Professional Documents

Culture Documents

BETONAC-SCC (Technical Info Eng.)

BETONAC-SCC (Technical Info Eng.)

Uploaded by

aurelia200688Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BETONAC-SCC (Technical Info Eng.)

BETONAC-SCC (Technical Info Eng.)

Uploaded by

aurelia200688Copyright:

Available Formats

Self-Compacting-Concrete - Limits of the Concrete Composition

Technical Information

Basic Situation

Self-Compacting Concrete - SCC was developed some years ago in Japan to improve the

quality of concrete. The characteristics of this concrete are its very advantageous rheological

and self-venting properties äs well äs its adequate resistance against segregation. Without any

additional compaction needed, this concrete - simply under the impact of gravity - practically

flows to levelling point, filling every void and all interstices between rebars inside a

formwork. The mixture design for SCC, which is presently based on the concept of an

increased content of powder (powder type), äs a rule is based on a design method according to

Okamura IM from Japan. This method includes time-consuming paste, mortar and concrete

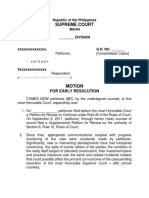

tests, starting from the following marginal conditions (fig. 1):

- The bulk volume of coarse aggregate (gravel) shall not exceed a maximum of 50%

of the concrete volume.

- The volume content of sand in the mortar shall be 40%.

Fig. 1: SCC acc. To Okamura

According to this procedure, concrete compositions are presently being developed more or less

systematically in the laboratories of ready-mixed concrete plants and plants for precast

concrete units. For reasons of costs and capacities, these three Steps are less often used in

practice, and the composition of the concrete is determined by trial and error method. The

following Standard composition proved a success as a basic mixture:

350 kg/m3 Cement

200 kg/m3 Fly ash

170-180 kg/m3 Water

650 kg/m3 Sand 0/2 mm

950 kg/m3 Gravel 2/16 mm

0,8-2,0% SP (PCE)

LEYCOCHEM LEYDE GMBH Tel.: +49 (0) 2236 - 9 66 00 – 0 e-mail:leycochem@leyde.com

D-50999 Köln • Industriestr. 155 Fax: +49 (0) 2236 - 9 66 00 – 10 www.leyde.com

Target of examination

Above Standard composition must be adapted to the individual marginal conditions (basic

materials, concrete requirements) in suitability tests. Searching for possibilities of

optimization, the following questions arise:

• How high is the optimal sand content?

• Are the high binder contents, most of all cement contents, necessary?

• What is the impact of various filiers (fly ash or limestone)?

• How much coarse aggregate can be used?

The examinations described in the following shall provide the information to answer these

questions. Four lest series with the following modified compositions were examined (Fig. 2):

Figure 2: schematic graph of modified compositions

- Increased sand volume and reduced gravel volume, with constant paste volume (Series

1).

- Reduction of paste volume (only filier) with constant mortar volume (Series 2).

Reduction of paste volume (cement filier, water) with constant mortar volume

(Series 3).

- Increasing gravel volume, with constant mortar composition and decreasing mortar

(Series 4)

In these tests, the impact of modified compositions on the properties of fresh concrete shall be

assessed

LEYCOCHEM LEYDE GMBH Tel.: +49 (0) 2236 - 9 66 00 – 0 e-mail:leycochem@leyde.com

D-50999 Köln • Industriestr. 155 Fax: +49 (0) 2236 - 9 66 00 – 10 www.leyde.com

Basic materials and concrete compositions

The examinations were conducted with commercial-grade basic materials. The concrete

composition is based on approved SCC compositions (Table 1).

Test performance

The tests were performed by means of a laboratory forced pan mixer with a content of 50 Itrs

and a concrete temperature of approx. 20°C. The target consistency (slump flow of approx. 72

- 75 cm) was adjusted by an appropriate dosage of superplasticizer. The water-cement ratio

was kept constant within series 1+2 and 3+4.

The following properties of fresh concrete were determined:

- Consistency

• Slump flow - the diameter of the concrete sample was determined by slump test

(indication of yield value).

• Flow time T50 - the flow time of concrete until sample reaches a diameter of 50 cm is

determined by slump test, as a rheological indication of viscosity.

