Professional Documents

Culture Documents

Kartal Konveyör

Kartal Konveyör

Uploaded by

Hasan arif KısaalioğluCopyright:

Available Formats

You might also like

- Suzuki VL1500 '98-'02 Service Manual (99500-39164-01E)Document444 pagesSuzuki VL1500 '98-'02 Service Manual (99500-39164-01E)Nikolas KarrerNo ratings yet

- D16A-D16B 470-520 SpecificationsDocument22 pagesD16A-D16B 470-520 Specificationsbugyman_02100% (7)

- 404D 22Document8 pages404D 22aiulica20100% (2)

- Deere+Yanmar+4TN82 PDFDocument10 pagesDeere+Yanmar+4TN82 PDFDavid RamirezNo ratings yet

- 202517C-0000-JSD-1300-008-B - Piping Stres CalculationDocument32 pages202517C-0000-JSD-1300-008-B - Piping Stres CalculationHasan arif KısaalioğluNo ratings yet

- INKOMA - Shaft-Hub Connections - Polygonaxlar Enligt DIN 32711 Och DIN 32712Document18 pagesINKOMA - Shaft-Hub Connections - Polygonaxlar Enligt DIN 32711 Och DIN 32712kristoffer_mossheden100% (2)

- ACI 318 99 Provisions For Seismic Design of Structural WallsDocument10 pagesACI 318 99 Provisions For Seismic Design of Structural WallsEssined Aividlav100% (1)

- Komatsu pc350lc 8 HRD High Reach Demolition Excavator SpecificationsDocument8 pagesKomatsu pc350lc 8 HRD High Reach Demolition Excavator SpecificationsSergeyNo ratings yet

- 4008-30TAG3 TPD2011E2 Nov2015Document5 pages4008-30TAG3 TPD2011E2 Nov2015tienlamNo ratings yet

- Lecture 5-2-Design of Bending MembersDocument26 pagesLecture 5-2-Design of Bending MembersHarold Jackson MtyanaNo ratings yet

- Continuous Slab Design ProgrammeDocument31 pagesContinuous Slab Design ProgrammeNikhilNo ratings yet

- Çan KoveyörDocument30 pagesÇan KoveyörHasan arif KısaalioğluNo ratings yet

- Conveyor DesignDocument7 pagesConveyor DesignLuis SantosNo ratings yet

- Kule 03-04 Arası KonveyorDocument34 pagesKule 03-04 Arası KonveyorHasan arif KısaalioğluNo ratings yet

- Conveyor Design Report: Batch Plant Coveyor System Cv1 - Receiving Conveyor - Wacom - Gmi MaliDocument35 pagesConveyor Design Report: Batch Plant Coveyor System Cv1 - Receiving Conveyor - Wacom - Gmi MaliRichmond YarrickNo ratings yet

- 1009 Calc Crd1 PDFDocument36 pages1009 Calc Crd1 PDFSasmit RaiNo ratings yet

- Conveyor Design Information Idler Set Data: Tension SummaryDocument31 pagesConveyor Design Information Idler Set Data: Tension SummaryonuroztkNo ratings yet

- Vdocuments - MX - System Information Idler Set Data Conveyor Name Tripper 1 Filename Tripper ConveyorDocument33 pagesVdocuments - MX - System Information Idler Set Data Conveyor Name Tripper 1 Filename Tripper ConveyorilfakeNo ratings yet

- 6520-CV-5443-5448-90 CM Den KesmeDocument21 pages6520-CV-5443-5448-90 CM Den KesmeHasan arif KısaalioğluNo ratings yet

- System Information Idler Set DataDocument7 pagesSystem Information Idler Set DataAlex BurgosNo ratings yet

- BOMAG - Datasheet - BF300P - PRE89105010 - SA04Document4 pagesBOMAG - Datasheet - BF300P - PRE89105010 - SA04Jason TanNo ratings yet

- 12 M KonveyörDocument36 pages12 M KonveyörHasan arif KısaalioğluNo ratings yet

- Cerebro Mix Diseño de Tanque Asistido Por SoftwareDocument12 pagesCerebro Mix Diseño de Tanque Asistido Por SoftwareAriel Fernando Peña VillarroelNo ratings yet

- LT80K6 Spec PDFDocument1 pageLT80K6 Spec PDFCarlos ToralNo ratings yet

- Komatsu Pc210lc 10 Hydraulic Crawler Excavator SpecificationsDocument6 pagesKomatsu Pc210lc 10 Hydraulic Crawler Excavator SpecificationsHugo BelgraveNo ratings yet

- Valve Guides and Valve SpringsDocument1 pageValve Guides and Valve SpringsNikNo ratings yet

- Pecifications: Ydraulic XcavatorDocument5 pagesPecifications: Ydraulic XcavatorwalisonNo ratings yet

- 12 - VX800N (Mod92)Document19 pages12 - VX800N (Mod92)zaq94No ratings yet

- 1300 WD-WJ Series SpecificationsDocument13 pages1300 WD-WJ Series SpecificationsCuan HappyNo ratings yet

- Global 1200 PDFDocument6 pagesGlobal 1200 PDFعاطف صدقىNo ratings yet

- Caracteristici Tehnice Pod Rulant PDFDocument1 pageCaracteristici Tehnice Pod Rulant PDFCristian PaladeNo ratings yet

- Pod RulantDocument1 pagePod RulantCristian PaladeNo ratings yet

- Specifi Cations: Swing System EngineDocument5 pagesSpecifi Cations: Swing System EngineLU YONo ratings yet

- Bomag bw219Document2 pagesBomag bw219ZabdyRA YT0% (1)

- Bomag bw219 INGLES PDFDocument2 pagesBomag bw219 INGLES PDFDaniel Gregorio LacastroNo ratings yet

- Senda Adatok 1Document2 pagesSenda Adatok 1AndrewNo ratings yet

- Series: Ferrite Magnet Chassis Driver Die-CastDocument1 pageSeries: Ferrite Magnet Chassis Driver Die-CastAkhmad GuiNo ratings yet

- Datasheet Bomag MPH 122 2Document2 pagesDatasheet Bomag MPH 122 2Dennis Ojok OciiNo ratings yet

- Konecranes 10TDocument10 pagesKonecranes 10TAya AlgalladNo ratings yet

- Selenium 18SW1PDocument2 pagesSelenium 18SW1PIsus Audio100% (1)

- Buldozer - CASE 550H - Specs 1-18-2012 - ENDocument4 pagesBuldozer - CASE 550H - Specs 1-18-2012 - ENMaurizio De LucaNo ratings yet

- cgl25Document10 pagescgl25ianwashere123No ratings yet

- C560B 2pg PDFDocument2 pagesC560B 2pg PDFwalk111No ratings yet

- Service Bulletin Trucks: SpecificationsDocument40 pagesService Bulletin Trucks: SpecificationsKomatsu Nna100% (1)

- Slewing Gantry Crane With Double-Link SystemDocument11 pagesSlewing Gantry Crane With Double-Link Systemduyhp231296No ratings yet

- 06 EngineDocument19 pages06 EngineMuhamad Dwi CahyonoNo ratings yet

- Rodillo Bomag BW - 211 - D - PD - 40 - en (33c)Document2 pagesRodillo Bomag BW - 211 - D - PD - 40 - en (33c)Taller ManttoNo ratings yet

- M/V Wedellsborg: General Information Dimensions CranesDocument2 pagesM/V Wedellsborg: General Information Dimensions CranesDavephilsNo ratings yet

- BW 216Document2 pagesBW 216THRTHQANo ratings yet

- Bw211d-40 Technical SpecsDocument2 pagesBw211d-40 Technical SpecsCESARALARCON10% (1)

- Series: Neodymium Magnet Die-Cast Chassis DriverDocument1 pageSeries: Neodymium Magnet Die-Cast Chassis Driverromeodatinh1989No ratings yet

- Subwoofer 18SWS800: SpecificationsDocument2 pagesSubwoofer 18SWS800: SpecificationsJorge WelzelNo ratings yet

- BW219D 4Document2 pagesBW219D 4Charles GrantNo ratings yet

- DMRC DBR ChennaiDocument25 pagesDMRC DBR ChennaiTarun Kant GoyalNo ratings yet

- Subwoofer 18SWS1100: SpecificationsDocument2 pagesSubwoofer 18SWS1100: SpecificationsFran CascoNo ratings yet

- Performance Data: Single Drum Vibratory Rollers BW 211 D-40, BW 211 PD-40Document2 pagesPerformance Data: Single Drum Vibratory Rollers BW 211 D-40, BW 211 PD-40EndraNo ratings yet

- 18SWS1000 SpecSheetDocument2 pages18SWS1000 SpecSheetEzequiel FernandezNo ratings yet

- Concorde Simulation Quick GuideDocument3 pagesConcorde Simulation Quick GuideDanilo SalgadoNo ratings yet

- Belt Stacker BSDocument69 pagesBelt Stacker BSRahmat HidayatNo ratings yet

- Vibro Spec Sheet BW219 D-4Document2 pagesVibro Spec Sheet BW219 D-4adhie_aeroNo ratings yet

- Performance Data: Single Drum Vibratory Rollers BW 211 D-40, BW 211 PD-40Document2 pagesPerformance Data: Single Drum Vibratory Rollers BW 211 D-40, BW 211 PD-40Tyrex HallNo ratings yet

- BW211D-40 SpecDocument2 pagesBW211D-40 SpecOlab BolaNo ratings yet

- Bw211d40 Performance DataDocument2 pagesBw211d40 Performance DataCESARALARCON1No ratings yet

