Professional Documents

Culture Documents

VB Multiple Limit Switch

VB Multiple Limit Switch

Uploaded by

Muhamad PriyatnaCopyright:

Available Formats

You might also like

- Tarjeta Inverter Exterior Univesal Nuevo ModeloDocument7 pagesTarjeta Inverter Exterior Univesal Nuevo ModeloEdison EspinalNo ratings yet

- V3435CI - CI Programming and Front Cover Manual PDFDocument28 pagesV3435CI - CI Programming and Front Cover Manual PDFSergeiNo ratings yet

- ANIC-15S Instruction ManualDocument18 pagesANIC-15S Instruction ManualMuhamad PriyatnaNo ratings yet

- Project Proposal (Jkuat)Document108 pagesProject Proposal (Jkuat)Florian Osore86% (7)

- Truck Systems Design Handbook PT 41 P 62519365Document5 pagesTruck Systems Design Handbook PT 41 P 62519365Shaswat SinghNo ratings yet

- VB Multiple SwitchDocument5 pagesVB Multiple SwitchrozaqNo ratings yet

- Model Number Structure: Enclosed SwitchDocument11 pagesModel Number Structure: Enclosed SwitchMuhamad PriyatnaNo ratings yet

- EE 435 Lect 9 Spring 2021Document50 pagesEE 435 Lect 9 Spring 2021jeevamk423No ratings yet

- Altivar 312 Quick Reference GuideDocument4 pagesAltivar 312 Quick Reference GuideMaky Hermosa ReinaNo ratings yet

- Sealed Miniature Basic Switch D2VWDocument6 pagesSealed Miniature Basic Switch D2VWMuhamad PriyatnaNo ratings yet

- 45W Ac-Dc Adapter With Standby Function: AN1134 Application NoteDocument9 pages45W Ac-Dc Adapter With Standby Function: AN1134 Application NoteGrzegorz WegnerNo ratings yet

- Contactores: Advanced Industrial AutomationDocument4 pagesContactores: Advanced Industrial AutomationemilianoNo ratings yet

- 20-D5 DCV05 Solenoid Valves CatalogDocument10 pages20-D5 DCV05 Solenoid Valves CatalogHIDRAULICA MANSE SERVICIO TECNICONo ratings yet

- JVC Av-2115ee Chassis CGDocument150 pagesJVC Av-2115ee Chassis CGDarwin Yasmani Martinez ColqueNo ratings yet

- Schemi DC Macchine 48 20081Document41 pagesSchemi DC Macchine 48 20081Andreyna BreaNo ratings yet

- D4E - N Small Sealed SwitchDocument13 pagesD4E - N Small Sealed SwitchMuhamad PriyatnaNo ratings yet

- FAN1117A: 1A Adjustable/Fixed Low Dropout Linear RegulatorDocument9 pagesFAN1117A: 1A Adjustable/Fixed Low Dropout Linear RegulatorVicente MiróNo ratings yet

- ProductComparison 02-341822 02-341814Document2 pagesProductComparison 02-341822 02-341814Justus ReidNo ratings yet

- ZE, ZV, XE, XV EnclosedDocument12 pagesZE, ZV, XE, XV EnclosedMuhamad PriyatnaNo ratings yet

- Final de Carrera D4enDocument14 pagesFinal de Carrera D4enJonatan Ferney Valenzuela ForeroNo ratings yet

- Comatrol Catalogo MVB10 Mar18Document40 pagesComatrol Catalogo MVB10 Mar18Felipe Doria RibeiroNo ratings yet

- 20-D5 DCV05 Solenoid Valves CatalogDocument10 pages20-D5 DCV05 Solenoid Valves CatalogFederico TomiNo ratings yet

- BBV-1.i CE 117518Document1 pageBBV-1.i CE 117518cris2450No ratings yet

- BBV 0NDocument1 pageBBV 0Nbenj bandalNo ratings yet

- Amplificador LNDocument24 pagesAmplificador LNjocordoba2398No ratings yet

- 27 Combi R: Urface-Mounting EnclosuresDocument2 pages27 Combi R: Urface-Mounting EnclosuresOvidiu GavrilasNo ratings yet

- General Description Features: 52Khz Simple 1A Buck RegulatorDocument12 pagesGeneral Description Features: 52Khz Simple 1A Buck Regulatorahmad salahNo ratings yet

- DatasheetDocument26 pagesDatasheetpopeyeNo ratings yet

- Model Number Structure: Enclosed SwitchDocument10 pagesModel Number Structure: Enclosed SwitchMuhamad PriyatnaNo ratings yet

- Low Offset Voltage Dual Comparators LM393, LM393E, LM293, LM2903, LM2903E, LM2903V, NCV2903Document13 pagesLow Offset Voltage Dual Comparators LM393, LM393E, LM293, LM2903, LM2903E, LM2903V, NCV2903alllim88No ratings yet

- Page13 - Folded CascodeDocument28 pagesPage13 - Folded Cascodejeevamk423No ratings yet

- Three-Phase Motor/Three-phase Generator KP 0001: Conn. DiagramDocument1 pageThree-Phase Motor/Three-phase Generator KP 0001: Conn. DiagramDejan Jure JurišićNo ratings yet

- Per Unit System - ExampleDocument9 pagesPer Unit System - ExampleCrystal Cheung100% (1)

- Fairchild@Fan 7384Document18 pagesFairchild@Fan 7384Bin WangNo ratings yet

- WS22 - 400 P 121100 e 03Document4 pagesWS22 - 400 P 121100 e 03Eng-Mohammed SalemNo ratings yet

- STNC Válvula Uwk e TeDocument1 pageSTNC Válvula Uwk e TeCOMPRESORES Y SOLUCIONES INDUSTRIALESNo ratings yet

- CATALOG OF Indicating Lamp & PushbuttonDocument16 pagesCATALOG OF Indicating Lamp & PushbuttonAVIJIT MITRANo ratings yet

- MK-46xx Series: Pneumatic Valve ActuatorsDocument4 pagesMK-46xx Series: Pneumatic Valve Actuatorshamza alhassanNo ratings yet

- V3435CI - CI Programming ManualDocument28 pagesV3435CI - CI Programming ManualHerman StornebrinkNo ratings yet

- Getting Started With ATV312: Verify The Delivery of The DriveDocument4 pagesGetting Started With ATV312: Verify The Delivery of The Driveteguh perkasaNo ratings yet

- DSARS0044817Document4 pagesDSARS0044817Andresilitonga silitongaNo ratings yet

- Lndverb enDocument14 pagesLndverb enmrgreengenesNo ratings yet

- Bi-Power Relays LY DatasheetDocument21 pagesBi-Power Relays LY DatasheetcoronaqcNo ratings yet

