Professional Documents

Culture Documents

Hvac Data Sheet For For Fahahil South - Gate House: DOC No.:3507-FAHS-9-13-0002 REV.# 0 Page 2 of 5

Hvac Data Sheet For For Fahahil South - Gate House: DOC No.:3507-FAHS-9-13-0002 REV.# 0 Page 2 of 5

Uploaded by

Selvaraj BalajiCopyright:

Available Formats

You might also like

- Switching Power Supply Design: A Concise Practical HandbookFrom EverandSwitching Power Supply Design: A Concise Practical HandbookNo ratings yet

- Data Sheet For PSVDocument1 pageData Sheet For PSVBABILIN VNo ratings yet

- Ycua Ydf (Tech. Guide) 2Document20 pagesYcua Ydf (Tech. Guide) 2Elmer80% (5)

- Ap2d Pump SeriesDocument12 pagesAp2d Pump SeriesAdal Vera60% (5)

- Pressure Safety Valve-Preliminary Sizing: Input DataDocument6 pagesPressure Safety Valve-Preliminary Sizing: Input DataPIDNo ratings yet

- MAVSP-P19002-W01-M-DS-0002 Rev. 0 Data sheet for Fire Pumps (Elctrical, Diesel and Jockey)Document16 pagesMAVSP-P19002-W01-M-DS-0002 Rev. 0 Data sheet for Fire Pumps (Elctrical, Diesel and Jockey)fendi zulfiantoNo ratings yet

- Himod UsuarioDocument76 pagesHimod UsuarioJuanita Pardo MirandaNo ratings yet

- 141014.datasheet For PSV-1323Document2 pages141014.datasheet For PSV-1323ocanhthuNo ratings yet

- Vertiv - HPM DX User ManualDocument3 pagesVertiv - HPM DX User ManualMUHAMMED SHAMVILNo ratings yet

- Control Valve Data Sheet: (Printed 2007-01-16 9:46 AM) K2 - 2006 (A1.3)Document2 pagesControl Valve Data Sheet: (Printed 2007-01-16 9:46 AM) K2 - 2006 (A1.3)Mateus EliasNo ratings yet

- G. Pumps and DriversDocument14 pagesG. Pumps and DriversJithinNo ratings yet

- Pressure Safety Valve-Preliminary Sizing: Input DataDocument5 pagesPressure Safety Valve-Preliminary Sizing: Input DataTun Naing WinNo ratings yet

- Gas Compressor Package DatasheetDocument69 pagesGas Compressor Package Datasheetjohn100% (2)

- PSV-Scrapper TrapDocument1 pagePSV-Scrapper TrapUmer KhanNo ratings yet

- Data Sheet For Tank-To-tank Transfer Pump (Rev.a) - Returned (P-1501)Document7 pagesData Sheet For Tank-To-tank Transfer Pump (Rev.a) - Returned (P-1501)Panisa BanimaNo ratings yet

- Planilla Calculo PSVDocument66 pagesPlanilla Calculo PSVPROCESOS PROCESOSNo ratings yet

- Storage Tank Data SheetDocument2 pagesStorage Tank Data SheetsandyaNo ratings yet

- ALIVIATORDocument14 pagesALIVIATORPROCESOS PROCESOSNo ratings yet

- Datasheet For PSVDocument1 pageDatasheet For PSVlãng duNo ratings yet

- Packaged Positive Displacement Rotary Screw Plant and Instrument Air CompressorDocument6 pagesPackaged Positive Displacement Rotary Screw Plant and Instrument Air CompressorNuzul FurqonyNo ratings yet

- UntitledDocument5 pagesUntitledJuan Bautista Rojas VillegasNo ratings yet

- H-25 Series: Configuration PDocument1 pageH-25 Series: Configuration PROMEE REY CALDERONNo ratings yet

- Mitsubishi Power, Ltd. - H-25 Series 1Document1 pageMitsubishi Power, Ltd. - H-25 Series 1ROMEE REY CALDERONNo ratings yet

- Kcn411lag BXXXDocument5 pagesKcn411lag BXXXRajeesh P RaviNo ratings yet

- 22-DS-R-001 Rev 1 API 617 GTCPsDocument25 pages22-DS-R-001 Rev 1 API 617 GTCPsChike Nwachukwu100% (1)

- Cam Characteristic Air Consumption: Control Valve Air Act. Instrument Data SheetDocument2 pagesCam Characteristic Air Consumption: Control Valve Air Act. Instrument Data SheetJHONATAN RODRIGUEZ VENTONo ratings yet

- PCR SvformDocument5 pagesPCR SvformHendrias A.SNo ratings yet

- MQ13 02 DS 3510 Inhv142b - R0Document2 pagesMQ13 02 DS 3510 Inhv142b - R0JHONATAN RODRIGUEZ VENTONo ratings yet

- Cam Characteristic Air Consumption: Control Valve Air Act. Instrument Data SheetDocument2 pagesCam Characteristic Air Consumption: Control Valve Air Act. Instrument Data SheetJHONATAN RODRIGUEZ VENTONo ratings yet

- CONTOH SpecificationsDocument6 pagesCONTOH Specificationsmiii22ajaNo ratings yet

