Professional Documents

Culture Documents

Part 2 Concrete Materials - ACK

Part 2 Concrete Materials - ACK

Uploaded by

mohamedyahaiCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- EN2314 Hydraulics - Formula Sheet 30oct19 PDFDocument3 pagesEN2314 Hydraulics - Formula Sheet 30oct19 PDFmohamedyahaiNo ratings yet

- Hamill 2011 - Solutions Chapter 09Document6 pagesHamill 2011 - Solutions Chapter 09mohamedyahai100% (1)

- EN2314 Hydraulics - Module Booklet of Exam Style Questions - Summer Exam 05may20Document5 pagesEN2314 Hydraulics - Module Booklet of Exam Style Questions - Summer Exam 05may20mohamedyahaiNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 0 HYFM300 CW LabDocument3 pages0 HYFM300 CW LabmohamedyahaiNo ratings yet

- General Notes and Standard Details: Rafter DetailDocument1 pageGeneral Notes and Standard Details: Rafter DetailLiza MarieNo ratings yet

- Unit 8 (SERVICEABILITY LIMIT STATE (SLS) )Document26 pagesUnit 8 (SERVICEABILITY LIMIT STATE (SLS) )Zara Nabilah100% (2)

- Compression Test For MetalsDocument11 pagesCompression Test For MetalsmohamedyahaiNo ratings yet

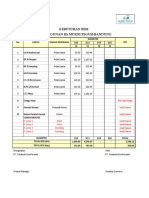

- Cost Control: Tender /construction: Boq - SchedulesDocument21 pagesCost Control: Tender /construction: Boq - SchedulesmohamedyahaiNo ratings yet

- Lecture Sessions 7-9: Principles of Management Cost Modeling and EstimatingDocument13 pagesLecture Sessions 7-9: Principles of Management Cost Modeling and EstimatingmohamedyahaiNo ratings yet

- Procurement and Cost TCQDocument10 pagesProcurement and Cost TCQmohamedyahaiNo ratings yet

- EN2314 Hydraulics - Lecture Notes 08 - 09mar20 PDFDocument12 pagesEN2314 Hydraulics - Lecture Notes 08 - 09mar20 PDFmohamedyahaiNo ratings yet

- Eurocode 7-Easily Explained: The CodeDocument4 pagesEurocode 7-Easily Explained: The CodemohamedyahaiNo ratings yet

- Cive 3261 - Revision Cost StudiesDocument10 pagesCive 3261 - Revision Cost StudiesmohamedyahaiNo ratings yet

- EN2314 Hydraulics - Lecture Notes 05 - 28jan20Document14 pagesEN2314 Hydraulics - Lecture Notes 05 - 28jan20mohamedyahaiNo ratings yet

- EN2314 Hydraulics - Lecture Notes 08 - 09mar20Document12 pagesEN2314 Hydraulics - Lecture Notes 08 - 09mar20mohamedyahaiNo ratings yet

- Session 7 - Shear Strength of SoilsDocument27 pagesSession 7 - Shear Strength of SoilsmohamedyahaiNo ratings yet

- EN2314 Hydraulics - Formula Sheet 30oct19Document3 pagesEN2314 Hydraulics - Formula Sheet 30oct19mohamedyahaiNo ratings yet

- Hamill 2011 - Solutions Chapter 08Document11 pagesHamill 2011 - Solutions Chapter 08mohamedyahaiNo ratings yet

- Session 9.1 - Compaction PDFDocument10 pagesSession 9.1 - Compaction PDFmohamedyahaiNo ratings yet

- Session 8.2 - Slope StabilzationDocument9 pagesSession 8.2 - Slope StabilzationmohamedyahaiNo ratings yet

- Session 10.1 - Site InvestigationDocument34 pagesSession 10.1 - Site InvestigationmohamedyahaiNo ratings yet

- Session 9.1 - Compaction PDFDocument10 pagesSession 9.1 - Compaction PDFmohamedyahaiNo ratings yet