- FAN73711 High-Current, High-Side Gate Drive IC: Features DescriptionDocument12 pagesFAN73711 High-Current, High-Side Gate Drive IC: Features DescriptionAndres AlegriaNo ratings yet

- Anomaly DocumentationDocument10 pagesAnomaly Documentationvkpwdcmm25No ratings yet

- 500ma Variable/Fixed Output LDO Regulators: DatasheetDocument18 pages500ma Variable/Fixed Output LDO Regulators: DatasheetDiego OliveiraNo ratings yet

- Schneider Electric List Prices Sub-Collection 5 Industry Configurable June 2022 V1 enDocument163 pagesSchneider Electric List Prices Sub-Collection 5 Industry Configurable June 2022 V1 enSidali Hadj BenaliNo ratings yet

- Standard Namur Valve - VSNCDocument5 pagesStandard Namur Valve - VSNCPutri ChairanyNo ratings yet

- Single Supply Dual Operational Amplifiers LM258, LM358, LM358A, LM358E, LM2904, LM2904A, LM2904E, LM2904V, NCV2904Document16 pagesSingle Supply Dual Operational Amplifiers LM258, LM358, LM358A, LM358E, LM2904, LM2904A, LM2904E, LM2904V, NCV2904Mancilla Aguirre J. JesusNo ratings yet

- XC6219 11Document30 pagesXC6219 11Luis SantosNo ratings yet

- General Description Features: 52Khz Simple 3A Buck RegulatorDocument9 pagesGeneral Description Features: 52Khz Simple 3A Buck RegulatorMAJID SADEGHIANNo ratings yet

- Victaulic Firelock Series FL-SR Standard Coverage, Standard Response Upright Pendent and Recessed Pendent Sprinklers, K2.8 (4.0), K4.2 (6.1), K5.6 (8.1), K8.0 (11.5)Document7 pagesVictaulic Firelock Series FL-SR Standard Coverage, Standard Response Upright Pendent and Recessed Pendent Sprinklers, K2.8 (4.0), K4.2 (6.1), K5.6 (8.1), K8.0 (11.5)Deni SutisnaNo ratings yet

- ATV312 Quick Start en S1A10942 03Document4 pagesATV312 Quick Start en S1A10942 03w.priatmadiNo ratings yet

- Transformadores Schneider CatalogoDocument15 pagesTransformadores Schneider CatalogoCristhian RamirezNo ratings yet

- Aoz1212ai PDFDocument18 pagesAoz1212ai PDF060279No ratings yet

- Ultra-Compact and Slim DPDT RelayDocument8 pagesUltra-Compact and Slim DPDT RelaylalithkumartNo ratings yet

- A Product Line of Diodes Incorporated: KS/K Package (SC-70-5/SOT-23-5)Document16 pagesA Product Line of Diodes Incorporated: KS/K Package (SC-70-5/SOT-23-5)Piman MiriNo ratings yet

- Data Sheet: 2 6 W Hi-Fi Audio Power AmplifierDocument12 pagesData Sheet: 2 6 W Hi-Fi Audio Power AmplifierLangstrumNo ratings yet

- (Simple) Ap-1sDocument2 pages(Simple) Ap-1sYevgeniy ShabelnikovNo ratings yet

- Optional Generating Set Wiring - Connection at Not Standard Voltage (Ref. Pag. in "A")Document26 pagesOptional Generating Set Wiring - Connection at Not Standard Voltage (Ref. Pag. in "A")Daniel MuratallaNo ratings yet

- Microwave Devices, Circuits and Subsystems for Communications EngineeringFrom EverandMicrowave Devices, Circuits and Subsystems for Communications EngineeringRating: 4 out of 5 stars4/5 (1)

- Fuzzy Control Systems Design and Analysis: A Linear Matrix Inequality ApproachFrom EverandFuzzy Control Systems Design and Analysis: A Linear Matrix Inequality ApproachNo ratings yet

- 8-16mm A Series EP1149-0Document44 pages8-16mm A Series EP1149-0Muhamad PriyatnaNo ratings yet

- Industrial Automation Catalog Section - U906: Switches & Pilot Devices AP Series Miniature Switches & Pilot DevicesDocument8 pagesIndustrial Automation Catalog Section - U906: Switches & Pilot Devices AP Series Miniature Switches & Pilot DevicesMuhamad PriyatnaNo ratings yet

- ANIC-15S Catalog JapaneseDocument7 pagesANIC-15S Catalog JapaneseMuhamad PriyatnaNo ratings yet

- EP1116-0 ControlUnits Relays 060217Document404 pagesEP1116-0 ControlUnits Relays 060217Muhamad PriyatnaNo ratings yet

- Relay Barriers: Intrinsically Safe Explosion ProtectionDocument8 pagesRelay Barriers: Intrinsically Safe Explosion ProtectionMuhamad PriyatnaNo ratings yet

- EP1132-0 FBcontrolbox 060704Document8 pagesEP1132-0 FBcontrolbox 060704Muhamad PriyatnaNo ratings yet

- Eb3C Eb3L: Relay Barriers Lamp BarriersDocument20 pagesEb3C Eb3L: Relay Barriers Lamp BarriersMuhamad PriyatnaNo ratings yet

- AS-Interface Devices: (Slave Modules)Document48 pagesAS-Interface Devices: (Slave Modules)Muhamad PriyatnaNo ratings yet

- EB3C & 3L - Sales ManualDocument10 pagesEB3C & 3L - Sales ManualMuhamad PriyatnaNo ratings yet

- Power Supplies: Smart ProductsDocument6 pagesPower Supplies: Smart ProductsMuhamad PriyatnaNo ratings yet

- Power Supplies BrochureDocument12 pagesPower Supplies BrochureMuhamad PriyatnaNo ratings yet

- PS5R-SB Switching Power SuppliesDocument2 pagesPS5R-SB Switching Power SuppliesMuhamad PriyatnaNo ratings yet

- H2F 24 Hour or Weekly TimerDocument8 pagesH2F 24 Hour or Weekly TimerMuhamad PriyatnaNo ratings yet

- 16 MM XA Series & 22 MM XW Series Emergency Stop SwitchesDocument20 pages16 MM XA Series & 22 MM XW Series Emergency Stop SwitchesMuhamad PriyatnaNo ratings yet

- 8F Drains and Breathers: Application: ECD Type 4X''Document1 page8F Drains and Breathers: Application: ECD Type 4X''Muhamad PriyatnaNo ratings yet

- Operator Interface ProductsDocument38 pagesOperator Interface ProductsMuhamad PriyatnaNo ratings yet

