Professional Documents

Culture Documents

Charaterization of Liquid Solid Reaction

Charaterization of Liquid Solid Reaction

Uploaded by

Yuni_Arifwati_5495Copyright:

Available Formats

You might also like

- 9bn0 01 Que 20230608Document32 pages9bn0 01 Que 20230608Ahmed AbdelrhemNo ratings yet

- MYP3 Unit 1 Summative Assessment Criterion DDocument5 pagesMYP3 Unit 1 Summative Assessment Criterion D2059964904No ratings yet

- Chemistry For The IB Diploma Exam Preparation Guide - PublicDocument53 pagesChemistry For The IB Diploma Exam Preparation Guide - PublicMălina IoneteNo ratings yet

- Daikin Perfera FTXM-R User Manual EngDocument20 pagesDaikin Perfera FTXM-R User Manual EngZoltán KozmaNo ratings yet

- Database Investigation Homologous SeriesDocument6 pagesDatabase Investigation Homologous SeriesDiana100% (1)

- Marking Scheme For Core Worksheet - Chapter 2: 1 Protons Neutrons Electrons A B C D e F 2 3Document2 pagesMarking Scheme For Core Worksheet - Chapter 2: 1 Protons Neutrons Electrons A B C D e F 2 3Paul Murray0% (1)

- Topic 9 QDocument19 pagesTopic 9 QIndraneel BhattacharjeeNo ratings yet

- h2 Chem ChecklistDocument3 pagesh2 Chem ChecklistJohn TanNo ratings yet

- 4 Ec 4 BB 419 Cdab 2 D 5 C 3 F 3Document4 pages4 Ec 4 BB 419 Cdab 2 D 5 C 3 F 3api-2306408280% (1)

- Acid Rain ExperimentDocument5 pagesAcid Rain ExperimentSAAHIBA BHATIANo ratings yet

- Dissolution CaCO3 in Aqueous SolutionsDocument2 pagesDissolution CaCO3 in Aqueous SolutionsYuni_Arifwati_5495No ratings yet

- Antibacterial Activity of Wiregrass (Eleusine Indica) and Pandanus Specie Leaves Extract Against Escherichia ColiDocument28 pagesAntibacterial Activity of Wiregrass (Eleusine Indica) and Pandanus Specie Leaves Extract Against Escherichia ColiKristian Dave Diva100% (6)

- Study On The Stoichiometry and Reaction Products of Extra Virgin Olive Oil OzonationDocument5 pagesStudy On The Stoichiometry and Reaction Products of Extra Virgin Olive Oil OzonationAlexiss Chavez-De la Mora100% (1)

- Four Probe MethodDocument101 pagesFour Probe MethodPanthoiba AkoijamNo ratings yet

- Topic 4 BondingDocument29 pagesTopic 4 BondingXandi NalepaNo ratings yet

- T SC 2550043 Ks2 Year 6 Living Things and Their Habitats Revision Activity Mat Ver 4 2Document8 pagesT SC 2550043 Ks2 Year 6 Living Things and Their Habitats Revision Activity Mat Ver 4 2zacktudorukNo ratings yet

- IB Questionbank Chemistry 1Document25 pagesIB Questionbank Chemistry 1raja_tanukuNo ratings yet

- Atomic Structure and Periodic Table Mark SchemeDocument5 pagesAtomic Structure and Periodic Table Mark SchemeDiyaNo ratings yet

- Longest Poem Written by Nikhil Parekh - Only As LifeDocument28 pagesLongest Poem Written by Nikhil Parekh - Only As LifeNikhil ParekhNo ratings yet

- KE - Chapter 14 - Chemical KineticsDocument16 pagesKE - Chapter 14 - Chemical KineticsjoaseNo ratings yet

- HL Paper 2: Full Electron Configuration of The Ruthenium (II) IonDocument20 pagesHL Paper 2: Full Electron Configuration of The Ruthenium (II) IonfuduNo ratings yet

- Option E - Astrophysics Self Study 10Document9 pagesOption E - Astrophysics Self Study 10sudkNo ratings yet

- 0654 (Biology) ChecklistDocument4 pages0654 (Biology) ChecklistHồ Liên KhảiNo ratings yet

- GCE in Chemistry Course PlannerDocument35 pagesGCE in Chemistry Course PlannerMary MannuNo ratings yet

- Market Structure Worksheets and AnswersDocument16 pagesMarket Structure Worksheets and AnswersNate ChenNo ratings yet

- Structure 1.1, 1.2, 1.3 PracticeDocument6 pagesStructure 1.1, 1.2, 1.3 PracticeEthan ElliotNo ratings yet

- Paper 1 Section B Question-Answer Book BDocument20 pagesPaper 1 Section B Question-Answer Book BKathy WongNo ratings yet

- A2 CHM Sol 05 Acid and Base WSDocument28 pagesA2 CHM Sol 05 Acid and Base WSnsNo ratings yet

- 9a Alkaseltzer Rates of ReactionDocument13 pages9a Alkaseltzer Rates of Reactionapi-298247873100% (1)

- Mark Scheme Q4 MicroeconomicsDocument5 pagesMark Scheme Q4 MicroeconomicsVittoria RussoNo ratings yet

- Atomic Structure (AP MC)Document4 pagesAtomic Structure (AP MC)Nyxas IoannisNo ratings yet

- TB - 83 (Ka and KB) Weakacidandbaseequilibrium - 61edf9de533071.61edf9e14301f7.77090779Document20 pagesTB - 83 (Ka and KB) Weakacidandbaseequilibrium - 61edf9de533071.61edf9e14301f7.77090779任思诗No ratings yet

- January 2014 (IAL) MS - Unit 2 Edexcel Chemistry A-LevelDocument21 pagesJanuary 2014 (IAL) MS - Unit 2 Edexcel Chemistry A-LevelNabindra RuwaliNo ratings yet

- Edexcel GCSE Additonal Science P2 Topic 4 Test 13 - 14 With Marks SchemeDocument15 pagesEdexcel GCSE Additonal Science P2 Topic 4 Test 13 - 14 With Marks SchemePaul BurgessNo ratings yet

- N17 H2 P2 AnswersDocument10 pagesN17 H2 P2 AnswersSamuel TeohNo ratings yet

- Complex IonsDocument4 pagesComplex Ionsmikey12345452863879No ratings yet

- Chemistry ShipwrecksCorrosion&ConservationDocument17 pagesChemistry ShipwrecksCorrosion&ConservationMarco Huang100% (7)

- Chemistry HSSC I Paper I (2019)Document12 pagesChemistry HSSC I Paper I (2019)Tayyib Khan100% (1)

- 9701 s12 QP 11 PDFDocument16 pages9701 s12 QP 11 PDFHubbak KhanNo ratings yet

- SP 2007 (3-5)Document52 pagesSP 2007 (3-5)Maheer100% (1)

- Unit 2 NotesDocument28 pagesUnit 2 NotesMuhammad ZaiNo ratings yet

- Lesson 1 Thermochemistry-Exothermic and EndothermicDocument28 pagesLesson 1 Thermochemistry-Exothermic and EndothermicNadine TariganNo ratings yet

- MM435 CDP-1 3 Cell PotentialsDocument16 pagesMM435 CDP-1 3 Cell Potentialsamjad sattarNo ratings yet

- Chap 2Document72 pagesChap 2miguel0angel0ramos-1100% (6)

- 2022 H1 Chemistry Dec Revision Book - Question - FinalDocument42 pages2022 H1 Chemistry Dec Revision Book - Question - Final2022 BALAKRISHNAN ADHITHINo ratings yet

- Chapter: 1 Stoichiometric Relationships: SubtopicsDocument108 pagesChapter: 1 Stoichiometric Relationships: SubtopicsBNo ratings yet

- Effect of Oxidation in Day To Day LifeDocument4 pagesEffect of Oxidation in Day To Day LifeSamreenKhanNo ratings yet

- Quantum and Nuclear Questions and AnswersDocument43 pagesQuantum and Nuclear Questions and AnswersemilyNo ratings yet

- CHM1 Enthalpy Change QDocument121 pagesCHM1 Enthalpy Change Qpaolo maldini0% (1)

- Test 1 Paper2 - Grade 10-11 IGCSE - 2020 - MoodleDocument13 pagesTest 1 Paper2 - Grade 10-11 IGCSE - 2020 - MoodleJadNo ratings yet