- Session 3.1 - Soil Classification and DescriptionDocument19 pagesSession 3.1 - Soil Classification and DescriptionmohamedyahaiNo ratings yet

- Mock 20Xx Examinations: Paper Code NO. EN4630/ENT630Document14 pagesMock 20Xx Examinations: Paper Code NO. EN4630/ENT630mohamedyahaiNo ratings yet

- Ent501r Ent515rDocument5 pagesEnt501r Ent515rmohamedyahaiNo ratings yet

- ENT501 Numerical Techniques in Civil Engineering - BookletDocument11 pagesENT501 Numerical Techniques in Civil Engineering - BookletmohamedyahaiNo ratings yet

- Stability Systems PDFDocument4 pagesStability Systems PDFmohamedyahaiNo ratings yet

- Structural StabilityDocument4 pagesStructural Stabilitymohamedyahai100% (1)

- Whole Body Vibration Standarized Safety LevelsDocument1 pageWhole Body Vibration Standarized Safety LevelsmohamedyahaiNo ratings yet

- Conceptual DesignDocument4 pagesConceptual DesignmohamedyahaiNo ratings yet

- Chapter 8. Numerical Solution of Ordinary Differential EquationsDocument18 pagesChapter 8. Numerical Solution of Ordinary Differential EquationsmohamedyahaiNo ratings yet

- 5.4 Numerical Integration: D D F AreaDocument18 pages5.4 Numerical Integration: D D F AreamohamedyahaiNo ratings yet

- Halfen Cast-In Channels: HTA-CE 50/30P HTA-CE 40/22PDocument92 pagesHalfen Cast-In Channels: HTA-CE 50/30P HTA-CE 40/22PTulusNo ratings yet

- CE 311 MODULE 4 - Structural Analysis of FramesDocument23 pagesCE 311 MODULE 4 - Structural Analysis of FramesBryanHarold BrooNo ratings yet

- Shay Murtag Precast BeamsDocument49 pagesShay Murtag Precast BeamsMilind GuptaNo ratings yet

- The Y BeamDocument7 pagesThe Y BeamSivakumarNo ratings yet

- 1.1 Concrete: Partial Replacement of Coarse Aggregate With Ceramic Tile 2019-2020Document25 pages1.1 Concrete: Partial Replacement of Coarse Aggregate With Ceramic Tile 2019-2020Naveen S100% (2)

- RETAINING WALL-ModelDocument1 pageRETAINING WALL-ModelArchana PansareNo ratings yet

- Lecture-1 - Introduction To BridgesDocument109 pagesLecture-1 - Introduction To Bridgesjoy cho100% (1)

- 1993 AndradeDocument12 pages1993 AndradeDaniel JamesNo ratings yet

- Defect Danone l9 CompilationDocument12 pagesDefect Danone l9 CompilationJimmy_JambulNo ratings yet

- RAM Connection Standalone CE ReportDocument2 pagesRAM Connection Standalone CE ReportjasekanNo ratings yet

- PCI Sandwich Wall Panels SOA Guide Rev (1!11!11)Document62 pagesPCI Sandwich Wall Panels SOA Guide Rev (1!11!11)Nuno FerreiraNo ratings yet

- Preliminary Design Rules of ThumbDocument11 pagesPreliminary Design Rules of Thumbnimal1234No ratings yet

- Bridge Column Design Based On AASHTO 17th & ACI 318-14: Input Data & Design SummaryDocument5 pagesBridge Column Design Based On AASHTO 17th & ACI 318-14: Input Data & Design SummaryPn EkanayakaNo ratings yet

- Dramix® Steel Fibre Reinforcement For Concrete Tunnel LiningsDocument24 pagesDramix® Steel Fibre Reinforcement For Concrete Tunnel LiningsHeri SiswantoNo ratings yet

- Catalogo FischerDocument52 pagesCatalogo FischerVictor Manuel BonettoNo ratings yet

