Professional Documents

Culture Documents

Mhs18-Tyre and Rims

Mhs18-Tyre and Rims

Uploaded by

Widya BungaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mhs18-Tyre and Rims

Mhs18-Tyre and Rims

Uploaded by

Widya BungaCopyright:

Available Formats

Final Draft (Eng & Ind) 230705

MAJOR HAZARD STANDARD

TYRES AND RIMS

(BAN DAN PELEK)

(MHS 18)

This Major Hazard Standard has been approved for use by:

Jim Gowans

Senior Vice President and Chief Executive Officer PT Inco

th

27 July 2005

EHS Standard Originator Date Published

Title: Tyres and Rims PTI EHS August 2008

Page 1 of 27

Ref: EHS/12/STD/MHS/MHS18 Approved by To be reviewed

EHS Management Version: 2 Michael Winship August 2010

System

UNCONTROLLED DOCUMENT WHEN PRINTED

ABOUT THE PT INCO MAJOR HAZARD STANDARDS

These Standards are designed to address the major safety hazards at PT Inco. For each major

hazard they define the full range of available controls that could be implemented to address all

aspects of the hazard in the context of industry best-practice.

Compliance with these Standards comprises a long-term management goal for the site, as does

our commitment to zero injury for all workers. It is not expected that all areas of operation could

be in complete compliance with all aspects of each Standard, just as it is not expected that all

risk can be eliminated from any mining and processing operation.

However, the concept of best practice includes a commitment to ongoing improvement, and

these Standards provide a means of measuring and guiding that progress. A baseline audit will

be conducted in 2006 to measure compliance with all 18 Major hazard Standards, and this in

turn will form the basis for improvement plans in all Departments that will result in progressive

reduction of risk of injury from accidents.

Standar ini dirancang untuk mengatur bahaya keselamatan utama di PT Inco. Untuk tiap

bahaya utama yang sudah mempunyai pengendalian dengan jangkauan penuh yang dapat

diterapkan untuk mengatur semua aspek bahaya dalam konteks praktek-praktek terbaik dalam

industri.

Pematuhan terhadap standar ini terdiri dari tujuan manajemen jangka panjang di lokasi,

sebagaimana halnya komitmen kami untuk menuju nihil cidera bagi pekerja. Tidaklah

diharapkan bahwa semua area operasi dapat seluruhnya mematuhi semua aspek dari setiap

standar, sebagaimana yang tak diharapkan bahwa semua resiko dapat dieliminasi dari setiap

operasi penambangan dan pengolahan.

Namun demikian, konsep tentang praktek-praktek terbaik termasuk merupakan suatu komitmen

untuk terus menerus mengupayakan peningkatan, dan Standar ini memberikan suatu cara untuk

mengukur dan memberikan pedoman kemajuan itu. Suatu audit sebagai garis dasar akan

dilakukan pada tahun 2006 untuk mengukur kepatuhan terhadap seluruh 18 Standar Bahaya

Utama, dan ini pada gilirannya akan membentuk suatu basis dalam melakukan peningkatan

yang bakal memberikan hasil pengurangan secara progressiv terhadap resiko cedera yang

terjadi akibat kecelakaan.

EHS Standard Originator Date Published

Title: Tyres and Rims PTI EHS August 2008

Page 2 of 27

Ref: EHS/12/STD/MHS/MHS18 Approved by To be reviewed

EHS Management Version: 2 Michael Winship August 2010

System

UNCONTROLLED DOCUMENT WHEN PRINTED

CONTENTS / DAFTAR ISI

About The PT Inco Major Hazard Standards ............................................................................... 2

Contents / Daftar Isi ..................................................................................................................... 3

Purpose / Tujuan.......................................................................................................................... 4

Scope / Ruang Lingkup................................................................................................................ 4

1. Hazard Identification, Risk Assessment and Control / Identifikasi Bahaya, Penilaian Risiko dan

Pengendaliannya ............................................................................................................................................... 4

2. Selection, Training, Competency and Authorisation / Pemilihan, Pelatihan, Kompetensi, dan Wewenang .... 7

3. Communication and Awareness / Komunikasi dan Kesadaran Bagi Karyawan............................................. 10

4. Specifications / Spesifikasi .............................................................................................................................. 11

5. Work Method and Condition Control / Metode Kerja dan Pengendalian Kondisi ........................................... 13

6. Maintenance / Pemeliharaan ........................................................................................................................... 19

7. Emergency Controls / Pengendalian Keadaan Darurat .................................................................................. 21

8. Monitoring, Inspections and Audits / Pemantauan, Inspeksi dan Audit .......................................................... 23

9. Reporting, Assessment and Corrective Actions / Pelaporan, Penilaian dan Tindakan Perbaikan ................ 24

Attachment A – Tyres and Rims Equipment Register (example only) ...................................... 25

Lampiran A – Register Peralatan Ban dan Pelek (Contoh) ....................................................... 26

Document Control / Kontrol Dokumen ....................................................................................... 27

EHS Standard Originator Date Published

Title: Tyres and Rims PTI EHS August 2008

Page 3 of 27

Ref: EHS/12/STD/MHS/MHS18 Approved by To be reviewed

EHS Management Version: 2 Michael Winship August 2010

System

UNCONTROLLED DOCUMENT WHEN PRINTED

PURPOSE / TUJUAN

To ensure all maintenance of tyres and rims at PT Inco is conducted in a safe manner so that the potential for failure or

uncontrolled movement of a tyre, rim, or wheel is controlled.

Memastikan semua pemeliharaan ban dan pelek di PT Inco dilakukan dengan cara yang aman, sehingga potensi

kerusakan atau gerakan tak terkontrol pada ban, pelek atau roda dapat dikendalikan.

SCOPE / RUANG LINGKUP

This Standard applies to:

¾ All tyres, rims and wheels on vehicles and mobile equipment owned and operated by PT Inco.

¾ All tyres, rims and wheels on contractor’s vehicles and mobile equipment operated on PT Inco lease areas.

Standar ini berlaku pada:

¾ Semua ban, pelek dan roda pada kendaraan dan alat berat yang dimiliki dan yang dioperasikan oleh PT Inco.

¾ Semua ban, pelek dan roda pada kendaraan dan alat berat kontraktor yang dioperasikan di wilayah kerja PT

Inco.

REQUIREMENTS / PERSYARATAN

1. HAZARD IDENTIFICATION, RISK ASSESSMENT AND CONTROL / IDENTIFIKASI BAHAYA, PENILAIAN

RISIKO DAN PENGENDALIANNYA

Objectives

To apply a risk management process to determine tyres and rims types authorise for use at PT Inco.

To ensure all approved tyre and rims types are recorded on a central register.

To require the PT Inco Job Safety Analysis procedure is applied.

To ensure PT Inco Change Management process is applied.

Tujuan

Menerapkan sebuah proses pengelolaan risiko untuk menentukan jenis ban dan pelek yang diizinkan untuk

digunakan di PT Inco.

Memastikan semua jenis ban dan pelek yang disetujui tercatat dalam sebuah pusat register.

Mengharuskan prosedur Job Safety Analysis PT Inco diterapkan.

Memastikan proses Change Management PT Inco diterapkan.

Outcome Accountability Tool

1.1 Tyres and Rims Equipment Register / Register Peralatan Ban dan General PT Inco Tyres

Pelek Manager and Rims

Miningand Equipment

All approved tyre and rim types shall be recorded in a PT Inco Tyres and Rims Contractor Register

Equipment Register that will be accessible and kept up to date. Company

Managers

The register shall include, but is not limited to the following:

1. A list of all vehicles and mobile equipment types fitted with tyres.

EHS Standard Originator Date Published

Title: Tyres and Rims PTI EHS August 2008

Page 4 of 27

Ref: EHS/12/STD/MHS/MHS18 Approved by To be reviewed

EHS Management Version: 2 Michael Winship August 2010

System

UNCONTROLLED DOCUMENT WHEN PRINTED

2. A list of tyres and rims types approved for use on each vehicle and mobile

equipment type.

3. The categorisation of all tyres and rims shall be as follows;

¾ Category A – One and two piece rims used on light vehicles and light

trucks and one piece tractor rims and divided rims, up to 24” (600 mm)

in diameter.

¾ Category B – All divided rims larger than 24” (600 mm) in diameter.

4. Minimum requirements and specifications for the assembly and

maintenance of tyre and rims.

Note: Attachment A - Tyres and Rims Equipment Register (example).

Semua jenis ban dan pelek yang disetujui harus tercatat di dalam Tyres and

Rims Equipment Register PT Inco, yang mudah diakses dan selalu diperbarui.

Register ini harus mencakup, tapi tidak terbatas pada:

1. Daftar seluruh jenis kendaraan dan alat berat yang dilengkapi ban.

2. Daftar jenis-jenis ban dan pelek yang telah disetujui untuk digunakan pada

masing-masing jenis kendaraan dan alat berat.

3. Kategorisasi semua ban dan pelek harus sebagai berikut;

¾ Kategori A – Pelek dengan satu dan dua bagian yang digunakan pada

kendaraan ringan dan truk ringan serta pelek traktor satu bagian dan

pelek yang terbagi, sampai dengan diameter 24” (600 mm).

¾ Kategori B – Semua pelek yang terbagi dan lebih besar diameter 24”

(600 mm).

4. Persyaratan minimum dan spesifikasi untuk pemasangan dan

pemeliharaan ban dan pelek.

Catatan: Lampiran A - Tyres and Rims Equipment Register (contoh).

1.2 Risk Assessment / Penilaian Risiko General Risk

Manager Mining Assessment

All risk assessments on vehicle and mobile equipment types shall follow the Register

process outlined in the PT Inco Risk Assessment Procedure.

The risk assessment shall assess the hazards associated with the operation,

maintenance and emergencies of tyre and rim types to determine suitability for

use at PT Inco and identify any limitations that must apply.

