Professional Documents

Culture Documents

Section I - Product and Company Identification: Asphalt

Section I - Product and Company Identification: Asphalt

Uploaded by

MichelleCopyright:

Available Formats

You might also like

- Breathe in New Mexico - Final ReportDocument33 pagesBreathe in New Mexico - Final ReportswopreaderNo ratings yet

- Textbook Part 3Document87 pagesTextbook Part 3CY OnuorahNo ratings yet

- Safety Data Sheet For Ready Mix ConcreteDocument4 pagesSafety Data Sheet For Ready Mix Concretealbarajeel forwarding001No ratings yet

- Material Safety Data Sheet For Concrete/Concrete Products : Section I-Product and Company IdentificationDocument5 pagesMaterial Safety Data Sheet For Concrete/Concrete Products : Section I-Product and Company Identificationmalaya tripathyNo ratings yet

- Pyrogel XTF AIS EnglishDocument5 pagesPyrogel XTF AIS EnglishramNo ratings yet

- MATERIAL-SAFETY-DATA-SHEET-08 CandFRMCDocument5 pagesMATERIAL-SAFETY-DATA-SHEET-08 CandFRMCMadison ChanNo ratings yet

- Vier Cylinders 2022Document5 pagesVier Cylinders 2022sobheysaidNo ratings yet

- MSDS Sanding SpongeDocument9 pagesMSDS Sanding Spongefebrin rohmanNo ratings yet

- Rex-Cut Cotton Fiber SDS - 2018Document7 pagesRex-Cut Cotton Fiber SDS - 2018BepdjNo ratings yet

- Components Battens Hi Bor Pressure Treated MsdsDocument3 pagesComponents Battens Hi Bor Pressure Treated MsdsBima MahendraNo ratings yet

- Safety Data Sheet: 3M™ Abrasive Products, 216U, 236UDocument9 pagesSafety Data Sheet: 3M™ Abrasive Products, 216U, 236Uzubair1951No ratings yet

- 0204-Greentherm 26 Li - (Usa)Document7 pages0204-Greentherm 26 Li - (Usa)adamdwaldropNo ratings yet

- MSDS 7440Document9 pagesMSDS 7440febrin rohmanNo ratings yet

- 321U Safety Data SheetDocument9 pages321U Safety Data SheetDaniel LealNo ratings yet

- MediawebserverDocument10 pagesMediawebserverfebrin rohmanNo ratings yet

- MSDS giấy nhám 3MDocument9 pagesMSDS giấy nhám 3MNguyễn Tiến DũngNo ratings yet

- Safety Data Sheet: Section 1 - Chemical Product / Company InformationDocument6 pagesSafety Data Sheet: Section 1 - Chemical Product / Company InformationAriel Rojas BarrientosNo ratings yet

- Fire Barrier 135 Msds PDFDocument8 pagesFire Barrier 135 Msds PDFE Hammam El MissiryNo ratings yet

- 048011-04029 27 AU EN safetyDataSheet Sds 8799831064580 0 1Document11 pages048011-04029 27 AU EN safetyDataSheet Sds 8799831064580 0 1Jonatan BernalNo ratings yet

- Msds Sealant 2Document4 pagesMsds Sealant 2Khairull AzwanNo ratings yet

- XZ677 (C, L) MSDS EngDocument5 pagesXZ677 (C, L) MSDS Engs_d_sudhirrajNo ratings yet

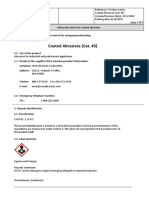

- Coated Abrasives Cat 5 USA 2022Document9 pagesCoated Abrasives Cat 5 USA 2022Nazım YıldırımNo ratings yet

- G-Rapid Plus PasteDocument14 pagesG-Rapid Plus PasteFandrio PermataNo ratings yet

- Msds SPC BambooDocument18 pagesMsds SPC BambooDevi AstriniNo ratings yet

- Msds Sample Usgs GSP 2 Art No 54480078 enDocument5 pagesMsds Sample Usgs GSP 2 Art No 54480078 enK59 Ha Hoang Thao MyNo ratings yet

- Form 5 For The Year 2017 18Document20 pagesForm 5 For The Year 2017 18rooftopsolarpower08No ratings yet

- Msds tk21, CuredDocument3 pagesMsds tk21, CuredBachrul UlumNo ratings yet

- Instructions On RE-FLAMEDocument5 pagesInstructions On RE-FLAMEDIEGONo ratings yet

- Safety Data Sheet: Threebond1282BDocument5 pagesSafety Data Sheet: Threebond1282BMarco CulquiNo ratings yet

- Flyash MSDSDocument6 pagesFlyash MSDSManuel CardosoNo ratings yet

- Msds Certificate: 1. Product and Company IdentificationDocument5 pagesMsds Certificate: 1. Product and Company IdentificationWaleed MedhatNo ratings yet

- Safety Data Sheet: Chemical Name Cas # Percent Classification NoteDocument6 pagesSafety Data Sheet: Chemical Name Cas # Percent Classification NotesharathNo ratings yet

- 500 Technical Questions Safety & FireDocument7 pages500 Technical Questions Safety & FireAbinesh ABNo ratings yet

- Carbolite - Todas Las Mallas FDS PDFDocument3 pagesCarbolite - Todas Las Mallas FDS PDFwilmerNo ratings yet

- Safety Data Sheet: Section 1 - Chemical Product / Company InformationDocument6 pagesSafety Data Sheet: Section 1 - Chemical Product / Company InformationNijin NpNo ratings yet

- Safety Data Sheet: 1. IdentificationDocument8 pagesSafety Data Sheet: 1. IdentificationPaul RamosNo ratings yet