- Prokon FootingDocument58 pagesProkon Footingmbhanusagar.keynesNo ratings yet

- Typical Stair DetailsDocument1 pageTypical Stair DetailsM IQbalNo ratings yet

- QCS 2010 Section 4 Part 10 Static Load Testing of Piles PDFDocument14 pagesQCS 2010 Section 4 Part 10 Static Load Testing of Piles PDFbryanpastor106No ratings yet

- Construction of Multi-Purpose Building (MPB) in Datu Mamintal National High School, Bubong, Lanao Del SurDocument31 pagesConstruction of Multi-Purpose Building (MPB) in Datu Mamintal National High School, Bubong, Lanao Del SurSalaman II Bongcarawan MangcaNo ratings yet

- A TowerDocument4 pagesA Towerriz2010No ratings yet

- Bbs Pot. Besi RS MTDocument8 pagesBbs Pot. Besi RS MTAmudNo ratings yet

- What Is Precast ConcreteDocument27 pagesWhat Is Precast ConcreteMarrielle BalagotNo ratings yet

- UB 203x102x23: Cross-Section PropertiesDocument2 pagesUB 203x102x23: Cross-Section PropertiesRanjit S KashyapNo ratings yet

- Excavation Design in Stratified RockDocument14 pagesExcavation Design in Stratified RockRobert PrinceNo ratings yet

- 05-05 Vikarabad Shops V Venkatesh - 001Document55 pages05-05 Vikarabad Shops V Venkatesh - 001deerangareddyofficeNo ratings yet

- Number:: 2045 Placentia Avenue Costa Mesa, California 92627Document12 pagesNumber:: 2045 Placentia Avenue Costa Mesa, California 92627CarsonBakerNo ratings yet

- 2933 Tencent Seafront Tower Practice On Binding BuildingsDocument8 pages2933 Tencent Seafront Tower Practice On Binding BuildingskhatribharatNo ratings yet

- Behavior of Cantilever SlabsDocument1 pageBehavior of Cantilever Slabsatoz2033No ratings yet

Part 2 Concrete Materials - ACK

Part 2 Concrete Materials - ACK

Uploaded by

mohamedyahaiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Part 2 Concrete Materials - ACK

Part 2 Concrete Materials - ACK

Uploaded by

mohamedyahaiCopyright:

Available Formats

15FCVE221

Concrete Structures

Part 2:

Concrete Materials

Structural Use of Concrete

• Concrete consists of:

• Portland cement (binder)

• Gravel (coarse aggregate)

• Sand (fine aggregate)

• Water

• Concrete is strong in

compression and weak in

tension

• Steel reinforcement is

provided in tension zones.

2

Part 2 – Concrete Materials Page 1

Concrete + Reinforcing Steel

Reinforced Concrete

Concrete + Steel

Vertical Load

Column Column Column

Part 2 – Concrete Materials Page 2

Concrete + Steel

T T T

C C

C C

C

T T

Concrete + Steel

Part 2 – Concrete Materials Page 3

Reinforced Concrete Elements

Whenever tension

exist from loading,

reinforcement is

needed

Whenever tension

exist from loading,

reinforcement is

needed

Part 2 – Concrete Materials Page 4

Whenever tension

exist from loading,

reinforcement is

needed

Concrete: Compressive Stress‐Strain Curve

- curve is obtained

by testing a 28 days

cured cylindrical

concrete sample with

150 mm dia. and 300

mm height.

D2

A r 2

4

10

10

Part 2 – Concrete Materials Page 5

Concrete: Compressive Stress‐Strain Curve

• fc’ is the specified compressive strength of concrete. It

is the peak stress of the curve = “peak load” / Area

• fc’ shall not be less than 17 MPa.

• Strain at peak stress fc’ is 0.002 for fc’ = 30 MPa, and is

higher for higher fc’.

• Ec = modulus of elasticity for concrete (slope of initial

linear range).

