Professional Documents

Culture Documents

Radiography Examination Produre

Radiography Examination Produre

Uploaded by

Nguyen PhucOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Radiography Examination Produre

Radiography Examination Produre

Uploaded by

Nguyen PhucCopyright:

Available Formats

SONG HAU 1 THERMAL POWER PLANT (2 Unit x 600MW)

RADIOGRAPHIC EXAMINATION PROCEDURE

Vu Quang Hung Vu Quang Hung Dao Duy Dung

A

Jul. 8, 2016 Jul. 8, 2016 Jul. 8, 2016

Demonstrated

Prepared by Reviewed by Approved by

Reviewed

NDE Level II NDE Level II NDE Level III

to the satisfaction of AI

Rev EMETC Authorized Inspector

Doc No.: SH1-EMETC-P0ZEN-QA-M01-PRO-2001 Rev.A Page 1 of 29

SONG HAU 1 THERMAL POWER PLANT (2 Unit x 600MW)

CONTENTS

SECTION DESCRIPTION PAGE

1 SCOPE 4

2 REFERENCE 4

3 PERSONNEL 4

4 RADIATION SAFETY 4

5 GENERAL REQUIREMENTS 4

6 EQUIPMENT AND MATERIAL 6

7 CALIBRATION 8

8 EXAMINATION 9

9 EVALUATION 16

10 DOCUMENTATION 17

11 ACCEPTANCE CRITERIA 18

12 APPENDIX 25

APP. I SPOT EXAMINATION OF WELDED JOINTS 26

APP. II RADIOGRAPHIC EXAMINATION REPORT 28

Doc No.: SH1-EMETC-P0ZEN-QA-M01-PRO-2001 Rev.A Page 2 of 29

SONG HAU 1 THERMAL POWER PLANT (2 Unit x 600MW)

TERMS AND DEFINITIONS

- ASME: The American society of Mechanical Engineers

- ASME B.V.P Code: ASME Boiler & Pressure Vessel Code

- ASTM: The American Society for Testing and Materials

- IIW: The International Institute of Welding

- ASNT: The American Society for Nondestructive Testing

- SNT-TC-1A: Recommended Practice No.SNT-TC-1A Personnel Qualifi-

cation and Certification in Nondestructive Testing

- EMETC: Erection - ElectroMechanics Testing Joint Stock Company

- NDE: Non-destructive Examination.

- RT: Radiographic Testing

- IQI: Image Quality Indicators

Doc No.: SH1-EMETC-P0ZEN-QA-M01-PRO-2001 Rev.A Page 3 of 29

SONG HAU 1 THERMAL POWER PLANT (2 Unit x 600MW)

1. SCOPE

This procedure defines the conditions to perform the radiographic examination

of Carbon and Alloy steel butt-welded joints in thickness up to 75 mm in

accordance with the ASME Boiler and Pressure Vessel Code.

2. REFERENCES

- SH1.RFP_P4 OTR_Ch13 General Technical Requirements_140530

- SH1-LI-P0001-GE-G01-PRO-0001

- ASME SEC I, V, VIII Div.1, IX 2013 Edition;

- ASME B31.1, 2012 Edition, Chapter VI.

- ASNT Recommended Practice No. SNT-TC-1A, 2006 edition: Recommended

Practice for NDT Personnel Qualification and Certification;

- EMETC Personnel Certification Program: EMETC-TR-01

- EMETC Radiation Safety Procedure. SH1-LLM-P0001-HS-G01-PRO-0010

3. PERSONNEL

Individuals who perform Radiographic Examination shall be qualified and

certified in accordance with EMETC Written Practice, Personnel Certification

Program, which is based on the ASNT Recommended Practice No.: SNT-TC-

1A, 2006 Edition.

4. RADIATION SAFETY

All radiographic operations shall be conducted in accordance with National and

Local Regulations of Radiation Protection and Safety and Radiation safety

procedure (SH1-LLM-P0001-HS-G01-PRO-0010).

5. GENERAL REQUIREMENTS

5.1 PROCEDURE REQUIREMENTS

Doc No.: SH1-EMETC-P0ZEN-QA-M01-PRO-2001 Rev.A Page 4 of 29

SONG HAU 1 THERMAL POWER PLANT (2 Unit x 600MW)

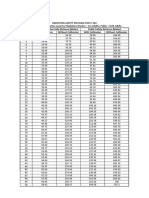

TABLE 1

REQUIREMENTS OF A RADIOGRAPHIC EXAMINATION PROCEDURE

Para.

No Requirement Applicable Range

No.

Carbon and Alloy Steel up to

1 Material type and thickness range 1.0 75 mm in thickness In

thickness

2 Isotope or maximum voltage used 6.1 Ir 192 or X- ray up to 300 kV

3 Source to object distance. 8.4 As far as practical optimum

Distance from source side of object

4 8.4 As close to object as practical

to film

5 Source size 6.1 Maximum 3.0 mm x 2.5 mm

Fuji IX #50,#80,#100 or

6 Film brand and designation 6.2.1

equivalent

Lead Screen, 0.01 to 0.20

7 Screens used 6.3

mm

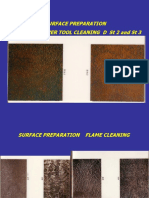

5.2 SURFACE PREPARATION

The weld ripples or weld surface irregularities on both the inside (where

accessible) and outside shall be removed by any suitable process to such a

degree that the resulting radiographic image due to any surface irregul-arities

cannot mask or be confused with the image of any discontinuity. The finished

surface of all butt-welded joints shall be flush with the base material or shall

have reasonably uniform crowns, with reinforcement not to exceed that is

specified in the manufacture's specification which is in accordance with

referencing Code Section.

5.3 BACKSCATTER RADIATION

A lead Symbol "B", with minimum dimensions of 13 mm in height and 1.5 mm

in thickness, shall be attached to the back of each film holder during each

exposure to determine if backscatter radiation is exposing the film.

5.4 SYSTEM OF IDENTIFICATION

A system be used to permanent identification on the radiograph traceable to the

Contract (Project, Drawing No Rev, Joint No, Diameter, Thickness), Repair

Condition of Weld, Reshoot of films, the Manufacturer's Name or Symbol,

NDE Sub-constructor and the date of the radiograph and these information shall

not obscure the area of interest, as followings for illustration:

DOOSAN : Doosan Heavy Industries & Construction Co, Ltd

LLM : LILAMA corporation

SH1 : SONG HAU 1 Thermal Power Plant

D60xt6 : Diameter (60) x Thickness (6) (mm)

J4 -1 : Joint No 4-1.

Doc No.: SH1-EMETC-P0ZEN-QA-M01-PRO-2001 Rev.A Page 5 of 29

SONG HAU 1 THERMAL POWER PLANT (2 Unit x 600MW)

R## : First Repair, Second Repair,

RS : Reshoot.

12 03 16 : 12 March 2016 (date of the Radiograph)

5.5 MONITORING DENSITY LIMITATION OF RADIOGRAPH

Densitometer shall be used for judging film density.

5.6 EXTENT OF EXAMINATION

The extent of radiographic examination shall be as specified by the

manufactures in the written request in accordance with referencing Code

Section.

