Professional Documents

Culture Documents

Installation and Start-Up Manual IM 1287 Rebel Applied Packaged Rooftop

Installation and Start-Up Manual IM 1287 Rebel Applied Packaged Rooftop

Uploaded by

Ernesto GarzaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Installation and Start-Up Manual IM 1287 Rebel Applied Packaged Rooftop

Installation and Start-Up Manual IM 1287 Rebel Applied Packaged Rooftop

Uploaded by

Ernesto GarzaCopyright:

Available Formats

Installation and Start-up Manual

IM 1287

Group: Applied Air Handling

Part Number: IM 1287

Date: January 2020

Rebel Applied™ Packaged Rooftop

Heating and Cooling

Models DPSA

30 to 52 Tons

R-410A Refrigerant

Table of Contents

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 Start Up Operating State . . . . . . . . . . . . . . . . . . . . 37

Nameplate Information . . . . . . . . . . . . . . . . . . . . . . . . 4 Recirculating Operating State . . . . . . . . . . . . . . . . 37

Unit Nameplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 Fan Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Compressor Nameplate . . . . . . . . . . . . . . . . . . . . . 4 Fan Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Gas Burner Nameplate . . . . . . . . . . . . . . . . . . . . . . 4 Economizer Operation . . . . . . . . . . . . . . . . . . . . . 37

Electric Heater Nameplate . . . . . . . . . . . . . . . . . . . 4 Fixed Speed Compressor Operation . . . . . . . . . . 38

Hazardous Information Messages . . . . . . . . . . . . . . . 4 External Time Clock . . . . . . . . . . . . . . . . . . . . . . . 38

Unit Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 VAV Box Signal/Fan Operation Signal . . . . . . . . . 38

Refrigeration Piping . . . . . . . . . . . . . . . . . . . . . . . . . . 7 Fan Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Controlled Component Locations . . . . . . . . . . . . . . . 10 VAV Box Output . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 Entering Fan Temperature Sensor . . . . . . . . . . . . 39

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 Duct High Pressure Limit . . . . . . . . . . . . . . . . . . . 39

Unit Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 Variable Frequency Drive Operation . . . . . . . . . . . 39

Receiving Inspection . . . . . . . . . . . . . . . . . . . . . . . . 14 Convenience Receptacle/Section Lights . . . . . . . 39

Unit Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 Propeller Exhaust Fan Option . . . . . . . . . . . . . . . . 39

Service Clearance . . . . . . . . . . . . . . . . . . . . . . . . . 14 Fan Prestarting Checks . . . . . . . . . . . . . . . . . . . . 40

Ventilation Clearance . . . . . . . . . . . . . . . . . . . . . . 15 Fan Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . 40

Overhead Clearance . . . . . . . . . . . . . . . . . . . . . . . 16 Damper Counterbalance Adjustment . . . . . . . . . . 40

Roof Curb Assembly and Installation . . . . . . . . . . . . 17 Ultraviolet Lights Option . . . . . . . . . . . . . . . . . . . . 40

Post and Rail Mounting . . . . . . . . . . . . . . . . . . . . . . 21 Convenience Receptacle/Section Lights . . . . . . . 41

Rigging and Handling . . . . . . . . . . . . . . . . . . . . . . . . 21 Check, Test and Start Procedures . . . . . . . . . . . . 41

Unit Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 Servicing High Voltage Control Panel Components .

Condensate Drain Connection . . . . . . . . . . . . . . . 23 41

Hot Water Coil Piping . . . . . . . . . . . . . . . . . . . . . . 23 Initial Manual Mode Start-Up . . . . . . . . . . . . . . . . 42

Steam Coil Piping . . . . . . . . . . . . . . . . . . . . . . . . . 25 OA Damper Start-up . . . . . . . . . . . . . . . . . . . . . . . 42

Damper Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . 27 Cooling/Heating Start up . . . . . . . . . . . . . . . . . . . . 43

Economizer Dampers . . . . . . . . . . . . . . . . . . . . . . 27 Economizer/OA Damper Start-up . . . . . . . . . . . . . 43

Intake Hood Damper (0% to 30% outside air) . . . 27 Fixed Speed Compressor Startup . . . . . . . . . . . . . 43

Exhaust Hood Assembly . . . . . . . . . . . . . . . . . . . . 28 Expansion Valve Superheat Adjustment

(Thermal Expansion Valve) . . . . . . . . . . . . . . . . . . 45

Installing Ductwork . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Heating System Startup . . . . . . . . . . . . . . . . . . . . 45

Installing Duct Pressure Taps . . . . . . . . . . . . . . . . . . 29

Air Balancing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Installing Building Static Pressure Sensor Taps . . . . 30

Maintaining Control Parameter Records . . . . . . . . 47

Installing Discharge Air Temperature Sensor . . . . 30

Using the Keypad/Display . . . . . . . . . . . . . . . . . . . 47

Unit Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Navigation Mode . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Field Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Edit Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Field Control Wiring . . . . . . . . . . . . . . . . . . . . . . . . . 34

Smoke and Fire Protection . . . . . . . . . . . . . . . . . . 49

Field Output Signals . . . . . . . . . . . . . . . . . . . . . . . . . 36

MicroTech® 4 Remote User Interface . . . . . . . . . . . . 51

Unit Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Preparing Unit for Operation . . . . . . . . . . . . . . . . . . 37

MicroTech 4 Field Installed Sensors . . . . . . . . . . . 52

Power-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Space Temperature Sensors . . . . . . . . . . . . . . . . . 52

IM 1287 • REBEL APPLIED ROOFTOP 2 www.DaikinApplied.com

Table of Contents

DDC Space Sensors . . . . . . . . . . . . . . . . . . . . . . . 52 Sequence of Operation . . . . . . . . . . . . . . . . . . . . . 99

Communicating Network Space Sensors . . . . . . . 53 Furnace Wiring Diagrams . . . . . . . . . . . . . . . . . . . . 100

Keypad and Display Menu Structure . . . . . . . . . . . . 54 Rooftop Equipment Warranty Registration Form . 108

Unit Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60 Warranty Exclusion . . . . . . . . . . . . . . . . . . . . . . 108

Servicing Control Panel Components . . . . . . . . . . . 60 In-Warranty Return Material Procedure . . . . . . . . . 108

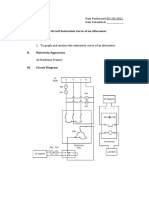

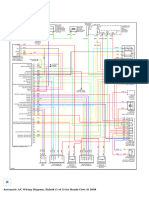

Example Wiring Diagram . . . . . . . . . . . . . . . . . . . . . 61 North America . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Planned Maintenance . . . . . . . . . . . . . . . . . . . . . . . 71 Exceptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Unit Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72 Assistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Restart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73 Sole Remedy . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Daikin Electric Heater Modules . . . . . . . . . . . . . . . . 74 Rooftop Equipment Warranty Registration Form . 110

Electric Heater General Information . . . . . . . . . . . 74 Quality Assurance Survey Form . . . . . . . . . . . . . . 116

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Electric Heater Wiring Diagrams . . . . . . . . . . . . . . 79

Daikin Tubular Gas Heater Series . . . . . . . . . . . . . . 83

Packaged Gas Heater Module . . . . . . . . . . . . . . . 83

General Gas Furnace Information . . . . . . . . . . . . 83

Unit Location and Clearances . . . . . . . . . . . . . . . 84

DPSA Gas Furnace Capacity Data . . . . . . . . . . . . 85

Ventilation and Flue Pipe Requirements . . . . . . . . 87

Gas Piping Requirements . . . . . . . . . . . . . . . . . . 88

Field Gas Piping . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Altitude Conversion . . . . . . . . . . . . . . . . . . . . . . . . 90

Gas Conversion . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Condensate Management . . . . . . . . . . . . . . . . . . 91

Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Operating Procedures . . . . . . . . . . . . . . . . . . . . . 92

Burner and Gas Manifold Pressure Adjustment

Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Maxitrol EXA Star Controller . . . . . . . . . . . . . . . . . . 96

Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Valve Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

High Fire Setting - Button #1 . . . . . . . . . . . . . . . . . 96

Low Fire Setting - Button #2 . . . . . . . . . . . . . . . . . 96

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

VB1285 BPP Split Manifold Modulating Control . . . . 98

Sequence of Operation . . . . . . . . . . . . . . . . . . . . . 98

VB1287 BPP 2-Stage and 2-Stage Split Control . . . 99

www.DaikinApplied.com 3 IM 1287 • REBEL APPLIED ROOFTOP

Introduction

Introduction

This manual provides installation information about the Rebel

Applied Daikin rooftop unit, DPSA models. In addition to an Hazardous Information Messages

overall description of the unit, it includes mechanical and

CAUTION

electrical installation and start-up procedures. For operations

and/or maintenance procedures, see OM 1288 Caution indicates potentially hazardous situations which can result in injury,

death, and property damage if not avoided.