As a minimum the risk assessment must address potential injury by:

1. Crushing – due to heavy and unwieldy nature of large tyres and rims.

2. Projectile impact – as in the case of a wrongly assembled lock ring.

3. Chemical or pressure explosion (including fire) of the tyre and rim

assembly.

4. Loss of vehicle control should a tyre or rim fail in a critical situation.

Any risk identified as having a potential to cause injury or incident shall be

controlled before a tyre or rim type is approved for use at PT Inco.

All risk assessment documents and records shall be retained.

Semua penilaian risiko terhadap kendaraan dan alat berat harus mematuhi

proses yang dijabarkan dalam Risk Assessment Procedure PT Inco.

EHS Standard Originator Date Published

Title: Tyres and Rims PTI EHS August 2008

Page 5 of 27

Ref: EHS/12/STD/MHS/MHS18 Approved by To be reviewed

EHS Management Version: 2 Michael Winship August 2010

System

UNCONTROLLED DOCUMENT WHEN PRINTED

Penilaian risiko ini harus menilai bahaya-bahaya yang terkait dengan

pengoperasian, pemeliharaan dan situasi darurat pada ban dan pelek, untuk

menentukan kelayakan penggunaannya di PT Inco dan mengidentifikasi

keterbatasan yang harus berlaku.

Minimal, penilaian risiko ini harus mencakup potensi cedera karena:

1. Tergilas – akibat sifat dari ban dan pelek yang besar dan sukar ditangani.

2. Terkena lontaran – misalnya jika cincin pengunci salah pasang.

3. Ledakan kimia atau akibat tekanan tinggi (termasuk kebakaran) pada ban

dan pelek.

4. Kehilangan kontrol terhadap kendaraan jika ban atau pelek ternyata rusak

saat situasi genting.

Setiap risiko yang diidentifikasi berpotensi menyebabkan cedera atau insiden

harus dikendalikan terlebih dahulu sebelum jenis ban atau pelek itu diizinkan

untuk digunakan di PT Inco.

Semua dokumen penilaian risiko dan catatan-catatannya harus disimpan

dengan baik.

1.3 Change Management / Manajemen Perubahan PTI General PT Inco

Managers and Change

The PT Inco Change Management Procedure must be followed to authorise Contractor Management

modifications to tyres or rims on PT Inco vehicles or mobile equipment. Company Procedure

Managers

Change Management Procedure PT Inco harus dipatuhi dalam memberi

wewenang modifikasi terhadap ban dan pelek di kendaraan atau alat berat PT

Inco.

1.4 Job Safety Analysis (JSA) / Analisa Keselamatan Kerja PTI General

Managers and

All JSA’s conducted on tyres and rims tasks shall follow the process outlined in Contractor

the PT Inco JSA procedure. Company

Managers

A JSA shall be completed prior to work being conducted with tyres and rims

tasks when any of the following circumstances exist:

1. The work is non-routine and no Standard Operation Procedure (SOP)

exists.

2. The work is routine, a SOP exists but the conditions or scope has

changed.

3. When hazards exist that require specialist controls to ensure the work can

be completed safely.

Semua JSA pekerjaan pada ban dan pelek harus mematuhi proses yang telah

dijabarkan dalam prosedur JSA PT Inco.

JSA harus diselesaikan terlebih dahulu sebelum pekerjaan dengan ban dan

pelek dilaksanakan, jika ada salah satu dari situasi berikut ini:

1. Pekerjaan itu bersifat non-rutin dan tidak ada Standard Operation Procedure

(SOP).

2. Pekerjaan itu bersifat rutin, SOP ada namun kondisi atau ruang lingkupnya

berubah.

3. Jika ada bahaya yang mengharuskan ada pengendalian dari tenaga ahli

untuk memastikan pekerjaan dapat dilakukan dengan aman.

EHS Standard Originator Date Published

Title: Tyres and Rims PTI EHS August 2008

Page 6 of 27

Ref: EHS/12/STD/MHS/MHS18 Approved by To be reviewed

EHS Management Version: 2 Michael Winship August 2010

System

UNCONTROLLED DOCUMENT WHEN PRINTED

2. SELECTION, TRAINING, COMPETENCY AND AUTHORISATION / PEMILIHAN, PELATIHAN,

KOMPETENSI, DAN WEWENANG

Objectives

To ensure personnel required to conduct risk assessment are competent.

To ensure personnel required to perform maintenance on tyres and rims are trained and competent.

To require a skills matrix to be maintained for personnel required to perform maintenance work on tyres and rims.

Tujuan

Memastikan karyawan yang ditugaskan untuk melakukan penilaian risiko berkompeten.

Memastikan karyawan yang ditugaskan melakukan pemeliharaan pada ban dan pelek telah terlatih dan

kompeten.

Mengharuskan adanya daftar keahlian (skills matrix) bagi karyawan yang ditugaskan untuk melakukan pekerjaan

pemeliharaan pada ban dan pelek.

Outcome Accountability Tool

2.1 Risk Assessment Competency / Konpetensi Penilaian Risiko General Training

Manager Mining Records – Risk

Team or personnel conducting risk assessments must be recognised as and Contractor Assessment

collectively: Company

Managers

1. Possessing relevant area, operational or system experience (eg specialist

tyre/rim handling),

2. Hold the relevant qualifications

3. Having 2 or more people trained in PTI Risk Assessment (SP01) and

nominated by their general manager as competent in this role.

Semua orang atau tim yang melaksanakan penilaian resiko harus memiliki:

1. Memiliki Pengalaman tentang area yang sesuai, pengalaman operasional

atau system (misalnya spesialis menangani ban/pelek).

2. Mempunyai kualifikasi yang relevan

3. Butuh 2 orang atau lebih yang akan diikutkan dalam training PTI Risk

Assessment (SP01). Nama-nama yang berkemampuan untuk tugas ini

diusulkan oleh manajer masing-masing.

2.2 Training and Competency / Pelatihan dan Kompetensi Director HR Tyres and

Rims Skills

A training and competency system shall be implemented to ensure that all Matrix

persons at PT Inco have adequate knowledge and skills pertaining to the

risks being being addressed by the MHS and the associated controls. This shall

include:

1. Mandatory training and licensing requirements for certain types of work

that may expose persons to the major hazards. This shall include:

General Inductions for all employees, and site specific

inductions for certain employee groups based on risk (that

include reference to the major hazards at PT Inco and the

MHS system and related controls).

A program of Basic Safety Training for persons involved in

working at heights, confined space, rigging (and other work

EHS Standard Originator Date Published

Title: Tyres and Rims PTI EHS August 2008

Page 7 of 27

Ref: EHS/12/STD/MHS/MHS18 Approved by To be reviewed

EHS Management Version: 2 Michael Winship August 2010

System

UNCONTROLLED DOCUMENT WHEN PRINTED

based on risk).

A program of mandatory licensing for certain types of work

requiring specialized skill sets (e.g. light vehicle operation).

2. Department-based training to meet specific needs based on risk.

3. Competency in these defined training requirements assessed by

qualified workplace assessors and recorded in a system that allows

ready verification and tracking of workplace competencies.

Competency standards shall be in place for personnel required to:

¾ Conduct maintenance on all types of tyres and rims.

¾ Operate specialist tyres and rims equipment, and attachments.

¾ Direct movement of tyres and rims equipment.

¾ Inspect all types of tyres and rims.

¾ Conduct fire fighting operations (FES only).

Workplace assessments of tyres and rims maintenance personnel in all types of

tyres and rims shall be conducted.

Workplace assessments shall be conducted by Workplace Assessors who have

been trained in assessment techniques and either:

o Possess relevant tyres and rims equipment maintenance

experience, or

o Utilise a specialist who possess the relevant technical

knowledge

Note: The competencies required for changing passenger vehicle and light truck

wheels, shall be covered in the site induction and shall included correct

procedures for chocking, jacking and wheel replacement.

Harus dilaksanakan sistem pelatihan dan kompetensi untuk memastikan bahwa

semua orang di PT Inco mempunyai pengetahuan dan keahlian yang cukup

mengenai risiko yang ditangani oleh MHS dan tindakan pengendalian

terkait. Sistem dan pelatihan ini harus termasuk:

1. Pelatihan wajib dan persyaratan lisensi untuk jenis pekerjaan tertentu

yang dapat membahayakan seseorang. Pelatihan ini harus termasuk:

Induksi Umum untuk semua karyawan, dan induksi khusus

berdasarkan lokasi untuk kelompok karyawan tertentu

berdasarkan risiko (yang termasuk referensi terhadap bahaya-

bahaya utama di PT Inco dan sistem MHS dan kontrol-kontrol

terkait).

Program Pelatihan Keselamatan Dasar untuk orang yang

bekerja di ketinggian, ruang tertutup, rigging/tali-temali (dan

pekerjaan lain berdasarkan risiko).

Program pengaturan lisensi wajib untuk jenis pekerjaan

tertentu yang memerlukan serangkaian keahlian khusus

(misalnya operasi kendaraan ringan).

2. Pelatihan berdasarkan departemen untuk memenuhi kebutuhan

tertentu (berdasarkan risiko).

3. Kompetensi dalam persyaratan pelatihan tertentu ini dinilai oleh penilai

tempat kerja yang berkualifikasi, dan dicatat dalam sistem yang

EHS Standard Originator Date Published

Title: Tyres and Rims PTI EHS August 2008

Page 8 of 27

Ref: EHS/12/STD/MHS/MHS18 Approved by To be reviewed

EHS Management Version: 2 Michael Winship August 2010

System

UNCONTROLLED DOCUMENT WHEN PRINTED

memungkinkan verifikasi kesiapan dan pelacakan kompetensi di tempat

kerja.

Harus ada standar kompetensi bagi personil yang diharuskan untuk:

¾ Memelihara semua jenis ban dan pelek.

¾ Mengoperasikan peralatan ban dan pelek khusus, dan alat-alat

tambahannya.

¾ Mengarahkan gerakan peralatan ban dan pelek.

¾ Memeriksa semua jenis ban dan pelek.

¾ Melakukan operasi pemadaman kebakaran (khusus FES).