- Technical Data - BW 211 D-40 and BW 211 PD-40Document2 pagesTechnical Data - BW 211 D-40 and BW 211 PD-40subandi pippoNo ratings yet

- Incompressible Flow Turbomachines: Design, Selection, Applications, and TheoryFrom EverandIncompressible Flow Turbomachines: Design, Selection, Applications, and TheoryNo ratings yet

- 1271 Yığın Yoğunlu Hız 0,09, Yatak 90 CM Kesme Malzeme Yüksekliği 1,5 MDocument18 pages1271 Yığın Yoğunlu Hız 0,09, Yatak 90 CM Kesme Malzeme Yüksekliği 1,5 MHasan arif KısaalioğluNo ratings yet

- ANT Birikim BCDocument4 pagesANT Birikim BCHasan arif KısaalioğluNo ratings yet

- Boru Bant Versiyon 3Document38 pagesBoru Bant Versiyon 3Hasan arif KısaalioğluNo ratings yet

- m-1 ReportDocument58 pagesm-1 ReportHasan arif KısaalioğluNo ratings yet

- Boru Bant3Document46 pagesBoru Bant3Hasan arif KısaalioğluNo ratings yet

- Boru Bant2Document40 pagesBoru Bant2Hasan arif KısaalioğluNo ratings yet

- 12 M KonveyörDocument36 pages12 M KonveyörHasan arif KısaalioğluNo ratings yet

- System Information Cross Sectional LoadingDocument62 pagesSystem Information Cross Sectional LoadingHasan arif KısaalioğluNo ratings yet

- 61 Fe 07Document28 pages61 Fe 07Hasan arif KısaalioğluNo ratings yet

- m-2 ReportDocument62 pagesm-2 ReportHasan arif KısaalioğluNo ratings yet

- m-3 ReportDocument72 pagesm-3 ReportHasan arif KısaalioğluNo ratings yet

- 12 (B 100) Metre KonveyörDocument30 pages12 (B 100) Metre KonveyörHasan arif KısaalioğluNo ratings yet

- System Information Idler Set DataDocument48 pagesSystem Information Idler Set DataHasan arif KısaalioğluNo ratings yet

- Wodo A Ski - v16 - 4 - enDocument4 pagesWodo A Ski - v16 - 4 - enHasan arif KısaalioğluNo ratings yet

- 107071-RP-P0005-40443-001 Request For Budgetary QuotationDocument9 pages107071-RP-P0005-40443-001 Request For Budgetary QuotationHasan arif KısaalioğluNo ratings yet

- m-4 ReportDocument47 pagesm-4 ReportHasan arif KısaalioğluNo ratings yet

- Ee 00000 27281 001Document10 pagesEe 00000 27281 001Hasan arif KısaalioğluNo ratings yet

- 6 KM 2 BoosterDocument62 pages6 KM 2 BoosterHasan arif KısaalioğluNo ratings yet

- 107071-RP-P0005-40440-001 Form of AcknowledgementDocument1 page107071-RP-P0005-40440-001 Form of AcknowledgementHasan arif KısaalioğluNo ratings yet

- em 00000 27280 001Document20 pagesem 00000 27280 001Hasan arif KısaalioğluNo ratings yet

- 15 M3 Tank ReportDocument41 pages15 M3 Tank ReportHasan arif KısaalioğluNo ratings yet

- ETI BAKIR P&IDs Mark-Up 29-11-2022Document47 pagesETI BAKIR P&IDs Mark-Up 29-11-2022Hasan arif KısaalioğluNo ratings yet

- Slury Sump Calculation ReportDocument2 pagesSlury Sump Calculation ReportHasan arif KısaalioğluNo ratings yet

- Vs 50 20Document1 pageVs 50 20Hasan arif KısaalioğluNo ratings yet

- 202517C-0000-JSD-1300-022-A - Piping Class DetailedDocument70 pages202517C-0000-JSD-1300-022-A - Piping Class DetailedHasan arif KısaalioğluNo ratings yet

- Kule 03-04 Arası KonveyorDocument34 pagesKule 03-04 Arası KonveyorHasan arif KısaalioğluNo ratings yet

- Vs 99 01Document1 pageVs 99 01Hasan arif KısaalioğluNo ratings yet

- 202517C-0000-JSD-1300-010-A - Piping SupportDocument33 pages202517C-0000-JSD-1300-010-A - Piping SupportHasan arif KısaalioğluNo ratings yet

- Conveyor Pulley Design Conveyor Pulley DesignDocument2 pagesConveyor Pulley Design Conveyor Pulley DesignHasan arif KısaalioğluNo ratings yet

- Swept Back WingDocument7 pagesSwept Back WingYashNo ratings yet

- Physics ImplementationDocument5 pagesPhysics ImplementationAmelia JonesNo ratings yet

- Saint Joseph Catholic School-Adama: Grade 11 Physics Worksheet April 2012 (2020)Document3 pagesSaint Joseph Catholic School-Adama: Grade 11 Physics Worksheet April 2012 (2020)Nardos AlemayewNo ratings yet

- Magnetism in SolidsDocument11 pagesMagnetism in SolidsNeelam KapoorNo ratings yet

- NAC Theory of Flight SyllabusDocument2 pagesNAC Theory of Flight SyllabusHana LeransoNo ratings yet

- Output Gear Root SafetyDocument10 pagesOutput Gear Root SafetyDaggupati PraveenNo ratings yet

- Power Point 2 Study IslandDocument15 pagesPower Point 2 Study Islandapi-294483847No ratings yet

- Noise Pollution TableDocument3 pagesNoise Pollution Tablefekeceh343No ratings yet

- Experiment-3 Study of Critical Heat Flux (Boiling Heat Transfer)Document7 pagesExperiment-3 Study of Critical Heat Flux (Boiling Heat Transfer)Mukul ChandraNo ratings yet

- Plate Girders With Corrugated WebsDocument6 pagesPlate Girders With Corrugated WebsLệnh BùiNo ratings yet

- Problem 548Document14 pagesProblem 548mike jobernard f. solangonNo ratings yet

- Poll P-01Document3 pagesPoll P-01Mag GamingNo ratings yet

- PhysicsDocument2 pagesPhysicsMts GonzalesNo ratings yet

- E401 Guide QuestionsDocument1 pageE401 Guide QuestionsWinvel DotimasNo ratings yet

- Gear SystemDocument2 pagesGear Systemwalmir.f.navarroNo ratings yet

- Elements of Polymer Structure and Viscoelasticity: David M. Parks Mechanics and Materials II 2.002 February 18, 2004Document15 pagesElements of Polymer Structure and Viscoelasticity: David M. Parks Mechanics and Materials II 2.002 February 18, 2004Jeffrey GuevaraNo ratings yet

- Shinken ME AE - 2021 Model AnswersDocument13 pagesShinken ME AE - 2021 Model AnswersresearchditNo ratings yet

- ADES Wind TurbineDocument8 pagesADES Wind TurbinebmyertekinNo ratings yet

- S.H.M-TheoryDocument16 pagesS.H.M-TheoryViren PatelNo ratings yet

- Statics and Dynamics Structural AnalysisDocument12 pagesStatics and Dynamics Structural AnalysisVaibhav JadhavNo ratings yet

- Finite Element AnalysisDocument17 pagesFinite Element AnalysisSHANZYYNo ratings yet

- Solution To Problem 208 Axial Deformation - Strength of Materials ReviewDocument2 pagesSolution To Problem 208 Axial Deformation - Strength of Materials ReviewimrancenakkNo ratings yet

- Non-Dimensional Rates - Aircraft Flight Mechanics by Harry Smith, PHDDocument1 pageNon-Dimensional Rates - Aircraft Flight Mechanics by Harry Smith, PHDhung dangNo ratings yet

- Sir Besa July 13 PDFDocument21 pagesSir Besa July 13 PDFRagalagNo ratings yet

- SG 2 CE 411 Properties of SoilDocument9 pagesSG 2 CE 411 Properties of SoilkennsindayenNo ratings yet

- CH 8Document31 pagesCH 8KhalidNo ratings yet

Kartal Konveyör

Kartal Konveyör

Uploaded by

Hasan arif KısaalioğluOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Kartal Konveyör

Kartal Konveyör

Uploaded by

Hasan arif KısaalioğluCopyright:

Available Formats

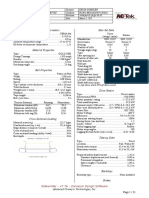

Client Name Designer HAK

Project Name Company

Conveyor Name cv01 Filename

Location Date Nisan 5, 2021

Description

System Information Idler Set Data

Calculation method .......................................... CEMA 6th Carry Return

Conveyor Length / Height .................................. 8 / 2,6 m Series name Series 20 Series 20

Material lift .............................................................. 2,4 m Bearing 6204 6204

Ambient temperature range ........................... -15 to 35 °C Number of rolls 3 1

Kt factor at minimum temperature............................. 1,21 Trough angle (deg) 30 0

Type Inline Inline

Material Properties Idler spacing (m) 1,00 3,00

Type ..................................................................copper ore Number of ıdler sets 12 3

Design Tonnage ....................................................... 30 t/h Roll diameter 89 89

Density ............................................................ 2000 kg/m3 Roll rpm 303 303

Maximum lump size .............................................. 15 mm Total drag (N) 11,5 3,8

