Professional Documents

Culture Documents

MDS Sarlink 4155 Black

MDS Sarlink 4155 Black

Uploaded by

taranpCopyright:

Available Formats

You might also like

- Operation Management ReportDocument14 pagesOperation Management ReportClaudia SmithNo ratings yet

- Paperboard GuideDocument60 pagesPaperboard GuidemaksimilNo ratings yet

- Carlisle - Training Jan 27-10Document106 pagesCarlisle - Training Jan 27-10Dani Susanto100% (1)

- Zara Agile Supply ChainDocument3 pagesZara Agile Supply ChainBilal ManzoorNo ratings yet

- Procedures in Receiving and Storing Tools and MaterialsDocument14 pagesProcedures in Receiving and Storing Tools and Materialsdanit100% (3)

- TPE-TPV Sarlink 4155 Teknor Apex - 2017Document4 pagesTPE-TPV Sarlink 4155 Teknor Apex - 2017countzeroaslNo ratings yet

- DocumentDocument3 pagesDocumentSreedhar PugalendhiNo ratings yet

- Sarlink® 3190 (ShA 90)Document4 pagesSarlink® 3190 (ShA 90)Fumel EsquivelNo ratings yet

- AmodelDocument4 pagesAmodelPeter EvansNo ratings yet

- Product PDF 37722Document3 pagesProduct PDF 37722Marcelo VicentiniNo ratings yet

- TPE-TPV Sarlink 4155 ProspectorDocument4 pagesTPE-TPV Sarlink 4155 ProspectorcountzeroaslNo ratings yet

- P1700 WH6417 TDSDocument4 pagesP1700 WH6417 TDSnikos.a.kyriakouNo ratings yet

- 1072 - Ppo Noryl gfn1720Document4 pages1072 - Ppo Noryl gfn1720pava16230.meNo ratings yet

- 4.36. Millsheet COUPLER 6P MINI F 32671-KYZ - 9010-Y1 Housing (66 Nylon)Document7 pages4.36. Millsheet COUPLER 6P MINI F 32671-KYZ - 9010-Y1 Housing (66 Nylon)Rizki Eka SiswantoNo ratings yet

- PC-ABS Bayblend FR110Document3 pagesPC-ABS Bayblend FR110countzeroaslNo ratings yet

- DocumentDocument3 pagesDocumentKablayialijanNo ratings yet

- Catalogo Petro ScopeDocument31 pagesCatalogo Petro ScopeDALADIER LOZANO PASCUASNo ratings yet

- Para - Solvay Ixef 1022Document8 pagesPara - Solvay Ixef 1022armandoNo ratings yet

- Pigments For Industrail ApplicationDocument41 pagesPigments For Industrail ApplicationArturo Barjau RiveraNo ratings yet

- TDS SantopreneT 8211-55B100Document3 pagesTDS SantopreneT 8211-55B100Adi HermawanNo ratings yet

- Hifax TRC 277P S71487 - Generic PP Copolymer - MineralDocument4 pagesHifax TRC 277P S71487 - Generic PP Copolymer - MineralYouness LATAFI100% (1)

- POM Delrin 100Document5 pagesPOM Delrin 100countzeroaslNo ratings yet

- Sabic: Polybutylene TerephthalateDocument14 pagesSabic: Polybutylene TerephthalateAkshay BNo ratings yet

- FP - Catalog 2016 - 1 15 16Document32 pagesFP - Catalog 2016 - 1 15 16Nep ParelNo ratings yet

- Ppsu R5100Document7 pagesPpsu R5100kls.thorodinsonNo ratings yet

- Castrol Deformation RangtrainingDocument32 pagesCastrol Deformation RangtrainingcotteNo ratings yet

- Cutting ToolsDocument58 pagesCutting Toolsspy_raj89No ratings yet

- Technical Data Sheet: Full Synthetic ATF-MVDocument1 pageTechnical Data Sheet: Full Synthetic ATF-MVDaniel ColinsNo ratings yet

- 3m Aad Performance Spray Gun Collision Poster en Nor LRDocument1 page3m Aad Performance Spray Gun Collision Poster en Nor LRGregNo ratings yet

- CatálogoDocument1 pageCatálogoNataly BenavidesNo ratings yet

- No-Bake: Product Line OverviewDocument14 pagesNo-Bake: Product Line OverviewkarahandevrimNo ratings yet

- Repsol Atfluid MV 6Document1 pageRepsol Atfluid MV 6pthalojasaNo ratings yet

- Tiona Quimicoplásticos PDFDocument1 pageTiona Quimicoplásticos PDFEduardo PérezNo ratings yet

- 01 Vi Roll Manufacturing & Reclamation WorkDocument9 pages01 Vi Roll Manufacturing & Reclamation Workraj patelNo ratings yet

- ProOne Industrial Catalog 2020 - FINAL - 4mbDocument26 pagesProOne Industrial Catalog 2020 - FINAL - 4mbEnrique PeraltaNo ratings yet