Table 1: Program Specific Rooftop Unit Literature

WARNING

Product Manual Title Manual Number

Warning (sign) indicate potentially hazardous situations which can result in

Unit Installation and IM 1287 property damage, severe personal injury, or death if not avoided.

Start Up

Daikin, Rebel Applied Unit Operations and

DPSA units OM 1288

Maintenance

WARNING

Non-Daikin See vendor manuals

Warning indicates potentially hazardous situations for PVC (Polyvinyl

Chloride) and CPVC (Clorinated Polyvinyl Chloride) piping in chilled water

Nameplate Information systems. In the event the pipe is exposed to POE (Polyolester) oil used

in the refrigerant system, the pipe can be chemically damaged and pipe

Unit Nameplate failure can occur.

The unit nameplate is located on the outside lower right

corner on the main control box door. It includes the unit DANGER

model number, serial number, unit part number, electrical Danger (Danger lightning sign) indicates a hazardous situation which will

characteristics, and refrigerant charge. result in death or serious injury if not avoided.

Compressor Nameplate DANGER

On units that utilize the tandem compressor design, each Danger (Danger gas sign) indicates a hazardous gas situation which will

compressor includes an individual nameplate. result in death or serious injury if not avoided.

Gas Burner Nameplate NOTICE

On units that include gas heat, the cabinet furnace nameplate Notices give important information concerning a process, procedure,

is located next to the furnace access door. It includes the gas special handling or equipment attributes.

pressures, minimum/maximum input, maximum temperature

rise, and minimum CFM. The furnace rating plate is included

on the furnace; this includes the burner model number.

Electric Heater Nameplate

On units that include electric heat, the cabinet electric heater

nameplate is located next to the electric heater access door.

The electric heater rating plate is included on the electric

heater; this includes the electric heater model number.

IM 1287 • REBEL APPLIED ROOFTOP 4 www.DaikinApplied.com

Introduction

Figure 1: Nomenclature

D PS A 050 A 4 B S

Daikin Rebel Cooling Configuration

0 = No cooling, heat only

C = Chilled water coil

Packaged DX Cooling System

S = Standard efficiency air-cooled DX

PS = Packaged DX Cooling

H = High efficiency air-cooled DX

AH = Air Handler

P = Premium efficiency air-cooled DX

FS = Permanent Split System

Cabinet Size

Applied

B = B cabinet (31 – 52 tons)

Unit Size

Voltage

B00 = B cabinet, no cooling coil

2 = 208V

B24 = B cabinet, 24 ft2 coil

3 = 230V

B29 = B cabinet 29 ft2 coil 4 = 460V

B34 = B cabinet 34 ft2 coil 5 = 575V

031 = 31 ton

035 = 35 ton

040 = 40 ton Vintage

050 = 50 ton

052 = 52 ton

Unit Description

Figure 2 shows a typical DPSA unit. Figure 3 shows a typical

DPSA unit with the locations of the major components. These

figures are for general information only. See the project’s

certified submittals for actual specific dimensions and locations.

Figure 2: DPS-A Unit, Typical

www.DaikinApplied.com 5 IM 1287 • REBEL APPLIED ROOFTOP

Introduction

Figure 3: Typical Component Locations—DPS-A Units

Top View

Condensate Connection 1.5” NPT Bottom Discharge Air

Bottom Return Air Opening Opening

Side View

Outside/Return Air Dampers Filter

(Economizer Dampers) Supply Air Fan Condenser Fan

Outdoor Air

Hood

Exhaust

Hood

Low Voltage Control

Panel

Evaporator Heat Section (Natural Gas, Main Control Panel

Coil Oil, Steam, Hot Water,

Return Air Fan

Electric)

Condenser Coils

Condenser Coils (Circuit 2)

(Circuit 1)

IM 1287 • REBEL APPLIED ROOFTOP 6 www.DaikinApplied.com

Introduction

Refrigeration Piping

This section presents the unit refrigeration piping diagrams for

the various available configurations.

Figure 4: Schematic, Standard Circuit

Figure 5: Schematic, Hot Gas Bypass Circuit

www.DaikinApplied.com 7 IM 1287 • REBEL APPLIED ROOFTOP

Introduction

Figure 6: Schematic, MHGRH Circuit

Figure 7: Low Ambient Circuit Schematic

Low Ambient Configurations

Speedtrol (Variable speed fans) down to 25F

Speedtrol (Variable speed fans) + Splitter solenoid down to -10F

IM 1287 • REBEL APPLIED ROOFTOP 8 www.DaikinApplied.com

Introduction

Figure 8: Condenser Piping, Compressors, 1 to 2 Compressors per Circuit are Provided*

Splitter Solenoid Ckt 2

(optional) Comp 4

Suction Shut-off Valve (optional)

Ckt 1 Comp 2

Comp 3

Comp 1

To DX

Coil

Optional Refrigerant Hot gas Bypass

Temperature and Pressure Valves and Liquid

Transducers Line solenoids

(not shown)

Filter Dryer (replaceable core optional)

Liquid Line Sight Glass shown)

*Unit with 4 fixed speed compressors shown

www.DaikinApplied.com 9 IM 1287 • REBEL APPLIED ROOFTOP

Introduction

Controlled Component Locations

Figure 9 shows basic control and component locations within a

typical unit

Figure 9: Control and Component Locations

Outdoor Air Pre Heater

Energy Wheel

Energy Wheel

Control Box

Leaving Wheel

Temp. Sensor Outside Air

Damper

Exhaust

Fans

Energy

Recovery VFD

Exhaust Wheel Condenser

Temperature Fans

Sensor

Return Temp

And/Or Humidity

Sensors

Return Air Dampers

(Economizer Dampers)

Hot Water Coil Leaving Coil Service

Valve Temperature ports

Supply Fans

Furnace

Discharge Air Furnace

Temp. (DAT) Controller

Outdoor Temp

and/or humidity

Refrigerant Pressure

Discharge Air Temp. Sensors/Switches

Sensor (Field Installed)

Low

Voltage

Control

Box

(MT4)

IM 1287 • REBEL APPLIED ROOFTOP 10 www.DaikinApplied.com

Introduction

Control Panel

The unit control panels and their locations are shown in the

following figures. These figures show a typical unit.

Specific unit configurations may differ.

Figure 10: Control Panel Locations

Energy Wheel /Electric

Pre heater Control

Panel (if applicable)

Low Voltage

Control

Panel

Main Control Panel

(includes gas heat

controls if applicable)

Electric Heat

Control Panel (if

applicable)

Return

Control

Panel

Figure 11: Typical Main Control Panel

www.DaikinApplied.com 11 IM 1287 • REBEL APPLIED ROOFTOP

Introduction

Figure 12: Typical Low Voltage Control Panel

Figure 13: Typical Return Control Panel (with Prop Exhaust Fan VFD)

IM 1287 • REBEL APPLIED ROOFTOP 12 www.DaikinApplied.com

Introduction

Figure 14: Typical Return Control Panel (without Prop Exhaust Fan VFD)

Figure 15: Typical Return Control Panel (with Energy Recovery Wheel)

www.DaikinApplied.com 13 IM 1287 • REBEL APPLIED ROOFTOP

Installation

Installation

Unit Installation Unit Clearances

WARNING

Service Clearance

Sharp edges on sheet metal and fasteners can can cause personal injury.

Allow service clearance as indicated in Figure 16 or Figure

Please wear appropriate person protective equipment such as gloves,

17. Figure 16 denotes clearances required if large component

protective clothing, footwear, eye protection, etc. This equipment must

replacement would be completed through side access doors.

be installed, operated, and serviced only by an experienced installation

Figure 17 denotes clearances needed if large component

company and fully trained personnel.

replacement would be completed from the top of the unit (with

The installation of this equipment shall be in accordance a crane) after removing roof panels. Also, Daikin recommends

with the regulations of authorities having jurisdiction and all providing a roof walkway to the rooftop unit, as well as along

applicable codes. It is the responsibility of the installer to at least the two sides of the unit that provide access to most

determine and follow the applicable codes. controls and serviceable components.

