Professional Documents

Culture Documents

Chapter 4 Numericcals Assignment

Chapter 4 Numericcals Assignment

Uploaded by

UmbertoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chapter 4 Numericcals Assignment

Chapter 4 Numericcals Assignment

Uploaded by

UmbertoCopyright:

Available Formats

PRODUCTION AND

OPERATIONS MANAGEMENT

ASSIGNMENT NO: 4

PROBLEM S7.1 Amy Xia’s plant was designed to produce 7,000 hammers per day but is limited to making

6,000 hammers per day because of the time needed to change equipment between styles of hammers. What

is the utilization?

SOLUTION

Actual: 6000 hammers per day

Design: 7000 hammers per day

Utilization: 6000/7000 = 0.875 (85.7%)

PROBLEM S7.2 For the past month, the plant in Problem S7.1, which has an effective capacity of 6,500, has

made only 4,500 hammers per day because of material delay, employee absences, and other problems. What

is its efficiency?

SOLUTION

EFFECTIVE = 6500 hammers per day

Actual = 4500 hammers per day

Efficiency = 4500/6500 = 0.692 (69.2%)

PROBLEM S7.3 If a plant has an effective capacity of 6,500 and an efficiency of 88%, what is the actual

(planned) output?

SOLUTION

Effective = 6500

Efficiency = 88%

Actual = 6500*0.88 = 5720 units

PROBLEM S7.4 A plant has an effective capacity of 900 units per day and produces 800 units per day with

its product mix; what is its efficiency?

SOLUTION

Effective = 900 units per day

Actual = 800 units per day

Efficiency = 800/900 = 0.88 (88%)

PROBLEM S7.5 Material delays have routinely limited production of household sinks to 400 units per day. If

the plant efficiency is 80%, what is the effective capacity?

SOLUTION

Actual = 400 units per day

Efficiency = 80%

Effective = 400/0.8 = 500 units per

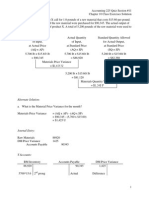

PROBLEM S7.6 The effective capacity and efficiency for the next quarter at MMU Mfg. in Waco, Texas, for

each of three departments are shown:

DEPARTMENT EFFECTIVE CAPACITY RECENT EFFICIENCY

Design 93,600 .95

Fabrication 156,000 1.03

Finishing 62,400 1.05

Compute the expected production for next quarter for each department

SOLUTION

Design Fabrication Finishing

Effective: 93600 156000 62400

Efficiency: 0.93 1.03 1.05

Actual/Effective: - Effective*Efficiency

88.920 units 160680 units 65520 units

PROBLEM S7.7 Southeastern Oklahoma State University’s business program has the facilities and faculty to

handle an enrollment of 2,000 new students per semester. However, in an effort to limit class sizes to a

“reasonable” level (under 200, generally), Southeaster’s dean, Holly Lutze, placed a ceiling on enrollment of

1,500 new students. Although there was ample demand for business courses last semester, conflicting

schedules allowed only 1,450 new students to take business courses. What are the utilization and efficiency

of this system?

SOLUTION

Design Capacity = 2000

Effective = 1500

Actual = 1450

Utilization = Actual/Design = 1450/2000 = 72.5%

Efficiency = Actual/Effective = 1450/1500 = 97%

You might also like

- Payment Systems: Dominique Rambure and Alec NacamuliDocument260 pagesPayment Systems: Dominique Rambure and Alec Nacamulimy name is hwat100% (2)

- Solution Manual For Introduction To Management Science Quantitative Approaches To Decision Making 14th Edition Anderson 1111823618 9781111823610Document46 pagesSolution Manual For Introduction To Management Science Quantitative Approaches To Decision Making 14th Edition Anderson 1111823618 9781111823610joyceNo ratings yet

- 06 ReviewProblemSolutionDocument6 pages06 ReviewProblemSolutionsubash1111@gmail.com100% (1)

- United Aluminum Company of Cincinnati Produces Three Grades (High, Medium, and Low) of Aluminum At... - HomeworkLibDocument7 pagesUnited Aluminum Company of Cincinnati Produces Three Grades (High, Medium, and Low) of Aluminum At... - HomeworkLibNiyati ShahNo ratings yet

- London Calling Entertainment v. NKSFBDocument14 pagesLondon Calling Entertainment v. NKSFBBillboardNo ratings yet

- LP03 Reiser Sports Products 1Document5 pagesLP03 Reiser Sports Products 1Jacob NavarroNo ratings yet

- Fashion ShoeDocument5 pagesFashion ShoeManal ElkhoshkhanyNo ratings yet

- TusmingmobDocument5 pagesTusmingmobRadinne Fakhri Al Wafa100% (1)

