Professional Documents

Culture Documents

Model 3:1 Pilot Ratio, Vented Counterbalance Valve: SERIES 4 / CAPACITY: 480 L/min. / CAVITY: T-24A

Model 3:1 Pilot Ratio, Vented Counterbalance Valve: SERIES 4 / CAPACITY: 480 L/min. / CAVITY: T-24A

Uploaded by

Андрей9Copyright:

You might also like

- CFII Instrument Oral Exam GuideDocument14 pagesCFII Instrument Oral Exam GuideRichard Mitchell82% (11)

- Zapi Dual Ace2Document169 pagesZapi Dual Ace2Андрей9No ratings yet

- Zapi MPBDocument58 pagesZapi MPBАндрей9100% (4)

- Wipro Oracle Solutions HandbookDocument40 pagesWipro Oracle Solutions Handbookjennyosh88No ratings yet

- Modelo Proporción de Pilotaje 5:1, Venteado (A) Contrabalance VálvulaDocument2 pagesModelo Proporción de Pilotaje 5:1, Venteado (A) Contrabalance VálvulaManuel Patricio Gonzalez SanhuezaNo ratings yet

- CBGA Full en Us A4Document2 pagesCBGA Full en Us A4Epul HaqNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveVignesh PandiyanNo ratings yet

- CBCY Full en Us LetterDocument2 pagesCBCY Full en Us LetterVentas Control HidráulicoNo ratings yet

- Model Vented, 3:1 Pilot Ratio, Load Reactive, Load Control ValveDocument2 pagesModel Vented, 3:1 Pilot Ratio, Load Reactive, Load Control ValveRonildo - HydraparNo ratings yet

- Model 1.5:1 Pilot Ratio, Semi-Restrictive Counterbalance ValveDocument2 pagesModel 1.5:1 Pilot Ratio, Semi-Restrictive Counterbalance ValveVignesh PandiyanNo ratings yet

- Model 10:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 10:1 Pilot Ratio, Standard Capacity Counterbalance ValveVignesh PandiyanNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValvemateusT850No ratings yet

- CBEALBN Full en Us LetterDocument2 pagesCBEALBN Full en Us Letterangelo.araza0913No ratings yet

- Model 1.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 1.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveVignesh PandiyanNo ratings yet

- Model 3:1 Pilot Ratio, Vented Counterbalance Valve - Atmospherically ReferencedDocument2 pagesModel 3:1 Pilot Ratio, Vented Counterbalance Valve - Atmospherically ReferencedVinit ChoudharyNo ratings yet

- CBCA Es Metric A4Document1 pageCBCA Es Metric A4martin.riosNo ratings yet

- Contrabalance SunHydraulicDocument2 pagesContrabalance SunHydraulicMatias Oñate ArriagadaNo ratings yet

- CBEALAN Full Es Metric LetterDocument2 pagesCBEALAN Full Es Metric Letternicole tapiaNo ratings yet

- Model 1.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 1.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveVignesh PandiyanNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveLennyn Mamani VenturaNo ratings yet

- Model 4.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 4.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveAnurag JainNo ratings yet

- Model 1.5:1 Pilot Ratio, Semi-Restrictive Counterbalance ValveDocument2 pagesModel 1.5:1 Pilot Ratio, Semi-Restrictive Counterbalance ValveVignesh PandiyanNo ratings yet

- CBEWLJN Full en Metric A4Document2 pagesCBEWLJN Full en Metric A4Ηρακλης ΤσαπραζηςNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveAlaa saidNo ratings yet

- Model 2.3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 2.3:1 Pilot Ratio, Standard Capacity Counterbalance ValveErasmo LimaNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity, Loadadaptive™ Counterbalance ValveDocument1 pageModel 3:1 Pilot Ratio, Standard Capacity, Loadadaptive™ Counterbalance ValveAlexis PeñaNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 3:1 Pilot Ratio, Standard Capacity Counterbalance Valveதமிழன் இராமசாமிNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument1 pageModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveMuhtadin RizkiNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveJavier AriasNo ratings yet