NOTICE

Unit/equipment must be installed in a location that is not accessible to the

general public.

Receiving Inspection

When the equipment is received, all items should be carefully

checked against the bill of lading to be sure all crates and

cartons have been received. If the unit has become dirty during

shipment (winter road chemicals are of particular concern),

clean it when received.

All units should be carefully inspected for damage when

received. Report all shipping damage to the carrier and file a

claim. In most cases, equipment is shipped F.O.B. factory and

claims for freight damage should be filed by the consignee.

Before unloading the unit, check the unit nameplate to make

sure the voltage complies with the power supply available.

Remove all shipping protection prior to installation

Figure 16: Service Clearances (Scenario A)

Condenser Section

Heat Section

Supply Fan Section

Filter section

Return 60”

Section

96”

72”

60”

60”

IM 1287 • REBEL APPLIED ROOFTOP 14 www.DaikinApplied.com

To roof

access

location

Installation

Figure 17: Service Clearances (Scenario B)

Condenser Section

Heat Section

Supply Fan Section

Filter section

Return 48”

Section

96”

48”

48”

72”

To roof

access

location

Recommended

roof walkway

Ventilation Clearance

Figure 18 denotes minimum ventilation clearance Do not locate outside air intakes near exhaust vents or other

recommendations. The system designer must consider each sources of contaminated air.

application and provide adequate ventilation. If this is not done,

the unit will not perform properly. If the unit is installed where windy conditions are common,

install wind screens around the unit, maintaining the

Unit(s) surrounded by a screen or a fence: clearances specified (Figure 16). This is particularly important

to prevent blowing snow from entering outside air intake and

1. The bottom of the screen or fence should be at least 1 ft. to maintain adequate head pressure control when mechanical

(305 mm) above the roof surface. cooling is required at low outdoor air temperatures.

2. The distance between the unit and a screen or fence For pad-mounted units, it is recommended that the condenser

should be as described in Figure 16. section be lifted a minimum of 12ʺ off the ground for proper

3. The distance between any two units within a screen or underside ventilation. This clearance allows for proper airflow,

fence should be at least 120ʺ (3048 mm). optimal condenser performance and to prevent any minor

reductions in performance.

Unit(s) surrounded by solid walls:

1. If there are walls on one or two adjacent sides of the unit,

the walls may be any height. If there are walls on more

than two adjacent sides of the unit, the walls should not

be higher than the unit.

2. The distance between the unit and the wall should be at

least 96ʺ (2438 mm) on all sides of the unit.

3. The distance between any two units within the walls

should be at least 120ʺ (3048 mm).

www.DaikinApplied.com 15 IM 1287 • REBEL APPLIED ROOFTOP

Installation

Overhead Clearance

1. If clearances from Scenario B (Figure 17) are applied to 4. The following restrictions must be observed for overhead

the installation, then unit must not have any overhead obstructions above the air handler section where ground

obstructions over any part of the unit. clearances noted in scenario A are applied (i.e. if

Figure 16 is applicable, then Figure 18 shows allowable

2. If unit is surrounded by solid walls or screens, then unit

overhead canopy) :

must not have any overhead obstructions over any part

of the unit. a. There must be no overhead obstructions above the

furnace flue, or within 9ʺ (229 mm) of the flue box.

3. The area above the condenser must be unobstructed in

all installations to allow vertical air discharge. b. Overhead obstructions must be no less than 96ʺ

(2438 mm) above the top of the unit.

c. There must be no overhead obstructions in the

areas above the outside air intake and exhaust

dampers that are farther than 24ʺ (610 mm) from

the side of the unit.

Figure 18: Overhead Clearance

Overhead Canopy

Furnace flue (if

24” applicable)

max No overhead

obstructions allowed

within 9”

24”

max

96” minimum from top

of unit to permanent

overhead construction

24”

max

IM 1287 • REBEL APPLIED ROOFTOP 16 www.DaikinApplied.com

Installation

Roof Curb Assembly and Installation

WARNING Curb Assembly instructions

Mold can cause serious illness and property damage. Some materials 1. Set curbing parts in accordance with assembly

such as gypsum wall board can promote mold growth when damp. Such instructions provided with unit. Take careful note of the

materials must be protected from moisture that can enter units during location of return and supply air openings, Figure 19.

maintenance or normal operation. 2. If applicable, set other curbing parts in place making

sure that the orientation complies with the assembly

Locate the roof curb and unit on a portion of the roof that can

instructions. Check alignment of all mating bolt holes.

support the weight of the unit. The unit must be supported to

See Figure 21, Detail A.

prevent bending or twisting of the machine.

3. Bolt curbing parts together using fasteners provided.

If building construction allows sound and vibration into the

Tighten all bolts finger tight.

occupied space, locate the unit over a non-critical area. It

is the responsibility of the system designer to make 4. Square entire curbing assembly and securely tighten all

adequate provisions for noise and vibration in the bolts.

occupied space. 5. Position curb assembly over roof openings. Curb must

Install the curb and unit level to allow the condensate drain to be level from side to side and over its length. Check that

flow properly and allow service access doors to open and close top surface of the curb is flat with no bowing or sagging.

without binding. 6. Weld curbing in place. Caulk all seams watertight.

Integral supply and return air duct flanges are provided with the Remove backing from 0.25ʺ (6 mm) thick × 1.50ʺ (38

DPSA roof curb, allowing connection of duct work to the mm) wide gasketing and apply to surfaces shown by

cross-hatching.

curb before the unit is set. The gasketed top surface of the duct

flanges seals against the unit when it is set on the curb. 7. Flash curbing into roof as shown in Figure 21, Detail A.

These flanges must not support the total weight of the 8. Be Sure that electrical connection are coordinated (see

ductwork. It is critical that the condensate drain side of the Figure 23)

unit be no higher than the opposite side. Assembly of a typical

DPSA roof curb is shown in Figure 19.

Figure 19: Standard Roof Curb Assembly

J Condenser

Section Support

K

(if applicable)

L

B M

A

www.DaikinApplied.com 17 IM 1287 • REBEL APPLIED ROOFTOP

Installation

Figure 20: B – Full Perimeter Roof Curb Assembly

L

K M

B

A

C

D

E

Figure 21: Detail Views

Detail A Detail B

1. Unit Base

2. Curb Gasketing

3. 2x4 Nailer Strip

4. Galvanized Curb

5. Cant Strip (not furnished)

6. Roofing Material (not furnished)

7. Rigid Insulation (not furnished)

8. Counterflashing (not furnished)

9. Flashing (not furnished)

Note: height of perimeter curb and

condensing section support are not equal

IM 1287 • REBEL APPLIED ROOFTOP 18 www.DaikinApplied.com

Installation

Table 2: Rebel Applied Roof Curb Assembly Dimensions, Table 3: Rebel Applied Roof Curb Assembly Dimensions,

Return Configurations Supply Configurations

A B C D E Unit Supply J K L M P

Unit Return

in. in. in. size Configuration in. (mm) in. (mm) in. (mm) in. (mm) in. (mm)

Size Configuration in. (mm) in. (mm)

(mm) (mm) (mm)

Standard 4.03

None Discharge (102.4)

Standard B Short Out of 52.03 24.75 1.5 70.5 55.75

Return Fans 3.70 Cabinet Air Stream (1322) (628.6) (38.1) (1791) (1416)

Offset Return (93.9) Long Out of 76.03

B Fans 36 3.70 82.0 55.75 Air Stream (1931)

Cabinet Prop Exhaust (914.4) (93.9) (2082.8) (1416)

High Static 30.86

Exhaust (783.8)

56.86

Energy Wheel (1444.2)

Figure 22: Rebel Applied Plenum Curb Application

www.DaikinApplied.com 19 IM 1287 • REBEL APPLIED ROOFTOP

Installation

The base of the unit has structural steel between the floor the factory before application with a plenum curb. Refer to

of the unit and the curb sealing surface. For plenum curb Figure 22.

applications, exta insulation and sealing is required. Consult

Figure 23: Typical Power Wire Entrance, Curb View, See Project Certified Drawings

Power Wire Entrance (route

wires up from bottom, and route

through provided patch plate)

IM 1287 • REBEL APPLIED ROOFTOP 20 www.DaikinApplied.com

Installation

Post and Rail Mounting Rigging and Handling

WARNING Cabinet Weather Protection

The unit must be level side to side and over the entire length. Equipment

damage can result if the unit is not level. CAUTION

Transportation, rigging, or maintenance can damage the unit’s weather seal.