- 16 MM XA Series & 22 MM XW Series SEMI S2 Compliant EMO SwitDocument8 pages16 MM XA Series & 22 MM XW Series SEMI S2 Compliant EMO SwitMuhamad PriyatnaNo ratings yet

- 8F Drains and Breathers: Application: ECD Type 4X''Document1 page8F Drains and Breathers: Application: ECD Type 4X''Muhamad PriyatnaNo ratings yet

- PLC, IO & Communications ProductsDocument46 pagesPLC, IO & Communications ProductsMuhamad PriyatnaNo ratings yet

- Series: 611G 611V 611GE 611VE: Installation DrawingDocument1 pageSeries: 611G 611V 611GE 611VE: Installation DrawingMuhamad PriyatnaNo ratings yet

- 16 MM XA Series & 22 MM HW, XW Series SEMI S2 Compliant EMODocument4 pages16 MM XA Series & 22 MM HW, XW Series SEMI S2 Compliant EMOMuhamad PriyatnaNo ratings yet

- Motor Control CentersDocument20 pagesMotor Control CentersMuhamad PriyatnaNo ratings yet

- Medium Voltage Motor Control AssembliesDocument4 pagesMedium Voltage Motor Control AssembliesMuhamad PriyatnaNo ratings yet

- NEMA Manual StartersDocument12 pagesNEMA Manual StartersMuhamad PriyatnaNo ratings yet

- Vacuum Contactors & StartersDocument32 pagesVacuum Contactors & StartersMuhamad PriyatnaNo ratings yet

- Cross Reference List: GE Series SB1 To Electroswitch Series 24Document2 pagesCross Reference List: GE Series SB1 To Electroswitch Series 24Muhamad PriyatnaNo ratings yet

- Stacklights 46-1: February 2007Document12 pagesStacklights 46-1: February 2007Muhamad PriyatnaNo ratings yet

- Modular I/O System Modbus: Technical Description, Installation and ConfigurationDocument218 pagesModular I/O System Modbus: Technical Description, Installation and ConfigurationMuhamad PriyatnaNo ratings yet

- Cordsets & Sensor AccessoriesDocument4 pagesCordsets & Sensor AccessoriesMuhamad PriyatnaNo ratings yet

- Cosmology GitaDocument122 pagesCosmology GitabaijumohanNo ratings yet

- University Students' Attitudes Towards E-Learning: A Case Study in University of Business & Technology (UBT) - Saudi Arabia-JeddahDocument11 pagesUniversity Students' Attitudes Towards E-Learning: A Case Study in University of Business & Technology (UBT) - Saudi Arabia-JeddahManuel FranciscoNo ratings yet

- Factor Effecting RecruitmentDocument4 pagesFactor Effecting RecruitmentsogatNo ratings yet

- 40K Bunker TutorialDocument26 pages40K Bunker TutorialRandomizm100% (2)

- Sewers For Adoption: - A Design and Construction Guide For Developers - Small Developments Version - September 2013Document48 pagesSewers For Adoption: - A Design and Construction Guide For Developers - Small Developments Version - September 2013humayriNo ratings yet

- Free Mastic G 316Document5 pagesFree Mastic G 316Kelly RobertsNo ratings yet

- Chap 2 Psychological Testing NormsDocument35 pagesChap 2 Psychological Testing NormsAmna KhanNo ratings yet

- Building Services Branch Testing and Commissioning ProcedureDocument211 pagesBuilding Services Branch Testing and Commissioning ProcedurePHYRAK100% (1)

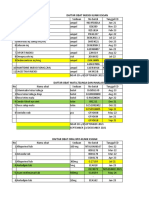

- Hasil Stok Opname Untuk Bap (Fix)Document35 pagesHasil Stok Opname Untuk Bap (Fix)WARDA NABIELANo ratings yet

- 13 - Electronics and Sensor Design of AnDocument204 pages13 - Electronics and Sensor Design of AnRox DamianNo ratings yet

- Book PlantAnimalDiversityinValmikisRamayanaDocument6 pagesBook PlantAnimalDiversityinValmikisRamayanaRaghavendra BhatNo ratings yet

- Test Bank For Stuttering Foundations and Clinical Applications 0131573101Document24 pagesTest Bank For Stuttering Foundations and Clinical Applications 0131573101JimmyHaynessfmg100% (46)

- Prove That 7 Is Irrational ?: 10th ClassDocument11 pagesProve That 7 Is Irrational ?: 10th ClassMahesh YadavNo ratings yet

- Accessories Verins ShefferDocument20 pagesAccessories Verins ShefferAristideNo ratings yet

- 25 Common Surgical ConditionsDocument3 pages25 Common Surgical ConditionsMu AbNo ratings yet

- Adiabatic Saturation Temperature of AirDocument2 pagesAdiabatic Saturation Temperature of AirRahul ChandrawarNo ratings yet

- 1677071391BS German Final Term Result Jan 2023Document2 pages1677071391BS German Final Term Result Jan 2023Raja ZainNo ratings yet

- Chapter 12Document61 pagesChapter 12AmalNo ratings yet

- Installation Manual: KX-TDA100 KX-TDA200Document188 pagesInstallation Manual: KX-TDA100 KX-TDA200Gilmar JesusNo ratings yet

- Locust Test Report: Request StatisticsDocument3 pagesLocust Test Report: Request StatisticsParikansh AhluwaliaNo ratings yet

- LM10b XSLT To Code ExecutionDocument10 pagesLM10b XSLT To Code ExecutionSaw GyiNo ratings yet

- Sustainable Competitive AdvantageDocument49 pagesSustainable Competitive AdvantageakashniranjaneNo ratings yet

- Bella Luna (Jason Mraz With Chords)Document5 pagesBella Luna (Jason Mraz With Chords)Mario CorroNo ratings yet

- Ice Melting Methods For Overhead LinesDocument28 pagesIce Melting Methods For Overhead LinesKirana Shree100% (1)

- Asf First Half ProgramDocument3 pagesAsf First Half ProgramEbuka AniNo ratings yet

- Guidelines For Education and TrainingDocument9 pagesGuidelines For Education and Trainingsunrise755No ratings yet

- Unit-I Introduction To Management Management Is A Universal Phenomenon. It Is A Very Popular and Widely Used Term. AllDocument40 pagesUnit-I Introduction To Management Management Is A Universal Phenomenon. It Is A Very Popular and Widely Used Term. AllSarath ChandraNo ratings yet

VB Multiple Limit Switch

VB Multiple Limit Switch

Uploaded by

Muhamad PriyatnaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

VB Multiple Limit Switch

VB Multiple Limit Switch

Uploaded by

Muhamad PriyatnaCopyright:

Available Formats

Multiple Limit Switch

VB

A New Monoblock Multiple Limit Switch

Incorporating a Head Box with a Tough Head

and Ensuring High Sealing Performance and

a Mechanical Durability of 5,000,000

Operations

• Used for the sequential control of a variety of engineering ma-

chines and belt conveyor lines.

