Professional Documents

Culture Documents

TP70 On-Site Flexible Rod Switch

TP70 On-Site Flexible Rod Switch

Uploaded by

Muhamad PriyatnaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TP70 On-Site Flexible Rod Switch

TP70 On-Site Flexible Rod Switch

Uploaded by

Muhamad PriyatnaCopyright:

Available Formats

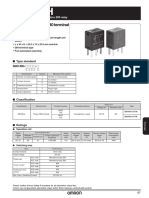

On-site Flexible Rod Switch

TP70

Easy on-site input on-the-move.

• Incorporation of plastic rod actuator makes the Switch easy on

hands.

• One-way operation:

Equipped with stopper so that operation is only possible from

one direction.

• Distinctive yellow used for the body.

• Three different types of mounting are available.

• Models with emergency-stop switch are available to suit the

application.

Model Number Structure

■ Model Number Legend

TP70-@@@

1 2 3

1. Built-in Switch Model 3. Mounting Method

1: D4D-2187N 1: Front mounting

2. Function 2: Base mounting (with height adjustment)

A: Integrated switch only 3: C-clamp mounting (with height adjustment)

S: With separable emergency-stop switch

Ordering Information

■ List of Models

Name Mounting method Model

On-site Flexible Rod Switch (integrated switch only) Front mounting TP70-1A1

Base mounting TP70-1A2

C-clamp mounting TP70-1A3

On-site Flexible Rod Switch (with separable emergency- Front mounting TP70-1S1

stop switch) Base mounting TP70-1S2

C-clamp mounting TP70-1S3

On-site Flexible Rod Switch TP70 235

Specifications

■ Ratings

Rated voltage Non-inductive load Inductive load

Resistive load Lamp load Inductive load Motor load

NC NO NC NO NC NO NC NO

125 VAC 10 A 10 A 3A 1.5 A 10 A 10 A 5A 2.5 A

30 VDC 6A 6A 4A 3A 6A 6A 4A 4A

125 VDC 0.8 A 0.8 A 0.2 A 0.2 A 0.8 A 0.8 A 0.2 A 0.2 A

Note: 1. The above figures are for steady-state currents.

2. Lamp loads have an inrush current of 10 times the steady-state current.

3. Inductive loads have a power factor of 0.4 min. (AC), or a time constant of 7 ms max. (DC).

4. Motor loads have an inrush current of 6 times the steady-state current.

■ Characteristics

Degree of protection (See note 3.) IP65

Vibration resistance Malfunction: 10 to 55 Hz, 0.65-mm single amplitude, 100 m/s2 max.

Shock resistance Destruction: 1,000 m/s2 max.

Malfunction: 20 m/s2 max.

Ambient temperature Operating: –10°C to 70°C

Ambient humidity Operating: 35% to 95%

Built-in switch specifications Switch model D4D-2187N

Allowable operating speed 1 mm/s to 0.5 m/s

Allowable operating frequency Mechanical: 60 operations/min

Electrical: 30 operations/min (with resistive load)

Durability Mechanical: 1,000,000 operations min.

(See note 4.) Electrical: 200,000 operations min. (for a resistive load of 10 A at 125 VAC)

Contact type SPST-NO+SPST-NC

Terminal type Screw terminals

Emergency-stop switch specifi- Switch model A165E-M-02

cations

Operating method Slow action, positive-opening mechanism

Operating functions Push to lock, turn to reset

Contact is opened by pushing in switch and closed by returning switch to original position.

Contact type DPST-NC

Operating part Size: 40 dia. Color: red, non-illuminated

Terminal type Soldered terminals

Note: 1. The values in the above table are the initial values.

2. For more details on specifications, refer to individual specification sheets for the relevant models.

3. The specification given for the degree of protection is for the built-in switch (D4D-2187N) and does not apply to the casing for the whole

product.

4. The durability values shown above are for operation at an ambient temperature of 5°C to 35°C, an ambient humidity of 40% to 70%, with

an operating stroke of 30 mm at a point 20 mm away from the end of the actuator.

Contact your OMRON representative for details on other operating conditions.

