Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

24 viewsTY CET - Open Ended Assignment (Mid-Sem)

TY CET - Open Ended Assignment (Mid-Sem)

Uploaded by

yaseen sheikhThe document is a problem statement from a Chemical Engineering Thermodynamics exam that involves calculating various parameters of a vapor-compression refrigeration system using ammonia as the refrigerant. Students are provided data on the enthalpies and temperatures of ammonia at different states and asked to determine: (1) the rate of heat removal, (2) temperature at state P1, (3) enthalpy at state P1, (4) coefficient of performance, (5) power input, (6) heat rejection rate, (7) refrigerant flow rate, and (8) cooling water flow rate. A table with the rating of 80 refrigeration systems (tonnage and pressures P2 and P1) is

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- LPG Handbook PDFDocument50 pagesLPG Handbook PDFAhmed Sherif100% (1)

- Weekly Planning Meeting Date Plant Sr. #Document10 pagesWeekly Planning Meeting Date Plant Sr. #HamzaNoumanNo ratings yet

- Weekly Planning Meeting Date Plant Sr. #Document10 pagesWeekly Planning Meeting Date Plant Sr. #HamzaNoumanNo ratings yet

- List Check Thickness Bio 1 - APM 15 Jan 2022Document8 pagesList Check Thickness Bio 1 - APM 15 Jan 2022Bernacleboy IDNo ratings yet

- FCC 2Document17 pagesFCC 2bac_nobita7657No ratings yet

- BoQ Type EEDocument192 pagesBoQ Type EEBung AsriNo ratings yet

- Techfill Nicad Manual - T-SeriesDocument25 pagesTechfill Nicad Manual - T-Seriesvideo irfanNo ratings yet

- Engine Torque Wrench SettingsDocument2 pagesEngine Torque Wrench SettingsDNo ratings yet

- MENG615L Experiment 1 2 JFDocument14 pagesMENG615L Experiment 1 2 JFAhmad ShreifNo ratings yet

- Dorin K4PDocument6 pagesDorin K4Pfrigoremont100% (1)

- Bestway Cement Chakwal Waste Heat Recovery Power Plant Tapping Point Status of Steam Turbine and GeneratorDocument4 pagesBestway Cement Chakwal Waste Heat Recovery Power Plant Tapping Point Status of Steam Turbine and Generatorraobabar21No ratings yet

- ATD AssignmentDocument2 pagesATD AssignmentsamarthgkNo ratings yet

- (자재구매) PO list from ThachDocument104 pages(자재구매) PO list from Thachnguyen.hienNo ratings yet

- Lesson 2.2.1 - Actual Rankine CycleDocument10 pagesLesson 2.2.1 - Actual Rankine Cyclesuga linNo ratings yet

- Diccionario V1Document1,308 pagesDiccionario V1Ed VanegasNo ratings yet

- Thermal Lab1st CycleDocument26 pagesThermal Lab1st CyclesreyajerryNo ratings yet

- Ysis From The Steam Tables (Tables A-4, A-5, and A-6) ,: S S H H P TDocument11 pagesYsis From The Steam Tables (Tables A-4, A-5, and A-6) ,: S S H H P TEdison GuachambozaNo ratings yet

- D1.pan Reactor Energy Model - 23062023Document53 pagesD1.pan Reactor Energy Model - 2306202319bt01019No ratings yet

- 07.17 S - 3 29cDocument4 pages07.17 S - 3 29cAnjana WNo ratings yet

- LP-Gas Service Mans ManualDocument52 pagesLP-Gas Service Mans Manualprocha1100% (1)

- Turbine Heat Rate Calculations...Document9 pagesTurbine Heat Rate Calculations...prasol thermaxNo ratings yet

- Tube Calculation: Cylinder DataDocument1 pageTube Calculation: Cylinder DataMamank Ira SudrajatNo ratings yet

- National Examinations - December 2011: NotesDocument26 pagesNational Examinations - December 2011: NotesNiko Garcia MeythalerNo ratings yet

- 10-Chem ATP (SVKM)Document7 pages10-Chem ATP (SVKM)Jashan LoombaNo ratings yet

- Data Di PrintDocument16 pagesData Di PrinturikelNo ratings yet

- Amine Processing Unit DEADocument9 pagesAmine Processing Unit DEAFlorin Daniel AnghelNo ratings yet

- Du DT M C DT DT c1T T P: C Chapter Summary and Study GuideDocument24 pagesDu DT M C DT DT c1T T P: C Chapter Summary and Study Guidekrntomboy25% (4)

- Report CSTRDocument14 pagesReport CSTRniraj_bairagiNo ratings yet

- Kosan HandbookDocument74 pagesKosan HandbookranganathrajaratneNo ratings yet

- Industrial ReactorsDocument10 pagesIndustrial ReactorssarahNo ratings yet

- Capacity Regulator CpceDocument8 pagesCapacity Regulator CpceNovan AndriantoNo ratings yet

- Tutorials Week2 SolutionDocument3 pagesTutorials Week2 Solutionfivos_rgNo ratings yet