- Air content

- Levelling behaviour, or blocking behaviour, determined by means of the L-Box (Fig. 3):

• The rheological properties are examined in an L-shaped chute. When a slider is opened,

the concrete must flow through an obstacle of rebars. The ratio calculated from concrete

height in the beginning and in the end of the chute is used as the assessment criterion.

- Stability - Assessment by visual inspection

Consistency tests are performed after 5, 30 & 60 min., all other tests after approx. 15 min

Test results

Series 1:

Increase of sand content - reduction of gravel content (Table 2)

In the tests, the sand content in the mortar was increased from 40 to 49 Vol.-%.

Correspondingly, the gravel content was reduced from 59 to 42 Vol.-% (bulk volume). The

sand content was increased from 630 to 917 kg/m3. An increase in superplasticizer

BETONAC-SCC from 0,72 to 1% by weight of cement (% v.Z.) was necessary to obtain the

target consistency. The results of slump flow measurements (Fig. 4) show a good constant

consistency for the first three mixtures over a period of 60 minutes. However, a slight

stiffening and a slight segregation were observed with the highest sand content.

LEYCOCHEM LEYDE GMBH Tel.: +49 (0) 2236 - 9 66 00 – 0 e-mail:leycochem@leyde.com

D-50999 Köln • Industriestr. 155 Fax: +49 (0) 2236 - 9 66 00 – 10 www.leyde.com

The segregation is explained by the necessary increase in superplasticizer to obtain the

identical slump flow. The flow time T50 tends to increase with an increasing sand content,

indicating an increased viscosity of the concrete (Fig. 5).

Table 2: Compositions and properties of fresh concrete of test-series 1 and 2

1) Sand content of Mortar.

2) Bulk volume of coarse aggregates in relation to concrete volume.

Fig. 4: Serie 1: Slump -Flow depending on sand content Fig. 5: Serie 1: T50 and aircontent depending on sand content

If the sand content is increased, the air content also slightly rises from 2,2 to 3,5 Vol.-%. This

effect might be explained by a deterioration of the self-venting properties of the concrete as a

consequence of the increased viscosity and/or the increased sand content and the pores caused

by the latter.

LEYCOCHEM LEYDE GMBH Tel.: +49 (0) 2236 - 9 66 00 – 0 e-mail:leycochem@leyde.com

D-50999 Köln • Industriestr. 155 Fax: +49 (0) 2236 - 9 66 00 – 10 www.leyde.com

The levelling or blocking behaviour of concretes in the L-Box with ratio values of H2/H1 to

0,93 - 0,97 was, as expected with the reduced gravel content, very advantageous.

During the visual assessment of stability, only the mixture with the highest sand content of 917

kg/m3 showed a significant settling.

Series 2:

Reduction of filler content - increase of sand content (Table2)

These four tests are designed to determine the possible reduction of powder content, keeping

the concrete properties constant. For this purpose, the fly ash content was reduced from 200 to

100 kg/m3 . The sand content was correspondingly increased to compensate the volume.

The dosing of BETONAC-SCC which is necessary to obtain the target consistency, was

reduced simultaneously with the reduction of fly ash. If water content remains constant, this

can be explained by the reduced water requirement of the mixture. The reduction of filier has a

significant impact on consistency (Fig. 6). The first two concretes (Nr. 2.1 and Nr. 2.2) show

no clear impact of the filier reduction by 34 kg/m3; the differences in slump flow might have

been compensated by an increased dosing of

superplasticizer. The tests with an even lower

content of fly ash (Nr. 2.3 and Nr. 2.4) show

clear deteriorations in consistency. This

becomes apparent by a stronger stiffening

from 71 to 63 cm slump flow in Nr. 2.3.

Mixture Nr. 2.4, i.e. with 100 kg/m3 fly ash

was not able to obtain the target consistency.

The concrete showed distinctive bleeding

before, which can be explained by the

increased volume ratio of water and powder, Fig. 6: serie 2. Slumo -flow deoendina on filier content (fly ash)

making more „free water” available in the

concrete.