0.043w1.5 f ' for values of w between 1440 and 2560 kg/m 3

Ec

c c c

4700 f c'

for normal - weight concrete

f c' in MPa and wc unit weight of concrete 11

11

Tensile Strength of Concrete

• Tensile strength of concrete shall be neglected in axial

and flexural (bending moment) calculations.

• The strength of concrete in tension, however, is

important in cracking and deflection considerations @

service loads. The parameter of concern is the modulus

of rupture (fr).

• fr is defined as the flexural tensile stress @ which a

crack forms in a plain concrete prism.

f r 0.62 f c'

for normal weight concrete f r and f c' are in MPa

12

12

Part 2 – Concrete Materials Page 6

Steel Rebars

• The steel reinforcing bars

(rebars) are made with surface

deformations to prevent slip

between bars and concrete;

hence improving the bond.

• At the time concrete is placed,

steel bars shall be free of mud

and oil that decreases the

bond.

13

13

Rebars Sizes (Metric & US Customary)

14

14

Part 2 – Concrete Materials Page 7

Steel Rebars

15

15

Steel Rebars

16

16

Part 2 – Concrete Materials Page 8

Steel Rebars

17

17

Coated Rebars

Structural elements can be subjected to severe

environmental conditions, such as:

1- bridge decks or parking garages subject to

deicing chemicals,

2- port and marine structures subject to sea

water,

3- wastewater treatment plants,

4- Bridge Columns under water or seabed.

In this case, the rebars can be specified as

galvanized (zinc coated) or epoxy-coated to

minimize corrosion of reinforcement and

consequent spalling of concrete

18

18

Part 2 – Concrete Materials Page 9

Coated Rebars

ASTM A767, “Standard Specification for Zinc-Coated (Galvanized)

Steel Bars for Concrete Reinforcement,” includes requirements for

the zinc coating material, the galvanizing process, the class or weight

of coating, finish and adherence of coating, and the method of

fabrication.

Bars are usually galvanized after cutting and bending. Supplementary

requirements pertain to coating of sheared ends and repair of

damaged coating if bars are fabricated after galvanizing.

19

19

Coated Rebars

Epoxy-coated bars, presently more widely used than galvanized bars,

are governed by ASTM A775, “Standard Specification for Epoxy-

Coated Reinforcing Steel Bars,” which includes requirements for the

coating material, surface preparation prior to coating, method of

application, and limits on coating thickness, and by ASTM A934,

“Standard Specification for Epoxy-Coated Prefabricated Steel

Reinforcing Bars.” Under ASTM A775, the coating is applied to

straight bars in a production-line operation, and bars are cut and bent

after coating. Under ASTM A934, bars are bent to final shape prior to

coating. Cut ends and small spots of damaged coating are suitably

repaired after fabrication. Extra care is required in the field to ensure

that the coating is not damaged during shipment and placing and that

repairs are made if necessary.

20

20

Part 2 – Concrete Materials Page 10

Fundamental Design Assumptions for

Reinforced Concrete Behavior

1. The internal forces (such as bending moments, shear, and

normal forces) at any section of a member are in

equilibrium with the effects of the external loads at that

section. This is not an assumption but a fact, because any

body or any portion thereof can be at rest only if all forces

acting on it are in equilibrium

21

21

Fundamental Design Assumptions for

Reinforced Concrete Behavior

2. The strain in an embedded reinforcing bar (either tension

or compression) is the same as that of the surrounding

concrete. It is assumed that perfect bonding exists between

concrete and steel at the interface, so that no slip can occur

between the two materials. Hence, deformation of both is

the same at the same location. With modern deformed bars,

a high degree of mechanical interlocking is provided.

In addition, the natural surface adhesion makes this

assumption very close to reality.

22

22

Part 2 – Concrete Materials Page 11

Fundamental Design Assumptions for

Reinforced Concrete Behavior

3. Cross sections that were plane prior to loading continue

to be plane in the member under load. Accurate

measurements have shown that when a reinforced concrete

member is loaded close to failure, this assumption is not

absolutely accurate. However, the deviations are usually

minor and the results of theory based on this assumption

check well with extensive test information.