- DP Chem Unit 12 Option C - EnergyDocument8 pagesDP Chem Unit 12 Option C - EnergyPatrick AbidraNo ratings yet

- Zumdahl Chapter 12Document23 pagesZumdahl Chapter 12Spidy MoveNo ratings yet

- A Level Physics CIE: 17. OscillationsDocument28 pagesA Level Physics CIE: 17. OscillationsA2-A23030 Trivedi Parshva JigneshNo ratings yet

- A Level H2 Paper 2Document6 pagesA Level H2 Paper 2newtonian_physics100% (1)

- Combined As Chemistry Theory 9701 Paper 2Document460 pagesCombined As Chemistry Theory 9701 Paper 2Deshpande Shashibhushan AshokNo ratings yet

- Chapter 2 Atomic StructureDocument13 pagesChapter 2 Atomic StructureBetty BavorováNo ratings yet

- Keep It Simple Science 3 - MetalsDocument13 pagesKeep It Simple Science 3 - Metalsricerocketz1231231No ratings yet

- 7.2.6.2.6. Non Aqueous Titration NewDocument2 pages7.2.6.2.6. Non Aqueous Titration NewimambollNo ratings yet

- Free Body Diagram WorksheetDocument6 pagesFree Body Diagram WorksheetAshleigh JarrettNo ratings yet

- 2.2. Forces and DinamicsDocument161 pages2.2. Forces and DinamicsMartinNo ratings yet

- (Competition Science Vision IIT JEE NEET) Collection - Toppers Notes of Organic Chemistry Competition Science Vision Volume 872 Extra Special Issue-Competition Science Vision PDFDocument69 pages(Competition Science Vision IIT JEE NEET) Collection - Toppers Notes of Organic Chemistry Competition Science Vision Volume 872 Extra Special Issue-Competition Science Vision PDFDevansh MishraNo ratings yet

- 2Document11 pages2Sophia Rubio100% (1)

- Ib PPT 4 SL PDFDocument103 pagesIb PPT 4 SL PDFzarna nirmal rawalNo ratings yet

- Tris Oxalato 3Document7 pagesTris Oxalato 3nathaloaNo ratings yet

- Calcium Carbonate Dissolution and Precipitation in Water - FactorsDocument46 pagesCalcium Carbonate Dissolution and Precipitation in Water - FactorsYuni_Arifwati_5495No ratings yet

- A Review of Acid Mine Drainage in A Water-Scarce Country: Case of South AfricaDocument20 pagesA Review of Acid Mine Drainage in A Water-Scarce Country: Case of South AfricaYuni_Arifwati_5495No ratings yet

- Dissolution of Caco3Document8 pagesDissolution of Caco3Yuni_Arifwati_5495100% (1)

- Geochemistry of Acid Mine Drainage For Coal MineDocument16 pagesGeochemistry of Acid Mine Drainage For Coal MineYuni_Arifwati_5495No ratings yet

- Oxygen Influx and Geochemistry of Percolate Water From Reactive Mine Waste Rock Underlying A Sloping Channelled Soil CoverDocument11 pagesOxygen Influx and Geochemistry of Percolate Water From Reactive Mine Waste Rock Underlying A Sloping Channelled Soil CoverYuni_Arifwati_5495No ratings yet

- Kinetics of Dissolution of Solid Substances: Exercise 4Document5 pagesKinetics of Dissolution of Solid Substances: Exercise 4Yuni_Arifwati_5495No ratings yet

- The Effectiveness Study On Cao Lime Dose and Operation Time Variation and Its Influence On Acid Mine Drainage TreatmentDocument5 pagesThe Effectiveness Study On Cao Lime Dose and Operation Time Variation and Its Influence On Acid Mine Drainage TreatmentYuni_Arifwati_5495No ratings yet

- Chapter 5 Characterisation of Limestone and LimeDocument37 pagesChapter 5 Characterisation of Limestone and LimeYuni_Arifwati_5495No ratings yet

- Bahan Bagus Okeee First-Order Reactions - Chemistry LibreTexts PDFDocument9 pagesBahan Bagus Okeee First-Order Reactions - Chemistry LibreTexts PDFYuni_Arifwati_5495No ratings yet

- Kinetics - Reaction Rate (Bagus)Document6 pagesKinetics - Reaction Rate (Bagus)Yuni_Arifwati_5495No ratings yet

- IJEE 06 v5n6Document8 pagesIJEE 06 v5n6Muhammad Fajrin ArifinNo ratings yet

- Symbols Lect. No. Tim E: K E E HDocument15 pagesSymbols Lect. No. Tim E: K E E HYuni_Arifwati_5495No ratings yet

- Blast Fume Clearance Reentry TimesDocument8 pagesBlast Fume Clearance Reentry TimesYuni_Arifwati_5495No ratings yet

- 035-Procedure For Material Traceability and Marking PDFDocument16 pages035-Procedure For Material Traceability and Marking PDFKöksal Patan100% (10)

- Air PumpDocument7 pagesAir PumpRobert Ryan SantiagoNo ratings yet

- From Gene To ProteinDocument9 pagesFrom Gene To ProteincrookedspookNo ratings yet

- MSDS Auramix 300 PDFDocument3 pagesMSDS Auramix 300 PDFkk mishra0% (1)

- Calcium Carbonate Ball Mill PDFDocument3 pagesCalcium Carbonate Ball Mill PDFAnonymous yy8In96j0rNo ratings yet

- Sandeep NewDocument2 pagesSandeep Newvignesh kumarNo ratings yet

- Building Materials and Technology 1 & 2 MODULE - IDocument156 pagesBuilding Materials and Technology 1 & 2 MODULE - IAr Anil KumarNo ratings yet

- Titanium Dioxide-Modified Activated CarbonDocument8 pagesTitanium Dioxide-Modified Activated Carbonpetru apopeiNo ratings yet

- Why Is Rigor Mortis Absent in AnthraxDocument25 pagesWhy Is Rigor Mortis Absent in Anthraxravigg100% (2)

- DS Granipan F30Document1 pageDS Granipan F30faridNo ratings yet

- Av 650 Recent MSDSDocument6 pagesAv 650 Recent MSDSMounir BoutaghaneNo ratings yet

- MSDS - DK PGT Paste R27Document4 pagesMSDS - DK PGT Paste R27RND PT SIPNo ratings yet

- Well Log Suites - SEPM StrataDocument2 pagesWell Log Suites - SEPM StrataSatken AinelNo ratings yet

- Kor-N-Seal Technical SpecDocument1 pageKor-N-Seal Technical SpecJohn BolgerNo ratings yet

- Hort. 305 Turmeric Cultivation and Processing-6Document9 pagesHort. 305 Turmeric Cultivation and Processing-6meriiNo ratings yet

- Comb - Chemkin - Format PDFDocument5 pagesComb - Chemkin - Format PDFMUHAMMAD FAREEZ IZWAN BIN ABDUL JALILNo ratings yet

- 0620 QP 53Document12 pages0620 QP 53mk mkNo ratings yet

- 1 s2.0 S0169409X16300552 MainDocument19 pages1 s2.0 S0169409X16300552 MainpavaniNo ratings yet

- Corvine Chemicals & Pharmaceuticals LTD.: Training For The Production of SODIUM AZIDEDocument3 pagesCorvine Chemicals & Pharmaceuticals LTD.: Training For The Production of SODIUM AZIDENiraNo ratings yet

- Chemical Process Calculations - Short TutorialDocument5 pagesChemical Process Calculations - Short TutorialMohammad AtifNo ratings yet

- Analysis of Microstructure and Hardness Behaviour of Grain Refined A390 Alloy Mini Project ReportDocument23 pagesAnalysis of Microstructure and Hardness Behaviour of Grain Refined A390 Alloy Mini Project ReportRahul SanjayanNo ratings yet

- The Disadvantages of Fly AshDocument8 pagesThe Disadvantages of Fly AshShariar Masud TowhidNo ratings yet

- Antioxidant Activity of Ayosep Leaf Formulated As Tea: Vaccinium MyrtoidesDocument7 pagesAntioxidant Activity of Ayosep Leaf Formulated As Tea: Vaccinium Myrtoidesrigor simbaNo ratings yet

- 13.02 Phil Irwin - Importance of Thermal ManagementDocument10 pages13.02 Phil Irwin - Importance of Thermal ManagementBijuNo ratings yet

- Creii-3 2Document35 pagesCreii-3 2Chem-Youth FestNo ratings yet

- Experiment 1: Identification of A CompoundDocument14 pagesExperiment 1: Identification of A CompoundNur Faizatul AtiqahNo ratings yet

- SaponinDocument1 pageSaponinIbrahim AlmesallamyNo ratings yet

Charaterization of Liquid Solid Reaction

Charaterization of Liquid Solid Reaction

Uploaded by

Yuni_Arifwati_5495Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Charaterization of Liquid Solid Reaction

Charaterization of Liquid Solid Reaction

Uploaded by

Yuni_Arifwati_5495Copyright:

Available Formats

Jakob, M., Phys. Z. 22, 65 (1921). Price, D., Ind. Eng. Chem., Chem. Eng. Data Ser. 1, 83 (1956).

