Professional Documents

Culture Documents

SAP APO Overview and Function of Planning Application: You Get Complete Coverage of The Topics Below

SAP APO Overview and Function of Planning Application: You Get Complete Coverage of The Topics Below

Uploaded by

Suraj PillaiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SAP APO Overview and Function of Planning Application: You Get Complete Coverage of The Topics Below

SAP APO Overview and Function of Planning Application: You Get Complete Coverage of The Topics Below

Uploaded by

Suraj PillaiCopyright:

Available Formats

You get complete coverage of the topics below:

SAP APO Overview and Function of Planning Application

Concepts of Supply Chain Management

List the Advantages of APO

Summarize the functions of the planning applications in APO

Integration and Technology (Live Cache,Integration with OLTP system

using CIF)

Modeling and Evaluation in APO (Overview of Master Data

and Transaction data for

supply chain planning,Function of Model and Version)

Overview of master data and Transaction data in APO

Internal SAP SCM APO Business Warehouse

Purpose of Internal Business warehouse and concept

of extraction of transactional data

Role and Function of Data warehousing workbench and Components

Structure of Characteristics and Key Figures

Overview of data source and data extraction

Process of configuring LIS for data structure

Info source,Info packages and Info cube in detail

Set up Demand and Supply planning in SCM APO-Configuration of DP

and SNP

Creating Planning Object Structure

Planning levels of demand planning in POS

Task of planning object structure,master data and characteristics values

combinations

Creation of Characteristics values combinations

Create planning area and Planning Book with data view

Set aggregation and disaggregation for key figures

create time series in live cache

Key figures setting in planning area

Describe aggregation and disaggregation methods

Calculate proportional factors

Planning Object structure

Planning area

Planning Book and Data view

Macro and Alerts

Apply Demand Planning DP for forecasting

Demand Integrative planning Table and additional features in DP

Forecasting Process (Univariant Forecast,MLR,composite

,consensus planning)

Generation of proportional factor in DP

Life Cycle planning (Realignment,Life cycle planning and

Product interchangeability

Advance Macros in DP

Promotion Planning

Mass Processing

Process chain in DP

Integration between SAP APO and ECC systems using CIF

Architecture of the integration of the system SAP ECC with the system

SAP SCM: logical systems, target systems, queued RFC, RFC-destinations,

business system group

Generation of integration models for the core interface (selection of

master and transaction data which should be transferred)

Activation of integration models (transfer of the selected data)

Initial and change transfer of fundamental master data from the SAP

ECC (e.g. Plant, distribution center, material)

Real-time transfer of transaction data (stocks, orders) from SAP ECC as

well as retransfer of transaction data like planning results from SAP SCM to

SAP ECC

Reports for routine operation

Monitoring and treatment of errors during the transmission (CIF cockpit,

SCM queue manager, qRFC monitor, application log, and so on)

Apply supply network planing (SNP) for cross location planning

SNP Overview ,SNP Process flow.

Master data and Transaction data in SNP

Supply Network Planning Methods (Heuristic,optimizer and CTM)

Supply Network Planning Heuristic (Heuristic Run,Capacity Check and

Leveling)

SNP Heuristic scheduling

Aggregated Planning

Optimization in SNP (Supply planning with Optimizer,Optimizer

costs,profile used by optimizer)

Product interchangeability

Safety stock Planning in SNP

Basic of Deployment and TLB

Capable to Match (CTM) in SCM

Functionality of CTM

CTM master data selection

CTM planning process types

System landscape required for CTM

CTM demand and supply processing

CTM planning algorithm

Supply control with CTM

Set up Production Planning and Detailed Scheduling in SAP SCM

Maintain Number ranges for orders

Maintain Strategy Profiles

Maintain Planning Procedures and Planning Groups

Set up times

Maintain PPDS Heuristic setting and Profiles

Maintain work area

Maintain Period board profile and Time profiles

Set up management and alert monitor

Set up propagation ranges

Apply Production Planning and Detailed Scheduling for planing of

orders

Role of PPDS in SCM

Master Data overview

Demand Management (PIR and sales orders,MTS & MTO)

Production planning (Prerequisite and Setting,Planning

Process,Heuristic for MRP planning and Firming)

Steps in PP (Net requirement calculation and lot size calculation,Source

determination,PPM/PDS explosion,Set up times ,Pegging)

Tools and Production planning (Product view,Product planing

table,Pegging overview,Days supply,Detailed scheduling board,Resource

planing table,PPDS optimizer and Alert monitor)

Set Up Global Available to Promise

Maintain Global Setting for Available check

Maintain Category,Check mode and Check instruction

Maintain ATP group and check control

Maintain Allocation object ,group and Procedure

Sequence of product allocation procedure

Maintain Rule strategy and sequence for rule-based available check

Parallelizing backorder processing.

