Professional Documents

Culture Documents

Manual Joints (QW - 402) : Page 1 of 12

Manual Joints (QW - 402) : Page 1 of 12

Uploaded by

miteshpatel191Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Manual Joints (QW - 402) : Page 1 of 12

Manual Joints (QW - 402) : Page 1 of 12

Uploaded by

miteshpatel191Copyright:

Available Formats

Page 1 of 12

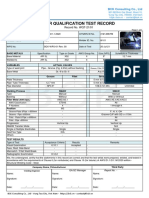

Welding Process :GTAW Type(s) : Manual Automatic Machine Semi-Auto

Joints (QW - 402)

Joint Design : As shown in the Sketch

Backing :No

Backing Material (Type) : N/A

Welding sequence to conform to good welding practice

Joint Type : Single V butt weld

70° +/- 5°

1.6 mm

2 to 3 mm

Base Metals(QW - 403)

P No : 1 Group No: 1 To P No : 1 Group No: 1

Specification Type and Grade : A106 Gr B or Equivalent To A106 Gr B or Equivalent

Chemical analysis and Mechanical Properties --------To Chemical analysis and Mechanical Properties --------

Thickness Range

Base Metal : Groove : 1.6 mm to 17.44 mm Fillet : All

Dia Range : Groove : All Fillet : All

Others : ------

FILLER METALS (QW- 404) GTAW

Spec No. (SFA) : 5.18

AWS No. (class) : ER 70S2

F- No :6

A- No :1

Size of Filler Metals : 2.4mm

Electrode- Flux (Type) : N/A

Flux Trade Name : N/A

Consumable Insert : N/A

Deposited Weld Metal Thickness Range

Groove : 17.44mm + Weld reinforcement

517885783.xls DPQC: F19 Rev 0

Page 2 of 12

POSITION(S) (QW- 405) POST WELD HEAT TREATMENT (QW-407)

Positions of Groove : All Temperature Range : N/A

Welding Progression : Uphill Time Range : N/A

Positions of Fillets : All Heating Rate : N/A

Cooling Rate : N/A

Soaking Time : N/A

Others : N/A

PRE- HEAT (QW- 406) GAS (QW- 408) : N.A

Percentage Composition

Pre Heat (min)

: 10 °C (Preheat Gases Mixtures Flow Rate

required to remove

moisture from plate)

Interpass (max) : 200 °C

Pre-Heat maintenance : Yes Shielding Gas Argon 99.9 % pure 8 - 12 LPM

: LPG/ Oxygen heaters/

Any other suitable

Pre Heat Method method Trailing NA NA NA

Temperature Measuring Method Thermo pen

(If required)

Backing NA NA NA

ELECTRICAL CHARACTERISTICS (QW- 409)

Current AC or DC : DC Polarity : EN

Amps Range : Refer Table Volts : Refer Table

Tungsten Electrode Size and Type : 2.4mm 2% thoriated

Mode of Metal Transfer (GMAW) : N/A

Electrode wire Feed Speed Range : N/A

TECHNIQUE (QW- 410)

String or Weave Bead : Weave

Orifice or Gas cup Size : 6 to 8mm

Initial and Interpass Cleaning (Brushing,

Grinding, etc) : Brushing/Grinding

Weaving / Oscillation : 15mm or 3 times of fillerwire dia. Which ever is less.

Contact Tube To Work Distance : N/A

Multiple or Single Pass (Per side) : Multiple

Multiple or Single Electrodes : Single

Travel Speed (Range) : Refer Table

Peening : Not Allowed

Others : Nil

517885783.xls DPQC: F19 Rev 0

Page 3 of 12

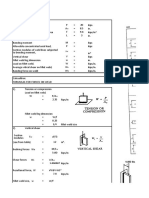

Filler Metal Current Minimum

Volts Travel

Weld Layer Process Brand Name

Amps Range Speed in

Class Dia mm Polarity mm/min

Range

Root GTAW ER 70S2 2.5 DC EN 60 - 90 A 12-18 V 60 GE TIG

Fill up &

Capping GTAW ER 70S2 2.5 DC EN 60 - 90 A 12-18 V 60 GE TIG

NOTE:

1 All weld layers must be cleaned by brushing prior to starting next layers.

2 Complies with Welding Specification GS-400 Latest revision

Prepared (NSCL) Checked (CEL) Approved (CEL)

Name: Name: Name:

Date: Date: Date:

517885783.xls DPQC: F19 Rev 0

Page 4 of 12

Welding Process :GTAW + SMAW Type(s) : Manual Automatic Machine Semi-Auto

Joints (QW - 402)

Joint Design : As shown in the Sketch

Backing :No

Backing Material (Type) : N/A

Welding sequence to conform to good welding practice

Joint Type : Single V butt weld

70° +/- 5°

1.6 mm

2 to 3 mm

Base Metals(QW - 403)

P No : 1 Group No: 1 To P No : 1 Group No: 1

Specification Type and Grade : A106 GrB or Equivalent To A106 GrB or Equivalent

Chemical analysis and Mechanical Properties --------To Chemical analysis and Mechanical Properties --------

Thickness Range

Base Metal : Groove : 4.8mm to 19.05 mm Fillet : All

Dia Range : 2" & above Groove : All Fillet : All

Others : ------

FILLER METALS (QW- 404) GTAW SMAW

Spec No. (SFA) : 5.18 5.1

AWS No. (class) : ER 70S2 E7018

F- No :6 4

A- No :1 1

Size of Filler Metals : 2.4mm 2.5mm , 3.2mm, 4.0 mm

Electrode- Flux (Type) : N/A N/A

Flux Trade Name : N/A N/A

Consumable Insert : N/A N/A

Deposited Weld Metal Thickness Range

Groove : 6mm max for GTAW + Reminder and reinforcement by SMAW

517885783.xls DPQC: F19 Rev 0

Page 5 of 12

POSITION(S) (QW- 405) POST WELD HEAT TREATMENT (QW-407)

Positions of Groove : All Temperature Range : N/A

Welding Progression : Uphill Time Range : N/A

Positions of Fillets : All Heating Rate : N/A

Cooling Rate : N/A

Soaking Time : N/A

Others : N/A

PRE- HEAT (QW- 406) GAS (QW- 408) : N.A

Percentage Composition

Pre Heat (min)

: 10 °C (Preheat Gases Mixtures Flow Rate

required to remove

moisture from plate)

Interpass (max)

: 250 °C

Pre-Heat maintenance

: Yes Shielding Gas Argon 99.9 % pure 8 - 12 LPM

Pre Heat Method (If required)

: LPG/ Oxygen heaters/

Any other suitable

method Trailing NA NA NA

Temperature Measuring Method Thermo pen

(If required)

Backing NA NA NA

ELECTRICAL CHARACTERISTICS (QW- 409)

Current AC or DC : DC Polarity : EN for GTAW , EP for SMAW

Amps Range : Refer Table Volts : Refer Table

Tungsten Electrode Size and Type : 2.4mm 2% thoriated

Mode of Metal Transfer (GMAW) : N/A

Electrode wire Feed Speed Range : N/A

TECHNIQUE (QW- 410)

: String / Weave ( 3 Times of core diameter of electrode or 15mm Width whichever

String or Weave Bead is less for SMAW) - Weave for GTAW

Orifice or Gas cup Size : 6 to 8mm

Initial and Interpass Cleaning (Brushing,

Grinding, etc) : Brushing/Grinding

Weaving / Oscillation : 15mm or 3 times of electrode dia. Whichever is less.

Contact Tube To Work Distance : N/A

Multiple or Single Pass (Per side) : Multiple

Multiple or Single Electrodes : Single

Travel Speed (Range) : Refer Table

Peening : Not Allowed

Others : Nil

517885783.xls DPQC: F19 Rev 0

Page 6 of 12

Filler Metal Current Minimum

Volts Travel

Weld Layer Process Remarks

Amps Range Speed in

Class Dia mm Polarity mm/min

Range

Root GTAW ER 70S2 2.5 DC EN 60 - 90 A 12-18 V 60 GE TIG

SMAW E 7018 2.5 DC EP 60-130 A 12-18 V 60 ESSAB

Fill up & SMAW E 7018 3.2 DC EP 60-140 A 12-24 V 70 ESSAB

Capping passes SMAW E 7018 4.0 DC EP 70-140 A 12-24 V 80 ESSAB

NOTE:

1 All weld layers must be cleaned by grinding/brushing prior to starting next layers.

2 Complies with Welding Specification GS-400 Latest revision

Prepared (NSCL) Checked (CEL) Approved (CEL)

Name: Name: Name:

Date: Date: Date:

517885783.xls DPQC: F19 Rev 0

Page 7 of 12

Welding Process :GTAW + SMAW Type(s) : Manual Automatic Machine Semi-Auto

Joints (QW - 402)

Joint Design : As shown in the Sketch

Backing :No

Backing Material (Type) : N/A

Welding sequence to conform to good welding practice

Joint Type : Single V butt weld

70° +/- 5°

1.6 mm

2 to 3 mm

Base Metals(QW - 403)

P No : 1 Group No: 1 To P No : 1 Group No: 1

Specification Type and Grade : A106 GrB or Equivalent To A106 GrB or Equivalent

Chemical analysis and Mechanical Properties --------To Chemical analysis and Mechanical Properties --------

Thickness Range

Base Metal : Groove : 4.8mm to 50.8 mm Fillet : All

Dia Range : Above 2" Groove : All Fillet : All

Others : ------

FILLER METALS (QW- 404) GTAW SMAW

Spec No. (SFA) : 5.18 5.1

AWS No. (class) : ER 70S2 E7018

F- No :6 4

A- No :1 1

Size of Filler Metals : 2.4mm 2.5mm , 3.2mm, 4.0mm, 5.0mm

Electrode- Flux (Type) : N/A N/A

Flux Trade Name : N/A N/A

Consumable Insert : N/A N/A

Deposited Weld Metal Thickness Range

Groove : 10 mm max for GTAW + (Reminder and Reinforcement by SMAW

517885783.xls DPQC: F19 Rev 0

Page 8 of 12

POSITION(S) (QW- 405) POST WELD HEAT TREATMENT (QW-407)

Positions of Groove : All Temperature Range : 593°C to 649 °C

Welding Progression : Uphill Heating Rate : 150 ° C / Hr max

Positions of Fillets : All Cooling Rate : 200 ° C / Hr max

Soaking Time : 1 Hour (min.)

Others : Nil

PRE- HEAT (QW- 406) GAS (QW- 408) : N.A

Percentage Composition

Pre Heat (min) : 79 °C

Gases Mixtures Flow Rate

Interpass (max)

: 250 °C

Pre-Heat maintenance

: Yes Shielding Gas Argon 99.9 % pure 8 - 12 LPM

Pre Heat Method : LPG/ Oxygen heaters/

Any other suitable

method Trailing NA NA NA

Temperature Measuring Method Thermo pen

Backing NA NA NA

ELECTRICAL CHARACTERISTICS (QW- 409)

Current AC or DC : DC Polarity : EN for GTAW , EP for SMAW

Amps Range : Refer Table Volts : Refer Table

Tungsten Electrode Size and Type : 2.4mm 2% thoriated

Mode of Metal Transfer (GMAW) : N/A

Electrode wire Feed Speed Range : N/A

TECHNIQUE (QW- 410)

: String / Weave ( 3 Times of core diameter of electrode or 15mm Width whichever

String or Weave Bead is less for SMAW )

Orifice or Gas cup Size : 6 to 8mm

Initial and Interpass Cleaning (Brushing,

Grinding, etc) : Brushing/Grinding

Oscillation : yes

Contact Tube To Work Distance : N/A

Multiple or Single Pass (Per side) : Multiple

Multiple or Single Electrodes : Single

Travel Speed (Range) : Refer Table

Peening : Not Allowed

Others : Nil

517885783.xls DPQC: F19 Rev 0

Page 9 of 12

Filler Metal Current Minimum

Volts Travel

Weld Layer Process Remarks

Amps Range Speed in

Class Dia mm Polarity mm/min

Range

Root GTAW ER 70S2 2.5 DC EN 60 - 90 A 12-18 V 60 GE TIG

Hot pass GTAW ER 70S2 2.5 DC EN 60 - 90 A 12-18 V 60 GE TIG

SMAW E 7018 2.5 DC EP 60-130 A 12-18 V 60 ESSAB

SMAW E 7018 3.2 DC EP 60-140 A 12-24 V 70 ESSAB

Fill up & SMAW E 7018 4.0 DC EP 70-140 A 12-24 V 70 ESSAB

Capping passes SMAW E 7018 5.0 DC EP 80-140 A 12-24 V 75 ESSAB

NOTE:

1 All weld layers must be cleaned by grinding/brushing prior to starting next layers.

2 Complies with Welding Specification GS-400 Latest revision

Prepared (NSCL) Checked (CEL) Approved (CEL)

Name: Name: Name:

Date: Date: Date:

517885783.xls DPQC: F19 Rev 0

Page 10 of 12

Welding Process :GTAW Type(s) : Manual Automatic Machine Semi-Auto

Joints (QW - 402)

Joint Design : As shown in the Sketch

Backing :No

Backing Material (Type) : N/A

Welding sequence to conform to good welding practice

Joint Type : Single V butt weld

70° +/- 5°

1.6 mm

2 to 3 mm

Base Metals(QW - 403)

P No : 1 Group No: 1 To P No : 1 Group No: 1

Specification Type and Grade : A333 Gr 6 or Equivalent To A333 Gr 6 or Equivalent

Chemical analysis and Mechanical Properties --------To Chemical analysis and Mechanical Properties --------

Thickness Range

Base Metal : Groove : 1.6 mm to 11.08 mm Fillet : All

Dia Range : Groove : All Fillet : All

Others : ------

FILLER METALS (QW- 404) GTAW

Spec No. (SFA) : 5.18

AWS No. (class) : ER 80SB2

F- No :6

A- No :1

Size of Filler Metals : 2.4mm

Electrode- Flux (Type) : N/A

Flux Trade Name : N/A

Consumable Insert : N/A

Deposited Weld Metal Thickness Range

Groove : 11.08 mm + 1.6mm Reinforcement

517885783.xls DPQC: F19 Rev 0

Page 11 of 12

POSITION(S) (QW- 405) POST WELD HEAT TREATMENT (QW-407)

Positions of Groove : All Temperature Range : N/A

Welding Progression : Uphill Time Range : N/A

Positions of Fillets : All Heating Rate : N/A

Cooling Rate : N/A

Soaking Time : N/A

Others : N/A

PRE- HEAT (QW- 406) GAS (QW- 408) : N.A

Percentage Composition

Pre Heat (min)

: 10 °C (Preheat Gases Mixtures Flow Rate

required to remove

moisture from plate)

Interpass (max)

: 200 °C

Pre-Heat maintenance

: Yes Shielding Gas Argon 99.9 % pure 8 - 12 LPM

Pre Heat Method (If required)

: LPG/ Oxygen heaters/

Any other suitable

method Trailing NA NA NA

Temperature Measuring Method Thermo pen

(If required)

Backing NA NA NA

ELECTRICAL CHARACTERISTICS (QW- 409)

Current AC or DC : DC Polarity : EN

Amps Range : Refer Table Volts : Refer Table

Tungsten Electrode Size and Type : 2.4mm 2% thoriated

Mode of Metal Transfer (GMAW) : N/A

Electrode wire Feed Speed Range : N/A

TECHNIQUE (QW- 410)

String or Weave Bead : Weave

Orifice or Gas cup Size : 6 to 8mm

Initial and Interpass Cleaning (Brushing,

Grinding, etc) : Brushing/Grinding

Oscillation : yes

Contact Tube To Work Distance : N/A

Multiple or Single Pass (Per side) : Multiple

Multiple or Single Electrodes : Single

Travel Speed (Range) : Refer Table

Peening : Not Allowed

Others : Nil

517885783.xls DPQC: F19 Rev 0

Page 12 of 12

Filler Metal Current Minimum

Volts Travel

Weld Layer Process Brand Name

Amps Range Speed in

Class Dia mm Polarity mm/min

Range

Root GTAW ER 80SB2 2.5 DC EN 60 - 90 A 12-18 V 60 ESSAB

Fill up &

Capping GTAW ER 80SB2 2.5 DC EN 60 - 90 A 12-18 V 60 ESSAB

NOTE:

1 All weld layers must be cleaned by brushing prior to starting next layers.

2 Complies with Welding Specification GS-400 Latest revision

Prepared (NSCL) Checked (CEL) Approved (CEL)

Name: Name: Name:

Date: Date: Date:

517885783.xls DPQC: F19 Rev 0

You might also like

- Lifting Trunnion Calculations On Horizontal Vessel - 1Document1 pageLifting Trunnion Calculations On Horizontal Vessel - 1miteshpatel191No ratings yet

- Aerospace Material Specification: (R) In-Process Welding of CastingsDocument13 pagesAerospace Material Specification: (R) In-Process Welding of CastingsRamesh R100% (1)

- ALN FP ESA MEC SPC 0001 - 92B2.1 General Welding, Fabrication and InspectionDocument31 pagesALN FP ESA MEC SPC 0001 - 92B2.1 General Welding, Fabrication and Inspectionahmed.njahNo ratings yet

- Design Data 610 3450 9.5 1650 2 3300 2 1650 120Document3 pagesDesign Data 610 3450 9.5 1650 2 3300 2 1650 120miteshpatel191100% (1)

- WPSDocument6 pagesWPSYASH BARDHAN SinghNo ratings yet

- Piping WPS SMAWDocument2 pagesPiping WPS SMAWJk KarthikNo ratings yet

- WPS PQR PDFDocument23 pagesWPS PQR PDFAhmad Daniel100% (1)

- WPS Pipe 08'' SHD 40 SMAW REV02Document2 pagesWPS Pipe 08'' SHD 40 SMAW REV02Amine MaalejNo ratings yet

- Joints (Qw-402) DetailsDocument3 pagesJoints (Qw-402) DetailsNaqqash SajidNo ratings yet

- QW-484A (WPQ) GTAW 4MM FilletDocument2 pagesQW-484A (WPQ) GTAW 4MM FilletBalkishan Dyavanapelly100% (1)

- WPQ-1083 3G PDFDocument2 pagesWPQ-1083 3G PDFduendex360100% (1)

- Company Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsDocument11 pagesCompany Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsMAT-LIONNo ratings yet

- PQR - PipeDocument3 pagesPQR - PipeAdvanced Quality Centre AQC100% (1)

- Sa 516 WPQDocument1 pageSa 516 WPQElgen IgloriaNo ratings yet

- WPS Reg Rev.0Document3 pagesWPS Reg Rev.0Ed FangNo ratings yet

- TopCoreBelco 101 FCDocument9 pagesTopCoreBelco 101 FCCesar ArellanoNo ratings yet

- Welding Procedure SpecificationDocument27 pagesWelding Procedure SpecificationGopakumar K100% (3)

- 1 5 1Document5 pages1 5 1daemsalNo ratings yet

- 163 Gmaw Zug Asme (Sri Supatmi 3g) WPQDocument4 pages163 Gmaw Zug Asme (Sri Supatmi 3g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Format WPQDocument2 pagesFormat WPQAkash Singh TomarNo ratings yet

- Sample Wps Carbon Steel GTAW SMAW PDFDocument2 pagesSample Wps Carbon Steel GTAW SMAW PDFirwanNo ratings yet

- Limak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Document2 pagesLimak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Alam MD SazidNo ratings yet

- WPS 19Document15 pagesWPS 19Avishek Gupta100% (1)

- Welding Procedure Specification For GTAW & GMAWDocument4 pagesWelding Procedure Specification For GTAW & GMAWanh thoNo ratings yet

- ASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationDocument2 pagesASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationAmit SharmaNo ratings yet

- Wps Aws d1.1 NEWDocument2 pagesWps Aws d1.1 NEWIkhy Tohepaly100% (1)

- Welding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Document3 pagesWelding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Ahmad DanielNo ratings yet

- SMAW DuniDocument4 pagesSMAW DuniMuhammad Fitransyah Syamsuar PutraNo ratings yet