Joule, J. P., Thomson, W., Phil. Mag. 4, 481 (1852). Redlich, O., Kwong, J. N. S., Chem. Revs. 44, 233 (1949).

Koeppe, W., Kaeltetechnik 14, 399 (1962). Reid, R. C., Sherwood, T. K., “Properties of Gases and Liquids,”

Koeppe, W., Proceedings of 10th International Congress on 2nd ed., pp. 50-2, McGraw-Hill, New York, 1966a.

Refrigeration (Copenhagen, 1959), Vol. 1, pp. 156-63, Per- Reid, R. C., Sherwood, T. K., “Properties of Gases and Liquids,”

gamon Press, New York, 1960. 2nd ed., Appendix A, pp. 571-84, McGraw-Hill, New York,

Kordbachen, R., Tien, C., Can. J. Chem. Eng. 37, 162 (1959). 1966b.

Lydersen, A. L., Greenkorn, R. A., Hougen, O. A., “Generalized Roebuck, J. R., Murrell, T. A., Miller, E. E., J. Amer. Chem. Soc.

Thermodynamic Properties of Pure Fluids,” University of 64,400 (1942).

Wisconsin, College of Engineering, Rept. 4 (October 1955). Roebuck, J. R., Osterberg, H., J. Amer. Chem. Soc. 60, 341 (1938).

Martin, J. J., Chem. Eng. Progr. Symp. Ser. 59, No. 44, 120 (1963). Roebuck, J. R., Osterberg, H., J. Chem. Phys. 8, 627 (1940).

Martin, J. J., Ind. Eng. Chem.. 59 (12), 34 (1967). Roebuck, J. R., Osterberg, H., Phys. Rev. 46, 785 (1934).

Onnes, . K., Commun. Phys. Lab. Univ. Leiden, No. 23 (1896). Roebuck, J. R., Osterberg, H., Phys. Rev. 48, 450 (1935).

Onnes, . K., Keesom, W. H., “Die Zustandgleichungen,” in Shah, K. K., Thodos, G., Ind. Eng. Chem. 57 (3), 30 (1965).

Encyclopedia Math. Wiss. V-10, p. 842, B. G. Teubner, Leip- van der Waals, J. D., Proc. Sect. Sci. Kon. Med. Akad. Wctcnschap.

zig, 1912. (Amsterdam), 2, 379 (1900).

Partington, J. R., “Advanced Treatise on Physical Chemistry,” Witkowski, A. W., Bull. Acad. Sci. Cracovie (July 1898).

Vol. 1, p. 622, Longmans, Green, London, 1949. Yen, L. C., Alexander, R. E., A.I.Ch.E. J. 11, 334 (1965).

Pitzer, K., Brewer, L., revisers, “Lewis and Randall's Thermo- Received for review September 29, 1969

dynamics,” Appendix 1, p. 611, McGraw-Hill, New York, Accepted July 13, 1970

1961.

Porter, A. W., Phil. Mag. (6) 11, 554 (1906). W’ork carried out under the auspices of the L'. S. Atomic Energy

Porter, A. W., Phil. Mag. (6) 19, 888 (1910). Commission.

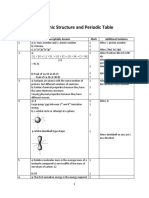

Characterization of Liquid-Solid Reactions

Hydrochloric Acid-Calcium Carbonate Reaction

Bert B. Williams,1 John L. Gidley,2 James A. Guin,3 and Robert S. Schechter4

Esso Production Research Co., Houston, Tex. 77001

Techniques commonly used to determine reaction rates for heterogeneous liquid-solid

reactions such as the hydrochloric acid-calcium carbonate reaction are mass transport-

limited and do not reflect surface kinetics. A procedure where liquid flows through a

channel composed of solid reactant is proposed for obtaining kinetic data. An exact solu-

tion for reaction rate with an arbitrary kinetic model is obtained by numerical methods

based upon Duhamel’s theory, for first- and second-order reversible and irreversible reac-

tions. The method is easily extended to other models. An exact boundary layer solution is

given for the first-order irreversible reaction and an approximate boundary layer tech-

nique for solution of the arbitrary reaction rate case is developed. The approximate tech-

nique yields simple solutions which are accurate under certain prescribed conditions.

Existing experimental data for the hydrochloric acid-calcium carbonate reaction are

analyzed in light of the proposed kinetic models.

^Xcidizing of subsurface reservoirs to increase oil or gas pendent upon knowledge of the surface reaction rate of the

production has been practiced since the late 1800’s. In these acid. It is, therefore, of practical importance to be able to

techniques an acid, such as hydrochloric acid, is forced to flow obtain correct expressions for the surface reaction rate under

within the pore structure of the rock matrix, or along a hy- a variety of conditions of temperature, pressure, and acid

draulically induced fracture, reacting with the rock and alter- composition. The reaction rate is relatively fast and only care-

ing reservoir characteristics. Schechter and Gidley (1969) have fully performed experiments, analyzed to account for diffu-

developed a method of computing the rate of acid spending sion correctly, are of general applicability.

and the effect of acid reaction on formation flow capacity for Reaction of an acid with calcium carbonate can be gener-

the case of matrix acidizing. These computations, as well as alized as

calculations of reaction rate in flow along a fracture, are de- hi

2H+ + CaC03 <=í C02 + Ca2+ + H20

1

To whom correspondence should be sent.

2

Present address, Humble Oil & Refining Co., Houston, Tex.

77001

Present address, Auburn University, Auburn, Ala. 36830

3

Present address, Department of Chemical Engineering,

4

2A + B<=*C + D + E

University of Texas, Austin, Tex. 78712 k2

Ind, Eng. Chem. Fundam., Vol. 9, No. 4, 1 970 589

Therefore, the general rate expression for reaction of slightly

Table I. Effective Mass Transfer Ratio for 1 to 1 dissociated acids will have the form

Ratio of Acid Volume to Rock Area

Time, Min f (D//2)°.5

-r =

ki{Cs?Kd)a -

hCcoaCc,.^a (8)

10 0.25 0.009 Historically, acid reaction rate data have been determined

20 0.40 0.010 in a static reaction test, in which a cube of rock of known sur-

30 0.50 0.010 face area is placed in a basket at the top of a reaction vessel

40 0.58 0.010 and a known volume of acid is placed in the bottom of the

50 0.63 0.010

container. Test pressure is usually applied to the chamber by

60 0.71 0.010

70 0.76 0.010 injecting nitrogen so as to stimulate reservoir conditions, and

a test is started by inverting the equipment, thereby bringing

. 0.010

rock and acid in contact. After a set time, the cell is righted

and an analysis made to determine the quantity of rock dis-

solved. Data from this test are normally reported as the frac-

For this reaction, tion of acid spent, /, as a function of contact time for various

a general rate expression is

ratios of acid volume to rock surface area.

—r =

k1aAaacyaDs -

kzaAa'acy'aDs' (1) Some insight into what is occurring during static tests can

be obtained as follows. First, assume a model with two parallel

where o< is the activity of the fth species. To satisfy equi-

walls separated by a distance l with no fluid circulation, a

librium requirements, the ratio of the rate coefficients must be

reaction rate at the solid surface very fast relative to the rate

equal to the equilibrium constant to a power n. This means

that the exponents of the activities in Equation 1 are related

of acid transfer to the surface (C 0 at y l), no alteration

= =

in diffusivity of hydrogen ion with increase in product concen-

by Equation 2.

tration, and at y 0, an inert surface where the concentration

=

(^~ gradient is zero [dC(y 0)/dy =

0]. For this system solution

=

=

(7' -

7) =

(S' ~

5) =

n (2) of the mass-balance equation can be simplified for typical

values of D, l, and t to the form

Highly dissociated acids such as hydrochloric acid are

most commonly used in stimulation techniques. If we assume f = 1 -

C =

(IDí/tt/2)1''2 (9)

that the activity coefficient for all reactants at the surface is where C is the mean concentration in the cell at time t divided

1, and the reaction is first-order in hydrogen ion activity

by the initial concentration. / is the fraction of the acid that

(a =

1), the rate expression is has reacted. Many results obtained in the static cell can be

—r =

kxCA -

hCc^Cy-'2 (3) explained with this equation in terms of mass transfer proper-

ties independent of rate of surface reaction.