In this series, no differences were found concerning the air content. The levelling and blocking

behaviour in the L-Box is influenced. Although even concretes Nr. 2.3. and 2.4. were able to

comply with test criterion H2/H1 > 0,8 these values could not be used for assessment due to a

lack of stability.

LEYCOCHEM LEYDE GMBH Tel.: +49 (0) 2236 - 9 66 00 – 0 e-mail:leycochem@leyde.com

D-50999 Köln • Industriestr. 155 Fax: +49 (0) 2236 - 9 66 00 – 10 www.leyde.com

Series 3+4:

In test series 3+4 limestone was used as a filler, resulting in similar fresh concrete properties

as with fly ash in series 1+2 (compare Nr.1.1 and Nr.3.1). The biggest differences were found

in superplasticizer and water requirements. These can be explained by the less advantageous

grain shape and the higher degree of fineness of the limestone filler, compared with fly ash. In

addition, the air content values of the mixtures with limestone lie clearly below those with fly

ash.

Table 3: Compositions and properties of fresh concrete of test-series 3 and 4

1) Sand Content of Moratr

2) Bulk volume of coarse aggregates in relation to concrete volume

Series 3

Reduction of paste content - increase of sand content (Table 3)

In the tests of these series, the paste volume was

reduced from 380 l/m3 to 320 l/m3. The sand

content was increased from 664 kg/m3 to 814

kg/m3 so as to keep the mortar volume constant

at 650 l/m3. This corresponds to a modification

of the initial ratio of sand:paste = 40:60 to

sand:paste = 49:51 (see fig. 1). Due to the lack of

paste volume, the initial consistency as well as

the stiffening behaviour of the concrete

deteriorated (Fig. 7).

Fig.7: Serie 3-Slump -Flow depending on paste volume

LEYCOCHEM LEYDE GMBH Tel.: +49 (0) 2236 - 9 66 00 – 0 e-mail:leycochem@leyde.com

D-50999 Köln • Industriestr. 155 Fax: +49 (0) 2236 - 9 66 00 – 10 www.leyde.com

The curves of mixtures Nr. 3.2 and 3.3 which are almost congruent, were only possible as a

consequence of an increase in the addition of superplasticizer BETONAC-SCC. The mixture

containing the most sand (Nr.3.4) was not able to reach the target consistency as in Series 2.

Before this the concrete already started to segregate and to bleed. Simultaneously, the levelling

behaviour clearly deteriorated. The distinct deterioration of the fresh concrete properties can,

similarly to series 2, be traced back to an insufficient quantity of paste. The lack of an

adequate thickness of paste layer between the individual sand grains in the mortar phase leads

to a restriction of the rheological properties of the mortar and consequently of the concrete.

Series 4:

Reduction of mortar content - increase of gravel content (Table 3)

These test series were designed to determine how much gravel can possibly be used in an

SCC. For this purpose, the mortar volume was reduced from 665 l/m3 to 537 l/m3.

Consequently , the gravel content was increased from 834 kg/m3 (4 50 % bulk gravel, see fig.

1) to 1165 kg/m3 (4 70 % bulk gravel). Although the target consistency could be adjusted in

tests 4.2 and 4.3 (fig. 8), a larger amount of BETONAC-SCC had to be added. Furthermore

mixture 4.3 did not demonstrate an adequate stability . Simultaneously, the workability time of

these concretes was clearly reduced, if compared with initial concrete Nr. 4.1. It was no longer

possible to obtain the target consistency with the mixture containing the highest quantity of

gravel (Nr. 4.4). The concrete showed intense bleeding and segregation.

The levelling behaviour (fig. 9) decreased strongly, as expected. Although mixture Nr. 4.2 was

able to comply with „blocking criterion” H2/H1 = 0,81 > 0,8 it was already clearly worse than

the initial concrete. In regard to levelling behaviour, tests 4.3 and 4.4 were absolutely out of

the question, also as a consequence of the segregation.