236 On-site Flexible Rod Switch TP70

Connections

■ Contact Form

Built-in Switch

Za

Emergency-stop Switch

Nomenclature

Top plate (to prevent malfunction due to falling objects)

Plastic rod

(Built-in Switch: D4D-2187N)

Stopper (one-way operation)

Cover (yellow)

Engineering Data

Electrical Durability (SPST-NO+SPST-NC; Snap-action)

(cosφ = 1) (cosφ = 0.4)

Operating frequency: Operating frequency:

30 operations/min 30 operations/min

cosφ = 1 cosφ = 0.4

250 VAC

Operations (x10 4)

Operations (x10 4)

250 VAC

500 VAC

500 VAC

Switching current (A) Switching current (A)

On-site Flexible Rod Switch TP70 237

Dimensions

Note: 1. All units are in millimeters unless otherwise indicated.

2. Unless otherwise specified, a tolerance of ±4 mm applies to all dimensions.

TP70-1A3

Plastic rod

262 to 367

Three, M3

Allen-head bolts

A (see note)

50 max.

Note: There is no base plate at A.

■ Operating Characteristics

Item Standard value

OF max. 1.47 N

PT 15° max.

Precautions

Refer to the “Precautions for General-purpose Limit Switches (Including Multiple Limit Switches, Mechanical Touch Switches, High-precision

Switches, Touch Switches, On-site Flexible Switches; Not Including Safety Switches)” on page 17.

■ Notice The casing has no sealing properties. The bottom of the casing is

open. Do not use the product in locations subject to splashes of oil or

chemicals. Do not handle the product with oily or wet hands. Bringing

Do not use the product in installations that require safety counter-

the product into contact with certain types of oil or chemical may

measures for operation, such as presses, shears, mills, spinning

result in faulty contact, insulation problems, current leakage, or fire.

machinery, or cotton-making machinery.

To prevent damage to the switch due to short-circuiting, connect a

fuse that has a breaking current value of 1.5 to 2 times the rated cur-

rent in series with the switch.

Do not use the product in locations subject to explosive or flammable

gases.

Be sure to use the product only at load currents less than the rated

values.

238 On-site Flexible Rod Switch TP70

■ Correct Use Mounting the Main Body

Operating Environment Front Mounting and Base Mounting

Mount the product using M5 screws and washers. Be sure to tighten

1. Do not use the product in the following environments: the screws to the correct torque.

• Locations subject to severe changes in temperature.

• Locations subject to condensation as a result of high humidity. Mounting Hole Dimensions

• Locations subject to severe vibration.

Front Mounting Base Mounting

2. The product is intended for indoor use only. Using the product

outdoors may result in malfunction. 5.2-dia. or M5 hole 5.2-dia. or M5 hole

Tightening Torque

Type Proper tightening

torque

Main body mounting screws (M5 screws) 2.4 to 2.7 N·m

Terminal screws (M3.5 screws) 0.59 to 0.78 N·m

Mounting screws for built-in switch cover 0.78 to 0.88 N·m

Connectors 1.8 to 2.2 N·m

Stopper mounting bolts 12.7 to 19.3 N·m

(M3 Allen-head bolts)

Cover mounting bolts 12.7 to 19.3 N·m

(M3 Allen-head bolts)

C-clamp Mounting

Removing the Cover Mount the product using a wing nut. Ensure that there is no loose-

ness or rattling. The maximum mountable panel thickness is 50 mm.

Remove the cover by loosening the Allen-head bolts that are located

in 3 places on the front of the cover, and perform wiring for the built-in

switch and indicator. After wiring is completed, remount the cover by

tightening the bolts to the correct torque.

Wiring 50 max.

Do not connect the lead wires for the built-in switch or counter

directly to terminals. Wire via insulating tubes and crimp terminals

and tighten securely.

Connect lead wires to the indicator or emergency-stop switch by sol-

dering. Perform soldering at 30 W within 5 seconds. Do not apply any

external force to the soldered parts for 1 minute after soldering.

Processing the Conduit Opening

Tighten the connector to a torque of 1.8 to 2.2 N⋅m. Excessive tight-

ening torque may damage the casing.

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Cat. No. C119-E1-03 In the interest of product improvement, specifications are subject to change without notice.