- ARUV168BTE5Document2 pagesARUV168BTE5jaimegutierrezlinganNo ratings yet

- 150FV104-IFT-Data SheetDocument1 page150FV104-IFT-Data SheetgerardoNo ratings yet

- m16-1 C-R Packaged Air Conditioner-Final Drawing (Inc. Instruction Book) - CompressedDocument54 pagesm16-1 C-R Packaged Air Conditioner-Final Drawing (Inc. Instruction Book) - CompressedsfssullconnectNo ratings yet

- 150FV054-IFT-Data SheetDocument1 page150FV054-IFT-Data SheetgerardoNo ratings yet

- Datasheet For Pressure Safety Valve - IfbDocument66 pagesDatasheet For Pressure Safety Valve - Ifbfathan fathullahNo ratings yet

- 150HV003-IFT-Data SheetDocument1 page150HV003-IFT-Data SheetgerardoNo ratings yet

- GBCPP PCV 2030Document1 pageGBCPP PCV 2030Firstyan Dhika AldaniNo ratings yet

- ARUN240LTE5Document2 pagesARUN240LTE5Edgard Chara CarhuayoNo ratings yet

- Intel+peb 7710vla R2Document36 pagesIntel+peb 7710vla R2eduardo mendesNo ratings yet

- Data Sheet For Jockey Pumps (Rev.a) - Returned (P-1101)Document7 pagesData Sheet For Jockey Pumps (Rev.a) - Returned (P-1101)Panisa BanimaNo ratings yet

- Technical Bid Tabulation: Vendor Description SpecificationDocument8 pagesTechnical Bid Tabulation: Vendor Description SpecificationGunturMudaAliAkbarNo ratings yet

- Data Sheet & Sizing SheetDocument3 pagesData Sheet & Sizing SheetazitaggNo ratings yet

- ARUV241BTE5Document2 pagesARUV241BTE5jaimegutierrezlinganNo ratings yet

- ARU V144BTE5: Multi V™ 5 Cooling Only 12 RT Outdoor UnitDocument2 pagesARU V144BTE5: Multi V™ 5 Cooling Only 12 RT Outdoor UnitMorelia ObregónPríncipeNo ratings yet

- Master Planning of Utility Compound and Preliminary Engineering Design (30% Design Level) (30% Design Level)Document5 pagesMaster Planning of Utility Compound and Preliminary Engineering Design (30% Design Level) (30% Design Level)bubbles82No ratings yet

- FTK (X) - A Series (Wall Mount)Document54 pagesFTK (X) - A Series (Wall Mount)khant kyaw khaingNo ratings yet

- DS-Simple Heat ExchangerDocument22 pagesDS-Simple Heat ExchangerAbdullah KutbiNo ratings yet

- Comp 10 6 X 7 Phe7 Ba2Document2 pagesComp 10 6 X 7 Phe7 Ba2Ravi KantNo ratings yet

- 9ha Power PlantsDocument2 pages9ha Power PlantsGaurav DuttaNo ratings yet

- Anderson GreenwodDocument6 pagesAnderson Greenwoding.henrypcruzNo ratings yet

- GTM-COM-SA-DS-0004-08 - Fire Water PumpDocument4 pagesGTM-COM-SA-DS-0004-08 - Fire Water PumpFranscois Van RooyenNo ratings yet

- Copeland Scroll Compressors Bom Overview Technical Information en GB 4848778Document22 pagesCopeland Scroll Compressors Bom Overview Technical Information en GB 4848778hozaifaalturaikyNo ratings yet

- Case 2 DataDocument23 pagesCase 2 Datajuhee010062No ratings yet

- 9f Power PlantDocument2 pages9f Power Plantsoccer3_2003No ratings yet

- ARUN100BSS0Document2 pagesARUN100BSS0jaimegutierrezlinganNo ratings yet

- ARUN160BTE5Document2 pagesARUN160BTE5Jeyson Sandoval LópezNo ratings yet

- AP2D Series PumpDocument12 pagesAP2D Series PumpSoeLettNo ratings yet

- Pump DatasheetsDocument10 pagesPump DatasheetsNavNo ratings yet

- Hvac Data Sheet For For Fahahil Main - Control Building: Explosion Proof Exhaust FansDocument1 pageHvac Data Sheet For For Fahahil Main - Control Building: Explosion Proof Exhaust FansSelvaraj BalajiNo ratings yet

- P68313-Feed For Nitrogen StorageDocument2 pagesP68313-Feed For Nitrogen StorageSelvaraj BalajiNo ratings yet

- Material Approval Schedule Status - Hvac Services: Rev.02 Rev.01Document3 pagesMaterial Approval Schedule Status - Hvac Services: Rev.02 Rev.01Selvaraj BalajiNo ratings yet

- Gravitational RadiationDocument14 pagesGravitational RadiationSelvaraj BalajiNo ratings yet

- Best Practice Poor TASR On Double BCF SiteDocument2 pagesBest Practice Poor TASR On Double BCF SiteShailendra SinghNo ratings yet