- WPQR2Document3 pagesWPQR2Thanasis KyrgiazoglouNo ratings yet

- VLG02 NGUYEN QUANG TUAN - 6G Duplex, T 18.26mmDocument3 pagesVLG02 NGUYEN QUANG TUAN - 6G Duplex, T 18.26mmTuTuy AnNo ratings yet

- Welding Parameters Control PipelineDocument1 pageWelding Parameters Control PipelinemusheerNo ratings yet

- Welding Procedure Specification: ST NDDocument1 pageWelding Procedure Specification: ST NDMaung SleeperNo ratings yet

- Dokumen - Tips Wqt-FormatDocument2 pagesDokumen - Tips Wqt-FormatMr Pie100% (1)

- QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Document1 pageQW-301, Section IX, ASME Boiler and Pressure Vessel Code)rajuNo ratings yet

- Welder'S Qualification Test Certificate: (As Per Asme Sec Ix)Document2 pagesWelder'S Qualification Test Certificate: (As Per Asme Sec Ix)vijay100% (1)

- 26.WPS Log CoilDocument1 page26.WPS Log CoilAvishek GuptaNo ratings yet

- wps63 PDFDocument4 pageswps63 PDFErick HoganNo ratings yet

- Aws 001Document1 pageAws 001akshay sarfareNo ratings yet

- WPS FormatDocument2 pagesWPS FormatAmit SarkarNo ratings yet

- WPS GTAW-SMAW h1Document1 pageWPS GTAW-SMAW h1Jesus Gabrielw Blanco GhostbustersIzNo ratings yet

- Fit-Up and Daily Welding Visual Inspection ReportDocument1 pageFit-Up and Daily Welding Visual Inspection ReportAws AbduljaleelNo ratings yet

- WQT Aws D1.1Document1 pageWQT Aws D1.1Ali HammoudaNo ratings yet

- Prequalified X Qualified by Testing Procedure Qualification Records (PQR) YES .Document2 pagesPrequalified X Qualified by Testing Procedure Qualification Records (PQR) YES .Midhun K Chandrabose100% (1)

- Welding & NDE Summary Sheet (BE)Document12 pagesWelding & NDE Summary Sheet (BE)MulPXNo ratings yet

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Ramadhan AdityaNo ratings yet

- Final - WPS PQR 86Document4 pagesFinal - WPS PQR 86Parag WadekarNo ratings yet

- WPS ListDocument2 pagesWPS ListAdeel OmerNo ratings yet

- Preliminary Welding Procedure Specification (PWPS) : South Pars Gas Field Development Phase 14Document2 pagesPreliminary Welding Procedure Specification (PWPS) : South Pars Gas Field Development Phase 14Vijaya Barani100% (1)

- Welding Procedure Specification Register: Company AddressDocument20 pagesWelding Procedure Specification Register: Company Addressmurshid badshahNo ratings yet

- Welding Procedure Specification For GTAWDocument9 pagesWelding Procedure Specification For GTAWraja reyhanNo ratings yet

- 1662 15Document117 pages1662 15RajamanikkamNo ratings yet

- PQR TipsDocument4 pagesPQR TipsWaqas WaqasNo ratings yet

- WPS 05Document4 pagesWPS 05Naqqash SajidNo ratings yet

- ASME P NumbersDocument1 pageASME P NumbersFahri Risfa ZulfiNo ratings yet

- QW 483Document2 pagesQW 483delta lab sangliNo ratings yet

- Draft WPSDocument3 pagesDraft WPSWale OyeludeNo ratings yet

- Sembcorp Marine Integrated Yard PteDocument3 pagesSembcorp Marine Integrated Yard PteMd. Mizanur Rahaman100% (1)

- Pt. Astar Testing & InspectionDocument2 pagesPt. Astar Testing & InspectionSASINo ratings yet

- Welding Procedure Specification (PWPS) - 5fpipe To Plate: Joint Design Used PositionDocument2 pagesWelding Procedure Specification (PWPS) - 5fpipe To Plate: Joint Design Used PositionTrudie0% (1)

- Welding Coordinator WeldMap Weld Data Sheet PDFDocument1 pageWelding Coordinator WeldMap Weld Data Sheet PDFAzhar AhmadNo ratings yet