Experimental data show that even at high C02 partial pres- Values for the group (Z)/Z2)0,5 computed for the data of

sure, reaction with strong acids goes essentially to completion. Hendrickson et al. (1960) for a 1 to 1 acid volume to rock

Therefore, the backward rate will be negligible in most appli- surface area ratio are given in Table I.

cations and the rate expression can be written The average spacing from the rock sample to a wall in the

test cell is not known, but would appear to be about 2 cm.

—r =

kiCA (4)

Assuming this is representative, the effective mass transfer

By a similar argument, the rate expression assuming the coefficient for the test is 4 X 10-4 cm2 per second, or about 20

reaction is of order N can be written times the molecular diffusion coefficient-. Therefore, this reac-

tion is entirely controlled by mass transfer to the rock surface.

—r =

ZciCa-v (5) In these tests, the apparent mass transfer rate is much more

rapid than is possible by diffusion alone, indicating that con-

Acids that only slightly dissociated in aqueous solution

are

vection occurring in the aqueous phase controls reaction rate.

are also used to acidize formations: formic, acetic, propionic, It appears that this test is sensitive to any change that

and other organic acids. Study of these acids is complicated alters fluid circulation properties and is completely insensitive

by the dissociation process. A general acid (HP) dissociates to reaction rate at the rock surface. Therefore, changes in

according to the relation over-all reaction rate attributed to changes in kinetic rate by

HP^H++ P- Chamberlain and Boyer (1939), Hendrickson et al. (1960), and

van Poollen (1968) are apparently caused by changes in rate

wit-h equilibrium described by an equilibrium constant, Kd, of fluid convection.

defined as Since these tests are mass transfer-limited, data will indi-

cate a first-order reaction regardless of the true order of the

v + ~ surface reaction. For these reasons, kinetic data from static

Kd = -

(6)

Ohp tests cannot be used with confidence to predict rate of acid

spending in field operations. In this paper a procedure for

Again assuming first-order kinetics in hydrogen ion activity

and unit activity coefficients, and introducing acid dissocia- determining accurate kinetic data is proposed and a theory

developed for expected kinetic rate expressions.

tion, gives the rate expression

—r =

kiCs* —

A)2Cco1/2Cca2+1/2 Dynamic Acid Reaction Tests

Or, in terms of the undissociated acid concentration (approxi- General Consideration. Experiments cited to demon-

mately equal to total acid concentration), strate the first-order dependence of acid reaction rate on

acid concentration are diffusion-controlled and therefore,

—r =

fci(CHpXt¡)1/2 —

Zc2Cco1,2Cca2+1/2 (7) are not reliable indicators of the true nature of the surface

590 Ind. Eng. Chem. Fundam., Vol. 9, No. 4, 1970

reaction. Flow tests in which acid in fully developed

laminar flow comes in contact with a reactive surface are X CENTERLINE

Y V = AVERAGE

well suited for experimental determination of reaction rate t VELOCITY X/VELOCITY =

coefficients—for example, laminar flows through a tube or *x 1

h

between parallel walls of calcium carbonate can be used to 1

determine reaction rate, if the experiment is devised so

that the steady-state acid effluent concentration can be Figure 1. Geometry for parallel plate reaction system

obtained before there is a significant change in the dimen-

sions of the system owing to solution of the carbonate

walls. An additional assumption is that diffusivity for each To solve the unit flux problem, the following change of

ion is constant for all ionic concentrations and independent variables is convenient:

of concentration of other ions. Experiments satisfying the

above conditions have been performed by Hoelscher and

Cowhead (1965) in studying kinetics of interfacial reac-

gt(e{,v) =

Ui(u,v) —

—

Hr Jo Jo

f () \ (14)

tions. where

Consider first reaction in flow between parallel walls of a

2

reactive solid, as shown in Figure 1. Since the correct reac-

Qr 3

tion rate expression at the rock surface is not known a

priori, a general solution for this problem follows for the for laminar flow between parallel plates. The gt{( (, ) must then

surface chemical reaction symbolized as < 0, where =

satisfy the differential equation

di are stoichiometric coefficients (positive for reactants

and negative for products). A mass balance for the fth Ogi Wgt v(y)

v(v) (15)

component gives 0(t 2 Qr

* and the boundary conditions

VW =

(10)

de, 2

=

p p (& ;

1 OgÁufi) OgÁtu i)

Qi{0,v)

This equation must be solved subject to the boundary condi- ~q/J0 J0

tions

The solution of this problem is

\ n OCiiti, 1) pq(tt) J act(e¡,0)

and---=0 n

——; (11)

^Hr

= =

Ci(0,77) Cid,·

---

0v Di gÁu,v) =

Bsfs(v)ex (- ) + (16)

5=0

Solutions for mass transport problems in flowing fluids are where the /„(»?) are eigenfunctions defined by the differential

often expressed in terms of eigenvalue expansions, but near

equation

the inlet (e< 0) such expansions converge slowly and bound-

=

ary-layer solutions are more convenient. This development d2fn / n

+ xMv).fn

.

2 =

0 (17)

makes use of both solutions. To write the solution to the j^F

general problem, the solution to the unit flux problem is

denoted as ^ , ), where ut satisfies Equation 10 together subject to the boundary conditions

with the boundary conditions dfn{ 1) dfn{0)

_ _

Q (18)

Mi( 0, )

,) 1

The Bs are determined by

and

dMXoO)

;r

Hr Jo Jo Jo_

(f \/ ( ) ( )

= B, (19)

Then by Duhamel’s theorem,

The solution to the unit flux problem is then

" pg(x)

=

I

Jo ¿-'ll 0(1

[Ui(«i —

\, )] \ + Cid (12)

Ui((i,v) =

Bsfs(v) exp (-Xs26i) + +

q

Integrating this expression by parts, a form more convenient

for numerical computation is obtained: 7T

Hr Jo Jo

() (20)

For fully developed laminar flow where ( ) 1 v2 and = —

Qf —

2/3, the eigenvalues and eigenfunctions evaluated at the

Ci((,v)

wall are tabulated in Table II.

A similar analysis for a circular tube with a reactive wall

(13) gives for the solution of the unit flux problem

where all axial positions are referred to e = e4. ut{Zi,y) =

¿

$

—

0

DsFs{y) exp (-XS2Z4) + W +

Vc

Equation 13 provides a means of obtaining the solution for

acid concentration for an arbitrary surface reaction, once the 1 1 f

unit flux solution has been obtained.

7

-

v&md\ (21)

yc Jo a jo

Ind. Eng. Chem. Fundam., Vol. 9, No. 4, 1970 591

Table II. Mathematical Properties of Unit Flux Solution

Parallel Plates Circular Tubes

s » Ml) 8, , F.(l> D,

0 0 1 -39/280 0 1 -7/24

1 4.2872 -1.2697 0.17503 5.0675 -0.49252 0.40348

2 8.3037 1.4022 -0.05173 9.1576 0.39551 -0.17511

3 12.3106 -1.4916 0.02505 13.1972 -0.34587 0.10559

4 16.3145 1.5601 -0.01492 17.2202 0.31405 -0.07328

5 20.3171 -1.6161 0.009969 21.2355 -0.29125 0.05504

6 24.3189 1.6638 -0.007164 25.2465 0.27381 -0.04348

7 28.3203 -1.7054 0.005415 29.2549 -0.25985 0.03560

8 32.3214 1.7425 -0.004248 33.2615 0.24833 -0.02991

where artificial introduction of additional terms as was done by

-f

Solbrig (1967).

yv(y)dy By assuming a value of gw+1), the concentrations at point

ew+1> along the surface can be computed using Equation 23,

and the Fs satisfy the differential equation and in turn, be used to compute a corrected value of g(2f+1).

