Professional Documents

Culture Documents

High-Temperature Basic Switch TZ

High-Temperature Basic Switch TZ

Uploaded by

Muhamad PriyatnaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

High-Temperature Basic Switch TZ

High-Temperature Basic Switch TZ

Uploaded by

Muhamad PriyatnaCopyright:

Available Formats

High-temperature Basic Switch

TZ

Stable Operation at an Ambient

Temperature of 400°C

• Incorporates a ceramic insulator, cobalt-alloy spring, and

special-alloy contact, thus ensuring high contact reliability

at high ambient temperature.

• Smoothly operates at an ambient temperature of 400°C.

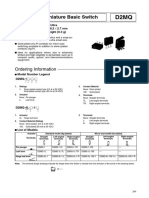

Model Number Structure

■ Model Number Legend

TZ-1G@

1 2 3

1. Rating

1: 1 A, 250 VAC

2. Contact Gap

G: 0.5 mm

3. Actuator

None: Pin plunger

V: Hinge lever

V2: Hinge roller lever

V22: Short hinge roller lever

Ordering Information

■ List of Model

Actuator Model

Pin plunger TZ-1G

Hinge lever TZ-1GV

Short hinge roller lever TZ-1GV22

Hinge roller lever TZ-1GV2

High-temperature Basic Switch TZ 83

Specifications

■ Ratings

Rated Non-inductive load (A) Inductive load (A)

voltage

Resistive load Lamp load Inductive load Motor load

NC NO NC NO NC NO NC NO

125 VAC 1 0.9 0.45 1 1.5 0.75

250 VAC 1 0.45 0.3 1 0.45 0.3

8 VDC 1 0.9 0.45 1 1.5 1.5

14 VDC 1 0.9 0.45 1 1.5 1.5

30 VDC 1 0.9 0.45 1 1.5 1.5

125 VDC 0.4 0.05 0.05 0.4 0.05 0.05

Note: 1. The above current ratings are the values of the steady-state current.

2. Inductive load has a power factor of 0.4 min. (AC) and a time constant of 7 ms max. (DC).

3. Lamp load has an inrush current of 10 times the steady-state current.

4. Motor load has an inrush current of 6 times the steady-state current.

5. The above ratings are tested under the following conditions.

1. Ambient temperature: 20±2 °C

2. Ambient humidity: 65±5%

3. Switching frequency: 20 times/min

■ Characteristics

Operating speed 0.05 mm to 1 m/s (see note 1)

Operating frequency Mechanical: 60 operations/min

Electrical: 20 operations/min

Insulation resistance 100 MΩ min. (at 500 VDC)

Contact resistance 100 mΩ max. (initial value)

Dielectric strength 1,000 VAC, 50/60 Hz for 1 min between terminals of same polarity

1,500 VAC, 50/60 Hz for 1 min between current-carrying metal parts and ground and between

each terminal and non-current-carrying metal parts

Vibration resistance Malfunction: 10 to 55 Hz, 1.5-mm double amplitude (see note 2)

Shock resistance Destruction: 500 m/s2 max.

Malfunction: 300 m/s2 max. (see note 2)

Durability Mechanical: 100,000 operations min.

Electrical: 50,000 operations min.

Degree of protection IP00

Electric shock protection Class I

Ambient temperature Operating: −65°C to 400°C (with no icing)

Ambient humidity Operating: 35% to 85% max.

Weight Approx. 45 to 54 g

Note: 1. This operating speed applies to switches with pin-type pushbuttons.

2. This refers to a malfunction period of 1 ms max.

■ Contact Specifications

Item

Contact Specification Cross bar

Material Platinum alloy

Gap (standard value) 0.5 mm

Inrush current NC 9 A max.

NO 4.5 A max.