- 08 VESDA Cold Stores App Brochure A4 LoresDocument4 pages08 VESDA Cold Stores App Brochure A4 LoresPepe ZapataNo ratings yet

- Digital WorldDocument2 pagesDigital WorldRegine RamentoNo ratings yet

- HP Envy x360 Convertible 15m-Eu0043dx OverviewDocument2 pagesHP Envy x360 Convertible 15m-Eu0043dx Overviewrom mNo ratings yet

- Lab 1 Ec501Document8 pagesLab 1 Ec501adamwaizNo ratings yet

- Personal Resume For EngineerDocument3 pagesPersonal Resume For EngineerwhatehoNo ratings yet

- 06 Foster AdsbDocument13 pages06 Foster AdsbMartin GallardoNo ratings yet

- Astra SPX Avionics SystemDocument710 pagesAstra SPX Avionics Systemnixon_b_2000100% (2)

- Scrathch CardDocument28 pagesScrathch CardMadhu PreethiNo ratings yet

- Sew What Inc - Case StudyDocument12 pagesSew What Inc - Case Studytaniya17No ratings yet

- Pin & Win With BoConcept Contest RulesDocument6 pagesPin & Win With BoConcept Contest RulesThe Province100% (1)

- Pirelli DRG A226m PDFDocument2 pagesPirelli DRG A226m PDFAndrea ButtafavaNo ratings yet

- Topic: - Story of Entrepreneur (Dhirubhai Ambani) and Start-Up Plan (Affiliate Marketing)Document19 pagesTopic: - Story of Entrepreneur (Dhirubhai Ambani) and Start-Up Plan (Affiliate Marketing)Mavani snehaNo ratings yet

- (BookRAR - Net) - Computer NetworkingDocument89 pages(BookRAR - Net) - Computer NetworkingAster Jane ArjonaNo ratings yet

- Visa USA Interchange Reimbursement FeesDocument26 pagesVisa USA Interchange Reimbursement FeesMark Jasper DabuNo ratings yet

- Computer Organization and Architecture 10th Edition Stallings Solutions ManualDocument32 pagesComputer Organization and Architecture 10th Edition Stallings Solutions Manualmitchellunderwooda4p4d100% (18)

- HTTTKT Bài 10.1 DangDocument1 pageHTTTKT Bài 10.1 DangDANG PHAM HAINo ratings yet

- Biomeca Res PropDocument5 pagesBiomeca Res PropUras TuzcuoğluNo ratings yet

- Lightroom Actions & Presets CollectionDocument4 pagesLightroom Actions & Presets CollectionJunaid RashidNo ratings yet

- Daikin Reiri Catalogue v2Document21 pagesDaikin Reiri Catalogue v2Royal EagleNo ratings yet

- Sigma Plate Heat ExchangersDocument6 pagesSigma Plate Heat ExchangersDirkNo ratings yet

- Operationsmanagement 130121065458 Phpapp02Document678 pagesOperationsmanagement 130121065458 Phpapp02Jassi JiNo ratings yet

- Chapter 4 Production Planning and ControlDocument26 pagesChapter 4 Production Planning and ControlgcldesignNo ratings yet

- Class: Xi Session: 2022-23 Computer Science (083) Practice Paper-1 (Theory) Maximummarks:70 Time Allowed: 3 Hrs General InstructionsDocument26 pagesClass: Xi Session: 2022-23 Computer Science (083) Practice Paper-1 (Theory) Maximummarks:70 Time Allowed: 3 Hrs General InstructionsCyber Aeonic Dark ModeNo ratings yet

- PIP-LV 3KVA Manual-20160823Document46 pagesPIP-LV 3KVA Manual-20160823luigigerulaNo ratings yet

- Power PC ArchitectureDocument24 pagesPower PC ArchitectureArkadip RayNo ratings yet

- Grading SheetDocument5 pagesGrading SheetnhaaileenNo ratings yet

- MTB-MLE Lesson PlanDocument9 pagesMTB-MLE Lesson PlanGlessy AlvaroNo ratings yet

- Afton Industrial Overview Booklet 2019Document11 pagesAfton Industrial Overview Booklet 2019Clairin LohNo ratings yet

Hvac Data Sheet For For Fahahil South - Gate House: DOC No.:3507-FAHS-9-13-0002 REV.# 0 Page 2 of 5

Hvac Data Sheet For For Fahahil South - Gate House: DOC No.:3507-FAHS-9-13-0002 REV.# 0 Page 2 of 5

Uploaded by

Selvaraj BalajiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hvac Data Sheet For For Fahahil South - Gate House: DOC No.:3507-FAHS-9-13-0002 REV.# 0 Page 2 of 5

Hvac Data Sheet For For Fahahil South - Gate House: DOC No.:3507-FAHS-9-13-0002 REV.# 0 Page 2 of 5

Uploaded by

Selvaraj BalajiCopyright:

Available Formats

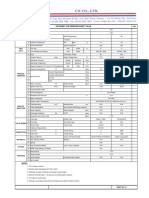

HVAC DATA SHEET FOR FOR FAHAHIL SOUTH - GATE HOUSE

1 ROOF TOP AIR COOLED PACKAGED UNITS

2 Area Classification : Hazardous (Safe Area) Type : Air Cooled Packaged Outdoor DX Units

3 Refrigerant : R-134a or R407C, R410A Quantity : Two (2) Nos. (1 working + 1 standby)

4 Location : Fahahil South -FSDS-Gate House Installation HVAC yard without any cover

5 Tag no. : 13-H-0001A & 13-H-0001B

6 CAPACITY OF AIR CONDITIONING UNITS

7 Station Total Capacity(NET),KW Air Entering Condition Air Leaving Condition 1 : Vendor shall consider 20% spare capacity for the HVAC

Air flow rate

equipment as future requirement.