6. EQUIPMENT AND MATERIALS

6.1 RADIATION SOURCES

6.1.1 Gamma ray:

- Manufacturer: Sentinel

- Model: 660 B, Sigma 880 and Delta 880

- Isotope: Iridium 192

- Activity: Max. 110 Ci,

- Size of source: 3.0 mm x 2.5 mm or other makes equivalent

6.1.2 X-ray:

- Manufacturer: RIGAKU …

- Model: EGM Series

- Maximum voltage: 300 kV

- Maximum Tube current: 5 mA

- Focal spot size: 3.0 mm (~1.5mm IEC 336)

- Beam concentration: elliptic 40° x 60°

- Or other makes equivalent

6.2 FILM AND PROCESSING

6.2.1 Film

Radiographs shall be made by using industrial radiographic film. The film

brand designated and used are recommended as follows:

(a) X ray:

- t up to 12.5 mm : Fuji # 50 or equivalent or better

- t > 12.5 mm : Fuji # 80 or equivalent or better

(b) Ir 192 Isotope:

- t up to 12.5 mm : Fuji # 50 or equivalent or better

- t > 12.5 mm : Fuji # 80 or equivalent or better

• where: t is nominal thickness of weld

• Note: Actual selection of a film brand to use shall be based on the ability to

see the prescribed IQI image and the designated wire of a wire IQI (Refer to

Table 2 and Table 3 in this procedure)

6.2.2 Film Processing

Doc No.: SH1-EMETC-P0ZEN-QA-M01-PRO-2001 Rev.A Page 6 of 29

SONG HAU 1 THERMAL POWER PLANT (2 Unit x 600MW)

Standard Guide for Controlling the Quality of Industrial Radiographic Film

Processing, SE-999 (BPV Code, Section V) or paragraphs 23 through 26 of

Standard Guide for Radiographic Examination SE-94 (BPV Code, Section V)

shall be used as a guide for processing film.

6.3 INTENSIFYING SCREENS

Lead intensifying screens shall be used and selected as follows:

• For Iridium 192:

Lead screen with thickness in the range of 0.125mm- 0.20 mm

• For X ray:

Lead screen with thickness in the range of 0.01 mm- 0.125 mm

6.4 IMAGE QUALITY INDICATOR (IQI) DESIGN

6.4.1 Standard IQI Design

IQIs shall be either the hole type or the wire type. Hole-type IQIs shall be

manufactured and identified in accordance with the requirements or alternates

allowed in SE-1025, (BPV Code, Section V). Wire-type IQIs shall be manufac-

tured and identified in accordance with the requirements or alternates allowed

in SE-747, (BPV Code, Section V), except that the largest wire number or the

identity number may be omitted. ASME standard IQIs shall consist of those in

Table 2 for hole type and those in Table 3 for wire type.

6.4.1.1Alternative IQI Design

IQIs designed and manufactured in accordance with other national or inter-

national standards may be used provided the requirements of either (a) or (b)

below, and the material requirements of para.8.6.1 are met.

(a) Hole Type IQIs. The calculated Equivalent IQI Sensitivity (EPS), per SE-

1025, Appendix XI, is equal to or better than the required standard hole

type IQI.

(b) Wire Type IQIs. The alternative wire IQI essential wire diameter is equal to

or less than the required standard IQI essential wire.

TABLE 2

Doc No.: SH1-EMETC-P0ZEN-QA-M01-PRO-2001 Rev.A Page 7 of 29

SONG HAU 1 THERMAL POWER PLANT (2 Unit x 600MW)

TABLE 3

6.5 FACILITIES FOR VIEWING OF RADIOGRAPHS

Viewing facilities shall provide subdued background lighting of an intensity

that will not cause reflections shadows or glare on the radiographs that interfere

with the interpretation process. Equipment used to view radiographs for

interpretation shall provide a variable light source sufficient for the essential

IQI wire to be visible for the specified density range. The viewing conditions

shall be such that light from around the outer edge of the radiograph or coming

through low density portions of the radiograph does not interfere with

interpretation.

7. CALIBRATION

7.1 Source Size

The equipment manufacturer’s publications, such as technical, manuals, decay

curves, or written statements documenting the actual or maximum source size

or focal spot, shall be acceptable as source size verification

7.2 Densitometers

7.2.1 Densitometers shall be calibrated at least every 90 days during the use as

follows:

(a) A step wedge calibration film, traceable to a national Standard step tablet

and having at least 5 steps with neutral densities from at least 1.0 through

4.0, shall be used. This film shall be verified within the last year by

comparison with a national Standard step tablet unless, prior to first use, it

was maintained in an original light-tight and waterproof sealed package as

supplied by the Manufacturer. Step wedge calibration films may be used

without verification for one year upon opening, provided it is within the

Doc No.: SH1-EMETC-P0ZEN-QA-M01-PRO-2001 Rev.A Page 8 of 29

SONG HAU 1 THERMAL POWER PLANT (2 Unit x 600MW)

manufacturer's stated shelf life.

(b) The densitometer manufacturer's step-by-step instructions for the operation

of the densitometer shall be followed.

(c) The density steps closest to 1.0, 2.0, 3.0, and 4.0 on the step wedge

calibration film shall be read.

(d) The densitometer is acceptable if the density readings do not vary by more

than ±0.05 density units from the actual density stated on the national

standard step tablet or step wedge calibration film.

7.2.2 Periodic Verification

(a) Densitometers. Periodic calibration verification checks shall be performed

as described in 7.2.1 at the beginning of each shift, after 8 hr of continuous

use, or after change of apertures, whichever comes first.

7.2.3 Documentation

(a) Densitometers. Densitometer calibrations required by 7.2.1 shall be

documented, but the actual readings for each step do not have to be

recorded. Periodic densitometer verification checks required by 7.2.3 (a) do

not have to be documented.

8. EXAMINATION

8.1 RADIOGRAPHIC TECHNIQUES

8.1.1 Single wall technique

In the single-wall technique, the radiation passes through only one wall of the

weld (material), which is viewed for acceptance on the radiograph. An

adequate number of exposures shall be made to demonstrate that the required

coverage has been obtained.

Figure 1 - Single Wall – Single Image technique (SWSI)

8.1.2 Double wall technique

Doc No.: SH1-EMETC-P0ZEN-QA-M01-PRO-2001 Rev.A Page 9 of 29

SONG HAU 1 THERMAL POWER PLANT (2 Unit x 600MW)

When it is not practical to use a single wall technique, one of the following

double-wall techniques shall be used.

8.1.2.1Single-Wall Viewing

For materials and for welds in components, a technique may be used in which

the radiation passes through two walls and only the weld (material) on the film

side wall is viewed for acceptance. An adequate number of exposures shall be

made to demonstrate that the required coverage has been obtained. When

complete coverage is required for circumferential welds (materials), a

minimum of three exposures taken 120 deg to each other shall be made.

Figure 2 - Double Wall – Single Image technique (DWSI)

8.1.2.2Double-Wall Viewing

For materials and for welds in components 89mm or less in nominal outside

diameter, a technique may be used in which the radiation passes through two

walls and the weld (material) in both walls is viewed for acceptance on the

same radiograph. For double-wall viewing, only a source side IQI shall be

used.

(a) For welds, the radiation beam may be offset from the plane of the weld at

an angle sufficient to separate the images of the source side and film side

portions of the weld so that there is no overlap of the areas to be

interpreted. When complete coverage is required, a minimum of two

exposures taken 90deg to each other shall be made for each joint.

(b) As an alternative, the weld may be radiographed with the radiation beam

positioned so that the images of both walls are superimposed. When

complete coverage is required, a minimum of three exposures taken at

either 60deg or 120deg to each other shall be made for each joint.

(c) Additional exposures shall be made if the required radiographic coverage

cannot be obtained using the minimum number of exposures indicated in

(a) or (b) above

Figure 3 - Double Wall – Double Image technique (DWDI)

Doc No.: SH1-EMETC-P0ZEN-QA-M01-PRO-2001 Rev.A Page 10 of 29

SONG HAU 1 THERMAL POWER PLANT (2 Unit x 600MW)

8.2 RADIATION ENERGY

The radiation energy employed from the sources mentioned in Paragraph 6.1 for

any radiographic technique shall achieve the density and IQI image as specified

in TABLE 1, or 2 of this procedure

8.3 DIRECTION OF RADIATION

The direction of the central beam of radiation should be centered on the area of

interest whenever practical

8.4 GEOMETRIC UN-SHARPNESS

8.4.1 Geometric un-sharpness determination

Geometric un-sharpness (Ug) of the radiograph is determined in accordance

with:

Ug = Fd/D

Where: Ug : Geometric un-sharpness

F : Source size, the maximum projected dimension of the

radiating source (or effective focal spot) in the plane

perpendicular to the distance D from the weld or object being

radiographed, in.