WARNING Periodically inspect the unit for leakage. Standing moisture can promote

microbial growth, disease, or damage to the equipment and building.

Lifting points may not be symmetrical to the center of gravity of the unit.

Ballast or unequal cable lengths maybe required.

This unit ships from the factory with fully gasketed access

doors and cabinet caulking to provide weather resistant

CAUTION operation. After the unit is set in place, inspect all door gaskets

Use all lifting points. Improper lifting can cause injury, death, and property for shipping damage and replace if necessary.

damage. Protect the unit from overhead runoff from overhangs or other

such structures.

When mounting by post and rail, run the structural support the

full length of the unit. Locate the structural member at the base Re-caulk field assembled options such as external piping or

of the unit as shown in Figure 24, assuring the I-beam is well vestibules per the installation instructions provided with the

supported by the structural member. option.

If resilient material is placed between the unit and the rail,

Lifting Brackets

insert a heavy steel plate between the unit and the resilient

material to distribute the load. Seal cabinet penetrations Lifting brackets with 2ʺ (51 mm) diameter holes are provided

(electrical, piping, etc.) properly to protect against moisture on the sides of the unit.

and weather.

Cabling

Figure 24: Post and Rail Mounting • Dedicated Cables from each lift connection point to

spreader bars are required.

MAX. MAX.

• No Looped Cables, Pulleys or other “self-leveling” riging

methods are allowed as the can cause excessive flexing

and damage

• Mid-Point connection points receive two cables each or a

dedicated spreader bar can be used instead.

• The Cable length from the spreader bar to the hook

should always be longer than the distance between the

outer lifting points

Spreader Bars

• Perpendicular spreader bars should be used for each lift

point.

• A Longitudinal spreader bar along the length of the unit

* Beam can extend beneath unit no more than 5" to allow adequate space for is required for units with more than 6 lift points to limit the

duct connections and electrical entry. cable angles and the reuslting stress on the unit structure.

• Spreader bars should be at least 96ʺ to 100ʺ (2438 to

Table 4: Post and Rail Mounting Dimensions 2540 mm) wide to prevent damage to the unit cabinet.

B Cabinet If the unit is stored at the construction site for an intermediate

A 96.5" period, take these additional precautions:

B 94.5" 1. Support the unit well along the length of the base rail.

2. Level the unit (no twists or uneven ground surface).

3. Provide proper drainage around the unit to prevent

flooding of the equipment.

4. Provide adequate protection from vandalism, mechanical

contact, etc.

5. Securely close the doors and lock the handles

6. If there are isolation dampers, make sure they are

www.DaikinApplied.com 21 IM 1287 • REBEL APPLIED ROOFTOP

Installation

properly installed and fully closed to prevent the entry Lifting Points

of animals and debris through the supply and return air

openings. Lifting points are predetermined from factory. When lifting,

make sure all factory installed lifting lugs are used. Figure

7. Cover the supply and return air openings on units without 19 gives examples of typical 4 point and 6 point lifting

isolation dampers. configurations. Unit must remain level during all lifts. Also

shown in Figure 26, lifting cable angle from vertical should

Figure 25 shows an example of the rigging instruction label

never be greater than 30°. Be aware that the center of gravity

shipped with each unit.

for each may not necessarily be in the geometric center of the

unit. Refer to certified drawings for center of gravity location.

Figure 25: Rigging and Handling Instruction Label

NOTE: Be careful of lifting cable proximity to handles to

prevent damage

Figure 26: DPSA Lifting Points

4 Lifting Points 6 Lifting Points (alternative)

Spreader Bar

30° 30°

MAX MAX

6 Lifting Points

30°

MAX

IM 1287 • REBEL APPLIED ROOFTOP 22 www.DaikinApplied.com

Installation

Unit Piping

Condensate Drain Connection Hot Water Coil Piping

WARNING CAUTION

Drain pans must be cleaned periodically. Uncleaned drain pans can cause Coil freeze possible when the ambient temperature is below 35°f and can

illness. Cleaning should be performed by qualified personnel with an result in poor equipment operation or damage to the equipment. Follow

alkaline based biodegradable cleaning solution. instructions for mixing antifreeze solution used. Some products have higher

freezing points in their natural state than when mixed with water. The

The unit is provided with a 1.5ʺ male NPT condensate drain freezing of coils is not the responsibility of Daikin.

connection. Refer to certified drawings for the exact location.

For proper drainage, level the unit and drain pan side to side Hot water coils are not normally recommended for use with

and install a P-trap entering air temperatures below 35°F (1.6°C). No control

system can guarantee a 100% safeguard against coil freeze-

Units may have positive or negative pressure sections. Use

up. Glycol solutions or brines are the only freeze-safe media

traps in both cases with extra care given to negative pressure

for operation of water coils at low entering air temperature

sections. In Figure 27, “P” is the static pressure at the drain

conditions.

pan in inches W.C. As a conservative measure to prevent

the cabinet static pressure from blowing or drawing the water NOTE: All coils have vents and drains factory installed.

out of the trap and causing air leakage, dimension A should

be two times the maximum static pressure encountered in Hot water coils are provided without valves as a standard

the coil section in inches w.c. or a minimum of 4 inches, unit, requiring field installation of valves and piping. As an

whichever dimension is greater. Dimension B should also have option, the hot water coil is supplied with either a two-way or

a dimension of twice the maximum static pressure at the drain three-way valve and actuator motor from the factory. Refer to

pan or a minimum of 8 inches, whichever dimension is greater. the submittal drawings to determine unit configuration. The

submittal drawing will also have information about the line size

Draining condensate directly onto the roof may be acceptable; connections.

refer to local codes. Provide a small drip pad of stone, mortar,

wood, or metal to protect the roof against possible damage. NOTE: Factory-installed water valves and piping are bronze,

brass, and copper. Dissimilar metals within the

If condensate is piped into the building drainage system, pitch plumbing system can cause galvanic corrosion. To

the drain line away from the unit a minimum of 1/8ʺ per foot. avoid corrosion, provide proper dielectric fittings as

The drain line must penetrate the roof external to the unit. well as appropriate water treatment when making

a connection to a pipe that is not copper, bronze or

Refer to local codes for additional requirements. Sealed drain brass.

lines require venting to provide proper condensate flow.

Where the cooling coils have intermediate condensate pans on A factory provided floor knockout location is provided on

the face of the evaporator coil, copper tubes near both ends of every unit equiped with a hot water coil. Refer to the certified

the coil provide drainage to the main drain pan. Check that the drawings for the recommended piping entrance locations. Seal

copper tubes are in place and open before the unit is put into all piping penetrations to prevent air and water leakage.

operation.Check that this tube is open before putting the unit

into operation and as a part of routine maintenance. Table 5: Hot Water Connection Size

Drain pans in any air conditioning unit have some moisture in Hot Water Connections

them, allowing micro-organisms to grow. Therefore, periodically

B 1 Row 2-1/2"

clean the drain pan to prevent this buildup from plugging the

Cabinet 2 Row 2-1/2”

drain and causing the drain pan to overflow.

Figure 27: Condensate Drain Connection

Static Pressure at

the drain Pan (P)

A= (4” min)

B= (8” min)

www.DaikinApplied.com 23 IM 1287 • REBEL APPLIED ROOFTOP

Installation

Figure 28: Hot Water Heat Section (Shown with Factory Valve and Piping, no Bypass)

Return

Supply

Figure 29: Hot Water Bypass Valve Package

Bypass

Valve

Return

Supply

Bypass

Piping

IM 1287 • REBEL APPLIED ROOFTOP 24 www.DaikinApplied.com

Installation

Steam Coil Piping Table 6: Steam Connection Size

Steam coils are provided without valves as a standard unit, Steam Connections

requiring field installation of valves and pipig. As an optionthe B

steam coil coil is upplied with a two-way valve and actuator Cabinet All Rows 2”

motor from the factory. Refer to the submittal drawings to

determine unit configuration. The submittal drawing will also

have information about the line size connections.