- Scotch Brite VerdeDocument8 pagesScotch Brite VerdesantiagoNo ratings yet

- Battery Optima InterstateDocument4 pagesBattery Optima InterstateBatanNo ratings yet

- 51-Msds Planigrout 310 CDocument8 pages51-Msds Planigrout 310 CJanella ChancanNo ratings yet

- Dowwsil 791 Weather SealantDocument14 pagesDowwsil 791 Weather SealantMuhd HabiNo ratings yet

- Apex Msds - 27 Nov 2019Document6 pagesApex Msds - 27 Nov 2019Jason GlassNo ratings yet

- Perfumes (Fragrance Materials) : Ingredient Safety Information - Phys-Chem, Environmental Hazard and Fate DataDocument6 pagesPerfumes (Fragrance Materials) : Ingredient Safety Information - Phys-Chem, Environmental Hazard and Fate DatatnssbhaskarNo ratings yet

- Material Safety Data Sheet - SAN EARTHDocument3 pagesMaterial Safety Data Sheet - SAN EARTHPaulo CLNo ratings yet

- C SELLADOR U470612Document13 pagesC SELLADOR U470612fercas.dfcgNo ratings yet

- ZS 15890Document3 pagesZS 15890F.Javier LobeiraNo ratings yet

- Material Safety Data Sheet: Silicomanganese SlagDocument8 pagesMaterial Safety Data Sheet: Silicomanganese SlagbamboNo ratings yet

- Abc EnglishDocument8 pagesAbc EnglishshammyacNo ratings yet

- Msds For Skim CoatDocument8 pagesMsds For Skim Coatlovely palomaNo ratings yet

- Khảo sát tỉ lệ TiO2 2Document6 pagesKhảo sát tỉ lệ TiO2 2Nghĩa Tô TrungNo ratings yet

- Color Change Desiccant MSDSDocument5 pagesColor Change Desiccant MSDSAmir RahbariNo ratings yet

- CLT-K806S MsdsDocument9 pagesCLT-K806S MsdsChong Gyu SongNo ratings yet

- Available Data On Naphthalene Exposures: Strengths and LimitationsDocument42 pagesAvailable Data On Naphthalene Exposures: Strengths and LimitationsAmeet BandodkarNo ratings yet

- FGL 1Document9 pagesFGL 1Julio Pacheco SoberanisNo ratings yet

- Astec2000 Finish Coat MsdsDocument4 pagesAstec2000 Finish Coat MsdsFebrianto DimazNo ratings yet

- Carbon BLK SpecificationDocument2 pagesCarbon BLK Specificationmohsen siahpooshNo ratings yet

- Hempadur Primer 1530yDocument4 pagesHempadur Primer 1530yRodrigo CondorettyNo ratings yet

- R 405 SachtlebenDocument1 pageR 405 Sachtlebenmedo.k016No ratings yet

- Safety Data Sheet: 3M Brand Fire Barrier CP-25WB+Document12 pagesSafety Data Sheet: 3M Brand Fire Barrier CP-25WB+ErickoNo ratings yet

- MSDS N2XHDocument3 pagesMSDS N2XHH. NurzeinNo ratings yet

- Hindalco Esr Compliance Hirakud April19 March2020Document20 pagesHindalco Esr Compliance Hirakud April19 March2020amitav dashNo ratings yet

- RAL 9005 Jet Black 179A MSDSDocument4 pagesRAL 9005 Jet Black 179A MSDSSimonNo ratings yet

- Highly Efficient Methods for Sulfur Vulcanization Techniques, Results and Implications: Selection and Management of Rubber CurativesFrom EverandHighly Efficient Methods for Sulfur Vulcanization Techniques, Results and Implications: Selection and Management of Rubber CurativesNo ratings yet

- RBA Auditor Guide BookDocument18 pagesRBA Auditor Guide BookMichelleNo ratings yet

- Customer Complaint Handling Training 13485Document6 pagesCustomer Complaint Handling Training 13485Michelle100% (1)

- Brake Fluid MSDSDocument8 pagesBrake Fluid MSDSMichelleNo ratings yet

- Thank-You For Downloading The Final Validation Report Template!Document3 pagesThank-You For Downloading The Final Validation Report Template!MichelleNo ratings yet

- Thank-You For Downloading The SW Tool IQ-OQ-PQ Template!Document14 pagesThank-You For Downloading The SW Tool IQ-OQ-PQ Template!MichelleNo ratings yet

- ASQ Best Practices For Process ValidationDocument26 pagesASQ Best Practices For Process ValidationMichelleNo ratings yet

- Thank-You For Downloading The Project Management Plan Template!Document7 pagesThank-You For Downloading The Project Management Plan Template!MichelleNo ratings yet

- How To Write An Ebook & Sell It On Amazon in 5 Easy StepsDocument12 pagesHow To Write An Ebook & Sell It On Amazon in 5 Easy StepsMichelleNo ratings yet

- Test-1: GS Subject: (Insta Prelims Test Series 2023)Document24 pagesTest-1: GS Subject: (Insta Prelims Test Series 2023)Manan GhoshNo ratings yet

- Exogenous and Endogenous Pigment.....Document30 pagesExogenous and Endogenous Pigment.....Mohan ChoudharyNo ratings yet

- Material Safety Data Sheet Blended Cement FinalDocument14 pagesMaterial Safety Data Sheet Blended Cement FinalAndrea Dela CruzNo ratings yet

- Gangoso - Butuan CityDocument12 pagesGangoso - Butuan CityRafaela GangosoNo ratings yet