By continuing this iterative process, new reaction rates and

d_ d,Fs\ concentrations satisfying Equation 23 can be found. This

7 ’-' $$ =

0

dy ~dy J process of calculation can be continued to yield both the

and the boundar)· conditions concentrations and the reaction rates evaluated along the

surface. The amount of acid reacted is given by

dFs( 0) dF,(l) =

0 p rL*

dy dy R*

-gJQ g(')d*

=

(24)

The coefficients Ds are determined from

This quantity is easily shown to be related to the mean concen-

f1 r i

I Fs711(7) I -

I v(£)£didXdy tration divided by the inlet concentration according to the

Jo Jo Jo relationship

D, = -

6,

/‘ FJyv(y)dy R* = 1 -

Ci

where Ci is the average dimensionless concentration at L*.

(25)

Using the method given below, it can be shown that the

boundary-layer solution to the unit flux problem evaluated

along the surface of the wall is First-Order Irreversible Reactions

While it appears that the experiments leading to the ac-

M<(e<,l) =

G-r

'2 (22) cepted conclusion that the rate of acid reaction with carbonate

is first-order are not valid, it is possible that this is, in fact, the

*3 nature of the reaction. First-order irreversible reactions are

also of interest, since the resulting equations are linear and

where («) is the gamma function of the argument e.

can be solved without using Duhamel’s theorem or the unit

In the general case, the dimensionless reaction rate g(e)

flux solutions developed above. The solutions developed by

depends on the local value of the concentrations at the reac- numerical methods based on Duhamel’s theorem were tested

tive surface. Equation 13 can be used in an iterative fashion

against these exact solutions and found to be in agreement

to evaluate both the surface concentration and the reaction

within 1% over the entire range of e. Also, approximate solu-

rate along the surface. Suppose that the rate of reaction has

tions introduced below can be compared to these exact solu-

been established at positions e(0), e(1), ew), giving the . ..

tions.

particular values g(1), g(2), gw). It is desired to establish

The first-order irreversible case is studied by putting q(ei)

. . .

=

g(.v+iy From Equation 13, we can write —

Ci. For larger values of the dimensionless distance ei,

n ££(0) U\

p N

q(‘+D

—

q(’) (d = e), solution in terms of an infinite series using the

Cío -j-

1

n + methods of separation of variables can be found. However, in

On U H s = 0 e('+i) —

e(*)

the entry region, the rate of diffusion to the reactive surface is

controlled by the development of a diffusion boundary layer,

U -

), dX (23)

) the rate-limiting processes occur very near the wall, and the

assuming that bq/be is a constant between the nodal points. velocity distribution can be replaced by the approximation

In performing the calculations, it must be remembered that

() =

1(1

-

v)

the boundary layer solution, Equation 22, should be used for

small values of e and then switched to Equation 20 for larger For this special case, the expression developed by Acrivos

values of the argument. The solutions as computed from 20 and Chambre (1957) reduces to

and 22 agree to within 2% over the region 10~3 to =

£(=

7 X 10'3 and thus the switching point should be in this dCi(|,l)

interval. This method of calculation does not require the

—

Ci(x*,l)

592 Ind. Eng. Chem. Fundam,, Vol. 9, No. 4, 1970

where

Table III. Values of Coefficienls in Power Law Solution

[-TM0 €

n

1

2

-0.82699

ß

0.60412

Making the substitution

3 -0.40275

Z3 =

4 0.24980

5 -0.14598

Zi3 =

£

6 0.08110

gives 7 -0.04306

8 0.02143

fz dCtZi.l)

' ’ 9 -0.00724

-C(Z, 1) =

[Z3

-

Z,3]-!/3 dZi (26) 10 0.00047

Jo “Zi

11 -0.00000

The concentration at the wall is obtained in terms of the

power series

Cl = 1 +

=

ß (27)

1

Substituting Equation 27 into Equation 26, it is found that

-1 -

ß =

(n + l)/w„ (28)

n—l =

0

where

-f [Z3

Zl”

-Zv

dZ i (29)

Equation 29 can be integrated to give

Figure 2. Surface reaction rate in circular tube

+ Irreversible reaction

3 /

;z" (30)

<)

Substituting Equation 30 into Equation 28 and equating

coefficients of like powers, it is found that

ft =

and

r

() Figure 3. Surface reaction rate between parallel plates

Irreversible reaction

The first eleven values of ß„ are given in Table III.

Reversible Reactions

With these values known, concentration at the wall is given by

The reaction of weak acids should be considered as revers-

ible. Figures 4 and 5 show dimensionless conversion R* as a

function of length in a parallel plate system for reactions hav-

Ci(e,l) —

1 + ß (31)

= 1 ing the form

Using Equation 24 gives the final result -g(e) =

Ci -

KC21,2C31/2, K = 0.1

-g(e) =

CJ -

KC2C3, K =

1.0

PL* 3 In these figures the dimensionless quantity, P, is defined as

R* 1 + ß (32)

~Q~f =

1 71 3

k\ fclCl

A similar analysis for a circular tube gives Equation 32, again P =

—

and P =

respectively

üi Di

with R*, Qf, and L* replaced by their analogs for the circular

case. Results predicted by combination of infinite series These calculations have been performed for Dn —0.125 =

solution and the boundary layer solution are shown in Figures and Dzi = —0.375, which are approximately valid for the

2 and 3. system HCl(Ci), CaCl2(C2), and CO2(C3).

Ind. Eng. Chem. Fundam., Vol. 9, No. 4, 1970 593

with the boundary conditions C^ei, oo) =

Ci0 and

&C,(x„0) =

/9ei\1/3 mW

d7< V 2 / Dtl

Equation 34 can be integrated directly to yield, after applying

the boundary conditions,

Ci(et, 0) (35)

This expression represents an approximate solution for the

wall concentration for an arbitrary surface reaction rate.

Figure 4. Surface reaction rate between parallel plates Applying this expression to the unit flux problem in which

Reversible reaction dw,(e,,0)

dy<

and

Mi(e<,°°) =

0

yields

(36)

When compared with Equation 22, Equation 36 is in error

by about 20%. The approximation improves considerably as

the order of the reaction increases with the unit flux problem

being of order zero.

For an nth-order irreversible reaction,

9(e) =

-[Ci(e,0)]B

Reversible reaction

and Ci is given implicitly by Equation 35. In particular, if

n =

1,

The simple iteration scheme previously suggested did not

converge in all cases for reversible reaction and it was some-

times necessary to use a direct search technique to find values

for Ci, C2, and C3 that satisfied Equation 23. The technique

of Powell (1964) worked well in these cases. In this tech-

3

ñique, the quantity 23 [C,p+1 —

C,27]2 is minimized, where

i = l

C^ is the concentration of component i at the pth iteration

as found from Equation 23.

Approximate Solutions

The results of an approximate boundary layer technique

introduced by Solbrig (Solbrig and Gedaspow, 1967) are

compared with the exact results obtained earlier. This ap-

proximate method is useful because the calculations involved

are simpler than those required to solve the integral equations This approximate result is compared with the exact solution

resulting from the exact boundary layer method. in Table IV.

In this procedure t is defined as the dimensionless distance Similarly for n 2, =

measured from the reactive surface—i.e., t .1 (for = —

1/2

small , 1 —

t;2 ·—' 2£). Changing variables in Equation 10 from

(ei,v) to (<·,,.£,) where Zi <e,-1/3 gives

= -3A + 3A 1 + 1

—--—-

4 (t)

L_

3 3AA

3 J

dC,

7 1 2 ^C &!£<

*

,

2 (33) 2pr

(I)

Z te i '

de¿ 3 c)Zt dZ,2

Neglecting the term on the left-hand side of Equation 33 and

For the second-order reversible reaction where q(x) =

defining —

Ci2 + KC2C¡ and assuming that the inlet concentrations of

1/3

2 both substances 2 and 3 vanish from Equation 35, it is found

y t

=

Zi that

Equation 33 can be written Ci(e,l) =

d2C, c)Ct (1 -

2BE) + {(2BE -

l)2 4(1 - -

BE)(B -

BE)}112

C—, + 37 i2 c- =

0 (34)

97< 97, 2(B BE) -

594 Ind. Eng. Chem. Fundam., Vol. 9, No. 4, 1970

Table IV. Comparison of Approximate with Exact Boundary Layer Solutions for First-Order Irreversible Reactions

R*(P =

0.1) R*(P =

1.0)

L* Exact Approx. L* Exact Approx.