The steam heat coil is pitched at 1/8ʺ (3 mm) per foot (305

mm) to provide positive condensate removal.

Refer to the certified drawings for the recommended piping

entrance locations. All piping penetrations must be sealed to

prevent air and water leakage.

NOTE: The valve actuator spring returns to a stem up

position upon power failure. This allows full flow

through the coil.

Figure 30: Steam Heat Section (Shown with Valve and Factory Piping)

Supply

Return

www.DaikinApplied.com 25 IM 1287 • REBEL APPLIED ROOFTOP

Installation

Steam Piping Recommendations Steam Coil Freeze Conditions

1. Be certain that adequate piping flexibility is provided. If the air entering the steam coil is below 35°F (2°C), note the

Stresses resulting from expansion of closely coupled following recommendations:

piping and coil arrangement can cause serious damage. 1. Supply 5 psi (34.5 kPa) steam to coils at all times.

2. Do not reduce pipe size at the coil return connection. 2. Modulating valves are not recommended. Control should

Carry return connection size through the dirt pocket, be by means of face and bypass dampers.

making the reduction at the branch leading to the trap.

3. As additional protection against freeze-up, install the

3. Install vacuum breakers on all applications to prevent

tap sufficiently far below the coil to provide an adequate

retaining condensate in the coil. Generally, the vacuum hydrostatic head to ensure removal of condensate during

breaker is to be connected between the coil inlet and the

an interruption on the steam pressure. Estimate 3 ft. (914

return main. However, if the system has a flooded return mm) for each 1 psi (7 kPa) of trap differential required.

main, the vacuum breaker to the atmosphere; the trap

design should allow venting of the large quantities of air. 4. If the unit is to be operated in environments with

possible freezing temperatures, an optional freezestat is

4. Do not drain steam mains or takeoffs through coils. Drain recommended.

mains ahead of coils through a steam trap to the return

line.

5. Do not attempt to lift condensate.

6. Pitch all supply and return steam piping down a minimum

of 1ʺ (25 mm) per 10 feet (3 m) of direction of flow.

Steam Trap Recommendations

1. Size traps in accordance with manufacturers’

recommendations. Be certain that the required pressure

differential will always be available. Do not undersize.

2. Float and thermostatic or bucket traps are recommended

for low pressure steam. Use bucket traps on systems

with ON/OFF control only.

3. Locate traps at least 12ʺ (305 mm) below the coil return

connection.

4. Always install strainers as close as possible to the inlet

side of the trap.

5. A single tap may generally be used for coils piped in

parallel, but an individual trap for each coil is preferred.

IM 1287 • REBEL APPLIED ROOFTOP 26 www.DaikinApplied.com

Installation

Damper Assemblies

The optional damper assemblies described in this section Intake Hood Damper (0% to 100%

normally are ordered with factory-installed actuators and

linkages. The following sections describe operation and linkage outside air)

adjustment of the factory-installed air damper options. Units requiring 100% outside air are provided with a rain hood

and dampers that can be controlled by a single actuator. The

Economizer Dampers actuator provides two-position control for opening the dampers

fully during unit operation and closing the dampers during the

Outside air intake is provided at end of the unit, and the return

off cycle. No unit mounted exhaust dampers are provided. See

air path is at the bottom of the damper set. As the actuators

Figure 32 for operation of the the damper.

modulate the outside air damper open, the return air damper

closes. Exhaust air exits the unit through the gravity relief Intake Hood Damper (0% to 30% outside

dampers provided at the sides of the economizer section.

air)

The damper is set so that the actuator moves through a 90-

degree angle to bring the economizer damper from full open These dampers are intended to remain at a fixed position

to full close (Figure 31). Access to the actuator is from the filler during unit operation, providing fresh air quantities from 0 to

section. 30% of the total system airflow, depending on the damper

setting.

NOTE: Do not “overclose” low leak damper blades. The edge

seal should just lightly contact the adjoining blade. On units provided with MicroTech 4 controls, the damper

position may be set at the controller keypad. During unit

The blades will lock up if they are closed so far the seal goes

operation, the analog controlled actuator drives the damper

over center.

to the position set on the keypad. During the OFF cycle, the

damper is automatically closed.

No unit-mounted exhaust dampers are provided with this

option.

Figure 31: Damper Adjustment

Return Section

Outdoor Air Damper

Damper Actuator

Damper Actuator

Manual Override

(adjusted with

Allen key,

provided with

unit)

www.DaikinApplied.com 27 IM 1287 • REBEL APPLIED ROOFTOP

Installation

Figure 32: Intake Hood Damper Adjustment 2. Fold top of hood up.

0% Outside Air 3. Fold left side and right side out and put screws provided

with unit into corresponding holes to lock in position

of left side and top of the hood as shown in figure YY.

(reinstall 2 shipping screws and use 4 additional screws

provided with unit).

4. Place caulk where shown belowin figure YY to seal all

seams between unit cabinet and hood to create a leak

proof water tight seal.

Figure 34: Exhaust Hood Folded Out

100% Outside Air

Exhaust Hood Assembly

On units equipped with exhaust dampers, a hood is provided

on the unit and must be set up properly prior to operation. This

section describes the procedure for setting up the hood. Failure

to complete this set up may cause damage to unit.

1. As shown in the figure below, the unit is shipped with the

hood assembly folded in. To begin set up, remove and

retain two shipping screws holding the hood pieces in

place.

Figure 33: Exhaust Hood Folded In

IM 1287 • REBEL APPLIED ROOFTOP 28 www.DaikinApplied.com

Installation

Installing Ductwork Improperly locating or installing the DSP1 or DSP2 tap may

cause unsatisfactory operation of the building VAV system.

WARNING Consider the following pressure tap location and installation

Mold can cause serious illness or property damage. Materials such as recommendations. The installation must comply with all

gypsum wallboard can promote mold growth when damp. Such materials applicable local code requirements.

must be protected from moisture that can enter units during maintenance 1. Install a tee fitting with a leak-tight removable cap in each

or normal operation. tube near the sensor fitting. This facilitates connecting a

manometer or pressure gauge if testing is required.

On bottom-supply/bottom-return units, if a Daikin roof curb

is not used, installing contractor should make an airtight 2. Differentiate between the duct pressure (HI) and

connection by attaching field fabricated duct collars to the reference pressure (LO) taps by using different color

tubing or by tagging the tubes. Daikin recommends 3/16ʺ

bottom surface of either the roof curb’s duct flange or the unit’s

I.D. plastic tubing.

duct opening. Do not support the total weight of the duct work

from the unit or these duct flanges. See Figure 33. 3. Locate the duct pressure (HI) tap near the end of a long

duct to ensure that all terminal box take-offs along the

Use flexible connections between the unit and ductwork to

run have adequate static pressure.

avoid transmission of vibration from the unit to the structure.

4. Locate the duct pressure tap in a non-turbulent flow area

To minimize losses and sound transmission, design duct work

of the duct. Keep it several duct diameters away from

per ASHRAE and SMACNA recommendations.

take-off points, bends, neckdowns, attenuators, vanes, or

Where return air ducts are not required, connect a sound other irregularities that may create turbulent air flow.

absorbing T or L section to the unit return to reduce noise

5. Use a static pressure tip (Dwyer A302 or equivalent) or

transmission to the occupied space.

the bare end of the plastic tubing for the duct tap. (If the

Ductwork exposed to outdoor conditions must be built in duct is lined inside, use a static pressure tip device.)

accordance with ASHRAE and SMACNA recommendations

6. Install the pressure tap so that it senses only static

and local building codes.

pressure (not velocity pressure). If a bare tube end is

used, it must be smooth, square (not cut at an angle) and

Figure 35: Installing Duct Work perpendicular to the airstream.

7. Locate the reference pressure (LO) tap somewhere near

Unit duct opening the duct pressure tap within the building.

Unit base

8. If the reference pressure tap is not connected to the

sensor, unsatisfactory operation will result.