8 Cooling LoadSensible Load (Actual) ºC DB ºC WB ºC DB ºC WB

9 1. FSDS -Gate House

34.3 27.5 1,638 l/s 26.80 19.0 13.0 12.9

10

11

12

12

13 MANUFACTURER SPECIFICATION

14 COMPRESSOR

15 Make

16 Model

17 Quantity of compressors per package units

18 Saturated suction temperature o

C

19 Saturated suction pressure Kpa(g)

20 Saturated discharge temperature o

C

21 Saturated discharge pressure Kpa(g)

22 Nominal capacity KW

23 Capacity at design conditions KW

24 Capacity control arrangement

25 Type Sealed/Open/Semi hermetic

26 Method of lubrication Oil pump/Splash

27 Shaft power BkW

28 Shaft speed RPM

29 Motor KW / RPM

30 Guaranteed power at motor terminals KW

31 Grade of lubrication oil

32 Detail of unloaded starting arrangement

33 AIR COOLED CONDENSER

34 Make

35 Model

36 Quantity of condensers per package unit Nos.

37 Type Air-cooled

38 Total heat rejection KW

39 Condenser ambient air entering temperature o

C

40 Face area of each coil mm x mm

41 Face velocity across coil M/sec

42 Tube O.D. mm

43 Tube Thickness mm

44 Bends thickness mm

45 Fin spacing mm per mm

46 Fin thickness mm

47 Quantity of fans per condenser Nos.

48 Air flow rate per fan Lit / Sec

49 Type of fan for air circulation

50 Motor (kW/RPM) per fan Kw / RPM

51 Diameter of fan impeller mm

52 FILTER UNIT PREFILTER BAGFILTER

53 Make

54 Model

55 Total air flow rate Lit / Sec Lit / Sec

56 Size of filter element mm x mm x mm mm x mm x mm

57 Air flow rate per element Lit / Sec Lit / Sec

58 Quantity of filter elements Nos. Nos.

59 Face velocity M/sec M/sec

60 Filtration efficiency % down to micron % down to micron

61 Pressure drop in clean condition mm WC mm WC

62 Maximum allowable pressure drop mm WC mm WC

63 Fixing Flange/Channel Flange/Channel

64 Filtration media Dry type reusable Dry type reusable

65 NOTES

66 1 Micro-vee fine filters (efficiency 99% down to 5 microns) to be provided at package AC outlet.

67 2 Prefilter and Bag filters deign & efficiencies shall comply to the details specified in the HVAC specification requirement.