84 High-temperature Basic Switch TZ

Nomenclature

Ceramic

pushbutton

Fixed contact

Bracket

Movable spring

COM NC

NO

Movable contact

Ceramic terminal block

Fixed contact

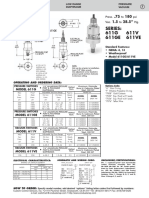

Dimensions

■ Dimensions and Operating Characteristics

Note: 1. All units are in millimeters unless otherwise indicated.

2. Each dimension has a tolerance of ±0.4 mm unless otherwise specified.

OF max. 4.9 N

Pin Plunger

RF min. 1.12 N

TZ-1G

(Ceramic pushbutton) 8.2 dia. PT max. 0.4 mm

3 dia.

Two, 3.56-dia. holes OT min. 0.13 mm

MD max. 0.15 mm

OP 15.6±0.6 mm

Three, M3.5

11.4

OF max. 0.98 N

Hinge Lever RF min. 0.14 N

TZ-1GV PT max. 3.5 mm

(Stainless-steel lever)

63.5R OT min. 4.6 mm

MD max. 1.3 mm

OP 18±1.2 mm

Two, 3.56-dia.

holes

Three, M3.5

11.4

Short Hinge Roller Lever (Stainless-steel lever)

OF max. 2.35 N

RF min. 0.34 N

TZ-1GV22 9.5 dia. 4 (stainless-steel roller)

PT max. 1.5 mm

OT min. 1.9 mm

26.2R

MD max. 0.6 mm

OP 28.6±1.2 mm

Two, 3.56-dia.

holes

11.4 Three, M3.5

High-temperature Basic Switch TZ 85

Hinge Roller Lever OF max. 1.27 N

(Stainless-steel lever) RF min. 0.2 N

TZ-1GV2

9.5 dia. 4 (stainless-steel roller) PT max. 2.6 mm

48.4R

OT min. 3.5 mm

MD max. 1 mm

OP 28.6±1.2 mm

Two, 3.56-dia.

holes

11.4 Three, M3.5

Precautions

Refer to pages 25 to 30 of General Information for details.

■ Correct Use

Handling Operation

The Switch has a ceramic casing. Do not drop the Switch from a Do not modify the Actuator and change the operating position.

height of 30 cm or more. Doing so will break the casing.

Make sure that the switching speed is not extremely slow or do

not use the Switch so that the pushbutton will be set to a position

Mounting between the FP and OP.

Make sure that the pin-type pushbutton and the switching stroke

Be sure to turn OFF the power supply to the Switch before mount-

are on the same vertical line.

ing, dismounting, wiring, or working on the Switch for mainte-

nance. Not doing so may result in an electric shock or the Switch Make sure that the switching frequency or speed is within the

may burn. specified range.

Mount the switch with M3.5 stainless-steel screws with plane • If the switching speed is extremely slow, the contact may not be

washer and spring washers securely. switched smoothly, which may result in a contact failure or con-

tact welding.

Use M3.5 stainless-steel mounting screws with plane washers or

spring washers to securely mount the Switch. Tighten the screws • If the switching speed is extremely fast, switching shock may

to a torque of 0.69 to 0.98 N·m. damage the Switch soon. If the switching frequency is too high,

the contact may not catch up with the speed.

Mounting Holes The rated permissible switching speed and frequency indicate the

switching reliability of the Switch.

Two, 3.56-dia. mounting holes or

M3.5 screw holes The life of a Switch is determined at the specified switching

speed. The life varies with the switching speed and frequency

even when they are within the permissible ranges. In order to

determine the life of a Switch model to be applied to a particular

25.4 ± 0.1 use, it is best to conduct an appropriate durability test on some

samples of the model under actual conditions.

Connect nickel-plated solderless terminals to the TZ. Each termi-

nal must be secured on the TZ with M3.5 nut. Make sure that the actuator travel does not exceed the permissi-

ble OT position. The operating stroke must be set to 70% to 100%

Make sure that the ceramic case is free of metal powder or other

of the rated OT.

impurities.