D : Distance from source of radiation to weld or object being

radiographed, in.

d : Distance from source side of weld or object being

radiographed to the film

D and d shall be determined at the approximate center of the interested area

8.4.2 Geometric un-sharpness limitations

Maximum value for geometric un-sharpness is as follows:

Material Thickness, in. (mm) Ug Maximum, in. (mm)

Under 2 (50) 0.020 (0.51)

2 through 3 (50 75) 0.030 (0.76)

Over 3 through 4 (75 100) 0.040 (1.02)

Greater than 4 (100) 0.070(1.78)

Note: (a) When the radiographic examination method is used for a weld

requiring volumetric examination by PW-11, SECTION I, ASME

B.P.V Code maximum the geometrical un-sharpness is 1.8 mm.

(b) When the radiographic examination method required by Chapter

VI, ASME B31.1, the maximum geometrical un-sharpness is 2.0

mm.

8.5 LOCATION MARKERS

Location markers, (see Figure 4 in below) which are to appear as radiographic

images on the film, shall be placed on the part, not on the exposure

holder/cassette. Their locations shall be marked on the surface of the part being

Doc No.: SH1-EMETC-P0ZEN-QA-M01-PRO-2001 Rev.A Page 11 of 29

SONG HAU 1 THERMAL POWER PLANT (2 Unit x 600MW)

radiographed or on a map, in a manner permitting the area of interest on a

radiograph to be accurately traceable to its location on the part for the required

retention period of the radiograph. If welds are allowed by the specification to

be permanently marked, low stress stamps and/or vibratooling without sharp

edge or pin ends may be used. Markings applied after final stress relief of the

component shall not be any deeper than 0.5mm.

Evidence shall also be provided on the radiograph that the required coverage of

the region being examined has been obtained.

Location markers shall be placed as follows:

Figure 4 – Location Marker Sketches

8.5.1 Single wall viewing

8.5.1.1Source Side Markers

Source side location markers shall be used when radiographing the following:

(a) Flat components or longitudinal joints in cylindrical or conical components.

(b) Curved or spherical components whose concave side is toward the source

and when the "source-to-material" distance is less than the inside radius of

the component;

(c) Curved or spherical components whose convex side is toward the source.

8.5.1.2 Film Side Markers

(a) Film side location markers shall be used when radiographing either curved

or spherical components whose concave side is toward the source and when

the "source-to-material" distance is greater than the inside radius.

(b) As an alternative for source side markers in Para. 8.5.1.1 (a), film side

markers may be used when the radiograph shows coverage beyond the

location markers to the extent demonstrated by Figure. 1 (e) and when this

alternate is documented in the record.

8.5.1.3Either Side Markers.

Location markers may be placed on either source side or film side when

radiographing either curved or spherical components whose concave side is

toward the source and the "source-to-material" distance equals the inside radius

of the component.

Doc No.: SH1-EMETC-P0ZEN-QA-M01-PRO-2001 Rev.A Page 12 of 29

SONG HAU 1 THERMAL POWER PLANT (2 Unit x 600MW)

8.5.2 Double wall viewing

For double wall viewing, at least one location marker shall be placed adjacent to

the weld (or on the material in the area of interest) for each radiograph.

8.5.2.1Mapping the Placement of Location Markers.

When inaccessibility or other limitations prevent the placement of markers as

stipulated in 8.5.1 and 8.5.2, a dimensioned map of the actual marker placement

shall accompany the radiographs to show that full coverage has been obtained.

8.6 IQI SELECTION

8.6.1 Material

IQIs shall be selected from either the same alloy material group or grade as

identified in SE-1025, or SE-747, as applicable, or from an alloy material group

or grade with less radiation absorption than the material being radiographed.

8.6.2 Size

The designated hole IQI or essential wire shall be as specified in TABLE 4 as

below. A thinner or thicker hole-type IQI may be substituted for any section

thickness listed in Table 4, provided an equivalent IQI sensitivity is maintained.

See TABLE 5.

(a) Welds With Reinforcements

The thickness on which the IQI is based is the nominal single-wall thickness

plus the estimated weld reinforcement not to exceed the maximum permitted by

the referencing Code Section. Backing rings or strips shall not be considered as

part of the thick-ness in IQI selection. The actual measurement of the weld

reinforcement is not required

(b) Welds Without Reinforcements

The thickness on which the IQI is based is the nominal single-wall thickness.

Backing rings or strips shall not be considered as part of the weld thickness in

IQI selection

TABLE 4

Doc No.: SH1-EMETC-P0ZEN-QA-M01-PRO-2001 Rev.A Page 13 of 29

SONG HAU 1 THERMAL POWER PLANT (2 Unit x 600MW)

Note: The nominal single wall material thickness will be taken in

calculation to select IQI for both single wall technique and double

wall thickness

8.7 USE IQIS TO MONITOR RADIOGRAPHIC EXAMINATION

8.7.1 Placement of IQIs

(a) Source Side IQIs

The IQIs shall be placed on the source side of the part being examined,

except for the condition described in 8.7.1 (b) below.

(b) Film Side IQIs

Where inaccessibility prevents hand placing the IQI(s) on the source side,

the IQI(s) shall be placed on the film side in contact with the part being

examined. A lead letter “F” shall be placed adjacent to or on the IQI(s).

(c) IQI Placement for Welds - Hole IQIs.

TheIQI(s) may be placed adjacent to or on the weld. The identification

number(s) and, when used, the lead letter “F” shall not be in the area of

interest, except when geometric configuration makes it impractical.

(d) IQI Placement for Welds - Wire IQIs

The IQIs shall be placed on the weld so that the length of the wires is

perpendicular to the length of the weld. The identification numbers and,

when used, the lead letter “F”, shall not be in the area of interest, except

when geometric configuration makes it impractical.

8.7.2 Number of IQIs

When one or more film holders are used for an exposure, at least one IQIs

image shall appear on each radiograph except as outlined in 8.6.2 (b) below.

(a) Multiple IQIs

If the requirements of paragraph 9.2 are met by using more than one IQI,

one shall be representative of the lightest area of interest and the other the

darkest area of interest; the intervening densities on the radiograph shall be

considered as having acceptable density.

(b) Special Case

1) For cylindrical components where the source is placed on the axis of the

object and one or more film holders are used for a single exposure of a

complete circumference, at least three IQIs shall be spaced

approximately 120deg. apart are required under the following

conditions:

- When the complete circumference is radiographed using one or more

film holders, or;

- When a section or sections of the circumference, where the length

between the ends of the outermost sections span 240 or more deg., is

radiographed using one or more film holders Additional film locations

may be required to obtain necessary IQI spacing.

2) For cylindrical components where the source is placed on the axis of the

component for a single exposure, at least three IQIs, with one placed at

each end of span of the circumference radiographed and one in the

approximate center of the span, are required under the following

conditions:

Doc No.: SH1-EMETC-P0ZEN-QA-M01-PRO-2001 Rev.A Page 14 of 29

SONG HAU 1 THERMAL POWER PLANT (2 Unit x 600MW)

- When a section of a circumference, the length of which is greater than

120deg. and less than 240 deg., is radiographed using just one film

holder, or;

- When a section or sections of the circumference, where the length

between the ends of the outermost sections span less than 240deg., is

radiographed using more than One film holder.

3) In (1) and (2) above, where sections of longitudinal welds adjoining the

circumferential weld area radiographed simultaneously with the

circumferential weld, an additional IQI shall be placed on each

longitudinal weld at the end of section most remote from the junction

with the circumferential weld being radiographed.

4) For spherical components where the source is placed at the center of the

component for a single exposure, at least three IQIs, spaced approximately

120deg. apart, are required under the following conditions:

- When a complete circumference is radiographed using one or more

film holders, or;

- When a section or sections of a circumference, where the length

between the ends of the outermost sections span 240 or more deg., is

radiographed using on or more film holders. Additional film locations

may be required to obtain necessary IQI spacing.