Penilaian tempat kerja terhadap para personil yang bertugas memelihara ban

dan pelek (untuk semua jenis ban dan pelek) juga harus dilakukan.

Penilaian tempat kerja ini harus dilakukan oleh Penilai Tempat Kerja (Workplace

Assessor) yang telah terlatih dalam teknik penilaian dan:

o Memiliki pengalaman dalam pemeliharaan peralatan ban dan

pelek yang relevan, atau

o Menggunakan spesialis yang memiliki pengetahuan teknis

yang relevan

2.3 Competency - Skills Matrix / Kompetensi – Matriks Keahlian General Tyres and

Manager Mining Rims Skills

The competencies referred to in Section 2.2 for personnel required to perform and Contractor Register

maintenance work on Category A and B tyres and rims are as follows: Company

Managers

Changing Category A Wheels;

1. Site safety requirements.

2. Isolation of area and equipment.

3. Chocking and jacking procedures.

4. Removal and replacement of wheel assembly.

5. Tightening wheel nuts.

6. Checking the wheel nut tension, where required.

Maintaining Category A Wheels (criteria 1 – 6, plus);

7. Strip and assembly procedures.

8. Inspection and assessment including criteria for re-use or disposal.

9. Repair procedures.

10. Mandatory use of safety restraining device.

11. Inflation procedures.

Changing Category B Wheels (criteria 1 – 6, plus);

12. Operation of tyre handling equipment.

13. Deflation procedures for specialist, large wheels.

14. Storage and stacking requirements.

15. Record keeping requirements.

Maintaining Category B Wheels (criteria 1 – 6, and 12 - 15 plus);

16. Operation of tyre presses and equipment.

EHS Standard Originator Date Published

Title: Tyres and Rims PTI EHS August 2008

Page 9 of 27

Ref: EHS/12/STD/MHS/MHS18 Approved by To be reviewed

EHS Management Version: 2 Michael Winship August 2010

System

UNCONTROLLED DOCUMENT WHEN PRINTED

17. Assessment of tyre status, suspected to have experienced an internal fire.

18. Where applicable:

¾ Ballasting and liquid filling.

¾ Nitrogen usage.

19. Storage and stacking requirements.

20. Record keeping requirements.

Kompetensi yang dimaksud di Bagian 2.2 bagi karyawan yang bertugas

melakukan pekerjaan pemeliharaan pada ban dan pelek Kategori A dan B

adalah sebagai berikut:

Mengganti Roda Kategori A;

1. Persyaratan keselamatan pada area kerja.

2. Isolasi area dan alat tersebut.

3. Prosedur pengganjalan dan pendongkrakan.

4. Pelepasan dan penggantian rakitan roda.

5. Pengencangan baut roda.

6. Pemeriksaan ketegangan baut roda, jika diperlukan.

Memelihara Roda Kategori A (kriteria 1 – 6, ditambah);

7. Prosedur pelepasan dan perakitan.

8. Inspeksi dan penilaian, termasuk kriteria apakah dapat digunakan ulang

atau dibuang.

9. Prosedur perbaikan.

10. Kewajiban penggunaan alat penahan.

11. Prosedur pengisian angin ban.

Mengganti Roda Kategori B (kriteria 1 – 6, ditambah);

12. Pengoperasian alat penanganan ban.

13. Prosedur pengempesan untuk ban yang besar dan khusus.

14. Persyaratan penyimpanan dan penumpukan.

15. Persyaratan dalam penyimpanan catatan.

Memelihara Roda Kategori B (kriteria 1 – 6, dan 12 - 15 ditambah);

16. Pengoperasian alat pres ban.

17. Penilaian status ban, dengan dugaan terkena api internal.

18. Jika memungkinkan:

Ballasting dan pengisian cairan.

Penggunaan nitrogen.

19. Persyaratan penyimpanan dan penumpukan.

20. Persyaratan dalam penyimpanan catatan.

3. COMMUNICATION AND AWARENESS / KOMUNIKASI DAN KESADARAN BAGI KARYAWAN

Objectives

To ensure personnel required to work on tyres and rims are provided with hazard update information.

EHS Standard Originator Date Published

Title: Tyres and Rims PTI EHS August 2008

Page 10 of 27

Ref: EHS/12/STD/MHS/MHS18 Approved by To be reviewed

EHS Management Version: 2 Michael Winship August 2010

System

UNCONTROLLED DOCUMENT WHEN PRINTED

Tujuan

Memastikan karyawan yang ditugaskan bekerja pada ban dan pelek telah mendapat informasi bahaya yang

terbaru.

Outcome Accountability Tool

3.1 Communication / Komunikasi General

Manager Mining

Regular (weekly) safety updates must be provided to all personnel required to and Contractor

maintain tyres and rims to reinforce identification of hazards and to provide Company

training update as necessary based on industry experience. Managers

Informasi terbaru mengenai keselamatan kerja harus diberikan secara berkala

(mingguan) bagi semua karyawan yang bertugas memelihara ban dan pelek,

untuk meningkatkan identifikasi bahaya dan untuk mengetahui perkembangan

pelatihan, sesuai kebutuhan berdasarkan pengalaman industri.

4. SPECIFICATIONS / SPESIFIKASI

Objectives

To ensure manufacturer’s tyre and rim specifications are not exceeded.

To define the minimum tyre tread depth.

To define the criteria for tyre and rim rejection.

To ensure personnel required to make purchasing decisions for tyres and rims are competent.

To outline procedural requirements for the loading and unloading, storage and handling of tyres and rims.

To define tyre and rim categories.

Tujuan

Memastikan spesifikasi ban dan pelek dari pabrik sesuai standard.

Menentukan kedalaman minimum tapak ban.

Menentukan kriteria ban dan pelek yang tidak layak pakai.

Memastikan kompetensi karyawan yang bertugas mengambil keputusan pembelian untuk ban dan pelek

kompeten.

Menjabarkan persyaratan prosedural untuk bongkar pasang, penyimpanan dan penanganan ban dan pelek.

Menentukan kategori ban dan pelek.

Outcome Accountability Tool

4.1 Manufacturers Specifications / Spesifikasi Pabrik General Tyres and

Manager Rims

Tyres shall be operated within the manufacturers / suppliers specification limits Mining, PTI Equipment

including speed, loads, pressures and Tons, Kilometres per Hour (tkph) ratings. General Register

Managers &

Ban harus dioperasikan di dalam batas spesifikasi dari pabrik / pemasok, Contractor

termasuk kecepatan, beban, tekanan dan rating Tons, Kilometers per hour Company

(tkph). Managers

General

Manager

Tambang,

General

Manager PTI &

EHS Standard Originator Date Published

Title: Tyres and Rims PTI EHS August 2008

Page 11 of 27

Ref: EHS/12/STD/MHS/MHS18 Approved by To be reviewed

EHS Management Version: 2 Michael Winship August 2010

System

UNCONTROLLED DOCUMENT WHEN PRINTED

Manajer

Perusahaan

Kontraktor

4.2 Minimum Tyre Tread Depth / Kedalaman Minimum Tapak Ban General Tyres and

Manager Rims

There shall be sufficient tread remaining on tyres to ensure safe operation as per Mining, PTI Equipment

the tyre wear indicator. The minimum tread depth for light vehicles is 1.5 mm as General Register

indicated by the tyre wear indicator on all light vehicle tyres. Managers &

Contractor

All other tyre minimum tread depths (where no tyre wear indicators are present) Company

shall be defined by vehicle and mobile equipment maintenance department Managers

based on manufacturer’s recommendations and local operating conditions and

General

shall be recorded in the tyres and rims register.

Manager

Note: Refer to section 4 in MHS 01 Vehicle and Mobile Equipment Condition Tambang,

Standard for all other vehicle condition specifications. General

Manager PTI &

Harus terdapat sisa tapak (ulir) yang memadai pada ban untuk memastikan Manajer

pengoperasian yang aman menurut indikator keausan ban. Kedalaman tapak Perusahaan

ban minimum untuk kendaraan ringan adalah 1,5 mm, seperti yang ditunjukkan Kontraktor

oleh indikator keausan ban pada semua ban kendaraan ringan.

Semua kedalaman minimum tapak ban lainnya (jika tidak terdapat indikator

keausan ban) harus ditentukan oleh departemen pemeliharaan kendaraan dan

alat berat berdasarkan rekomendasi dari pabrik dan ketentuan pengoperasian

lokal, dan harus dicatat dalam daftar ban dan pelek.

Catatan: Lihat ke bagian 4 dalam MHS 01 Vehicle and Mobile Equipment

Condition Standard untuk spesifikasi kondisi kendaraan lainnya.

4.3 Tyres and Rims Rejection Criteria / Kriteria Ketidaklayakan Ban dan General Tyres and

Pelek Manager Mining Rims

and Contractor Equipment

Criteria for the rejection of tyres and rims shall be developed based on the Company Register

recommendation of the supplier / manufacturer and local conditions and Managers

recorded in the tyres and rims register.

Routine testing of rims utilising Non Destructive Testing (NDT) procedures shall

be established and maintained to ensure rim faults are detected and the rims

withdrawn from service before failure.

Kriteria ban dan pelek dinyatakan tidak layak harus dibuat berdasarkan

rekomendasi dari pabrik / pemasok dan berdasarkan kondisi setempat, serta

harus dicatat dalam register ban dan pelek.

Pengujian rutin dari pelek dengan menggunakan prosedur Non Destructive

Testing (NDT) harus dibuat dan diterapkan untuk memastikan kerusakan pelek

segera terdeteksi dan pelek itu disingkirkan sebelum gagal berfungsi.

4.4 Purchasing / Pembelian General

Manager SCM &

Personnel who are required to make purchasing decisions for tyres and rims General

shall be technically competent. Manager Mining

General

Karyawan yang bertugas mengambil keputusan pembelian untuk ban dan pelek

Manager SCM &

harus kompeten secara teknis.