10 ~4 1.493 X 10-5 1.492 X 10-5 10-3 1.374 X 10~3 1.352 X 10-3

10-3 1.486 X 10 ~4 1.484 X 10-4 10-2 1.251 X -2 1.215 X "2

10-2 1.471 X 10-3 1.465 X 10-3 10-1 1.047 X 10-1 9.997 X -2

10-1 1.439 X 10-2 1.427 X 10-2

Table V. Apparent Reaction Rate Coefficients from

Data of Barron et al. (1962)

Plate Spacing, Inch P

0.025 1.25

0.05 2.5

0.10 5.0

0.20 10.0

where

B =

K(D2D3yi*

Pl2lSP2lPsi

Figure 6. Experimental and theoretical data for HCI reac-

Similarly, tion between parallel walls

=

Cl -1

P3l(Pl/P3 )1/3

cm2 per second, the rate coefficient for reaction of HCI and

and calcium carbonate is approximately 1.0 X 10“3 cm per

second. This value for the rate coefficient should be con-

c2 =

(D2/p3yiyp31/p2i)C3

sidered as qualitative until additional, carefully controlled

These expressions can be substituted into Equation 24 and experiments have been obtained. To verify the order of the

the dimensionless reaction rate computed. These approximate reaction, these experiments must include variation in acid

expressions have been found to represent a very accurate (to

concentration as well as flow rate and system geometry.

within 2 %) approximation of the solution for values of L* less

than 0.1 for P 0.1. Since they are much more compact and

=

Nomenclature

provide straightforward solutions compared to the use of

Duhamel’s theorem, their use in the inlet region is recom-

a¿ activity coefficient for i'th component

5, coefficients in unit flux solution

mended. C dimensionless average concentration

actual inlet concentration of component i, moles/liter

o concentration of component i at pth iteration as

Dynamic Reaction Rate Tests calculated from Equation 23

Ci dimensionless reactant concentration—i.e., Ca/Ci°

The only available data from which a reaction rate coeffi-

dimensionless initial concentration of reactant—i.e.,

cient for hydrochloric acid can be obtained are those of CS/CS

Barron et al. (1962), who studied the reaction of 15% HCI in Z), molecular diffusivity for ith component, cm2/second

flow between parallel walls of calcium carbonate. The results Pa dimensionless diffusivity ratio, PSi/Piii

of their experiments are compared to predicted reaction rates f fraction of spent acid

h distance from center line of parallel plate system to

for a first-order irreversible model in Figure 6. At low- velocity reactive wall, cm

these data appear to fit the first-order irreversible reaction ki reaction rate coefficient, cm/second

model with the approximate values of dimensionless rate Keq equilibrium coefficient, k2/ki

given in Table V. L total system length in flow experiments, cm

At the higher velocities, observed reaction rates are larger

2 LPi i i LPi

, \ . ....

L* i i i

dimensionless length, (plates), (cylinder)

g_^2

than expected if mass transport to the rock surface is diffusion- surface in

l spacing between reactive and nonreacting

limited. This would indicate that instability in the flcnv may static test, cm

occur even though the Reynolds number is well in the laminar n order of reaction with respect to component 1

range. These instabilities may in part be caused by heat hki(C i°)n_1

P reaction rate coefficient,-^- (parallel plates),

evolution at the surface, surface roughness, or entry effects in Ui

the model. Rh(C i0)"-1

Pi (cylinder)

Assuming that experiments at knv velocity represent the dimensionless reaction rate, r(e)//cl(C'i°)n

g(e)

diffusion-controlled reaction, that first-order kinetics are

Q constant, Qf for plates, Qc for cylinder

applicable, and the diffusion coefficient for HCI is 2.6 X 10~5 r(e) reaction rate at position e, moles/cm2/second

Ind. Eng. Chem. Fundam., Vol. 9, No. 4, 1970 595

B =

radius of tube in calculations for reaction along cylin- 5, =

stoichiometric coefficient

drical channel, cm 2xDi

R* =

dimensionless position along x coordinate, (flat

=

dimensionless reaction rate, Ci

g^r

(cylinder) plate)

{w(plate); y =

dimensionless position along y coordinate, y/h

fíave =

average reaction rate over total reactive surface p =

density, grams/cm3

Re =

Reynolds number, dvp/µ

t =

seconds Literature Cited

=

average velocity, centimeter/second

() =

dimensionless velocity profile, for laminar flow, Acrivos, A., Chambre, P. L., Ind. Eng. Chem. 49, 1025 (1957).

v(y)=

(1

-

42) Barron, A. N., Hendrickson, A. R., Wieland, D. R., Trans. .

x =

distance in axial direction, cm 225, 409 (1962).

y =

distance in transverse direction, cm Chamberlain, L. C., Boyer, R. F., Ind. Eng. Chem. 31, 400 (1939).

Zi —

dimensionless distance along x coordinate xDi/2vR2 Hoelscher, . E., Cowhead, C., Ind. Eng. Chem. Fundam. 4,

150-4 (1965).

(cylinder) Hendrickson, A. R., Rosene, R. B., Wieland, D. R., Division of

Petroleum Chemistry, 137th Meeting ACS, Cleveland, Ohio,

Greek Letters April 1960.

Powell, J. J. D., Computer J. 7, 155 (1964).

a =

apparent reaction order for weak acids Schechter, R. S., Gidley, J. L., A.I.Ch.E. J. 15, 339 (1969).

ß —

coefficients in series approximation to boundary layer Solbrig, C. W., Gidaspow, D., Can. J. Chem. Eng. 45, 35 (1967).

van Poollen, . K., Jargon, J. R., OilGas J. 66, 84 (1968).

problem

7 =

dimensionless radial position, r/R Received for review November 12, 1969

r(n) =

gamma function of variable n, tabulated function Accepted July 15, 1970

Flow of Single-Phase Fluids through Fibrous Beds

Chwan P. Kyan, Darshanlal T. Wasan,1 and Robert C. Kintner

Department of Chemical Engineering, Illinois Institute of Technology, Chicago, III. 60616

A pore model for the flow of a single-phase fluid through a bed of random fibers is proposed. An effective

pore number, Ne, accounts for the influence of dead space on flow; deflection number, N<j, characterizes the

effect of fiber deflection on pressure drop. Experimental data were obtained with glass, nylon, and Dacron

fibers of 8- to 28-micron diameter and with fluids of viscosity ranging from 1 to 22 cp. A generalized fric-

tion factor-Reynolds number equation is presented. The effects of dead space in a fibrous bed on flow

and of fiber deflection on pressure drop have no parallels in a granular bed.

The flow of fluids through porous media has been a subject In this equation, the fact that k depends on fiber orientation

of investigation for many years. A considerable amount of and porosity had been observed and discussed by Sullivan

research has been done on the flow through granular beds and Hertel (Sullivan, 1941; Sullivan and Hertel, 1940)

and many useful results have been obtained (Brownell and based on their experimental work. Thus Equation 1 was in-

Katz, 1947, 1956; Ergun, 1952; Ergun and Orning, 1949). adequate for pressure drop correlations. Various workers

A lesser number of investigations have been done on the using the channel model have elaborated upon Equation 1

phenomena of flow of fluids through fibrous media, mostly with modification for shape and orientation (Davies, 1952;

in connection with aerosol filtration. Fowler and Hertel, 1940; Langmuir, 1942; Sullivan and

General approaches pursued by most workers on the flow Hertel, 1941).

of fluids through fibrous beds involved the development of Most workers (Chen, 1955; Iberall, 1950; Wong et al.,

theoretical pressure drop equations from either a “channel 1956) using the drag model rejected the applicability of the

model” or a “drag model.” The former was the more exten- channel model because of the high porosity of a fibrous bed

sively used. and derived a pressure drop equation by considering the drag

Most workers using the channel model started with the forces due to fluid flow on the fibers.

Kozeny-Carman equation, Wong et al. (1956) employed an effective drag coefficient,

Cdc, to account for the fiber orientation, interference of

=

frUS* ~

(1) neighboring fibers, fiber ends, and nonuniformity of fiber

L e3

distribution in the bed. They concluded that the fiber volume

which in the friction factor form becomes fraction, y, has a marked effect on CDe. The higher the value

of 7, the higher is the neighboring fiber interference which

k

/ =

(2) leads to a higher CDe. They also noticed the leveling off of

kATRe' the effective drag coefficient-Reynolds number plot at

Reynolds numbers greater than 6.