- Bentonite MSDSDocument10 pagesBentonite MSDSkhai ruleNo ratings yet

- Silicosis - A Case Report Case Report: Address of The CorrespondenceDocument3 pagesSilicosis - A Case Report Case Report: Address of The CorrespondenceBunga RamadhaniNo ratings yet

- C19 P04 PneumoconiosisDocument17 pagesC19 P04 PneumoconiosisChandana KrishnaNo ratings yet

- Manual de Fallas y Mantenimiento de Aceros Atlas CopcoDocument80 pagesManual de Fallas y Mantenimiento de Aceros Atlas CopcoLuis AsfuraNo ratings yet

- Safety Data Sheet ConcreteDocument6 pagesSafety Data Sheet ConcreteItalo RicardoNo ratings yet

- Silicosis: SeminarDocument11 pagesSilicosis: SeminarFelipe Barbosa CordeiroNo ratings yet

- Wet Disc Brake With Dowel Pins: Model W3H (360 MM) Maintenance Manual MM-20195Document52 pagesWet Disc Brake With Dowel Pins: Model W3H (360 MM) Maintenance Manual MM-20195Antonio MejicanosNo ratings yet

- Lafarge Terraflow en 190617Document12 pagesLafarge Terraflow en 190617Pat AuffretNo ratings yet

- Aioh Position Paper Rcs Update Sep2018 Final Unmarked DraftDocument19 pagesAioh Position Paper Rcs Update Sep2018 Final Unmarked Drafthitman1363No ratings yet

- OSHA3768Document6 pagesOSHA3768Shazayn KhanNo ratings yet

- Dust Lung DiseasesDocument38 pagesDust Lung Diseasesankitkumaramit99No ratings yet

- The Year in U.S. Occupational Health & Safety 2015Document64 pagesThe Year in U.S. Occupational Health & Safety 2015Celeste MonfortonNo ratings yet

- Health Hazards in Construction: John NewquistDocument45 pagesHealth Hazards in Construction: John NewquistAkhil VenugopalNo ratings yet

- Amended Silicate SorbDocument45 pagesAmended Silicate SorbAzeam AnjumNo ratings yet

- Best Sand Silica Sand and Gravel TDS 417Document2 pagesBest Sand Silica Sand and Gravel TDS 417Sandy BottomsNo ratings yet

- br420 ManualDocument70 pagesbr420 ManualCitlali MoránNo ratings yet

- MSDS BentonitaDocument5 pagesMSDS BentonitaKitsuneMasterNo ratings yet

- Artista Columns ManualDocument24 pagesArtista Columns ManualsotirisNo ratings yet

- Dgms Circular 2010Document33 pagesDgms Circular 2010Ajeet Kumar100% (1)

- Msds p500 NagpurDocument7 pagesMsds p500 NagpurAnkur BarsainyaNo ratings yet

- Restrictive Lung Diseases.Document59 pagesRestrictive Lung Diseases.Salman KhanNo ratings yet

- Material Safety Data Sheet: S100 70/140-Mesh Sand S100Document7 pagesMaterial Safety Data Sheet: S100 70/140-Mesh Sand S100sajad gohariNo ratings yet

- Fundamentals of Hazard Management PDFDocument226 pagesFundamentals of Hazard Management PDFMogana GunasigrenNo ratings yet

- Meritor Wedge BrakesDocument32 pagesMeritor Wedge Brakespankituna5487No ratings yet

Section I - Product and Company Identification: Asphalt

Section I - Product and Company Identification: Asphalt

Uploaded by

MichelleOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Section I - Product and Company Identification: Asphalt

Section I - Product and Company Identification: Asphalt

Uploaded by

MichelleCopyright:

Available Formats

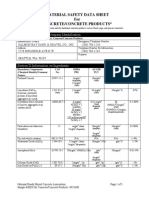

MATERIAL SAFETY DATA SHEET

for

ASPHALT

(unhardened and hardened asphalt)

Section I - Product and Company Identification

Material Identity (Trade Names): Asphalt (a mixture of 93-97 % aggregate, 4-7% asphalt, and 0.01-0.04 % antistripping agent)

Manufacturer's Name: Rinker Materials Corporation Emergency Telephone Number: 1-800-226-3768 ext. 2436

Address: 701 North 44th Telephone Number for Information: 1-800-226-3768 ext. 2436

Phoenix, Arizona 85008 Internet Web Site: www.rinker.com

Preparer: Clayton Group Services, Inc.

Section II - Hazardous Ingredients/Identity Information

Hazardous Components CAS No. OSHA PEL ACGIH MSHA %

(Chemical Identity/Common Names) TLV PEL

Asphalt (hot liquid) 8052-42-4 Not Listed 0.5 mg/m3 5 mg/m3 4-7%

(Fume) (Fume)

(as benzene-

soluble aerosol

or equivalent

method)

Crystalline silica (Quartz) (contained in 14808-60-7 30/(%SiO2 +2) mg/m3 0.05 mg/m3 30/(%SiO2+ 0-95%

aggregate) (Total) (Respirable 3) mg/m3

10/(%SiO2 +2) mg/m3 quartz) (Total)

(Respirable) 10/(%SiO2

+2) mg/m3

(Respirable)

10 mg/m3 10 mg/m3

-------- 15 mg/m3 (Total)

(Inhalable) (Total)

Particulates not otherwise classified 5 mg/m3 (Respirable)

3 mg/m3 0-95%

(Respirable)

Section III - Physical/Chemical Characteristics

Boiling Point Not Applicable Specific Gravity (H20 = 1) Variable

Vapor Pressure (mm Hg) Not Applicable Melting Point N/A

Vapor Density (Air = 1) Not Applicable Evaporation Rate N/A

(Butyl Acetate = 1)

Solubility in Water: N/A.