23

23

Fundamental Design Assumptions for

Reinforced Concrete Behavior

4. In view of the fact that the tensile strength of concrete is only a

small fraction of its compressive strength, the concrete in that part

of a member which is in tension is usually cracked. While these

cracks, in well-designed members, are generally so narrow as to

be hardly visible (they are known as hairline cracks), they make

the cracked concrete incapable of resisting any tension stress.

Correspondingly, it is assumed that concrete is not capable of

resisting any tension stress whatsoever. This assumption is

evidently a simplification of the actual situation because, in fact,

concrete prior to cracking, as well as the concrete located between

cracks, does resist tension stresses of small magnitude. 24

24

Part 2 – Concrete Materials Page 12

Modular Ratio

Because the compression strain in the concrete, at any given load, is

equal to the compression strain in the steel,

fc f

c s s

Ec Es

from which the relation between the steel stress fs and the concrete

stress fc is obtained as:

Es

fs f c nf c

Ec

where n = Es/Ec is known as the modular ratio.

25

25

Modular Ratio

Let

Ac = net area of concrete, i.e., gross area minus area occupied by

reinforcing bars

Ag = gross area

Ast = total area of reinforcing bars

P = axial load

Then

P f c Ac f s Ast f c Ac nf c Ast

or P f c ( Ac nAst )

The term Ac + nAst can be interpreted as the area of a fictitious

concrete cross section, the transformed area, which when subjected

to the particular concrete stress fc results in the same axial load P as

the actual section composed of both steel and concrete.

26

26

Part 2 – Concrete Materials Page 13

Effect of Load rating on f’c

The curves for the two materials are (MPa)

(420)

drawn on the same graph using (42)

different vertical stress scales. Curve

b has the shape that would be (350) (35)

obtained in a concrete cylinder test.

The rate of loading in most structures (28)

(280)

is considerably slower than that in a

cylinder test, and this affects the shape

of the curve. Curve c, therefore, is (210) (21)

drawn as being characteristic of the

performance of concrete under slow (14)

(140)

loading. Under these conditions, tests

have shown that the maximum

reliable compressive strength of (70) (7)

reinforced concrete is about 0.85f ′c ,

as shown.

27

27

Steel: Tension and Compression Stress‐Strain Curve

Actual tensile and compressive ACI idealized tensile and compressive

stress-strain curve for steel bars stress-strain curve for steel bars

fs

Perfectly plastic

fy

Elastic-perfectly plastic curve

(increase in strength due to strain

Es hardening is neglected)

1

y = yield strain s

fy is the specified yield strength for the deformed reinforcement. It is

the same in tension and compression. The value of fy used in design

calculations shall not exceed 550 MPa, except for spiral transverse

reinforcement used in columns.

Always use fy ≤ 420 MPa. 28

28

Part 2 – Concrete Materials Page 14

Steel: Tension and Compression Stress‐Strain Curve

Es = modulus of elasticity of steel = 200GPa

Since Es >> Ec

then

Es

modular ratio : n 1.0

Ec

fy when s y f s E s s

y Yield strain

E s when s y f s f y

Note that ws = unit weight of steel = 7,850 kg/m3

29

29

Example 2.1

• A cylindrical concrete specimen with 150 mm

diameter and 300 mm height is tested in

compression after 28 days of production. It

attains a maximum compressive load of 530

kN in the process of testing till failure

(crushing). The concrete is normal weight.

1. What is the concrete compressive strength, fc’?

2. What is the modulus of elasticity of the concrete , Ec?

3. What is the concrete strain at the end of the linear range of the

compressive stress‐strain curve of this concrete specimen?