- LeDucThinh-BABAIU14255-Decision TreeDocument7 pagesLeDucThinh-BABAIU14255-Decision TreeVô Thường50% (2)

- Yankee Fork and Hoe Company Case StudyDocument4 pagesYankee Fork and Hoe Company Case StudyDeepak K Sundharan100% (1)

- Opeman MIDTERM 2Document2 pagesOpeman MIDTERM 2Michelle Ann WongNo ratings yet

- Material Requirements PlanDocument3 pagesMaterial Requirements PlanNuricha Fajariani100% (2)

- Acct 1Document2 pagesAcct 1Kintan Permata DeroseNo ratings yet

- OPS Man Assignment - 1Document13 pagesOPS Man Assignment - 1Angelie Menia50% (2)

- Session 12. Facilities layout-IIDocument34 pagesSession 12. Facilities layout-IIsandeep kumarNo ratings yet

- Inventory ExampleDocument14 pagesInventory ExampleSrijan Shetty100% (1)

- Chapter 7 Operations Management by Render and Heizer Solutions To ProblemsDocument4 pagesChapter 7 Operations Management by Render and Heizer Solutions To ProblemsKatrina BartoliniNo ratings yet

- Production and Operations Management: Assignment No: 3Document3 pagesProduction and Operations Management: Assignment No: 3UmbertoNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Production and Operations Management: Assignment No: 3Document3 pagesProduction and Operations Management: Assignment No: 3UmbertoNo ratings yet

- Human Resource Management Practices QuestionnaireDocument1 pageHuman Resource Management Practices QuestionnaireAravind RNo ratings yet

- Nama: Nabila Indri Yani No. BP: 2010931037 Tugas 1: Analisis Dan Estimasi BiayaDocument4 pagesNama: Nabila Indri Yani No. BP: 2010931037 Tugas 1: Analisis Dan Estimasi BiayaInnabilaNo ratings yet

- Final Examination - Operations ManagementDocument3 pagesFinal Examination - Operations ManagementVaughn GaneloNo ratings yet

- Operations MGT Module #5Document2 pagesOperations MGT Module #5Jude Vicente100% (2)

- MGMT PART 1Document27 pagesMGMT PART 1Anthony AnthonyNo ratings yet

- Assignment CH 4Document17 pagesAssignment CH 4Svetlana100% (2)

- Linear Programming Applications in Marketing, Finance and Operations ManagementDocument12 pagesLinear Programming Applications in Marketing, Finance and Operations ManagementMarwa HassanNo ratings yet

- What Is MollyDocument3 pagesWhat Is MollyKhairulNo ratings yet

- Southwestern University CaseDocument2 pagesSouthwestern University CaseimpurewolfNo ratings yet

- Om Case StudyDocument17 pagesOm Case StudyHMM HMMNo ratings yet

- FINAL OPS-MAN-Assignment-chapter-4Document11 pagesFINAL OPS-MAN-Assignment-chapter-4Angelie Menia100% (1)

- Week 2 HW Jason WilkinsDocument2 pagesWeek 2 HW Jason WilkinsJason Wilkins100% (1)

- Case 01 CompleteDocument12 pagesCase 01 Completeertizashuvo100% (1)

- Examination Spring 12 Online 302-AlmorqiDocument4 pagesExamination Spring 12 Online 302-AlmorqiCheick Omar CompaoreNo ratings yet

- Guideline Demo SIPROTEC DigitalTwinDocument68 pagesGuideline Demo SIPROTEC DigitalTwinengenheiroigorNo ratings yet

- Joint Report On Corporate Practice of Dentistry in The Medicaid Program July 2013Document1,517 pagesJoint Report On Corporate Practice of Dentistry in The Medicaid Program July 2013Dentist The MenaceNo ratings yet

- Production Operation ManagementDocument5 pagesProduction Operation ManagementStevando MonoarfaNo ratings yet

- Ops ManagementDocument6 pagesOps ManagementAkshay Mehta100% (2)

- Tugas Chapter 7 Nama: Steffi Dorothy NIM: 201870019Document5 pagesTugas Chapter 7 Nama: Steffi Dorothy NIM: 201870019Steffi DorothyNo ratings yet

- Mississippi River Shipyards Is Considering The Replacement of An - Appendix 11B-3 Replacement Project AnalysisDocument1 pageMississippi River Shipyards Is Considering The Replacement of An - Appendix 11B-3 Replacement Project AnalysisRajib DahalNo ratings yet

- 18Document4 pages18Aditya Wisnu P100% (1)