On-site Flexible Rod Switch TP70 239

You might also like

- Switching Power Supply Design: A Concise Practical HandbookFrom EverandSwitching Power Supply Design: A Concise Practical HandbookNo ratings yet

- ANIC-15S Instruction ManualDocument18 pagesANIC-15S Instruction ManualMuhamad PriyatnaNo ratings yet

- 1354189340-GSM 41 C Eng.Document39 pages1354189340-GSM 41 C Eng.gfg fgfgf100% (1)

- A Study On Remote Code Execution Vulnerability in Web ApplicationsDocument9 pagesA Study On Remote Code Execution Vulnerability in Web ApplicationshiepleeNo ratings yet

- Model Number Structure: Relays With Forcibly Guided ContactsDocument22 pagesModel Number Structure: Relays With Forcibly Guided Contactselkin mezaNo ratings yet

- HL-500 General-Purpose Limit SwitchDocument9 pagesHL-500 General-Purpose Limit SwitchMuhamad PriyatnaNo ratings yet

- g8h Manual 4b11tDocument6 pagesg8h Manual 4b11tAdam AqasyahNo ratings yet

- G8V-RH: High Current Micro 280 Terminal LayoutDocument3 pagesG8V-RH: High Current Micro 280 Terminal Layoutchrdue1No ratings yet

- Sealed Basic Switch For Vehicles D2FW-GDocument4 pagesSealed Basic Switch For Vehicles D2FW-GMuhamad PriyatnaNo ratings yet

- 8567 RelayDocument3 pages8567 RelayAmandaNo ratings yet

- Data Sheet 3UG4512-1BR20Document6 pagesData Sheet 3UG4512-1BR20Otolino CostaNo ratings yet

- Quasi-Resonant Control Type DC/DC Converter IC: DatasheetDocument28 pagesQuasi-Resonant Control Type DC/DC Converter IC: DatasheetRaka Satria PradanaNo ratings yet

- 2017 559 Seg en KBDocument4 pages2017 559 Seg en KB01666754614No ratings yet

- Datasheet A3M60A-BEPB014x17 1053332 enDocument8 pagesDatasheet A3M60A-BEPB014x17 1053332 enRadu StamatinNo ratings yet

- 3SK11111AB30 Datasheet enDocument8 pages3SK11111AB30 Datasheet enmtcsjogoNo ratings yet

- g7t Datasheet enDocument7 pagesg7t Datasheet enDenny PanjaitanNo ratings yet

- lg2 Ds e 4 1 csm388Document5 pageslg2 Ds e 4 1 csm388julioferoNo ratings yet

- Mechanical Pressure Switch S4130: Description FeaturesDocument2 pagesMechanical Pressure Switch S4130: Description FeaturesRolando Jara Young100% (1)

- High-Temperature Basic Switch TZDocument4 pagesHigh-Temperature Basic Switch TZMuhamad PriyatnaNo ratings yet

- Switches and SensorsDocument2 pagesSwitches and SensorsmathemartinsrioNo ratings yet

- 3TK28252BB40 Datasheet enDocument4 pages3TK28252BB40 Datasheet enRemei RemeiNo ratings yet

- Carlo Over Current RelayDocument3 pagesCarlo Over Current RelayJoão Gualter Machado RigorNo ratings yet

- Ml7420a8088 e Honeywell Valve ActuatorDocument4 pagesMl7420a8088 e Honeywell Valve ActuatorstranfirNo ratings yet

- Ys 6235Document2 pagesYs 6235pabloperezmtz1No ratings yet

- 3TK28241BB40 Datasheet enDocument4 pages3TK28241BB40 Datasheet enAli AlhadithyNo ratings yet

- Door Interlock Switch D2DDocument8 pagesDoor Interlock Switch D2DMuhamad PriyatnaNo ratings yet

- 3SK11111AW20 SafetyRelayDocument7 pages3SK11111AW20 SafetyRelayDonRainotzNo ratings yet

- Safety Relay ConfigurationDocument9 pagesSafety Relay ConfigurationAlladin BegovićNo ratings yet

- Linde 7919040093 & 7919040095 JoystickDocument3 pagesLinde 7919040093 & 7919040095 JoystickRunnTechNo ratings yet

- Takamisawa Sy 24w K PCB Mount Relay 24vdc 1 Co SPDT Sy 24w K Data SheetDocument5 pagesTakamisawa Sy 24w K PCB Mount Relay 24vdc 1 Co SPDT Sy 24w K Data Sheetremon thereminNo ratings yet