Surcharge angle ...................................................... 22 deg Drag range (N) 8,5 - 26,0 2,9 - 8,8

Roll length 213 640

Shaft diameter (mm) 20,0 20,0

Belt Properties

Dynamic capacity (kN) 13,5 13,5

Type ............................................................ Fabric (3-Ply) L10 life1 (1000 hrs) 350,0 / 350,0 0,0

Width ................................................................... 550 mm Shaft deflection (min) 0,10 / 0,32 2,19

Rating............................................................... 400 N/mm 1 L10 life above which 95% of idlers exceed

Speed ................................................................... 1,41 m/s

Top / bottom cover thickness ....................... 4,0 x 2,0 mm Drive Station

Total thickness ....................................................... 10 mm

Type ............................................................. Squirrel cage

Weight (new / worn) ................................... 6,0 / 4,2 kg/m

Synchronous RPM ...........................................1500 RPM

Modulus ......................................................... 4.447 kN/m

Motor quantity / rating ................................... 1 / 5,50 kW

Tape length .......................................................... 17,36 m

Total ınstalled power ........................................... 5,50 kW

Belt cycle time ............................................................ 12 s

Nominal empty / full power .... (55 / 59%) 3,01 / 3,23 kW

Tension Summary Running Momentary Min / max demand power........ (32 / 86%) 1,74 / 4,71 kW

Maximum tension (kN) 4,05 4,73 Frame Size......................................................... IEC 132S

Minimum safety factor 54,35 46,49 Motor Voltage ............................................. Not Specified

Minimum tension (kN) 2,34 2,09 Efficiency .................................................... 94,5 to 97,5%

Maximum belt sag (%) 0,99 1,14 Maximum starting torque .........................................180%

Inertia - Motor ................................................... 0,1 kg·m²

Cross Sectional Loading Pulley lagging type ................................................ Rubber

Material mass (wm) ............................................. 5,9 kg/m Motor wrap angles....................................................... 180

Combined mass (wm + wb) ................................ 11,9 kg/m Lagging friction factor (run / accel) ................. 0,32 / 0,38

Edge distance (required / actual)................... 53 / 172 mm

Cross sectional area ............................................ 0,003 m² Take-up Data

Cross sectional loading (utility / total) ............. 10 % / 6 %

Bed depth ............................................................... 21 mm Type ......................................................................... Fixed

Location ................................................... Tail / Pulley #2

Steady state tension .................................. 2,34 to 2,59 kN

Momentary tension................................... 2,25 to 2,67 kN

Required pulley displacement ................................ 0,68 m

Dynamic displacement (incl thermal) .............. 0,00 m

Permanent elongation ...................................... 0,11 m

Splice length (1 included) ................................ 0,31 m

Clearance ......................................................... 0,25 m

Backstops

Flooded belt tonnage.............................................. 468 t/h

Flooded (wm + wb) ............................................ 98,2 kg/m Location ...............................................Head on Pulley #1

Backstop (quantity x type) .........................1 x Low speed

Sidewinder - v7.22 - Conveyor Design Software

Advanced Conveyor Technologies, Inc.

Page 1 / 26

Client Name Designer HAK

Project Name Company

Conveyor Name cv01 Filename

Location Date Nisan 5, 2021

Description

Pulley diameter .................................................... 274 mm Estimated Splice Data

Load Share Factor % .................................................. 100 Splice type ...............................................................2-Step

Service Factor - Material Lift .................................... 1,50 Splice step length ................................................. 200 mm

Service Factor - Motor Rating ................................... 1,50 22 degree bias angle ............................................. 225 mm

Material Lift Criteria.......................................... 0,00 N·m Total splice length ................................................ 625 mm

Motor Torque Criteria......................................... 807 N·m

Torque rating at low speed shaft ......................... 807 N·m

Other Information

Brakes Loaded beltline mass (excluding motors)............... 345 kg

Brake type .................................................. None installed Total inertia (ref HS shaft) .............................. 0,03 kg·m2

Reducer Information Demand Power (kW)

Manufacture ................................................................N/A Demand % Motor

Case

Frame size ...................................................................N/A power Nameplate

Reducer ratio.......................................................... 15,140 Empty - NF 3,0 54,8

Catalog reducer ratio................................................ 0,000 Full - NF 3,2 58,8

RPM (High Speed) .......................................... 1500 RPM Full - LF 1,7 31,6

RPM (Low Speed) ............................................ 99,1 RPM Full - HF 4,7 85,6

Configuration ................................................ Shaft Mount

Number of stages ............................................................ 3 Din Factor and Total Equivalent Mass

Service factor ............................................................... 1,4 Belt line

Case Din factor

Power rating............................................................... 0,00 mass (kg)

Empty - NF 0,1481 911

Full - NF 0,1195 957

Motor Torque

Full - LF 0,0730 926

100% Motor Torque - High Speed........................ 36 N·m Full - HF 0,1732 968

Motor Shaft Torque - Running (FN) ..................... 21 N·m

Motor Shaft Torque - Starting (FN) ...................... 64 N·m Maximum Belt Tensions (kN)

100% Motor Torque - Low Speed ...................... 538 N·m Case Running Dynamic

Low Speed Shaft Torque - Running (FN)........... 294 N·m Empty - NF 3,57 4,22

Low Speed Shaft Torque - Running (Max) ........ 432 N·m Full - NF 3,73 4,53

Low Speed Shaft Torque - Starting (FN) ............ 506 N·m Full - LF 3,32 4,16

Low Speed Shaft Torque - Starting (Max).......... 600 N·m Full - HF 4,05 4,73

Starting and Stopping Belt Safety Factor

Start control ............................................. Constant torque Case Running Dynamic

Start time.......................................................... 0,2 to 0,4 s Empty - NF 61,57 52,14

Emergency stop control ............................................. Drift Full - NF 59,00 48,59

Emergency stop time ....................................... 0,4 to 1,1 s Full - LF 66,30 52,86

Material buildup in chute ........................................ 0,0 m³ Full - HF 54,35 46,49

Splice Safety Factor

Tension Ratios

Case Running Dynamic

Allowable (running)................................................... 2,73 Empty - NF 41,05 34,76

Running tension ratio ................................................. 1,64 Full - NF 39,33 32,40

Allowable (dynamic) ................................................. 3,30 Full - LF 44,20 35,24

Starting tension ratio .................................................. 2,22 Full - HF 36,24 30,99

Transition Lengths

Transition method ............................................... CEMA 7

Tail transition length (inline) ................................. 1,00 m

Head transition length (inline) ............................... 1,00 m

Sidewinder - v7.22 - Conveyor Design Software

Advanced Conveyor Technologies, Inc.

Page 2 / 26

Client Name Designer HAK

Project Name Company

Conveyor Name cv01 Filename

Location Date Nisan 5, 2021

Description

Minimum Belt Tensions (kN)

Case Running Dynamic

Empty - NF 2,50 2,13

Full - NF 2,50 2,14

Full - LF 2,59 2,09

Full - HF 2,34 2,13

Maximum Belt Sag (%)

Case Running Dynamic

Empty - NF 0,84 1,03

Full - NF 0,84 1,02

Full - LF 0,57 0,74

Full - HF 0,99 1,14

Sidewinder - v7.22 - Conveyor Design Software

Advanced Conveyor Technologies, Inc.

Page 3 / 26

Client Name Designer HAK

Project Name Company

Conveyor Name cv01 Filename

Location Date Nisan 5, 2021

Description

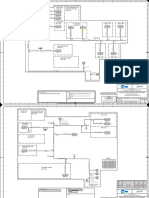

Conveyor Profile

Overall length = 8 m - Overall height = 2,6 m - True Length = 8,4 m

Pulleys

Pulleys - Top View

Maximum Pulley Tensions (without any additional safety factors)

Steady State Tensions (kN) Momentary Tensions (kN)

Wrap

Pulley Type Resultant Resultant

(deg) T1 T2 T1 T2

Force Force

Mtr 1 - Bstp 1 1-LT 180 4,05 2,69 6,52 4,73 2,90 7,59

Take-up Pulley 2-LT 180 2,59 5,50 2,67 5,71

T1 & T2 values may not be from the same load cases. Therefore the max resultant force is not the vector sum of these values.

Sidewinder - v7.22 - Conveyor Design Software

Advanced Conveyor Technologies, Inc.

Page 4 / 26

Client Name Designer HAK

Project Name Company

Conveyor Name cv01 Filename

Location Date Nisan 5, 2021

Description

Pulley Shaft Results

Shaft Shaft Design Design

Bearing Pulley & Resultant Resultant Resultant Bending

Pulley Safety Slope at Deflection T1 T2

L10 Life Shaft Force Angle Torque Moment

# Factor Hub at Center Tension Tension

1000 hrs Mass (kg) (kN) (deg) (kN·m) (kN·m)

(min) (% span) (kN) (kN)

1 7,83 3,67 0,038 500 4,45 2,72 100 7,53 205 0,2 0,5

2 9,61 3,04 0,032 500 2,75 3,30 100 5,82 9 0,1 0,4

Design tensions for shaft fatigue are based on all design level 1 cases. Running tensions have an added multiplier of 1,25 on high tension

pulleys, and a multiplier of 1,10 on all other pulleys.