Rinker Materials Corporation Page 1 of 5

MSDS for: Asphalt Effective Date: August 1, 2001

MSDS #0011 Revision: 2

Appearance and Odor: Hardened asphalt is an odorless solid material of varying black to brown color and texture. Unhardened hot

asphalt may exhibit characteristic asphalt fume (tar) or petroleum hydrocarbon odor.

Rinker Materials Corporation Page 2 of 5

MSDS for: Asphalt Effective Date: August 1, 2001

MSDS #0011 Revision: 2

Section IV - Fire and Explosion Hazard Data

Flash Point: > 450o F (liquid asphalt) Flammable Limits: Not Flammable LEL: N/A UEL: N/A

Extinguishing Media: Use foam, dry chemical, or carbon dioxide to fight fire.

Special Fire Fighting Procedures: Since fire may produce toxic fumes, wear a self-contained breathing apparatus (SCBA) with a full

facepiece operated in the pressure-demand or positive pressure mode. Wear protective clothing and face and eye protection when

handling hot asphalt. If feasible, move containers from fire hazard since they may explode in the heat of the fire. Otherwise, use water

spray to cool fire-exposed containers. Be aware of runoff from fire control methods. Do not release to sewers or waterways since it

may create a fire hazard and cause pollution.

Unusual Fire and Explosion Hazards: Hot asphalt is a slight fire hazard when exposed to heat, flame, or fluorine. Vapors may travel

to an ignition source and flash back.

Section V - Reactivity Data

Stability: Stable Conditions to Avoid: Avoid contact of hot asphalt with heat, flame, or fluorine.

Asphalt cooled in a closed tank can evolve high concentrations of hydrogen sulfide

gas, carbon monoxide, and other aliphatic hydrocarbons.

Incompatibility (Materials to Avoid): When mixed with naphtha or other volatile solvents, asphalt may readily ignite.

Hazardous Decomposition or Byproducts: Thermal oxidative decomposition of asphalt can produce carbon monoxide, various

aliphatic hydrocarbons, and hydrogen sulfide. Inhalation of carbon monoxide and hydrogen sulfide produces tissue hypoxia

(insufficient oxygen). The various aliphatic hydrocarbons can also produce asphyxia.

Hazardous Polymerization: Will Not Occur Conditions to Avoid: Hazardous polymerization cannot occur. Avoid excessive

dust/fume generation and contact with incompatible materials listed above.

Section VI - Health Hazard Data

Route(s) of Entry: Inhalation? Yes Skin? Yes Ingestion? Unlikely

Health Hazards:

Acute Effects: Inhalation of hot asphalt fumes can cause headache, nausea, eye, and respiratory tract irritation, and nervousness due to

formation of hydrogen sulfide gas. Inhalation of hydrogen sulfide gas can cause upper respiratory tract irritation and, if exposure is

prolonged at levels above the OSHA PEL, pulmonary edema and even coma or death. Direct skin contact with hot asphalt produces a

scald-like lesion. The asphalt tends to adhere to the skin but may come off in blistered areas. Patchy areas of full thickness skin loss

are common. Eye exposure to hot asphalt also produces a direct thermal burn.

Cutting, grinding, crushing, or drilling hardened asphalt may generate dust containing crystalline silica. Acute effects of exposure to

such dust may include:

EYE CONTACT: Direct contact with dust may cause irritation by mechanical abrasion.

SKIN CONTACT: Direct contact may cause irritation by mechanical abrasion.

SKIN ABSORPTION: Not expected to be a significant route of exposure.

INGESTION: Expected to be relatively non-toxic. Ingestion of large amounts may cause gastrointestinal irritation and blockage.

INHALATION: Dusts may irritate the nose, throat, and respiratory tract by mechanical abrasion. Coughing, sneezing, and shortness of

breath may occur following exposures in excess of recommended exposure limits.

Use of asphalt for construction purposes is not believed to cause additional acute toxic effects. However, repeated overexposures to

very high levels of respirable crystalline silica (quartz, cristobalite, tridymite) for periods as short as six months have caused acute

Rinker Materials Corporation Page 3 of 5

MSDS for: Asphalt Effective Date: August 1, 2001

MSDS #0011 Revision: 2

silicosis. Acute silicosis is a rapidly progressive, incurable lung disease that is typically fatal. Symptoms include

Section VI - Health Hazard Data (continued)

(but are not limited to): shortness of breath, cough, fever, weight loss, and chest pain.

Chronic Effects: On prolonged or repeated exposure, asphalt fumes can cause dermatitis, acne-like lesions, mild keratosis ( a skin

disease marked by an overgrowth of horny tissue), melanosis, and photosensitization. Chronic inhalation exposure can cause chronic

pneumonitis and bronchitis.

Cutting, grinding, crushing, or drilling hardened asphalt can produce exposure to dust containing crystalline silica (quartz), which is a

cancer hazard if inhaled. Cancer risk depends on level and duration of exposure. Prolonged exposure to crystalline silica can also cause

silicosis, a progressive pneumoconiosis (lung disease).

Respirable dust containing newly broken silica particles has been shown to be more hazardous to animals in laboratory tests than

respirable dust containing older silica particles of similar size. Respirable silica particles which had aged for sixty days or more showed

less lung injury in animals than equal exposures of respirable dust containing newly broken particles of silica.