Fig. 8: Serie 4 – Slump -Flow depending on gravel content Fig. 9: Serie 4 – L-Box-Performance depending on gravel content

LEYCOCHEM LEYDE GMBH Tel.: +49 (0) 2236 - 9 66 00 – 0 e-mail:leycochem@leyde.com

D-50999 Köln • Industriestr. 155 Fax: +49 (0) 2236 - 9 66 00 – 10 www.leyde.com

Summary and outlook

A quality assessment of all test results is provided in Table 4. It shows the tendencies in the

behaviour of fresh concrete depending on the modified concrete compositions. Special

emphasis shall be attributed to the following individual items:

- A gravel reduction with a simultaneous sand increase (Series 1) has only minor impact

on the properties. If sand content is 40-43 Vol.% of the mortar, the difference in

superplasticizer requirement is irrelevant. This is why this ränge may be regarded

compatible with practical application.

- A reduction of binder content (here: fly ash) is only possible in a minor degree. If

reduced by 35kg/m3, or approx. 151/m3, the deterioration of fresh concrete properties

was tolerable. The application of an SCC with slight reduction of binder is therefore

imaginable, for example, in structural parts with minor reinforcement (blocking).

- The reduction of paste content by up to

40 l/m3 and a simultaneous increase of

sand content (Series 3) influenced the

properties of fresh concrete in a

tolerable ränge, however with an

increase in superplasticizer of almost

30%. However, no SCC could produced

with a paste content of only 320 l/ .

Tab. 4: Influences of modifications of Compositions to

properties of fresh concrete

- An increased gravel content of 56,6% (Series 4), based on 50 Vol.-%, together with a

sand content of 43 Vol.% (!) results in a clear deterioration of consistency and of

levelling and blocking behaviour. A sand content of 40 Vol.% of mortar allows a higher

gravel content (see Series 1).

These results on the whole demonstrate that the selected basic compositions are a good basis

for SCC concretes. An optimization of concrete composition, however, makes sense in any

case. The examinations described above can be helpful for this purpose. Basically, however,

all examinations should be based on the knowledge that the Self-Compacting Concrete SCC

does not exist, but that various compositions with slightly different properties of fresh concrete

are possible, depending on the basic materials and the concrete requirements.

LEYCOCHEM LEYDE GMBH Tel.: +49 (0) 2236 - 9 66 00 – 0 e-mail:leycochem@leyde.com

D-50999 Köln • Industriestr. 155 Fax: +49 (0) 2236 - 9 66 00 – 10 www.leyde.com

Literature:

1. Okamura, Hajime; Ozawa, Kazumasa: Mix Design For Self-Compacting Concrete.

Concrete Library Of JSCE, 25.6.1995

2. Billberg, Peter: Energymodified Cement in SCC, RILEM Symposium 1999, Stockholm

LEYCOCHEM LEYDE GMBH Tel.: +49 (0) 2236 - 9 66 00 – 0 e-mail:leycochem@leyde.com

D-50999 Köln • Industriestr. 155 Fax: +49 (0) 2236 - 9 66 00 – 10 www.leyde.com

You might also like

- Final Document of SQL Project With QuestionsDocument5 pagesFinal Document of SQL Project With QuestionsAnkita MishraNo ratings yet

- Use of Aluminium Powder in The Production of Lightweight ConcreteDocument12 pagesUse of Aluminium Powder in The Production of Lightweight ConcreteTan Khern Wee17% (6)

- Additives For A Challenging Cement MarketDocument5 pagesAdditives For A Challenging Cement MarketkidcatNo ratings yet

- Somebody That I Used To Know Ukulele TabsDocument5 pagesSomebody That I Used To Know Ukulele Tabsafcabanas100% (2)

- Teaching CertificateDocument1 pageTeaching Certificateapi-240193138No ratings yet

- Materials Selection, Proportioning and Quality Control: S MindessDocument25 pagesMaterials Selection, Proportioning and Quality Control: S MindessThắng LưuNo ratings yet

- Effect of y Ash and Silica Fume On Compressive Strength of Self-Compacting Concrete Under Different Curing ConditionsDocument8 pagesEffect of y Ash and Silica Fume On Compressive Strength of Self-Compacting Concrete Under Different Curing ConditionsgeostaterNo ratings yet

- R. Nagendra - Paper On Mix Proportioning As Per Is 10262-2009Document31 pagesR. Nagendra - Paper On Mix Proportioning As Per Is 10262-2009Vinod JogurNo ratings yet