9. Route the tubes between the curb and the supply

duct, feeding them into the Main Control Panel through

9.76"

the Panel Entrance Plate. Connect the tubes to their

respective inlets on the appropriate pressure sensor in

the Low Voltage Control Panel. See Figure 34 for the

suggested routing for the tubing.

4.58"

Flexible

connector

Figure 36: Recommended Tubing Route to Sensors

Roof curb

Ductwork Duct flanger

in roof curb

Installing Duct Pressure Taps

Units that will operate as a VAV unit require a reading of the

duct static pressure. This requires that pressure taps be field

installed and plumbed back to the pressure sensors in the unit.

There may be up to two duct static pressure sensors on a unit;

DSP1 is provided when the unit is built for VAV operation and

an additional sensor DSP2 is optional. When present, these

sensors are located within the Low Voltage Control Panel

shown in Figure 3 on page 6.

Carefully locate and install the field provided pressure tap.

www.DaikinApplied.com 29 IM 1287 • REBEL APPLIED ROOFTOP

Installation

Installing Building Static Pressure Sensor Taps

CAUTION 6. Locate the reference pressure (LO) tap in the area

surrounding the controlled space. Improperly locating the

Please be careful when removing tubing from the fragile pressure sensor reference tap may result in unsatisfactory operation.

fitting. Do not use excessive force or wrench the tubing back and forth when

removing the tubing. Excessive force and motion can break off and damage 7. If the reference pressure (LO) tap is to be located

the sensor. outside, locate it away from condenser fans, walls,

or anything else that may cause air turbulence. The

Units that are selected with the capability for direct building reference pressure (LO) tap must be mounted high

static pressure control require a reading of the building static enough above the roof or ground so that it is not affected

pressure. This requires that pressure taps be field installed and by snow. Additionally, use an outdoor static pressure

plumbed back to the Building Static Pressure sensor (BSP) in tip (Dwyer A306 or equivalent) to minimize the adverse

the unit. When present, the BSP sensor is found in the Low effects of wind. Place some type of screen over the

Voltage Control Panel sensor to keep out insects. Loosely packed cotton works

well.

Carefully locate and install the field provided pressure taps.

Improperly locating or installing the BSP pressure taps may 8. Route tubing between the reference pressure tap and

result in unsatisfactory operation. Consider the following the Building Static Pressure sensor (LO) tap. The tubing

pressure tap locations and installation recommendations. should be routed between the curb and the supply duct,

The installation must comply with all applicable local code entering the Main Control Panel through the Panel

requirements. Entrance Plate. See Figure 3 on page 6 for the

recommended route for field installed tubing to the BSP.

1. Install a tee fitting with a leak-tight removable cap in each

Seal the penetration to prevent water from entering.

tube near the sensor fitting. This facilitates connecting a

manometer or pressure gauge if testing is required.

Installing Discharge Air Temperature

2. Differentiate between the building pressure (HI) and

outdoor pressure (LO) taps by using different color tubing Sensor

or by tagging the tubes. Daikin recommends 3/16ʺ I.D. The discharge air temperature sensor should be installed in

plastic tubing. the supply air duct. downstream of the rooftop unit. Locate

3. Regardless whether the pressure in the controlled space the sensor at a location that approximates the average duct

is to be positive or negative with respect to its reference, temperature. To avoid the affects of radiation, the sensor

the building pressure tap will be the HI pressure tap on should not be in direct line of sight with the gas furnace.

the Building Static Pressure sensor. Generally, locate the sensor 5-10’ from the unit discharge

and after one duct turn to allow for air mixing. Do not install

4. Locate the building pressure (HI) tap in the area that downstream of VAV boxes or other dampers.

requires the closest control. Typically, this is a ground

level floor that has doors to the outside. The location 1. Drill a 7/8” Diameter hole in the duct, insert the

must not allow the reading to be influenced by any temperature probe and secure plate to duct using 2-#10

source of moving air (velocity pressure). These sources screws.

may include air diffusers or outside doors. 2. Be sure to apply gasket or sealant to back of mounting

5. Route tubing between the building pressure tap and plate prior to screwing the plate to the duct to create an

the Building Static Pressure sensor (HI) tap. The tubing air tight seal.

should be routed between the curb and the supply duct,

entering into the Main Control Panel through the Panel Figure 37: Temperature Sensor Installation

Entrance Plate. See Figure 34 on page 29 for the

recommended route for field installed tubing to the BSP.

IM 1287 • REBEL APPLIED ROOFTOP 30 www.DaikinApplied.com

Unit Wiring

Field Power Wiring

DANGER The point of connection for service conductors will be within

the Main Control Panel. However, on some units service

LOCKOUT/TAGOUT all power sources prior to wiring or servicing the unit. conductors may be required to be installed in the Electric

Hazardous voltage can cause serious injury or death. Disconnect electric Heater Control Panel. Consult the Unit Specific Electrical

power before servicing equipment. More than one disconnect may be Schematics to determine if the electric heater will require its

required to de-energize the unit. own set of service conductors. Refer to “Daikin Electric Heater

Modules” on page 74 for service conductor entrance details

DANGER pertaining to the electric heater.

Dangers indicate a hazardous electrical situation which will result in death The recommended entrance for field installed service

or serious injury if not avoided. conductors that terminate in the Main Control Panel is through

the Panel Entrance Plate in the bottom right corner of the

DANGER control panel enclosure. This entrance to the Main Control

Proper line voltage and phase balance must be provided. Improper voltage Panel is shown in Figure 35 on page 32 and also noted in

or excessive phase imbalance may result in severe damage to the electrical Figure 36

components within the unit. When planning the installation of the service conductors,

consider the information in Table 6, Table 7, and Table 8 on

For the unit to operate, power must be supplied to the page 32. These tables provide details for the field wired

unit through field installed service conductors. Electrical service conductor connections including the number of

characteristics, such as Unit Voltage, Minimum Current ports that will be available per phase as well as the range of

Ampacity (MCA), and Maximum Overcurrent Protection (MOP) conductor gauge that they will accept. Table 6 provides this

are found on the Unit Nameplate. These characteristics must information for non-fused disconnects, Table 7 covers the

be considered when planning the installation of the service fused disconnects, and Table 8 details power block ports.

conductors and other applicable field wiring.

NOTE: The installation of all field wiring, must comply with all

applicable local codes and ordinances. The warranty

is void if the field wiring is not in accordance with

these standards.

Depending on the unit configuration, the unit will come with

either a Fused Disconnect, a Non-Fused Disconnect, a power

block, or a combination in cases where multiple sources

of power are specified. Consult the Unit Specific Electrical

Schematics to determine the number of required sources of

power. Refer to Table 5 for the standard multiple point power

connection options and their function.

Table 7: Multiple Point Power Connection Options

Power Disconnect Load Location

Sources Designation

Supply and return

DS2 fan motors plus Main control panel

2 controls

DS1 Balance of unit Main control panel

Field Connect Electric heat Electric heat control panel

2

DS1 Balance of unit Main control panel

Field Connect Electric heat Electric heat control panel

Supply and return

3 DS2 fan motors plus Main control panel

controls

DS1 Balance of unit Main control panel

www.DaikinApplied.com 31 IM 1287 • REBEL APPLIED ROOFTOP

Unit Wiring

Table 8: Non-Fused Disconnect Lug Port Details Copper wire is required for all field installed conductors.

Supply voltage must not vary by more than 10% of the unit

Non Fused Type 1 Ports Type 2 Ports

voltage specified on the nameplate. Phase voltage imbalance

Disconnect Min Max

Size Qty AWG AWG Qty Min Awg Max Awg must not exceed 2%. (Calculate the average voltage of the

30 1 #10 2/0 — — — three legs. The leg with voltage deviating the farthest from

60 1 #10 2/0 — — — the average value must not be more than 2% away.) Contact

100 1 #10 2/0 — — — the local power company for correction of improper voltage or

200 1 #6 300MCM — — — phase imbalance.

400 2 1/0 250MCM 1 #4 600MCM

The unit has an option to come with a GFCI service outlet

pre-installed in order to satisfy the code requirements of NEC

Table 9: Fused Disconnect Lug Port Details

210.63. If the GFCI or the service lights were selected as field

Fused Type 1 Ports Type 2 Ports powered, conductors supplying a 115V 20/15A source must be

Disconnect Qty Min Max Qty Min Awg Max Awg run to terminals in the control panel as shown in the example

Size AWG AWG

in Figure 35. These terminals are typically located in the Main

60 1 #14 #6 — — —

Control Panel at the High Voltage Terminal Block, TBHV.