There are reports in the literature suggesting that excessive crystalline silica exposure may be associated with adverse health effects

involving the kidney, scleroderma (thickening of the skin caused by swelling and thickening of fibrous tissue) and other autoimmune

disorders. However, this evidence has been obtained primarily from case reports involving individuals working in high exposure

situations or those who have already developed silicosis; and therefore, this evidence does not conclusively prove a causal relationship

between silica or silicosis and these adverse health effects. Several studies of persons with silicosis also indicate an increased risk in

developing lung cancer, a risk that increases with duration of exposure. Many of these studies of silicotics do not account for lung

cancer confounders, especially smoking.

Carcinogenicity: The IARC, NTP and OSHA do not list asphalt as a carcinogen. However, liquid petroleum asphalt may contain

carcinogenic compounds. In general, oxidation of polycyclic aromatic hydrocarbons destroys their carcinogenic potential. Petroleum

asphalt, shale oil asphalts, and coal tars show distinct variations in their relative carcinogenicity for experimental animals. Diluting with

natural asphalts or converting to air-blown asphalt can reduce petroleum asphalt’s carcinogenicity. NIOSH describes asphalt as a

carcinogen with no further categorization.

Asphalt mix contains aggregate products which may contain crystalline silica. In October 1996, IARC classified respirable crystalline

silica from occupational sources as carcinogenic (Group 1). The NTP indicates that crystalline silica (respirable size) is a known

human carcinogen (Group 1). These classifications are based on sufficient evidence of carcinogenicity in certain experimental animals

and on selected epidemiological studies of workers exposed to crystalline silica.

Signs and Symptoms of Exposure: See acute and chronic health effects. Chronic exposure to respirable dust containing crystalline

silica in excess of applicable OSHA PELs , MSHA PELs, and ACGIH TLVs has caused silicosis, a progressive lung disease. Chronic

tobacco smoking may further increase the risk of developing chronic lung problems. Not all individuals with silicosis will exhibit

symptoms (signs) of the disease. However, silicosis is progressive, and symptoms can appear at any time, even years after exposures

have ceased. Symptoms of silicosis may include (but are not limited to): shortness of breath, difficulty breathing with or without

exertion, coughing, diminished work capacity, diminished chest expansion, reduction of lung volume, right heart enlargement and/or

failure. Persons with silicosis have an increased risk of pulmonary tuberculosis infection.

Medical Conditions Generally Aggravated by Exposure: Individuals with chronic respiratory disorders or skin diseases should

minimize inhalation and skin contact with asphalt. Inhaling respirable dust and/or crystalline silica may aggravate existing respiratory

system disease(s) or dysfunction. Exposure to dust may aggravate existing skin and/or eye conditions.

Physicians Note: Remove hardened asphalt and treat as a thermal burn. Apply liberal amounts of polysorbate over the affected area,

cover with wet dressings, and allow to remain for 6 hours. Consider applying commercially available sterile surfactant such as De-

Solv-It or Shur-Clens to wash away remaining asphalt. Skin grafting may be necessary.

Rinker Materials Corporation Page 4 of 5

MSDS for: Asphalt Effective Date: August 1, 2001

MSDS #0011 Revision: 2

Section VI - Health Hazard Data (continued)

Emergency and First Aid Procedures:

Eyes: For hot asphalt in eyes, gently lift the eyelids and flush immediately and continuously with flooding amounts of water until

transported to an emergency medical facility. Consult a physician immediately. For hardened asphalt dust in eyes, flush immediately

and continuously with running water for 15 minutes. Consult a physician if irritation persists.

Skin: Quickly remove contaminated clothing. Immerse asphalt covered skin in cool water until the material cools and hardens.

Transport to a medical facility immediately. For asphalt dust, wash skin thoroughly with soap and water. Consult a physician if

irritation persists.

Inhalation of dust or fume: Remove exposed person to fresh air and support breathing as needed. For dust inhalation, encourage

victim to cough, spit out, and blow nose to remove dust. Consult a physician immediately if irritation persists or later develops.

Ingestion: Oral ingestion of cool asphalt is relatively nontoxic. Never give anything by mouth to an unconscious or convulsing person.

Consult a physician immediately.

Section VII - Precautions for Safe Handling and Use

Steps to Be Taken in Case Material is Released or Spilled: If hot asphalt is spilled, notify safety personnel, evacuate all unnecessary

personnel, remove all heat and ignition sources, and provide maximum explosion-proof ventilation. Cleanup personnel should protect

against vapor inhalation and skin or eye contact. Use water spray to reduce vapors. For small spills, take up with sand or some

noncombustible inert material and place in appropriate containers for disposal. Dike far ahead of larger liquid spills and contain for

later disposal.

Waste Disposal Method: Follow applicable Federal, State, and local regulations. The material is not listed as a hazardous waste under

designations by the EPA or DOT.

Precautions to Be Taken in Handling and Storing: Store liquid asphalt in tightly closed containers in a cool, dry, well-ventilated

area away from heat and ignition sources. To prevent static sparks, electrically ground and bond all containers and equipment used in

shipping, receiving, or transferring operations in production and storage areas. Prevent containers from physical damage. Use

protective clothing and respirators, if needed, to minimize contact with material. See Section VIII.

Silica-containing respirable dust particles may be generated by handling, crushing, cutting, grinding, or drilling hardened asphalt.

Follow protective controls defined in Section VIII when handling these products.

Rinker Materials Corporation Page 5 of 5

MSDS for: Asphalt Effective Date: August 1, 2001

MSDS #0011 Revision: 2

Section VIII - Control Measures

Respiratory Protection: When exposed or likely to be exposed to fume, vapor, or dust (from cutting, grinding, crushing or drilling

hardened asphalt) above recommended limits, wear a suitable NIOSH-approved respirator with a protection factor appropriate for

the level of exposure. Seek guidance from a qualified industrial hygienist, safety professional, or other suitably knowledgeable

individual prior to respirator selection and use. For emergency or nonroutine operations (e.g., confined spaces), additional

precautions or equipment may be required. Respirator use must comply with applicable MSHA or OSHA standards, which include

provisions for a user training program, respirator repair and cleaning, respirator fit testing, and other requirements.