- CBGH Full en Us LetterDocument2 pagesCBGH Full en Us LetterPrakash VasudevanNo ratings yet

- Model Vented, 3:1 Pilot Ratio, Load Reactive, Load Control ValveDocument1 pageModel Vented, 3:1 Pilot Ratio, Load Reactive, Load Control ValveRonildo - HydraparNo ratings yet

- CAEGCGN Full en Us A4Document2 pagesCAEGCGN Full en Us A4david mendozaNo ratings yet

- Valvula Contrabalance CBGA LIN HCLDocument2 pagesValvula Contrabalance CBGA LIN HCLcarlos pachecoNo ratings yet

- Modelo Proporción de Pilotaje 2:1, Restrictiva Contrabalance VálvulaDocument1 pageModelo Proporción de Pilotaje 2:1, Restrictiva Contrabalance VálvulaErasmo LimaNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument1 pageModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveRonildo - HydraparNo ratings yet

- Model 10:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 10:1 Pilot Ratio, Standard Capacity Counterbalance ValveVignesh PandiyanNo ratings yet

- Model 50%, Accumulator Sense, Pump Unload Valve - Pilot CapacityDocument2 pagesModel 50%, Accumulator Sense, Pump Unload Valve - Pilot CapacityleosignareNo ratings yet

- Model Anti-Shock, Pilot-Operated, Balanced Poppet Relief ValveDocument2 pagesModel Anti-Shock, Pilot-Operated, Balanced Poppet Relief ValveJustinNo ratings yet

- Cbcalin ValveDocument2 pagesCbcalin ValveArun51092No ratings yet

- RDJA Full en Metric LetterDocument2 pagesRDJA Full en Metric LetteressamNo ratings yet

- Sun Hydraulics CWEL Technical SpecificationsDocument1 pageSun Hydraulics CWEL Technical SpecificationsJustinNo ratings yet

- 5 - Counter Balance Valve TSCA 70-10 - CBCHDocument4 pages5 - Counter Balance Valve TSCA 70-10 - CBCHIvan MaltsevNo ratings yet

- Direct-Acting Relief Valve: DownloadDocument2 pagesDirect-Acting Relief Valve: Downloadaristi51No ratings yet

- CCCALBN Full en Us LetterDocument2 pagesCCCALBN Full en Us Letterisaiahsamsonm_948069No ratings yet

- RDHA - Direct-Acting Relief ValveDocument3 pagesRDHA - Direct-Acting Relief ValvezengguoxuanNo ratings yet

- CACLLGN en Us A4Document1 pageCACLLGN en Us A42fqdw8s8yxNo ratings yet

- Model 4.5:1 Pilot Ratio, Ultra-Restrictive Counterbalance ValveDocument1 pageModel 4.5:1 Pilot Ratio, Ultra-Restrictive Counterbalance ValveRinaldo BompieriNo ratings yet

- CAIGLGN Full en Us A4Document2 pagesCAIGLGN Full en Us A4david mendozaNo ratings yet

- RDHA Full en Metric LetterasdDocument2 pagesRDHA Full en Metric LetterasdessamNo ratings yet

- CBGG Es Metric LetterDocument2 pagesCBGG Es Metric LetterjesusNo ratings yet

- CBIALAN en Metric Letter PDFDocument1 pageCBIALAN en Metric Letter PDFPritesh KoratNo ratings yet

- CBIALAN en Metric Letter PDFDocument1 pageCBIALAN en Metric Letter PDFPritesh KoratNo ratings yet

- Pump Unload Pilot Valve SUN QPABDocument2 pagesPump Unload Pilot Valve SUN QPABankesh_ghoghariNo ratings yet

- RPGC Full en Us A4Document2 pagesRPGC Full en Us A4zapchasty29No ratings yet

- Sun Hydraulics MWEB-LJN Technical SpecificationsDocument1 pageSun Hydraulics MWEB-LJN Technical SpecificationsJustinNo ratings yet

- RPEI Full en Metric LetterDocument4 pagesRPEI Full en Metric LetteressamNo ratings yet