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Cat. No. B102-E1-02 In the interest of product improvement, specifications are subject to change without notice.

86 High-temperature Basic Switch TZ

You might also like

- Telecommunications Wiring - Clyde N Herrick 3rd Edition - Chapter 1Document24 pagesTelecommunications Wiring - Clyde N Herrick 3rd Edition - Chapter 1bhameed-1958No ratings yet

- ANIC-15S Instruction ManualDocument18 pagesANIC-15S Instruction ManualMuhamad PriyatnaNo ratings yet

- Astm E337 15Document24 pagesAstm E337 15Yeferson Fabian Rico Osma100% (1)

- Stastical Physics: The Energy DistributionDocument17 pagesStastical Physics: The Energy DistributionAnonymous xuIlHNxNo ratings yet

- Special-Purpose Basic Switch DZDocument5 pagesSpecial-Purpose Basic Switch DZMuhamad PriyatnaNo ratings yet

- Ultra Subminiature Detection Switch With Slide Mechanism and Lever ActuatorDocument3 pagesUltra Subminiature Detection Switch With Slide Mechanism and Lever ActuatorSgly ZemogNo ratings yet

- TZDocument21 pagesTZDicky Nurul IlhamNo ratings yet

- HL-500 General-Purpose Limit SwitchDocument9 pagesHL-500 General-Purpose Limit SwitchMuhamad PriyatnaNo ratings yet

- 28 DS 250 TM1 Voltage 24V Screw Flange - enDocument9 pages28 DS 250 TM1 Voltage 24V Screw Flange - enPaulo CésarNo ratings yet

- Door Interlock Switch D2TDocument4 pagesDoor Interlock Switch D2TMuhamad PriyatnaNo ratings yet

- TP70 On-Site Flexible Rod SwitchDocument5 pagesTP70 On-Site Flexible Rod SwitchMuhamad PriyatnaNo ratings yet

- General-Purpose Limit Switch HL-5000: Ordering InformationDocument7 pagesGeneral-Purpose Limit Switch HL-5000: Ordering InformationBudKhNo ratings yet

- Sanyou WJ31X RelayDocument3 pagesSanyou WJ31X Relaypratik gautamNo ratings yet

- Sealed Ultra Subminiature Basic Switch D2JWDocument5 pagesSealed Ultra Subminiature Basic Switch D2JWMuhamad PriyatnaNo ratings yet

- Relé Tianbo 5V PDFDocument3 pagesRelé Tianbo 5V PDFjhonny gonzalezNo ratings yet

- TM1 Series CombinedDocument75 pagesTM1 Series CombinedmecNo ratings yet

- FTR p1Document7 pagesFTR p1José María Paredes LorenzoNo ratings yet

- Automotive Power Relay: Technical Data For Contact SideDocument3 pagesAutomotive Power Relay: Technical Data For Contact SideRakesh SutharNo ratings yet

- Automotive Power Relay: Technical Data For Contact SideDocument3 pagesAutomotive Power Relay: Technical Data For Contact SideRakesh SutharNo ratings yet

- b060 DZ Special-Purpose Basic Switch Datasheet enDocument6 pagesb060 DZ Special-Purpose Basic Switch Datasheet enKlan ZangoNo ratings yet

- (Material Number Old: 95353308) : Ex Solenoid Interlock Ex STM 295 1Ö1S/1Ö1S-R-FE Material Number: 1186394Document2 pages(Material Number Old: 95353308) : Ex Solenoid Interlock Ex STM 295 1Ö1S/1Ö1S-R-FE Material Number: 1186394RD 88No ratings yet

- Rele Ac Peugeot 406Document7 pagesRele Ac Peugeot 406Alvaro HorcajoNo ratings yet

- TR 5 VDocument4 pagesTR 5 VЯн ПавловецNo ratings yet

- Limit Switch Micro Switch Foot Switch CWLDocument3 pagesLimit Switch Micro Switch Foot Switch CWLProc. RembangNo ratings yet