1

To whom correspondence should be sent. Gunn and Aitken (1961) in their study of the mechanism

596 Ind. Eng. Chem. Fundam., Vol. 9, No. 4, 1 970

You might also like

- 9bn0 01 Que 20230608Document32 pages9bn0 01 Que 20230608Ahmed AbdelrhemNo ratings yet

- MYP3 Unit 1 Summative Assessment Criterion DDocument5 pagesMYP3 Unit 1 Summative Assessment Criterion D2059964904No ratings yet

- Chemistry For The IB Diploma Exam Preparation Guide - PublicDocument53 pagesChemistry For The IB Diploma Exam Preparation Guide - PublicMălina IoneteNo ratings yet

- Daikin Perfera FTXM-R User Manual EngDocument20 pagesDaikin Perfera FTXM-R User Manual EngZoltán KozmaNo ratings yet

- Database Investigation Homologous SeriesDocument6 pagesDatabase Investigation Homologous SeriesDiana100% (1)

- Marking Scheme For Core Worksheet - Chapter 2: 1 Protons Neutrons Electrons A B C D e F 2 3Document2 pagesMarking Scheme For Core Worksheet - Chapter 2: 1 Protons Neutrons Electrons A B C D e F 2 3Paul Murray0% (1)

- Topic 9 QDocument19 pagesTopic 9 QIndraneel BhattacharjeeNo ratings yet

- h2 Chem ChecklistDocument3 pagesh2 Chem ChecklistJohn TanNo ratings yet

- 4 Ec 4 BB 419 Cdab 2 D 5 C 3 F 3Document4 pages4 Ec 4 BB 419 Cdab 2 D 5 C 3 F 3api-2306408280% (1)

- Acid Rain ExperimentDocument5 pagesAcid Rain ExperimentSAAHIBA BHATIANo ratings yet

- Dissolution CaCO3 in Aqueous SolutionsDocument2 pagesDissolution CaCO3 in Aqueous SolutionsYuni_Arifwati_5495No ratings yet

- Antibacterial Activity of Wiregrass (Eleusine Indica) and Pandanus Specie Leaves Extract Against Escherichia ColiDocument28 pagesAntibacterial Activity of Wiregrass (Eleusine Indica) and Pandanus Specie Leaves Extract Against Escherichia ColiKristian Dave Diva100% (6)

- Study On The Stoichiometry and Reaction Products of Extra Virgin Olive Oil OzonationDocument5 pagesStudy On The Stoichiometry and Reaction Products of Extra Virgin Olive Oil OzonationAlexiss Chavez-De la Mora100% (1)

- Four Probe MethodDocument101 pagesFour Probe MethodPanthoiba AkoijamNo ratings yet

- Topic 4 BondingDocument29 pagesTopic 4 BondingXandi NalepaNo ratings yet

- T SC 2550043 Ks2 Year 6 Living Things and Their Habitats Revision Activity Mat Ver 4 2Document8 pagesT SC 2550043 Ks2 Year 6 Living Things and Their Habitats Revision Activity Mat Ver 4 2zacktudorukNo ratings yet

- IB Questionbank Chemistry 1Document25 pagesIB Questionbank Chemistry 1raja_tanukuNo ratings yet

- Atomic Structure and Periodic Table Mark SchemeDocument5 pagesAtomic Structure and Periodic Table Mark SchemeDiyaNo ratings yet

- Longest Poem Written by Nikhil Parekh - Only As LifeDocument28 pagesLongest Poem Written by Nikhil Parekh - Only As LifeNikhil ParekhNo ratings yet

- KE - Chapter 14 - Chemical KineticsDocument16 pagesKE - Chapter 14 - Chemical KineticsjoaseNo ratings yet

- HL Paper 2: Full Electron Configuration of The Ruthenium (II) IonDocument20 pagesHL Paper 2: Full Electron Configuration of The Ruthenium (II) IonfuduNo ratings yet

- Option E - Astrophysics Self Study 10Document9 pagesOption E - Astrophysics Self Study 10sudkNo ratings yet

- 0654 (Biology) ChecklistDocument4 pages0654 (Biology) ChecklistHồ Liên KhảiNo ratings yet

- GCE in Chemistry Course PlannerDocument35 pagesGCE in Chemistry Course PlannerMary MannuNo ratings yet

- Market Structure Worksheets and AnswersDocument16 pagesMarket Structure Worksheets and AnswersNate ChenNo ratings yet

- Structure 1.1, 1.2, 1.3 PracticeDocument6 pagesStructure 1.1, 1.2, 1.3 PracticeEthan ElliotNo ratings yet

- Paper 1 Section B Question-Answer Book BDocument20 pagesPaper 1 Section B Question-Answer Book BKathy WongNo ratings yet

- A2 CHM Sol 05 Acid and Base WSDocument28 pagesA2 CHM Sol 05 Acid and Base WSnsNo ratings yet

- 9a Alkaseltzer Rates of ReactionDocument13 pages9a Alkaseltzer Rates of Reactionapi-298247873100% (1)

- Mark Scheme Q4 MicroeconomicsDocument5 pagesMark Scheme Q4 MicroeconomicsVittoria RussoNo ratings yet

- Atomic Structure (AP MC)Document4 pagesAtomic Structure (AP MC)Nyxas IoannisNo ratings yet

- TB - 83 (Ka and KB) Weakacidandbaseequilibrium - 61edf9de533071.61edf9e14301f7.77090779Document20 pagesTB - 83 (Ka and KB) Weakacidandbaseequilibrium - 61edf9de533071.61edf9e14301f7.77090779任思诗No ratings yet

- January 2014 (IAL) MS - Unit 2 Edexcel Chemistry A-LevelDocument21 pagesJanuary 2014 (IAL) MS - Unit 2 Edexcel Chemistry A-LevelNabindra RuwaliNo ratings yet

- Edexcel GCSE Additonal Science P2 Topic 4 Test 13 - 14 With Marks SchemeDocument15 pagesEdexcel GCSE Additonal Science P2 Topic 4 Test 13 - 14 With Marks SchemePaul BurgessNo ratings yet

- N17 H2 P2 AnswersDocument10 pagesN17 H2 P2 AnswersSamuel TeohNo ratings yet

- Complex IonsDocument4 pagesComplex Ionsmikey12345452863879No ratings yet

- Chemistry ShipwrecksCorrosion&ConservationDocument17 pagesChemistry ShipwrecksCorrosion&ConservationMarco Huang100% (7)

- Chemistry HSSC I Paper I (2019)Document12 pagesChemistry HSSC I Paper I (2019)Tayyib Khan100% (1)

- 9701 s12 QP 11 PDFDocument16 pages9701 s12 QP 11 PDFHubbak KhanNo ratings yet

- SP 2007 (3-5)Document52 pagesSP 2007 (3-5)Maheer100% (1)

- Unit 2 NotesDocument28 pagesUnit 2 NotesMuhammad ZaiNo ratings yet

- Lesson 1 Thermochemistry-Exothermic and EndothermicDocument28 pagesLesson 1 Thermochemistry-Exothermic and EndothermicNadine TariganNo ratings yet

- MM435 CDP-1 3 Cell PotentialsDocument16 pagesMM435 CDP-1 3 Cell Potentialsamjad sattarNo ratings yet

- Chap 2Document72 pagesChap 2miguel0angel0ramos-1100% (6)

- 2022 H1 Chemistry Dec Revision Book - Question - FinalDocument42 pages2022 H1 Chemistry Dec Revision Book - Question - Final2022 BALAKRISHNAN ADHITHINo ratings yet

- Chapter: 1 Stoichiometric Relationships: SubtopicsDocument108 pagesChapter: 1 Stoichiometric Relationships: SubtopicsBNo ratings yet

- Effect of Oxidation in Day To Day LifeDocument4 pagesEffect of Oxidation in Day To Day LifeSamreenKhanNo ratings yet

- Quantum and Nuclear Questions and AnswersDocument43 pagesQuantum and Nuclear Questions and AnswersemilyNo ratings yet

- CHM1 Enthalpy Change QDocument121 pagesCHM1 Enthalpy Change Qpaolo maldini0% (1)

- Test 1 Paper2 - Grade 10-11 IGCSE - 2020 - MoodleDocument13 pagesTest 1 Paper2 - Grade 10-11 IGCSE - 2020 - MoodleJadNo ratings yet

- DP Chem Unit 12 Option C - EnergyDocument8 pagesDP Chem Unit 12 Option C - EnergyPatrick AbidraNo ratings yet