5) For spherical components where the source is placed at the center of the

component for a single exposure, at least three IQIs, with one placed at

each end of the radiographed span of circumference radiographed and

one in approximate center of the span, are required under the following

conditions:

When a section of a circumference, the length of which is greater than

120 deg. and less than 240 deg., is radiographed using just one film

holder, or;

When a section or sections of a circumference, where the length between

the ends of the outermost sections span less than 240deg., is

radiographed using more than one film holders.

6) In (4) and (5) above, where other welds are radiographed simultaneously

with the circumferential weld, one additional IQI shall be placed on each

other weld.

7) For segments of a flat or a curved (i.e., ellipsoidal, torispherical, toriconi-

cal, elliptical, etc.) component where the source is placed perpendicular

to the center of a length of weld for a single exposure when using more

than three film holders, at least three IQIs, one placed at each end of the

radiographed span and one in the approximate center of the span, are

required.

8) When an array of components in a circle is radiographed, at least one IQI

shall show on each component image.

9) In order to maintain the continuity of records involving subsequent

exposures, all radiographs exhibiting IQIs which qualify the techniques

permitted in accordance with (1) through (7) above shall be retained.

Doc No.: SH1-EMETC-P0ZEN-QA-M01-PRO-2001 Rev.A Page 15 of 29

SONG HAU 1 THERMAL POWER PLANT (2 Unit x 600MW)

9.0 EVALUATION

9.1 QUALITY OF RADIOGRAPHS

All radiographs shall be free from mechanical, chemical or other blemishes to

the extent that they cannot mask or be confused with the image of any

discontinuity in the area of interest of the object being radiographed. Such

blemishes include, but are not limited to:

(a) Fogging

(b) Processing defects such as streaks, water marks, or chemical stains.

(c) Scratches, finger marks, crimps, dirtiness, static marks, smudges, or tears

(d) False indications due to defective screens.

9.2 RADIOGRAPHIC DENSITY

9.2.1 Density Limitation

(a) The transmitted film density through the radiographic image of the body of

the appropriate hole IQI adjacent to the essential hole or adjacent to the

designated wire of a wire IQI and the area of interest shall be 1.8 minimum

for single film viewing for radiographs made with an X-ray source and 2.0

minimum for radiographs made with a gamma ray source.

(b) For composite viewing of multiple film exposures, each film of the compo-

site set shall have a minimum density of l.3.

(c) The maximum density shall be 4.0 for either single or composite viewing.

(d) A tolerance of 0.05 in density is al-lowed for variations between densito-

meter readings.

9.2.2 Density Variation

(a) The density of the radiograph anywhere through the area of interest shall not

vary by more than minus 15% or plus 30% from the density through the

body of the designated hole-type IQI adjacent to the essential hole or

adjacent to the essential wire of a wire-type IQI, and exceed the

minimum/maximum allowable density ranges specified in 9.2.1. When

calculating the allowable variation in density, the calculation may be

rounded to the nearest 0.1 within the range specified in 9.2.1.

(b) When the requirements of (a) above are not met, then an additional IQI shall

be used for each exceptional area or areas and the radiograph retaken.

(c) When shims are used with hole-type IQIs, the plus 30% density restriction

of (a) above may be exceeded, and the minimum density requirements of

9.2.1 above do not apply for the IQI, provided the required IQI sensitivity

of 9.3 below is met.

9.3 IQI SENSITIVITY

9.3.1 Required Sensitivity

Radiography shall be performed with a technique of sufficient sensitivity to

display the designated hole-type IQI image and the essential hole, or the

essential wire of a wire-type IQI. The radio-graphs shall also display the IQI

identifying numbers and letters. If the designated hole-type IQI image and

essential hole, or essential wire of a wire-type IQI, do not show on any film in a

Doc No.: SH1-EMETC-P0ZEN-QA-M01-PRO-2001 Rev.A Page 16 of 29

SONG HAU 1 THERMAL POWER PLANT (2 Unit x 600MW)

multiple film technique, but do show in composite film viewing, interpretation

shall be permitted only by composite film viewing.

9.3.2 Equivalent Hole-Type IQI Sensitivity

A thinner or thicker hole-type IQI than the designated IQI may be substituted,

provided an equivalent or better IQI sensitivity, as listed in Table 5, is achieved

and all other requirements for radiography are met. Equivalent IQI sensitivity is

shown in any row of Table 5 which contains the designated IQI and hole.

Better IQI sensitivity is shown in any row of Table 5 which is above the

equivalent sensitivity row. If the designated IQI and hole are not represented in

the table, the next thinner IQI row from Table 5 may be used to establish

equivalent IQI sensitivity.

TABLE 5

9.4 EXCESSIVE BACK SCATTER

If a light image of the “B” as described in Para.5.3 appears on a darker

background of the radiograph, protection from backscatter is insufficient and

the radiograph shall be considered unacceptable. A dark image of the “B” on

the lighter background is not cause for rejection

9.5 EVALUATION

RT Level II individuals of EMETC shall be responsible for the review,

interpretation, evaluation, and QC inspector of Lilama shall be acceptance of

the completed radiographs to assure compliance with the requirements of

Article 2, ASME Section V and the referencing Code Sections. As an aid to

review and evaluation, the radiographic technique documentation in Para.10.1

shall be completed prior to the evaluation. The radiograph review form required

by 10.2 shall be completed during the evaluation.

10.0 DOCUMENTATION

10.1 RADIOGRAPHIC TECHNIQUE DOCUMENTATION DETAILS

Doc No.: SH1-EMETC-P0ZEN-QA-M01-PRO-2001 Rev.A Page 17 of 29

SONG HAU 1 THERMAL POWER PLANT (2 Unit x 600MW)

RT Level II individuals of EMETC, on behalf of the Manufacturer, shall

prepare and document the radiographic technique details. As a minimum, the

following information shall be provided:

- Identification as required in Para. 5.4;

- Number of radiographs (exposures);

- The dimension map (if used) of marker placement in accordance with Para.

8.5.3

- X-ray voltage or isotope type used;

- Source size;

- Base material type and thickness, weld thickness, weld reinforcement

thickness, as applicable;

- Source to object distance (D);

- Distance from source side of object to film (d);

- Film manufacturer and Manufacturer’s type/designation;

- Number of film in each film holder/cassette;

- Single or double wall exposure;

- Single or double wall viewing.

10.2 RT REPORT

RT Level II individuals of EMETC shall prepare a radiograph review form or

RT Report. As a minimum, the following information shall be provided.

- Listing of each radiograph location;

- The information required in Para. 10.1;

- Evaluation of disposition of the material or weld examined.

- Identification (name) of the Manufacturer’s representative (EMETC) who

performed the final acceptance of the radiographs.

- Date of Manufacturer’s evaluation

A radiographic examination report shall be made as shown in Appendix 2.

11.0 ACCEPTANCE CRITERIA

For acceptance criteria, the following standard shall be referred to as per

applicable:

11.1 ASME Section VIII Div.1 UW-51(b), Section I and B31.1 Code, Chapter V,

Paragraph 136.4.5.

(Full Radiography that is examined radiographically for their full length in the

manner prescribed in Specification and Drawing)

Welds that are shown by radiography to have any of the following types of

indications are unacceptable;

(a) Any indication characterized as a crack or zone of incomplete fusion or

penetration;

(b) Any other elongated indication on the radiograph which has a length

greater than:

- 6mm for t up to 19 mm;

- 1/3t for t from 19 mm to 57mm;

- 19 mm for t over 57mm

Doc No.: SH1-EMETC-P0ZEN-QA-M01-PRO-2001 Rev.A Page 18 of 29

SONG HAU 1 THERMAL POWER PLANT (2 Unit x 600MW)

Where t is the thickness of the weld excluding any allowable

reinforcement. For a butt weld joining two members having different

thicknesses at the weld, t is the thinner of these two thicknesses. If a full

penetration weld includes a fillet weld, the thickness of the throat of the

fillet shall be included in t.