- Mechanical Seals - Agitator Seals - Liquid-Lubricated Seals: Rely On ExcellenceDocument6 pagesMechanical Seals - Agitator Seals - Liquid-Lubricated Seals: Rely On ExcellenceDikaAnindyajatiNo ratings yet

- RDH Hy08-M1320-1 Na PDFDocument64 pagesRDH Hy08-M1320-1 Na PDFMauricio Ariel H. OrellanaNo ratings yet

- Elvax® 460 PDFDocument2 pagesElvax® 460 PDFXuân Giang NguyễnNo ratings yet

- Amercoat-235-Data Sheet PDFDocument4 pagesAmercoat-235-Data Sheet PDFPubcrawlNo ratings yet

- Gravotech MachineDocument17 pagesGravotech MachineSundarmahesh RajarammohanNo ratings yet

- Mechanical Seals - Mechanical Seals For Pumps - Pusher SealsDocument4 pagesMechanical Seals - Mechanical Seals For Pumps - Pusher SealsAndré Silva RibeiroNo ratings yet

- YG-1 คัตติ้งทูล by PTSCDocument8 pagesYG-1 คัตติ้งทูล by PTSCRenishaw-ThaiNo ratings yet

- Demonstration and Sample Kit ContentsDocument2 pagesDemonstration and Sample Kit ContentsClaudio Antonio Figueroa PulgarNo ratings yet

- Product Selection ChartDocument1 pageProduct Selection ChartAaron HeapsNo ratings yet

- Rex-Cut CatalogDocument36 pagesRex-Cut CatalogBepdjNo ratings yet

- Ti NAMITEDocument2 pagesTi NAMITEalphatoolsNo ratings yet

- 1 Grey, 8A Red: Visible Dry-Method Magnetic ParticlesDocument2 pages1 Grey, 8A Red: Visible Dry-Method Magnetic ParticlesaravindanNo ratings yet

- TMC - Metal 3D Printing HubDocument11 pagesTMC - Metal 3D Printing HubTHE METAL COMPANYNo ratings yet

- EagleBurgmann AX25 ENDocument4 pagesEagleBurgmann AX25 ENswosthi sambitNo ratings yet

- PinkMoose Full Syn. ATF MV TECHDocument1 pagePinkMoose Full Syn. ATF MV TECHHewa PCNo ratings yet

- NS8 Datasheet 060422Document3 pagesNS8 Datasheet 060422Fawwaz KhanNo ratings yet

- 04 SharpeMixers V-SeriesDocument2 pages04 SharpeMixers V-SeriesQiNo ratings yet

- Santoprene 101-73Document4 pagesSantoprene 101-73Ewerthon Brand'sNo ratings yet

- Natural Rubber Insertion TDSDocument2 pagesNatural Rubber Insertion TDSwawan setiawanNo ratings yet

- Weldon Pump Data SheetDocument46 pagesWeldon Pump Data SheetDheeraj Chowdary DhanekulaNo ratings yet

- 2021 Equipment Blades Catalog - EMAILDocument32 pages2021 Equipment Blades Catalog - EMAILjose miguelNo ratings yet

- TPE-TPV Sarlink 4155 Teknor Apex - 2013Document3 pagesTPE-TPV Sarlink 4155 Teknor Apex - 2013countzeroaslNo ratings yet

- Para - Solvay Ixef 1032Document7 pagesPara - Solvay Ixef 1032armandoNo ratings yet

- Mitsui EPT™ 3072EM - Generic EPDMDocument4 pagesMitsui EPT™ 3072EM - Generic EPDMgowind1092pNo ratings yet

- Cold Rolled SteelDocument13 pagesCold Rolled SteelRanjeet DongreNo ratings yet

- TEFC Vertical Pump Motors: Innovation and QualityDocument2 pagesTEFC Vertical Pump Motors: Innovation and QualityDinalpinNo ratings yet

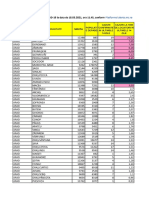

- PPC5TF3-Black: Physical Properties Typical Values Test MethodDocument1 pagePPC5TF3-Black: Physical Properties Typical Values Test MethodtaranpNo ratings yet

- Safety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingDocument8 pagesSafety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingtaranpNo ratings yet

- S107198-PPC5TF3-Black (10% CQB) - SDS EU-EU EnglishDocument7 pagesS107198-PPC5TF3-Black (10% CQB) - SDS EU-EU EnglishtaranpNo ratings yet

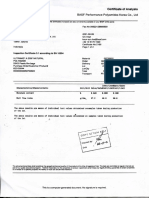

- CoA - Order - PRK171103-R2, Delivered 2018 - Jan - 01Document1 pageCoA - Order - PRK171103-R2, Delivered 2018 - Jan - 01taranpNo ratings yet

- Fisa Tehnica Si de Securitate Solvent Coloris, Tipul 410 - EnglezaDocument7 pagesFisa Tehnica Si de Securitate Solvent Coloris, Tipul 410 - EnglezataranpNo ratings yet