- Model 2.3:1 Pilot Ratio, Semi-Restrictive Counterbalance ValveDocument1 pageModel 2.3:1 Pilot Ratio, Semi-Restrictive Counterbalance ValveCorradoNo ratings yet

- Sun Hydraulics-Cbca Lan EccDocument5 pagesSun Hydraulics-Cbca Lan EcchendntdNo ratings yet

- CBGGLJN_en_us_a4Document1 pageCBGGLJN_en_us_a4sony SonyNo ratings yet

- CBCALHN-EAC Full en Us LetterDocument5 pagesCBCALHN-EAC Full en Us LetterVentas Control HidráulicoNo ratings yet

- Pressure Reducing - Relieving Valve PRFBDocument3 pagesPressure Reducing - Relieving Valve PRFBkocho79No ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- AMPSEAL Automotive Plug Connector and Header Assembly: Application SpecificationDocument9 pagesAMPSEAL Automotive Plug Connector and Header Assembly: Application SpecificationАндрей9No ratings yet

- 23-Position Connector Shown, See Table Below For Alternate DimensionsDocument2 pages23-Position Connector Shown, See Table Below For Alternate DimensionsАндрей9No ratings yet

- RX User ManualDocument25 pagesRX User ManualАндрей9No ratings yet

- Zapi M..WDocument64 pagesZapi M..WАндрей9No ratings yet

- Ace5 Inverter: User ManualDocument72 pagesAce5 Inverter: User ManualАндрей9No ratings yet

- Ace3 Inverter: User ManualDocument139 pagesAce3 Inverter: User ManualАндрей9No ratings yet

- Lenovo B40Document96 pagesLenovo B40Alberto JiménezNo ratings yet

- Breviar de Calcul - Cos C.R.Document63 pagesBreviar de Calcul - Cos C.R.tulvyNo ratings yet

- Automobile IndustryDocument30 pagesAutomobile IndustrychakshuNo ratings yet

- Arc Flash Hazard Analysis/Short-Circuit/Coordination Study: Part 1 GeneralDocument7 pagesArc Flash Hazard Analysis/Short-Circuit/Coordination Study: Part 1 GeneraladhyarthaNo ratings yet

- RAYCHEM - EPKT Terminations: Termination Systems For Polymeric and MIND Paper Insulated Cables From 7.2kV Up To 36kVDocument1 pageRAYCHEM - EPKT Terminations: Termination Systems For Polymeric and MIND Paper Insulated Cables From 7.2kV Up To 36kVStephen BridgesNo ratings yet

- Bayes TheoremDocument15 pagesBayes TheoremRahul EkhandeNo ratings yet

- ETS 0071 Am 1Document17 pagesETS 0071 Am 1AnthonyNo ratings yet

- Codigo Del DESDocument6 pagesCodigo Del DESwilkeni94No ratings yet

- Automatic Sectionalizing Link: Life Cycle Cost - Cooper Bussmann vs. CompetitorDocument2 pagesAutomatic Sectionalizing Link: Life Cycle Cost - Cooper Bussmann vs. CompetitorNguyen Anh TuNo ratings yet

- INtroduction To Thin Film Transistor PDFDocument494 pagesINtroduction To Thin Film Transistor PDFBheim LlonaNo ratings yet

- Electro Beam Lithography and X Ray LithographyDocument4 pagesElectro Beam Lithography and X Ray LithographyRia Rushin JosephNo ratings yet

- S1100 Ventilator Machine: Adult PediatricDocument4 pagesS1100 Ventilator Machine: Adult PediatricRay FNNo ratings yet

- (Mechanical Engineering Series) Krzysztof Czolczynski (Auth.) - Rotordynamics of Gas-Lubricated Journal Bearing Systems-SpringDocument155 pages(Mechanical Engineering Series) Krzysztof Czolczynski (Auth.) - Rotordynamics of Gas-Lubricated Journal Bearing Systems-SpringsaurabhchandrakerNo ratings yet

- SeparatorsDigest 1999 1 enDocument28 pagesSeparatorsDigest 1999 1 enRicardo LopezNo ratings yet