(c) Any group of aligned indications that have an aggregate length greater than

t in a length of 12t, except when the distance between the successive

imperfections exceeds 6L where L is the length of the longest imperfection

in the group

(d) Rounded indications in excess of that specified by the acceptance standards

ASME Section I, Section VIII, Div. 1 - Rounded Indication Charts (Figure

5a, 5b, 5c, 6 shall be used only for example. Rounded indication chart of

original code without enlargement or reduction shall be used)

(e) For ASME B31.1, root concavity when there is an abrupt change in density

as indicated on the radiograph.

11.2 ASME Section VIII, Div.1 UW-52

NOTE: Spot radiographing of a welded joint is recognized as an effective

inspection tool. The spot radiography rules are also considered to be an aid to

quality control. Spot radiographs made directly after a welder or an operator

has completed a unit of weld proves that the work is or is not being done in

accordance with a satisfactory procedure. If the work is unsatisfactory,

corrective steps can then be taken to improve the welding in the subsequent

units, which unquestionably will improve the weld quality Spot radiography in

accordance with these rules will not ensure a fabrication product of

predetermined quality level throughout. It must be realized that an accepted

vessel under these spot radiography rules may still contain defects which might

be disclosed on further examination. If all radiographically disclosed weld

defects must be eliminated from a vessel, then 100% radiography must be

employed.

(a) Butt welded joints which are to be spot radiographed shall be examined

locally as provided herein.

(b) Minimum Extent of Spot Radiographic Examination.

1) One spot shall be examined on each vessel for each 50 ft (15 m)

increment of weld or fraction thereof for which a joint efficiency from

column (b) of Table UW-12 is selected. However, for identical vessels

or parts, each with less than 50 ft (15 m) of weld for which a joint

efficiency from column (b) of Table UW-12 is selected, 50 ft (15 m)

increments of weld may be represented by one spot examination.

2) For each increment of weld to be examined, a sufficient number of spot

radiographs shall be taken to examine the welding of each welder or

welding operator. Under conditions where two or more welders or

welding operators make weld layers in a joint, or on the two sides of a

double‐welded butt joint, one spot may represent the work of all welders

or welding operators.

3) Each spot examination shall be made as soon as practicable after

completion of the increment of weld to be examined. The location of the

Doc No.: SH1-EMETC-P0ZEN-QA-M01-PRO-2001 Rev.A Page 19 of 29

SONG HAU 1 THERMAL POWER PLANT (2 Unit x 600MW)

spot shall be chosen by the Inspector after completion of the increment

of welding to be examined, except that when the Inspector has been

notified in advance and cannot be presentor other wise make the

selection, the Manufacturer may exercise his own judgment in selecting

the spots.(4) Radiographs required at specific locations to satisfy the

rules of other paragraphs, such as UW-9(d), UW-11(a)(5)(-b), and UW-

14(b), shall not be used to satisfy the requirements for spot radiography.

(c) Standards for Spot Radiographic Examination. Spot examination by

radiography shall be made in accordance with the technique prescribed in

UW-51(a).The minimum length of spot radiograph shall be 6 in. (150 mm).

Spot radiographs may be retained or be discarded by the Manufacturer after

acceptance of the vessel by the Inspector.

The acceptability of welds examined by spot radiography shall be judged

by the following standards:

1) Welds in which indications are characterized as cracks or zones of

incomplete fusion or penetration shall be unacceptable.

2)Welds having indications characterized as slag inclusions or cavities are

unacceptable when the indication length exceeds 2/3t, where t is defined

as shown in UW-51(b)(2). For all thicknesses, indications less than 1/4

in. (6 mm) are acceptable, and indications greater than ¾ in. (19 mm)

are unacceptable. Multiple aligned indications meeting these acceptance

criteria are acceptable when the sum of their longest dimensions

indications does not exceed t within a length of 6t (or proportionally for

radiographs shorter than 6t), and when the longest length L for each

indication is separated by a distance not less than 3L from adjacent

indications.

3) Rounded indications are not a factor in the acceptability of welds not

required to be fully radiographed.

(d) Evaluation and Retests

1) When a spot, radiographed as required in (b)(1) or (b)(2) above, is

acceptable in accordance with (c)(1) and (c)(2) above, the entire weld

increment represented by this radiograph is acceptable.

2) When a spot, radiographed as required in (b)(1) or (b)(2) above, has

been examined and the radiograph discloses welding which does not

comply with the minimum quality requirements of (c)(1) or (c)(2)

above, two additional spots shall be radiographically examined in the

same weld increment at locations away from the original spot. The

locations of these additional spots shall be determined by the Inspector

or fabricator as provided for the original spot examination in (b)(3)

above.

• If the two additional spots examined show welding which meets the

minimum quality requirements of (c)(1) and (c)(2) above, the entire

weld increment represented by the three radiographs is acceptable

provided the defects disclosed by the first of the three radiographs are

removed and the area repaired by welding. The weld repaired area

shall be radiographically examined in accordance with the foregoing

requirements of UW-52.

Doc No.: SH1-EMETC-P0ZEN-QA-M01-PRO-2001 Rev.A Page 20 of 29

SONG HAU 1 THERMAL POWER PLANT (2 Unit x 600MW)

• If either of the two additional spots examined shows welding which

does not comply with the minimum quality requirements of (c)(1) or

(c)(2) above, the entire increment of weld represented shall be

rejected. The entire rejected weld shall be removed and the joint shall

be re-welded or, at the fabricator’s option, the entire increment of

weld represented shall be completely radiographed and only defects

need be corrected.

• Repair welding shall be performed using a qualified procedure and in

a manner acceptable to the Inspector. The re-welded joint, or the weld

repaired areas, shall be spot radiographically examined at one

location in accordance with the foregoing requirements of UW-52.

11.3 ASME Section IX, Part QW-191.1.2

(Acceptance Standards for Qualification of Welder or Welding Operator)

11.3.1 Terminology:

(a) Linear Indications - Cracks, incomplete fusion, inadequate penetration, and

slag are represented on the radiograph as linear indications in which the

length is more than three times the width

(b) Rounded Indications - Porosity and inclusions such as slag or tungsten are

represented on the radiograph as rounded indications with a length three

times the width or less. These indications may be circular, elliptical, or

irregular in shape; may have tails; and may vary in density.

11.3.2 Acceptance Standard: Welder and welding operator performance tests by

radiography of welds in test assemblies shall be judged unacceptable when the

radiograph exhibits any imperfections in excess of the limits specified below.

(a) Linear Indications

- Any type of crack or zone of incomplete fusion or penetration;

- Any elongated slag inclusion which has a length greater than:

• 3 mm for t up to 10 mm;

• 1/3t for t over 10 mm to 57 mm

• 19 mm for t over 57mm

- Any group of slag inclusions in line that have an aggregate length greater

than t in a length of 12t, except when the distance between the successive

imperfections exceeds 6L where L is the length of the longest imperfection

in the group.

(b) Rounded Indications

- The maximum permissible dimension for rounded indications shall be 20%

of t or 3 mm, whichever is smaller.

- For welds in material less than 3mm in thickness, the maximum number of

acceptable rounded indications shall not exceed 12 in a 150mm length of

weld. A proportionately fewer number of rounded indications shall be

permitted in welds less than 150 mm in length.

- For welds in material 3 mm or greater in thickness, the charts in Figure. 6

represent the maximum acceptable of rounded indications illustrated in

typical clustered, assorted, and randomly dispersed configurations.

Rounded indications less than 0.8 mm in maximum diameter shall not be

considered in the radiographic acceptance tests of welders and welding

Doc No.: SH1-EMETC-P0ZEN-QA-M01-PRO-2001 Rev.A Page 21 of 29

SONG HAU 1 THERMAL POWER PLANT (2 Unit x 600MW)

operators in these ranges of material thicknesses.

