚C) may be applicable in thin-walled plates, whose

tested impact energy value corresponds with the minimum demand in the table.

9) Requirements according to the standard EN 10294-1 and EN 10297-1. In addition, weldability

and impact strength are required (cf. Ovako 280 T).

10) EN 10025-2 – S235JR+N is meant for counterweights etc. unstrained structures.

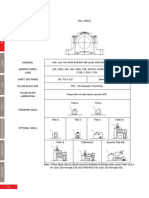

Example for applications of SMC materials in a drill rig.

Revision Date Revised by Accepted by

25.11.2009 Arto Vento A. Huhmarkangas, J. Uotila, P. Julkunen

Original Date Created by Accepted by

STA-02-030E

STEEL DESIGNATIONS AND MARKINGS

Page 3/4

3. Standards

Steel designations are presented in the following standards:

EN 10027-1: 2005 Designation systems for steels. Part 1: Steel names

EN 10027-2: 1992 Designation systems for steels. Part 2: Numerical system

The following standards define requirements, composition and properties as well as methods for

inspection and testing for the steel qualities:

EN 10025-1: 2004 Hot rolled products of structural steels.

Part 1: General technical delivery conditions

EN 10025-2: 2004 Hot rolled products of structural steels.

Part 2: Technical delivery conditions for non-alloy structural steels

EN 10025-3: 2004 Hot rolled products of structural steels.

Part 3: Technical delivery conditions for normalized/normalized rolled

weldable fine grain structural steels

EN 10025-4: 2004 Hot rolled products of structural steels.

Part 4: Technical delivery conditions for thermomechanical rolled weldable

fine grain structural steels

EN 10025-5: 2004 Hot rolled products of structural steels.

Part 5: Structural steels with improved atmospheric corrosion resistance.

Technical delivery conditions

EN 10025-6: 2004 Hot rolled products of structural steels.

Part 6: Technical delivery conditions for flat products of high yield strength

structural steels in the quenched and tempered condition

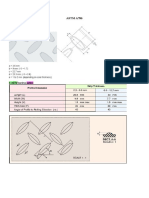

4. A list of corresponding national steel designations

Table 1. presents former corresponding national designations for steel qualities. The first column

contains the designations accordant with EN 10027-1 and the second one contains numerical

designations.

Revision Date Revised by Accepted by

25.11.2009 Arto Vento A. Huhmarkangas, J. Uotila, P. Julkunen

Original Date Created by Accepted by

STA-02-030E

STEEL DESIGNATIONS AND MARKINGS

Page 4/4

Revision Date Revised by Accepted by

25.11.2009 Arto Vento A. Huhmarkangas, J. Uotila, P. Julkunen

Original Date Created by Accepted by

You might also like

- Rothe Erde Slewing BearingDocument194 pagesRothe Erde Slewing BearingRafael FurquimNo ratings yet

- Materials Used in ShipbuildingDocument6 pagesMaterials Used in Shipbuildingagknair100% (1)

- Nippon Steel & Sumitomo Metal Seamless Steel Line PipeDocument8 pagesNippon Steel & Sumitomo Metal Seamless Steel Line Pipeharan2000No ratings yet

- The Essentials of Material Science and Technology for EngineersFrom EverandThe Essentials of Material Science and Technology for EngineersRating: 5 out of 5 stars5/5 (1)

- Table of Material Properties For Structural Steel S235, S275, S355, S420Document4 pagesTable of Material Properties For Structural Steel S235, S275, S355, S420vodounnou0% (1)

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Astm - Mag. PropertiesDocument2 pagesAstm - Mag. PropertiesPetr HavelNo ratings yet

- Technical Information: Radial Play (Internal Clearance) in Ball BearingsDocument4 pagesTechnical Information: Radial Play (Internal Clearance) in Ball Bearingsluisbmwm6No ratings yet

- Multi-Purpose Fenders: Trelleborg Marine SystemsDocument7 pagesMulti-Purpose Fenders: Trelleborg Marine SystemssivakumarNo ratings yet

- SKF Pillow Block HousingsDocument64 pagesSKF Pillow Block HousingsJulio Deyvis Ayala Gutierrez100% (1)

- External Internal: Major Dia Pitch Dia Minor DiaDocument5 pagesExternal Internal: Major Dia Pitch Dia Minor DiaDenis StruggleNo ratings yet