- WebADM ManualDocument76 pagesWebADM Manualgeorges17100% (1)

- Problem Strength)Document13 pagesProblem Strength)Arjean VelascoNo ratings yet

- Manual Simatic S7-200 em 1hDocument53 pagesManual Simatic S7-200 em 1hbigopostNo ratings yet

- MiVoice Business NCR - Tech Update - R8.0 Iss 1Document60 pagesMiVoice Business NCR - Tech Update - R8.0 Iss 1Guillaume HochainNo ratings yet

- E6566 Code List CodeMyCarDocument1 pageE6566 Code List CodeMyCarAudrius StarostenkoNo ratings yet

- PEP Onshore PipelineDocument76 pagesPEP Onshore PipelineYudha MaulanaNo ratings yet

- Problems in Cementing Horizontal Wells: Fred L. SabinsDocument3 pagesProblems in Cementing Horizontal Wells: Fred L. SabinsCoolProphetNo ratings yet

- Iso 4586Document14 pagesIso 4586ms_macadamiaNo ratings yet

- Electromagnetic Field: Jump ToDocument9 pagesElectromagnetic Field: Jump ToidigitiNo ratings yet

- Thermosolar Catalogue PDFDocument28 pagesThermosolar Catalogue PDFbagastcNo ratings yet

- CBLM For Eim TMDocument57 pagesCBLM For Eim TMrommel montilla100% (2)

- Vocabulary For IELTSDocument6 pagesVocabulary For IELTShananhdNo ratings yet

- Meeting Room ChecklistDocument2 pagesMeeting Room ChecklistLartoonNo ratings yet

- TurbiinikalvotDocument32 pagesTurbiinikalvotAbdalmalek shamsanNo ratings yet

Model 3:1 Pilot Ratio, Vented Counterbalance Valve: SERIES 4 / CAPACITY: 480 L/min. / CAVITY: T-24A

Model 3:1 Pilot Ratio, Vented Counterbalance Valve: SERIES 4 / CAPACITY: 480 L/min. / CAVITY: T-24A

Uploaded by

Андрей9Original Description:

Original Title

Copyright

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Model 3:1 Pilot Ratio, Vented Counterbalance Valve: SERIES 4 / CAPACITY: 480 L/min. / CAVITY: T-24A

Model 3:1 Pilot Ratio, Vented Counterbalance Valve: SERIES 4 / CAPACITY: 480 L/min. / CAVITY: T-24A

Uploaded by

Андрей9Copyright:

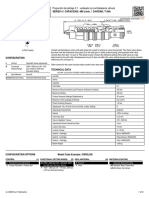

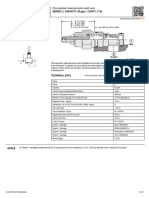

MODEL 3:1 pilot ratio, vented counterbalance valve

CWIA SERIES 4 / CAPACITY: 480 L/min. / CAVITY: T-24A

sunhydraulics.com/model/CWIA

4-Port Vented

Vented counterbalance valves with pilot assist are meant to control an overrunning load. The check valve allows

free flow from the directional valve (port 2) to the load (port 1) while a direct-acting, pilot-assisted relief valve

controls flow from port 1 to port 2. Pilot assist at port 3 lowers the effective setting of the relief valve at a rate

determined by the pilot ratio. Backpressure at port 2 does not affect the valve setting because the spring chamber

references the vent (port 4).

Other names for this valve include motion control valve and over-center valve.

4-Port Vented, Non-adjustable

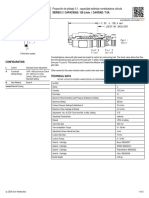

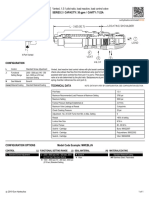

TECHNICAL DATA NOTE: DATA MAY VARY BY CONFIGURATION. SEE CONFIGURATION SECTION.

Cavity T-24A

Series 4

Capacity 480 L/min.

Pilot Ratio 3:1

Maximum Recommended Load Pressure at Maximum Setting 215 bar

Maximum Setting 280 bar

Factory Pressure Settings Established at 30 cc/min.