- g7t Ds csm51Document7 pagesg7t Ds csm51CRISENTENANo ratings yet

- 3RN20121BW31 Datasheet enDocument7 pages3RN20121BW31 Datasheet enAmir YuliNo ratings yet

- 3TK28211CB30 Datasheet enDocument7 pages3TK28211CB30 Datasheet enAnonymous SEveDwSUNo ratings yet

- Encoder DBS36E-BBEP01000 1064687 enDocument8 pagesEncoder DBS36E-BBEP01000 1064687 enTomasz KownackiNo ratings yet

- Special-Purpose Basic Switch DZDocument5 pagesSpecial-Purpose Basic Switch DZMuhamad PriyatnaNo ratings yet

- 3TK28251BB40 DatashnDocument4 pages3TK28251BB40 DatashnVinicius MateusNo ratings yet

- G5V-1 PCB Relay: Ordering InformationDocument3 pagesG5V-1 PCB Relay: Ordering InformationAli ShanNo ratings yet

- La 55pDocument3 pagesLa 55pb_dupNo ratings yet

- Az979 Auto Iso Relay 24v 80aDocument3 pagesAz979 Auto Iso Relay 24v 80asvirkomartinkoNo ratings yet

- ZT3001 ZillTekDocument7 pagesZT3001 ZillTekManohar TmNo ratings yet

- 1md8a 3upDocument3 pages1md8a 3upDirson Volmir WilligNo ratings yet

- Monitoring Relays 1-Phase True RMS AC/DC Over or Under Current Types DIB02, PIB02Document4 pagesMonitoring Relays 1-Phase True RMS AC/DC Over or Under Current Types DIB02, PIB02ShiaTVfanNo ratings yet

- Miniature Basic Switch D2MVDocument7 pagesMiniature Basic Switch D2MVMuhamad PriyatnaNo ratings yet

- Sitrans F M Magflo: Electromagnetic Flowmeters Transmitter Types MAG 5000, MAG 6000Document16 pagesSitrans F M Magflo: Electromagnetic Flowmeters Transmitter Types MAG 5000, MAG 6000Daniela KroetzNo ratings yet

- TZDocument21 pagesTZDicky Nurul IlhamNo ratings yet

- Ex Solenoid Interlock Ex STM 298 01/12 R-3G/D Material No.: 1273831Document3 pagesEx Solenoid Interlock Ex STM 298 01/12 R-3G/D Material No.: 1273831suadNo ratings yet

- High Current Relay 200Document3 pagesHigh Current Relay 200ShiaTVfanNo ratings yet

- Rele Ac Peugeot 406Document7 pagesRele Ac Peugeot 406Alvaro HorcajoNo ratings yet

- BM060FNCDocument4 pagesBM060FNCismail mijasNo ratings yet

- D5C Touch SwitchDocument8 pagesD5C Touch SwitchMuhamad PriyatnaNo ratings yet

- 3RN2010 1BW30Document7 pages3RN2010 1BW30dachinicuNo ratings yet

- En 3SK1211-1BB00Document7 pagesEn 3SK1211-1BB00dachinicuNo ratings yet

- 3TK28241BB40 Datasheet enDocument4 pages3TK28241BB40 Datasheet enDads DragNo ratings yet

- FTR p1Document7 pagesFTR p1José María Paredes LorenzoNo ratings yet

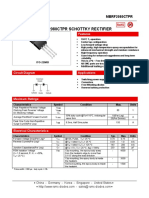

- Mbrf2080Ctpr Schottky Rectifier: FeaturesDocument4 pagesMbrf2080Ctpr Schottky Rectifier: FeaturesThanh LeeNo ratings yet

- 3TK28251AB20 Datasheet enDocument4 pages3TK28251AB20 Datasheet enMarco PoliNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Industrial Automation Catalog Section - U906: Switches & Pilot Devices AP Series Miniature Switches & Pilot DevicesDocument8 pagesIndustrial Automation Catalog Section - U906: Switches & Pilot Devices AP Series Miniature Switches & Pilot DevicesMuhamad PriyatnaNo ratings yet

- 8-16mm A Series EP1149-0Document44 pages8-16mm A Series EP1149-0Muhamad PriyatnaNo ratings yet