- Vdocuments - MX - Din 332 2 Gauri de Centrare PDFDocument1 pageVdocuments - MX - Din 332 2 Gauri de Centrare PDFMikeNo ratings yet

- Unc Unf Metric Thread Chart Northwest FastenerDocument1 pageUnc Unf Metric Thread Chart Northwest FastenerthailanNo ratings yet

- Is-5372-Taper Washer For ChannelDocument2 pagesIs-5372-Taper Washer For ChannelSurendra Kumar ChordiaNo ratings yet

- Westermann Table 8Document1 pageWestermann Table 8muhd.qasimNo ratings yet

- 1.0038 Steel S235JR Material Equivalent, Composition, Properties - World Steel GradesDocument4 pages1.0038 Steel S235JR Material Equivalent, Composition, Properties - World Steel GradesAdebanjo TomisinNo ratings yet

- Aar603 StructureDocument9 pagesAar603 StructureMUHAMMAD AQIL BIN RAMLINo ratings yet

- Alloy 6022 Sheet: Higher Strength With Improved FormabilityDocument6 pagesAlloy 6022 Sheet: Higher Strength With Improved Formabilitywulfgang66No ratings yet

- En 10025 2004 BDocument10 pagesEn 10025 2004 BPrasanna RajaNo ratings yet

- Structural Steel Design L 03A-19.11.2021Document74 pagesStructural Steel Design L 03A-19.11.2021LUGHANO NGAJILONo ratings yet

- Fracture Toughness and Fracture Behavior of SA508-III Steel at Different TemperaturesDocument9 pagesFracture Toughness and Fracture Behavior of SA508-III Steel at Different TemperaturesFajar Sri Lestari PangukirNo ratings yet

- High Strength SteelDocument2 pagesHigh Strength SteelTargetRockNo ratings yet

- brochures__DX51D - DX52D ENDocument2 pagesbrochures__DX51D - DX52D ENSuttisak SuriyachanhomNo ratings yet

- SE P5r1Document18 pagesSE P5r1BQ HeNo ratings yet

- Materials and Cold Work of Forming: 2.1 Steel StandardsDocument23 pagesMaterials and Cold Work of Forming: 2.1 Steel Standardshunter8080No ratings yet

- Steel Properties (Notes)Document27 pagesSteel Properties (Notes)ellesor macalamNo ratings yet

- Set 8-3 PDFDocument56 pagesSet 8-3 PDFAek JayNo ratings yet

- Table of Design Material Properties For Structural Steel: Eurocode 3Document5 pagesTable of Design Material Properties For Structural Steel: Eurocode 3Erikas AbepaNo ratings yet

- Structural Steels Equivalent ChartDocument2 pagesStructural Steels Equivalent ChartHamdan PkNo ratings yet

- EN10025 - Steel Grades SpecificationsDocument6 pagesEN10025 - Steel Grades SpecificationsFYNo ratings yet

- Tubos Huecos Seccion Cuadrada - PROTUBSADocument56 pagesTubos Huecos Seccion Cuadrada - PROTUBSACarlos Di Perna AriniNo ratings yet

- Structural Steel Plate, Beams, Columns, Channels, Angles - S275, S355Document2 pagesStructural Steel Plate, Beams, Columns, Channels, Angles - S275, S355توفيق عبداللهNo ratings yet

- Longitudinalbeam Production by Controlled Rolling at MMKDocument3 pagesLongitudinalbeam Production by Controlled Rolling at MMKjuan carlosNo ratings yet

- SECTION 05 40 00 Cold-Formed Metal FramingDocument10 pagesSECTION 05 40 00 Cold-Formed Metal FramingJuanPaoloYbañezNo ratings yet

- Steel Construction Products PDFDocument20 pagesSteel Construction Products PDFMohammed ShamilNo ratings yet

- JIS G3101 SS 400 Steel Plate StandardDocument6 pagesJIS G3101 SS 400 Steel Plate StandardArun kumarNo ratings yet

- Adi Design DataDocument14 pagesAdi Design DatalucianoNo ratings yet

- MATERIAL - S235JR (1.0038) - DatasheetDocument4 pagesMATERIAL - S235JR (1.0038) - DatasheetcorbesNo ratings yet