- High-Performance Pushbutton Switch With Built-In Subminiature Basic SwitchDocument3 pagesHigh-Performance Pushbutton Switch With Built-In Subminiature Basic Switchkasim leeNo ratings yet

- Az979 Auto Iso Relay 24v 80aDocument3 pagesAz979 Auto Iso Relay 24v 80asvirkomartinkoNo ratings yet

- Relay HJR-4102-L PDFDocument3 pagesRelay HJR-4102-L PDFAnom ManelaNo ratings yet

- G5V-1 PCB Relay: Ordering InformationDocument3 pagesG5V-1 PCB Relay: Ordering InformationAli ShanNo ratings yet

- Sanyou Relays: Miniature High Power RelayDocument3 pagesSanyou Relays: Miniature High Power RelayTV Cinaqui ContiNo ratings yet

- Datasheet - HK 17pcsa104mc19p 2390846Document2 pagesDatasheet - HK 17pcsa104mc19p 2390846Kroscop San Martin de LunaNo ratings yet

- 8567 RelayDocument3 pages8567 RelayAmandaNo ratings yet

- General Purpose Relay: TA, TR Series Part Number DescriptionDocument17 pagesGeneral Purpose Relay: TA, TR Series Part Number DescriptionMIKENo ratings yet

- Takamisawa Sy 24w K PCB Mount Relay 24vdc 1 Co SPDT Sy 24w K Data SheetDocument5 pagesTakamisawa Sy 24w K PCB Mount Relay 24vdc 1 Co SPDT Sy 24w K Data Sheetremon thereminNo ratings yet

- 1N5400 THRU 1N5408: FeaturesDocument3 pages1N5400 THRU 1N5408: FeaturesWijaya TeknikNo ratings yet

- Relay Telecom SPDT 1 Form C 12vdc 3a TH Bulk FlourishingDocument2 pagesRelay Telecom SPDT 1 Form C 12vdc 3a TH Bulk Flourishingjose omar pleitez mejiaNo ratings yet

- Sima Electronics Automotive Relays: Ordering InformationDocument2 pagesSima Electronics Automotive Relays: Ordering InformationJHelfNo ratings yet

- Ultra Subminiature Basic Switch D2MQDocument5 pagesUltra Subminiature Basic Switch D2MQMuhamad PriyatnaNo ratings yet

- DataSheet Rele12VDocument2 pagesDataSheet Rele12Vemp007No ratings yet

- PCRB Rerlay For Stablrizer TTTDocument2 pagesPCRB Rerlay For Stablrizer TTTMarudhasalamMarudhaNo ratings yet

- Miniature Basic Switch D2MVDocument7 pagesMiniature Basic Switch D2MVMuhamad PriyatnaNo ratings yet

- Az 850Document2 pagesAz 850Aravindh RaNo ratings yet

- Automotive Power Relay: Technical Data For Contact SideDocument3 pagesAutomotive Power Relay: Technical Data For Contact SideJesus HernadezNo ratings yet

- PCB Relay: NRP - 17 - C - 12DDocument2 pagesPCB Relay: NRP - 17 - C - 12DZaman SahibNo ratings yet

- Fast Switching Diode: Lead Free Finish, Rohs Compliant (Note 2)Document2 pagesFast Switching Diode: Lead Free Finish, Rohs Compliant (Note 2)zileNo ratings yet

- Ic Regulator Timbangan 6214A LDODocument26 pagesIc Regulator Timbangan 6214A LDOSlamet GojazzNo ratings yet

- G8V-RH: High Current Micro 280 Terminal LayoutDocument3 pagesG8V-RH: High Current Micro 280 Terminal Layoutchrdue1No ratings yet