- Greaves 10 To 500 Kva Genset ECatalogueDocument2 pagesGreaves 10 To 500 Kva Genset ECatalogueArpit VermaNo ratings yet

- General Product Catalog Low Res Part47 PDFDocument1 pageGeneral Product Catalog Low Res Part47 PDFJosephRusselVizmanosNo ratings yet

- H PLC ColumnsDocument103 pagesH PLC Columnschem6310No ratings yet

- In DiceDocument5 pagesIn DiceAroldo RamirezNo ratings yet

- Me 303 CH9Document72 pagesMe 303 CH9Osman KutluNo ratings yet

- 004 TanksDocument25 pages004 TanksNicandroGonzalesNo ratings yet

- Refer This Lab Manual For Preparing Your Experimental Work.Document22 pagesRefer This Lab Manual For Preparing Your Experimental Work.Prem ChaudharyNo ratings yet

- Ache-High Pour Point Feb11Document21 pagesAche-High Pour Point Feb11Poncho RmzNo ratings yet

- Thermal Cracking Reaction Kinetics - Hemendra KhakharDocument21 pagesThermal Cracking Reaction Kinetics - Hemendra Khakhargolden retrieverNo ratings yet

- Series LFN170 Specification SheetDocument2 pagesSeries LFN170 Specification SheetWattsNo ratings yet

- 10 104 PDFDocument2 pages10 104 PDFkidanemariam teseraNo ratings yet

- Technical Data Sheet Gly12Rra 115-127V 60Hz 1 R134A: Compressor Model Voltage RefrigerantDocument5 pagesTechnical Data Sheet Gly12Rra 115-127V 60Hz 1 R134A: Compressor Model Voltage RefrigerantGerman Gaspar RiveraNo ratings yet

- Manual Formacion D722-B, D1005-E, D1105-B y D1703-BDocument16 pagesManual Formacion D722-B, D1005-E, D1105-B y D1703-BTerah Pio100% (1)

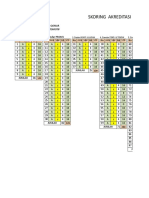

- Skoring SMK Islam Al-Qomar 2018 (TKR)Document4 pagesSkoring SMK Islam Al-Qomar 2018 (TKR)ridhoplexNo ratings yet

- Kinetics of In-Situ CombijstionDocument324 pagesKinetics of In-Situ CombijstionkavanayenNo ratings yet

- Document GDFJFFFDocument2 pagesDocument GDFJFFFVi JäìNo ratings yet

- United States Patent (19) 11 4,083,889: 51 Int. Cl. ........................ Coic 1/24 Co7.c 11/04 ''Document8 pagesUnited States Patent (19) 11 4,083,889: 51 Int. Cl. ........................ Coic 1/24 Co7.c 11/04 ''irfan mahierNo ratings yet

- Lab ManualDocument6 pagesLab ManualAnshikha NautiyalNo ratings yet

- United States Patent (19) : 11 Patent Number: 45 Date of PatentDocument25 pagesUnited States Patent (19) : 11 Patent Number: 45 Date of Patentfitri rowiyahNo ratings yet

- T2 TE Expansion ValveDocument16 pagesT2 TE Expansion ValveIvan KurniadiNo ratings yet

- Ekspansi T2 Dan TE2Document16 pagesEkspansi T2 Dan TE2Arfa ZaynNo ratings yet

- Tanker Gantry Estimation Sheet Aegis 2020Document9 pagesTanker Gantry Estimation Sheet Aegis 2020shubhamNo ratings yet

- Engineering Bulletin No 1: Boiler and Furnace TestingFrom EverandEngineering Bulletin No 1: Boiler and Furnace TestingRating: 4.5 out of 5 stars4.5/5 (2)

- Southern Marine Engineering Desk Reference: Second Edition Volume IiFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IiNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Practical Rules for the Management of a Locomotive Engine in the Station, on the Road, and in cases of AccidentFrom EverandPractical Rules for the Management of a Locomotive Engine in the Station, on the Road, and in cases of AccidentNo ratings yet

- Operator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingFrom EverandOperator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingRating: 5 out of 5 stars5/5 (1)

- CED Mse OpenendDocument6 pagesCED Mse Openendyaseen sheikhNo ratings yet

- .Ihtennal Bol: PraureDocument4 pages.Ihtennal Bol: Praureyaseen sheikhNo ratings yet

- CEDtheory Assign5Document3 pagesCEDtheory Assign5yaseen sheikhNo ratings yet

- Esi - Ji Hecct: Ben - T 1 atDocument5 pagesEsi - Ji Hecct: Ben - T 1 atyaseen sheikhNo ratings yet

- Assignment Assignment: School of Chemical Engineering School of Chemical EngineeringDocument2 pagesAssignment Assignment: School of Chemical Engineering School of Chemical Engineeringyaseen sheikhNo ratings yet

- CED Lab Tuto5 DecantDocument3 pagesCED Lab Tuto5 Decantyaseen sheikhNo ratings yet

- CED Theory Support AssignDocument10 pagesCED Theory Support Assignyaseen sheikhNo ratings yet