68

69

70

71

DOC No.:3507-FAHS-9-13-0002 REV.# 0 Page 2 of 5

HVAC DATA SHEET FOR FOR FAHAHIL SOUTH - GATE HOUSE

1 COOLING COIL

2 Make

3 Model

4 Air entering condition o

C DB / o

C WB

5 Air leaving condition o

C DB / o

C WB

6 ADP o

C

7 Capacity KW

8 Total air flow rate Lit/sec (minimum)

9 Face size mm x mm

10 Number of rows Nos.

11 Type DX

12 Bypass factor

12 Tube wall thickness mm

13 Bends thickness mm

14 Fin spacing mm per mm

15 Bonding of fins Hydraulically/Mechanically

16 Velocity of air across coil M/sec

17 BLOWER

18 Make

19 Model

20 Type Centrifugal

21 Blade profile Forward/Backward/Radial

22 No. of impellers Nos.

23 Impeller diameter mm

24 Impeller speed RPM

25 Static Pressure 50 mm WC (minimum)

26 Power consumption at shaft KW

27 Guaranteed power at motor terminals KW

28 Air outlet velocity M/sec.

29 Drive arrangement V-belt drive

30 Motor KW / RPM

31 Bearing lubrication Oil/grease

32 Noise level Not more than 85 dBA at 1 m from source

33 No. of belts Nos.

34 ACCESSORIES Contractor’s Requirement Vendor’s Confirmation

35 Guard for moving parts Required YES

36 Belt tensioner Required YES

37 Insulted drain pan with drain connection Required YES

38 First charge of refrigerant, oil, lubricants Required YES

39 Grease nipple for bearings Required YES

40 Painting Required YES

41 Drain piping Required YES

42 V-belt drive packages with V-belts Required YES

43 Anti vibration mounting Required YES

44 Lifting lugs Required YES

45 Base frame Required YES

46 On-Off damper at the outlet of each package unit Required YES

47 Back Draft damper at the outlet of each package unit Required No

48 HP/LP cut out Required YES

49 Low oil pressure cut out Required YES

50 Audio/visual annunciator Required Microprocessor based controller

51 Refrigerant control Required YES

52 Refrigerant piping between air cooled condensers & package units and insulation of suction piping Required YES

53 Pressure relief valve Required YES

54 MATERIAL OF CONSTRUCTION

55 Air condenser coil/Cooling coil

56 Tubes Seamless copper tubes

57 Fins Aluminium

58 Frame/Casing Carbon steel/Galvanised sheet

59 Filter

60 Filter media Dry fabric/HDPE mesh-reusable

61 Blower

62 Impeller Carbon steel/aluminium/stainless steel

63 Shaft EN-8

64 V-pulleys C.I. Multi grooves

65

66

67 DIMENSIONS / WEIGHTS

68 Overall size

69 Overall weight

70

DOC No.:3507-FAHS-9-13-0002 REV.# 0 Page 3 of 5

HVAC DATA SHEET FOR FOR FAHAHIL SOUTH - GATE HOUSE

2 NOTE:

3

1

4 A/C units shall be Factory assembled, tested, pre-charged with refrigerant, pre-

wired, and ready to operate.

5 The microprocessor based control system(Integral Control panel) shall be

2 supplied as part of the unit.

6 The above panel noted in the point no 2. shall be compatible to the BMS

3 integrated HVAC Panel for Control & monitoring works.

7 4 The Working & standby HVAC units shall be provided with Manual & Auto

changeover option.

The construction and rating of the units shall be in accordance with ASHRAE

8 5 Std, latest ARI 590 Std, ANSI 9-1safety code, NEC code ASTM, UL and NFPA

70.

9

10

11 General requirement

12 2 Guaranteed/warranted for the Period Specified Elsewhere

13 as whole from the date of successful performance test.

14 3 List of Spares:

15 Startup/Commissioning spares to be Provided

16 First year Operating spares to be Provided

17 Two year Operating spares to be Provided

18 Insurance Spares to be Provided

19 Recommended special tools & tackle list to be Provided

20 Manufacturer List for the above List of spares to be Provided

21 4 The selected HVAC units shall be from the QP's approved vendor list.

22 5 HVAC Vendor to fill up data sheet for each HVAC units separately.

23 6 The All HVAC Equipment Condenser & Cooling Coils Coating Shall be

24 Heresite with 5 year warranty as minimum shall be provided.

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

DOC No.:3507-FAHS-9-13-0002 REV.# 0 Page 4 of 5

HVAC DATA SHEET FOR FOR FAHAHIL SOUTH - GATE HOUSE

1 INLINE EXHAUST FANS

2 Area Classification : Non Hazardous (Safe) Type : In Line Centrifugal fan

3 Location : FAHS - FAHAHIL SOUTH GATE HOUSE Quantity : Refer below

4 Tag No. : Installation : Ceiling suspended Inline Fan

5 Serving to : Gate house rooms

6 CAPACITY OF INLINE EXHAUST FANS

7 Type of fan Tag no. Qty. Lit/Sec Ext.Static

Pr.Pa

Note:

8 FAHN - Gate House Building

9 Pantry Room Ceiling suspended Inline Fan 13-HEF-0001 1 45 1. Refer Summary of sizing calculations for detail capacity.

10 Toilet Ceiling suspended Inline Fan 13-HEF-0002 1 30 2. Vendor shall duly fill up the datasheet for each fan and submit for approval

11

12

13

14 MANUFACTURER SPECIFICATION

15 FANS

16 Manufacturer Model No.

17 Type

18 Actual air Flow Lit / Sec

19 Selected air Flow Lit / Sec

20 External Static head mm of WG

21 Fan handling Medium

22 Temperature of the handling medium C

0

23 Fan Speed RPM

24 Fan Opening Size mm

25 Material

26 Fan Blade

27 Wire guard

28 Mounting

29 Electrical Characteristic V / ph / Hz

30 Fan Efficiency %

31 Fan Motor Rating

32 Motor type

33 KW

34 Make/Frame size

35 Speed RPM

36 Fan Initial starting current amps

37 Fan running current amps

38 Unit Classification

39 Sound Power level

40 Accessories

41 Fan Housing material

42 Impeller Housing material

43 Fan Controls

44 Speed Controller type through auto transformer or Electronic control design to suit Present

& Future flow requirements. Not applicable

45 Working & standby fans shall be provided with Auto changeover option. Not applicable

46 Fan Operation are compatible to BMS integrated Panel for monitoring.

47 Fan Design

48 1 Fans shall be Inline Ceiling Suspended.Fans shall be Centrifugal,axial or mixed flow type

Casing shall be rigidly constructed of heavy gauge galvanized mild steel or aluminium alloy and

49 2 shall be stiffened and braced to obviate drumming and vibration.Mounting feet shall be provided for

bottling to a base or supports.

The fan housing shall be square in shape and readily attachable to building ductwork. Unit side

50 3 panels shall be removable for easy access for maintenance and service. The power assembly shall

be removable as a complete module through the side access panel.

51 4 Fan wheels shall be of the non-overloading centrifugal backward inclined type, constructed of

aluminum and containing a matching inlet venturi for optimum unit performance. Wheels shall be

statically and dynamically balanced.