- RBV1000 - RBV1010: Silicon Bridge Rectifiers PRV: 50 - 1000 Volts Io: 10 AmperesDocument2 pagesRBV1000 - RBV1010: Silicon Bridge Rectifiers PRV: 50 - 1000 Volts Io: 10 AmperesmaheseeeNo ratings yet

- Low-Torque Basic Switch D2MCDocument5 pagesLow-Torque Basic Switch D2MCMuhamad PriyatnaNo ratings yet

- Dold Safety RelayDocument8 pagesDold Safety RelayMohammad Anis HashimNo ratings yet

- SMIH NingBoSongleDocument3 pagesSMIH NingBoSongleatlas tajhizNo ratings yet

- HJR-21FF TboDocument3 pagesHJR-21FF Tboalisalar1No ratings yet

- Datasheet rm85z012 10wDocument4 pagesDatasheet rm85z012 10wVicont 1991No ratings yet

- Data Sheet For Precision Potentiometer: Singleturn Wirewound Potentiometer Series RPS50Document5 pagesData Sheet For Precision Potentiometer: Singleturn Wirewound Potentiometer Series RPS50Vasile DumitruNo ratings yet

- TCR5AM105A Datasheet en 20170622-1627697Document15 pagesTCR5AM105A Datasheet en 20170622-1627697EPSONURIELNo ratings yet

- Relafy 30 Amps T Typfe RelfayDocument2 pagesRelafy 30 Amps T Typfe RelfayMarudhasalamMarudhaNo ratings yet

- RI-80 SMD Series Dry Reed SwitchDocument2 pagesRI-80 SMD Series Dry Reed Switchmicimacko_No ratings yet

- RelêDocument3 pagesRelênelsongomessantosNo ratings yet

- Rla12w KDocument8 pagesRla12w KMichał DubininNo ratings yet

- Tn-Relays: Slim Polarized RelayDocument4 pagesTn-Relays: Slim Polarized Relayparsa mahvisNo ratings yet

- Rele Zetler AZ9731Document3 pagesRele Zetler AZ9731Dakovic AleksandarNo ratings yet

- 2p en dpd1t - dpd2tDocument2 pages2p en dpd1t - dpd2tghNo ratings yet

- Operator's Manual Vibration Switch VS2: 1. ApplicationDocument4 pagesOperator's Manual Vibration Switch VS2: 1. ApplicationDwi Mulyanti DwimulyantishopNo ratings yet

- Specifications: 1. Refers To The Lamp Terminals of The Illuminated Push Buttons and Selector SwitchesDocument1 pageSpecifications: 1. Refers To The Lamp Terminals of The Illuminated Push Buttons and Selector SwitchesRohit karlekarNo ratings yet

- Industrial Automation Catalog Section - U906: Switches & Pilot Devices AP Series Miniature Switches & Pilot DevicesDocument8 pagesIndustrial Automation Catalog Section - U906: Switches & Pilot Devices AP Series Miniature Switches & Pilot DevicesMuhamad PriyatnaNo ratings yet

- EP1132-0 FBcontrolbox 060704Document8 pagesEP1132-0 FBcontrolbox 060704Muhamad PriyatnaNo ratings yet

- Power Supplies BrochureDocument12 pagesPower Supplies BrochureMuhamad PriyatnaNo ratings yet

- EP1116-0 ControlUnits Relays 060217Document404 pagesEP1116-0 ControlUnits Relays 060217Muhamad PriyatnaNo ratings yet

- Relay Barriers: Intrinsically Safe Explosion ProtectionDocument8 pagesRelay Barriers: Intrinsically Safe Explosion ProtectionMuhamad PriyatnaNo ratings yet

- 8-16mm A Series EP1149-0Document44 pages8-16mm A Series EP1149-0Muhamad PriyatnaNo ratings yet

- EB3C & 3L - Sales ManualDocument10 pagesEB3C & 3L - Sales ManualMuhamad PriyatnaNo ratings yet