- Name: Yaseen Sheikh Roll No.: TCH-37 Title: Rigorous Distillation ColumnDocument6 pagesName: Yaseen Sheikh Roll No.: TCH-37 Title: Rigorous Distillation Columnyaseen sheikhNo ratings yet

- Torispheicas: Roll O3 CED LcebDocument8 pagesTorispheicas: Roll O3 CED Lcebyaseen sheikhNo ratings yet

- P L A T e S 3 (4hemti Cas) : Yaeer $hi LCDocument2 pagesP L A T e S 3 (4hemti Cas) : Yaeer $hi LCyaseen sheikhNo ratings yet

- Name: Yaseen Sheikh Roll No.: TCH-37 Title: Rigorous Distillation ColumnDocument5 pagesName: Yaseen Sheikh Roll No.: TCH-37 Title: Rigorous Distillation Columnyaseen sheikhNo ratings yet

- Paper Chromatography Aim: Apparatus: No. 21 Filter Paper, Glass Jar, Lid, Thread, Capillary Tube ChemicalsDocument2 pagesPaper Chromatography Aim: Apparatus: No. 21 Filter Paper, Glass Jar, Lid, Thread, Capillary Tube Chemicalsyaseen sheikhNo ratings yet

- Aim: To Study The Soldering TechniquesDocument3 pagesAim: To Study The Soldering Techniquesyaseen sheikhNo ratings yet

- NAME: Swapnil Sanjay Gaikwad Roll No: Sch-15Document4 pagesNAME: Swapnil Sanjay Gaikwad Roll No: Sch-15yaseen sheikhNo ratings yet

- Aim: To Determine The Hardness of Test Pieces Using Vicker's Hardness Test. PrincipleDocument4 pagesAim: To Determine The Hardness of Test Pieces Using Vicker's Hardness Test. Principleyaseen sheikhNo ratings yet

- Astm 388Document8 pagesAstm 388Joseph RefuerzoNo ratings yet

- Teacher ResearcherDocument17 pagesTeacher ResearcherAmanda EvansNo ratings yet

- Imagining Lives Through Korean DramasDocument11 pagesImagining Lives Through Korean DramasLuis FernandoNo ratings yet

- CH 1 - Introduction To FMADocument22 pagesCH 1 - Introduction To FMAIPloboNo ratings yet

- Vikram Kumar Devops Notes: Build ManagementDocument6 pagesVikram Kumar Devops Notes: Build ManagementSANANo ratings yet

- SKF Bearing Select PDFDocument9 pagesSKF Bearing Select PDFBharat KumarNo ratings yet

- Optimal Capacitor Placement For Loss Reduction and Voltage Profile Improvement in Distribution System Using Genetic AlgorithmDocument5 pagesOptimal Capacitor Placement For Loss Reduction and Voltage Profile Improvement in Distribution System Using Genetic AlgorithmNateNo ratings yet

- CJ Relays (Acj) : Features Typical ApplicationsDocument7 pagesCJ Relays (Acj) : Features Typical ApplicationsFranciscoMedinaNo ratings yet

- Loading, Discharging and Cleaning of Belt Conveyors PDFDocument11 pagesLoading, Discharging and Cleaning of Belt Conveyors PDFJaco KotzeNo ratings yet

- Torsten Husén A Co-Founder and Chairman of IEA From 1962 To 1978Document15 pagesTorsten Husén A Co-Founder and Chairman of IEA From 1962 To 1978Teodora GenovaNo ratings yet

- UNIT-2-NOTES - Self Management Skills-IXDocument8 pagesUNIT-2-NOTES - Self Management Skills-IXVaishnavi JoshiNo ratings yet

- FastLink CAT6 (SFTP) OutdoorDocument3 pagesFastLink CAT6 (SFTP) OutdoorHaiderNo ratings yet

- When My Autism Gets Too BigDocument67 pagesWhen My Autism Gets Too Bighchristen100% (1)

- Ajit Vadakayil - WALL WASH METHOD CHEMICAL TANKERS - CAPT AJIT VADAKAYILDocument150 pagesAjit Vadakayil - WALL WASH METHOD CHEMICAL TANKERS - CAPT AJIT VADAKAYILosman goniNo ratings yet

- Impact of Chronic Illness On ChildrenDocument6 pagesImpact of Chronic Illness On ChildrenDeepa ThomasNo ratings yet

- SMT Mechanical Suspensions: ROR Trailer ProductsDocument24 pagesSMT Mechanical Suspensions: ROR Trailer ProductsOskarNo ratings yet

- Agexcomm 1 Q&aDocument25 pagesAgexcomm 1 Q&aWaren LlorenNo ratings yet

- Filtro Canastillo FMCDocument4 pagesFiltro Canastillo FMCCristian Rodrigo Gonzalez SoteloNo ratings yet

- Sbi3C Name: Characteristics of Bacteria Worksheet: Big Idea! IdeasDocument2 pagesSbi3C Name: Characteristics of Bacteria Worksheet: Big Idea! IdeasPaulina JakubiecNo ratings yet