TABLE A-250.3.2

Maximum Permissible Size of Rounded Indication

Doc No.: SH1-EMETC-P0ZEN-QA-M01-PRO-2001 Rev.A Page 22 of 29

SONG HAU 1 THERMAL POWER PLANT (2 Unit x 600MW)

Figure 5a-Rounded Indication Charts (Examples only)

Figure 5b-Rounded Indication Charts (Examples only)

Doc No.: SH1-EMETC-P0ZEN-QA-M01-PRO-2001 Rev.A Page 23 of 29

SONG HAU 1 THERMAL POWER PLANT (2 Unit x 600MW)

Figure 5c-Rounded Indication Charts (Examples only)

Doc No.: SH1-EMETC-P0ZEN-QA-M01-PRO-2001 Rev.A Page 24 of 29

SONG HAU 1 THERMAL POWER PLANT (2 Unit x 600MW)

Figure 6 – Rounded Indication Charts (Examples only)

12.0 APPENDIX

APPENDIX I SPOT EXAMINATION OF WELDED JOINTS (SECTION

VIII, DIVISION 1, UW–52)

APPENDIX II RADIOGRAPHIC EXAMINATION REPORT

Doc No.: SH1-EMETC-P0ZEN-QA-M01-PRO-2001 Rev.A Page 25 of 29

SONG HAU 1 THERMAL POWER PLANT (2 Unit x 600MW)

APPENDIX 1 SPOT EXAMINATION OF WELDED JOINTS (SECTION VIII,

DIVISION 1, UW–52)

(a) Butt welded joints which are to be spot radiograph tested shall be examined

locally as provided herein.

(b) Minimum Extent of Spot Radiographic Examination

1) One spot shall be examined on each vessel for each 50 ft (15.2 m)

increment of weld or fraction thereof for which a joint efficiency from

column (b) of Table UW-12 is selected. However, for identical vessels,

each with less than 50 ft (15.2 m) of weld for which a joint efficiency

from column (b) of Table UW-12 is selected, 50 ft (15.2 m) increments

of weld may be represented by one spot examination.

2) For each increment of weld to be examined, a sufficient number of spot

radiographs shall be taken to examine the welding of each welder or

welding operator. Under conditions where two or more welders or

welding operators make weld layers in a joint, or on the two sides of a

double-welded butt joint, one spot may represent the work of all welders

or welding operators.

3) Each spot examination shall be made as soon as practicable after

completion of the increment of weld to be examined. The location of the

spot shall be chosen by the Inspector after completion of the increment of

welding to be examined, except that when the Inspector has been notified

in advance and cannot be present or otherwise make the selection, the

fabricator may exercise his own judgment in selecting the spots.

4) Radiographs required at specific locations to satisfy the rules of other

paragraphs, such as UW-9(d), UW-11(a)(5)(b), and UW-14(b), shall not

be used to satisfy the requirements for spot radiography.

(c) Standards for Spot Radiographic Examination. Spot examination by

radiography shall be made in accordance with the technique prescribed in

UW-51(a). The minimum length of spot radiograph shall be 6 in. Spot

radiographs may be retained or be discarded by the Manufacturer after

acceptance of the vessel by the Inspector. The acceptability of welds

examined by spot radiography shall be judged by the following standards.

1) Welds in which indications are characterized as cracks or zones of

incomplete fusion or penetration shall be unacceptable.

2) Welds in which indications are characterized as slag inclusions or

cavities shall be unacceptable if the length of any such indication is

greater than 2⁄3t where t is the thickness of the weld excluding any

allowable reinforcement. For a butt weld joining two members having

different thicknesses at the weld, t is the thinner of these two thicknesses.

If a full penetration weld includes a fillet weld, the thickness of the throat

of the fillet shall be included in t. If several indications within the above

limitations exist in line, the welds shall be judged acceptable if the sum

of the longest dimensions of all such indications is not more than t in a

length of 6t (or proportionately for radiographs shorter than 6t) and if the

longest indications considered are separated by at least 3L of acceptable

weld metal where L is the length of the longest indication. The maximum

Doc No.: SH1-EMETC-P0ZEN-QA-M01-PRO-2001 Rev.A Page 26 of 29

SONG HAU 1 THERMAL POWER PLANT (2 Unit x 600MW)

length of acceptable indications shall be 3⁄4 in. (19 mm). Any such

indications shorter than 1⁄4 in. (6 mm) shall be acceptable for any plate

thickness.

3) Rounded indications are not a factor in the acceptability of welds not

required to be fully radiograph tested.

(d) Evaluation and Retests

1) When a spot, radiograph tested as required in (b)(1) or (b)(2) above, is

acceptable in accordance with (c)(1) and (c)(2) above, the entire weld

increment represented by this radiograph is acceptable.

2) When a spot, radiograph tested as required in (b)(1) or (b)(2) above, has

been examined and the radiograph discloses welding which does not

comply with the minimum quality requirements of (c)(1) or (c)(2) above,

two additional spots shall be radiographic examined in the same weld

increment at locations away from the

3) Original spot. The locations of these additional spots shall be determined

by the Inspector or fabricator as provided for the original spot

examination in (b)(3) above.

▪ If the two additional spots examined show welding which meets the

minimum quality requirements of (c)(1) and (c)(2) above, the entire

weld increment represented by the three radiographs is acceptable

provided the defects disclosed by the first of the three radiographs are

removed and the area repaired by welding. The weld repaired area

shall be radiographic examined in accordance with the foregoing

requirements of UW-52.

▪ If either of the two additional spots examined shows welding which

does not comply with the minimum quality requirements of (c) (1) or

(c) (2) above, the entire increment of weld represented shall be

rejected. The entire rejected weld shall be removed and the joint shall

be re-welded or, at the fabricator’s option, the entire increment of

weld represented shall be completely radiograph tested and only

defects need be corrected.

▪ Repair welding shall be performed using a qualified procedure and in

a manner acceptable to the Inspector. The re-welded joint, or the weld

repaired areas, shall be spot radiographic tested examined at one

location in accordance with the foregoing requirements of UW-52.

Doc No.: SH1-EMETC-P0ZEN-QA-M01-PRO-2001 Rev.A Page 27 of 29

SONG HAU 1 THERMAL POWER PLANT (2 Unit x 600MW)

APPENDIX II: RADIOGRAPHIC EXAMINATION REPORT

Report No.:

RADIOGRAPHIC Request No.:

EXAMINATION REPORT Date:

Project: SONG HAU THERM AL POWER PLANT- 2X600M W Accept/ Standard:

Client : Procedure: Rev:

Working Area: : NDT Extent :

Drawing No.: : Traveler No. :

Sheet : Spool No. :

MATERIAL INFORMATION

M aterial Spec.: Weld reinforcement : mm Welding Process: Joint Type:

X-RAY GAM M A RAY

EQUIPMENT

Type: ……….. Voltage max: ……... Kv Source type:

Focal Spot Size: …………... mm Isotope:

Tube voltage used: ……….Kv Tube current used: ……... mA Source Size:

OFD (d): …….. mm SOD (D): …. mm

M anufacturer: Fuji IQI Type: ASTM E 747 WIRE TYPE :

MATERIAL

TECHNIQUE

Film Type: IQI Location: Source side Film side

Size: Development: M anual Automatic

Intensifying screen Pb/ Front: …….. mm / Rear: ……. mm Exposure Single wall Double wall

1.8 ≤ X-Ray ≤ 4.0 technique Panoramic

Density Required:

2.0 ≤ Gamma ray ≤ 4.0 Viewing Single image Double image

Sensitivity Required (Wire No.): Ug : ……..mm Number of film in each film cassette: Number of exposure:

RES ULTS OF EXAMINATION

WELD IDENTIFICATION INTERPRETATION EVALUATION

Dia. Thk. Film Date of

No. Density Size Location Remarks

Joint No. Welder I.D (mm) (mm) location Type ACC REJ shooting

(mm) (mm)