- Chapter Three HomeworkDocument11 pagesChapter Three HomeworkJunmirMalicVillanueva100% (1)

- 1 Ch1 QuestionsDocument2 pages1 Ch1 QuestionsE100% (1)

- Operations Management 1 - Chapter 4 Handouts 1Document10 pagesOperations Management 1 - Chapter 4 Handouts 1Sambil MukwakunguNo ratings yet

- Answer 2269 17Document10 pagesAnswer 2269 17Syed Salman Abbas100% (2)

- Practice Problems Upto Forecasting - Dec 2010Document6 pagesPractice Problems Upto Forecasting - Dec 2010Suhas ThekkedathNo ratings yet

- Case 1 Chap 4 ObDocument6 pagesCase 1 Chap 4 ObDuy Levine50% (4)

- DocumentDocument4 pagesDocumentRyan CapistranoNo ratings yet

- Chapter16 PDFDocument29 pagesChapter16 PDFervin sasongkoNo ratings yet

- IA CHPR 5 (Inventory)Document13 pagesIA CHPR 5 (Inventory)FatinAzwani RusmiNo ratings yet

- ACC00152 Business Finance Topic 6 Tutorial AnswersDocument2 pagesACC00152 Business Finance Topic 6 Tutorial AnswersPaul TianNo ratings yet

- Week 5 AssignmentDocument2 pagesWeek 5 AssignmentNGUYEN HAINo ratings yet

- Chapter 10 - Standard Costs and The Balance ScorecardDocument101 pagesChapter 10 - Standard Costs and The Balance ScorecardAmy SIlverbergNo ratings yet

- Value Chain of PepsiCoDocument3 pagesValue Chain of PepsiCoFasion InstaNo ratings yet

- QS11 - Class Exercises SolutionDocument8 pagesQS11 - Class Exercises Solutionlyk0tex100% (2)

- Hi-Ho, Yo-Yo, Inc. ReportDocument4 pagesHi-Ho, Yo-Yo, Inc. ReportEdyta OdorowskaNo ratings yet

- Group 10 - Global Marketing Study CaseDocument5 pagesGroup 10 - Global Marketing Study CaseNam NguyenNo ratings yet

- Balanced and Unbalanced Transportation ModelDocument7 pagesBalanced and Unbalanced Transportation ModelSophia Garcia100% (1)

- Problem Solving Decision Analysis Problem No. 1Document2 pagesProblem Solving Decision Analysis Problem No. 1Mj Ong Pierson Garbo100% (2)

- Lecture 5.2-General Cost Classifications (Problem 2)Document2 pagesLecture 5.2-General Cost Classifications (Problem 2)Nazmul-Hassan Sumon80% (5)

- Chapter 6:part Two Cost-Volume-ProfitDocument44 pagesChapter 6:part Two Cost-Volume-ProfitFidelina CastroNo ratings yet

- Utilization and Efficutilizattion and Efficiency Problems Operations Managementiency ProblemsDocument1 pageUtilization and Efficutilizattion and Efficiency Problems Operations Managementiency ProblemsAriadna BarnadasNo ratings yet

- QSO 300 Problems 4Document2 pagesQSO 300 Problems 4Andrei EsemNo ratings yet

- Sekolah Tinggi Teknologi Mutu (STTM) Muhammadiyah Tangerang: Subject: Production Planning & Inventory Control (PPIC)Document41 pagesSekolah Tinggi Teknologi Mutu (STTM) Muhammadiyah Tangerang: Subject: Production Planning & Inventory Control (PPIC)RisnandarEriechaCandraNo ratings yet

- No 12Document1 pageNo 12Cherie Diaz100% (1)

- Capacity Planning Chapter5 Feb 11Document44 pagesCapacity Planning Chapter5 Feb 11JOANNECHUNo ratings yet

- Optimizing Factory Performance: Cost-Effective Ways to Achieve Significant and Sustainable ImprovementFrom EverandOptimizing Factory Performance: Cost-Effective Ways to Achieve Significant and Sustainable ImprovementNo ratings yet

- Opportunities Weight Rating Weighted Score: Chosen Opportunity: Chosen ThreatDocument8 pagesOpportunities Weight Rating Weighted Score: Chosen Opportunity: Chosen ThreatUmbertoNo ratings yet

- Social Advocacy Report-1Document15 pagesSocial Advocacy Report-1UmbertoNo ratings yet

- ManagingSalesForceTurnover SriLankaDocument15 pagesManagingSalesForceTurnover SriLankaUmbertoNo ratings yet

- The Role of Humor and Fear in AdvertisingDocument22 pagesThe Role of Humor and Fear in AdvertisingUmbertoNo ratings yet