100 1 #12 #1 — — —

200 1 #6 300MCM — — — If the GFCI or service lights were selected as unit powered,

400 2 1/0 250MCM 1 #4 600MCM then no additional wiring must be run beyond the 3 phase

service conductors to power the 115V service outlet. Consult

Table 10: Power Block Port Details the Unit Specific Electrical Schematics to determine the

Power

installation requirements.

Type 1 Ports Type 2 Ports

Block

Min Max

Ampacity Qty Qty Min Awg Max Awg

AWG AWG

510 1 #2 600MCM 12 #14 #4

760 4 #4 500MCM — — —

950 2 1/0 750MCM 10 #14 2/0

Figure 38: Typical Field Power Entrance – Main Control Box

IM 1287 • REBEL APPLIED ROOFTOP 32 www.DaikinApplied.com

Unit Wiring

Figure 39: Typical Field Power Entrance – Panel Entrance Plate

Figure 40: Field Wired GFCI Power

www.DaikinApplied.com 33 IM 1287 • REBEL APPLIED ROOFTOP

Unit Wiring

Field Control Wiring

DANGER Figure 41: Graphical Representation of TB2

LOCKOUT/TAGOUT all power sources prior to wiring or servicing the unit.

Electrical shock hazard that may cause severe injury or death. Connect only

low voltage NEC Class II circuits to the Error! Reference source not found.

Error! Reference source not found.. Reinstall and secure all protective front

panels when the wiring installation is complete.

Rebel Applied units are available with several control schemes

which may require low voltage field wiring. Use the Unit

Specific Electrical Schematics to determine which control

connections will be required for installation. Check unit specific

electrical documentation in the door of the control panel. Figure

Z is a graphical representation of TB2 and Table 9 shows the

possible field connections that can be made.

Table 11: Potential field Connections and Locations on TB2

Terminal Block Number Description Signal

200 Power 24V AC

201 Signal for Tennant Override Contact Closure

202 Condensate Overflow Switch Contact 1 Contact Closure

Condensate Overflow Switch Contact 2 & feed into

203 Contact Closure

SD2 E-stop series

204 Feed from SD2 into E-Stop Series Contact Closure

205 Field Provisions for E-Stop Contact Closure

206 Field Provisions for E-Stop Contact Closure

207E Relative Humidity Sensor #1 (ZRH1) 4-20mA

208E Humidity Sensor 4-20mA

208G Relative Humidity Sensor #2 (ZRH2) 4-20mA

210 Space Temeprature Sensor 1 Thermistor

210E Space Temperature Sensor 2 thermistor

210G Space Temperature Sensor 3 thermistor

212 Setpoint Adjustment, Wallstat Signal

214 CO2 / Ext OA Reset 0-10V DC

215 Alarm Output 24VAC relay

216 Alarm Return 24VAC relay

217 Fan Operation 24VAC relay

220 Freezestat Sensor Terminal 1 Contact Closure

221 Freezestat Sensor Terminal 2 Contact Closure

231 Alarm Reset Contact Closure

236 Controller Common

240 Local / Remote Status relay output

240C System Ready Output relay output

242 Cooling system Interlock (From Field) Contact Closure

246 Reheat Valve Cmd 0-10V DC

247 Cooling Capacity Input 0-10V DC

250 Cooling Actual Capacity Output 0-10V DC

267 SAF1 Capacity Cmd (From Field) 0-10V DC

275 EF Capacity Cmd (From Field) 0-10V DC

296A Return Air SD Aux Contact relay output

296B Return Air SD Aux Contact relay output

296C Supply Air SD Aux Contact relay output

296D Supply Air SD Aux Contact relay output

297 Passive Ventilation Input Contact Closure

297A Passive Ventilation Input Contact Closure

2100 Smoke Purge - Purge Contact Closure

2101 Smoke Purge - Pressurize Contact Closure

2102 Smoke Purge - Vent Contact Closure

2103 Smoke Purge - Shutdown Contact Closure

IM 1287 • REBEL APPLIED ROOFTOP 34 www.DaikinApplied.com

Unit Wiring

Rebel Applied units operate with 115V and 24V control circuit

power. All field control wiring connections are made at the class

II terminal block TBLV2 which is located in the Low Voltage

Control Panel, shown in Figure 40

NOTE: The installation of all field wiring, must comply with all

applicable local codes and ordinances. The warranty

may be limited or certain aspects excluded if the field

wiring is not in accordance with these standards.

If a single conduit containing 24V and 115V wiring is

run above the roofline between units, consider the

24V wiring within as an NEC Class I wiring system.

Figure 42: Wiring Raceway, Air Handler Sections

Wiring raceway (remove cover for access to

harnesses from main control box to unit-

mounted control devices)

Figure 43: Wiring Connections Control Box (located in Condenser Section, Shown without Doors or Panels)

Wiring entrance point for

condenser fan wires

Wiring entrance point from air

handler sec�on

Wiring entrance

point to low

Wiring entrance point voltage control box

to main control box

from outside of unit

www.DaikinApplied.com 35 IM 1287 • REBEL APPLIED ROOFTOP

Unit Wiring

Field Output Signals

There are several output signals on the MicroTech 4 Controller Figure 44: Field Output Schematic

that may be available for field connections. For example, the

Alarm Output and the Auxillary Output, shown in Figure 41, can

be used to send signals to external systems.

A field supplied 24VAC relay must be installed in order to

interface these outputs with a system external to the unit.

When the respective signal is active, the signal terminal

will be energized with 24VAC. The coil of the field supplied

24VAC relay must be wired between the signal terminal and

the common terminal. These would be terminals TBLV2-215

and TBLV2-217 in the case of the Alarm Output and terminals

TBLV2-216 and TBLV2-217 in the case of the Auxiliary Output.

The field installed relay coil may draw no more than 3VA or

125mA at 24VAC.

IM 1287 • REBEL APPLIED ROOFTOP 36 www.DaikinApplied.com

Unit Operation

Unit Operation

Preparing Unit for Operation

Power-up Fan Operation

There is a 115 VAC control circuit transformer and several Within 120 seconds after the fans start, the controller expects

24VAC circuit transformers within the unit to control the various to get feedback from the fans (via modbus) that they are

loads and sensors within the unit. See as-built schematics that operating properly. If MCB-the controller does receive that

are sent with the unit to familiarize yourself with the various feedback, the controller assumes the fans did not start. It then

features and control circuits. shuts down the unit and generates an alarm. Units configured

NOTE: Unit ships with factory installed jumpers in the for VAV control, the supply fan(s) is modulated to maintain

emergency override circuit on TB2 between terminals the duct static pressure setpoint. On VAV units or CAV

202 and 203. units equipped with return fan capacity control, the fan(s) is

modulated to maintain an acceptable building static pressure.

Start Up Operating State

When a unit is commanded to start it will always enter the

Economizer Operation

Startup operating state from the OFF operating state. The unit If the unit is equipped with a 0-100% modulating economizer

remains in the Startup operating state for an adjustable time and the conditions are suitable for free cooling, the unit

period (default 180 seconds) before entering the recirculating attempts to satisfy the cooling load by using the outdoor air

operating state. economizer before using mechanical cooling.