4. What is the modular ratio, n?

30

30

Part 2 – Concrete Materials Page 15

Solution

1502

1. Pmax 530kN 530,000 N , A 17,670mm 2

4

530,000

f c' 30MPa

17,670

2. Normal weight concrete Ec 4,700 30 25,740 MPa

Stress @ end of linear range 0.4530

3. c 0.0005245

Ec 25,740

200,000

4. n 7.77

25,740

31

31

Example 2.2

• A steel bar with 16 mm diameter (i.e. No. 16 or

16: db=16 mm, Ab=199 mm2) has a specified yield

strength fy = 420 MPa.

1. What is the yield strain, y?

2. What is the stress in the steel bar, fs, @ a strain s =

0.004? @ a strain s = 0.0012?

3. What is the weight of the bar in kg/m?

32

32

Part 2 – Concrete Materials Page 16

Solution

fy 420

1. y 0.0021

Es 200,000

2. @ s 0.004 y f s f y 420MPa

@ s 0.0012 y f s 200,0000.0012 240MPa

3. Weight = (bar cross‐sectional area)(unit weight)

Ab ws

1m 2 kgf kg

199mm . 6

2

7,850 3 1.56

2

10 mm m m 33

33

Part 2 – Concrete Materials Page 17

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- EN2314 Hydraulics - Formula Sheet 30oct19 PDFDocument3 pagesEN2314 Hydraulics - Formula Sheet 30oct19 PDFmohamedyahaiNo ratings yet

- Hamill 2011 - Solutions Chapter 09Document6 pagesHamill 2011 - Solutions Chapter 09mohamedyahai100% (1)

- EN2314 Hydraulics - Module Booklet of Exam Style Questions - Summer Exam 05may20Document5 pagesEN2314 Hydraulics - Module Booklet of Exam Style Questions - Summer Exam 05may20mohamedyahaiNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 0 HYFM300 CW LabDocument3 pages0 HYFM300 CW LabmohamedyahaiNo ratings yet

- General Notes and Standard Details: Rafter DetailDocument1 pageGeneral Notes and Standard Details: Rafter DetailLiza MarieNo ratings yet

- Unit 8 (SERVICEABILITY LIMIT STATE (SLS) )Document26 pagesUnit 8 (SERVICEABILITY LIMIT STATE (SLS) )Zara Nabilah100% (2)

- Compression Test For MetalsDocument11 pagesCompression Test For MetalsmohamedyahaiNo ratings yet

- Cost Control: Tender /construction: Boq - SchedulesDocument21 pagesCost Control: Tender /construction: Boq - SchedulesmohamedyahaiNo ratings yet

- Lecture Sessions 7-9: Principles of Management Cost Modeling and EstimatingDocument13 pagesLecture Sessions 7-9: Principles of Management Cost Modeling and EstimatingmohamedyahaiNo ratings yet

- Procurement and Cost TCQDocument10 pagesProcurement and Cost TCQmohamedyahaiNo ratings yet

- EN2314 Hydraulics - Lecture Notes 08 - 09mar20 PDFDocument12 pagesEN2314 Hydraulics - Lecture Notes 08 - 09mar20 PDFmohamedyahaiNo ratings yet

- Eurocode 7-Easily Explained: The CodeDocument4 pagesEurocode 7-Easily Explained: The CodemohamedyahaiNo ratings yet

- Cive 3261 - Revision Cost StudiesDocument10 pagesCive 3261 - Revision Cost StudiesmohamedyahaiNo ratings yet

- EN2314 Hydraulics - Lecture Notes 05 - 28jan20Document14 pagesEN2314 Hydraulics - Lecture Notes 05 - 28jan20mohamedyahaiNo ratings yet

- EN2314 Hydraulics - Lecture Notes 08 - 09mar20Document12 pagesEN2314 Hydraulics - Lecture Notes 08 - 09mar20mohamedyahaiNo ratings yet

- Session 7 - Shear Strength of SoilsDocument27 pagesSession 7 - Shear Strength of SoilsmohamedyahaiNo ratings yet