You might also like

- Invisible Contracts PDFDocument584 pagesInvisible Contracts PDFNETER432100% (16)

- Autonomy PitchbookDocument23 pagesAutonomy PitchbookZerohedge100% (29)

- SCM220/225 - Demand Planning/ Advanced Demand Planning: Course Version: 081Document2 pagesSCM220/225 - Demand Planning/ Advanced Demand Planning: Course Version: 081Kiran KumarNo ratings yet

- Google Cloud Platform for Data Engineering: From Beginner to Data Engineer using Google Cloud PlatformFrom EverandGoogle Cloud Platform for Data Engineering: From Beginner to Data Engineer using Google Cloud PlatformRating: 5 out of 5 stars5/5 (1)

- BCB Strategic Plan 20221Document29 pagesBCB Strategic Plan 20221BernewsAdmin100% (1)

- Effects of Foreign Currency Transaction - CCDocument28 pagesEffects of Foreign Currency Transaction - CCKanbiro OrkaidoNo ratings yet

- SAP APO OverviewDocument114 pagesSAP APO OverviewjsNo ratings yet

- SAP Project Systems TrainingDocument6 pagesSAP Project Systems Trainingitprofessionalsnetwo0% (5)

- SAP Controlling (ECC+S4HANA)Document6 pagesSAP Controlling (ECC+S4HANA)HoNo ratings yet

- SNP Heuristic-Based PlanningDocument65 pagesSNP Heuristic-Based PlanningyareddyNo ratings yet

- APO Overview PPT For SAPDocument33 pagesAPO Overview PPT For SAPPrabhakar67% (3)

- ERP: Enterprise Resource Planning: Sap Modules: Technical ModulesDocument11 pagesERP: Enterprise Resource Planning: Sap Modules: Technical ModulesPradeep Kumar100% (1)

- Dima Records - NEWBILT SINGLE - Newbilt Offer 200312-01Document16 pagesDima Records - NEWBILT SINGLE - Newbilt Offer 200312-01David Laszlo100% (1)

- OCSO Inventory Turnover AuditDocument160 pagesOCSO Inventory Turnover AuditOKCFOXNo ratings yet

- SAP APO Online TrainingDocument6 pagesSAP APO Online TrainingonlineitguruNo ratings yet

- Sap Dp/snp/pp/ds Functional Team Member Resume: Hire NowDocument8 pagesSap Dp/snp/pp/ds Functional Team Member Resume: Hire NowGopalakrishnan Subb100% (2)

- Sap Apo Training Video TutorialDocument5 pagesSap Apo Training Video TutorialsapdemovideoNo ratings yet

- Kamran Shaikh KS259151 191Document8 pagesKamran Shaikh KS259151 191akeey4uNo ratings yet

- SAP APO Online TrainingDocument3 pagesSAP APO Online TrainingSureshNo ratings yet

- SAP PP-Production Planning & Control Training ContentsDocument2 pagesSAP PP-Production Planning & Control Training ContentsShankar GangannaNo ratings yet

- SCM Overview Introduction Lab 1Document27 pagesSCM Overview Introduction Lab 1Evgeny MarkinNo ratings yet

- Apo Interview QuestionsDocument10 pagesApo Interview QuestionsHari KrishnaNo ratings yet

- Supply Network Planning APO SNPDocument2 pagesSupply Network Planning APO SNPAlper SarıcıoğluNo ratings yet

- Sap PP Course Syllabus in ChennaiDocument5 pagesSap PP Course Syllabus in ChennaiSandeep Kumar PraharajNo ratings yet

- High Level Overview of APO Demand Planning - Scribd UploadDocument35 pagesHigh Level Overview of APO Demand Planning - Scribd UploadChandru ThirumurthiNo ratings yet

- Email: Boaetech@Gmail - Com Skype: BoaetechDocument3 pagesEmail: Boaetech@Gmail - Com Skype: BoaetechspkirubaakaranNo ratings yet

- SAP PPDocument2 pagesSAP PPNaseer SapNo ratings yet

- S4 PP PDFDocument2 pagesS4 PP PDFNaveen KumarNo ratings yet

- APO DP TechnicalDocument14 pagesAPO DP Technicalravi.gundavarapu5532No ratings yet

- Production Planning and Detailed Scheduling (PP/DS) in SCMDocument50 pagesProduction Planning and Detailed Scheduling (PP/DS) in SCMVijay HajnalkerNo ratings yet