Maximum Valve Leakage at Reseat 0,3 cc/min.

Check Cracking Pressure 1,5 bar

Adjustment - No. of CCW Turns from Min. to Max. Setting 5

Operating Characteristic Standard

Reseat >85% of setting

Valve Hex Size 41,3 mm

Valve Installation Torque 474 - 508 Nm

Adjustment Screw Internal Hex Size 4 mm

Locknut Hex Size 15 mm

Locknut Torque 9 - 10 Nm

Seal kit - Cartridge Buna: 990024007

Seal kit - Cartridge Polyurethane: 990024002

Seal kit - Cartridge Viton: 990024006

Model Weight 1.60 kg.

c 2019 Sun Hydraulics

1 of 2

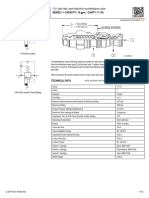

CONFIGURATION OPTIONS Model Code Example: CWIALHN

CONTROL (L) FUNCTIONAL SETTING RANGE (H) SEAL MATERIAL (N) MATERIAL/COATING

L Standard Screw Adjustment H 1000 - 4000 psi (70 - 280 bar), 3000 psi N Buna-N Standard Material/Coating

C Tamper Resistant - Factory Set (210 bar) Standard Setting E EPDM /AP Stainless Steel, Passivated

I 400 - 1500 psi (28 - 105 bar), 1000 psi V Viton /LH Mild Steel, Zinc-Nickel

(70 bar) Standard Setting

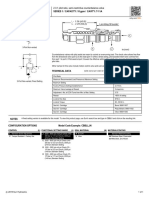

TECHNICAL FEATURES

Counterbalance valves should be set at least 1.3 times the maximum load induced pressure.

Turn adjustment clockwise to decrease setting and release load.

Full clockwise setting is 200 psi (14 bar).

All 4-port counterbalance, load control, and pilot-to-open check cartridges are physically interchangeable (i.e. same flow path, same cavity for a given frame size).

Reseat exceeds 85% of set pressure when the valve is standard set. Settings lower than the standard set pressure may result in lower reseat percentages.

Pressure at port 4 is added to the effective relief setting at a rate of 1 plus the pilot ratio times the pressure.

Sun counterbalance cartridges can be installed directly into a cavity machined in an actuator housing for added protection and improved stiffness in the circuit.

This valve has positive seals between all ports.

With vented valves, a lower pilot ratio may be required to achieve machine stability compared to non-vented valves.

Incorporates the Sun floating style construction to minimize the possibility of internal parts binding due to excessive installation torque and/or cavity/cartridge

machining variations.

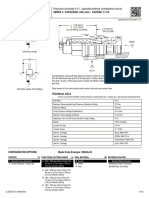

PERFORMANCE CURVES

c 2019 Sun Hydraulics

2 of 2

You might also like

- CFII Instrument Oral Exam GuideDocument14 pagesCFII Instrument Oral Exam GuideRichard Mitchell82% (11)

- Zapi Dual Ace2Document169 pagesZapi Dual Ace2Андрей9No ratings yet

- Zapi MPBDocument58 pagesZapi MPBАндрей9100% (4)

- Wipro Oracle Solutions HandbookDocument40 pagesWipro Oracle Solutions Handbookjennyosh88No ratings yet

- Modelo Proporción de Pilotaje 5:1, Venteado (A) Contrabalance VálvulaDocument2 pagesModelo Proporción de Pilotaje 5:1, Venteado (A) Contrabalance VálvulaManuel Patricio Gonzalez SanhuezaNo ratings yet

- CBGA Full en Us A4Document2 pagesCBGA Full en Us A4Epul HaqNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveVignesh PandiyanNo ratings yet

- CBCY Full en Us LetterDocument2 pagesCBCY Full en Us LetterVentas Control HidráulicoNo ratings yet

- Model Vented, 3:1 Pilot Ratio, Load Reactive, Load Control ValveDocument2 pagesModel Vented, 3:1 Pilot Ratio, Load Reactive, Load Control ValveRonildo - HydraparNo ratings yet