52 5 Motors shall be of the heavy-duty ball bearing type, closely matched to the fan load. A disconnect

switch shall be factory installed and wired to the fan motor as standard. Motor shall be mounted on

the outside of the unit, isolated from the airstream All motors shall be UL recognized.

53 6 Ferrous metal parts are adequately painted against corrosive gases and vapours.

54 7

Certified explosion proof motor suitable for Explosion proff type shall be provided for battery room

55 8 The motor shall be fitted with permanent lubricated ball bearings and shall be provided with inbuilt

automatic reset thermal overload protection.

56 9 Fan performance duty point shall be selected away from the surges developing region.

57 10 Unit Shall Comply to the Project Specification.

58 11 Vendor shall submit selections with static heat, based on the actual components

59

60 General requirements

61 1 Capable of continuous operation under site conditions without maintenance.

62 2 Guaranteed/warranted for the Period Specified Elsewhere

63 as whole from the date of successful performance test.

64 3 List of Spares:

65 Startup/Commissioning spares to be Provided

66 First year Operating spares to be Provided

67 Two year Operating spares to be Provided

68 Insurance Spares to be Provided

69 Recommended special tools & tackle list to be Provided

70 Manufacturer List for the above List of spares to be Provided

71 4 The selected Fan unit shall be from the QP's approved vendor list.

72

DOC No.:3507-FAHS-9-13-0002 REV.# 0 Page 5 of 5

You might also like

- Switching Power Supply Design: A Concise Practical HandbookFrom EverandSwitching Power Supply Design: A Concise Practical HandbookNo ratings yet

- Data Sheet For PSVDocument1 pageData Sheet For PSVBABILIN VNo ratings yet

- Ycua Ydf (Tech. Guide) 2Document20 pagesYcua Ydf (Tech. Guide) 2Elmer80% (5)

- Ap2d Pump SeriesDocument12 pagesAp2d Pump SeriesAdal Vera60% (5)

- Pressure Safety Valve-Preliminary Sizing: Input DataDocument6 pagesPressure Safety Valve-Preliminary Sizing: Input DataPIDNo ratings yet

- MAVSP-P19002-W01-M-DS-0002 Rev. 0 Data sheet for Fire Pumps (Elctrical, Diesel and Jockey)Document16 pagesMAVSP-P19002-W01-M-DS-0002 Rev. 0 Data sheet for Fire Pumps (Elctrical, Diesel and Jockey)fendi zulfiantoNo ratings yet

- Himod UsuarioDocument76 pagesHimod UsuarioJuanita Pardo MirandaNo ratings yet

- 141014.datasheet For PSV-1323Document2 pages141014.datasheet For PSV-1323ocanhthuNo ratings yet

- Vertiv - HPM DX User ManualDocument3 pagesVertiv - HPM DX User ManualMUHAMMED SHAMVILNo ratings yet

- Control Valve Data Sheet: (Printed 2007-01-16 9:46 AM) K2 - 2006 (A1.3)Document2 pagesControl Valve Data Sheet: (Printed 2007-01-16 9:46 AM) K2 - 2006 (A1.3)Mateus EliasNo ratings yet

- G. Pumps and DriversDocument14 pagesG. Pumps and DriversJithinNo ratings yet

- Pressure Safety Valve-Preliminary Sizing: Input DataDocument5 pagesPressure Safety Valve-Preliminary Sizing: Input DataTun Naing WinNo ratings yet

- Gas Compressor Package DatasheetDocument69 pagesGas Compressor Package Datasheetjohn100% (2)

- PSV-Scrapper TrapDocument1 pagePSV-Scrapper TrapUmer KhanNo ratings yet

- Data Sheet For Tank-To-tank Transfer Pump (Rev.a) - Returned (P-1501)Document7 pagesData Sheet For Tank-To-tank Transfer Pump (Rev.a) - Returned (P-1501)Panisa BanimaNo ratings yet

- Planilla Calculo PSVDocument66 pagesPlanilla Calculo PSVPROCESOS PROCESOSNo ratings yet

- Storage Tank Data SheetDocument2 pagesStorage Tank Data SheetsandyaNo ratings yet

- ALIVIATORDocument14 pagesALIVIATORPROCESOS PROCESOSNo ratings yet

- Datasheet For PSVDocument1 pageDatasheet For PSVlãng duNo ratings yet

- Packaged Positive Displacement Rotary Screw Plant and Instrument Air CompressorDocument6 pagesPackaged Positive Displacement Rotary Screw Plant and Instrument Air CompressorNuzul FurqonyNo ratings yet

- UntitledDocument5 pagesUntitledJuan Bautista Rojas VillegasNo ratings yet

- H-25 Series: Configuration PDocument1 pageH-25 Series: Configuration PROMEE REY CALDERONNo ratings yet

- Mitsubishi Power, Ltd. - H-25 Series 1Document1 pageMitsubishi Power, Ltd. - H-25 Series 1ROMEE REY CALDERONNo ratings yet