- Zumdahl Chapter 12Document23 pagesZumdahl Chapter 12Spidy MoveNo ratings yet

- A Level Physics CIE: 17. OscillationsDocument28 pagesA Level Physics CIE: 17. OscillationsA2-A23030 Trivedi Parshva JigneshNo ratings yet

- A Level H2 Paper 2Document6 pagesA Level H2 Paper 2newtonian_physics100% (1)

- Combined As Chemistry Theory 9701 Paper 2Document460 pagesCombined As Chemistry Theory 9701 Paper 2Deshpande Shashibhushan AshokNo ratings yet

- Chapter 2 Atomic StructureDocument13 pagesChapter 2 Atomic StructureBetty BavorováNo ratings yet

- Keep It Simple Science 3 - MetalsDocument13 pagesKeep It Simple Science 3 - Metalsricerocketz1231231No ratings yet

- 7.2.6.2.6. Non Aqueous Titration NewDocument2 pages7.2.6.2.6. Non Aqueous Titration NewimambollNo ratings yet

- Free Body Diagram WorksheetDocument6 pagesFree Body Diagram WorksheetAshleigh JarrettNo ratings yet

- 2.2. Forces and DinamicsDocument161 pages2.2. Forces and DinamicsMartinNo ratings yet

- (Competition Science Vision IIT JEE NEET) Collection - Toppers Notes of Organic Chemistry Competition Science Vision Volume 872 Extra Special Issue-Competition Science Vision PDFDocument69 pages(Competition Science Vision IIT JEE NEET) Collection - Toppers Notes of Organic Chemistry Competition Science Vision Volume 872 Extra Special Issue-Competition Science Vision PDFDevansh MishraNo ratings yet

- 2Document11 pages2Sophia Rubio100% (1)

- Ib PPT 4 SL PDFDocument103 pagesIb PPT 4 SL PDFzarna nirmal rawalNo ratings yet

- Tris Oxalato 3Document7 pagesTris Oxalato 3nathaloaNo ratings yet

- Calcium Carbonate Dissolution and Precipitation in Water - FactorsDocument46 pagesCalcium Carbonate Dissolution and Precipitation in Water - FactorsYuni_Arifwati_5495No ratings yet

- A Review of Acid Mine Drainage in A Water-Scarce Country: Case of South AfricaDocument20 pagesA Review of Acid Mine Drainage in A Water-Scarce Country: Case of South AfricaYuni_Arifwati_5495No ratings yet

- Dissolution of Caco3Document8 pagesDissolution of Caco3Yuni_Arifwati_5495100% (1)

- Geochemistry of Acid Mine Drainage For Coal MineDocument16 pagesGeochemistry of Acid Mine Drainage For Coal MineYuni_Arifwati_5495No ratings yet

- Oxygen Influx and Geochemistry of Percolate Water From Reactive Mine Waste Rock Underlying A Sloping Channelled Soil CoverDocument11 pagesOxygen Influx and Geochemistry of Percolate Water From Reactive Mine Waste Rock Underlying A Sloping Channelled Soil CoverYuni_Arifwati_5495No ratings yet

- Kinetics of Dissolution of Solid Substances: Exercise 4Document5 pagesKinetics of Dissolution of Solid Substances: Exercise 4Yuni_Arifwati_5495No ratings yet

- The Effectiveness Study On Cao Lime Dose and Operation Time Variation and Its Influence On Acid Mine Drainage TreatmentDocument5 pagesThe Effectiveness Study On Cao Lime Dose and Operation Time Variation and Its Influence On Acid Mine Drainage TreatmentYuni_Arifwati_5495No ratings yet

- Chapter 5 Characterisation of Limestone and LimeDocument37 pagesChapter 5 Characterisation of Limestone and LimeYuni_Arifwati_5495No ratings yet

- Bahan Bagus Okeee First-Order Reactions - Chemistry LibreTexts PDFDocument9 pagesBahan Bagus Okeee First-Order Reactions - Chemistry LibreTexts PDFYuni_Arifwati_5495No ratings yet

- Kinetics - Reaction Rate (Bagus)Document6 pagesKinetics - Reaction Rate (Bagus)Yuni_Arifwati_5495No ratings yet

- IJEE 06 v5n6Document8 pagesIJEE 06 v5n6Muhammad Fajrin ArifinNo ratings yet

- Symbols Lect. No. Tim E: K E E HDocument15 pagesSymbols Lect. No. Tim E: K E E HYuni_Arifwati_5495No ratings yet

- Blast Fume Clearance Reentry TimesDocument8 pagesBlast Fume Clearance Reentry TimesYuni_Arifwati_5495No ratings yet

- 035-Procedure For Material Traceability and Marking PDFDocument16 pages035-Procedure For Material Traceability and Marking PDFKöksal Patan100% (10)

- Air PumpDocument7 pagesAir PumpRobert Ryan SantiagoNo ratings yet

- From Gene To ProteinDocument9 pagesFrom Gene To ProteincrookedspookNo ratings yet

- MSDS Auramix 300 PDFDocument3 pagesMSDS Auramix 300 PDFkk mishra0% (1)

- Calcium Carbonate Ball Mill PDFDocument3 pagesCalcium Carbonate Ball Mill PDFAnonymous yy8In96j0rNo ratings yet

- Sandeep NewDocument2 pagesSandeep Newvignesh kumarNo ratings yet

- Building Materials and Technology 1 & 2 MODULE - IDocument156 pagesBuilding Materials and Technology 1 & 2 MODULE - IAr Anil KumarNo ratings yet

- Titanium Dioxide-Modified Activated CarbonDocument8 pagesTitanium Dioxide-Modified Activated Carbonpetru apopeiNo ratings yet

- Why Is Rigor Mortis Absent in AnthraxDocument25 pagesWhy Is Rigor Mortis Absent in Anthraxravigg100% (2)

- DS Granipan F30Document1 pageDS Granipan F30faridNo ratings yet

- Av 650 Recent MSDSDocument6 pagesAv 650 Recent MSDSMounir BoutaghaneNo ratings yet

- MSDS - DK PGT Paste R27Document4 pagesMSDS - DK PGT Paste R27RND PT SIPNo ratings yet

- Well Log Suites - SEPM StrataDocument2 pagesWell Log Suites - SEPM StrataSatken AinelNo ratings yet

- Kor-N-Seal Technical SpecDocument1 pageKor-N-Seal Technical SpecJohn BolgerNo ratings yet

- Hort. 305 Turmeric Cultivation and Processing-6Document9 pagesHort. 305 Turmeric Cultivation and Processing-6meriiNo ratings yet

- Comb - Chemkin - Format PDFDocument5 pagesComb - Chemkin - Format PDFMUHAMMAD FAREEZ IZWAN BIN ABDUL JALILNo ratings yet

- 0620 QP 53Document12 pages0620 QP 53mk mkNo ratings yet

- 1 s2.0 S0169409X16300552 MainDocument19 pages1 s2.0 S0169409X16300552 MainpavaniNo ratings yet

- Corvine Chemicals & Pharmaceuticals LTD.: Training For The Production of SODIUM AZIDEDocument3 pagesCorvine Chemicals & Pharmaceuticals LTD.: Training For The Production of SODIUM AZIDENiraNo ratings yet

- Chemical Process Calculations - Short TutorialDocument5 pagesChemical Process Calculations - Short TutorialMohammad AtifNo ratings yet

- Analysis of Microstructure and Hardness Behaviour of Grain Refined A390 Alloy Mini Project ReportDocument23 pagesAnalysis of Microstructure and Hardness Behaviour of Grain Refined A390 Alloy Mini Project ReportRahul SanjayanNo ratings yet

- The Disadvantages of Fly AshDocument8 pagesThe Disadvantages of Fly AshShariar Masud TowhidNo ratings yet

- Antioxidant Activity of Ayosep Leaf Formulated As Tea: Vaccinium MyrtoidesDocument7 pagesAntioxidant Activity of Ayosep Leaf Formulated As Tea: Vaccinium Myrtoidesrigor simbaNo ratings yet

- 13.02 Phil Irwin - Importance of Thermal ManagementDocument10 pages13.02 Phil Irwin - Importance of Thermal ManagementBijuNo ratings yet

- Creii-3 2Document35 pagesCreii-3 2Chem-Youth FestNo ratings yet

- Experiment 1: Identification of A CompoundDocument14 pagesExperiment 1: Identification of A CompoundNur Faizatul AtiqahNo ratings yet

- SaponinDocument1 pageSaponinIbrahim AlmesallamyNo ratings yet