- Introduction of Steel SectionDocument44 pagesIntroduction of Steel SectionAmirul Asyraf Bin Mohd BekeriNo ratings yet

- HPDC Crack Line Issue PDFDocument6 pagesHPDC Crack Line Issue PDFpurushothaman1234566No ratings yet

- Macsteel VRN: Material Datasheet Edition: March 2019Document1 pageMacsteel VRN: Material Datasheet Edition: March 2019sorin robertNo ratings yet

- Böhler Fox CN 29/9-A: DescriptionDocument1 pageBöhler Fox CN 29/9-A: DescriptionKadir Koray BozyelNo ratings yet

- Acroni PDFDocument15 pagesAcroni PDFIgor GrujićNo ratings yet

- Structural Steel Standard SANS 50025 / EN 10025:2004: Macsteel Trading Macsteel VRN Tel: 011-871-4600 Tel: 011-861-5200Document11 pagesStructural Steel Standard SANS 50025 / EN 10025:2004: Macsteel Trading Macsteel VRN Tel: 011-871-4600 Tel: 011-861-5200JakesNo ratings yet

- En 10025 - 2004Document11 pagesEn 10025 - 2004Abhishek GoelNo ratings yet

- Cerjak Enzinger Pudar 39735Document18 pagesCerjak Enzinger Pudar 39735alok987No ratings yet

- Structural Steel Sub-Grades JR, J0 and J2 Does It Matter PDFDocument1 pageStructural Steel Sub-Grades JR, J0 and J2 Does It Matter PDFJafarNo ratings yet

- Structural Steel Sub-Grades JR, J0 and J2 Does It MatterDocument1 pageStructural Steel Sub-Grades JR, J0 and J2 Does It MatterJafarNo ratings yet

- Structural Steel Sub-Grades JR, J0 and J2 PDFDocument1 pageStructural Steel Sub-Grades JR, J0 and J2 PDFJafarNo ratings yet

- Weldeability Offshore SteelDocument12 pagesWeldeability Offshore Steelcarrotiron100% (1)

- SSAB Product and Delivery Information Oxelosund - Site PDFDocument14 pagesSSAB Product and Delivery Information Oxelosund - Site PDFAslam ShaikhNo ratings yet

- En 10025Document4 pagesEn 10025Jayesh83% (6)

- Introd-Steel Struc.Document4 pagesIntrod-Steel Struc.Fuad AhmedinNo ratings yet

- Ncma Tek: Steel Reinforcement For Concrete Masonry TEK 12-4DDocument4 pagesNcma Tek: Steel Reinforcement For Concrete Masonry TEK 12-4DReinaldo Andrei SalazarNo ratings yet

- The Impact of 500 MPA Reinforcement On The DuctilityDocument7 pagesThe Impact of 500 MPA Reinforcement On The Ductilitymehdi_hoseineeNo ratings yet

- EA Risk Society 2015-10-27 - Steel Standards FinalDocument84 pagesEA Risk Society 2015-10-27 - Steel Standards FinalChien KsNo ratings yet

- Stainless Steel Grade 2205 Duplex (UNS S32205)Document7 pagesStainless Steel Grade 2205 Duplex (UNS S32205)ingegnere1234No ratings yet

- 115-How To Specify SteelDocument2 pages115-How To Specify SteelTimmy VoNo ratings yet

- Structural Steel Sub-Grades JR, J0 and J2 Does It MatterDocument1 pageStructural Steel Sub-Grades JR, J0 and J2 Does It MatterJafarNo ratings yet

- Sheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkFrom EverandSheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkNo ratings yet

- ASTM A786 - Rozměry ReliéfuDocument1 pageASTM A786 - Rozměry ReliéfuPetr HavelNo ratings yet

- One-Dimensional Consolidation Properties of Soils Using ... : Uploads 2020/01Document2 pagesOne-Dimensional Consolidation Properties of Soils Using ... : Uploads 2020/01Petr HavelNo ratings yet

- Ductile Cast Iron ASTM A536Document1 pageDuctile Cast Iron ASTM A536Petr HavelNo ratings yet

- L11a Weld - DesignDocument36 pagesL11a Weld - Designtan zhiyuNo ratings yet

- Cellulosic ElectrodeDocument12 pagesCellulosic Electrodecisar0007No ratings yet