- Textbook Building Evidence For Active Ageing Policies Active Ageing Index and Its Potential 1St Edition Asghar Zaidi Ebook All Chapter PDFDocument53 pagesTextbook Building Evidence For Active Ageing Policies Active Ageing Index and Its Potential 1St Edition Asghar Zaidi Ebook All Chapter PDFmatthew.renfro133100% (17)

- Lesson Plan in English Using SRF: I. ObjectiveDocument10 pagesLesson Plan in English Using SRF: I. ObjectiveShee AntonioNo ratings yet

- Mis 024Document223 pagesMis 024ysanyasirajuNo ratings yet

- Tin Mill Products, Black Plate, Double Reduced: Standard Specification ForDocument2 pagesTin Mill Products, Black Plate, Double Reduced: Standard Specification ForsamehNo ratings yet

- Catalogue SDocument8 pagesCatalogue SSHINOS 3SNo ratings yet

- ASME - VIII Div. 2 2004 Edition - AM-211 PDFDocument2 pagesASME - VIII Div. 2 2004 Edition - AM-211 PDFEsapermana RiyanNo ratings yet

- Modular ExponentiationDocument2 pagesModular ExponentiationflaksherNo ratings yet

- Zrzut Ekranu 2022-11-20 o 23.44.07Document74 pagesZrzut Ekranu 2022-11-20 o 23.44.07Bartek SalahNo ratings yet

- UNCTAD DTL KDB 2016 1 Port Management Series Volume 4 - E - Web PDFDocument53 pagesUNCTAD DTL KDB 2016 1 Port Management Series Volume 4 - E - Web PDFHeb RuNo ratings yet

- 300+ TOP PIPING Engineering Interview Questions and Answers PDFDocument20 pages300+ TOP PIPING Engineering Interview Questions and Answers PDFjignesh chauhan100% (1)

- Herramientas CSDocument2 pagesHerramientas CSCAPCOMALLSTARS POWERNo ratings yet

TY CET - Open Ended Assignment (Mid-Sem)

TY CET - Open Ended Assignment (Mid-Sem)

Uploaded by

yaseen sheikh0 ratings0% found this document useful (0 votes)

24 views3 pagesThe document is a problem statement from a Chemical Engineering Thermodynamics exam that involves calculating various parameters of a vapor-compression refrigeration system using ammonia as the refrigerant. Students are provided data on the enthalpies and temperatures of ammonia at different states and asked to determine: (1) the rate of heat removal, (2) temperature at state P1, (3) enthalpy at state P1, (4) coefficient of performance, (5) power input, (6) heat rejection rate, (7) refrigerant flow rate, and (8) cooling water flow rate. A table with the rating of 80 refrigeration systems (tonnage and pressures P2 and P1) is

Original Description:

Original Title

TY CET - Open ended assignment (Mid-sem)

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document is a problem statement from a Chemical Engineering Thermodynamics exam that involves calculating various parameters of a vapor-compression refrigeration system using ammonia as the refrigerant. Students are provided data on the enthalpies and temperatures of ammonia at different states and asked to determine: (1) the rate of heat removal, (2) temperature at state P1, (3) enthalpy at state P1, (4) coefficient of performance, (5) power input, (6) heat rejection rate, (7) refrigerant flow rate, and (8) cooling water flow rate. A table with the rating of 80 refrigeration systems (tonnage and pressures P2 and P1) is

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

24 views3 pagesTY CET - Open Ended Assignment (Mid-Sem)

TY CET - Open Ended Assignment (Mid-Sem)

Uploaded by

yaseen sheikhThe document is a problem statement from a Chemical Engineering Thermodynamics exam that involves calculating various parameters of a vapor-compression refrigeration system using ammonia as the refrigerant. Students are provided data on the enthalpies and temperatures of ammonia at different states and asked to determine: (1) the rate of heat removal, (2) temperature at state P1, (3) enthalpy at state P1, (4) coefficient of performance, (5) power input, (6) heat rejection rate, (7) refrigerant flow rate, and (8) cooling water flow rate. A table with the rating of 80 refrigeration systems (tonnage and pressures P2 and P1) is

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 3

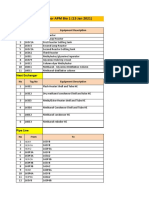

MIT Academy of Engineering

SCHOOL OF CHEMICAL ENGINEERING

Chemical Engineering Thermodynamics

T. Y. B. Tech. Sem-V 2020-21

Mid-Semester Examination

Open-Ended Assignment

Problem statement (15 Marks)

Ammonia is used as a refrigerant in an ordinary vapour-compression refrigeration machine

rated at ‘A’ ton. The temperature inside the chamber is to be maintained at 273 K. Cooling

water is available at 298 K. A 5 K approach is necessary, both in the evaporator and the

condenser. The ammonia vapours leaving the evaporator are adiabatically compressed from

pressure P2 bar to pressure P1 bar. Assume that the refrigerant behaves ideally (γ = 1.4). It has

been observed that the enthalpy (in kJ/kg) of the superheated vapour at P1 bar is four times

that of its temperature (in K). The enthalpy of saturated liquid and vapour at 268 K is 168

kJ/kg and 1300 kJ/kg, respectively. The enthalpy of saturated liquid and vapour at 303 K is