General

Manager

Tambang

4.5 Tyres and Rims - Loading and Unloading / Ban dan Pelek – Bongkar General SOP for

Pasang Manager SCM & Unloading and

EHS Standard Originator Date Published

Title: Tyres and Rims PTI EHS August 2008

Page 12 of 27

Ref: EHS/12/STD/MHS/MHS18 Approved by To be reviewed

EHS Management Version: 2 Michael Winship August 2010

System

UNCONTROLLED DOCUMENT WHEN PRINTED

General Loading of

Suitable equipment and procedures shall be provided to enable safe unloading Manager Mining Tyres and

and loading of tyres and rims. Rims

General

Personnel required to conduct loading and unloading operations shall be trained Manager SCM &

in the use of specialist equipment, following standard operating procedure and General

assessed as competent. Manager

Tambang

The procedure shall adhere to the following minimum requirements:

1. Tyres shall not be dropped from the delivery truck.

2. Forklift tines shall not contact the sidewalls of tyres in a way that can cause

damage.

3. Forklift tines shall not make contact with the tyre interior.

4. Crane type hooks shall not be used.

5. Flat hooks must have a minimum width of 250 mm.

Peralatan dan prosedur yang memadai harus tersedia agar pembongkaran dan

pemasangan ban dan pelek yang aman dapat dilakukan.

Karyawan yang bertugas melakukan bongkar pasang ini harus terlatih

menggunakan alat-alat khusus, dan harus mematuhi prosedur pengoperasian

standar dan harus dinilai berkompeten.

Prosedur ini harus mematuhi persyaratan minimum sebagai berikut:

1. Ban tidak boleh jatuh dari truk pengiriman.

2. Gigi forklift tidak boleh mengenai sisi samping ban yang dapat

menyebabkan kerusakan.

3. Gigi forklift tidak boleh terkena bagian dalam ban.

4. Kaitan (hook) jenis katrol tidak boleh digunakan.

5. Kaitan rata harus mempunyai lebar minimal 250 mm.

4.6 Tyres and Rims - Storage and Handling / Ban dan Pelek – General SOP for

Penyimpanan dan Penanganan Manager SCM Storage and

and General Handling of

Standard operating procedures for the handling and storage of tyres and rims Manager Mining Tyres and

must include specialist handling techniques as specified by the manufacturer. Rims

General

There shall be a storage system for tyres larger than 1 metre diameter that shall Manager SCM &

ensure that they cannot be displaced or fall. General

Manager

Prosedur pengoperasian standar untuk penanganan dan penyimpanan ban dan Tambang

pelek termasuk teknik penanganan khususnya sesuai spesifikasi pabrik.

Harus ada sistem penyimpanan khusus bagi ban yang berdiameter lebih besar

dari 1 meter, agar memastikan tidak jatuh.

5. WORK METHOD AND CONDITION CONTROL / METODE KERJA DAN PENGENDALIAN KONDISI

Objectives

To define requirements for a tyre and rim condition recording system.

To outline requirements for specialist tyres and rims equipment.

To specify the criteria that must be addressed via a Standard Operating Procedure for the deflation and removal

of tyres and rims.

To ensure all tyres and rims are inspected by competent personnel.

EHS Standard Originator Date Published

Title: Tyres and Rims PTI EHS August 2008

Page 13 of 27

Ref: EHS/12/STD/MHS/MHS18 Approved by To be reviewed

EHS Management Version: 2 Michael Winship August 2010

System

UNCONTROLLED DOCUMENT WHEN PRINTED

To specify the criteria that must be addressed via a Standard Operating Procedure for the inflation and assembly

of tyres and rims.

Tujuan

Menentukan persyaratan untuk sistem pencatatan kondisi ban dan pelek.

Menjabarkan persyaratan untuk peralatan ban dan pelek yang khusus.

Menjabarkan kriteria yang harus dipenuhi melalui sebuah Standard Operating Procedure untuk pengempesan

dan pembongkaran ban dan pelek.

Memastikan semua ban dan pelek telah diperiksa oleh karyawan yang berkompeten.

Menentukan kriteria yang harus dipenuhi melalui sebuah Standard Operating Procedure, untuk pengisian angina

dan pemasangan ban dan pelek.

Outcome Accountability Tool

5.1 Tyres and Rims Condition Recording System / Sistem Pencatatan General Tyres and

Kondisi Ban dan Pelek Manager Mining Rims

and Contractor Equipment

A recording system shall be maintained to ensure that all Category B Tyres and Company Register

Rims do not exceed a safe service life and will provide essential information Managers

should a component fail.

The following records shall be kept in a format that provides easy retrieval and

update:

1. Records for all Category B rim bases 25” (600 mm) and over including:

¾ History from purchase to disposal.

¾ Rim test methods, results and component repairs / replacements.

2. Records of Category B tyres 25” (600 mm) and over including:

¾ History from purchase to disposal.

¾ All repairs, re-lugs, retreads and re-grooves of the tyres.

Sebuah sistem pencatatan harus dilakukan, untuk memastikan bahwa semua

Ban dan Pelek Kategori B tidak melebihi usia pakai yang aman, dan akan

memberikan informasi berharga jika ada komponennya yang rusak.

Catatan berikut ini harus dibuat dalam format yang mudah dicari dan diperbarui:

1. Catatan untuk semua pelek Category B berukuran 25” (600 mm) atau lebih,

mencakup:

¾ Catatan mulai dari pembelian sampai pembuangan.

¾ Metode uji pelek, hasilnya, serta reparasi / penggantian komponen.

2. Catatan untuk semua ban Category B berukuran 25” (600 mm) atau lebih,

termasuk:

¾ Catatan mulai dari pembelian sampai pembuangan.

¾ Semua reparasi, dan proses rehabilitasi seperti re-lugs, retreads dan re-

grooves ban.

5.2 Specialist Tools and Equipment / Alat-Alat Khusus General SOP Removal

Manager Mining and Assembly

Standard Operating Procedures shall define required tools and equipment that and Contractor of Tyres and

must be used for the safe removal and assembly of all tyres and rims. Company Rims

Managers

The tools and equipment defined in these procedures shall be available and in

EHS Standard Originator Date Published

Title: Tyres and Rims PTI EHS August 2008

Page 14 of 27

Ref: EHS/12/STD/MHS/MHS18 Approved by To be reviewed

EHS Management Version: 2 Michael Winship August 2010

System

UNCONTROLLED DOCUMENT WHEN PRINTED

good working order.

Standard Operating Procedure akan menjabarkan alat-alat dan mesin yang

harus digunakan dalam pembongkaran dan pemasangan ban dan pelek yang

aman.

Alat-alat dan mesin yang dijabarkan dalam prosedur ini harus tersedia dan

dalam kondisi baik.

5.3 SOP - Deflation and Removal / SOP – Pengempesan dan General SOP Deflation

Pembongkaran Manager Mining and Removal

and Contractor of Tyres and

A Standard Operating Procedure shall exist for the deflation and removal of tyres Company Rims

and rims. Managers

The procedure must incorporate the following:

1. Hard standing: to ensure the jacking and standing process can be carried

out in a safe manner, the operational area is to be on firm ground, level and

free of obstruction, oil and grease.

2. Lighting: There shall be an adequate level of lighting in the work area to

enable safe operation of equipment.

3. Brake application: Requirement for all brakes to be applied.

4. Chocking:

¾ At least one wheel shall be chocked in both directions.

¾ vehicles shall never be driver over chocks.

¾ All brakes shall be applied.

5. Jacking:

¾ Use only manufacturers designated jacking points.

¾ No more than one spacer is to be used.

¾ The spacer shall have a recess or spigot to fit the head of the jack and

be of adequate strength.

¾ No part of a person’s body shall be under the vehicle supported only by a

jack or jacks except for the placing of stands, when due care must be

taken.

6. Stands:

¾ Use only purpose built stands capable of safely carrying the required

load.

¾ Spacers are not permitted.

¾ If a rubber cap is employed it must be a permanent fixture.

7. Deflation prior to loosening attachment bolts or nuts:

¾ Split rims must be fully deflated.

¾ Category A tyres fitted to passenger vehicles and light trucks with a rim

diameter of 16” (385 mm) or less, need to be deflated except for wheels

retained at the hub by a wheel disc.

¾ Category B wheels and rims deflate to a maximum of 35 kPa.

8. Deflation prior to stripping:

¾ Avoid shock loading of vulnerable parts (bead ring, lock ring) of multi-

piece rim assemblies.

EHS Standard Originator Date Published

Title: Tyres and Rims PTI EHS August 2008

Page 15 of 27

Ref: EHS/12/STD/MHS/MHS18 Approved by To be reviewed

EHS Management Version: 2 Michael Winship August 2010

System

UNCONTROLLED DOCUMENT WHEN PRINTED

¾ There shall be total deflation before stripping commences, including

valve core removal.

9. Use of hydraulic breaking tools:

¾ Inspect hydraulic tools before commencing.

¾ Do not use if worn or damaged.

¾ Create a no-go zone to control unauthorised access to work area which

has a minimum radius of the hydraulic hose length.

Harus tersedia Standard Operating Procedure untuk pengempesan dan

pembongkaran ban dan pelek.

Prosedur tersebut harus mencakup:

1. Landasan/permukaan yang kuat: untuk memastikan proses pendongkrakan

dan penyanggaan dapat berlangsung dengan aman, area operasinya harus

di tanah yang kokoh, rata dan bebas dari halangan, oli dan minyak.

2. Pencahayaan: Harus ada pencahayaan yang memadai di area kerja agar

pengoperasian alat dapat berjalan aman.

3. Aplikasi rem: rem harus dalam keadaan terpasang.

4. Ganjal:

¾ Sekurangnya satu roda harus diganjal di kedua arah.

¾ kendaraan tidak boleh berpenumpang saat diganjal.

¾ Semua rem harus dipasang.

5. Pendongkrakan:

¾ Gunakan titik dongkrak sesuai petunjuk pabrik.

¾ Jangan lebih dari satu spacer yang digunakan.