- Self Compacting ConcreteDocument32 pagesSelf Compacting Concreteamandeepdua2016No ratings yet

- Ilyas AdmixtureDocument13 pagesIlyas Admixturekashkhan802No ratings yet

- Art - Influence of The Cement Type On The Resistance of Concrete To Feed AcidsDocument9 pagesArt - Influence of The Cement Type On The Resistance of Concrete To Feed AcidsDEIVYD HEIVYSON DIOGENES COSTANo ratings yet

- Collepadri - Properties of SCC and Flowing ConcreteDocument7 pagesCollepadri - Properties of SCC and Flowing Concrete4493464No ratings yet

- 8253-18004-1-PBDocument8 pages8253-18004-1-PBsamanosukeakaechiNo ratings yet

- Polymer - Modified Mortars and Concrete Mix DesignDocument11 pagesPolymer - Modified Mortars and Concrete Mix DesignYoseph AshenafiNo ratings yet

- Dossage of ConcreteDocument14 pagesDossage of ConcreteAteafac Anastasia NjuafacNo ratings yet

- Self Compacting ConcreteDocument14 pagesSelf Compacting ConcretealpegambarliNo ratings yet

- Self Compacting ConcreteDocument87 pagesSelf Compacting ConcreteLaura Amorim100% (2)

- Improvement of Concrete Durability by Complex Mineral Super-Fine PowderDocument9 pagesImprovement of Concrete Durability by Complex Mineral Super-Fine Powdervinay rodeNo ratings yet

- Concept of Estimate-ConcreteDocument32 pagesConcept of Estimate-ConcretereymoreNo ratings yet

- Chapter Three 3.0 Methodology: 3.2.1 Aggregates of Requirement in EssentialDocument11 pagesChapter Three 3.0 Methodology: 3.2.1 Aggregates of Requirement in EssentialAsghar Hussain Shah S/o Zubair Shah MS Engg. Management (Swat Campus)No ratings yet

- Construction and Building Materials: Her-Yung Wang, Chih-Chung LinDocument5 pagesConstruction and Building Materials: Her-Yung Wang, Chih-Chung LinVishal VyasNo ratings yet

- Opc PPC Fly Ash Study Jan 06 by MR Anil Banchhor and MR S Krishnan 241Document15 pagesOpc PPC Fly Ash Study Jan 06 by MR Anil Banchhor and MR S Krishnan 241Abdul RashidNo ratings yet

- The Investigation of The Impact of Lucobit Polymer On Bitumen PerformanceDocument10 pagesThe Investigation of The Impact of Lucobit Polymer On Bitumen PerformanceJessica ClarkNo ratings yet

- Effect of Fly Ash On Durability of Leightweight ConcreteDocument10 pagesEffect of Fly Ash On Durability of Leightweight ConcreteRadna kurniasariNo ratings yet

- High Filler Concrete Using Fly Ash - Chloride Penetration and MicrostructureDocument16 pagesHigh Filler Concrete Using Fly Ash - Chloride Penetration and MicrostructureJHON WILMAR CARDENAS PULIDONo ratings yet

- Project GGBS 2023Document39 pagesProject GGBS 2023GOWTHAMNo ratings yet

- Concreting Methods That Produce Low CarbonDocument12 pagesConcreting Methods That Produce Low Carbonjamjam75No ratings yet

- Tehnologija BetonaDocument58 pagesTehnologija BetonaOglasi Za SveNo ratings yet

- Concrete Technology NOTEDocument54 pagesConcrete Technology NOTEJanmarc PadilskiNo ratings yet

- IATMI 20-044 Novel Low Expense Cement Slurry Design Based On Enhanced Cenosphere PropertiesDocument9 pagesIATMI 20-044 Novel Low Expense Cement Slurry Design Based On Enhanced Cenosphere Propertiesdiah ayu WulandariNo ratings yet

- Slump TestDocument10 pagesSlump TestLuqma Illieana86% (14)

- Cement & Concrete Composites: Dale P. Bentz, Andrew S. Hansen, John M. GuynnDocument8 pagesCement & Concrete Composites: Dale P. Bentz, Andrew S. Hansen, John M. GuynnChin KamRongNo ratings yet