Pulley Geometry Details (Pulley Types)

Diameter Shaft Bearing Pulley

Lagging Face Bearing

Lagging Diameter with Center Center Plummer Bearing Shaft

Type Thickness Width Diameter

Type (mm) Lagging Diameter Distance Block Series Bearing

(mm) (mm) (mm)

(mm) (mm) (mm) Mass (kg)

Rubber

1 Herringb 250 10,0 270 650 60 60 820 513 22213 121

one

Rubber

2 250 10,0 270 650 60 60 840 513 22213 121

Plain

Pulley Shaft Information

Hub Bearing Overhung

Tensile Yield Fatigue Hub Fillet Overhung

Locking Shaft Center to Fillet Moment

Type Strength Strength Strength Diameter Radius Load

Device Material Distance Distance Arm

(MPa) (MPa) (MPa) (mm) (mm) (kN)

(mm) (mm) (mm)

1 XT-25 C45 630,0 360,0 315,0 60 550 60 0 0,0 0

2 XT-25 C45 630,0 360,0 315,0 60 550 60 0 0,0 0

Sidewinder - v7.22 - Conveyor Design Software

Advanced Conveyor Technologies, Inc.

Page 5 / 26

Client Name Designer HAK

Project Name Company

Conveyor Name cv01 Filename

Location Date Nisan 5, 2021

Description

Conveyor Load Cases

During the course of operation, the conveyor experiences different operating conditions at various frequencies. Normal

operating conditions, such as steady state running, loading and unloading, and other common load cases are designated as

Design Level 1. Unusual operating conditions, such as when all incline or decline section are simultaneously loaded, are

defined as Design Level 2. These design levels allow easy summarization of the various possible loading conditions.

For this conveyor, there are two Design Level 1 loads, which are:

1. Empty

2. Fully Loaded

In the load case figures, the red line is the conveyor profile and the blue line indicates positions that are loaded.

Empty

Fully Loaded (Material Lift = 2,4 m)

Sidewinder - v7.22 - Conveyor Design Software

Advanced Conveyor Technologies, Inc.

Page 6 / 26

Client Name Designer HAK

Project Name Company

Conveyor Name cv01 Filename

Location Date Nisan 5, 2021

Description

Take-up Displacement Summary

1. Type ......................................................................................................................................................Fixed

2. Location ................................................................................................................................ Tail / Pulley #2

3. Steady state tension .............................................................................................................. 2,34 to 2,59 kN

4. Momentary tension ............................................................................................................... 2,25 to 2,67 kN

Take-up Pulley Displacement Summary

1. Dynamic displacement (incl thermal) .................................................................................................0,00 m

2. Permanent elongation .........................................................................................................................0,11 m

3. Splice length (1 included) ...................................................................................................................0,31 m

4. Clearance ............................................................................................................................................0,25 m

5. Required displacement .......................................................................................................................0,68 m

Sidewinder - v7.22 - Conveyor Design Software

Advanced Conveyor Technologies, Inc.

Page 7 / 26

Client Name Designer HAK

Project Name Company

Conveyor Name cv01 Filename

Location Date Nisan 5, 2021

Description

Pulley Details

The following table lists recommended pulley design tensions. The first column lists belt tensions for bearing L10

life and pulley fatigue stress calculations. Belt tensions for the fatigue design criterion are based on all design

level 1 cases. Running tensions have an added multiplier of 1,25 on high tension pulleys, and a multiplier of 1,10

on all other pulleys.

Pulleys are also to be design for the structural design tensions. For structural design tensions, the pulley

manufacturer is to ensure that the pulleys will be adequate to meet these worst case conditions.

Pulley Design Tensions (added safety factors as described above)

Fatigue Design Tensions (kN) Structural Design Tension (kN)

Wrap

Pulley Type Resultant Resultant

(deg) T1 T2 T1 T2

Force Force

Motor 1 - Backstop 1 1-LT 180 4,45 2,72 7,53 6,39 3,49 10,2

Take-up Pulley 2-LT 180 2,75 5,82 3,11 6,62

Required Pulley Diameter (Tension based on a safety factor of 10)

Required

%

Pulley Wrap Diameter Pulley % Running

Pulley Location Momentary

Type (deg) (mm) Diameter Tension

tension

(mm)

Motor 1 - Backstop 1 Head (4) 1 - LT 180 250 250 18 22

Take-up Pulley Tail (7) 2 - LT 180 250 250 14 15

Pulley Shaft Stress Analysis (Individual Pulleys)

Hub Hub Fillet Fillet Fillet Von Hub Von Overhung

Shaft Slope

Pulley Safety Bending Torsion Bending Torsion Mises Mises Von Mises

Type at Hub

# Factor Stress Stress Stress Stress Stress Stress Stress

(min)

(MPa) (MPa) (MPa) (MPa) (MPa) (MPa) (MPa)

1 1 7,83 3,67 24,0 5,6 10,7 5,6 25,9 14,4 0,0

2 2 9,61 3,04 19,9 1,8 8,2 1,8 20,1 8,8 0,0

Running Drive Tensions by Load Case (kN)

Motor 1 - Backstop 1

Load Case Resultant

T1 T2

Force

Empty - NF 3,57 2,63 6,20

Full - NF 3,73 2,63 6,36

Full - LF 3,32 2,69 6,00

Full - HF 4,05 2,47 6,52

Sidewinder - v7.22 - Conveyor Design Software

Advanced Conveyor Technologies, Inc.

Page 8 / 26

Client Name Designer HAK

Project Name Company

Conveyor Name cv01 Filename

Location Date Nisan 5, 2021

Description

Pulley Tension Summary - All Load Cases and Conditions

Load Case Running Starting O-Stop E-Stop

Pulley T1 T2 T1 T2 T1 T2 T1 T2

ID Description

(kN) (kN) (kN) (kN) (kN) (kN) (kN) (kN)

Mtr 1 - Bstp 1 3,57 2,63 4,22 2,13 3,27 2,88 3,27 2,88

EM-N Empty - NF

Take-up Pulley 2,50 3,00 2,32 3,11 2,61 2,99 2,61 2,99

Mtr 1 - Bstp 1 3,73 2,63 4,53 2,14 3,33 2,90 3,33 2,90

FL-N Full - NF

Take-up Pulley 2,50 3,00 2,32 3,08 2,64 3,01 2,64 3,01

Mtr 1 - Bstp 1 3,32 2,69 4,16 2,09 3,12 2,83 3,12 2,83

FL-L Full - LF

Take-up Pulley 2,59 2,84 2,28 2,86 2,67 2,86 2,67 2,86

Mtr 1 - Bstp 1 4,05 2,47 4,73 2,13 3,42 2,86 3,42 2,86

FL-H Full - HF

Take-up Pulley 2,34 3,08 2,25 3,19 2,50 3,07 2,50 3,07

Sidewinder - v7.22 - Conveyor Design Software

Advanced Conveyor Technologies, Inc.

Page 9 / 26

Client Name Designer HAK

Project Name Company

Conveyor Name cv01 Filename

Location Date Nisan 5, 2021

Description

28. Bearing L10.....................................500.000 hours

#1 - Motor 1 - Backstop 1

Pulley Location and Geometry Design Tensions and Loads

1. Name (Type-1)....................... Motor 1 - Backstop 1 29. Running T1 Tension ................................. 3,73 kN

2. Pulley Diameter ..........................................250 mm 30. Running T2 Tension ................................. 2,63 kN

3. Face Width..................................................650 mm 31. Design T1 Tension ................................... 4,45 kN

32. Design T2 Tension ................................... 2,72 kN

33. Wrap angle ................................................180 deg

Lagging

34. Design Resultant Tension......................... 7,53 kN

4. Lagging Type ............................................... Rubber

35. Resultant Angle .........................................205 deg

5. Lagging Pattern....................................Herringbone

36. Resultant Moment ................................ 0,51 kN·m

6. Lagging Thickness ........................................10 mm

37. Resultant Torque .................................. 0,24 kN·m

7. Diameter with lagging ................................270 mm

38. Estimated Pulley & Shaft Mass .................. 100 kg

39. Estimated Mass with Bearings ................... 121 kg

Shaft Specification

8. Shaft Center Diameter ..................................60 mm

Shaft Stresses & Deflections

9. Shaft Material ................................................... C45

40. Shaft slope at hub .................................... 3,67 min

10. Yield Strength ...................................... 360,0 MPa

41. Shaft slope at bearing .............................. 4,57 min

11. Fatigue Strength ................................... 315,0 MPa

42. Shaft deflection at center ......................... 0,31 mm

43. Shaft deflection at center (%) ....................... 0,038

Locking Device 44. Shaft Safety Factor (CEMA) .......................... 7,83

12. Hub Center Distance .................................550 mm 45. Shaft Safety Factor (AS1403) ........................ 6,28

13. Shaft diameter at hub ..................................60 mm 46. Bending Stress ........................................ 24,0 MPa

14. Turndown radius at hub ............................... 0 mm 47. Torsional Stress ........................................ 5,6 MPa

15. Locking Device ........................................... XT-25 48. Von Mises Stress .................................... 25,9 MPa

16. Size .......................................................... 60 x 114 49. Fillet Von Mises Stress .......................... 14,4 MPa

17. Hub width ...................................................32 mm

18. Hub pressure ........................................ 0,0 N/mm²

Shell Dimension and Stresses

19. Maximum torque ........................................ 0 N·m

50. Shell thickness ............................................ 14 mm

20. Hub outer diameter ...................................114 mm

51. Sitzwohl reqd shell thickness1 ...................... 2 mm

52. Sitzwohl shell stress ................................. 2,0 MPa

Bearing Specifications 53. Shell stress at 180 wa ............................... 2,0 MPa

21. Bearing Center Distance ...........................820 mm 1 Assumes 180 deg wrap and allowable stress of 34,0 MPa

22. Shaft diameter at bearing ............................60 mm

23. Bearing to Fillet Distance ...........................60 mm End Disk Dimension and Stresses

24. Turndown radius at bearing ......................... 0 mm 54. End disk thickness ...................................... 32 mm

25. Bearing......................................................... 22213 55. End disk stress .......................................... 5,7 MPa

26. SNL Plummer Block........................................ 513

27. Dynamic Capacity ..................................... 193 kN

Sidewinder - v7.22 - Conveyor Design Software

Advanced Conveyor Technologies, Inc.