¾ Spacer harus mempunyai ceruk atau tonjolan/spigot agar pas dengan

kepala dongkrak dan memiliki kekuatan yang memadai.

¾ Tidak boleh ada bagian tubuh yang berada di bawah kendaraan yang

hanya disangga oleh dongkrak kecuali saat menaruh penahan, dan saat

menaruh penahan itu harus dilakukan dengan hati-hati.

6. Penyangga:

¾ Gunakan penyangga yang khusus untuk tujuan ini, dan sanggup

menahan beban dengan aman.

¾ Spacer tidak diizinkan.

¾ Jika menggunakan penutup karet, maka harus bersifat permanen.

7. Pengempesan sebelum melonggarkan baut:

¾ Pelek jenis split harus dikempeskan seluruhnya.

¾ Ban Category A yang terpasang di kendaraan penumpang dan truk

ringan dengan diameter pelek 16” (385 mm) atau kurang, harus

dikempeskan kecuali rodanya ditahan di bagian poros oleh cakram roda.

¾ Roda dan pelek Category B harus dikempeskan ke maksimal 35 kPa.

8. Pengempesan sebelum pelepasan baut:

¾ Hindari pelepasan dengan mendadak bagian-bagian yang rentan (bead

ring, cincin pengunci) dalam rakitan pelek dengan multi-bagian.

¾ Harus dikempeskan seluruhnya sebelum pelepasan baut, termasuk

pelepasan inti katup.

EHS Standard Originator Date Published

Title: Tyres and Rims PTI EHS August 2008

Page 16 of 27

Ref: EHS/12/STD/MHS/MHS18 Approved by To be reviewed

EHS Management Version: 2 Michael Winship August 2010

System

UNCONTROLLED DOCUMENT WHEN PRINTED

9. Penggunaan alat pelepas hidrolik:

¾ Periksalah alat hidrolik itu sebelum digunakan.

¾ Jangan digunakan jika aus atau rusak.

¾ Buat zona tertutup, untuk menghindari orang tak berwenang masuk ke

area kerja, dengan radius minimum panjang selang hidrolik.

5.4 Inspection of Tyres / Inspeksi Ban General SOP

Manager Mining Inspection of

All tyres shall be inspected by a competent person for internal and external and Contractor Tyres and

damage each time the tyre is removed from the rim for maintenance. Company Rims

Managers

Defective tyres shall be scrapped or repaired and where any doubt over safety

exists, the tyre supplier shall be consulted before refitting.

Semua ban harus diperiksa oleh orang yang berwenang dan melihat apakah

ada kerusakan internal atau eksternal, setiap kali ban dilepas dari pelek saat

pemeliharaan.

Ban yang rusak harus diperbaiki atau direparasi dan jika ada keraguan akan

keamanannya, maka harus berkonsultasi dengan pemasok ban itu dahulu

sebelum menggunakannya kembali.

5.5 Inspection of Rims / Pemeriksaan Pelek General SOP

Manager Mining Inspection of

All rims shall be inspected by a competent person for cracks, distortion and wear and Contractor Tyres and

each time the rim is removed for maintenance. Company Rims

Managers

All rim components which are unfit for service, shall be scrapped in such a way

as to render them unusable.

Note: Inspection intervals shall be determined as recommended by rim suppliers

and dependent upon site conditions.

Semua pelek harus diperiksa oleh orang yang berkompeten dan melihat apakah

ada retakan, bengkok atau keausan, setiap kali pelek itu dilepas saat

pemeliharaan.

Semua komponen pelek yang tidak layak pakai, harus dibuang dan tidak

dipergunakan lagi.

Catatan: Selang waktu inspeksi harus berdasarkan rekomendasi pemasok

pelek dan tergantung kondisi site.

5.7 SOP - Assembly and Inflation / SOP – Pemasangan dan Pengisian General SOP Assembly

Angin Manager Mining and Inflation of

and Contractor Tyres and

A standard operating procedure shall exist for the assembly and inflation of tyres Company Rims

and rims. Managers

The procedure must incorporate the following:

1. Inspection prior to fitting.

2. Inflation;

¾ Determine if nitrogen (N2) or air is required.

¾ Where nitrogen (N2) is required ensure the supply is N2.

EHS Standard Originator Date Published

Title: Tyres and Rims PTI EHS August 2008

Page 17 of 27

Ref: EHS/12/STD/MHS/MHS18 Approved by To be reviewed

EHS Management Version: 2 Michael Winship August 2010

System

UNCONTROLLED DOCUMENT WHEN PRINTED

¾ Do not use, or vent N2 in an enclosed space.

¾ Use authorised equipment including a safety relief valve.

3. Clip-on air chucks - If line pressure exceeds inflation pressure by 35 kPa,

(5 psi) then a pressure regulator combined with a pressure relief valve shall

be fitted to the compressor.

4. Bead lubricants and sealants - Use only substances authorised by the tyre

supplier.

5. Compatibility of multi-piece rim components;

¾ Before assembly commences, component compatibility shall be

checked.

¾ Rim parts shall be clearly identified.

6. Use of containment devices for nitrogen filling;

7. Inflation of Category A only;

¾ Hearing and eye protection shall be worn for tyres on and off equipment.

¾ Safety cages or approved retraining device shall be used.

¾ Exception for passenger and light truck 16” (385 mm) and below on a

one piece rim.

8. Inflation of Category B;

¾ Hearing and eye protection shall be worn.

¾ Clip on air chucks with remote control shall be used.

¾ There shall be a restraining device or barrier immediately in front of the

lock ring.

¾ A no-go zone from the barrier to the tyre and a minimum distance of 4

metres either side of the tyre shall be established before inflation

commences to prevent unauthorised access.

¾ No excessive force, such as hitting with a heavy hammer, shall be used

to force components into place.

9. Intermediate pressure check for multi-piece rims;

¾ At 35 kPa inflation pressure a visual check of components for correct

seating shall be made.

¾ Only minimal force is permitted to tap components into place.

¾ If heavy force is required, tyre must be re-stripped to check for

component damage and compatibility.

10. Tightening wheel components follow equipment manufacturer’s

recommendations.

11. Checking the tightness of wheel components follow equipment

manufacturer’s recommendations.

Harus ada sebuah prosedur pengoperasian standar untuk pemasangan dan

pengisian angin pada ban dan pelek.

Prosedur itu harus mencakup:

1. Inspeksi sebelum pemasangan.

2. Pengisian angin;

¾ Tentukan apakah nitrogen (N2) atau udara yang diperlukan.

¾ Jika nitrogen (N2) yang diperlukan, pastikan isi pompa adalah N2.

¾ Jangan menggunakan atau mengalirkan N2 dalam ruang tertutup.

EHS Standard Originator Date Published

Title: Tyres and Rims PTI EHS August 2008

Page 18 of 27

Ref: EHS/12/STD/MHS/MHS18 Approved by To be reviewed

EHS Management Version: 2 Michael Winship August 2010

System

UNCONTROLLED DOCUMENT WHEN PRINTED

¾ Gunakan alat yang diizinkan, termasuk katup pelepasan pengaman.

3. Chuck udara jenis clip-on – Jika tekanan melebihi tekanan pengisian

sebesar 35 kPa, (5 psi) maka sebuah regulator (alat pengatur tekanan)

bersama katup pelepasan pengaman harus dipasang ke kompresor.

4. Pelumas bead dan sealants – gunakan larutan yang direkomendasikan

pemasok ban.

5. Kecocokan komponen untuk pelek jenis multi-bagian;

¾ Sebelum pemasangan dimulai, kecocokan komponennya harus

diperiksa terlebih dahulu.

¾ Bagian-bagian pelek harus diidentifikasi dengan jelas.

6. Gunakan alat penampung untuk pengisian dengan nitrogen;

7. Untuk pengisian Category A;

¾ Harus memakai pelindung mata dan telinga saat menggunakan alat

pelepas dan pemasang ban.

¾ Kerangkeng pengaman atau alat penahan lain yang diizinkan harus

digunakan.

¾ Kecuali kendaraan penumpang dan truk ringan 16” (385 mm) dan di

bawahnya, pada pelek jenis satu bagian.

8. Untuk pengisian Category B;

¾ Harus mengenakan pelindung mata dan telinga.

¾ Harus menggunakan chuck udara jenis clip on dengan remote control.

¾ Harus ada alat penahan langsung di depan cincin kunci.

¾ Sebelum pengisian dimulai, harus ada daerah tertutup mulai dari alat

penahan ke ban dengan jarak minimal 4 meter ke semua sisi ban,

untuk mencegah ada orang yang tak berwenang masuk.

¾ Tidak boleh menggunakan tenaga berlebihan, misalnya memukul

dengan palu, untuk memaksa komponen masuk.

9. Pemeriksaan tekanan menengah untuk pelek jenis multi-bagian;

¾ Di tekanan pengisian 35 kPa, harus dilakukan pemeriksaan visual

terhadap komponen apakah terpasang dengan benar.

¾ Hanya diizinkan tenaga minimal untuk mengetuk komponen masuk.

¾ Jika diperlukan tenaga yang besar, ban harus dilepas ulang untuk

memeriksa kerusakan dan kecocokan komponen.

10. Saat mengencangkan komponen roda, patuhi rekomendasi dari pabrik alat

tersebut.

11. Periksa kekencangan komponen roda, dan patuhi rekomendasi dari pabrik

alat tersebut.

6. MAINTENANCE / PEMELIHARAAN

Objectives

To outline the requirement for housekeeping in the tyres and rims workshop.

To specify the need for assurance of the quality of repairs on tyres and rims.

To outline the conditions that shall apply to re-treads, re-grooves and re-lugs.

To specify the need for disposal records for tyres.

Tujuan

Menjabarkan persyaratan kebersihan dan kerapihan dalam bengkel ban dan pelek.

EHS Standard Originator Date Published

Title: Tyres and Rims PTI EHS August 2008

Page 19 of 27

Ref: EHS/12/STD/MHS/MHS18 Approved by To be reviewed

EHS Management Version: 2 Michael Winship August 2010

System

UNCONTROLLED DOCUMENT WHEN PRINTED

Menentukan perlunya jaminan kualitas reparasi terhadap ban dan pelek.