- Quality of Ready Mix ConcreteDocument6 pagesQuality of Ready Mix ConcretemkausmallyNo ratings yet

- Hanson Portland Limestone Cement Data SheetDocument2 pagesHanson Portland Limestone Cement Data Sheetyaser666No ratings yet

- Unit-4 Special ConcreteDocument32 pagesUnit-4 Special Concretemeena y rNo ratings yet

- Surico - Rheological StudyDocument18 pagesSurico - Rheological StudyDvs RamaraoNo ratings yet

- REVISED Concrete Technology BOOK - by Sri P. SURESHDocument63 pagesREVISED Concrete Technology BOOK - by Sri P. SURESHV Venkata Narayana100% (1)

- Calcul Reteta BetonDocument3 pagesCalcul Reteta BetonDorin RoşuNo ratings yet

- 05 - Concrete Ceqtys42eDocument41 pages05 - Concrete Ceqtys42edebbydebby121101No ratings yet

- Foamin C®: Light Weight Cellular Concrete and CementDocument17 pagesFoamin C®: Light Weight Cellular Concrete and Cementvladoius_1No ratings yet

- Experimental Study On Concrete Carbonation To Work Out Performance-Based SpecificationsDocument5 pagesExperimental Study On Concrete Carbonation To Work Out Performance-Based Specificationscap3000No ratings yet

- Dhanya SCCDocument16 pagesDhanya SCCManther GenxNo ratings yet

- Lecture 5 - Fundamentals: September 11, 2001 CVEN 444Document53 pagesLecture 5 - Fundamentals: September 11, 2001 CVEN 444Satish KumarNo ratings yet

- The Effect of Using Granite Dust As A Component ofDocument11 pagesThe Effect of Using Granite Dust As A Component ofr HariNo ratings yet

- Concrete Mix Design DOE PDFDocument15 pagesConcrete Mix Design DOE PDFkarthiksamp100% (2)

- Romero Rodriguez Emmanuel Takahihsy TraduccionDocument9 pagesRomero Rodriguez Emmanuel Takahihsy TraduccionEmmanuel Takahishy Romero RodriguezNo ratings yet

- Mix Design of Structural Self-Compacting Concrete Using Void-Bulk Density MethodDocument11 pagesMix Design of Structural Self-Compacting Concrete Using Void-Bulk Density MethodPtpgStucNo ratings yet

- Experimental Laboratory Validation of ReproducingDocument8 pagesExperimental Laboratory Validation of Reproducingumitkakca04No ratings yet

- Proportioning Concrete MixesDocument7 pagesProportioning Concrete MixesJennifer DamascoNo ratings yet

- Report 1 Testing On Cement: Engineering MaterialsDocument9 pagesReport 1 Testing On Cement: Engineering MaterialsEman SalahNo ratings yet

- Effect of Addition of Flyash and Ggbs On CementDocument6 pagesEffect of Addition of Flyash and Ggbs On CementDebraj RoyNo ratings yet

- Fin 00357Document9 pagesFin 00357AhmedNo ratings yet

- Effective Applications of Retarding Admixture To Improve TheDocument13 pagesEffective Applications of Retarding Admixture To Improve Thegtarun22guptaNo ratings yet

- The Influence Factors of The Workability of Roller Compacted ConcreteDocument5 pagesThe Influence Factors of The Workability of Roller Compacted ConcreteRidwanNo ratings yet

- The Effect of CaO and MgO As Expanding Additives 2Document20 pagesThe Effect of CaO and MgO As Expanding Additives 2nabella nurul fitriNo ratings yet

- Setting Time and Bleeding of Concrete With Binary and Ternary CementsDocument10 pagesSetting Time and Bleeding of Concrete With Binary and Ternary Cementsmehdi_hoseineeNo ratings yet

- Concrete Lab ManualDocument20 pagesConcrete Lab ManualkelmazodroNo ratings yet

- 32 Autocompactant 17.04.2011 PDFDocument8 pages32 Autocompactant 17.04.2011 PDFDarius StanciuNo ratings yet

- New Admixtures For Eliminating Steam Curing and Its Negative Effects On DurabilityDocument21 pagesNew Admixtures For Eliminating Steam Curing and Its Negative Effects On Durabilityअभिषेक महर्षिNo ratings yet