- Model 1.5:1 Pilot Ratio, Semi-Restrictive Counterbalance ValveDocument2 pagesModel 1.5:1 Pilot Ratio, Semi-Restrictive Counterbalance ValveVignesh PandiyanNo ratings yet

- Model 10:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 10:1 Pilot Ratio, Standard Capacity Counterbalance ValveVignesh PandiyanNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValvemateusT850No ratings yet

- CBEALBN Full en Us LetterDocument2 pagesCBEALBN Full en Us Letterangelo.araza0913No ratings yet

- Model 1.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 1.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveVignesh PandiyanNo ratings yet

- Model 3:1 Pilot Ratio, Vented Counterbalance Valve - Atmospherically ReferencedDocument2 pagesModel 3:1 Pilot Ratio, Vented Counterbalance Valve - Atmospherically ReferencedVinit ChoudharyNo ratings yet

- CBCA Es Metric A4Document1 pageCBCA Es Metric A4martin.riosNo ratings yet

- Contrabalance SunHydraulicDocument2 pagesContrabalance SunHydraulicMatias Oñate ArriagadaNo ratings yet

- CBEALAN Full Es Metric LetterDocument2 pagesCBEALAN Full Es Metric Letternicole tapiaNo ratings yet

- Model 1.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 1.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveVignesh PandiyanNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveLennyn Mamani VenturaNo ratings yet

- Model 4.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 4.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveAnurag JainNo ratings yet

- Model 1.5:1 Pilot Ratio, Semi-Restrictive Counterbalance ValveDocument2 pagesModel 1.5:1 Pilot Ratio, Semi-Restrictive Counterbalance ValveVignesh PandiyanNo ratings yet

- CBEWLJN Full en Metric A4Document2 pagesCBEWLJN Full en Metric A4Ηρακλης ΤσαπραζηςNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveAlaa saidNo ratings yet

- Model 2.3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 2.3:1 Pilot Ratio, Standard Capacity Counterbalance ValveErasmo LimaNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity, Loadadaptive™ Counterbalance ValveDocument1 pageModel 3:1 Pilot Ratio, Standard Capacity, Loadadaptive™ Counterbalance ValveAlexis PeñaNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 3:1 Pilot Ratio, Standard Capacity Counterbalance Valveதமிழன் இராமசாமிNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument1 pageModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveMuhtadin RizkiNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveJavier AriasNo ratings yet

- CBGH Full en Us LetterDocument2 pagesCBGH Full en Us LetterPrakash VasudevanNo ratings yet

- Model Vented, 3:1 Pilot Ratio, Load Reactive, Load Control ValveDocument1 pageModel Vented, 3:1 Pilot Ratio, Load Reactive, Load Control ValveRonildo - HydraparNo ratings yet

- CAEGCGN Full en Us A4Document2 pagesCAEGCGN Full en Us A4david mendozaNo ratings yet

- Valvula Contrabalance CBGA LIN HCLDocument2 pagesValvula Contrabalance CBGA LIN HCLcarlos pachecoNo ratings yet

- Modelo Proporción de Pilotaje 2:1, Restrictiva Contrabalance VálvulaDocument1 pageModelo Proporción de Pilotaje 2:1, Restrictiva Contrabalance VálvulaErasmo LimaNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument1 pageModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveRonildo - HydraparNo ratings yet

- Model 10:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 10:1 Pilot Ratio, Standard Capacity Counterbalance ValveVignesh PandiyanNo ratings yet

- Model 50%, Accumulator Sense, Pump Unload Valve - Pilot CapacityDocument2 pagesModel 50%, Accumulator Sense, Pump Unload Valve - Pilot CapacityleosignareNo ratings yet

- Model Anti-Shock, Pilot-Operated, Balanced Poppet Relief ValveDocument2 pagesModel Anti-Shock, Pilot-Operated, Balanced Poppet Relief ValveJustinNo ratings yet

- Cbcalin ValveDocument2 pagesCbcalin ValveArun51092No ratings yet

- RDJA Full en Metric LetterDocument2 pagesRDJA Full en Metric LetteressamNo ratings yet