700 kJ/kg and 1327 kJ/kg, respectively. The temperature rise of water in the condenser is 10

K. Specific heat of water is 4.18 kJ/(kg K). Determine the following:

a) Rate of heat removal from refrigeration chamber in kW (2 marks)

b) Temperature of the superheated vapour at P1 bar in K (2 marks)

c) Enthalpy of superheated vapour at P1 bar in kJ/kg (1 mark)

d) Coefficient of performance (2 marks)

e) Power input in hp (2 marks)

f) Rate of heat loss to condenser in kJ/s (2 marks)

g) Refrigerant circulation rate in kmol/h (2 marks)

h) Cooling water rate in kg/s (2 marks)

A P2 P1

Roll No.

ton bar bar

TCH 01 1 4.00 11.00

TCH 02 2 4.01 11.01

TCH 03 3 4.02 11.02

TCH 04 4 4.03 11.03

TCH 05 5 4.04 11.04

TCH 06 6 4.05 11.05

TCH 07 7 4.06 11.06

TCH 08 8 4.07 11.07

TCH 09 9 4.08 11.08

TCH 10 10 4.09 11.09

TCH 11 11 4.10 11.10

TCH 12 12 4.11 11.11

TCH 13 13 4.12 11.12

TCH 14 14 4.13 11.13

TCH 15 15 4.14 11.14

TCH 16 16 4.15 11.15

TCH 17 17 4.16 11.16

TCH 18 18 4.17 11.17

TCH 19 19 4.18 11.18

TCH 20 20 4.19 11.19

TCH 21 21 4.20 11.20

TCH 22 22 4.21 11.21

TCH 23 23 4.22 11.22

TCH 24 24 4.23 11.23

TCH 25 25 4.24 11.24

TCH 26 26 4.25 11.25

TCH 27 27 4.26 11.26

TCH 28 28 4.27 11.27

TCH 29 29 4.28 11.28

TCH 30 30 4.29 11.29

TCH 31 31 4.30 11.30

TCH 32 32 4.31 11.31

TCH 33 33 4.32 11.32

TCH 34 34 4.33 11.33

TCH 35 35 4.34 11.34

TCH 36 36 4.35 11.35

TCH 37 37 4.36 11.36

TCH 38 38 4.37 11.37

TCH 39 39 4.38 11.38

TCH 40 40 4.39 11.39

TCH 41 41 4.40 11.40

TCH 42 42 4.41 11.41

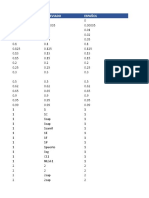

A P2 P1

Roll No.

ton bar bar

TCH 43 43 4.42 11.42

TCH 44 44 4.43 11.43

TCH 45 45 4.44 11.44

TCH 46 46 4.45 11.45

TCH 47 47 4.46 11.46

TCH 48 48 4.47 11.47

TCH 49 49 4.48 11.48

TCH 50 50 4.49 11.49

TCH 51 51 4.50 11.50

TCH 52 52 4.51 11.51

TCH 53 53 4.52 11.52

TCH 54 54 4.53 11.53

TCH 55 55 4.54 11.54

TCH 56 56 4.55 11.55

TCH 57 57 4.56 11.56

TCH 58 58 4.57 11.57

TCH 59 59 4.58 11.58

TCH 60 60 4.59 11.59

TCH 61 61 4.60 11.60

TCH 62 62 4.61 11.61

TCH 63 63 4.62 11.62

TCH 64 64 4.63 11.63

TCH 65 65 4.64 11.64

TCH 66 66 4.65 11.65

TCH 67 67 4.66 11.66

TCH 68 68 4.67 11.67

TCH 69 69 4.68 11.68

TCH 70 70 4.69 11.69

TCH 71 71 4.70 11.70

TCH 72 72 4.71 11.71

TCH 73 73 4.72 11.72

TCH 74 74 4.73 11.73

TCH 75 75 4.74 11.74

TCH 76 76 4.75 11.75

TCH 77 77 4.76 11.76

TCH 78 78 4.77 11.77

TCH 79 79 4.78 11.78

TCH 80 80 4.79 11.79

You might also like

- LPG Handbook PDFDocument50 pagesLPG Handbook PDFAhmed Sherif100% (1)

- Weekly Planning Meeting Date Plant Sr. #Document10 pagesWeekly Planning Meeting Date Plant Sr. #HamzaNoumanNo ratings yet

- Weekly Planning Meeting Date Plant Sr. #Document10 pagesWeekly Planning Meeting Date Plant Sr. #HamzaNoumanNo ratings yet

- List Check Thickness Bio 1 - APM 15 Jan 2022Document8 pagesList Check Thickness Bio 1 - APM 15 Jan 2022Bernacleboy IDNo ratings yet

- FCC 2Document17 pagesFCC 2bac_nobita7657No ratings yet

- BoQ Type EEDocument192 pagesBoQ Type EEBung AsriNo ratings yet

- Techfill Nicad Manual - T-SeriesDocument25 pagesTechfill Nicad Manual - T-Seriesvideo irfanNo ratings yet