Menjabarkan kondisi yang harus ada untuk melakukan re-treads, re-grooves dan re-lugs.

Menentukan perlunya catatan pembuangan ban.

Outcome Accountability Tool

6.1 Housekeeping / Kebersihan dan Kerapihan General

Manager Mining

The tyres and rims workshop must be kept clear of hazards that could cause

significant damage to tyres and present a risk of injury to personnel.

Bengkel ban dan pelek harus bersih dari bahaya-bahaya yang dapat

menyebabkan kerusakan besar terhadap ban, dan menimbulkan risiko cedera

bagi personil.

6.2 Quality of Repair / Kualitas Reparasi General Tyres and

Manager Mining Rims

Repairs to all tyres and rims shall not normally limit the service capability of the and Contractor Equipment

tyre or rim. However where a repair limits the service capability, (but does not Company Register

create a safety risk) the conditions of use must be specified, recorded (tyres and Managers

rims register) and communicated to the operator‘s of the vehicle or equipment.

Reparasi ban dan pelek tidak boleh mengurangi kemampuan pakai ban atau

pelek tersebut. Namun demikian, jika reparasi itu ternyata mengurangi

kemampuan pakainya (tapi tidak menimbulkan risiko keamanan), maka kondisi

pemakaian harus ditentukan, dicatat (dalam register ban dan pelek), dan

dikomunikasikan kepada operator dari kendaraan atau alat berat yang

bersangkutan.

6.3 Retreads, Re-lugs and Re-Grooving / Retreads, Re-lugs dan Re- General SOP Retreads,

Grooving Manager Mining Re-grooving

and Contractor and Re-lugs

The following conditions shall apply to all retreads and re-lugs: Company

Managers

1. Re-grooving is only permitted when authorised by the tyre manufacturer or

re-treader and is carried out by an authorised re-groover.

2. Re-grooved tyres can be fitted to any position, except in the case of re-

grooved retreads.

3. Re-treads and re-lugs are not permitted on steering axles (exception

applies for graders).

4. An identification system must be established to indicate how many times a

tyre has been retreaded or re-lugged (permanent symbol on the sidewall).

Kondisi berikut ini harus ada untuk melakukan retreads dan re-lugs:

1. Re-grooving atau re-treader hanya diizinkan jika diperbolehkan oleh

produsen ban dan dilakukan oleh re-groover yang berwenang.

2. Ban hasil re-grooved dapat dipasang ke posisi apapun, kecuali jika sudah

dilakukan re-grooved retreads.

3. Re-treads dan re-lugs tidak diizinkan pada poros kemudi (pengecualian

untuk graders).

4. Harus ada sistem identifikasi untuk menunjukkan berapa kali ban itu telah

mengalami retreaded atau re-lugged (simbol permanen di sisinya).

6.4 Disposal Records / Catatan Pembuangan General Tyres and

EHS Standard Originator Date Published

Title: Tyres and Rims PTI EHS August 2008

Page 20 of 27

Ref: EHS/12/STD/MHS/MHS18 Approved by To be reviewed

EHS Management Version: 2 Michael Winship August 2010

System

UNCONTROLLED DOCUMENT WHEN PRINTED

Manager Mining Rims

Prior to disposal of tyres and rims, the required records shall be completed and and Contractor Equipment

the tyres and rims register updated. Company Register

Managers

Items waiting disposal shall be stored in a way that does not create a fire hazard

or a mosquito borne disease hazard.

Tyres larger than 1 metre in diameter shall be restrained in such a way that they

cannot be displaced or have the potential to crush personnel.

Sebelum ban dan pelek dibuang, harus dibuat catatan wajib dan memperbarui

catatan di register ban dan pelek.

Benda-benda yang akan dibuang harus disimpan sedemikian rupa agar tidak

menimbulkan bahaya kebakaran atau bahaya penyakit karena nyamuk.

Ban dengan diameter lebih besar dari 1 meter harus disimpan sedemikian rupa

sehingga tidak jatuh atau berpotensi menimpa orang.

7. EMERGENCY CONTROLS / PENGENDALIAN KEADAAN DARURAT

Objectives

To outline the requirements for fire fighting and rescue that applies to tyres.

Tujuan

Menjabarkan persyaratan dalam pemadaman kebakaran dan cara penyelamatan, sehubungan dengan ban.

Outcome Accountability Tool

7.1 Fire Fighting – Tyres / Pemadaman Kebakaran - Ban General Fire Attack

Manager EHS Plan

Fire fighting procedures must be established, followed and there shall be

appointed persons (FES) on site who have control over the fighting of any fire.

The fire fighting procedures shall address the following tyre fire categories:

1. Tyre and Rim Category A.

2. Tyre and Rim Category B.

Specialist fire fighting processes in Fire Emergency Services (FES) Procedures

shall address the following:

1. Contingency / Planning Requirements;

¾ Emergency park-up areas shall be designated and be able to be

cordoned off for a minimum radius of 300 metres.

¾ All personnel shall be made aware of the location of the emergency

park-up areas which are to be planned as part of mine planning.

¾ All operational personnel shall have full knowledge of procedures for

removing drivers from affected vehicles.

2. Sectors of Extreme Danger - The blast from an exploding tyre affects a

360o radius with debris most likely to be ejected from the side of the tyre.

3. Parking-up Vehicles:

¾ If a fire or excessive heating is suspected, the designated person in

charge shall decide whether to leave the vehicle where it is, or have it

driven to an emergency park-up area.

EHS Standard Originator Date Published

Title: Tyres and Rims PTI EHS August 2008

Page 21 of 27

Ref: EHS/12/STD/MHS/MHS18 Approved by To be reviewed

EHS Management Version: 2 Michael Winship August 2010

System

UNCONTROLLED DOCUMENT WHEN PRINTED

¾ If a Vehicle suspected of having a fire is left where it is a quarantine

area of at least 300 metres shall be established to isolate the vehicle.

4. Evacuation of a Driver;

¾ The preferred method is to drive a similar vehicle to the affected vehicle

and evacuate across the platform.

¾ The escape route shall be in front of or to the rear of the vehicle.

5. Quarantine Radius;

¾ Once the driver is evacuated, road block shall be set up to give a

minimum of 300 metres quarantine.

¾ Except for fire fighting no other person shall enter the area.

6. Fire Fighting;

¾ The approach method is either from the front or rear of the vehicle for A

and B class tyre fires.

¾ The approach method of a vehicle with a C class tyre fire shall be

determined via completion of a dynamic risk assessment.

7. Quarantine Period;

¾ After heating, contact with electricity or being struck by lightning a

suspected fire shall be treated as an actual fire.

¾ Except for the purposes of fire fighting, the vehicle shall not be

approached for 36 hours.

8. Checking Status of Fire;

¾ Following the 36 hour period a suitably training person can approach

the vehicle to check on the condition of the fire.

¾ For dual assemblies, both wheels must be checked.

9. After the Fire is Out;

¾ FES will not release the equipment until they issue the FES ‘STOP’

order which identifies the emergency is over.

¾ Strip the tyre following established safe procedure.

Prosedur pemadaman kebakaran harus dibuat dan dipatuhi, dan harus ada

petugas yang ditunjuk di site yang mempunyai kontrol terhadap pemadaman

kebakaran.

Prosedur pemadaman kebakaran ini harus mencakup kategori kebakaran ban

berikut ini:

1. Ban dan Pelek Category A.

2. Ban dan Pelek Category B.

Spesialis bidang proses pemadaman api dalam Prosedur Fire Emergency

Services (FES/Pemadaman Kebakaran) harus mencakup berikut ini:

1. Persyaratan Kontinjensi / Perencanaan;

¾ Harus ditentukan area parkir darurat, dan dapat dikumpulkan dalam

minimum radius 300 meter.

¾ Semua karyawan harus mengetahui lokasi area parkir darurat itu, dan

harus tercakup dalam bagian perencanaan tambang.

¾ Semua karyawan operasi harus mengetahui penuh prosedur untuk

mengeluarkan pengemudi dari kendaraan yang terbakar.

2. Sektor yang Sangat Berbahaya – ledakan dari ban yang meledak dapat

mempengaruhi radius 360o dengan pecahannya, yang kemungkinan besar

terlontar dari bagian sisi ban.

EHS Standard Originator Date Published

Title: Tyres and Rims PTI EHS August 2008

Page 22 of 27

Ref: EHS/12/STD/MHS/MHS18 Approved by To be reviewed

EHS Management Version: 2 Michael Winship August 2010

System

UNCONTROLLED DOCUMENT WHEN PRINTED

3. Kendaraan yang Diparkir:

¾ Jika ada dugaan kebakaran atau panas yang berlebihan, petugas yang

berwenang harus memutuskan apakah akan meninggalkan kendaraan

atau dikemudikan ke area parkir darurat.

¾ Jika ada kendaraan yang diduga terbakar itu ditinggalkan, maka harus

dibuat area karantina sekurangnya 300 meter untuk mengisolasi

kendaraan tersebut.

4. Evakuasi pengemudi;

¾ Metode yang disarankan adalah mengemudikan kendaraan yang sama

menuju kendaraan yang terbakar, dan mengevakuasi dari platformnya.

¾ Jalan keluarnya harus di depan atau di belakang kendaraan tersebut.

5. Radius Karantina;

¾ Setelah pengemudi dikeluarkan, harus dibuat penghalang jalan untuk

membuat daerah karantina minimal 300 meter.

¾ Kecuali pemadam kebakaran, tidak ada yang boleh memasuki daerah

ini.

6. Pemadaman Kebakaran;

¾ Untuk kebakaran ban jenis A dan B, metode untuk mendekatinya

adalah dari depan atau belakang kendaraan.

¾ Untuk kendaraan dengan kebakaran ban jenis C, metode untuk

mendekatinya harus melalui penilaian risiko yang bersifat dinamis.