- Electrode Equivalaent NumbersDocument2 pagesElectrode Equivalaent NumbersRamdas100% (2)

- Ch-19 Gas Welding, Gas Cutting & Arc WeldingDocument184 pagesCh-19 Gas Welding, Gas Cutting & Arc WeldingDivya Soni0% (1)

- Tin Plate Latas PDFDocument27 pagesTin Plate Latas PDFGustavo BarreraNo ratings yet

- Classifications: Austenitic Stainless Welding Wire (Low C, 18%Cr-8%Ni)Document1 pageClassifications: Austenitic Stainless Welding Wire (Low C, 18%Cr-8%Ni)Joni HartonoNo ratings yet

- High Strength Low Alloy Steels in Naval Construction PDFDocument18 pagesHigh Strength Low Alloy Steels in Naval Construction PDFbiancogallazzi100% (1)

- Electrode Material SelectionDocument1 pageElectrode Material SelectionJoel BrasilBorgesNo ratings yet

- Avesta Welding ManualDocument300 pagesAvesta Welding Manual66apenlullenNo ratings yet

- Weld AbilityDocument34 pagesWeld AbilityGauthamSarangNo ratings yet

- Budownictwo Zeszyt 4 B (12) 2014 7Document20 pagesBudownictwo Zeszyt 4 B (12) 2014 7Kamille Santana KriegerNo ratings yet

- Welding of 5083 Aluminum AlloyDocument6 pagesWelding of 5083 Aluminum AlloyMario MirićNo ratings yet

- European Steel and Alloy GradesDocument3 pagesEuropean Steel and Alloy Gradesfarshid KarpasandNo ratings yet

- Evolution of Advanced High-Strength Steels in Automotive ApplicationsDocument27 pagesEvolution of Advanced High-Strength Steels in Automotive ApplicationsJoao daokNo ratings yet

- I.S - 2062-2021Document13 pagesI.S - 2062-2021Gajendrasingh Rajput100% (1)

- Design and Planning Manual For Cost-Effective WeldingDocument132 pagesDesign and Planning Manual For Cost-Effective WeldingCak Nhass100% (2)

- Selection of Materials For Prototype Fast Breeder Reactor S.L.Mannan, S.C.Chetal, Baldev Raj and S.B.BhojeDocument35 pagesSelection of Materials For Prototype Fast Breeder Reactor S.L.Mannan, S.C.Chetal, Baldev Raj and S.B.BhojeSatish Kumar GautamNo ratings yet

- Datasheet BOHLER AWS E7018-1 Stick ElectrodeDocument1 pageDatasheet BOHLER AWS E7018-1 Stick ElectrodeArhamNo ratings yet

- Effect of Heat Treatments On Mechanical Properties of Hsla-X70 WeldsDocument2 pagesEffect of Heat Treatments On Mechanical Properties of Hsla-X70 WeldsÄness BŝŁm Řm EverNo ratings yet

- LTTDocument7 pagesLTTvasek28No ratings yet

- Mild Steel Welding Handbook Vol 4Document2 pagesMild Steel Welding Handbook Vol 4Fasil ParuvanathNo ratings yet

- Metals: A Short Review On Welding and Joining of High Entropy AlloysDocument21 pagesMetals: A Short Review On Welding and Joining of High Entropy AlloysErimiyas Liyew AbebeNo ratings yet

- B. Tech.: Printed Pages: 3Document3 pagesB. Tech.: Printed Pages: 3arugeetNo ratings yet

- Nas 64 (Uns s32506) - Improved 329j1Document4 pagesNas 64 (Uns s32506) - Improved 329j1Afronie Cepoz D'nextNo ratings yet

- Optim 500 ML Structural SteelsDocument5 pagesOptim 500 ML Structural SteelsgreelmindNo ratings yet

- NBM RWMA Booklet PDFDocument48 pagesNBM RWMA Booklet PDFSebastian MolinaNo ratings yet

- British Standard 5289: 1976: Visual InspectionDocument10 pagesBritish Standard 5289: 1976: Visual InspectionMarcelo Rodriguez FujimotoNo ratings yet

- The Effect of An Aluminum Tip in Arc Stud Welding On The Properties of The Welded JointDocument9 pagesThe Effect of An Aluminum Tip in Arc Stud Welding On The Properties of The Welded JointMiguelNo ratings yet