- Kcn411lag BXXXDocument5 pagesKcn411lag BXXXRajeesh P RaviNo ratings yet

- 22-DS-R-001 Rev 1 API 617 GTCPsDocument25 pages22-DS-R-001 Rev 1 API 617 GTCPsChike Nwachukwu100% (1)

- Cam Characteristic Air Consumption: Control Valve Air Act. Instrument Data SheetDocument2 pagesCam Characteristic Air Consumption: Control Valve Air Act. Instrument Data SheetJHONATAN RODRIGUEZ VENTONo ratings yet

- PCR SvformDocument5 pagesPCR SvformHendrias A.SNo ratings yet

- MQ13 02 DS 3510 Inhv142b - R0Document2 pagesMQ13 02 DS 3510 Inhv142b - R0JHONATAN RODRIGUEZ VENTONo ratings yet

- Cam Characteristic Air Consumption: Control Valve Air Act. Instrument Data SheetDocument2 pagesCam Characteristic Air Consumption: Control Valve Air Act. Instrument Data SheetJHONATAN RODRIGUEZ VENTONo ratings yet

- CONTOH SpecificationsDocument6 pagesCONTOH Specificationsmiii22ajaNo ratings yet

- ARUV168BTE5Document2 pagesARUV168BTE5jaimegutierrezlinganNo ratings yet

- 150FV104-IFT-Data SheetDocument1 page150FV104-IFT-Data SheetgerardoNo ratings yet

- m16-1 C-R Packaged Air Conditioner-Final Drawing (Inc. Instruction Book) - CompressedDocument54 pagesm16-1 C-R Packaged Air Conditioner-Final Drawing (Inc. Instruction Book) - CompressedsfssullconnectNo ratings yet

- 150FV054-IFT-Data SheetDocument1 page150FV054-IFT-Data SheetgerardoNo ratings yet

- Datasheet For Pressure Safety Valve - IfbDocument66 pagesDatasheet For Pressure Safety Valve - Ifbfathan fathullahNo ratings yet

- 150HV003-IFT-Data SheetDocument1 page150HV003-IFT-Data SheetgerardoNo ratings yet

- GBCPP PCV 2030Document1 pageGBCPP PCV 2030Firstyan Dhika AldaniNo ratings yet

- ARUN240LTE5Document2 pagesARUN240LTE5Edgard Chara CarhuayoNo ratings yet

- Intel+peb 7710vla R2Document36 pagesIntel+peb 7710vla R2eduardo mendesNo ratings yet

- Data Sheet For Jockey Pumps (Rev.a) - Returned (P-1101)Document7 pagesData Sheet For Jockey Pumps (Rev.a) - Returned (P-1101)Panisa BanimaNo ratings yet

- Technical Bid Tabulation: Vendor Description SpecificationDocument8 pagesTechnical Bid Tabulation: Vendor Description SpecificationGunturMudaAliAkbarNo ratings yet

- Data Sheet & Sizing SheetDocument3 pagesData Sheet & Sizing SheetazitaggNo ratings yet

- ARUV241BTE5Document2 pagesARUV241BTE5jaimegutierrezlinganNo ratings yet

- ARU V144BTE5: Multi V™ 5 Cooling Only 12 RT Outdoor UnitDocument2 pagesARU V144BTE5: Multi V™ 5 Cooling Only 12 RT Outdoor UnitMorelia ObregónPríncipeNo ratings yet

- Master Planning of Utility Compound and Preliminary Engineering Design (30% Design Level) (30% Design Level)Document5 pagesMaster Planning of Utility Compound and Preliminary Engineering Design (30% Design Level) (30% Design Level)bubbles82No ratings yet

- FTK (X) - A Series (Wall Mount)Document54 pagesFTK (X) - A Series (Wall Mount)khant kyaw khaingNo ratings yet

- DS-Simple Heat ExchangerDocument22 pagesDS-Simple Heat ExchangerAbdullah KutbiNo ratings yet

- Comp 10 6 X 7 Phe7 Ba2Document2 pagesComp 10 6 X 7 Phe7 Ba2Ravi KantNo ratings yet

- 9ha Power PlantsDocument2 pages9ha Power PlantsGaurav DuttaNo ratings yet

- Anderson GreenwodDocument6 pagesAnderson Greenwoding.henrypcruzNo ratings yet

- GTM-COM-SA-DS-0004-08 - Fire Water PumpDocument4 pagesGTM-COM-SA-DS-0004-08 - Fire Water PumpFranscois Van RooyenNo ratings yet

- Copeland Scroll Compressors Bom Overview Technical Information en GB 4848778Document22 pagesCopeland Scroll Compressors Bom Overview Technical Information en GB 4848778hozaifaalturaikyNo ratings yet

- Case 2 DataDocument23 pagesCase 2 Datajuhee010062No ratings yet

- 9f Power PlantDocument2 pages9f Power Plantsoccer3_2003No ratings yet

- ARUN100BSS0Document2 pagesARUN100BSS0jaimegutierrezlinganNo ratings yet

- ARUN160BTE5Document2 pagesARUN160BTE5Jeyson Sandoval LópezNo ratings yet

- AP2D Series PumpDocument12 pagesAP2D Series PumpSoeLettNo ratings yet

- Pump DatasheetsDocument10 pagesPump DatasheetsNavNo ratings yet

- Hvac Data Sheet For For Fahahil Main - Control Building: Explosion Proof Exhaust FansDocument1 pageHvac Data Sheet For For Fahahil Main - Control Building: Explosion Proof Exhaust FansSelvaraj BalajiNo ratings yet