- Motivational Factors For Sales Representatives of FMCG CompanyDocument32 pagesMotivational Factors For Sales Representatives of FMCG CompanyUmbertoNo ratings yet

- McDonalds - Final SM Term ReportDocument52 pagesMcDonalds - Final SM Term ReportUmbertoNo ratings yet

- Ali Uzair 24677 Capacity Management Numerical POM Fall 2020Document2 pagesAli Uzair 24677 Capacity Management Numerical POM Fall 2020UmbertoNo ratings yet

- AQ Fitness Update 2Document13 pagesAQ Fitness Update 2UmbertoNo ratings yet

- Opentext™ Extended Ecm For Sap® Solutions Release NotesDocument82 pagesOpentext™ Extended Ecm For Sap® Solutions Release NotespeptaNo ratings yet

- Isogen Symbol Key (SKEY) Definitions: Reference GuideDocument97 pagesIsogen Symbol Key (SKEY) Definitions: Reference Guidewill_streetNo ratings yet

- Burger BaeDocument12 pagesBurger Baepriyal100% (1)

- Corporate Information: Scan To VerifyDocument7 pagesCorporate Information: Scan To VerifyALADDIN MAGIC DISHESNo ratings yet

- Special Laws RFBT Review I. Cooperative LawsDocument11 pagesSpecial Laws RFBT Review I. Cooperative LawsAcademeNo ratings yet

- 2020 Hikam - Audit Opinion and Fraud in Local Governm EngDocument13 pages2020 Hikam - Audit Opinion and Fraud in Local Governm EngDesiNo ratings yet

- Media IndustryReport 2020 Vietnam-Beverage-Industry-Report-2020 PDFDocument31 pagesMedia IndustryReport 2020 Vietnam-Beverage-Industry-Report-2020 PDFNam Duy VuNo ratings yet

- Detailed Training Activity Plan (DTAP) For NOCHRMPDocument6 pagesDetailed Training Activity Plan (DTAP) For NOCHRMPVeronica MiraflorNo ratings yet

- SW Synthetics Catalog PDFDocument27 pagesSW Synthetics Catalog PDFLC ChongNo ratings yet

- MH-weekly VCP - RANGE V2, Technical Analysis ScannerDocument6 pagesMH-weekly VCP - RANGE V2, Technical Analysis ScannerhamsNo ratings yet

- Success With Keywords How To Do Effective Keyword Research BR (Presentation)Document36 pagesSuccess With Keywords How To Do Effective Keyword Research BR (Presentation)Pradeep KNo ratings yet

- Ey How Internal Audit Can Build Trust Through TransformationDocument9 pagesEy How Internal Audit Can Build Trust Through TransformationISabella ARndorferNo ratings yet

- 4 Curriculum StructureDocument19 pages4 Curriculum StructurealiyazahirNo ratings yet

- 862b331f6f5249e7a06bb8bca39f82b2Document9 pages862b331f6f5249e7a06bb8bca39f82b2matthewNo ratings yet

- The API Management PlaybookDocument34 pagesThe API Management PlaybookSai CharanNo ratings yet

- Module 7A - Designing A Tailored System - Design Factors - 2Document47 pagesModule 7A - Designing A Tailored System - Design Factors - 2sovafNo ratings yet

- ACYMAG2 NotesDocument60 pagesACYMAG2 NotesAngel JamianaNo ratings yet

- Simulado 12Document13 pagesSimulado 12Danillo AraujoNo ratings yet

- Richa Gupta ResumeDocument4 pagesRicha Gupta Resumescribd@123No ratings yet

- Activity 2.A: Illegal Use of ElectricityDocument26 pagesActivity 2.A: Illegal Use of ElectricityMark Lawrence BuenviajeNo ratings yet

- CGT Tomanda AntokDocument1 pageCGT Tomanda AntokNvision PresentNo ratings yet

- Analisis Daya Dukung Wilayah Dalam Pengembangan Industri BesarDocument22 pagesAnalisis Daya Dukung Wilayah Dalam Pengembangan Industri BesarFresky Bin Bani MunajadNo ratings yet

- Chapter 4. Basel's Principle For Effective Risk Data Aggregation and Risk ReportingDocument30 pagesChapter 4. Basel's Principle For Effective Risk Data Aggregation and Risk ReportingBelle AnnaNo ratings yet

- Iso37001 Implementation Guide en MyDocument12 pagesIso37001 Implementation Guide en MylovishNo ratings yet

- Admit Card-1689084970Document1 pageAdmit Card-1689084970CodaDeskNo ratings yet