7. Periode Karantina;

¾ Setelah terjadi pemanasan, terkena listrik atau tersambar petir, dugaan

api harus dianggap sebagai kebakaran.

¾ Kecuali untuk tujuan pemadaman kebakaran, kendaraan tidak boleh

didekati selama 36 jam.

8. Pemeriksaan Status Api;

¾ Setelah periode 36 jam, petugas yang terlatih dapat mendekati

kendaraan untuk melihat kondisi api.

¾ Untuk rakitan ganda, kedua roda harus diperiksa.

9. Setelah Api Padam;

¾ FES tidak akan melepaskan sampai menerbitkan perintah FES ‘STOP’

yang menyatakan bahwa keadaan darurat telah berakhir.

¾ Lepaskan ban sesuai prosedur keamanan yang ada.

8. MONITORING, INSPECTIONS AND AUDITS / PEMANTAUAN, INSPEKSI DAN AUDIT

Objectives

To specify the requirements for auditing of this Standard.

Tujuan

Menentukan persyaratan audit terhadap Standar ini.

Outcome Accountability Tool

8.1 Auditing / Audit General MHS Audit

Manager EHS Schedule

Audits must be performed to assess compliance with this Standard as per an

approved audit schedule.

EHS Standard Originator Date Published

Title: Tyres and Rims PTI EHS August 2008

Page 23 of 27

Ref: EHS/12/STD/MHS/MHS18 Approved by To be reviewed

EHS Management Version: 2 Michael Winship August 2010

System

UNCONTROLLED DOCUMENT WHEN PRINTED

Pemeriksaan audit harus dilakukan untuk menilai kepatuhan dengan Standar ini

sesuai dengan jadwal pemeriksaan audit yang telah disetujui.

9. REPORTING, ASSESSMENT AND CORRECTIVE ACTIONS / PELAPORAN, PENILAIAN DAN

TINDAKAN PERBAIKAN

Objectives

To outline the need for the reporting of all hazards and defects with tyres and rims.

Tujuan

Menjabarkan perlunya pelaporan semua bahaya dan kerusakan yang ada pada ban dan pelek.

Outcome Accountability Tool

9.1 Hazards and Defects / Bahaya dan Kerusakan PTI General SOP Reporting

Managers Hazards

All identified defects on tyres and rims on any vehicle must be reported,

corrected and recorded.

If a defect in a tyre or rim renders the vehicle unsafe for operation, it must be put

Out of Service by use of a PT Inco - Out of Service Tag (to prevent unsafe use)

placed on the isolation / ignition switch as per the requirements of MHS 04

Isolation and Lockout.

Semua kerusakan yang teridentifikasi pada ban dan pelek di setiap kendaraan

harus dilaporkan, diperbaiki dan dicatat.

Jika kerusakan pada ban atau pelek itu menyebabkan kendaraan tidak aman

dioperasikan, maka kendaraan itu tidak boleh digunakan dan harus dipasangi

tanda Out of Service (mencegah digunakan secara tidak aman) dengan

menggunakan tanda Out of Service Tag PT Inco, yang ditaruh di tuas isolasi /

penyalaan sesuai persyaratan dalam MHS 04 Isolation and Lockout.

EHS Standard Originator Date Published

Title: Tyres and Rims PTI EHS August 2008

Page 24 of 27

Ref: EHS/12/STD/MHS/MHS18 Approved by To be reviewed

EHS Management Version: 2 Michael Winship August 2010

System

UNCONTROLLED DOCUMENT WHEN PRINTED

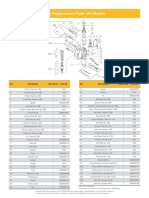

ATTACHMENT A – TYRES AND RIMS EQUIPMENT REGISTER (EXAMPLE ONLY)

Type No Tyre Load Speed Rim Inflation Record Skill Sealant Torque Re- Retread Regroove

Rating rating (kPa) Level (NM) torque

CAT 994 2 5 Piece N2 Yes 2 No - - - -

Axle 1 - 52/80-57 68PR L5 36.00 – 6 730 - - - 1,300 No No Yes

Axle 2 - 52/80-57 68PR L5 36.00 - 6 480 - - - 1,300 No Yes Yes

CAT 16G 6 3 Piece Air No 2 Yes - - - -

Axle 1 - 18.00-25 (12PR) E2 13.00 - 25 200 - - - 700 No No Yes

Axle 2 - 18.00-25 (12PR) E2 13.00 - 25 200 - - - 700 No Yes Yes

Axle 3 - 18.00-25 (12PR) E2 13.00 - 25 200 - - - 700 No Yes Yes

ISUZU 300 20 DC Air No 1 No - - - -

Axle 1 - 7.50R16 114/112 M 5.50Fx16 280 - - - 100 No No No

Axle2 - 7.50R16 114/112 M 5.50Fx16 280 - - - 100 No Yes No

Notes on Tyres and Rims Equipment Register

Item Description Authorisation

Inflation Cold Pressure (N2 indicates nitrogen fill, Air indicates compressed air.) Tyre suppliers or DOT for pressure. Local for N2

Record Yes indicates a full service history Local

Skill Level Refer to Section 2 of the Standard Local

Sealant Yes indicates use of approved sealant Local

Torque Required to tighten up wheel nuts, or bolts Vehicle suppliers

Re-Torque Yes indicates re-torque is required Vehicle suppliers

Retread Yes indicates retreads / re-lugs are permitted Local

Re-Groove Yes indicates re-grooving is permitted Local

EHS Standard Originator Date Published

Title: Tyres and Rims G Uren & M Orr 30/05/2005

Page 25 of 27

Ref: EHS/12/STD/MHS/MHS18 Approved by To be reviewed

Version: 1.5 Jim Gowans 30/05/2006

PRINT DATE: 29/11/2008 - UNCONTROLLED DOCUMENT WHEN PRINTED

LAMPIRAN A – REGISTER PERALATAN BAN DAN PELEK (CONTOH)

Tipe No Ban Rating Rating Pelek Pengisian Catatan Tingkat Sealant Torque Re-torque Retread Regroove

Beban Kecepat Angin (kPa) Keahlian (NM)

an

CAT 994 2 5 Buah N2 Ya 2 Tidak - - - -

Axle 1 - 52/80-57 68PR L5 36.00 – 6 730 - - - 1,300 Tidak Tidak Ya

Axle 2 - 52/80-57 68PR L5 36.00 - 6 480 - - - 1,300 Tidak Ya Ya

CAT 16G 6 3 Piece Udara Tidak 2 Ya - - - -

Axle 1 - 18.00-25 (12PR) E2 13.00 - 200 - - - 700 Tidak Tidak Ya

25

Axle 2 - 18.00-25 (12PR) E2 13.00 - 200 - - - 700 Tidak Ya Ya

25

Axle 3 - 18.00-25 (12PR) E2 13.00 - 200 - - - 700 Tidak Ya Ya

25

ISUZU 300 20 DC Udara Tidak 1 Tidak - - - -

Axle 1 - 7.50R16 114/112 M 5.50Fx16 280 - - - 100 Tidak Tidak Tidak

Axle2 - 7.50R16 114/112 M 5.50Fx16 280 - - - 100 Tidak Ya Tidak

Catatan pada Tyres and Rims Equipment Register

Perihal Keterangan Wewenang

Pengisian Tekanan dingin (N2 menunjukkan pengisian nitrogen, Air menunjukkan udara bertekanan.) Pemasok ban atau DOT untuk tekanan. Lokal untuk N2

Catatan Ya berarti memiliki sejarah servis lengkap Lokal

Level Keahlian Merujuk Bagian 2 Standar Lokal

Sealant Ya berarti menggunakan sealant yang disetujui Lokal

Torque Harus mengencangkan baut roda Pemasok kendaraan

Re-Torque Ya berarti diperlukan re-torque Pemasok kendaraan

Retread Ya berarti diizinkan untuk retreads / re-lugs Lokal

Re-Groove Yes indicates re-grooving is permitted Local

EHS Standard Originator Date Published

Title: Tyres and Rims G Uren & M Orr 30/05/2005

Page 26 of 27

Ref: EHS/12/STD/MHS/MHS18 Approved by To be reviewed

Version: 1.5 Jim Gowans 30/05/2006

PRINT DATE: 29/11/2008 - UNCONTROLLED DOCUMENT WHEN PRINTED

DOCUMENT CONTROL / KONTROL DOKUMEN

Version: Date: Reason for Change:

Versi: Tanggal: Alasan perubahan:

Added caveat “About the PT Inco Major Hazard Standards”.

1.1 14/01/2006

Section 9.1 – Changed accountability from”All Personnel” to “PTI Managers”.

Rationalised inconsistent descriptors for accountabilities. (eg. All Managers, All PTI

1.2 19/05/2006 Managers and Relevant Managers were changed to PTI General Managers to be

consistent descriptors in all standards) Note: No actual accountability was changed.

Revision in section 2.1

Relevant operational experience was changed to Possessing relevant area, operational or

system experience.

1.3 01/08/2007 Add Hold the relevant qualifications

Successfully completed a recognised risk assessment training course was changed to

Having 2 or more people trained in PTI Risk Assessment (SP01) and nominated by their

manager as competent in this role.

1.4 01/09/2007 Position Retitling (Managers were changed to General Manager)

Due to MEM report to Mining Department, SES General Managers were changed to

1.5 01/09/2007

Mining General Manager

Section 2.2 revised to reflect new training and competency requirements.

Section 2.3 incorporated into sections 2.2 and revised to reflect new workplace assessor

requirements

Section 4.1 – add PTI General Managers to accountability as othner departments also

operate large equipment

Section 4.2. Revise wording to include all equipment types that have tyre wear indicators –

not just light vehicles

2 August 2008

Section 4.2 – change accountability to PTI GM and Contractor Managers

Section 4.4 - Personnel who are required to make purchasing decisions for tyres and rims

shall be technically competent and add Mine General Manager to the accountability

section.