- Gta+sma PQRDocument3 pagesGta+sma PQRRahul MoottolikandyNo ratings yet

- PQR A106 HAL-1Document1 pagePQR A106 HAL-1Budi Setia RahmanNo ratings yet

- Aic Asf PQR 0122Document2 pagesAic Asf PQR 0122AHMED MEDANYNo ratings yet

- Lifting Lug CalculationDocument2 pagesLifting Lug Calculationmiteshpatel191No ratings yet

- Tie Rod Support For Retangular TanksDocument11 pagesTie Rod Support For Retangular Tanksmiteshpatel191No ratings yet

- Uc COLUMNSDocument4 pagesUc COLUMNSmiteshpatel191No ratings yet

- Section DataDocument5 pagesSection Datamiteshpatel191No ratings yet

- Weight CalculationDocument17 pagesWeight Calculationmiteshpatel191No ratings yet

- Section DataDocument5 pagesSection Datamiteshpatel191No ratings yet

- Platform Cleat CalculationDocument1 pagePlatform Cleat Calculationmiteshpatel191No ratings yet

- Weld Joint DesignDocument4 pagesWeld Joint Designmiteshpatel191No ratings yet

- Base Ring Fillet Size CalculationDocument4 pagesBase Ring Fillet Size Calculationmiteshpatel191No ratings yet

- Lug On SkidDocument8 pagesLug On Skidmiteshpatel191No ratings yet

- Lifting Lug Calculation For Small Horizontal VesselDocument2 pagesLifting Lug Calculation For Small Horizontal Vesselmiteshpatel191100% (2)

- Storage Tank Design Calculation - Api 650Document21 pagesStorage Tank Design Calculation - Api 650miteshpatel191100% (3)

- Ellipsoidal HEAD THICKNESS CALCULATION FOR INTERNAL PRESSUREDocument3 pagesEllipsoidal HEAD THICKNESS CALCULATION FOR INTERNAL PRESSUREmiteshpatel191No ratings yet

- Torispherical Heads THICKNESS CALCULATION FOR INTERNAL PRESSUREDocument3 pagesTorispherical Heads THICKNESS CALCULATION FOR INTERNAL PRESSUREmiteshpatel191No ratings yet

- Nozzle Reinforcement Calculations: HH1&HH2 (Hand Hole) : Description Regulation Formula Symbol Value UnitDocument1 pageNozzle Reinforcement Calculations: HH1&HH2 (Hand Hole) : Description Regulation Formula Symbol Value Unitmiteshpatel191No ratings yet

- Ug-116 - RT4Document3 pagesUg-116 - RT4miteshpatel191No ratings yet

- Silencer AnalysisDocument5 pagesSilencer Analysismiteshpatel191No ratings yet

- Code Case 2901Document2 pagesCode Case 2901miteshpatel191No ratings yet

- Figure UG-34 Forged HeadDocument8 pagesFigure UG-34 Forged Headmiteshpatel191No ratings yet

- WRC-107 (WRC-537) and WRC-297. (WELDING RESEARCH COUNCIL)Document1 pageWRC-107 (WRC-537) and WRC-297. (WELDING RESEARCH COUNCIL)miteshpatel191No ratings yet

- Microsoft Word - Report of Licenciate-2010-Final-BZDocument167 pagesMicrosoft Word - Report of Licenciate-2010-Final-BZmiteshpatel191No ratings yet

- Understanding How Changes in Pressure Vessel Codes May Impact Pressure Vessel PerformanceDocument33 pagesUnderstanding How Changes in Pressure Vessel Codes May Impact Pressure Vessel Performancemiteshpatel191No ratings yet

- 1.0 Load On Davit: (Ref:Pressure Vessel Design Manual 3rd Edition by Dennis R. Moss Page 291 295)Document1 page1.0 Load On Davit: (Ref:Pressure Vessel Design Manual 3rd Edition by Dennis R. Moss Page 291 295)miteshpatel191No ratings yet

- Esab, Dual Shield II 110 (265-En - US-FactSheet - Main-01) (26.10.16)Document2 pagesEsab, Dual Shield II 110 (265-En - US-FactSheet - Main-01) (26.10.16)RodrigoNo ratings yet