- Engine Torque Wrench SettingsDocument2 pagesEngine Torque Wrench SettingsDNo ratings yet

- MENG615L Experiment 1 2 JFDocument14 pagesMENG615L Experiment 1 2 JFAhmad ShreifNo ratings yet

- Dorin K4PDocument6 pagesDorin K4Pfrigoremont100% (1)

- Bestway Cement Chakwal Waste Heat Recovery Power Plant Tapping Point Status of Steam Turbine and GeneratorDocument4 pagesBestway Cement Chakwal Waste Heat Recovery Power Plant Tapping Point Status of Steam Turbine and Generatorraobabar21No ratings yet

- ATD AssignmentDocument2 pagesATD AssignmentsamarthgkNo ratings yet

- (자재구매) PO list from ThachDocument104 pages(자재구매) PO list from Thachnguyen.hienNo ratings yet

- Lesson 2.2.1 - Actual Rankine CycleDocument10 pagesLesson 2.2.1 - Actual Rankine Cyclesuga linNo ratings yet

- Diccionario V1Document1,308 pagesDiccionario V1Ed VanegasNo ratings yet

- Thermal Lab1st CycleDocument26 pagesThermal Lab1st CyclesreyajerryNo ratings yet

- Ysis From The Steam Tables (Tables A-4, A-5, and A-6) ,: S S H H P TDocument11 pagesYsis From The Steam Tables (Tables A-4, A-5, and A-6) ,: S S H H P TEdison GuachambozaNo ratings yet

- D1.pan Reactor Energy Model - 23062023Document53 pagesD1.pan Reactor Energy Model - 2306202319bt01019No ratings yet

- 07.17 S - 3 29cDocument4 pages07.17 S - 3 29cAnjana WNo ratings yet

- LP-Gas Service Mans ManualDocument52 pagesLP-Gas Service Mans Manualprocha1100% (1)

- Turbine Heat Rate Calculations...Document9 pagesTurbine Heat Rate Calculations...prasol thermaxNo ratings yet

- Tube Calculation: Cylinder DataDocument1 pageTube Calculation: Cylinder DataMamank Ira SudrajatNo ratings yet

- National Examinations - December 2011: NotesDocument26 pagesNational Examinations - December 2011: NotesNiko Garcia MeythalerNo ratings yet

- 10-Chem ATP (SVKM)Document7 pages10-Chem ATP (SVKM)Jashan LoombaNo ratings yet

- Data Di PrintDocument16 pagesData Di PrinturikelNo ratings yet

- Amine Processing Unit DEADocument9 pagesAmine Processing Unit DEAFlorin Daniel AnghelNo ratings yet

- Du DT M C DT DT c1T T P: C Chapter Summary and Study GuideDocument24 pagesDu DT M C DT DT c1T T P: C Chapter Summary and Study Guidekrntomboy25% (4)

- Report CSTRDocument14 pagesReport CSTRniraj_bairagiNo ratings yet

- Kosan HandbookDocument74 pagesKosan HandbookranganathrajaratneNo ratings yet

- Industrial ReactorsDocument10 pagesIndustrial ReactorssarahNo ratings yet

- Capacity Regulator CpceDocument8 pagesCapacity Regulator CpceNovan AndriantoNo ratings yet

- Tutorials Week2 SolutionDocument3 pagesTutorials Week2 Solutionfivos_rgNo ratings yet

- Greaves 10 To 500 Kva Genset ECatalogueDocument2 pagesGreaves 10 To 500 Kva Genset ECatalogueArpit VermaNo ratings yet

- General Product Catalog Low Res Part47 PDFDocument1 pageGeneral Product Catalog Low Res Part47 PDFJosephRusselVizmanosNo ratings yet

- H PLC ColumnsDocument103 pagesH PLC Columnschem6310No ratings yet

- In DiceDocument5 pagesIn DiceAroldo RamirezNo ratings yet

- Me 303 CH9Document72 pagesMe 303 CH9Osman KutluNo ratings yet

- 004 TanksDocument25 pages004 TanksNicandroGonzalesNo ratings yet

- Refer This Lab Manual For Preparing Your Experimental Work.Document22 pagesRefer This Lab Manual For Preparing Your Experimental Work.Prem ChaudharyNo ratings yet

- Ache-High Pour Point Feb11Document21 pagesAche-High Pour Point Feb11Poncho RmzNo ratings yet

- Thermal Cracking Reaction Kinetics - Hemendra KhakharDocument21 pagesThermal Cracking Reaction Kinetics - Hemendra Khakhargolden retrieverNo ratings yet

- Series LFN170 Specification SheetDocument2 pagesSeries LFN170 Specification SheetWattsNo ratings yet

- 10 104 PDFDocument2 pages10 104 PDFkidanemariam teseraNo ratings yet

- Technical Data Sheet Gly12Rra 115-127V 60Hz 1 R134A: Compressor Model Voltage RefrigerantDocument5 pagesTechnical Data Sheet Gly12Rra 115-127V 60Hz 1 R134A: Compressor Model Voltage RefrigerantGerman Gaspar RiveraNo ratings yet