Ventilation Local Exhaust: Provide general or local explosion-proof ventilation Other: Respirable dust and quartz

systems, as needed, to maintain airborne dust and fume concentrations levels from cutting, grinding, crushing

below the OSHA PELs, MSHA PELs, and ACGIH TLVs. Local exhaust or drilling hardened asphalt should be

ventilation is preferred since it prevents release of contaminants into the monitored regularly. Dust and quartz

work area by controlling it at the source. levels in excess of applicable OSHA

PELs, MSHA PELs, and ACGIH

TLVs should be reduced by all

feasible engineering controls including

(but not limited to) wet suppression,

ventilation, process enclosure, and

enclosed employee work stations.

Mechanical (General): See above recommendations. Special: None reported

Protective Gloves: Wear impervious gloves, boots, aprons, and Eye Protection: Wear safety glasses with side shields

gauntlets to prevent skin contact. Wash skin thoroughly with soap and when working around hot asphalt. When handling hot

water after handling. asphalt, wear face shields.

Other Protective Clothing or Equipment: Wear suitable protective clothing, as needed, to prevent skin contact. Make available

(if necessary) the use of eyewash stations, quick drench showers, and suitable washing facilities.

Work/Hygienic Practices: Avoid inhalation of dusts, fumes, and vapors, and direct contact of hot asphalt with skin and eyes.

Wear gloves, impervious boots, and other protective gear when handling hot asphalt. If respiratory protection is used, institute a

respiratory protection program that includes regular training, inspection, maintenance, and evaluation. Practice good personal

hygiene and housekeeping procedures when using this product. After using the material, especially before eating, drinking,

smoking, lavatory use, and applying cosmetics, wash contaminated skin thoroughly with soap and water.

DISCLAIMER:

The information contained in this Material Safety Data Sheet relates only to the specific material designated herein and does not relate

to use in combination with any other material or in any process. The information set forth herein is based on technical data that the

Company believes to be accurate. It is intended for use by persons having technical skill and at their own discretion and risk. Since

conditions of use are outside the Company’s control, the Company makes no warranties, expressed or implied, and assumes no liability

in connection with any use of this information.

Rinker Materials Corporation Page 6 of 5

MSDS for: Asphalt Effective Date: August 1, 2001

MSDS #0011 Revision: 2

You might also like

- Breathe in New Mexico - Final ReportDocument33 pagesBreathe in New Mexico - Final ReportswopreaderNo ratings yet

- Textbook Part 3Document87 pagesTextbook Part 3CY OnuorahNo ratings yet

- Safety Data Sheet For Ready Mix ConcreteDocument4 pagesSafety Data Sheet For Ready Mix Concretealbarajeel forwarding001No ratings yet

- Material Safety Data Sheet For Concrete/Concrete Products : Section I-Product and Company IdentificationDocument5 pagesMaterial Safety Data Sheet For Concrete/Concrete Products : Section I-Product and Company Identificationmalaya tripathyNo ratings yet

- Pyrogel XTF AIS EnglishDocument5 pagesPyrogel XTF AIS EnglishramNo ratings yet

- MATERIAL-SAFETY-DATA-SHEET-08 CandFRMCDocument5 pagesMATERIAL-SAFETY-DATA-SHEET-08 CandFRMCMadison ChanNo ratings yet

- Vier Cylinders 2022Document5 pagesVier Cylinders 2022sobheysaidNo ratings yet

- MSDS Sanding SpongeDocument9 pagesMSDS Sanding Spongefebrin rohmanNo ratings yet

- Rex-Cut Cotton Fiber SDS - 2018Document7 pagesRex-Cut Cotton Fiber SDS - 2018BepdjNo ratings yet

- Components Battens Hi Bor Pressure Treated MsdsDocument3 pagesComponents Battens Hi Bor Pressure Treated MsdsBima MahendraNo ratings yet

- Safety Data Sheet: 3M™ Abrasive Products, 216U, 236UDocument9 pagesSafety Data Sheet: 3M™ Abrasive Products, 216U, 236Uzubair1951No ratings yet

- 0204-Greentherm 26 Li - (Usa)Document7 pages0204-Greentherm 26 Li - (Usa)adamdwaldropNo ratings yet

- MSDS 7440Document9 pagesMSDS 7440febrin rohmanNo ratings yet

- 321U Safety Data SheetDocument9 pages321U Safety Data SheetDaniel LealNo ratings yet

- MediawebserverDocument10 pagesMediawebserverfebrin rohmanNo ratings yet

- MSDS giấy nhám 3MDocument9 pagesMSDS giấy nhám 3MNguyễn Tiến DũngNo ratings yet

- Safety Data Sheet: Section 1 - Chemical Product / Company InformationDocument6 pagesSafety Data Sheet: Section 1 - Chemical Product / Company InformationAriel Rojas BarrientosNo ratings yet

- Fire Barrier 135 Msds PDFDocument8 pagesFire Barrier 135 Msds PDFE Hammam El MissiryNo ratings yet

- 048011-04029 27 AU EN safetyDataSheet Sds 8799831064580 0 1Document11 pages048011-04029 27 AU EN safetyDataSheet Sds 8799831064580 0 1Jonatan BernalNo ratings yet