- MSDS Diluant Nitro E-Coll SD - GB - ED036 - 4317784524872Document9 pagesMSDS Diluant Nitro E-Coll SD - GB - ED036 - 4317784524872taranpNo ratings yet

- MSDS Handwashing Paste E-Coll 4317784243735, 4317784349741, 4317784349758Document5 pagesMSDS Handwashing Paste E-Coll 4317784243735, 4317784349741, 4317784349758taranpNo ratings yet

- Fisa Tehnica Si de Securitate Tus Coloris, Tip KRO4714P, Alb - EnglezaDocument7 pagesFisa Tehnica Si de Securitate Tus Coloris, Tip KRO4714P, Alb - EnglezataranpNo ratings yet

- Fisa Tehnica Si de Securitate Solvent Coloris, Tipul 410 - EnglezaDocument7 pagesFisa Tehnica Si de Securitate Solvent Coloris, Tipul 410 - EnglezataranpNo ratings yet

- Rata Incidenta COVID 18 03 2021Document28 pagesRata Incidenta COVID 18 03 2021taranpNo ratings yet

- Jollibee CaseDocument7 pagesJollibee Caseskald50% (2)

- Growth and Instability of Cotton Crop in Major Cotton Growing States in IndiaDocument5 pagesGrowth and Instability of Cotton Crop in Major Cotton Growing States in IndiaMultidisciplinary JournalNo ratings yet

- PR & Marketing ProposalDocument16 pagesPR & Marketing ProposalPrathigna YerakalaNo ratings yet

- Good Distribution PracticesDocument135 pagesGood Distribution PracticesAlok Kumar Sharma100% (7)

- Story of A ShoeDocument3 pagesStory of A ShoeDaisyNo ratings yet

- 03 - LetterPress-Flexo Printing ProcessDocument31 pages03 - LetterPress-Flexo Printing Processnur izzahNo ratings yet

- Weekly Report No. 1 & 2 N FULLDocument68 pagesWeekly Report No. 1 & 2 N FULLnikhil baidNo ratings yet

- A Summer Training Report On "Availablity of Badoda Dairy's Milk"Document166 pagesA Summer Training Report On "Availablity of Badoda Dairy's Milk"vipu1234100% (1)

- British American TobaccoDocument14 pagesBritish American TobaccoDipock Mondal100% (3)

- Dezeen X Samsung Out of The Box Competition - Brief and Rules - Dezeen PDFDocument5 pagesDezeen X Samsung Out of The Box Competition - Brief and Rules - Dezeen PDFVivek EadaraNo ratings yet

- A Study OnDocument79 pagesA Study OnMayank SinghalNo ratings yet

- Differientiation Through The Weave PU Hoses From 3 Ply PU HosesDocument9 pagesDifferientiation Through The Weave PU Hoses From 3 Ply PU HosesAaron Homing NiNo ratings yet

- Digital Brochure PDFDocument9 pagesDigital Brochure PDFimranNo ratings yet

- PIE INDUSTRIES QUOTE - OdsDocument18 pagesPIE INDUSTRIES QUOTE - OdsAbhishek goyalNo ratings yet

- Energy Refractories Ammonia Methanol en 1004 TdsDocument2 pagesEnergy Refractories Ammonia Methanol en 1004 Tdsshuyang zhangNo ratings yet

- Valencia Alejandro Completo UpdatedDocument4 pagesValencia Alejandro Completo UpdatedAlex ValenciaNo ratings yet

- E2 Abds Wear Indicator LeafletDocument2 pagesE2 Abds Wear Indicator LeafletKISKACNo ratings yet

- Ch-13 - Setting Product StrategyDocument16 pagesCh-13 - Setting Product Strategymuhib0030No ratings yet

- Brazil PresentationDocument15 pagesBrazil PresentationMaryamNo ratings yet

- Hijaz Leather Internship ReportDocument55 pagesHijaz Leather Internship ReportMuzammil Motoor90% (21)

- Banana Paper Paper Making Process Technology CompaDocument13 pagesBanana Paper Paper Making Process Technology Compaxiaoboshi0% (1)

- GMPDocument2 pagesGMPghostly_form4169No ratings yet

- POM REPORT On McDonald'sDocument22 pagesPOM REPORT On McDonald'snaveed009100% (1)

- Vulnerability Assessment Tool: Food Fraud Advisors 2017Document48 pagesVulnerability Assessment Tool: Food Fraud Advisors 2017Fitriyanti IzinilahNo ratings yet

- Piping Works Daily ReportDocument19 pagesPiping Works Daily ReportGomathyselviNo ratings yet

- FMCG - Men vs. BoysDocument43 pagesFMCG - Men vs. BoyschaltrikNo ratings yet

MDS Sarlink 4155 Black

MDS Sarlink 4155 Black

Uploaded by

taranpCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MDS Sarlink 4155 Black

MDS Sarlink 4155 Black

Uploaded by

taranpCopyright:

Available Formats

Sarlink® TPV

4155

Thermoplastic Vulcanizate

Teknor Apex Company www.ulprospector.com

Technical Data

Product Description

SARLINK® TPV 4100 series are engineered materials designed primarily for demanding automotive and industrial applications. Available in both

black and natural, SARLINK® 4155 is a low density, medium hardness thermoplastic vulcanizate that exhibits excellent compression set, flex

fatigue, high and low temperature performance. The material can be processed by injection molding, blow molding and extrusion for applications

such as seals, gaskets, chemical resistant hose and tube, boots and bellows.