- Sun Hydraulics CWEL Technical SpecificationsDocument1 pageSun Hydraulics CWEL Technical SpecificationsJustinNo ratings yet

- 5 - Counter Balance Valve TSCA 70-10 - CBCHDocument4 pages5 - Counter Balance Valve TSCA 70-10 - CBCHIvan MaltsevNo ratings yet

- Direct-Acting Relief Valve: DownloadDocument2 pagesDirect-Acting Relief Valve: Downloadaristi51No ratings yet

- CCCALBN Full en Us LetterDocument2 pagesCCCALBN Full en Us Letterisaiahsamsonm_948069No ratings yet

- RDHA - Direct-Acting Relief ValveDocument3 pagesRDHA - Direct-Acting Relief ValvezengguoxuanNo ratings yet

- CACLLGN en Us A4Document1 pageCACLLGN en Us A42fqdw8s8yxNo ratings yet

- Model 4.5:1 Pilot Ratio, Ultra-Restrictive Counterbalance ValveDocument1 pageModel 4.5:1 Pilot Ratio, Ultra-Restrictive Counterbalance ValveRinaldo BompieriNo ratings yet

- CAIGLGN Full en Us A4Document2 pagesCAIGLGN Full en Us A4david mendozaNo ratings yet

- RDHA Full en Metric LetterasdDocument2 pagesRDHA Full en Metric LetterasdessamNo ratings yet

- CBGG Es Metric LetterDocument2 pagesCBGG Es Metric LetterjesusNo ratings yet

- CBIALAN en Metric Letter PDFDocument1 pageCBIALAN en Metric Letter PDFPritesh KoratNo ratings yet

- CBIALAN en Metric Letter PDFDocument1 pageCBIALAN en Metric Letter PDFPritesh KoratNo ratings yet

- Pump Unload Pilot Valve SUN QPABDocument2 pagesPump Unload Pilot Valve SUN QPABankesh_ghoghariNo ratings yet

- RPGC Full en Us A4Document2 pagesRPGC Full en Us A4zapchasty29No ratings yet

- Sun Hydraulics MWEB-LJN Technical SpecificationsDocument1 pageSun Hydraulics MWEB-LJN Technical SpecificationsJustinNo ratings yet

- RPEI Full en Metric LetterDocument4 pagesRPEI Full en Metric LetteressamNo ratings yet

- Model 2.3:1 Pilot Ratio, Semi-Restrictive Counterbalance ValveDocument1 pageModel 2.3:1 Pilot Ratio, Semi-Restrictive Counterbalance ValveCorradoNo ratings yet

- Sun Hydraulics-Cbca Lan EccDocument5 pagesSun Hydraulics-Cbca Lan EcchendntdNo ratings yet

- CBGGLJN_en_us_a4Document1 pageCBGGLJN_en_us_a4sony SonyNo ratings yet

- CBCALHN-EAC Full en Us LetterDocument5 pagesCBCALHN-EAC Full en Us LetterVentas Control HidráulicoNo ratings yet

- Pressure Reducing - Relieving Valve PRFBDocument3 pagesPressure Reducing - Relieving Valve PRFBkocho79No ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- AMPSEAL Automotive Plug Connector and Header Assembly: Application SpecificationDocument9 pagesAMPSEAL Automotive Plug Connector and Header Assembly: Application SpecificationАндрей9No ratings yet

- 23-Position Connector Shown, See Table Below For Alternate DimensionsDocument2 pages23-Position Connector Shown, See Table Below For Alternate DimensionsАндрей9No ratings yet

- RX User ManualDocument25 pagesRX User ManualАндрей9No ratings yet

- Zapi M..WDocument64 pagesZapi M..WАндрей9No ratings yet

- Ace5 Inverter: User ManualDocument72 pagesAce5 Inverter: User ManualАндрей9No ratings yet

- Ace3 Inverter: User ManualDocument139 pagesAce3 Inverter: User ManualАндрей9No ratings yet

- Lenovo B40Document96 pagesLenovo B40Alberto JiménezNo ratings yet

- Breviar de Calcul - Cos C.R.Document63 pagesBreviar de Calcul - Cos C.R.tulvyNo ratings yet