- SAP PP ContentDocument7 pagesSAP PP Contentsrinivas raoNo ratings yet

- SAP SCM Demand Planning: Best Practice For Solution ManagementDocument12 pagesSAP SCM Demand Planning: Best Practice For Solution ManagementSagar BabarNo ratings yet

- SCM-APO DP OverviewDocument104 pagesSCM-APO DP Overviewnaveen_thumu100% (1)

- SAPSCM/APO European Initiative: APO Overview Internal Training Demand Planning OverviewDocument104 pagesSAPSCM/APO European Initiative: APO Overview Internal Training Demand Planning OverviewVipparti Anil KumarNo ratings yet

- Sanjaya Shrestha: SAP APO DP/SNP/Data Consultant - Nike, IncDocument6 pagesSanjaya Shrestha: SAP APO DP/SNP/Data Consultant - Nike, IncRam PNo ratings yet

- Sap IbpDocument6 pagesSap Ibpmail_girish20029690No ratings yet

- Test Data For Volume Testing - SAP SCM Demand Planning: Best Practice For Solution ManagementDocument12 pagesTest Data For Volume Testing - SAP SCM Demand Planning: Best Practice For Solution ManagementSagar BabarNo ratings yet

- APO Data For Volum TestingDocument11 pagesAPO Data For Volum TestingSagar BabarNo ratings yet

- Advanced Planning and OptimizationDocument13 pagesAdvanced Planning and OptimizationJyotidesaiNo ratings yet

- Sap SCM Apo SyllabusDocument3 pagesSap SCM Apo SyllabusxskiruNo ratings yet

- SCM210Document1 pageSCM210Anurag AgrawalNo ratings yet

- SCM APO DP OverviewDocument104 pagesSCM APO DP Overviewberater8No ratings yet

- Supply PlanningDocument34 pagesSupply Planningharry4sapNo ratings yet

- Planning Tool SAP - PelsisDocument19 pagesPlanning Tool SAP - PelsisBhaskar AmbikapathyNo ratings yet

- S4 HANA Simple Logistics-1709Document9 pagesS4 HANA Simple Logistics-1709Om Prakash Dubey50% (2)

- PLM150 EngineeringChangeAndConfigurationManagementDocument226 pagesPLM150 EngineeringChangeAndConfigurationManagementఈశ్వర్ భరణిNo ratings yet

- Sap Apo Course: IntroductionDocument3 pagesSap Apo Course: IntroductionArpan MahajanNo ratings yet

- Sap CifDocument38 pagesSap Cifnarendrak_12No ratings yet

- Apo Ppds Vs PP OverviewDocument66 pagesApo Ppds Vs PP Overviewvijay_apoNo ratings yet

- SAP Demand Planning Training Dutation: 40 HtsDocument4 pagesSAP Demand Planning Training Dutation: 40 Htsbalaji0907No ratings yet

- Section 1: SAP Overview: Please Find Macro Level SAP PP Chapter Like BelowDocument3 pagesSection 1: SAP Overview: Please Find Macro Level SAP PP Chapter Like Belowpramodrp2007No ratings yet

- SCM210 - 215 SyllabiDocument2 pagesSCM210 - 215 SyllabioksbalveenNo ratings yet

- My Preparation TopicsDocument10 pagesMy Preparation TopicsGokulNo ratings yet

- Sap PP SyllabusDocument4 pagesSap PP SyllabusZaheer AhamedNo ratings yet

- Implementing IT in Supply Chain ManagementDocument49 pagesImplementing IT in Supply Chain ManagementpdraiNo ratings yet

- Role of IT in SCM-notesDocument63 pagesRole of IT in SCM-notespiyushsithaNo ratings yet

- SAP PP Training Course ContentDocument3 pagesSAP PP Training Course ContentInnaiah PasalaNo ratings yet

- Sap PP Online TrainingDocument10 pagesSap PP Online Trainingexpertisesignin1No ratings yet

- Sap ApoDocument16 pagesSap Aponaveen_thumuNo ratings yet

- SAP APO DP NotesDocument4 pagesSAP APO DP NotesAnonymous 0v9zwXz6hFNo ratings yet

- Design Principles for Process-driven Architectures Using Oracle BPM and SOA Suite 12cFrom EverandDesign Principles for Process-driven Architectures Using Oracle BPM and SOA Suite 12cNo ratings yet

- 31 08 - Org MGT c5 BLDocument43 pages31 08 - Org MGT c5 BLSuraj PillaiNo ratings yet

- 31 08 - Org MGT c5 BLDocument43 pages31 08 - Org MGT c5 BLSuraj PillaiNo ratings yet

- What Is Data ExtractionDocument13 pagesWhat Is Data ExtractionSuraj PillaiNo ratings yet