General

Material Status • Commercial: Active

Literature 1 • Technical Datasheet

Search for UL Yellow Card

• Teknor Apex Company

• Sarlink® TPV

Availability

• Asia Pacific • Latin America

• Europe • North America

• Chemical Resistant • Good Moldability

• Excellent Elastic Recovery • Good Processability • Low Temperature Flexibility

Features

• Fatigue Resistant • Good Surface Finish • Medium Hardness

• Good Adhesion • High Melt Stability • Medium Heat Resistance

• Good Flexibility • Low Density • Resilient

• Good Melt Strength • Low Specific Gravity

• Agricultural Applications • Blow Molding Applications • Profiles

• Appliance Components • Gaskets • Rubber Replacement

Uses • Automotive Applications • Hose • Seals

• Automotive Interior Parts • Industrial Applications • White Goods & Small

• Automotive Under the Hood • Pipe Seals Appliances

Agency Ratings • UL 94

RoHS Compliance • RoHS Compliant

• CHRYSLER MS-AR-100 AGN • Natural

GM GMP.E/P.001 Color:

Color: Black

• CHRYSLER MS-AR-100 AGN • Black

GM GMW15813 Type 4 Color:

• HONDA Unspecified Color:

Color: Natural Black

• FORD WSD-M2D378-A1 Color: • Natural

GM GMW15813 Type 4 Color:

Automotive Specifications • RENAULT F.R.M. 7A-10-A11

Black Color: Black

• FORD WSD-M2D378-A1 Color: •

GM QK 3513 Type 3 Color:

• VAG VW501 23 Color: Black

Black

Natural

• GM GMP.E/P.001 Color: Black • Natural

GM QK 3513 Type 3 Color:

Appearance • Black • Natural Color • Opaque

Forms • Pellets

Processing Method • Blow Molding • Extrusion • Injection Molding

Physical Nominal Value Unit Test Method

Density / Specific Gravity

-- 0.958 g/cm³ ASTM D792

-- 0.960 g/cm³ ISO 1183

Elastomers Nominal Value Unit Test Method

Tensile Stress ISO 37

Across Flow : 100% Strain 2.00 MPa ASTM D412

Flow : 100% Strain 3.10 MPa

Tensile Stress ISO 37

Across Flow : Break 5.20 MPa ASTM D412

Flow : Break 4.30 MPa

Tensile Elongation ISO 37

Across Flow : Break 550 % ASTM D412

Flow : Break 240 %

1 of 4 Form No. TDS-23308-en

UL and the UL logo are trademarks of UL LLC © 2018. All Rights Reserved. Document Created: Wednesday, February 21, 2018

UL Prospector | 800-788-4668 or 307-742-9227 | www.ulprospector.com. Added to Prospector: November 2000

Last Updated: 3/29/2016

The information presented here was acquired by UL from the producer of the product or material or original information provider. However, UL

assumes no responsibility or liability for the accuracy of the information contained on this website and strongly encourages that upon final product

or material selection information is validated with the manufacturer. This website provides links to other websites owned by third parties. The

content of such third party sites is not within our control, and we cannot and will not take responsibility for the information or content.

Sarlink® TPV 4155

Thermoplastic Vulcanizate

Teknor Apex Company www.ulprospector.com

Elastomers Nominal Value Unit Test Method

Tear Strength - Across Flow

-- 22 kN/m ASTM D624

-- 3 22 kN/m ISO 34-1

Compression Set ISO 815

23°C, 22 hr 14 % ASTM D395

70°C, 22 hr 26 %

125°C, 70 hr 37 %

Hardness Nominal Value Unit Test Method

Shore Hardness ISO 868

Shore A, 5 sec, Extruded 53 ASTM D2240

Shore A, 5 sec, Injection Molded 56

Aging Nominal Value Unit Test Method

Change in Tensile Strength in Air - Across Flow ISO 188

135°C, 1000 hr -5.0 % ASTM D573

100% Strain 135°C, 1000 hr 2.0 %

150°C, 168 hr -9.0 %

100% Strain 150°C, 168 hr -2.0 %

Change in Tensile Strain at Break in Air - Across Flow ISO 188

135°C, 1000 hr 1.0 % ASTM D573

150°C, 168 hr -6.0 %

Change in Shore Hardness in Air ISO 188

Shore A, 135°C, 1000 hr 2.0 ASTM D573

Shore A, 150°C, 168 hr 2.0

Change in Volume ISO 1817

125°C, 70 hr, in IRM 903 Oil 85 % ASTM D471

Flammability Nominal Value Unit Test Method

Flame Rating UL 94

0.60 mm, BK HB

1.5 mm, NC HB

Additional Information Nominal Value Unit Test Method

Apparent Shear Viscosity - Capillary, @ 206/s

200°C 320 Pa·s ISO 11443

200°C 320 Pa·s ASTM D3835

Legal Statement

The information and recommendations contained in this bulletin are, to the best of our knowledge, accurate and reliable but no guarantee of their