- AS-Interface Devices: (Slave Modules)Document48 pagesAS-Interface Devices: (Slave Modules)Muhamad PriyatnaNo ratings yet

- Eb3C Eb3L: Relay Barriers Lamp BarriersDocument20 pagesEb3C Eb3L: Relay Barriers Lamp BarriersMuhamad PriyatnaNo ratings yet

- Power Supplies: Smart ProductsDocument6 pagesPower Supplies: Smart ProductsMuhamad PriyatnaNo ratings yet

- ANIC-15S Catalog JapaneseDocument7 pagesANIC-15S Catalog JapaneseMuhamad PriyatnaNo ratings yet

- PS5R-SB Switching Power SuppliesDocument2 pagesPS5R-SB Switching Power SuppliesMuhamad PriyatnaNo ratings yet

- 16 MM XA Series & 22 MM HW, XW Series SEMI S2 Compliant EMODocument4 pages16 MM XA Series & 22 MM HW, XW Series SEMI S2 Compliant EMOMuhamad PriyatnaNo ratings yet

- 16 MM XA Series & 22 MM XW Series Emergency Stop SwitchesDocument20 pages16 MM XA Series & 22 MM XW Series Emergency Stop SwitchesMuhamad PriyatnaNo ratings yet

- Motor Control CentersDocument20 pagesMotor Control CentersMuhamad PriyatnaNo ratings yet

- 16 MM XA Series & 22 MM XW Series SEMI S2 Compliant EMO SwitDocument8 pages16 MM XA Series & 22 MM XW Series SEMI S2 Compliant EMO SwitMuhamad PriyatnaNo ratings yet

- Series: 611G 611V 611GE 611VE: Installation DrawingDocument1 pageSeries: 611G 611V 611GE 611VE: Installation DrawingMuhamad PriyatnaNo ratings yet

- 8F Drains and Breathers: Application: ECD Type 4X''Document1 page8F Drains and Breathers: Application: ECD Type 4X''Muhamad PriyatnaNo ratings yet

- NEMA Manual StartersDocument12 pagesNEMA Manual StartersMuhamad PriyatnaNo ratings yet

- Modular I/O System Modbus: Technical Description, Installation and ConfigurationDocument218 pagesModular I/O System Modbus: Technical Description, Installation and ConfigurationMuhamad PriyatnaNo ratings yet

- 8F Drains and Breathers: Application: ECD Type 4X''Document1 page8F Drains and Breathers: Application: ECD Type 4X''Muhamad PriyatnaNo ratings yet

- Cordsets & Sensor AccessoriesDocument4 pagesCordsets & Sensor AccessoriesMuhamad PriyatnaNo ratings yet

- PLC, IO & Communications ProductsDocument46 pagesPLC, IO & Communications ProductsMuhamad PriyatnaNo ratings yet

- Vacuum Contactors & StartersDocument32 pagesVacuum Contactors & StartersMuhamad PriyatnaNo ratings yet

- Stacklights 46-1: February 2007Document12 pagesStacklights 46-1: February 2007Muhamad PriyatnaNo ratings yet

- Operator Interface ProductsDocument38 pagesOperator Interface ProductsMuhamad PriyatnaNo ratings yet

- Medium Voltage Motor Control AssembliesDocument4 pagesMedium Voltage Motor Control AssembliesMuhamad PriyatnaNo ratings yet

- Cross Reference List: GE Series SB1 To Electroswitch Series 24Document2 pagesCross Reference List: GE Series SB1 To Electroswitch Series 24Muhamad PriyatnaNo ratings yet

- H2F 24 Hour or Weekly TimerDocument8 pagesH2F 24 Hour or Weekly TimerMuhamad PriyatnaNo ratings yet

- E53 DocumentationDocument41 pagesE53 DocumentationPasupuleti arunaNo ratings yet

- Datasheet VTL OptoDocument6 pagesDatasheet VTL OptoJc Valve RecordNo ratings yet