• Built-in oil filter shuts out oil and water.

• Approved by EN, IEC, and CCC (Chinese standard). (Ground

terminal models only.)

• Ground terminal models bear the CE mark.

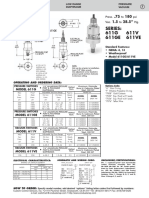

Model Number Structure

■ Model Number Legend

VB-@@@@@@

1 2 3 4 5 6

1. Number of Plungers 4. Scraper

2: 2 plungers 1: NBR scraper

3: 3 plungers 2: FPM scraper

4: 4 plungers 5. Contact

5: 5 plungers None: 10 A (standard)

6: 6 plungers A: 0.1 A (micro load)

2. Actuator 6. Ground Terminal

1: Bevel plunger None: Without ground terminal

2: Roller plunger E: With ground terminal

3. Switch Box

1: Flange switch box with two conduit holes on the side

2: Flange switch box with four conduit holes

4: Non-flange switch box with two conduit holes on the side

5: Non-flange switch box with four conduit holes

Replaceable Switch Unit

Rating Model

Standard load model VB-S101N

192 Multiple Limit Switch VB

Ordering Information

■ List of Models

Actuator Conduit Model

With flange Without flange

Roller plunger Two on the side VB-2211 VB-2241

(with a 6.8-dia. roller) VB-3211 VB-3241

VB-4211 VB-4241

VB-5211 VB-5241

VB-6211 VB-6241

Four VB-2221 VB-2251

VB-3221 VB-3251

VB-4221 VB-4251

VB-5221 VB-5251

VB-6221 VB-6251

Bevel plunger Two on the side VB-2111 VB-2141

VB-3111 VB-3141

VB-4111 VB-4141

VB-5111 VB-5141

VB-6111 ---

Four VB-2121 VB-2151

VB-3121 VB-3151

VB-4121 VB-4151

VB-5121 ---

VB-6121 ---

Note: 1. Other than the above models, minute load models switching 0.1 A are available. When ordering a minute load model, add the suffix A to

the model number (i.e., VB-2211A for example).

2. SC connectors can be connected to VB models.

3. Models with ground terminals are also available. When ordering a ground terminal model, add the suffix E to the model number (i.e., VB-

2211E for example).

4. Since the actuator is incorporated into the monoblock switch, the actuator cannot be replaced.

Multiple Limit Switch VB 193

Specifications

■ Approved Standards

Agency Standards File No. Approved models

TÜV Rheinland EN60947-5-1 R9551017 Only models with ground terminals

(IEC947-5-1)

CCC (CQC) GB14048.5 2003010305077628 Ask your OMRON representative for infor-

mation on approved models.

Note: Ground terminal models only.

■ Approved Standard Ratings ■ General Ratings

TÜV (EN60947-5-1) (Only Ground Standard Load

Terminal Models are Approved) Rated voltage Resistive load Inrush

current

Inrush

current

Standard Load NC NO NC NO

125 VAC 10 A 24 A max.

Applicable category and ratings

250 VAC 10 A

AC-15 2 A/250 VAC

125 VDC 0.6 A

DC-12 2 A/48 VDC

250 VDC 0.3 A

Micro Load Note: The above currents are steady-state currents.

Applicable category and ratings

Micro Load Ratings

AC-14 0.1 A/125 VAC

Rated voltage Resistive load

DC-12 0.1 A/30 VDC

125 VAC 0.1 A

CCC (GB14048.5) 8 VDC 0.1 A

30 VDC 0.1 A

Applicable category and ratings

AC-15 2 A/250 VAC

■ Characteristics

Degree of protection IP67

Durability (See note 2.) Mechanical: 5,000,000 operations min.

Electrical: 300,000 operations min. (10 A at 250 VAC, resistive load)

Operating speed 0.1 mm to 0.5 m/s

Operating frequency Mechanical: 120 operations min.

Electrical: 30 operations min.

Rated frequency 50/60 Hz (AC)

Insulation resistance 100 MΩ min. (at 500 VDC)

Contact resistance 15 mΩ max. (initial value)

Dielectric strength 1,000 VAC/Uimp 4,000 VAC between terminals of same polarity

1,500 VAC/Uimp 4,000 VAC between current-carrying metal parts and ground

1,500 VAC/Uimp 4,000 VAC between each terminal and non-current-carrying metal part

Uimp 4 kV (EN60947-5-1) between terminals of different polarity

Rated insulation voltage (Ui) 300 VAC (EN60947-5-1)

Switching overvoltage 1,000 V max. (EN60947-5-1)

Pollution degree (operating environment) 3 (EN60947-5-1)

Short-circuit protective device (SCPD) 10 A fuse type gG or gI (IEC269)

Conditional short-circuit current 100 A (EN60947-5-1)

Conventional enclosed thermal current (Ithe) 5 A, 0.5 A (EN60947-5-1)

Protection against electric shock Insulation class I (Use the grounding terminal or ground on the machine side.)

Vibration resistance Malfunction: 10 to 55 Hz, 1.5-mm double amplitude

Shock resistance Destruction: 1,000 m/s2 min.

Malfunction: 200 m/s2 min.

Ambient temperature Operating: –10°C to 80°C (with no icing)

Ambient humidity Operating: 35% to 95%

Weight Approx. 580 g (in the case of VB-4211)

Note: 1. The above values are initial values.

2. The values are calculated at an operating temperature of 5°C to 35°C, and an operating humidity of 40% to 70%. Contact your OMRON

sales representative for more detailed information on other operating environments.

194 Multiple Limit Switch VB

Connections

■ Contact Form

COM NC

NO

Nomenclature (for the VB-2211)

Plunger

Scraper

Box

Cover

Seal, gasket

Switch

assembly

Engineering Data

■ Electrical Durability (with more than 300,000 Operations)

(Ambient temperature: 5°C to 35°C; Ambient humidity: 40% to 70%)

1,000

700

Operating frequency:

500

30 operations/min

Durability (x 104 operations)

300 250 VAC, cosφ = 1

200

100

70

50

30

10

0

Switching current (A)

Multiple Limit Switch VB 195

Dimensions

Note: All units are in millimeters unless otherwise indicated.

Bevel Plunger Bevel Plunger

VB-@111 Cable drawing hole VB-@141 Cable drawing hole

FP with 3 threads min. with 3 threads min.