accuracy is made. All products are sold upon condition that purchasers shall make their own tests to determine the suitability of such products for

their particular purposes and uses and purchaser assumes all risks and liability for the results of use of the products, including use in accordance

with seller's recommendations. Nothing in this bulletin constitutes permission or a recommendation to practice or use any invention covered by

any patent owned by this company or others. There is no warranty of merchantability and there are no other warranties for the products

described. For detailed Product Stewardship information, please contact us. Any product of Teknor Apex, including product names, shall not be

used or tested in medical or food contact applications without the prior written acknowledgement of Teknor Apex as to the intended use. Please

note that some products may not be available in one or more countries.

Injection Nominal Value Unit

Drying Temperature 82 °C

Drying Time 3.0 hr

Rear Temperature 180 to 215 °C

Middle Temperature 180 to 215 °C

Front Temperature 180 to 215 °C

Nozzle Temperature 187 to 220 °C

Processing (Melt) Temp 185 to 220 °C

Mold Temperature 10 to 55 °C

Back Pressure 0.100 to 1.00 MPa

Screw Speed 100 to 200 rpm

2 of 4 Form No. TDS-23308-en

UL and the UL logo are trademarks of UL LLC © 2018. All Rights Reserved. Document Created: Wednesday, February 21, 2018

UL Prospector | 800-788-4668 or 307-742-9227 | www.ulprospector.com. Added to Prospector: November 2000

Last Updated: 3/29/2016

The information presented here was acquired by UL from the producer of the product or material or original information provider. However, UL

assumes no responsibility or liability for the accuracy of the information contained on this website and strongly encourages that upon final product

or material selection information is validated with the manufacturer. This website provides links to other websites owned by third parties. The

content of such third party sites is not within our control, and we cannot and will not take responsibility for the information or content.

Sarlink® TPV 4155

Thermoplastic Vulcanizate

Teknor Apex Company www.ulprospector.com

Extrusion Nominal Value Unit

Drying Temperature 82 °C

Drying Time 3.0 hr

Cylinder Zone 1 Temp. 180 to 200 °C

Cylinder Zone 2 Temp. 180 to 205 °C

Cylinder Zone 3 Temp. 187 to 210 °C

Cylinder Zone 4 Temp. 187 to 210 °C

Melt Temperature 195 to 215 °C

Die Temperature 195 to 215 °C

Take-Off Roll 20 to 50 °C

Extrusion Notes

Screen Pack: 20 to 60 mesh

Screw: general purpose

Compression Ratio: 3:1

Notes

1

These links provide you with access to supplier literature. We work hard to keep them up to date; however you may find the most current

literature from the supplier.

2

Typical properties: these are not to be construed as specifications.

3

Method Ba, Angle (Unnicked)

3 of 4 Form No. TDS-23308-en

UL and the UL logo are trademarks of UL LLC © 2018. All Rights Reserved. Document Created: Wednesday, February 21, 2018

UL Prospector | 800-788-4668 or 307-742-9227 | www.ulprospector.com. Added to Prospector: November 2000

Last Updated: 3/29/2016

The information presented here was acquired by UL from the producer of the product or material or original information provider. However, UL

assumes no responsibility or liability for the accuracy of the information contained on this website and strongly encourages that upon final product

or material selection information is validated with the manufacturer. This website provides links to other websites owned by third parties. The

content of such third party sites is not within our control, and we cannot and will not take responsibility for the information or content.

Sarlink® TPV 4155

Thermoplastic Vulcanizate

Teknor Apex Company www.ulprospector.com

Where to Buy

Supplier

Teknor Apex Company

Pawtucket, RI USA

Telephone: 800-556-3864

Web: http://www.teknorapex.com/

Distributor

Chase Plastic Services, Inc.

Chase Plastics Services is a North American distributor with representatives throughout the region. Please find your rep here:

http://www.chaseplastics.com/contact/locations

Telephone: 800-232-4273

Web: http://www.chaseplastics.com/

Availability: North America

Distrupol Ltd

Distrupol Ltd is a Pan European distribution company. Contact Distrupol Ltd for availability of individual products by country.

Telephone: 08452003040

Web: http://www.distrupol.com/

Availability: Belgium, Denmark, Finland, Ireland, Luxembourg, Netherlands, Norway, Sweden, United Kingdom

Erteco Rubber & Plastics AB

Telephone: +46-8-587-517-00

Web: http://www.erteco.se/

Availability: Denmark, Finland, Norway, Sweden

Nexeo Solutions - Europe

Nexeo Solutions is a Pan European distribution company. Contact Nexeo for availability of individual products by country.