Page 10 / 26

Client Name Designer HAK

Project Name Company

Conveyor Name cv01 Filename

Location Date Nisan 5, 2021

Description

28. Bearing L10.....................................500.000 hours

#2 - Take-up Pulley

Pulley Location and Geometry Design Tensions and Loads

1. Name (Type-2)................................ Take-up Pulley 29. Running T1 Tension ................................. 2,50 kN

2. Pulley Diameter ..........................................250 mm 30. Running T2 Tension ................................. 3,00 kN

3. Face Width..................................................650 mm 31. Design T1 Tension ................................... 2,75 kN

32. Design T2 Tension ................................... 3,30 kN

33. Wrap angle ................................................180 deg

Lagging

34. Design Resultant Tension......................... 5,82 kN

4. Lagging Type ............................................... Rubber

35. Resultant Angle .............................................9 deg

5. Lagging Pattern............................................... Plain

36. Resultant Moment ................................ 0,42 kN·m

6. Lagging Thickness ........................................10 mm

37. Resultant Torque .................................. 0,08 kN·m

7. Diameter with lagging ................................270 mm

38. Estimated Pulley & Shaft Mass .................. 100 kg

39. Estimated Mass with Bearings ................... 121 kg

Shaft Specification

8. Shaft Center Diameter ..................................60 mm

Shaft Stresses & Deflections

9. Shaft Material ................................................... C45

40. Shaft slope at hub .................................... 3,04 min

10. Yield Strength ...................................... 360,0 MPa

41. Shaft slope at bearing .............................. 3,85 min

11. Fatigue Strength ................................... 315,0 MPa

42. Shaft deflection at center ......................... 0,27 mm

43. Shaft deflection at center (%) ....................... 0,032

Locking Device 44. Shaft Safety Factor (CEMA) .......................... 9,61

12. Hub Center Distance .................................550 mm 45. Shaft Safety Factor (AS1403) ........................ 8,06

13. Shaft diameter at hub ..................................60 mm 46. Bending Stress ........................................ 19,9 MPa

14. Turndown radius at hub ............................... 0 mm 47. Torsional Stress ........................................ 1,8 MPa

15. Locking Device ........................................... XT-25 48. Von Mises Stress .................................... 20,1 MPa

16. Size .......................................................... 60 x 114 49. Fillet Von Mises Stress ............................ 8,8 MPa

17. Hub width ...................................................32 mm

18. Hub pressure ........................................ 0,0 N/mm²

Shell Dimension and Stresses

19. Maximum torque ........................................ 0 N·m

50. Shell thickness ............................................ 14 mm

20. Hub outer diameter ...................................114 mm

51. Sitzwohl reqd shell thickness1 ...................... 2 mm

52. Sitzwohl shell stress ................................. 1,7 MPa

Bearing Specifications 53. Shell stress at 180 wa ............................... 1,7 MPa

21. Bearing Center Distance ...........................840 mm 1 Assumes 180 deg wrap and allowable stress of 34,0 MPa

22. Shaft diameter at bearing ............................60 mm

23. Bearing to Fillet Distance ...........................60 mm End Disk Dimension and Stresses

24. Turndown radius at bearing ......................... 0 mm 54. End disk thickness ...................................... 32 mm

25. Bearing......................................................... 22213 55. End disk stress .......................................... 4,7 MPa

26. SNL Plummer Block........................................ 513

27. Dynamic Capacity ..................................... 193 kN

Sidewinder - v7.22 - Conveyor Design Software

Advanced Conveyor Technologies, Inc.

Page 11 / 26

Client Name Designer HAK

Project Name Company

Conveyor Name cv01 Filename

Location Date Nisan 5, 2021

Description

Belt Flap Summary

Belt flap may occur when the natural frequency of the belt matches the rotational frequency of the idlers. If belt flap is

severe, it can destroy the idlers and increase the demand power of the conveyor. Belt flap should be avoided.

The belt flap ratio is defined as the rotational frequency of the idler divided by the natural frequency of the belt. If this ratio

is equal to an integer (i.e. 1, 2, 3) then the idler may induce transverse vibrations at the natural frequency mode and result in

resonance.

The chart below shows the flap ratio along the length of the conveyor. The solid green line shows flap mode of the empty

belt under the normal friction case. The shaded pink areas should be avoided.

*

Belt flap resonance occurs at flap ratios 1, 2, 3, and 4

Sidewinder - v7.22 - Conveyor Design Software

Advanced Conveyor Technologies, Inc.

Page 12 / 26

Client Name Designer HAK

Project Name Company

Conveyor Name cv01 Filename

Location Date Nisan 5, 2021

Description

Material Trajectory

The image below shows the material trajectory for the fully loaded normal friction case.

Material Trajectory

Sidewinder - v7.22 - Conveyor Design Software

Advanced Conveyor Technologies, Inc.

Page 13 / 26

Client Name Designer HAK

Project Name Company

Conveyor Name cv01 Filename

Location Date Nisan 5, 2021

Description

Belt Transition Length Requirements

The table below lists the required transition length at head and tail pulleys. Transition lengths are based on the CEMA 7th

Method. The figure below shows the geometry of the inline transition and elevated pulley transition.

Geometry of inline and elevated pulley transition

Required transition lengths

Head pulley transition

Tail pulley transition (m)

(m)

Inline transition (L1) 0,99 0,99

Elevated pulley transition (L2) 0,66 0,66

Pulley elevation (h) 28,125 28,125

Sidewinder - v7.22 - Conveyor Design Software

Advanced Conveyor Technologies, Inc.

Page 14 / 26

Client Name Designer HAK

Project Name Company

Conveyor Name cv01 Filename

Location Date Nisan 5, 2021

Description

Material Loading Profiles

Material Properties

Type ..................................................................copper ore

Design Tonnage ....................................................... 30 t/h

Density ............................................................ 2000 kg/m3

Maximum lump size .............................................. 15 mm

Surcharge angle ...................................................... 22 deg

Tonnage ................................................................... 30 t/h

Belt speed ............................................................ 1,41 m/s

Material mass ...................................................... 5,9 kg/m

Edge distance (required / actual)................... 53 / 172 mm

Cross sectional loading (utility / total) ............. 10 % / 6 %

Bed depth ............................................................... 21 mm

Sidewinder - v7.22 - Conveyor Design Software

Advanced Conveyor Technologies, Inc.

Page 15 / 26

Client Name Designer HAK

Project Name Company

Conveyor Name cv01 Filename

Location Date Nisan 5, 2021

Description

Idler Specifications

Idler Specifications

Equal Roll

Type Flat Idler

Trough

Number of rolls 3 1

Trough angle (deg) 30 0

Roll diameter (mm) 89 89

Roll length (mm) 213 640

Shaft diameter (mm) 20,0 20,0

Bearing series 6204 6204

Maximum roll RPM 303 303

Min Life (1000 hrs) 350 / 350 350

95% life1 (1000 hrs) 350 / 350

Shaft deflection (min) 0,10 / 0,32 2,19

Mass per Roll (kg) 1,7 4,4

Rotating mass for set (kg) 5,0 4,4

Wk2 for set (kg·mm²) 8.403 7.851

Idler Spacing and Count Summary

General Carry Return

Idler spacing (m) 1,00 3,00

Number of ıdler sets 12 3

Number of rolls 36 3

Total drag (N)

Nominal friction 11,5 3,8

High friction 26,0 8,8

Low friction 8,5 2,9

Idler Life and Shaft Deflection Summary-Carry Side

Center

Idler Wing L10 Center L10 Wing Shaft

Vertical Idler Shaft

# Station (m) Length (m) Spacing Life Life Deflection

Radius (m) Type Deflection

(m) (hours) (hours) (min)

(min)

1 0,0 0,7 1,00 1 350.000 350.000 0,13

2 0,7 1,6 0,30 1 350.000 350.000 0,32

3-4 2,2 6,1 1,00 1 350.000 350.000 0,29

Sidewinder - v7.22 - Conveyor Design Software

Advanced Conveyor Technologies, Inc.

Page 16 / 26

Client Name Designer HAK

Project Name Company

Conveyor Name cv01 Filename

Location Date Nisan 5, 2021

Description

Idler Life and Shaft Deflection Summary-Return Side

Center

Idler Wing L10 Center L10 Wing Shaft

Vertical Idler Shaft

# Station (m) Length (m) Spacing Life Life Deflection

Radius (m) Type Deflection

(m) (hours) (hours) (min)

(min)

6-7 8,1 8,4 3,00 2 350.000 2,19

Sidewinder - v7.22 - Conveyor Design Software

Advanced Conveyor Technologies, Inc.