- Msds Sealant 2Document4 pagesMsds Sealant 2Khairull AzwanNo ratings yet

- XZ677 (C, L) MSDS EngDocument5 pagesXZ677 (C, L) MSDS Engs_d_sudhirrajNo ratings yet

- Coated Abrasives Cat 5 USA 2022Document9 pagesCoated Abrasives Cat 5 USA 2022Nazım YıldırımNo ratings yet

- G-Rapid Plus PasteDocument14 pagesG-Rapid Plus PasteFandrio PermataNo ratings yet

- Msds SPC BambooDocument18 pagesMsds SPC BambooDevi AstriniNo ratings yet

- Msds Sample Usgs GSP 2 Art No 54480078 enDocument5 pagesMsds Sample Usgs GSP 2 Art No 54480078 enK59 Ha Hoang Thao MyNo ratings yet

- Form 5 For The Year 2017 18Document20 pagesForm 5 For The Year 2017 18rooftopsolarpower08No ratings yet

- Msds tk21, CuredDocument3 pagesMsds tk21, CuredBachrul UlumNo ratings yet

- Instructions On RE-FLAMEDocument5 pagesInstructions On RE-FLAMEDIEGONo ratings yet

- Safety Data Sheet: Threebond1282BDocument5 pagesSafety Data Sheet: Threebond1282BMarco CulquiNo ratings yet

- Flyash MSDSDocument6 pagesFlyash MSDSManuel CardosoNo ratings yet

- Msds Certificate: 1. Product and Company IdentificationDocument5 pagesMsds Certificate: 1. Product and Company IdentificationWaleed MedhatNo ratings yet

- Safety Data Sheet: Chemical Name Cas # Percent Classification NoteDocument6 pagesSafety Data Sheet: Chemical Name Cas # Percent Classification NotesharathNo ratings yet

- 500 Technical Questions Safety & FireDocument7 pages500 Technical Questions Safety & FireAbinesh ABNo ratings yet

- Carbolite - Todas Las Mallas FDS PDFDocument3 pagesCarbolite - Todas Las Mallas FDS PDFwilmerNo ratings yet

- Safety Data Sheet: Section 1 - Chemical Product / Company InformationDocument6 pagesSafety Data Sheet: Section 1 - Chemical Product / Company InformationNijin NpNo ratings yet

- Safety Data Sheet: 1. IdentificationDocument8 pagesSafety Data Sheet: 1. IdentificationPaul RamosNo ratings yet

- Scotch Brite VerdeDocument8 pagesScotch Brite VerdesantiagoNo ratings yet

- Battery Optima InterstateDocument4 pagesBattery Optima InterstateBatanNo ratings yet

- 51-Msds Planigrout 310 CDocument8 pages51-Msds Planigrout 310 CJanella ChancanNo ratings yet

- Dowwsil 791 Weather SealantDocument14 pagesDowwsil 791 Weather SealantMuhd HabiNo ratings yet

- Apex Msds - 27 Nov 2019Document6 pagesApex Msds - 27 Nov 2019Jason GlassNo ratings yet

- Perfumes (Fragrance Materials) : Ingredient Safety Information - Phys-Chem, Environmental Hazard and Fate DataDocument6 pagesPerfumes (Fragrance Materials) : Ingredient Safety Information - Phys-Chem, Environmental Hazard and Fate DatatnssbhaskarNo ratings yet

- Material Safety Data Sheet - SAN EARTHDocument3 pagesMaterial Safety Data Sheet - SAN EARTHPaulo CLNo ratings yet

- C SELLADOR U470612Document13 pagesC SELLADOR U470612fercas.dfcgNo ratings yet

- ZS 15890Document3 pagesZS 15890F.Javier LobeiraNo ratings yet

- Material Safety Data Sheet: Silicomanganese SlagDocument8 pagesMaterial Safety Data Sheet: Silicomanganese SlagbamboNo ratings yet

- Abc EnglishDocument8 pagesAbc EnglishshammyacNo ratings yet

- Msds For Skim CoatDocument8 pagesMsds For Skim Coatlovely palomaNo ratings yet

- Khảo sát tỉ lệ TiO2 2Document6 pagesKhảo sát tỉ lệ TiO2 2Nghĩa Tô TrungNo ratings yet

- Color Change Desiccant MSDSDocument5 pagesColor Change Desiccant MSDSAmir RahbariNo ratings yet

- CLT-K806S MsdsDocument9 pagesCLT-K806S MsdsChong Gyu SongNo ratings yet

- Available Data On Naphthalene Exposures: Strengths and LimitationsDocument42 pagesAvailable Data On Naphthalene Exposures: Strengths and LimitationsAmeet BandodkarNo ratings yet

- FGL 1Document9 pagesFGL 1Julio Pacheco SoberanisNo ratings yet

- Astec2000 Finish Coat MsdsDocument4 pagesAstec2000 Finish Coat MsdsFebrianto DimazNo ratings yet

- Carbon BLK SpecificationDocument2 pagesCarbon BLK Specificationmohsen siahpooshNo ratings yet

- Hempadur Primer 1530yDocument4 pagesHempadur Primer 1530yRodrigo CondorettyNo ratings yet

- R 405 SachtlebenDocument1 pageR 405 Sachtlebenmedo.k016No ratings yet

- Safety Data Sheet: 3M Brand Fire Barrier CP-25WB+Document12 pagesSafety Data Sheet: 3M Brand Fire Barrier CP-25WB+ErickoNo ratings yet

- MSDS N2XHDocument3 pagesMSDS N2XHH. NurzeinNo ratings yet

- Hindalco Esr Compliance Hirakud April19 March2020Document20 pagesHindalco Esr Compliance Hirakud April19 March2020amitav dashNo ratings yet