Telephone: +34-93-480-9125

Web: http://www.nexeosolutions.com/

Availability: Russian Federation

4 of 4 Form No. TDS-23308-en

UL and the UL logo are trademarks of UL LLC © 2018. All Rights Reserved. Document Created: Wednesday, February 21, 2018

UL Prospector | 800-788-4668 or 307-742-9227 | www.ulprospector.com. Added to Prospector: November 2000

Last Updated: 3/29/2016

The information presented here was acquired by UL from the producer of the product or material or original information provider. However, UL

assumes no responsibility or liability for the accuracy of the information contained on this website and strongly encourages that upon final product

or material selection information is validated with the manufacturer. This website provides links to other websites owned by third parties. The

content of such third party sites is not within our control, and we cannot and will not take responsibility for the information or content.

You might also like

- Operation Management ReportDocument14 pagesOperation Management ReportClaudia SmithNo ratings yet

- Paperboard GuideDocument60 pagesPaperboard GuidemaksimilNo ratings yet

- Carlisle - Training Jan 27-10Document106 pagesCarlisle - Training Jan 27-10Dani Susanto100% (1)

- Zara Agile Supply ChainDocument3 pagesZara Agile Supply ChainBilal ManzoorNo ratings yet

- Procedures in Receiving and Storing Tools and MaterialsDocument14 pagesProcedures in Receiving and Storing Tools and Materialsdanit100% (3)

- TPE-TPV Sarlink 4155 Teknor Apex - 2017Document4 pagesTPE-TPV Sarlink 4155 Teknor Apex - 2017countzeroaslNo ratings yet

- DocumentDocument3 pagesDocumentSreedhar PugalendhiNo ratings yet

- Sarlink® 3190 (ShA 90)Document4 pagesSarlink® 3190 (ShA 90)Fumel EsquivelNo ratings yet

- AmodelDocument4 pagesAmodelPeter EvansNo ratings yet

- Product PDF 37722Document3 pagesProduct PDF 37722Marcelo VicentiniNo ratings yet

- TPE-TPV Sarlink 4155 ProspectorDocument4 pagesTPE-TPV Sarlink 4155 ProspectorcountzeroaslNo ratings yet

- P1700 WH6417 TDSDocument4 pagesP1700 WH6417 TDSnikos.a.kyriakouNo ratings yet

- 1072 - Ppo Noryl gfn1720Document4 pages1072 - Ppo Noryl gfn1720pava16230.meNo ratings yet

- 4.36. Millsheet COUPLER 6P MINI F 32671-KYZ - 9010-Y1 Housing (66 Nylon)Document7 pages4.36. Millsheet COUPLER 6P MINI F 32671-KYZ - 9010-Y1 Housing (66 Nylon)Rizki Eka SiswantoNo ratings yet

- PC-ABS Bayblend FR110Document3 pagesPC-ABS Bayblend FR110countzeroaslNo ratings yet

- DocumentDocument3 pagesDocumentKablayialijanNo ratings yet

- Catalogo Petro ScopeDocument31 pagesCatalogo Petro ScopeDALADIER LOZANO PASCUASNo ratings yet

- Para - Solvay Ixef 1022Document8 pagesPara - Solvay Ixef 1022armandoNo ratings yet

- Pigments For Industrail ApplicationDocument41 pagesPigments For Industrail ApplicationArturo Barjau RiveraNo ratings yet

- TDS SantopreneT 8211-55B100Document3 pagesTDS SantopreneT 8211-55B100Adi HermawanNo ratings yet

- Hifax TRC 277P S71487 - Generic PP Copolymer - MineralDocument4 pagesHifax TRC 277P S71487 - Generic PP Copolymer - MineralYouness LATAFI100% (1)

- POM Delrin 100Document5 pagesPOM Delrin 100countzeroaslNo ratings yet

- Sabic: Polybutylene TerephthalateDocument14 pagesSabic: Polybutylene TerephthalateAkshay BNo ratings yet

- FP - Catalog 2016 - 1 15 16Document32 pagesFP - Catalog 2016 - 1 15 16Nep ParelNo ratings yet

- Ppsu R5100Document7 pagesPpsu R5100kls.thorodinsonNo ratings yet

- Castrol Deformation RangtrainingDocument32 pagesCastrol Deformation RangtrainingcotteNo ratings yet

- Cutting ToolsDocument58 pagesCutting Toolsspy_raj89No ratings yet

- Technical Data Sheet: Full Synthetic ATF-MVDocument1 pageTechnical Data Sheet: Full Synthetic ATF-MVDaniel ColinsNo ratings yet

- 3m Aad Performance Spray Gun Collision Poster en Nor LRDocument1 page3m Aad Performance Spray Gun Collision Poster en Nor LRGregNo ratings yet

- CatálogoDocument1 pageCatálogoNataly BenavidesNo ratings yet

- No-Bake: Product Line OverviewDocument14 pagesNo-Bake: Product Line OverviewkarahandevrimNo ratings yet