Two, 6+0.1-dia. holes (G1/2) FP PT (G1/2)

for positioning Two screw caps Two screw caps

OP PT OP 8-dia. hard stainless

Four, 6.5 dia. holes steel plunger

8-dia. hard stainless

steel plunger Two, 8.5±0.1

dia. holes

Two, 8.5±0.1 114±0.8

dia. holes Filter

98±0.2 50±0.2

50±0.2

25° to

25° to 30° 30°

Four, M4 x 10 Scraper 10.5 to 11.5

Filter Scraper

screws Dog setting range

23.5 to 24.5 Pitch

Four, M4 x 10 28±0.3 Dog setting 68±0.8 12±0.2 Dog

14±0.2 30±0.2

screws 12±0.2 Dog range

30±0.2

68±0.8

Roller Plunger Roller Plunger

VB-@211 VB-@241 Cable drawing hole with 3

Cable drawing hole with threads min. (G1/2)

Two, 6+0.1-dia. FP 3 threads min. (G1/2) FP PT Two screw caps

holes for 6.8 dia. x 3.7

OP Two screw caps OP Stainless steel roller

positioning PT

Four, 6.5 dia. holes 6.8 dia. x 3.7 Two, 8.5 ±0.1

Stainless steel roller dia. holes

114±0.8 Filter

Two, 8.5 ±0.1

dia. holes

50±0.2

98±0.2

50±0.2

25° to 30°

25° to 30°

Four, M4 x 10 Scraper 16.5 to 17.5

Scraper screws Dog setting range

Filter 68±0.8 Pitch

14±0.2 29.5 to 30.5 12±0.2 30±0.2 Dog

Four, M4 x 10 28±0.3

Dog setting

screws 12+0.2 Dog

30±0.2 range

68±0.8

Model VB-@211 VB-@241 VB-@111 VB-@141

OF max. 14.71 N 14.71 N 14.71 N 14.71 N

RF min. 4.90 N 4.90 N 4.90 N 4.90 N

PT max. 1.5 mm 1.5 mm 1.5 mm 1.5 mm

OT (see note 2) (3.5 mm) (3.5 mm) (3.5 mm) (3.5 mm)

MD max. 0.5 mm 0.5 mm 0.5 mm 0.5 mm

OP 32±0.4 mm 19±0.4 mm 26±0.4 mm 13±0.4 mm

FP (see note 2) (33 mm) (20 mm) (27 mm) (14 mm)

Note: 1. The above operating characteristic values apply to a single switch.

2. The OT and FP values are reference values.

3. The actual model numbers of each of the above VB models have a figure 2 to 6, which indicate the number of plungers.

Number of plungers H

2 58 mm

3 70 mm

4 82 mm

5, 6 (see note) 106 mm

Note: When five plungers are mounted in series, no outer actuator will be provided.

196 Multiple Limit Switch VB

Precautions

Refer to the “Precautions for General-purpose Limit Switches (Including Multiple Limit Switches, Mechanical Touch Switches, High-precision

Switches, Touch Switches, On-site Flexible Switches; Not Including Safety Switches)” on page 17.

■ Correct Use

Operating Environment Sealing

• Seal material may deteriorate if a Switch is used outdoor or where The switch box and cover are made of die-cast aluminum and the

subject to special cutting oils, solvents, or chemicals. Always mounting part of the Switch is covered with a seal cap, and ensure a

appraise performance under actual application conditions and set sealing performance of more than 98×103 Pa for the VB Multiple

suitable maintenance and replacement periods. Limit Switch.

• Install Switches where they will not be directly subject to cutting

The filter on the side of the head prevents oil and water from pene-

chips, dust, or dirt. The Actuator and Switch must also be protected

trating into the interior of the VB Multiple Limit Switch while prevent-

from the accumulation of cutting chips or sludge.

ing the internal pressure of the VB Multiple Limit Switch from rising

Not Suitable Suitable when the plunger is pressed.

The seal scraper on the tip of the actuator prevents chips and dust

from penetrating into the moving parts of the VB Multiple Limit

Switch.

Operating plunger

• Constantly subjecting a Switch to vibration or shock can result in Cap Movable plunger

Seal cap Seal scraper

wear, which can lead to contact interference with contacts, opera-

Switch box

tion failure, reduced durability, and other problems. Excessive

vibration or shock can lead to false contact operation or damage.

Install Switches in locations not subject to shock and vibration and

in orientations that will not produce resonance.

• The Switches have physical contacts. Using them in environments

containing silicon gas will result in the formation of silicon oxide

(SiO2) due to arc energy. If silicon oxide accumulates on the con-

tacts, contact interference can occur. If silicon oil, silicon filling Cap screw

agents, silicon cables, or other silicon products are present near

the Switch, suppress arcing with contact protective circuits (surge Cover O ring

Seal gasket Standard switch

killers) or remove the source of silicon gas.

Be sure to connect a fuse with a breaking current 1.5 to 2 times Apply extra tightening to the cap screw on the conduit.

larger than the rated current to the Switch in series in order to protect In order to protect the plunger from abrasion and prolong its service

the Switch from damage due to short-circuiting. life, apply a small amount of grease to the plunger and dog or cam

If the VB is used for EN ratings, use a gI or gG 10-A fuse approved that come into contact with the plunger. (Molybdenum disulfide

by IEC269. grease is recommended.)

Operation

Make sure the notch of the plunger is not pressed into the scraper

when operating the VB Multiple Limit Switch, otherwise chips or dust

may penetrate into the VB Multiple Limit Switch.

Multiple Limit Switch VB 197

Tightening Torque Wiring

1. Tighten each cover mounting screw to a torque of 1.18 to Connect a cable with a thickness of 0.75 mm2 to the VB Multiple Limit

1.37 N·m. Switch through the M3 round solderless terminals with insulation

2. Tighten each switch terminal screw to a torque of 0.20 to covers.

0.49 N·m if the mounting screw is M3 in size.

Dimensions of Round Solderless Terminal

D dia.

dZ dia.

dz dia.: 3.2

D dia.: 1.9

B: 5.2

L: 16.4

Be sure to wire each solderless terminal correctly with a screw as

F: 5.8

shown below.

l: 8.0 (mm)

Solderless terminal

Correct Incorrect Wiring (Ground Terminal Models)

SC connector

Terminal screw

3. Apply a torque of 5.88 to 6.86 N·m to tighten each mounting bolt

of the casing if the mounting bolt is an Allen-head bolt that is M6

in size. Apply a torque of 8.04 to 9.22 N·m instead if the mounting Built-in switch

bolt is an Allen-head bolt that is M8 in size.

Ground terminal

■ Mounting

VB

Mounting Holes Note: Consult your OMRON representative for details on models with

3 to 6 plungers.