- The Biannual Releases Proved To Be Larger Than The Previous Quarterly ReleasesDocument2 pagesThe Biannual Releases Proved To Be Larger Than The Previous Quarterly ReleasesSuraj PillaiNo ratings yet

- Business SAP OMDocument22 pagesBusiness SAP OMSuraj PillaiNo ratings yet

- HCM CVR1Document3 pagesHCM CVR1Suraj PillaiNo ratings yet

- SAP SF FO ORG STR Full Lab NotesDocument39 pagesSAP SF FO ORG STR Full Lab NotesSuraj PillaiNo ratings yet

- Business Blueprint ESSDocument59 pagesBusiness Blueprint ESSSuraj PillaiNo ratings yet

- Sap HCM BCV 1Document5 pagesSap HCM BCV 1Suraj PillaiNo ratings yet

- Case StudyDocument13 pagesCase StudyDamola LashNo ratings yet

- Contents Table Butchery Business PlanDocument5 pagesContents Table Butchery Business PlanHyper X100% (1)

- Business Communication PDFDocument4 pagesBusiness Communication PDFjakke harshavardhiniNo ratings yet

- Zelalem: What Is The Accounting Equation?Document5 pagesZelalem: What Is The Accounting Equation?edosa. bedasaNo ratings yet

- An Introduction To New Product Development (NPD)Document20 pagesAn Introduction To New Product Development (NPD)binder8640No ratings yet

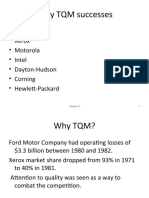

- Early TQM Successes: - Nashua - Xerox - Motorola - Intel - Dayton-Hudson - Corning - Hewlett-PackardDocument31 pagesEarly TQM Successes: - Nashua - Xerox - Motorola - Intel - Dayton-Hudson - Corning - Hewlett-Packardrocks tusharNo ratings yet

- Sandvik Exchange ProgramsDocument4 pagesSandvik Exchange ProgramsBenjamin MurphyNo ratings yet

- Construction Authority, Singapore 5 Days (June 2008)Document13 pagesConstruction Authority, Singapore 5 Days (June 2008)Raghavendra NaduvinamaniNo ratings yet

- Alhosni HalwaDocument236 pagesAlhosni HalwasultanalmazroueiNo ratings yet

- Aws B2.1.011 91Document12 pagesAws B2.1.011 91Martin Urriza VelazquezNo ratings yet

- Tradition and TasteDocument11 pagesTradition and TasteARAVINDAN A 2127011No ratings yet

- EPPM2033 - Group 5 Project ReportDocument30 pagesEPPM2033 - Group 5 Project ReportWai ChongNo ratings yet

- GBMT1006 Operations Management Test 1Document5 pagesGBMT1006 Operations Management Test 1shrey barotNo ratings yet

- Module 6 Part 2 Internal ControlDocument15 pagesModule 6 Part 2 Internal ControlKRISTINA CASSANDRA CUEVASNo ratings yet

- Strategic Decision Making For Sustainable Management of Industri 2021Document185 pagesStrategic Decision Making For Sustainable Management of Industri 2021addictedtospeedNo ratings yet

- Project 1 Briefing - SN Department - SEM2 - 1516Document33 pagesProject 1 Briefing - SN Department - SEM2 - 1516Akhmal HaziqNo ratings yet

- Narrative ReportDocument5 pagesNarrative ReportHazel BorboNo ratings yet

- Rapid7 InsightVM Product BriefDocument2 pagesRapid7 InsightVM Product BriefIM ContosoNo ratings yet

- Miles CPA RoadmapDocument72 pagesMiles CPA Roadmaproopa raniNo ratings yet

- FP Bhopal Edition 12 January 2023Document19 pagesFP Bhopal Edition 12 January 2023Abhishekh GuptaNo ratings yet

- Before The Notary Public, Bangladesh Affidavit of Financial SupportDocument2 pagesBefore The Notary Public, Bangladesh Affidavit of Financial SupportMohammed AsadujjamanNo ratings yet

- Assignment On Oligopoly (Puma) : Mi-122, Behind Pharma City, Selaqui Industrial Area, Dehradun, Uttarakhand 248001Document4 pagesAssignment On Oligopoly (Puma) : Mi-122, Behind Pharma City, Selaqui Industrial Area, Dehradun, Uttarakhand 248001Ammar AhmadNo ratings yet

- Answer Key TaxDocument3 pagesAnswer Key TaxAlvin QuintanaNo ratings yet

- 1: What Forces Have Led To The Boom in Entrepreneurship in The U.S. and Across The Globe?Document6 pages1: What Forces Have Led To The Boom in Entrepreneurship in The U.S. and Across The Globe?Samiir AhmedNo ratings yet