If the unit is configured for Zone Temperature Control the

Recirculating Operating State transition to economizer operation will occur if all the following

During the Start up operating state the fans remain off, are true:

the outdoor air dampers are driven closed, and variable • The control temperature rises above the occupied cooling

speed supply air fan’s remain at 0%. Cooling and heating set point by more that ½ the occupied cooling high

are disabled, except for 100% OA heating start sequences. deadband

Recirculating Operating State Units with return air always • The discharge air temperature is greater than the Min

enter the Recirculating operating state after the completion DAT limit by more than ½ the DAT heating deadband.

of the Startup operating state. In the Recirculating operating This will prevent more cold air from being brought in when

state fans are started and operate while the outdoor air the DAT is already cold

dampers remain closed. This allows temperature conditions

• The economizer operation is not disabled

throughout the unit and space to equalize before temperature

control begins. Cooling and heating remain disabled. The If the unit is configured for Discharge Air Temperature Control

unit remains in the Recirculating operating state until the the transition to Mechanical cooling will occur if all the following

Recirculate State Timer (default 180 seconds) expires. are true:

NOTE: 100% outdoor air units do not transition through the • The control temperature rises above the occupied cooling

Recirculating operating state. set point by more that ½ the occupied cooling deadband

• The discharge air temperature is greater than the DAT

Fan Only cooling set point by more than ½ the DAT cooling

The unit enters the Fan Only operating state after the deadband

recirculation timer expires. Units configured for 100% outside • Post heat operation is complete

air operation will transition directly from the Start up operating

• Economizer operation is not disabled

state into the Fan Only operating state. Once entering the Fan

Only state of operation the unit will then, based on sensor

inputs transition into any of the 4 remaining states of operation

- heating, cooling, economizer, or minimum discharge air

heating. Min DA

www.DaikinApplied.com 37 IM 1287 • REBEL APPLIED ROOFTOP

Unit Operation

Fixed Speed Compressor Operation External Time Clock

You can use an external time clock as an alternative to (or in

4-Compressor/4-Stage Unit addition to) the MicroTech 4 controller’s internal scheduling

In this configuration there are four equally sized compressors function. The external timing mechanism is set up to open

and two cooling circuits. In the following description, and close the circuit between field terminals 201 and 202.

compressor #1 is lead. However, if Auto Lead/Lag Staging is When the circuit is open, power is not supplied to digital input

selected on the keypad, the lead compressor is the one in the MCB- DI3. This is the normal condition where the controller

lead circuit with the least number of run hours. follows the programmable internal schedule. When the circuit

is closed, power is fed to DI3, the MicroTech 4 controller

When the unit disconnect is closed, 115 V (ac) power is

responds by placing the unit in the occupied mode, over riding

supplied directly from control transformer T1 to the compressor

any set internal schedule

crankcase heaters, and motor protectors (MMP).

Cross Load VAV Box Signal/Fan Operation Signal

During a call for mechanical cooling, if HP1 is closed, then Digital Output #10 (MCB-DO10) may be selected as either the

DO1 on expansion module C closes, energizing the M1 Fan Operation output or the VAV output via the keypad. The

compressor contactor. The M1 auxiliary brings on required VAV/Fan Pop selection can be selected by accessing the Unit

condenser fans, liquid line solenoid valve and de-energizes the Setup menu in the Extended Menu section. See “Field Power

crankcase heater. Wiring” on page 31 for details.

The second stage of cooling is controlled by DO1 on expansion

module D. Compressor 2 is on circuit 2 and is brought on in

Fan Operation

the same manner as compressor #1, as well as the condenser The Fan Operation output is ON when the unit is not Off and

fans, solenoid valve and crankcase heater on the circuit. when both the unit is OFF and airflow is detected. It is off when

the unit is off and airflow is not detected.

The 3rd stage of cooling is controlled by DO2 on expansion

module C and brings on compressor 3.

VAV Box Output

The 4th stage of cooling is controlled by DO2 on expansion

module D and brings on compressor 4. In the Heating state, the VAV Output is turned OFF to indicate

that hot air instead of the normal cool air is being supplied to

Lead Load the VAV boxes. The VAV boxes are driven to their Heating

Position when hot air is provided based on either the normally

The loading and unloading process is similar except that both open or normally closed contacts of the VAV output. The VFD

compressors in the lead cooling circuit 1 energize before will continue to be controlled to maintain the desired duct

energizing any compressors in lag circuit 2. static pressure. This output is also OFF when the unit is in

the Startup or Recirculation states. If this output is in the Heat

Phase Voltage Monitor (OFF) position when the unit enters the Fan Only state or

The phase voltage monitor protects against high voltage, Minimum DAT Control state, the output remains OFF for an

phase imbalance, and phase loss (single phasing) when any adjustable Post Heat Time (while the unit VFDs are driven to

one of three line voltages drops to 74% or less of setting. This minimum speed) or until the VFD gets to its minimum speed if

device also protects against phase reversal when improper the Post Heat Time is set greater than 0. The Post Heat Timer

phase sequence is applied to equipment, and low voltage can be adjusted via the keypad/display Timer Setting menu in

(brownout) when all three line voltages drop to 90% or less of the Extended Menus.

setting. An indicator run light is ON when all phase voltages are During unoccupied operation, the VAV Box Output is in the

within specified limits. The phase voltage monitor is located on Cool (ON) position unless airflow is detected. When airflow is

the load side of the power block with a set of contacts wired to detected, it switches to the Heat (OFF) position.

the 115-volt control circuit to shut the unit down whenever the

phase voltages are outside the specified limits.

IM 1287 • REBEL APPLIED ROOFTOP 38 www.DaikinApplied.com

Unit Operation

Entering Fan Temperature Sensor Propeller Exhaust Fan Option

The entering fan temperature (EFT) sensor and an associated Economizer units may include propeller exhaust or centrifugal

“Lo Airflow Problem” alarm are provided on VAV units with return fan options. This section covers maintenance and

MicroTech 4 control and gas or electric heat. The EFT sensor operating instructions for the propeller exhaust option.

is located in the supply fan section of the unit at the supply air Centrifugal return fan construction, maintenance and operation

funnel. is similar to supply fans and covered in other sections of this

Heat is disabled whenever the airflow is detected to be too low manual.

for safe heating operation. This condition is indicated when the

supply air temperature exceeds the mixed air temperature by Figure 45: Fan Rotation

more than 60°F (16°C).

NOTE: This value is not always 60°F. It depends on whether

the unit is gas or electric heat and on the burner/

baffling arrangement on gas heat units.

In this case, a “Lo Airflow Problem” alarm is generated and

heat is not enabled until the alarm is manually cleared. Refer

to the operation manual for information on clearing alarms (OM

1288).

Duct High Pressure Limit

The duct high pressure limit control (DHL) is provided on all

VAV units. The DHL protects the duct work, the terminal boxes,

and the unit from over pressurization, which could be caused

by, for example, tripped fire dampers or control failure. The Figure 46: Three Fans with Bottom Return

DHL control is factory set to open when the discharge plenum

pressure rises to 5.0ʺ wc.

If the DHL switch opens, digital input DI5 on the Main Control

Board de-energizes. The MicroTech 4 controller then shuts

down the unit and enters the Off-Alarm state. The alarm must

be manually cleared before the unit can start again.

Refer to the operation manual supplied with your unit for more

information on clearing alarms (OM 1288).

Variable Frequency Drive Operation

Refer to the vendor instructions supplied with the unit.

Convenience Receptacle/Section Lights

A Ground Fault Circuit Interrupter (GFCI) convenience

receptacle is provided in the main control box. Both unit-

powered and field-powered versions are offered.

Optional lights are available for certain sections in the unit.

Each light includes a switch and convenience receptacle and is

powered by the external 115V power supply connected to TB7.

www.DaikinApplied.com 39 IM 1287 • REBEL APPLIED ROOFTOP

Unit Operation

Fan Prestarting Checks Ultraviolet Lights Option

Check all fasteners and set screws for tightness. This is When this option is employed, ultraviolet C light bathes

especially important for bearing set screws. the moist surfaces on the coil and drain pan, killing most

microorganisms that can grow there.

The propeller should rotate freely and not rub on the fan

panel venturi. Rotation direction of the propeller should be Typically, ultraviolet lights are installed on the leaving side of

checked by momentarily turning the unit on. Rotation should the cooling coils in the unit. Each light module is mounted on a

be in the same direction as the rotation decal affixed to vertical rail and is removable for convenient bulb replacement.

the unit or as shown in Figure 42 on page 39. For three- UV Light Power Disconnect switches (one per door) are

phase installations, fan rotation can be reversed by simply factory installed on every door that allows a direct line of sight

interchanging any two of the three electrical leads. to the UV lamps when opened. These switches are designed

to prevent UV exposure when cabinet doors are opened and

Fan Maintenance must not be disabled.

Once the fan is put into operation, set up a periodic A viewing window near the UV lights allows viewing to

maintenance program to preserve the reliability and determine if the lights are energized. The viewing windows use

performance of the fan. Items to include in this program are: specially designed glass that blocks harmful UV light.

• Bearings

• Fasteners Figure 47: Typical Ultraviolet Light Installation

• Setscrews