- Automobile IndustryDocument30 pagesAutomobile IndustrychakshuNo ratings yet

- Arc Flash Hazard Analysis/Short-Circuit/Coordination Study: Part 1 GeneralDocument7 pagesArc Flash Hazard Analysis/Short-Circuit/Coordination Study: Part 1 GeneraladhyarthaNo ratings yet

- RAYCHEM - EPKT Terminations: Termination Systems For Polymeric and MIND Paper Insulated Cables From 7.2kV Up To 36kVDocument1 pageRAYCHEM - EPKT Terminations: Termination Systems For Polymeric and MIND Paper Insulated Cables From 7.2kV Up To 36kVStephen BridgesNo ratings yet

- Bayes TheoremDocument15 pagesBayes TheoremRahul EkhandeNo ratings yet

- ETS 0071 Am 1Document17 pagesETS 0071 Am 1AnthonyNo ratings yet

- Codigo Del DESDocument6 pagesCodigo Del DESwilkeni94No ratings yet

- Automatic Sectionalizing Link: Life Cycle Cost - Cooper Bussmann vs. CompetitorDocument2 pagesAutomatic Sectionalizing Link: Life Cycle Cost - Cooper Bussmann vs. CompetitorNguyen Anh TuNo ratings yet

- INtroduction To Thin Film Transistor PDFDocument494 pagesINtroduction To Thin Film Transistor PDFBheim LlonaNo ratings yet

- Electro Beam Lithography and X Ray LithographyDocument4 pagesElectro Beam Lithography and X Ray LithographyRia Rushin JosephNo ratings yet

- S1100 Ventilator Machine: Adult PediatricDocument4 pagesS1100 Ventilator Machine: Adult PediatricRay FNNo ratings yet

- (Mechanical Engineering Series) Krzysztof Czolczynski (Auth.) - Rotordynamics of Gas-Lubricated Journal Bearing Systems-SpringDocument155 pages(Mechanical Engineering Series) Krzysztof Czolczynski (Auth.) - Rotordynamics of Gas-Lubricated Journal Bearing Systems-SpringsaurabhchandrakerNo ratings yet

- SeparatorsDigest 1999 1 enDocument28 pagesSeparatorsDigest 1999 1 enRicardo LopezNo ratings yet

- WebADM ManualDocument76 pagesWebADM Manualgeorges17100% (1)

- Problem Strength)Document13 pagesProblem Strength)Arjean VelascoNo ratings yet

- Manual Simatic S7-200 em 1hDocument53 pagesManual Simatic S7-200 em 1hbigopostNo ratings yet

- MiVoice Business NCR - Tech Update - R8.0 Iss 1Document60 pagesMiVoice Business NCR - Tech Update - R8.0 Iss 1Guillaume HochainNo ratings yet

- E6566 Code List CodeMyCarDocument1 pageE6566 Code List CodeMyCarAudrius StarostenkoNo ratings yet

- PEP Onshore PipelineDocument76 pagesPEP Onshore PipelineYudha MaulanaNo ratings yet

- Problems in Cementing Horizontal Wells: Fred L. SabinsDocument3 pagesProblems in Cementing Horizontal Wells: Fred L. SabinsCoolProphetNo ratings yet

- Iso 4586Document14 pagesIso 4586ms_macadamiaNo ratings yet

- Electromagnetic Field: Jump ToDocument9 pagesElectromagnetic Field: Jump ToidigitiNo ratings yet

- Thermosolar Catalogue PDFDocument28 pagesThermosolar Catalogue PDFbagastcNo ratings yet

- CBLM For Eim TMDocument57 pagesCBLM For Eim TMrommel montilla100% (2)

- Vocabulary For IELTSDocument6 pagesVocabulary For IELTShananhdNo ratings yet

- Meeting Room ChecklistDocument2 pagesMeeting Room ChecklistLartoonNo ratings yet

- TurbiinikalvotDocument32 pagesTurbiinikalvotAbdalmalek shamsanNo ratings yet