- Ce6506 Ctep NotesDocument183 pagesCe6506 Ctep NotesPriya ThangamuthuNo ratings yet

- Durability Design of Concrete Structures: Phenomena, Modeling, and PracticeFrom EverandDurability Design of Concrete Structures: Phenomena, Modeling, and PracticeNo ratings yet

- Core Values Module PaoloDocument9 pagesCore Values Module PaoloLala BoraNo ratings yet

- Definition of StatisticsDocument2 pagesDefinition of StatisticsBilli ManoNo ratings yet

- Universal Greens: Grand - Green - GraciousDocument12 pagesUniversal Greens: Grand - Green - GraciousinfosurenNo ratings yet

- Circuit Diagram: 220V 240V 50Hz 60Hz 300VAC, 0.33uf 300VAC, 0.27uf F.I.R CapacitorDocument1 pageCircuit Diagram: 220V 240V 50Hz 60Hz 300VAC, 0.33uf 300VAC, 0.27uf F.I.R CapacitorRudyXPNo ratings yet

- 1ghadjzftewifvsmn PDFDocument282 pages1ghadjzftewifvsmn PDFAlex MingNo ratings yet

- Girls Camp ProposalDocument7 pagesGirls Camp ProposalRena SkNo ratings yet

- Final ReportDocument110 pagesFinal ReportmasabmuzamilNo ratings yet

- Weed Control Using GoatsDocument24 pagesWeed Control Using Goatsstormbaby100% (1)

- Application Form / Checklist : Department of Fire & Rescue Services, Government of KeralaDocument37 pagesApplication Form / Checklist : Department of Fire & Rescue Services, Government of KeralaStew884No ratings yet

- Aiwa Csd-A110, Csd-A170 PDFDocument28 pagesAiwa Csd-A110, Csd-A170 PDFRodrigo NegrelliNo ratings yet

- Steel ProjectDocument37 pagesSteel ProjectAvinash GunnaNo ratings yet

- Airbus CaseDocument7 pagesAirbus Caseclarabordas.lNo ratings yet

- Sample Motion For Early ResolutionDocument3 pagesSample Motion For Early ResolutionMark Pesigan0% (1)

- ,university of Caloocan City: I. Fill in The Blanks: Answer The Following QuestionsDocument4 pages,university of Caloocan City: I. Fill in The Blanks: Answer The Following QuestionsKhate BautistaNo ratings yet

- 3 San Miguel Corp V Heirs of InguitoDocument21 pages3 San Miguel Corp V Heirs of InguitokwonpenguinNo ratings yet

- The Odyssey: By: HomerDocument7 pagesThe Odyssey: By: HomerSteven ArajaNo ratings yet

- Hongkong and Shanghai Banking Corporation (HSBC) : International Money TransfersDocument3 pagesHongkong and Shanghai Banking Corporation (HSBC) : International Money TransfersThenmozhi ThambiduraiNo ratings yet

- Service Bulletin: Examining Compressor Failures in The FieldDocument12 pagesService Bulletin: Examining Compressor Failures in The Fieldnkrish21856No ratings yet

- Criminology TermsDocument4 pagesCriminology TermsTon RJ IdoNo ratings yet

- EQR UttarkashiDocument8 pagesEQR UttarkashiArjunNo ratings yet

- Aicte Exam ReformsDocument19 pagesAicte Exam ReformsBabu NarayananNo ratings yet

- Ielts Practice Listening Test (Pretest)Document7 pagesIelts Practice Listening Test (Pretest)adpNo ratings yet

- Fine Art - September 2022Document15 pagesFine Art - September 2022ArtdataNo ratings yet

- Advisory Circular: Subject: Crew Resource Management (CRM)Document51 pagesAdvisory Circular: Subject: Crew Resource Management (CRM)OlgaNo ratings yet

- Entity Relationship Modeling: ObjectivesDocument13 pagesEntity Relationship Modeling: Objectivesniravthegreate999No ratings yet

- Aakash Rank Booster Test Series For NEET-2020Document14 pagesAakash Rank Booster Test Series For NEET-2020Anish TakshakNo ratings yet