TOTAL NUM BER OF RADIOGRAPH: 0 films

Legend: TI : Tungsten Inclusion P: Porosity BT: Burn-through F/M: Film Mark

ACC: Accepted C: Crack ISI : Isolated slag Inclusion RC: Root concavity SD: Surface Defect

REJ: Rejected IP: Incomplete of Penetration ESI: Elongated Slag Inclution ER: ExcessRoot Other:

RS: Reshoot LF: Lack of fusion CP : Cluster Porosity UC: Undercut

EMETC REVIEWED BY REVIEWED BY REVIEWED BY

EXAM INED BY RT LEVEL II

Signature & Date

REVIEWED BY RT LEVEL II

Signature & Date Signature & Date Signature & Date Signature & Date

Report Form No.: EM ETC-RT-01-01

Doc No.: SH1-EMETC-P0ZEN-QA-M01-PRO-2001 Rev.A Page 28 of 29

SONG HAU 1 THERMAL POWER PLANT (2 Unit x 600MW)

Report No.:

RADIOGRAPHIC Request No.:

EXAMINATION REPORT Date:

RES ULTS OF EXAMINATION

WELD IDENTIFICATION INTERPRETATION EVALUATION

Dia Thk. Film Date of

No. Density Size Location Remarks

Joint No. Welder I.D (mm) (mm) location Type ACC. REJ. shooting

(mm) (mm)

###############################################################################################################################################################################################################################################################

###############################################################################################################################################################################################################################################################

TOTAL NUM BER OF RADIOGRAPH: 0 films

Legend: TI : Tungsten Inclusion P: Porosity BT: Burn-through F/M: Film Mark

ACC: Accepted C: Crack ISI : Isolated slag Inclusion RC: Root concavity SD: Surface Defect

REJ: Rejected IP: Incomplete of Penetration ESI: Elongated Slag Inclution ER: Excess Root Other:

RS: Reshoot LF: Lack of fusion CP : Cluster Porosity UC: Undercut

EMETC REVIEWED BY REVIEWED BY REVIEWED BY

EXAM INED BY RT LEVEL II

Signature & Date

REVIEWED BY RT LEVEL II

Signature & Date Signature & Date Signature & Date Signature & Date

Report Form No.: EM ETC-RT-01-02

Doc No.: SH1-EMETC-P0ZEN-QA-M01-PRO-2001 Rev.A Page 29 of 29

You might also like

- Risk Assesment - Utg - CtsiDocument6 pagesRisk Assesment - Utg - CtsiJohn Eric OliverNo ratings yet

- Feroxyl and Copper Sulfate TestingDocument23 pagesFeroxyl and Copper Sulfate TestingPrashant RaneNo ratings yet

- Thread Protector Testing - PTR-7.3.10-7-LCSG-FULL-PLASTIC-API-5-CT-PERFORMANCE-TEST-REPORTDocument38 pagesThread Protector Testing - PTR-7.3.10-7-LCSG-FULL-PLASTIC-API-5-CT-PERFORMANCE-TEST-REPORTInChy Rencarnation PoseidonNo ratings yet

- Procedure For Handling, Storage & Transportations of Bare & Coated PipesDocument6 pagesProcedure For Handling, Storage & Transportations of Bare & Coated Pipeskbpatel123No ratings yet

- Radio Graphic ExaminationDocument33 pagesRadio Graphic ExaminationSakthi PanneerSelvam Tanjai100% (6)

- Radiographic Testing ProcedureDocument12 pagesRadiographic Testing ProcedureJake SparrowNo ratings yet

- RT Procedures For WeldDocument19 pagesRT Procedures For WeldABHIJIT GIRINo ratings yet

- PT-Liquid Penetrant Testing Procedure R01 - 2 2Document12 pagesPT-Liquid Penetrant Testing Procedure R01 - 2 2George Ogbeche100% (1)

- Safe Distance Calculation For Radiation WorkDocument1 pageSafe Distance Calculation For Radiation WorkMohdHuzairiRusli100% (1)

- LPT Written ProcedureDocument8 pagesLPT Written ProcedureManikantaSumanthNo ratings yet

- D4228-SP For Qualification of Coating Applicators For Application ofDocument3 pagesD4228-SP For Qualification of Coating Applicators For Application ofshoaib1985No ratings yet

- Radiation Safety DistanceDocument1 pageRadiation Safety Distancesyanas90No ratings yet

- RNS - NDT - MT - 001 Rev.0Document10 pagesRNS - NDT - MT - 001 Rev.0Goutam Kumar DebNo ratings yet

- Denso Pipe Wrapping SolutionsDocument8 pagesDenso Pipe Wrapping SolutionsVinoth MechNo ratings yet

- Tle-02 Dossier.Document40 pagesTle-02 Dossier.suria qaqcNo ratings yet

- Hempadur Avantguard 750 1736g - Product DatasheetDocument2 pagesHempadur Avantguard 750 1736g - Product DatasheetWisnu Wardhana0% (1)

- QMS P 008 Procedure For Liquid Penetrant Testing Revision 0Document9 pagesQMS P 008 Procedure For Liquid Penetrant Testing Revision 0Jai BhandariNo ratings yet

- Procedure of UT-TestDocument2 pagesProcedure of UT-TestJohn ShermanNo ratings yet

- Vaccum Box Test ProcedureDocument3 pagesVaccum Box Test ProcedureAJOJOY009No ratings yet

- Penguard Special: Technical Data SheetDocument5 pagesPenguard Special: Technical Data Sheetajuhaseen100% (1)

- Radiation Safety Distance DiagramDocument3 pagesRadiation Safety Distance DiagramEswaranNo ratings yet

- Pds Hempadur Mastic 45881Document3 pagesPds Hempadur Mastic 45881kasosei0% (1)

- Application Guide Penguard MidcoatDocument6 pagesApplication Guide Penguard Midcoatadeoye_okunoyeNo ratings yet

- DPT ProcedureDocument4 pagesDPT ProcedureRohit Attri100% (1)

- Vc-Api 650 PDFDocument6 pagesVc-Api 650 PDFShinta ShowiantariNo ratings yet

- 1.0 Scope:: NDT & Corrosion Control ServicesDocument1 page1.0 Scope:: NDT & Corrosion Control Servicesm_armoutiNo ratings yet

- Fire Policy 1Document2 pagesFire Policy 1caleb99No ratings yet

- P 54 Holiday Testing Procedure R1Document43 pagesP 54 Holiday Testing Procedure R1rahul reyashNo ratings yet

- Pendulum Test MethodDocument1 pagePendulum Test MethodPavitra Singh0% (1)

- 1.4 Rope Access Job Method StatementDocument6 pages1.4 Rope Access Job Method StatementMohammad YusoffNo ratings yet

- Surface Treatment and Painting ProcedureDocument7 pagesSurface Treatment and Painting ProcedureMohamedNo ratings yet

- Qa-Qc Plan For Sharq R-0aDocument163 pagesQa-Qc Plan For Sharq R-0akbldamNo ratings yet

- Sat-Fat Procedures For ValvesDocument8 pagesSat-Fat Procedures For ValvesSofian Brahim100% (1)

- WIWA Airless Spray GunsDocument52 pagesWIWA Airless Spray Gunsosvaldo lopezNo ratings yet

- Hose Test Method StatementDocument6 pagesHose Test Method StatementRavi ValiyaNo ratings yet

- Surface Preparation Hand and Power Tool Cleaning D ST 2 and ST 3Document29 pagesSurface Preparation Hand and Power Tool Cleaning D ST 2 and ST 3Nilesh Pathare100% (1)

- Jotun Resist 86Document5 pagesJotun Resist 86Ansar AliNo ratings yet

- C1070 - NDE RequirementsDocument7 pagesC1070 - NDE RequirementsWill SmithNo ratings yet

- Scope: Painting ProcedureDocument2 pagesScope: Painting Procedureคุณพ่อน้อง บิ๊กบอสNo ratings yet