- Manual Formacion D722-B, D1005-E, D1105-B y D1703-BDocument16 pagesManual Formacion D722-B, D1005-E, D1105-B y D1703-BTerah Pio100% (1)

- Skoring SMK Islam Al-Qomar 2018 (TKR)Document4 pagesSkoring SMK Islam Al-Qomar 2018 (TKR)ridhoplexNo ratings yet

- Kinetics of In-Situ CombijstionDocument324 pagesKinetics of In-Situ CombijstionkavanayenNo ratings yet

- Document GDFJFFFDocument2 pagesDocument GDFJFFFVi JäìNo ratings yet

- United States Patent (19) 11 4,083,889: 51 Int. Cl. ........................ Coic 1/24 Co7.c 11/04 ''Document8 pagesUnited States Patent (19) 11 4,083,889: 51 Int. Cl. ........................ Coic 1/24 Co7.c 11/04 ''irfan mahierNo ratings yet

- Lab ManualDocument6 pagesLab ManualAnshikha NautiyalNo ratings yet

- United States Patent (19) : 11 Patent Number: 45 Date of PatentDocument25 pagesUnited States Patent (19) : 11 Patent Number: 45 Date of Patentfitri rowiyahNo ratings yet

- T2 TE Expansion ValveDocument16 pagesT2 TE Expansion ValveIvan KurniadiNo ratings yet

- Ekspansi T2 Dan TE2Document16 pagesEkspansi T2 Dan TE2Arfa ZaynNo ratings yet

- Tanker Gantry Estimation Sheet Aegis 2020Document9 pagesTanker Gantry Estimation Sheet Aegis 2020shubhamNo ratings yet

- Engineering Bulletin No 1: Boiler and Furnace TestingFrom EverandEngineering Bulletin No 1: Boiler and Furnace TestingRating: 4.5 out of 5 stars4.5/5 (2)

- Southern Marine Engineering Desk Reference: Second Edition Volume IiFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IiNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Practical Rules for the Management of a Locomotive Engine in the Station, on the Road, and in cases of AccidentFrom EverandPractical Rules for the Management of a Locomotive Engine in the Station, on the Road, and in cases of AccidentNo ratings yet

- Operator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingFrom EverandOperator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingRating: 5 out of 5 stars5/5 (1)

- CED Mse OpenendDocument6 pagesCED Mse Openendyaseen sheikhNo ratings yet

- .Ihtennal Bol: PraureDocument4 pages.Ihtennal Bol: Praureyaseen sheikhNo ratings yet

- CEDtheory Assign5Document3 pagesCEDtheory Assign5yaseen sheikhNo ratings yet

- Esi - Ji Hecct: Ben - T 1 atDocument5 pagesEsi - Ji Hecct: Ben - T 1 atyaseen sheikhNo ratings yet

- Assignment Assignment: School of Chemical Engineering School of Chemical EngineeringDocument2 pagesAssignment Assignment: School of Chemical Engineering School of Chemical Engineeringyaseen sheikhNo ratings yet

- CED Lab Tuto5 DecantDocument3 pagesCED Lab Tuto5 Decantyaseen sheikhNo ratings yet

- CED Theory Support AssignDocument10 pagesCED Theory Support Assignyaseen sheikhNo ratings yet

- Name: Yaseen Sheikh Roll No.: TCH-37 Title: Rigorous Distillation ColumnDocument6 pagesName: Yaseen Sheikh Roll No.: TCH-37 Title: Rigorous Distillation Columnyaseen sheikhNo ratings yet

- Torispheicas: Roll O3 CED LcebDocument8 pagesTorispheicas: Roll O3 CED Lcebyaseen sheikhNo ratings yet

- P L A T e S 3 (4hemti Cas) : Yaeer $hi LCDocument2 pagesP L A T e S 3 (4hemti Cas) : Yaeer $hi LCyaseen sheikhNo ratings yet

- Name: Yaseen Sheikh Roll No.: TCH-37 Title: Rigorous Distillation ColumnDocument5 pagesName: Yaseen Sheikh Roll No.: TCH-37 Title: Rigorous Distillation Columnyaseen sheikhNo ratings yet

- Paper Chromatography Aim: Apparatus: No. 21 Filter Paper, Glass Jar, Lid, Thread, Capillary Tube ChemicalsDocument2 pagesPaper Chromatography Aim: Apparatus: No. 21 Filter Paper, Glass Jar, Lid, Thread, Capillary Tube Chemicalsyaseen sheikhNo ratings yet

- Aim: To Study The Soldering TechniquesDocument3 pagesAim: To Study The Soldering Techniquesyaseen sheikhNo ratings yet

- NAME: Swapnil Sanjay Gaikwad Roll No: Sch-15Document4 pagesNAME: Swapnil Sanjay Gaikwad Roll No: Sch-15yaseen sheikhNo ratings yet

- Aim: To Determine The Hardness of Test Pieces Using Vicker's Hardness Test. PrincipleDocument4 pagesAim: To Determine The Hardness of Test Pieces Using Vicker's Hardness Test. Principleyaseen sheikhNo ratings yet