Page 17 / 26

Client Name Designer HAK

Project Name Company

Conveyor Name cv01 Filename

Location Date Nisan 5, 2021

Description

Structural Loads

The live load structural design tensions should be based on the maximum dynamic tensions plus 10% (to account for

misalignment and abnormalities in the belt, pulleys, and structures). Additionally they must include any other external loads

(wind & snow loads, seismic, etc.) that the system will encounter. These forces must then be multiplied by the required live

load structural design safety factor requirements (typically 1.6) to meet the specific structural design codes for the project.

The dead load structural design loads must be calculated from the masses of the pulleys, drives, reducers, and other

components. These loads are not included in this report as they will depend on the specific manufacture selection and other

details. These forces must then be multiplied by the required dead load structural design safety factor requirements (typically

1.2) to meet the specific structural design codes for the project. The live and dead loads are then added together to obtain the

total structural design forces.

The table below includes the belt tensions from all current load cases. Additionally, steady state and dynamic tensions for the

high friction case with 173 t/h have also been included. This specific load case results in 100% nameplate motor power,

excluding any reducer losses. The starting torque has been set to 180% for this case. The maximum tension values have been

multiplied by 110% and the pulley shaft calculations shown in the table reflect these values. The minimum tensions have

been reduced by 10%. The resultant force values include the vertical weight of the pulley.

Structural Live Loads - Includes case with 173 t/h under steady state and dynamic conditions + 110% multiplier

Shaft Shaft Shaft Minimum Tensions (kN) Maximum Tensions (kN)

Wrap Hub stress Center

Pulley Type Resultant Resultant

(deg) Slope safety Def. T1 T2 T1 T2

(min) factor (mm) Force Force

Motor 1 -

1 180 4,98 7,53 0,43 2,81 1,88 5,08 6,39 3,49 10,2

Backstop 1

Take-up Pulley 2 180 3,46 9,60 0,31 1,99 4,35 3,11 6,62

Bearing Reaction Forces (excluding any overhung loads)

Entry Exiting Pulley, Bearing Horizontal Direction (kN) Bearing Vertical Direction (kN)

Wrap Vector Vector Shaft & Structural Structural Structural Structural

Pulley FL-N FL-N

(deg) Angle Angle Bearings Min Max Min Max

Case Case

(deg) (deg) Mass (kg) Tension Tension Tension Tension

Motor 1 -

180 198 198 121 -4,46 -6,05 -9,40 -2,64 -3,16 -4,25

Backstop 1

Take-up Pulley 180 18 18 121 4,32 5,23 6,52 0,22 0,51 0,93

The idler stringer loading should be based on the flooded belt surge capacity of 468 t/h and 98,2 kg/m plus the idler and

frame masses. Additionally, all other loads (hood covers, wind loads, etc.) must also be taken into consideration.

Sidewinder - v7.22 - Conveyor Design Software

Advanced Conveyor Technologies, Inc.

Page 18 / 26

Client Name Designer HAK

Project Name Company

Conveyor Name cv01 Filename

Location Date Nisan 5, 2021

Description

Sidewinder - v7.22 - Conveyor Design Software

Advanced Conveyor Technologies, Inc.

Page 19 / 26

Client Name Designer HAK

Project Name Company

Conveyor Name cv01 Filename

Location Date Nisan 5, 2021

Description

Element Summary Details

Tension Summary

Power Summary

Sidewinder - v7.22 - Conveyor Design Software

Advanced Conveyor Technologies, Inc.

Page 20 / 26

Client Name Designer HAK

Project Name Company

Conveyor Name cv01 Filename

Location Date Nisan 5, 2021

Description

Element Summary Details

Summary of Conveyor Elements

Vertical Idler

Station Elevation Length Height Slope Idler

# Name Radius Spacing

(m) (m) (m) (m) (deg) Type

(m) (m)

1 0,0 0,00 0,7 0,23 18,00 1,00 1

2 Loading Point 0,7 0,23 1,6 0,49 18,00 0,30 1

3 2,2 0,71 0,8 0,26 18,00 1,00 1

4 3,0 0,97 5,3 1,62 18,00 1,00 1

5 Motor 1 - Backstop 1 8,0 2,60 0,3 -0,26 ---

6 8,1 2,34 1,0 -0,31 -18,00 3,00 2

7 7,1 2,03 7,4 -2,29 -18,00 3,00 2

8 Take-up Pulley 0,1 -0,26 0,3 0,26 ---

Sidewinder - v7.22 - Conveyor Design Software

Advanced Conveyor Technologies, Inc.

Page 21 / 26

Client Name Designer HAK

Project Name Company

Conveyor Name cv01 Filename

Location Date Nisan 5, 2021

Description

Min/Max Tension Summary per Element

Element Tension (kN)

Running Momentary

# Name

Maximum Minimum %Sag Maximum Minimum %Sag

1 3,08 2,84 0,26 3,19 2,84 0,26

2 Loading Point 3,12 2,86 0,15 3,26 2,86 0,15

3 3,65 3,07 0,43 3,94 2,99 0,46

4 3,70 3,11 0,42 4,05 3,01 0,46

Motor 1 -

5 4,05 3,32 0,00 4,73 3,12 0,00

Backstop 1

6 2,69 2,47 0,98 2,90 2,09 1,14

7 2,67 2,46 0,99 2,87 2,11 1,13

8 Take-up Pulley 2,59 2,34 0,00 2,67 2,25 0,00

Sidewinder - v7.22 - Conveyor Design Software

Advanced Conveyor Technologies, Inc.

Page 22 / 26

Client Name Designer HAK

Project Name Company

Conveyor Name cv01 Filename

Location Date Nisan 5, 2021

Description

Te Tension Summary per Load Cases

Belt Tension Summary per Load Case (N)

EM-N FL-N FL-L FL-H

Total (Beltline) 929 1.084 622 1.559

Total (Power) 2.138 2.295 1.227 3.353

Lift Force 0 138 137 138

Frictional Drag 929 947 485 1.420

Motor Pulley/Reducer Drag 1.209 1.211 605 1.795

Rolling Resistance 3 4 2 7

Material+Belt Flexure 0 0 0 0

Idler Bearing Drag 219 219 111 339

Idler Alignment 10 14 11 15

Pulleys & Accessories 560 560 280 840

Loading Point 138 150 81 219

Mechanical Losses 146 149 74 201

Motor Pulley Drag Components 1.063 1.063 531 1.594

Sidewinder - v7.22 - Conveyor Design Software

Advanced Conveyor Technologies, Inc.

Page 23 / 26

Client Name Designer HAK

Project Name Company

Conveyor Name cv01 Filename

Location Date Nisan 5, 2021

Description

Pulley Summary Table - All Cases

Pulley Geometry Details

Type 1 2

Lagging Type Rubber Rubber

Diameter (mm) 250 250

Lagging Thickness (mm) 10,0 10,0

Diameter with Lagging (mm) 270 270

Face Width (mm) 650 650

Shaft Center Diameter (mm) 60 60

Bearing Diameter (mm) 60 60

Bearing Center Distance (mm) 820 840

Plummer Block 513 513

Pulley & Shaft Mass (kg) 100 100

Locking Device XT-25 XT-25

Hub Center Distance (mm) 550 550

Hub Diameter (mm) 60 60

Bearing to Fillet Distance (mm) 60 60

Fillet Radius (mm) 0 0

Shaft Material C45 C45

Yield Strength (MPa) 360,0 360,0

Fatigue Strength (MPa) 315,0 315,0

Sidewinder - v7.22 - Conveyor Design Software

Advanced Conveyor Technologies, Inc.

Page 24 / 26

Client Name Designer HAK

Project Name Company

Conveyor Name cv01 Filename

Location Date Nisan 5, 2021

Description

Element Tension Details per Case

Element Tension Breakdown - (EM) Empty - Normal

Individual drag components per element

Running Running Element Pulley Feeder Extra

Wm+Wb Lift Belt Idler

# Tension Ten Diff Tonnage Drag Pt. Force Accessory

(kg/m) Force (N) Force (N) Force (N)

(N) (N) (t/h) Force (N) (N) Force (N)

1 3.000 26 6,0 13 0 13

2 3.026 331 6,0 28 0 89 138 75

3 3.357 30 6,0 15 0 15

4 3.387 187 6,0 95 1 91

5-M 3.573 -944 6,0 -15 100 963

6 2.629 -15 6,0 -18 0 2

7 2.614 -114 6,0 -134 1 18

8-T 2.500 500 6,0 15 100 385

Element Tension Breakdown - (FL) Fully Loaded - Normal

Individual drag components per element

Running Running Element Pulley Feeder Extra

Wm+Wb Lift Belt Idler

# Tension Ten Diff Tonnage Drag Pt. Force Accessory

(kg/m) Force (N) Force (N) Force (N)

(N) (N) (t/h) Force (N) (N) Force (N)

1 3.000 26 6,0 13 0 13

2 3.026 372 30 11,9 57 0 90 150 75

3 3.398 46 30 11,9 30 0 15

4 3.443 285 30 11,9 189 2 94

5-M 3.729 -1.099 6,0 -15 100 963

6 2.630 -15 6,0 -18 0 2

7 2.614 -114 6,0 -134 1 18

8-T 2.500 500 6,0 15 100 385

Element Tension Breakdown - (FL) Fully Loaded - Low

Individual drag components per element

Running Running Element Pulley Feeder Extra

Wm+Wb Lift Belt Idler

# Tension Ten Diff Tonnage Drag Pt. Force Accessory

(kg/m) Force (N) Force (N) Force (N)

(N) (N) (t/h) Force (N) (N) Force (N)

1 2.845 16 4,2 9 0 7

2 2.861 213 30 10,1 48 0 46 81 38

3 3.073 34 30 10,1 26 0 8

4 3.107 211 30 10,1 160 1 50

5-M 3.318 -632 4,2 -11 50 481

6 2.686 -11 4,2 -13 0 1

7 2.675 -83 4,2 -94 1 10

8-T 2.592 253 4,2 11 50 193

Sidewinder - v7.22 - Conveyor Design Software

Advanced Conveyor Technologies, Inc.