- EP1116-0 ControlUnits Relays 060217Document404 pagesEP1116-0 ControlUnits Relays 060217Muhamad PriyatnaNo ratings yet

- Relay Barriers: Intrinsically Safe Explosion ProtectionDocument8 pagesRelay Barriers: Intrinsically Safe Explosion ProtectionMuhamad PriyatnaNo ratings yet

- EB3C & 3L - Sales ManualDocument10 pagesEB3C & 3L - Sales ManualMuhamad PriyatnaNo ratings yet

- EP1132-0 FBcontrolbox 060704Document8 pagesEP1132-0 FBcontrolbox 060704Muhamad PriyatnaNo ratings yet

- PLC, IO & Communications ProductsDocument46 pagesPLC, IO & Communications ProductsMuhamad PriyatnaNo ratings yet

- AS-Interface Devices: (Slave Modules)Document48 pagesAS-Interface Devices: (Slave Modules)Muhamad PriyatnaNo ratings yet

- Power Supplies BrochureDocument12 pagesPower Supplies BrochureMuhamad PriyatnaNo ratings yet

- 16 MM XA Series & 22 MM XW Series Emergency Stop SwitchesDocument20 pages16 MM XA Series & 22 MM XW Series Emergency Stop SwitchesMuhamad PriyatnaNo ratings yet

- Eb3C Eb3L: Relay Barriers Lamp BarriersDocument20 pagesEb3C Eb3L: Relay Barriers Lamp BarriersMuhamad PriyatnaNo ratings yet

- ANIC-15S Catalog JapaneseDocument7 pagesANIC-15S Catalog JapaneseMuhamad PriyatnaNo ratings yet

- 16 MM XA Series & 22 MM HW, XW Series SEMI S2 Compliant EMODocument4 pages16 MM XA Series & 22 MM HW, XW Series SEMI S2 Compliant EMOMuhamad PriyatnaNo ratings yet

- Power Supplies: Smart ProductsDocument6 pagesPower Supplies: Smart ProductsMuhamad PriyatnaNo ratings yet

- 16 MM XA Series & 22 MM XW Series SEMI S2 Compliant EMO SwitDocument8 pages16 MM XA Series & 22 MM XW Series SEMI S2 Compliant EMO SwitMuhamad PriyatnaNo ratings yet

- PS5R-SB Switching Power SuppliesDocument2 pagesPS5R-SB Switching Power SuppliesMuhamad PriyatnaNo ratings yet

- 8F Drains and Breathers: Application: ECD Type 4X''Document1 page8F Drains and Breathers: Application: ECD Type 4X''Muhamad PriyatnaNo ratings yet

- Series: 611G 611V 611GE 611VE: Installation DrawingDocument1 pageSeries: 611G 611V 611GE 611VE: Installation DrawingMuhamad PriyatnaNo ratings yet

- 8F Drains and Breathers: Application: ECD Type 4X''Document1 page8F Drains and Breathers: Application: ECD Type 4X''Muhamad PriyatnaNo ratings yet

- Operator Interface ProductsDocument38 pagesOperator Interface ProductsMuhamad PriyatnaNo ratings yet

- Vacuum Contactors & StartersDocument32 pagesVacuum Contactors & StartersMuhamad PriyatnaNo ratings yet

- Stacklights 46-1: February 2007Document12 pagesStacklights 46-1: February 2007Muhamad PriyatnaNo ratings yet

- Modular I/O System Modbus: Technical Description, Installation and ConfigurationDocument218 pagesModular I/O System Modbus: Technical Description, Installation and ConfigurationMuhamad PriyatnaNo ratings yet

- Medium Voltage Motor Control AssembliesDocument4 pagesMedium Voltage Motor Control AssembliesMuhamad PriyatnaNo ratings yet

- Motor Control CentersDocument20 pagesMotor Control CentersMuhamad PriyatnaNo ratings yet

- Cordsets & Sensor AccessoriesDocument4 pagesCordsets & Sensor AccessoriesMuhamad PriyatnaNo ratings yet

- Cross Reference List: GE Series SB1 To Electroswitch Series 24Document2 pagesCross Reference List: GE Series SB1 To Electroswitch Series 24Muhamad PriyatnaNo ratings yet

- NEMA Manual StartersDocument12 pagesNEMA Manual StartersMuhamad PriyatnaNo ratings yet