- Astm 388Document8 pagesAstm 388Joseph RefuerzoNo ratings yet

- Teacher ResearcherDocument17 pagesTeacher ResearcherAmanda EvansNo ratings yet

- Imagining Lives Through Korean DramasDocument11 pagesImagining Lives Through Korean DramasLuis FernandoNo ratings yet

- CH 1 - Introduction To FMADocument22 pagesCH 1 - Introduction To FMAIPloboNo ratings yet

- Vikram Kumar Devops Notes: Build ManagementDocument6 pagesVikram Kumar Devops Notes: Build ManagementSANANo ratings yet

- SKF Bearing Select PDFDocument9 pagesSKF Bearing Select PDFBharat KumarNo ratings yet

- Optimal Capacitor Placement For Loss Reduction and Voltage Profile Improvement in Distribution System Using Genetic AlgorithmDocument5 pagesOptimal Capacitor Placement For Loss Reduction and Voltage Profile Improvement in Distribution System Using Genetic AlgorithmNateNo ratings yet

- CJ Relays (Acj) : Features Typical ApplicationsDocument7 pagesCJ Relays (Acj) : Features Typical ApplicationsFranciscoMedinaNo ratings yet

- Loading, Discharging and Cleaning of Belt Conveyors PDFDocument11 pagesLoading, Discharging and Cleaning of Belt Conveyors PDFJaco KotzeNo ratings yet

- Torsten Husén A Co-Founder and Chairman of IEA From 1962 To 1978Document15 pagesTorsten Husén A Co-Founder and Chairman of IEA From 1962 To 1978Teodora GenovaNo ratings yet

- UNIT-2-NOTES - Self Management Skills-IXDocument8 pagesUNIT-2-NOTES - Self Management Skills-IXVaishnavi JoshiNo ratings yet

- FastLink CAT6 (SFTP) OutdoorDocument3 pagesFastLink CAT6 (SFTP) OutdoorHaiderNo ratings yet

- When My Autism Gets Too BigDocument67 pagesWhen My Autism Gets Too Bighchristen100% (1)

- Ajit Vadakayil - WALL WASH METHOD CHEMICAL TANKERS - CAPT AJIT VADAKAYILDocument150 pagesAjit Vadakayil - WALL WASH METHOD CHEMICAL TANKERS - CAPT AJIT VADAKAYILosman goniNo ratings yet

- Impact of Chronic Illness On ChildrenDocument6 pagesImpact of Chronic Illness On ChildrenDeepa ThomasNo ratings yet

- SMT Mechanical Suspensions: ROR Trailer ProductsDocument24 pagesSMT Mechanical Suspensions: ROR Trailer ProductsOskarNo ratings yet

- Agexcomm 1 Q&aDocument25 pagesAgexcomm 1 Q&aWaren LlorenNo ratings yet

- Filtro Canastillo FMCDocument4 pagesFiltro Canastillo FMCCristian Rodrigo Gonzalez SoteloNo ratings yet

- Sbi3C Name: Characteristics of Bacteria Worksheet: Big Idea! IdeasDocument2 pagesSbi3C Name: Characteristics of Bacteria Worksheet: Big Idea! IdeasPaulina JakubiecNo ratings yet

- Textbook Building Evidence For Active Ageing Policies Active Ageing Index and Its Potential 1St Edition Asghar Zaidi Ebook All Chapter PDFDocument53 pagesTextbook Building Evidence For Active Ageing Policies Active Ageing Index and Its Potential 1St Edition Asghar Zaidi Ebook All Chapter PDFmatthew.renfro133100% (17)

- Lesson Plan in English Using SRF: I. ObjectiveDocument10 pagesLesson Plan in English Using SRF: I. ObjectiveShee AntonioNo ratings yet

- Mis 024Document223 pagesMis 024ysanyasirajuNo ratings yet

- Tin Mill Products, Black Plate, Double Reduced: Standard Specification ForDocument2 pagesTin Mill Products, Black Plate, Double Reduced: Standard Specification ForsamehNo ratings yet

- Catalogue SDocument8 pagesCatalogue SSHINOS 3SNo ratings yet

- ASME - VIII Div. 2 2004 Edition - AM-211 PDFDocument2 pagesASME - VIII Div. 2 2004 Edition - AM-211 PDFEsapermana RiyanNo ratings yet

- Modular ExponentiationDocument2 pagesModular ExponentiationflaksherNo ratings yet

- Zrzut Ekranu 2022-11-20 o 23.44.07Document74 pagesZrzut Ekranu 2022-11-20 o 23.44.07Bartek SalahNo ratings yet

- UNCTAD DTL KDB 2016 1 Port Management Series Volume 4 - E - Web PDFDocument53 pagesUNCTAD DTL KDB 2016 1 Port Management Series Volume 4 - E - Web PDFHeb RuNo ratings yet

- 300+ TOP PIPING Engineering Interview Questions and Answers PDFDocument20 pages300+ TOP PIPING Engineering Interview Questions and Answers PDFjignesh chauhan100% (1)

- Herramientas CSDocument2 pagesHerramientas CSCAPCOMALLSTARS POWERNo ratings yet