Page 25 / 26

Client Name Designer HAK

Project Name Company

Conveyor Name cv01 Filename

Location Date Nisan 5, 2021

Description

Element Tension Breakdown - (FL) Fully Loaded - High

Individual drag components per element

Running Running Element Pulley Feeder Extra

Wm+Wb Lift Belt Idler

# Tension Ten Diff Tonnage Drag Pt. Force Accessory

(kg/m) Force (N) Force (N) Force (N)

(N) (N) (t/h) Force (N) (N) Force (N)

1 3.080 35 6,6 15 0 20

2 3.115 530 30 12,6 60 1 138 219 113

3 3.645 55 30 12,6 32 1 23

4 3.701 347 30 12,6 200 3 143

5-M 4.047 -1.575 6,6 -17 150 1.444

6 2.472 -16 6,6 -20 0 4

7 2.456 -120 6,6 -149 2 26

8-T 2.336 744 6,6 17 150 578

Sidewinder - v7.22 - Conveyor Design Software

Advanced Conveyor Technologies, Inc.

Page 26 / 26

You might also like

- Suzuki VL1500 '98-'02 Service Manual (99500-39164-01E)Document444 pagesSuzuki VL1500 '98-'02 Service Manual (99500-39164-01E)Nikolas KarrerNo ratings yet

- D16A-D16B 470-520 SpecificationsDocument22 pagesD16A-D16B 470-520 Specificationsbugyman_02100% (7)

- 404D 22Document8 pages404D 22aiulica20100% (2)

- Deere+Yanmar+4TN82 PDFDocument10 pagesDeere+Yanmar+4TN82 PDFDavid RamirezNo ratings yet

- 202517C-0000-JSD-1300-008-B - Piping Stres CalculationDocument32 pages202517C-0000-JSD-1300-008-B - Piping Stres CalculationHasan arif KısaalioğluNo ratings yet

- INKOMA - Shaft-Hub Connections - Polygonaxlar Enligt DIN 32711 Och DIN 32712Document18 pagesINKOMA - Shaft-Hub Connections - Polygonaxlar Enligt DIN 32711 Och DIN 32712kristoffer_mossheden100% (2)

- ACI 318 99 Provisions For Seismic Design of Structural WallsDocument10 pagesACI 318 99 Provisions For Seismic Design of Structural WallsEssined Aividlav100% (1)

- Komatsu pc350lc 8 HRD High Reach Demolition Excavator SpecificationsDocument8 pagesKomatsu pc350lc 8 HRD High Reach Demolition Excavator SpecificationsSergeyNo ratings yet

- 4008-30TAG3 TPD2011E2 Nov2015Document5 pages4008-30TAG3 TPD2011E2 Nov2015tienlamNo ratings yet

- Lecture 5-2-Design of Bending MembersDocument26 pagesLecture 5-2-Design of Bending MembersHarold Jackson MtyanaNo ratings yet

- Continuous Slab Design ProgrammeDocument31 pagesContinuous Slab Design ProgrammeNikhilNo ratings yet

- Çan KoveyörDocument30 pagesÇan KoveyörHasan arif KısaalioğluNo ratings yet

- Conveyor DesignDocument7 pagesConveyor DesignLuis SantosNo ratings yet

- Kule 03-04 Arası KonveyorDocument34 pagesKule 03-04 Arası KonveyorHasan arif KısaalioğluNo ratings yet

- Conveyor Design Report: Batch Plant Coveyor System Cv1 - Receiving Conveyor - Wacom - Gmi MaliDocument35 pagesConveyor Design Report: Batch Plant Coveyor System Cv1 - Receiving Conveyor - Wacom - Gmi MaliRichmond YarrickNo ratings yet

- 1009 Calc Crd1 PDFDocument36 pages1009 Calc Crd1 PDFSasmit RaiNo ratings yet

- Conveyor Design Information Idler Set Data: Tension SummaryDocument31 pagesConveyor Design Information Idler Set Data: Tension SummaryonuroztkNo ratings yet

- Vdocuments - MX - System Information Idler Set Data Conveyor Name Tripper 1 Filename Tripper ConveyorDocument33 pagesVdocuments - MX - System Information Idler Set Data Conveyor Name Tripper 1 Filename Tripper ConveyorilfakeNo ratings yet

- 6520-CV-5443-5448-90 CM Den KesmeDocument21 pages6520-CV-5443-5448-90 CM Den KesmeHasan arif KısaalioğluNo ratings yet

- System Information Idler Set DataDocument7 pagesSystem Information Idler Set DataAlex BurgosNo ratings yet

- BOMAG - Datasheet - BF300P - PRE89105010 - SA04Document4 pagesBOMAG - Datasheet - BF300P - PRE89105010 - SA04Jason TanNo ratings yet

- 12 M KonveyörDocument36 pages12 M KonveyörHasan arif KısaalioğluNo ratings yet

- Cerebro Mix Diseño de Tanque Asistido Por SoftwareDocument12 pagesCerebro Mix Diseño de Tanque Asistido Por SoftwareAriel Fernando Peña VillarroelNo ratings yet

- LT80K6 Spec PDFDocument1 pageLT80K6 Spec PDFCarlos ToralNo ratings yet

- Komatsu Pc210lc 10 Hydraulic Crawler Excavator SpecificationsDocument6 pagesKomatsu Pc210lc 10 Hydraulic Crawler Excavator SpecificationsHugo BelgraveNo ratings yet

- Valve Guides and Valve SpringsDocument1 pageValve Guides and Valve SpringsNikNo ratings yet

- Pecifications: Ydraulic XcavatorDocument5 pagesPecifications: Ydraulic XcavatorwalisonNo ratings yet

- 12 - VX800N (Mod92)Document19 pages12 - VX800N (Mod92)zaq94No ratings yet

- 1300 WD-WJ Series SpecificationsDocument13 pages1300 WD-WJ Series SpecificationsCuan HappyNo ratings yet

- Global 1200 PDFDocument6 pagesGlobal 1200 PDFعاطف صدقىNo ratings yet

- Caracteristici Tehnice Pod Rulant PDFDocument1 pageCaracteristici Tehnice Pod Rulant PDFCristian PaladeNo ratings yet

- Pod RulantDocument1 pagePod RulantCristian PaladeNo ratings yet

- Specifi Cations: Swing System EngineDocument5 pagesSpecifi Cations: Swing System EngineLU YONo ratings yet

- Bomag bw219Document2 pagesBomag bw219ZabdyRA YT0% (1)

- Bomag bw219 INGLES PDFDocument2 pagesBomag bw219 INGLES PDFDaniel Gregorio LacastroNo ratings yet

- Senda Adatok 1Document2 pagesSenda Adatok 1AndrewNo ratings yet

- Series: Ferrite Magnet Chassis Driver Die-CastDocument1 pageSeries: Ferrite Magnet Chassis Driver Die-CastAkhmad GuiNo ratings yet

- Datasheet Bomag MPH 122 2Document2 pagesDatasheet Bomag MPH 122 2Dennis Ojok OciiNo ratings yet

- Konecranes 10TDocument10 pagesKonecranes 10TAya AlgalladNo ratings yet

- Selenium 18SW1PDocument2 pagesSelenium 18SW1PIsus Audio100% (1)

- Buldozer - CASE 550H - Specs 1-18-2012 - ENDocument4 pagesBuldozer - CASE 550H - Specs 1-18-2012 - ENMaurizio De LucaNo ratings yet

- cgl25Document10 pagescgl25ianwashere123No ratings yet

- C560B 2pg PDFDocument2 pagesC560B 2pg PDFwalk111No ratings yet

- Service Bulletin Trucks: SpecificationsDocument40 pagesService Bulletin Trucks: SpecificationsKomatsu Nna100% (1)

- Slewing Gantry Crane With Double-Link SystemDocument11 pagesSlewing Gantry Crane With Double-Link Systemduyhp231296No ratings yet

- 06 EngineDocument19 pages06 EngineMuhamad Dwi CahyonoNo ratings yet

- Rodillo Bomag BW - 211 - D - PD - 40 - en (33c)Document2 pagesRodillo Bomag BW - 211 - D - PD - 40 - en (33c)Taller ManttoNo ratings yet

- M/V Wedellsborg: General Information Dimensions CranesDocument2 pagesM/V Wedellsborg: General Information Dimensions CranesDavephilsNo ratings yet

- BW 216Document2 pagesBW 216THRTHQANo ratings yet

- Bw211d-40 Technical SpecsDocument2 pagesBw211d-40 Technical SpecsCESARALARCON10% (1)

- Series: Neodymium Magnet Die-Cast Chassis DriverDocument1 pageSeries: Neodymium Magnet Die-Cast Chassis Driverromeodatinh1989No ratings yet

- Subwoofer 18SWS800: SpecificationsDocument2 pagesSubwoofer 18SWS800: SpecificationsJorge WelzelNo ratings yet