- Repsol Atfluid MV 6Document1 pageRepsol Atfluid MV 6pthalojasaNo ratings yet

- Tiona Quimicoplásticos PDFDocument1 pageTiona Quimicoplásticos PDFEduardo PérezNo ratings yet

- 01 Vi Roll Manufacturing & Reclamation WorkDocument9 pages01 Vi Roll Manufacturing & Reclamation Workraj patelNo ratings yet

- ProOne Industrial Catalog 2020 - FINAL - 4mbDocument26 pagesProOne Industrial Catalog 2020 - FINAL - 4mbEnrique PeraltaNo ratings yet

- Mechanical Seals - Agitator Seals - Liquid-Lubricated Seals: Rely On ExcellenceDocument6 pagesMechanical Seals - Agitator Seals - Liquid-Lubricated Seals: Rely On ExcellenceDikaAnindyajatiNo ratings yet

- RDH Hy08-M1320-1 Na PDFDocument64 pagesRDH Hy08-M1320-1 Na PDFMauricio Ariel H. OrellanaNo ratings yet

- Elvax® 460 PDFDocument2 pagesElvax® 460 PDFXuân Giang NguyễnNo ratings yet

- Amercoat-235-Data Sheet PDFDocument4 pagesAmercoat-235-Data Sheet PDFPubcrawlNo ratings yet

- Gravotech MachineDocument17 pagesGravotech MachineSundarmahesh RajarammohanNo ratings yet

- Mechanical Seals - Mechanical Seals For Pumps - Pusher SealsDocument4 pagesMechanical Seals - Mechanical Seals For Pumps - Pusher SealsAndré Silva RibeiroNo ratings yet

- YG-1 คัตติ้งทูล by PTSCDocument8 pagesYG-1 คัตติ้งทูล by PTSCRenishaw-ThaiNo ratings yet

- Demonstration and Sample Kit ContentsDocument2 pagesDemonstration and Sample Kit ContentsClaudio Antonio Figueroa PulgarNo ratings yet

- Product Selection ChartDocument1 pageProduct Selection ChartAaron HeapsNo ratings yet

- Rex-Cut CatalogDocument36 pagesRex-Cut CatalogBepdjNo ratings yet

- Ti NAMITEDocument2 pagesTi NAMITEalphatoolsNo ratings yet

- 1 Grey, 8A Red: Visible Dry-Method Magnetic ParticlesDocument2 pages1 Grey, 8A Red: Visible Dry-Method Magnetic ParticlesaravindanNo ratings yet

- TMC - Metal 3D Printing HubDocument11 pagesTMC - Metal 3D Printing HubTHE METAL COMPANYNo ratings yet

- EagleBurgmann AX25 ENDocument4 pagesEagleBurgmann AX25 ENswosthi sambitNo ratings yet

- PinkMoose Full Syn. ATF MV TECHDocument1 pagePinkMoose Full Syn. ATF MV TECHHewa PCNo ratings yet

- NS8 Datasheet 060422Document3 pagesNS8 Datasheet 060422Fawwaz KhanNo ratings yet

- 04 SharpeMixers V-SeriesDocument2 pages04 SharpeMixers V-SeriesQiNo ratings yet

- Santoprene 101-73Document4 pagesSantoprene 101-73Ewerthon Brand'sNo ratings yet

- Natural Rubber Insertion TDSDocument2 pagesNatural Rubber Insertion TDSwawan setiawanNo ratings yet

- Weldon Pump Data SheetDocument46 pagesWeldon Pump Data SheetDheeraj Chowdary DhanekulaNo ratings yet

- 2021 Equipment Blades Catalog - EMAILDocument32 pages2021 Equipment Blades Catalog - EMAILjose miguelNo ratings yet

- TPE-TPV Sarlink 4155 Teknor Apex - 2013Document3 pagesTPE-TPV Sarlink 4155 Teknor Apex - 2013countzeroaslNo ratings yet

- Para - Solvay Ixef 1032Document7 pagesPara - Solvay Ixef 1032armandoNo ratings yet

- Mitsui EPT™ 3072EM - Generic EPDMDocument4 pagesMitsui EPT™ 3072EM - Generic EPDMgowind1092pNo ratings yet

- Cold Rolled SteelDocument13 pagesCold Rolled SteelRanjeet DongreNo ratings yet

- TEFC Vertical Pump Motors: Innovation and QualityDocument2 pagesTEFC Vertical Pump Motors: Innovation and QualityDinalpinNo ratings yet

- PPC5TF3-Black: Physical Properties Typical Values Test MethodDocument1 pagePPC5TF3-Black: Physical Properties Typical Values Test MethodtaranpNo ratings yet

- Safety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingDocument8 pagesSafety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingtaranpNo ratings yet

- S107198-PPC5TF3-Black (10% CQB) - SDS EU-EU EnglishDocument7 pagesS107198-PPC5TF3-Black (10% CQB) - SDS EU-EU EnglishtaranpNo ratings yet

- CoA - Order - PRK171103-R2, Delivered 2018 - Jan - 01Document1 pageCoA - Order - PRK171103-R2, Delivered 2018 - Jan - 01taranpNo ratings yet