- H2F 24 Hour or Weekly TimerDocument8 pagesH2F 24 Hour or Weekly TimerMuhamad PriyatnaNo ratings yet

- KIOGA 2018 DuboisDocument49 pagesKIOGA 2018 DuboisLumea PoliticaNo ratings yet

- Manual-4RY8812 Version 2.0Document36 pagesManual-4RY8812 Version 2.0Katty MenaNo ratings yet

- LB#820-2327 Macbook - 13 - A1278 - M97Document78 pagesLB#820-2327 Macbook - 13 - A1278 - M97Dan PerezNo ratings yet

- RTOS - Unit-5 NotesDocument16 pagesRTOS - Unit-5 NotesSasi BhushanNo ratings yet

- Catalogo Victaulic Pl2022 A GenDocument433 pagesCatalogo Victaulic Pl2022 A GenMohanaNo ratings yet

- GRADESDocument3 pagesGRADESAcele Dayne Rhiane BacligNo ratings yet

- Service Manual: Harman/kardonDocument229 pagesService Manual: Harman/kardonSang NhNo ratings yet

- Jhon Hue Investment Bank Resume'Document1 pageJhon Hue Investment Bank Resume'Luka KundovicNo ratings yet

- Monthly Service Bulletin: FEI Customer Service April 29, 2009Document14 pagesMonthly Service Bulletin: FEI Customer Service April 29, 2009Emad BNo ratings yet

- Public Speaking AssignmentDocument4 pagesPublic Speaking AssignmentSiti NursyafiqahNo ratings yet

- Enhancement of An Interactive Smart Refrigerator Based On Embedded SystemDocument1 pageEnhancement of An Interactive Smart Refrigerator Based On Embedded SystemAbhishek ChakrabortyNo ratings yet

- A6V10344991 - Valves VVF..VXF..VVG41.. VXG41.. VVI41.. VXI4 - enDocument108 pagesA6V10344991 - Valves VVF..VXF..VVG41.. VXG41.. VVI41.. VXI4 - enwalidNo ratings yet

- Promaster Tsuno Chronograph Racer - Setting - GuideDocument1 pagePromaster Tsuno Chronograph Racer - Setting - GuideAlexis BejarNo ratings yet

- Lagrange InterpolationDocument18 pagesLagrange InterpolationdiviyabhavaaniNo ratings yet

- Anime BingoDocument1 pageAnime Bingomusic -No ratings yet

- Research Papers On Fluid Dynamics PDFDocument8 pagesResearch Papers On Fluid Dynamics PDFwroworplg100% (1)

- Kvs TGT Admit CardDocument2 pagesKvs TGT Admit CardbrijeshNo ratings yet

- Master Microservices With Spring, Docker, KubernetesDocument87 pagesMaster Microservices With Spring, Docker, Kuberneteskarthik rNo ratings yet

- Ped GuidelinesDocument225 pagesPed GuidelinesMatteo PeddisNo ratings yet

- Proposal For Computer Based Exam ApplicationDocument8 pagesProposal For Computer Based Exam ApplicationdaniNo ratings yet

- OSC Feature DescriptionDocument166 pagesOSC Feature DescriptionkanthiituNo ratings yet

- Tur Bulat or WebDocument13 pagesTur Bulat or WebBakkiyarajNo ratings yet

- Richard Coffin Resume - PLAIN BAGELDocument1 pageRichard Coffin Resume - PLAIN BAGELOleksandr BidnykNo ratings yet

- India ImportDocument9 pagesIndia ImportvinothNo ratings yet

- SID-2015-Tutorial 3-Ruaumoko and Dynaplot in Batch ModeDocument26 pagesSID-2015-Tutorial 3-Ruaumoko and Dynaplot in Batch ModeDiego RojasNo ratings yet

- Arts 10 Quarter 3 Week 7 Las # 1Document2 pagesArts 10 Quarter 3 Week 7 Las # 1ariel velaNo ratings yet

- Lecture 8: Gradient Descent and Logistic RegressionDocument39 pagesLecture 8: Gradient Descent and Logistic RegressionAshish JainNo ratings yet

- Compactos 5 A 25 TNDocument3 pagesCompactos 5 A 25 TNhmalexisNo ratings yet