- BW219D 4Document2 pagesBW219D 4Charles GrantNo ratings yet

- DMRC DBR ChennaiDocument25 pagesDMRC DBR ChennaiTarun Kant GoyalNo ratings yet

- Subwoofer 18SWS1100: SpecificationsDocument2 pagesSubwoofer 18SWS1100: SpecificationsFran CascoNo ratings yet

- Performance Data: Single Drum Vibratory Rollers BW 211 D-40, BW 211 PD-40Document2 pagesPerformance Data: Single Drum Vibratory Rollers BW 211 D-40, BW 211 PD-40EndraNo ratings yet

- 18SWS1000 SpecSheetDocument2 pages18SWS1000 SpecSheetEzequiel FernandezNo ratings yet

- Concorde Simulation Quick GuideDocument3 pagesConcorde Simulation Quick GuideDanilo SalgadoNo ratings yet

- Belt Stacker BSDocument69 pagesBelt Stacker BSRahmat HidayatNo ratings yet

- Vibro Spec Sheet BW219 D-4Document2 pagesVibro Spec Sheet BW219 D-4adhie_aeroNo ratings yet

- Performance Data: Single Drum Vibratory Rollers BW 211 D-40, BW 211 PD-40Document2 pagesPerformance Data: Single Drum Vibratory Rollers BW 211 D-40, BW 211 PD-40Tyrex HallNo ratings yet

- BW211D-40 SpecDocument2 pagesBW211D-40 SpecOlab BolaNo ratings yet

- Bw211d40 Performance DataDocument2 pagesBw211d40 Performance DataCESARALARCON1No ratings yet

- Technical Data - BW 211 D-40 and BW 211 PD-40Document2 pagesTechnical Data - BW 211 D-40 and BW 211 PD-40subandi pippoNo ratings yet

- Incompressible Flow Turbomachines: Design, Selection, Applications, and TheoryFrom EverandIncompressible Flow Turbomachines: Design, Selection, Applications, and TheoryNo ratings yet

- 1271 Yığın Yoğunlu Hız 0,09, Yatak 90 CM Kesme Malzeme Yüksekliği 1,5 MDocument18 pages1271 Yığın Yoğunlu Hız 0,09, Yatak 90 CM Kesme Malzeme Yüksekliği 1,5 MHasan arif KısaalioğluNo ratings yet

- ANT Birikim BCDocument4 pagesANT Birikim BCHasan arif KısaalioğluNo ratings yet

- Boru Bant Versiyon 3Document38 pagesBoru Bant Versiyon 3Hasan arif KısaalioğluNo ratings yet

- m-1 ReportDocument58 pagesm-1 ReportHasan arif KısaalioğluNo ratings yet

- Boru Bant3Document46 pagesBoru Bant3Hasan arif KısaalioğluNo ratings yet

- Boru Bant2Document40 pagesBoru Bant2Hasan arif KısaalioğluNo ratings yet

- 12 M KonveyörDocument36 pages12 M KonveyörHasan arif KısaalioğluNo ratings yet

- System Information Cross Sectional LoadingDocument62 pagesSystem Information Cross Sectional LoadingHasan arif KısaalioğluNo ratings yet

- 61 Fe 07Document28 pages61 Fe 07Hasan arif KısaalioğluNo ratings yet

- m-2 ReportDocument62 pagesm-2 ReportHasan arif KısaalioğluNo ratings yet

- m-3 ReportDocument72 pagesm-3 ReportHasan arif KısaalioğluNo ratings yet

- 12 (B 100) Metre KonveyörDocument30 pages12 (B 100) Metre KonveyörHasan arif KısaalioğluNo ratings yet

- System Information Idler Set DataDocument48 pagesSystem Information Idler Set DataHasan arif KısaalioğluNo ratings yet

- Wodo A Ski - v16 - 4 - enDocument4 pagesWodo A Ski - v16 - 4 - enHasan arif KısaalioğluNo ratings yet

- 107071-RP-P0005-40443-001 Request For Budgetary QuotationDocument9 pages107071-RP-P0005-40443-001 Request For Budgetary QuotationHasan arif KısaalioğluNo ratings yet

- m-4 ReportDocument47 pagesm-4 ReportHasan arif KısaalioğluNo ratings yet

- Ee 00000 27281 001Document10 pagesEe 00000 27281 001Hasan arif KısaalioğluNo ratings yet

- 6 KM 2 BoosterDocument62 pages6 KM 2 BoosterHasan arif KısaalioğluNo ratings yet

- 107071-RP-P0005-40440-001 Form of AcknowledgementDocument1 page107071-RP-P0005-40440-001 Form of AcknowledgementHasan arif KısaalioğluNo ratings yet

- em 00000 27280 001Document20 pagesem 00000 27280 001Hasan arif KısaalioğluNo ratings yet

- 15 M3 Tank ReportDocument41 pages15 M3 Tank ReportHasan arif KısaalioğluNo ratings yet

- ETI BAKIR P&IDs Mark-Up 29-11-2022Document47 pagesETI BAKIR P&IDs Mark-Up 29-11-2022Hasan arif KısaalioğluNo ratings yet

- Slury Sump Calculation ReportDocument2 pagesSlury Sump Calculation ReportHasan arif KısaalioğluNo ratings yet

- Vs 50 20Document1 pageVs 50 20Hasan arif KısaalioğluNo ratings yet

- 202517C-0000-JSD-1300-022-A - Piping Class DetailedDocument70 pages202517C-0000-JSD-1300-022-A - Piping Class DetailedHasan arif KısaalioğluNo ratings yet

- Kule 03-04 Arası KonveyorDocument34 pagesKule 03-04 Arası KonveyorHasan arif KısaalioğluNo ratings yet

- Vs 99 01Document1 pageVs 99 01Hasan arif KısaalioğluNo ratings yet

- 202517C-0000-JSD-1300-010-A - Piping SupportDocument33 pages202517C-0000-JSD-1300-010-A - Piping SupportHasan arif KısaalioğluNo ratings yet

- Conveyor Pulley Design Conveyor Pulley DesignDocument2 pagesConveyor Pulley Design Conveyor Pulley DesignHasan arif KısaalioğluNo ratings yet

- Swept Back WingDocument7 pagesSwept Back WingYashNo ratings yet

- Physics ImplementationDocument5 pagesPhysics ImplementationAmelia JonesNo ratings yet

- Saint Joseph Catholic School-Adama: Grade 11 Physics Worksheet April 2012 (2020)Document3 pagesSaint Joseph Catholic School-Adama: Grade 11 Physics Worksheet April 2012 (2020)Nardos AlemayewNo ratings yet

- Magnetism in SolidsDocument11 pagesMagnetism in SolidsNeelam KapoorNo ratings yet

- NAC Theory of Flight SyllabusDocument2 pagesNAC Theory of Flight SyllabusHana LeransoNo ratings yet

- Output Gear Root SafetyDocument10 pagesOutput Gear Root SafetyDaggupati PraveenNo ratings yet

- Power Point 2 Study IslandDocument15 pagesPower Point 2 Study Islandapi-294483847No ratings yet

- Noise Pollution TableDocument3 pagesNoise Pollution Tablefekeceh343No ratings yet

- Experiment-3 Study of Critical Heat Flux (Boiling Heat Transfer)Document7 pagesExperiment-3 Study of Critical Heat Flux (Boiling Heat Transfer)Mukul ChandraNo ratings yet

- Plate Girders With Corrugated WebsDocument6 pagesPlate Girders With Corrugated WebsLệnh BùiNo ratings yet

- Problem 548Document14 pagesProblem 548mike jobernard f. solangonNo ratings yet

- Poll P-01Document3 pagesPoll P-01Mag GamingNo ratings yet

- PhysicsDocument2 pagesPhysicsMts GonzalesNo ratings yet

- E401 Guide QuestionsDocument1 pageE401 Guide QuestionsWinvel DotimasNo ratings yet

- Gear SystemDocument2 pagesGear Systemwalmir.f.navarroNo ratings yet

- Elements of Polymer Structure and Viscoelasticity: David M. Parks Mechanics and Materials II 2.002 February 18, 2004Document15 pagesElements of Polymer Structure and Viscoelasticity: David M. Parks Mechanics and Materials II 2.002 February 18, 2004Jeffrey GuevaraNo ratings yet

- Shinken ME AE - 2021 Model AnswersDocument13 pagesShinken ME AE - 2021 Model AnswersresearchditNo ratings yet

- ADES Wind TurbineDocument8 pagesADES Wind TurbinebmyertekinNo ratings yet

- S.H.M-TheoryDocument16 pagesS.H.M-TheoryViren PatelNo ratings yet

- Statics and Dynamics Structural AnalysisDocument12 pagesStatics and Dynamics Structural AnalysisVaibhav JadhavNo ratings yet

- Finite Element AnalysisDocument17 pagesFinite Element AnalysisSHANZYYNo ratings yet

- Solution To Problem 208 Axial Deformation - Strength of Materials ReviewDocument2 pagesSolution To Problem 208 Axial Deformation - Strength of Materials ReviewimrancenakkNo ratings yet

- Non-Dimensional Rates - Aircraft Flight Mechanics by Harry Smith, PHDDocument1 pageNon-Dimensional Rates - Aircraft Flight Mechanics by Harry Smith, PHDhung dangNo ratings yet

- Sir Besa July 13 PDFDocument21 pagesSir Besa July 13 PDFRagalagNo ratings yet

- SG 2 CE 411 Properties of SoilDocument9 pagesSG 2 CE 411 Properties of SoilkennsindayenNo ratings yet

- CH 8Document31 pagesCH 8KhalidNo ratings yet