With a Flange Switch Box

Four, 6.5-dia. or

Two, 8.5-dia. or

M8 mounting

Others

M6 mounting holes

holes Carefully connect a conduit to each conduit hole and apply a seal or

tape to seal the conduit hole so that cuttings or other materials will

not penetrate through the conduit hole.

Use the SC Connector. Consult your OMRON representative for

details on SC Connectors.

Two, 6 dia. -0.05/−0.15 Make sure that the position of the actuator that is traveling does not

protruding positions

exceed the overtravel (OT) position.

Without a Flange Switch Box Make sure that the operating stroke is 70% to 100% of the specified

Two, 8.5-dia. or OT distance.

M8 mounting

holes

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Cat. No. C115-E1-04 In the interest of product improvement, specifications are subject to change without notice.

198 Multiple Limit Switch VB

You might also like

- Tarjeta Inverter Exterior Univesal Nuevo ModeloDocument7 pagesTarjeta Inverter Exterior Univesal Nuevo ModeloEdison EspinalNo ratings yet

- V3435CI - CI Programming and Front Cover Manual PDFDocument28 pagesV3435CI - CI Programming and Front Cover Manual PDFSergeiNo ratings yet

- ANIC-15S Instruction ManualDocument18 pagesANIC-15S Instruction ManualMuhamad PriyatnaNo ratings yet

- Project Proposal (Jkuat)Document108 pagesProject Proposal (Jkuat)Florian Osore86% (7)

- Truck Systems Design Handbook PT 41 P 62519365Document5 pagesTruck Systems Design Handbook PT 41 P 62519365Shaswat SinghNo ratings yet

- VB Multiple SwitchDocument5 pagesVB Multiple SwitchrozaqNo ratings yet

- Model Number Structure: Enclosed SwitchDocument11 pagesModel Number Structure: Enclosed SwitchMuhamad PriyatnaNo ratings yet

- EE 435 Lect 9 Spring 2021Document50 pagesEE 435 Lect 9 Spring 2021jeevamk423No ratings yet

- Altivar 312 Quick Reference GuideDocument4 pagesAltivar 312 Quick Reference GuideMaky Hermosa ReinaNo ratings yet

- Sealed Miniature Basic Switch D2VWDocument6 pagesSealed Miniature Basic Switch D2VWMuhamad PriyatnaNo ratings yet

- 45W Ac-Dc Adapter With Standby Function: AN1134 Application NoteDocument9 pages45W Ac-Dc Adapter With Standby Function: AN1134 Application NoteGrzegorz WegnerNo ratings yet

- Contactores: Advanced Industrial AutomationDocument4 pagesContactores: Advanced Industrial AutomationemilianoNo ratings yet

- 20-D5 DCV05 Solenoid Valves CatalogDocument10 pages20-D5 DCV05 Solenoid Valves CatalogHIDRAULICA MANSE SERVICIO TECNICONo ratings yet

- JVC Av-2115ee Chassis CGDocument150 pagesJVC Av-2115ee Chassis CGDarwin Yasmani Martinez ColqueNo ratings yet

- Schemi DC Macchine 48 20081Document41 pagesSchemi DC Macchine 48 20081Andreyna BreaNo ratings yet

- D4E - N Small Sealed SwitchDocument13 pagesD4E - N Small Sealed SwitchMuhamad PriyatnaNo ratings yet

- FAN1117A: 1A Adjustable/Fixed Low Dropout Linear RegulatorDocument9 pagesFAN1117A: 1A Adjustable/Fixed Low Dropout Linear RegulatorVicente MiróNo ratings yet

- ProductComparison 02-341822 02-341814Document2 pagesProductComparison 02-341822 02-341814Justus ReidNo ratings yet

- ZE, ZV, XE, XV EnclosedDocument12 pagesZE, ZV, XE, XV EnclosedMuhamad PriyatnaNo ratings yet

- Final de Carrera D4enDocument14 pagesFinal de Carrera D4enJonatan Ferney Valenzuela ForeroNo ratings yet

- Comatrol Catalogo MVB10 Mar18Document40 pagesComatrol Catalogo MVB10 Mar18Felipe Doria RibeiroNo ratings yet

- 20-D5 DCV05 Solenoid Valves CatalogDocument10 pages20-D5 DCV05 Solenoid Valves CatalogFederico TomiNo ratings yet

- BBV-1.i CE 117518Document1 pageBBV-1.i CE 117518cris2450No ratings yet

- BBV 0NDocument1 pageBBV 0Nbenj bandalNo ratings yet

- Amplificador LNDocument24 pagesAmplificador LNjocordoba2398No ratings yet

- 27 Combi R: Urface-Mounting EnclosuresDocument2 pages27 Combi R: Urface-Mounting EnclosuresOvidiu GavrilasNo ratings yet

- General Description Features: 52Khz Simple 1A Buck RegulatorDocument12 pagesGeneral Description Features: 52Khz Simple 1A Buck Regulatorahmad salahNo ratings yet

- DatasheetDocument26 pagesDatasheetpopeyeNo ratings yet

- Model Number Structure: Enclosed SwitchDocument10 pagesModel Number Structure: Enclosed SwitchMuhamad PriyatnaNo ratings yet

- Low Offset Voltage Dual Comparators LM393, LM393E, LM293, LM2903, LM2903E, LM2903V, NCV2903Document13 pagesLow Offset Voltage Dual Comparators LM393, LM393E, LM293, LM2903, LM2903E, LM2903V, NCV2903alllim88No ratings yet

- Page13 - Folded CascodeDocument28 pagesPage13 - Folded Cascodejeevamk423No ratings yet

- Three-Phase Motor/Three-phase Generator KP 0001: Conn. DiagramDocument1 pageThree-Phase Motor/Three-phase Generator KP 0001: Conn. DiagramDejan Jure JurišićNo ratings yet

- Per Unit System - ExampleDocument9 pagesPer Unit System - ExampleCrystal Cheung100% (1)

- Fairchild@Fan 7384Document18 pagesFairchild@Fan 7384Bin WangNo ratings yet

- WS22 - 400 P 121100 e 03Document4 pagesWS22 - 400 P 121100 e 03Eng-Mohammed SalemNo ratings yet

- STNC Válvula Uwk e TeDocument1 pageSTNC Válvula Uwk e TeCOMPRESORES Y SOLUCIONES INDUSTRIALESNo ratings yet

- CATALOG OF Indicating Lamp & PushbuttonDocument16 pagesCATALOG OF Indicating Lamp & PushbuttonAVIJIT MITRANo ratings yet

- MK-46xx Series: Pneumatic Valve ActuatorsDocument4 pagesMK-46xx Series: Pneumatic Valve Actuatorshamza alhassanNo ratings yet

- V3435CI - CI Programming ManualDocument28 pagesV3435CI - CI Programming ManualHerman StornebrinkNo ratings yet