- Welcome: Faculty of Basic and Applied Science Undergraduate Lab - 1Document28 pagesWelcome: Faculty of Basic and Applied Science Undergraduate Lab - 1Sana AshfaqNo ratings yet

- Fully Submerged Canard Hydrofoil System For A Low Speed Solar Boat Neola Putnam Gregory Dickert Caleb WagnerDocument20 pagesFully Submerged Canard Hydrofoil System For A Low Speed Solar Boat Neola Putnam Gregory Dickert Caleb WagnerSaga Biju Lona na22b006No ratings yet

- Physical Properties of SolutionsDocument30 pagesPhysical Properties of SolutionsCalonanak Sithr2020No ratings yet

- SIF1004 / SMES1203: Modern Physics: (2 Credit Hours)Document13 pagesSIF1004 / SMES1203: Modern Physics: (2 Credit Hours)J KNo ratings yet

- Week 51 Listrik 2021Document28 pagesWeek 51 Listrik 2021Ari PurnamaNo ratings yet

- Rotating SphereDocument7 pagesRotating SphereRenata LobosNo ratings yet

- Lab 5 Bernouli TheoremDocument5 pagesLab 5 Bernouli TheoremismailNo ratings yet

- Powerelectronics in Power System (QB)Document9 pagesPowerelectronics in Power System (QB)T.l. SelvamNo ratings yet

- 12.CH (4) Design and Calculation of Ice Plant (Evaporator and Condenser)Document13 pages12.CH (4) Design and Calculation of Ice Plant (Evaporator and Condenser)thuggerb2020No ratings yet

- Problem 11Document6 pagesProblem 11Elbrent Paul M ObedencioNo ratings yet

- Agreement For Connecting Solar Energy System To The Distribution System of The LicenseeDocument7 pagesAgreement For Connecting Solar Energy System To The Distribution System of The LicenseeArun SasidharanNo ratings yet

- 20 - Technical Data & FormulationsDocument11 pages20 - Technical Data & FormulationsSnzy DelNo ratings yet

- Ial Maths Mech 1 Ex3d PDFDocument9 pagesIal Maths Mech 1 Ex3d PDFWandaNo ratings yet

- Coordination Protection of Low-Voltage AC Distribution Network in Vessel DC Zonal Electrical Distribution SystemDocument5 pagesCoordination Protection of Low-Voltage AC Distribution Network in Vessel DC Zonal Electrical Distribution SystemFreddy Roberto PerugachiNo ratings yet

- 1968, Veselago-ChihWeiChang PDFDocument6 pages1968, Veselago-ChihWeiChang PDFNiKhil ShindeNo ratings yet

- T, M &CS Question PaperDocument8 pagesT, M &CS Question PaperSharath Chandra H100% (7)

- Wind Energy Vehicle 7000Document5 pagesWind Energy Vehicle 7000Techky ManiacsNo ratings yet

- College Physics 1st Edition Freedman Solutions ManualDocument38 pagesCollege Physics 1st Edition Freedman Solutions Manualdoraphillipsooeot100% (20)

- GCM 14Document8 pagesGCM 14Soe ThuNo ratings yet

- Modern Physics NotesDocument14 pagesModern Physics Notesshweta khannaNo ratings yet

- Excel TranslineDocument145 pagesExcel TranslineHazel Grace Del MonteNo ratings yet

- Introduction To VRF Systems PDFDocument12 pagesIntroduction To VRF Systems PDFeimrehNo ratings yet

- Study of R-L-C Series CircuitDocument8 pagesStudy of R-L-C Series Circuitr21745566No ratings yet

- Data Alkes KalibrasiDocument41 pagesData Alkes Kalibrasianisa13No ratings yet

- A Most Incomprehensible Thing - Peter CollierDocument483 pagesA Most Incomprehensible Thing - Peter CollierDavidMarcosPerezMuñoz100% (4)