- Fisa Tehnica Si de Securitate Solvent Coloris, Tipul 410 - EnglezaDocument7 pagesFisa Tehnica Si de Securitate Solvent Coloris, Tipul 410 - EnglezataranpNo ratings yet

- MSDS Diluant Nitro E-Coll SD - GB - ED036 - 4317784524872Document9 pagesMSDS Diluant Nitro E-Coll SD - GB - ED036 - 4317784524872taranpNo ratings yet

- MSDS Handwashing Paste E-Coll 4317784243735, 4317784349741, 4317784349758Document5 pagesMSDS Handwashing Paste E-Coll 4317784243735, 4317784349741, 4317784349758taranpNo ratings yet

- Fisa Tehnica Si de Securitate Tus Coloris, Tip KRO4714P, Alb - EnglezaDocument7 pagesFisa Tehnica Si de Securitate Tus Coloris, Tip KRO4714P, Alb - EnglezataranpNo ratings yet

- Fisa Tehnica Si de Securitate Solvent Coloris, Tipul 410 - EnglezaDocument7 pagesFisa Tehnica Si de Securitate Solvent Coloris, Tipul 410 - EnglezataranpNo ratings yet

- Rata Incidenta COVID 18 03 2021Document28 pagesRata Incidenta COVID 18 03 2021taranpNo ratings yet

- Jollibee CaseDocument7 pagesJollibee Caseskald50% (2)

- Growth and Instability of Cotton Crop in Major Cotton Growing States in IndiaDocument5 pagesGrowth and Instability of Cotton Crop in Major Cotton Growing States in IndiaMultidisciplinary JournalNo ratings yet

- PR & Marketing ProposalDocument16 pagesPR & Marketing ProposalPrathigna YerakalaNo ratings yet

- Good Distribution PracticesDocument135 pagesGood Distribution PracticesAlok Kumar Sharma100% (7)

- Story of A ShoeDocument3 pagesStory of A ShoeDaisyNo ratings yet

- 03 - LetterPress-Flexo Printing ProcessDocument31 pages03 - LetterPress-Flexo Printing Processnur izzahNo ratings yet

- Weekly Report No. 1 & 2 N FULLDocument68 pagesWeekly Report No. 1 & 2 N FULLnikhil baidNo ratings yet

- A Summer Training Report On "Availablity of Badoda Dairy's Milk"Document166 pagesA Summer Training Report On "Availablity of Badoda Dairy's Milk"vipu1234100% (1)

- British American TobaccoDocument14 pagesBritish American TobaccoDipock Mondal100% (3)

- Dezeen X Samsung Out of The Box Competition - Brief and Rules - Dezeen PDFDocument5 pagesDezeen X Samsung Out of The Box Competition - Brief and Rules - Dezeen PDFVivek EadaraNo ratings yet

- A Study OnDocument79 pagesA Study OnMayank SinghalNo ratings yet

- Differientiation Through The Weave PU Hoses From 3 Ply PU HosesDocument9 pagesDifferientiation Through The Weave PU Hoses From 3 Ply PU HosesAaron Homing NiNo ratings yet

- Digital Brochure PDFDocument9 pagesDigital Brochure PDFimranNo ratings yet

- PIE INDUSTRIES QUOTE - OdsDocument18 pagesPIE INDUSTRIES QUOTE - OdsAbhishek goyalNo ratings yet

- Energy Refractories Ammonia Methanol en 1004 TdsDocument2 pagesEnergy Refractories Ammonia Methanol en 1004 Tdsshuyang zhangNo ratings yet

- Valencia Alejandro Completo UpdatedDocument4 pagesValencia Alejandro Completo UpdatedAlex ValenciaNo ratings yet

- E2 Abds Wear Indicator LeafletDocument2 pagesE2 Abds Wear Indicator LeafletKISKACNo ratings yet

- Ch-13 - Setting Product StrategyDocument16 pagesCh-13 - Setting Product Strategymuhib0030No ratings yet

- Brazil PresentationDocument15 pagesBrazil PresentationMaryamNo ratings yet

- Hijaz Leather Internship ReportDocument55 pagesHijaz Leather Internship ReportMuzammil Motoor90% (21)

- Banana Paper Paper Making Process Technology CompaDocument13 pagesBanana Paper Paper Making Process Technology Compaxiaoboshi0% (1)

- GMPDocument2 pagesGMPghostly_form4169No ratings yet

- POM REPORT On McDonald'sDocument22 pagesPOM REPORT On McDonald'snaveed009100% (1)

- Vulnerability Assessment Tool: Food Fraud Advisors 2017Document48 pagesVulnerability Assessment Tool: Food Fraud Advisors 2017Fitriyanti IzinilahNo ratings yet

- Piping Works Daily ReportDocument19 pagesPiping Works Daily ReportGomathyselviNo ratings yet

- FMCG - Men vs. BoysDocument43 pagesFMCG - Men vs. BoyschaltrikNo ratings yet