- Getting Started With ATV312: Verify The Delivery of The DriveDocument4 pagesGetting Started With ATV312: Verify The Delivery of The Driveteguh perkasaNo ratings yet

- DSARS0044817Document4 pagesDSARS0044817Andresilitonga silitongaNo ratings yet

- Lndverb enDocument14 pagesLndverb enmrgreengenesNo ratings yet

- Bi-Power Relays LY DatasheetDocument21 pagesBi-Power Relays LY DatasheetcoronaqcNo ratings yet

- FAN73711 High-Current, High-Side Gate Drive IC: Features DescriptionDocument12 pagesFAN73711 High-Current, High-Side Gate Drive IC: Features DescriptionAndres AlegriaNo ratings yet

- Anomaly DocumentationDocument10 pagesAnomaly Documentationvkpwdcmm25No ratings yet

- 500ma Variable/Fixed Output LDO Regulators: DatasheetDocument18 pages500ma Variable/Fixed Output LDO Regulators: DatasheetDiego OliveiraNo ratings yet

- Schneider Electric List Prices Sub-Collection 5 Industry Configurable June 2022 V1 enDocument163 pagesSchneider Electric List Prices Sub-Collection 5 Industry Configurable June 2022 V1 enSidali Hadj BenaliNo ratings yet

- Standard Namur Valve - VSNCDocument5 pagesStandard Namur Valve - VSNCPutri ChairanyNo ratings yet

- Single Supply Dual Operational Amplifiers LM258, LM358, LM358A, LM358E, LM2904, LM2904A, LM2904E, LM2904V, NCV2904Document16 pagesSingle Supply Dual Operational Amplifiers LM258, LM358, LM358A, LM358E, LM2904, LM2904A, LM2904E, LM2904V, NCV2904Mancilla Aguirre J. JesusNo ratings yet

- XC6219 11Document30 pagesXC6219 11Luis SantosNo ratings yet

- General Description Features: 52Khz Simple 3A Buck RegulatorDocument9 pagesGeneral Description Features: 52Khz Simple 3A Buck RegulatorMAJID SADEGHIANNo ratings yet

- Victaulic Firelock Series FL-SR Standard Coverage, Standard Response Upright Pendent and Recessed Pendent Sprinklers, K2.8 (4.0), K4.2 (6.1), K5.6 (8.1), K8.0 (11.5)Document7 pagesVictaulic Firelock Series FL-SR Standard Coverage, Standard Response Upright Pendent and Recessed Pendent Sprinklers, K2.8 (4.0), K4.2 (6.1), K5.6 (8.1), K8.0 (11.5)Deni SutisnaNo ratings yet

- ATV312 Quick Start en S1A10942 03Document4 pagesATV312 Quick Start en S1A10942 03w.priatmadiNo ratings yet

- Transformadores Schneider CatalogoDocument15 pagesTransformadores Schneider CatalogoCristhian RamirezNo ratings yet

- Aoz1212ai PDFDocument18 pagesAoz1212ai PDF060279No ratings yet

- Ultra-Compact and Slim DPDT RelayDocument8 pagesUltra-Compact and Slim DPDT RelaylalithkumartNo ratings yet

- A Product Line of Diodes Incorporated: KS/K Package (SC-70-5/SOT-23-5)Document16 pagesA Product Line of Diodes Incorporated: KS/K Package (SC-70-5/SOT-23-5)Piman MiriNo ratings yet

- Data Sheet: 2 6 W Hi-Fi Audio Power AmplifierDocument12 pagesData Sheet: 2 6 W Hi-Fi Audio Power AmplifierLangstrumNo ratings yet

- (Simple) Ap-1sDocument2 pages(Simple) Ap-1sYevgeniy ShabelnikovNo ratings yet

- Optional Generating Set Wiring - Connection at Not Standard Voltage (Ref. Pag. in "A")Document26 pagesOptional Generating Set Wiring - Connection at Not Standard Voltage (Ref. Pag. in "A")Daniel MuratallaNo ratings yet

- Microwave Devices, Circuits and Subsystems for Communications EngineeringFrom EverandMicrowave Devices, Circuits and Subsystems for Communications EngineeringRating: 4 out of 5 stars4/5 (1)

- Fuzzy Control Systems Design and Analysis: A Linear Matrix Inequality ApproachFrom EverandFuzzy Control Systems Design and Analysis: A Linear Matrix Inequality ApproachNo ratings yet

- 8-16mm A Series EP1149-0Document44 pages8-16mm A Series EP1149-0Muhamad PriyatnaNo ratings yet

- Industrial Automation Catalog Section - U906: Switches & Pilot Devices AP Series Miniature Switches & Pilot DevicesDocument8 pagesIndustrial Automation Catalog Section - U906: Switches & Pilot Devices AP Series Miniature Switches & Pilot DevicesMuhamad PriyatnaNo ratings yet

- ANIC-15S Catalog JapaneseDocument7 pagesANIC-15S Catalog JapaneseMuhamad PriyatnaNo ratings yet

- EP1116-0 ControlUnits Relays 060217Document404 pagesEP1116-0 ControlUnits Relays 060217Muhamad PriyatnaNo ratings yet

- Relay Barriers: Intrinsically Safe Explosion ProtectionDocument8 pagesRelay Barriers: Intrinsically Safe Explosion ProtectionMuhamad PriyatnaNo ratings yet

- EP1132-0 FBcontrolbox 060704Document8 pagesEP1132-0 FBcontrolbox 060704Muhamad PriyatnaNo ratings yet

- Eb3C Eb3L: Relay Barriers Lamp BarriersDocument20 pagesEb3C Eb3L: Relay Barriers Lamp BarriersMuhamad PriyatnaNo ratings yet

- AS-Interface Devices: (Slave Modules)Document48 pagesAS-Interface Devices: (Slave Modules)Muhamad PriyatnaNo ratings yet

- EB3C & 3L - Sales ManualDocument10 pagesEB3C & 3L - Sales ManualMuhamad PriyatnaNo ratings yet

- Power Supplies: Smart ProductsDocument6 pagesPower Supplies: Smart ProductsMuhamad PriyatnaNo ratings yet

- Power Supplies BrochureDocument12 pagesPower Supplies BrochureMuhamad PriyatnaNo ratings yet

- PS5R-SB Switching Power SuppliesDocument2 pagesPS5R-SB Switching Power SuppliesMuhamad PriyatnaNo ratings yet

- H2F 24 Hour or Weekly TimerDocument8 pagesH2F 24 Hour or Weekly TimerMuhamad PriyatnaNo ratings yet

- 16 MM XA Series & 22 MM XW Series Emergency Stop SwitchesDocument20 pages16 MM XA Series & 22 MM XW Series Emergency Stop SwitchesMuhamad PriyatnaNo ratings yet