- Operating Manual Stud Welding Products IncDocument78 pagesOperating Manual Stud Welding Products InccarlosmitecNo ratings yet

- WPS 2-A36 Rudder Shaft To FlangeDocument2 pagesWPS 2-A36 Rudder Shaft To FlangeNuwan RanaweeraNo ratings yet

- Metrode P92 Consumables Jul2006Document28 pagesMetrode P92 Consumables Jul2006Claudia MmsNo ratings yet

- MIG ManualDocument24 pagesMIG Manualvladyslav.kuzykNo ratings yet

- WPSAmerica Shielding Gases and Mechanical PropertiesDocument44 pagesWPSAmerica Shielding Gases and Mechanical PropertiesRameshBaskaranNo ratings yet

- Lab Manual WeldingDocument83 pagesLab Manual Weldingknizam1971No ratings yet

- An Experimental Study On The Effect of Increased Pressure On MIG Welding ArcDocument6 pagesAn Experimental Study On The Effect of Increased Pressure On MIG Welding ArcSaket PatwaNo ratings yet

- Duragal Easy Welding Guide PDFDocument28 pagesDuragal Easy Welding Guide PDFRrrrrrrNo ratings yet

- Welding (Unit Iv)Document19 pagesWelding (Unit Iv)Susheel GuptaNo ratings yet

- TIG Pulsed WeldingDocument5 pagesTIG Pulsed WeldingRajiv DamodarNo ratings yet

- A Review On Hybrid Laser Arc WeldingDocument22 pagesA Review On Hybrid Laser Arc WeldingAkshay AcchuNo ratings yet

- In General, The MIG/MAG Mode of Transfer Best Suited For Welding Thick Sheet Is Spray TransferDocument4 pagesIn General, The MIG/MAG Mode of Transfer Best Suited For Welding Thick Sheet Is Spray TransferLe TuanNo ratings yet

- DL-T 5018-2004Document98 pagesDL-T 5018-2004saliyarumesh2292No ratings yet

- Study of Shielded Gases For MIG WeldingDocument5 pagesStudy of Shielded Gases For MIG WeldingRajesh KumarNo ratings yet

- Department: Production Engineering LaboratoryDocument70 pagesDepartment: Production Engineering LaboratorySourabh PradhanNo ratings yet

- Body Repair NewsDocument16 pagesBody Repair NewsK-C Rock zubzerooNo ratings yet

- Welding Inspection Consumables PDFDocument28 pagesWelding Inspection Consumables PDFJoseph PeterNo ratings yet

- Welding TerminologiesDocument5 pagesWelding Terminologiescharlesbryan.martinezNo ratings yet

- Wis 5 Eoca AnswersDocument34 pagesWis 5 Eoca AnswersAli ClubistNo ratings yet

- WPQ 50-FcawDocument8 pagesWPQ 50-FcawDHANEESH VELLILAPULLINo ratings yet

- Standard Welding Procedure Specification (SWPS) For: Site LicenseDocument26 pagesStandard Welding Procedure Specification (SWPS) For: Site LicenseAlex MendozaNo ratings yet

- Guia Practica Eleccion AporteDocument26 pagesGuia Practica Eleccion AporteNegrito RosarinoNo ratings yet

- Unit III - Introduction To Manufacturing EngineeringDocument281 pagesUnit III - Introduction To Manufacturing EngineeringJohnNo ratings yet

- Harshit Bansal M.Tech.Document73 pagesHarshit Bansal M.Tech.192016006.sseNo ratings yet

- Hastelloy C-2000 Welding Data: General InformationDocument1 pageHastelloy C-2000 Welding Data: General Informationtuna61No ratings yet

- HDSD Mig OTC DM350 PDFDocument72 pagesHDSD Mig OTC DM350 PDFHOryshorNo ratings yet

- 3 - Module 3-FinalDocument102 pages3 - Module 3-FinalGHULAM NABINo ratings yet

- Shield-Bright 2209: Gas-Shielded Flux-Cored Wires (Fcaw) Stainless Steel WiresDocument1 pageShield-Bright 2209: Gas-Shielded Flux-Cored Wires (Fcaw) Stainless Steel WiresvallirajuNo ratings yet