- SOP Pipe WeldingDocument1 pageSOP Pipe WeldingAndre Mars100% (1)

- Ferrite Meter Manual OPMS FMP30Ferit 902-530 enDocument36 pagesFerrite Meter Manual OPMS FMP30Ferit 902-530 enFmc2100% (1)

- MSDS MtbeDocument5 pagesMSDS MtbeViệt HàNo ratings yet

- Hempel's Silicone Acrylic 56940Document2 pagesHempel's Silicone Acrylic 56940jeya vasanthNo ratings yet

- Kerosene Leak TestDocument3 pagesKerosene Leak TestsapkotamonishNo ratings yet

- ADOR Booklet F Web FDocument132 pagesADOR Booklet F Web FbadesharamkNo ratings yet

- Coating Specification: 1. ScopeDocument4 pagesCoating Specification: 1. ScopeThaiminh Vo100% (2)

- Ultrasonic Testing of Tube To Tube SheetDocument6 pagesUltrasonic Testing of Tube To Tube SheetDARSHIL RAJPURANo ratings yet

- Filmbadge and TLD ManualDocument2 pagesFilmbadge and TLD ManualAldrin Cabrera100% (1)

- Prebond 220 Acid Resistant PaintDocument4 pagesPrebond 220 Acid Resistant Paintsudhir64No ratings yet

- Covalence WPC100M Shrink Sleeves PDFDocument2 pagesCovalence WPC100M Shrink Sleeves PDFJMROMANTNo ratings yet

- Fabrication and Testing of Offshore Structures: Offshore Standard DNV-OS-C401Document46 pagesFabrication and Testing of Offshore Structures: Offshore Standard DNV-OS-C401rizkytrioNo ratings yet

- 15 - Nde Rev 011Document32 pages15 - Nde Rev 011Adnan RanaNo ratings yet

- Dye Penetrant InspectionDocument2 pagesDye Penetrant InspectionsuparnaNo ratings yet

- Instion Test Record-PaintingDocument1 pageInstion Test Record-PaintingkeronsNo ratings yet

- General Procedure of Manufacturing The Custom Built Sound Proof Enclosures With PanelsDocument14 pagesGeneral Procedure of Manufacturing The Custom Built Sound Proof Enclosures With PanelspawanNo ratings yet

- Schedule For Sand BlastingDocument2 pagesSchedule For Sand BlastingPratik GurungNo ratings yet

- Bgas Paint Faults, BittinessDocument49 pagesBgas Paint Faults, BittinessslxantoNo ratings yet

- Pipeline Repair Products: Repair Patch, Melt Stick, Epoxy Primer and Mastic FillerDocument2 pagesPipeline Repair Products: Repair Patch, Melt Stick, Epoxy Primer and Mastic FillerCherif GhalebNo ratings yet

- IRCA Application FormDocument7 pagesIRCA Application Formpatung patungNo ratings yet

- RT Procedure 10.09.16Document9 pagesRT Procedure 10.09.16mukeshsingh6No ratings yet

- MFL Floormap - How To Scan and Get DataDocument18 pagesMFL Floormap - How To Scan and Get DataNguyen PhucNo ratings yet

- Ect - Aerospace - OptimizedDocument30 pagesEct - Aerospace - OptimizedNguyen PhucNo ratings yet

- Advanced Manual Eddy Current TestingDocument201 pagesAdvanced Manual Eddy Current TestingNguyen PhucNo ratings yet

- Introduction To Magnetic Particle InspectionDocument55 pagesIntroduction To Magnetic Particle InspectionNguyen PhucNo ratings yet

- Resume-Gede Andi - Construction Piping SupervisorDocument6 pagesResume-Gede Andi - Construction Piping Supervisorandi dipayadnya100% (1)

- NDE Personnel QualificationDocument316 pagesNDE Personnel QualificationShanmuga Navaneethan100% (1)

- CMT MC-15 CopDocument24 pagesCMT MC-15 CopAnonymous ExpectusNo ratings yet

- Materials Evaluation Technical Paper On UT of ConcreteDocument10 pagesMaterials Evaluation Technical Paper On UT of ConcreteMuhammad UmairNo ratings yet

- 1 Training For HAMTANTOTOR  RTGs PDFDocument153 pages1 Training For HAMTANTOTOR  RTGs PDFAnonymous ahdhFMaNo ratings yet

- Curiculum Vitae Mei 2016Document6 pagesCuriculum Vitae Mei 2016Muhammad Amirul AkbarNo ratings yet

- NDT (Rebound and Pulse Velocity)Document34 pagesNDT (Rebound and Pulse Velocity)er.praveenraj30No ratings yet

- KunduDocument10 pagesKunduAshwary Sheel Wali Research Scholar, Dept of Mech Engg., IIT (BHU)No ratings yet

- NDT Report - Dovetail WheelsDocument4 pagesNDT Report - Dovetail WheelsOm Ar TanNo ratings yet

- Transport For NSW (TFNSW) TFNSW Specification D&C R164 Tunnel Jet FansDocument32 pagesTransport For NSW (TFNSW) TFNSW Specification D&C R164 Tunnel Jet FansAbu Bakar KhanNo ratings yet

- NDTDocument3 pagesNDTSUJITH G100% (2)

- 1.8 Non Destructive Testing DisciplineDocument1 page1.8 Non Destructive Testing DisciplineTechie ndtNo ratings yet

- COATING - List of International Coating-StandardsDocument8 pagesCOATING - List of International Coating-StandardsEdison Walit100% (1)

- QC Inspector ResumeDocument6 pagesQC Inspector ResumeEngr Primus Chinonye100% (1)

- Attachment-20 - STN-00-Z21-V-SP-0007 P01 - ENDocument36 pagesAttachment-20 - STN-00-Z21-V-SP-0007 P01 - ENrameshqcNo ratings yet

- TWI Enrolment Form Rev 25 (August 20)Document9 pagesTWI Enrolment Form Rev 25 (August 20)MazNo ratings yet

- Experimental Stress Analysis: Unit - 1 MeasurementsDocument79 pagesExperimental Stress Analysis: Unit - 1 Measurementsnokia n72No ratings yet

- 5 Methods For On-Site Evaluation of Concrete Strength - FPrimeC Solutions IncDocument9 pages5 Methods For On-Site Evaluation of Concrete Strength - FPrimeC Solutions IncAmjid AfridiNo ratings yet

- ABS Hal 21Document1 pageABS Hal 21Muhammad MaulanaNo ratings yet

- Astm E426Document4 pagesAstm E426Rafi YusohNo ratings yet

- DNV Os C103Document57 pagesDNV Os C103Wilson Barreta JuniorNo ratings yet

- General Repair Procedure For Welds R1 PDFDocument4 pagesGeneral Repair Procedure For Welds R1 PDFLuis Claro Ortiz100% (4)

- This Report Describes My Internship at SMEC LABSDocument49 pagesThis Report Describes My Internship at SMEC LABSNafizNo ratings yet

- Iogp S-563 MDS Is103 (A403 WP316)Document1 pageIogp S-563 MDS Is103 (A403 WP316)FIKRI BADRULNo ratings yet

- Liquid Dye Penetrant Test Inspection Sample ProcedureDocument8 pagesLiquid Dye Penetrant Test Inspection Sample Procedureم.ذكى فضل ذكىNo ratings yet

- OPSS - MUNI 903 - Nov 2020Document23 pagesOPSS - MUNI 903 - Nov 2020Tony ParkNo ratings yet

- Ultrasonic TestDocument116 pagesUltrasonic TestMuhamad AnwarudinNo ratings yet

- West Qurna-2 Well Pads and Oil Gathering System Project: Specification For Warning TapesDocument9 pagesWest Qurna-2 Well Pads and Oil Gathering System Project: Specification For Warning TapesAli MajeedNo ratings yet

- Ultrasonic Testing Procedure SampleDocument10 pagesUltrasonic Testing Procedure Samplekimia100% (1)