Section 4.5 – add GM mining to accountibility

Section 4.6 – change GM SES to GM mining accountibility

Section 6.4 – reword the requirement to reflect an outcome

EHS Standard Originator Date Published

Title: Tyres and Rims G Uren & M Orr 27/07/2005

Page 27 of 27

Ref: EHS/12/STD/MHS/MHS18 Approved by To be reviewed

Version: 1.5 Jim Gowans 27/07/2006

PRINT DATE: 29/11/2008 - UNCONTROLLED DOCUMENT WHEN PRINTED

You might also like

- Seadoo 07 Speedster 150 Challenger 180 Boats PDFDocument418 pagesSeadoo 07 Speedster 150 Challenger 180 Boats PDFsteveegoldberg100% (3)

- Headway User Manual 2.6.5.0 - DianellaDocument189 pagesHeadway User Manual 2.6.5.0 - Dianellamotor tankerNo ratings yet

- MESC - SPE - 85-203 February 2018 PDFDocument9 pagesMESC - SPE - 85-203 February 2018 PDFNIKESHNo ratings yet

- Iso 15686 5 2017Document15 pagesIso 15686 5 2017Kassahun AberaNo ratings yet

- Mhs11-Working Near or in WaterDocument29 pagesMhs11-Working Near or in WaterWidya Bunga100% (1)

- Contractor Safety ManagementDocument80 pagesContractor Safety Managementsafety.eng100% (7)

- Mhs11-Working Near or in WaterDocument29 pagesMhs11-Working Near or in WaterWidya Bunga100% (1)

- ISCC PLUS Cert 52092018 - AuditDocument12 pagesISCC PLUS Cert 52092018 - Audit아끄 AKENo ratings yet

- PARTLIST Benelli 150S 150S Key63 d2021 08 10 06 57 34pmDocument78 pagesPARTLIST Benelli 150S 150S Key63 d2021 08 10 06 57 34pmMohamed ali AmeurNo ratings yet

- Spare Parts CatalogueDocument269 pagesSpare Parts CatalogueVinod Kr Gupta100% (2)

- Final Revised Schedules (HHP Goods)Document59 pagesFinal Revised Schedules (HHP Goods)B KRISHNA RAONo ratings yet

- 1 - Technical Proposal For Oil Condition Monitoring ServicesDocument18 pages1 - Technical Proposal For Oil Condition Monitoring ServicesBrown EmmanuelNo ratings yet

- L1-CHE-MAN-001 Engineering Management System FrameworkDocument20 pagesL1-CHE-MAN-001 Engineering Management System FrameworkCK TangNo ratings yet

- L1-Che-Gdl-005 (8) Engineering Standards ListingDocument23 pagesL1-Che-Gdl-005 (8) Engineering Standards ListingCK TangNo ratings yet

- IMS Manual PDFDocument97 pagesIMS Manual PDFJAYFLOR PLANOSNo ratings yet

- Sno ShooDocument2 pagesSno ShooPierre le BretonNo ratings yet

- Mhs15-Rotating and Moving EquipmentDocument50 pagesMhs15-Rotating and Moving EquipmentWidya BungaNo ratings yet

- Mhs08-Lifting and SupportingDocument41 pagesMhs08-Lifting and SupportingWidya BungaNo ratings yet

- Mhs02-Operasi KendaraanDocument21 pagesMhs02-Operasi KendaraanWidya BungaNo ratings yet

- Orking at Eights: Ekerja Di EtinggianDocument53 pagesOrking at Eights: Ekerja Di EtinggianWidya BungaNo ratings yet

- Mhs16-Clearing OperationDocument15 pagesMhs16-Clearing OperationWidya BungaNo ratings yet

- Mhs09-Explosives ManagementDocument48 pagesMhs09-Explosives ManagementWidya BungaNo ratings yet

- Mhs12-Boliers and Pressures VesselDocument29 pagesMhs12-Boliers and Pressures VesselWidya BungaNo ratings yet

- Mhs17-Dangerous GoodsDocument43 pagesMhs17-Dangerous GoodsWidya BungaNo ratings yet

- Solation Ockout: Solasi Dan EnguncianDocument21 pagesSolation Ockout: Solasi Dan EnguncianWidya BungaNo ratings yet

- PD CEN-TR 15728 2008 Inserts For Lifting and Handling Precast ElementsDocument54 pagesPD CEN-TR 15728 2008 Inserts For Lifting and Handling Precast Elementsdicktracy11100% (1)

- HS00-Man-0001 HSE ManualDocument120 pagesHS00-Man-0001 HSE ManualRocker Maz100% (1)

- Rim Instruction Manual: WarningDocument64 pagesRim Instruction Manual: WarningNguyễn Thanh NhànNo ratings yet

- MHS03 Road Design Construction & Maintenance 3Document14 pagesMHS03 Road Design Construction & Maintenance 3command 13No ratings yet

- Internal Coating of Line Pipe For Non-Corrosive Gas Transmission Service (Amendmentssupplements To API RP 5L2)Document18 pagesInternal Coating of Line Pipe For Non-Corrosive Gas Transmission Service (Amendmentssupplements To API RP 5L2)Anonymous aIuHKoKZjNo ratings yet

- Corrosion Monitoring & Control Management StrategyDocument24 pagesCorrosion Monitoring & Control Management StrategyAbdul LatifNo ratings yet

- TS2022-08 Pet 05 Ancillary Fuel Installations Version 1Document56 pagesTS2022-08 Pet 05 Ancillary Fuel Installations Version 1Ahmed ElbarbaryNo ratings yet

- Hazop PDFDocument33 pagesHazop PDFSDP02No ratings yet

- Enerpac HTM100: Operation & Maintenance ManualDocument25 pagesEnerpac HTM100: Operation & Maintenance ManualMohammed Al-BayatiNo ratings yet

- TCSR 4.1Document148 pagesTCSR 4.1hidarioivan84No ratings yet

- E 09 GP 005 Contractor Health and Safety Plan AssessmentDocument9 pagesE 09 GP 005 Contractor Health and Safety Plan AssessmentJohn KalvinNo ratings yet

- Procedure System of Safe Lifting For Material, Plant and EquipmentDocument57 pagesProcedure System of Safe Lifting For Material, Plant and EquipmentImtiyaz AkhtarNo ratings yet

- Manual VoithDocument138 pagesManual Voithwalison100% (1)

- PTS - 18.03.01 HSE Committee PDFDocument16 pagesPTS - 18.03.01 HSE Committee PDFFateh AliyaNo ratings yet

- Procedure System of ScaffoldingDocument56 pagesProcedure System of ScaffoldingImtiyaz Akhtar100% (7)

- Opinion No 01-2017Document18 pagesOpinion No 01-2017TusharRoyNo ratings yet

- HRE-OPE-PRO-0035 Iss 1.0 - Technical Documentation Improvement - ProcessDocument9 pagesHRE-OPE-PRO-0035 Iss 1.0 - Technical Documentation Improvement - ProcesscolwadNo ratings yet

- EHS Plan - SiemensDocument15 pagesEHS Plan - Siemensabbas100% (2)

- Sunter LTD IMS Manual March 2018 1Document48 pagesSunter LTD IMS Manual March 2018 1samyfouadNo ratings yet

- 60.0301 HSE Assurance GuidelinesDocument24 pages60.0301 HSE Assurance GuidelinesHtoo Htoo Kyaw100% (1)

- Ourdev 515259Document25 pagesOurdev 515259Davi MoreiraNo ratings yet

- Mobile Camps - Civil Site Assessments: DEP 34.17.10.34-GenDocument31 pagesMobile Camps - Civil Site Assessments: DEP 34.17.10.34-GenMahesh MadasNo ratings yet

- XC 131Document186 pagesXC 131Luis Albarracin100% (1)

- Sebf 8185Document16 pagesSebf 8185Mariorosales MendezNo ratings yet

- National Grid Safety Procedure: N-1402 Contractor Safety Requirements DateDocument50 pagesNational Grid Safety Procedure: N-1402 Contractor Safety Requirements DateKevin DucusinNo ratings yet

- Certification Specifications For Standard Changes & Standard Repairs (CS-STAN) - Phase 1Document58 pagesCertification Specifications For Standard Changes & Standard Repairs (CS-STAN) - Phase 1BENoNo ratings yet

- Contractor Safety PolicyDocument2 pagesContractor Safety Policysharon Aisha malroyNo ratings yet

- Marimuthu RESUME Rotating Equipment Specialist June 2012Document10 pagesMarimuthu RESUME Rotating Equipment Specialist June 2012Shams TabrezNo ratings yet

- ACPU-AGE-PRJ-PRO-001-00 - Procedimiento para Implementacion de Etps SUPERADODocument5 pagesACPU-AGE-PRJ-PRO-001-00 - Procedimiento para Implementacion de Etps SUPERADOFernando RomeroNo ratings yet

- Development of Corrosion Management For New ProjectsDocument30 pagesDevelopment of Corrosion Management For New ProjectsĐiệnBiênNhâm100% (1)

- Omml 0495 06 Loadgear ADocument532 pagesOmml 0495 06 Loadgear APhong leNo ratings yet

- Duplex and Super Duplex Stainless Steel Fittings (Amendments/Supplements To Astm A 815)Document13 pagesDuplex and Super Duplex Stainless Steel Fittings (Amendments/Supplements To Astm A 815)aleeimeran100% (1)

- APGA Construction Health and Safety Guidelines Rev 3 FINAL CleanDocument78 pagesAPGA Construction Health and Safety Guidelines Rev 3 FINAL CleanjixiangNo ratings yet

- EN To ED Decision 2019-022-RDocument14 pagesEN To ED Decision 2019-022-RHugo ClementeNo ratings yet

- Bhagwat Engg ManualDocument134 pagesBhagwat Engg ManualHari NairNo ratings yet

- PTS FJCDocument10 pagesPTS FJCfikri bistami yahyaNo ratings yet

- Workers InvovementDocument5 pagesWorkers InvovementAldrien CabinteNo ratings yet