- P68313-Feed For Nitrogen StorageDocument2 pagesP68313-Feed For Nitrogen StorageSelvaraj BalajiNo ratings yet

- Material Approval Schedule Status - Hvac Services: Rev.02 Rev.01Document3 pagesMaterial Approval Schedule Status - Hvac Services: Rev.02 Rev.01Selvaraj BalajiNo ratings yet

- Gravitational RadiationDocument14 pagesGravitational RadiationSelvaraj BalajiNo ratings yet

- Best Practice Poor TASR On Double BCF SiteDocument2 pagesBest Practice Poor TASR On Double BCF SiteShailendra SinghNo ratings yet

- 08 VESDA Cold Stores App Brochure A4 LoresDocument4 pages08 VESDA Cold Stores App Brochure A4 LoresPepe ZapataNo ratings yet

- Digital WorldDocument2 pagesDigital WorldRegine RamentoNo ratings yet

- HP Envy x360 Convertible 15m-Eu0043dx OverviewDocument2 pagesHP Envy x360 Convertible 15m-Eu0043dx Overviewrom mNo ratings yet

- Lab 1 Ec501Document8 pagesLab 1 Ec501adamwaizNo ratings yet

- Personal Resume For EngineerDocument3 pagesPersonal Resume For EngineerwhatehoNo ratings yet

- 06 Foster AdsbDocument13 pages06 Foster AdsbMartin GallardoNo ratings yet

- Astra SPX Avionics SystemDocument710 pagesAstra SPX Avionics Systemnixon_b_2000100% (2)

- Scrathch CardDocument28 pagesScrathch CardMadhu PreethiNo ratings yet

- Sew What Inc - Case StudyDocument12 pagesSew What Inc - Case Studytaniya17No ratings yet

- Pin & Win With BoConcept Contest RulesDocument6 pagesPin & Win With BoConcept Contest RulesThe Province100% (1)

- Pirelli DRG A226m PDFDocument2 pagesPirelli DRG A226m PDFAndrea ButtafavaNo ratings yet

- Topic: - Story of Entrepreneur (Dhirubhai Ambani) and Start-Up Plan (Affiliate Marketing)Document19 pagesTopic: - Story of Entrepreneur (Dhirubhai Ambani) and Start-Up Plan (Affiliate Marketing)Mavani snehaNo ratings yet

- (BookRAR - Net) - Computer NetworkingDocument89 pages(BookRAR - Net) - Computer NetworkingAster Jane ArjonaNo ratings yet

- Visa USA Interchange Reimbursement FeesDocument26 pagesVisa USA Interchange Reimbursement FeesMark Jasper DabuNo ratings yet

- Computer Organization and Architecture 10th Edition Stallings Solutions ManualDocument32 pagesComputer Organization and Architecture 10th Edition Stallings Solutions Manualmitchellunderwooda4p4d100% (18)

- HTTTKT Bài 10.1 DangDocument1 pageHTTTKT Bài 10.1 DangDANG PHAM HAINo ratings yet

- Biomeca Res PropDocument5 pagesBiomeca Res PropUras TuzcuoğluNo ratings yet

- Lightroom Actions & Presets CollectionDocument4 pagesLightroom Actions & Presets CollectionJunaid RashidNo ratings yet

- Daikin Reiri Catalogue v2Document21 pagesDaikin Reiri Catalogue v2Royal EagleNo ratings yet

- Sigma Plate Heat ExchangersDocument6 pagesSigma Plate Heat ExchangersDirkNo ratings yet

- Operationsmanagement 130121065458 Phpapp02Document678 pagesOperationsmanagement 130121065458 Phpapp02Jassi JiNo ratings yet

- Chapter 4 Production Planning and ControlDocument26 pagesChapter 4 Production Planning and ControlgcldesignNo ratings yet

- Class: Xi Session: 2022-23 Computer Science (083) Practice Paper-1 (Theory) Maximummarks:70 Time Allowed: 3 Hrs General InstructionsDocument26 pagesClass: Xi Session: 2022-23 Computer Science (083) Practice Paper-1 (Theory) Maximummarks:70 Time Allowed: 3 Hrs General InstructionsCyber Aeonic Dark ModeNo ratings yet

- PIP-LV 3KVA Manual-20160823Document46 pagesPIP-LV 3KVA Manual-20160823luigigerulaNo ratings yet

- Power PC ArchitectureDocument24 pagesPower PC ArchitectureArkadip RayNo ratings yet

- Grading SheetDocument5 pagesGrading SheetnhaaileenNo ratings yet

- MTB-MLE Lesson PlanDocument9 pagesMTB-MLE Lesson PlanGlessy AlvaroNo ratings yet

- Afton Industrial Overview Booklet 2019Document11 pagesAfton Industrial Overview Booklet 2019Clairin LohNo ratings yet