- RAL 9005 Jet Black 179A MSDSDocument4 pagesRAL 9005 Jet Black 179A MSDSSimonNo ratings yet

- Highly Efficient Methods for Sulfur Vulcanization Techniques, Results and Implications: Selection and Management of Rubber CurativesFrom EverandHighly Efficient Methods for Sulfur Vulcanization Techniques, Results and Implications: Selection and Management of Rubber CurativesNo ratings yet

- RBA Auditor Guide BookDocument18 pagesRBA Auditor Guide BookMichelleNo ratings yet

- Customer Complaint Handling Training 13485Document6 pagesCustomer Complaint Handling Training 13485Michelle100% (1)

- Brake Fluid MSDSDocument8 pagesBrake Fluid MSDSMichelleNo ratings yet

- Thank-You For Downloading The Final Validation Report Template!Document3 pagesThank-You For Downloading The Final Validation Report Template!MichelleNo ratings yet

- Thank-You For Downloading The SW Tool IQ-OQ-PQ Template!Document14 pagesThank-You For Downloading The SW Tool IQ-OQ-PQ Template!MichelleNo ratings yet

- ASQ Best Practices For Process ValidationDocument26 pagesASQ Best Practices For Process ValidationMichelleNo ratings yet

- Thank-You For Downloading The Project Management Plan Template!Document7 pagesThank-You For Downloading The Project Management Plan Template!MichelleNo ratings yet

- How To Write An Ebook & Sell It On Amazon in 5 Easy StepsDocument12 pagesHow To Write An Ebook & Sell It On Amazon in 5 Easy StepsMichelleNo ratings yet

- Test-1: GS Subject: (Insta Prelims Test Series 2023)Document24 pagesTest-1: GS Subject: (Insta Prelims Test Series 2023)Manan GhoshNo ratings yet

- Exogenous and Endogenous Pigment.....Document30 pagesExogenous and Endogenous Pigment.....Mohan ChoudharyNo ratings yet

- Material Safety Data Sheet Blended Cement FinalDocument14 pagesMaterial Safety Data Sheet Blended Cement FinalAndrea Dela CruzNo ratings yet

- Gangoso - Butuan CityDocument12 pagesGangoso - Butuan CityRafaela GangosoNo ratings yet

- Bentonite MSDSDocument10 pagesBentonite MSDSkhai ruleNo ratings yet

- Silicosis - A Case Report Case Report: Address of The CorrespondenceDocument3 pagesSilicosis - A Case Report Case Report: Address of The CorrespondenceBunga RamadhaniNo ratings yet

- C19 P04 PneumoconiosisDocument17 pagesC19 P04 PneumoconiosisChandana KrishnaNo ratings yet

- Manual de Fallas y Mantenimiento de Aceros Atlas CopcoDocument80 pagesManual de Fallas y Mantenimiento de Aceros Atlas CopcoLuis AsfuraNo ratings yet

- Safety Data Sheet ConcreteDocument6 pagesSafety Data Sheet ConcreteItalo RicardoNo ratings yet

- Silicosis: SeminarDocument11 pagesSilicosis: SeminarFelipe Barbosa CordeiroNo ratings yet

- Wet Disc Brake With Dowel Pins: Model W3H (360 MM) Maintenance Manual MM-20195Document52 pagesWet Disc Brake With Dowel Pins: Model W3H (360 MM) Maintenance Manual MM-20195Antonio MejicanosNo ratings yet

- Lafarge Terraflow en 190617Document12 pagesLafarge Terraflow en 190617Pat AuffretNo ratings yet

- Aioh Position Paper Rcs Update Sep2018 Final Unmarked DraftDocument19 pagesAioh Position Paper Rcs Update Sep2018 Final Unmarked Drafthitman1363No ratings yet

- OSHA3768Document6 pagesOSHA3768Shazayn KhanNo ratings yet

- Dust Lung DiseasesDocument38 pagesDust Lung Diseasesankitkumaramit99No ratings yet

- The Year in U.S. Occupational Health & Safety 2015Document64 pagesThe Year in U.S. Occupational Health & Safety 2015Celeste MonfortonNo ratings yet

- Health Hazards in Construction: John NewquistDocument45 pagesHealth Hazards in Construction: John NewquistAkhil VenugopalNo ratings yet

- Amended Silicate SorbDocument45 pagesAmended Silicate SorbAzeam AnjumNo ratings yet

- Best Sand Silica Sand and Gravel TDS 417Document2 pagesBest Sand Silica Sand and Gravel TDS 417Sandy BottomsNo ratings yet

- br420 ManualDocument70 pagesbr420 ManualCitlali MoránNo ratings yet

- MSDS BentonitaDocument5 pagesMSDS BentonitaKitsuneMasterNo ratings yet

- Artista Columns ManualDocument24 pagesArtista Columns ManualsotirisNo ratings yet

- Dgms Circular 2010Document33 pagesDgms Circular 2010Ajeet Kumar100% (1)

- Msds p500 NagpurDocument7 pagesMsds p500 NagpurAnkur BarsainyaNo ratings yet

- Restrictive Lung Diseases.Document59 pagesRestrictive Lung Diseases.Salman KhanNo ratings yet

- Material Safety Data Sheet: S100 70/140-Mesh Sand S100Document7 pagesMaterial Safety Data Sheet: S100 70/140-Mesh Sand S100sajad gohariNo ratings yet

- Fundamentals of Hazard Management PDFDocument226 pagesFundamentals of Hazard Management PDFMogana GunasigrenNo ratings yet

- Meritor Wedge BrakesDocument32 pagesMeritor Wedge Brakespankituna5487No ratings yet