- 8F Drains and Breathers: Application: ECD Type 4X''Document1 page8F Drains and Breathers: Application: ECD Type 4X''Muhamad PriyatnaNo ratings yet

- Operator Interface ProductsDocument38 pagesOperator Interface ProductsMuhamad PriyatnaNo ratings yet

- 16 MM XA Series & 22 MM XW Series SEMI S2 Compliant EMO SwitDocument8 pages16 MM XA Series & 22 MM XW Series SEMI S2 Compliant EMO SwitMuhamad PriyatnaNo ratings yet

- 8F Drains and Breathers: Application: ECD Type 4X''Document1 page8F Drains and Breathers: Application: ECD Type 4X''Muhamad PriyatnaNo ratings yet

- PLC, IO & Communications ProductsDocument46 pagesPLC, IO & Communications ProductsMuhamad PriyatnaNo ratings yet

- Series: 611G 611V 611GE 611VE: Installation DrawingDocument1 pageSeries: 611G 611V 611GE 611VE: Installation DrawingMuhamad PriyatnaNo ratings yet

- 16 MM XA Series & 22 MM HW, XW Series SEMI S2 Compliant EMODocument4 pages16 MM XA Series & 22 MM HW, XW Series SEMI S2 Compliant EMOMuhamad PriyatnaNo ratings yet

- Motor Control CentersDocument20 pagesMotor Control CentersMuhamad PriyatnaNo ratings yet

- Medium Voltage Motor Control AssembliesDocument4 pagesMedium Voltage Motor Control AssembliesMuhamad PriyatnaNo ratings yet

- NEMA Manual StartersDocument12 pagesNEMA Manual StartersMuhamad PriyatnaNo ratings yet

- Vacuum Contactors & StartersDocument32 pagesVacuum Contactors & StartersMuhamad PriyatnaNo ratings yet

- Cross Reference List: GE Series SB1 To Electroswitch Series 24Document2 pagesCross Reference List: GE Series SB1 To Electroswitch Series 24Muhamad PriyatnaNo ratings yet

- Stacklights 46-1: February 2007Document12 pagesStacklights 46-1: February 2007Muhamad PriyatnaNo ratings yet

- Modular I/O System Modbus: Technical Description, Installation and ConfigurationDocument218 pagesModular I/O System Modbus: Technical Description, Installation and ConfigurationMuhamad PriyatnaNo ratings yet

- Cordsets & Sensor AccessoriesDocument4 pagesCordsets & Sensor AccessoriesMuhamad PriyatnaNo ratings yet

- Cosmology GitaDocument122 pagesCosmology GitabaijumohanNo ratings yet

- University Students' Attitudes Towards E-Learning: A Case Study in University of Business & Technology (UBT) - Saudi Arabia-JeddahDocument11 pagesUniversity Students' Attitudes Towards E-Learning: A Case Study in University of Business & Technology (UBT) - Saudi Arabia-JeddahManuel FranciscoNo ratings yet

- Factor Effecting RecruitmentDocument4 pagesFactor Effecting RecruitmentsogatNo ratings yet

- 40K Bunker TutorialDocument26 pages40K Bunker TutorialRandomizm100% (2)

- Sewers For Adoption: - A Design and Construction Guide For Developers - Small Developments Version - September 2013Document48 pagesSewers For Adoption: - A Design and Construction Guide For Developers - Small Developments Version - September 2013humayriNo ratings yet

- Free Mastic G 316Document5 pagesFree Mastic G 316Kelly RobertsNo ratings yet

- Chap 2 Psychological Testing NormsDocument35 pagesChap 2 Psychological Testing NormsAmna KhanNo ratings yet

- Building Services Branch Testing and Commissioning ProcedureDocument211 pagesBuilding Services Branch Testing and Commissioning ProcedurePHYRAK100% (1)

- Hasil Stok Opname Untuk Bap (Fix)Document35 pagesHasil Stok Opname Untuk Bap (Fix)WARDA NABIELANo ratings yet

- 13 - Electronics and Sensor Design of AnDocument204 pages13 - Electronics and Sensor Design of AnRox DamianNo ratings yet

- Book PlantAnimalDiversityinValmikisRamayanaDocument6 pagesBook PlantAnimalDiversityinValmikisRamayanaRaghavendra BhatNo ratings yet

- Test Bank For Stuttering Foundations and Clinical Applications 0131573101Document24 pagesTest Bank For Stuttering Foundations and Clinical Applications 0131573101JimmyHaynessfmg100% (46)

- Prove That 7 Is Irrational ?: 10th ClassDocument11 pagesProve That 7 Is Irrational ?: 10th ClassMahesh YadavNo ratings yet

- Accessories Verins ShefferDocument20 pagesAccessories Verins ShefferAristideNo ratings yet

- 25 Common Surgical ConditionsDocument3 pages25 Common Surgical ConditionsMu AbNo ratings yet

- Adiabatic Saturation Temperature of AirDocument2 pagesAdiabatic Saturation Temperature of AirRahul ChandrawarNo ratings yet

- 1677071391BS German Final Term Result Jan 2023Document2 pages1677071391BS German Final Term Result Jan 2023Raja ZainNo ratings yet

- Chapter 12Document61 pagesChapter 12AmalNo ratings yet

- Installation Manual: KX-TDA100 KX-TDA200Document188 pagesInstallation Manual: KX-TDA100 KX-TDA200Gilmar JesusNo ratings yet

- Locust Test Report: Request StatisticsDocument3 pagesLocust Test Report: Request StatisticsParikansh AhluwaliaNo ratings yet

- LM10b XSLT To Code ExecutionDocument10 pagesLM10b XSLT To Code ExecutionSaw GyiNo ratings yet

- Sustainable Competitive AdvantageDocument49 pagesSustainable Competitive AdvantageakashniranjaneNo ratings yet

- Bella Luna (Jason Mraz With Chords)Document5 pagesBella Luna (Jason Mraz With Chords)Mario CorroNo ratings yet

- Ice Melting Methods For Overhead LinesDocument28 pagesIce Melting Methods For Overhead LinesKirana Shree100% (1)

- Asf First Half ProgramDocument3 pagesAsf First Half ProgramEbuka AniNo ratings yet

- Guidelines For Education and TrainingDocument9 pagesGuidelines For Education and Trainingsunrise755No ratings yet

- Unit-I Introduction To Management Management Is A Universal Phenomenon. It Is A Very Popular and Widely Used Term. AllDocument40 pagesUnit-I Introduction To Management Management Is A Universal Phenomenon. It Is A Very Popular and Widely Used Term. AllSarath ChandraNo ratings yet