- EN2314 Hydraulics - Formula Sheet 30oct19Document3 pagesEN2314 Hydraulics - Formula Sheet 30oct19mohamedyahaiNo ratings yet

- Hamill 2011 - Solutions Chapter 08Document11 pagesHamill 2011 - Solutions Chapter 08mohamedyahaiNo ratings yet

- Session 9.1 - Compaction PDFDocument10 pagesSession 9.1 - Compaction PDFmohamedyahaiNo ratings yet

- Session 8.2 - Slope StabilzationDocument9 pagesSession 8.2 - Slope StabilzationmohamedyahaiNo ratings yet

- Session 10.1 - Site InvestigationDocument34 pagesSession 10.1 - Site InvestigationmohamedyahaiNo ratings yet

- Session 9.1 - Compaction PDFDocument10 pagesSession 9.1 - Compaction PDFmohamedyahaiNo ratings yet

- Session 3.1 - Soil Classification and DescriptionDocument19 pagesSession 3.1 - Soil Classification and DescriptionmohamedyahaiNo ratings yet

- Mock 20Xx Examinations: Paper Code NO. EN4630/ENT630Document14 pagesMock 20Xx Examinations: Paper Code NO. EN4630/ENT630mohamedyahaiNo ratings yet

- Ent501r Ent515rDocument5 pagesEnt501r Ent515rmohamedyahaiNo ratings yet

- ENT501 Numerical Techniques in Civil Engineering - BookletDocument11 pagesENT501 Numerical Techniques in Civil Engineering - BookletmohamedyahaiNo ratings yet

- Stability Systems PDFDocument4 pagesStability Systems PDFmohamedyahaiNo ratings yet

- Structural StabilityDocument4 pagesStructural Stabilitymohamedyahai100% (1)

- Whole Body Vibration Standarized Safety LevelsDocument1 pageWhole Body Vibration Standarized Safety LevelsmohamedyahaiNo ratings yet

- Conceptual DesignDocument4 pagesConceptual DesignmohamedyahaiNo ratings yet

- Chapter 8. Numerical Solution of Ordinary Differential EquationsDocument18 pagesChapter 8. Numerical Solution of Ordinary Differential EquationsmohamedyahaiNo ratings yet

- 5.4 Numerical Integration: D D F AreaDocument18 pages5.4 Numerical Integration: D D F AreamohamedyahaiNo ratings yet

- Halfen Cast-In Channels: HTA-CE 50/30P HTA-CE 40/22PDocument92 pagesHalfen Cast-In Channels: HTA-CE 50/30P HTA-CE 40/22PTulusNo ratings yet

- CE 311 MODULE 4 - Structural Analysis of FramesDocument23 pagesCE 311 MODULE 4 - Structural Analysis of FramesBryanHarold BrooNo ratings yet

- Shay Murtag Precast BeamsDocument49 pagesShay Murtag Precast BeamsMilind GuptaNo ratings yet

- The Y BeamDocument7 pagesThe Y BeamSivakumarNo ratings yet

- 1.1 Concrete: Partial Replacement of Coarse Aggregate With Ceramic Tile 2019-2020Document25 pages1.1 Concrete: Partial Replacement of Coarse Aggregate With Ceramic Tile 2019-2020Naveen S100% (2)

- RETAINING WALL-ModelDocument1 pageRETAINING WALL-ModelArchana PansareNo ratings yet

- Lecture-1 - Introduction To BridgesDocument109 pagesLecture-1 - Introduction To Bridgesjoy cho100% (1)

- 1993 AndradeDocument12 pages1993 AndradeDaniel JamesNo ratings yet

- Defect Danone l9 CompilationDocument12 pagesDefect Danone l9 CompilationJimmy_JambulNo ratings yet

- RAM Connection Standalone CE ReportDocument2 pagesRAM Connection Standalone CE ReportjasekanNo ratings yet

- PCI Sandwich Wall Panels SOA Guide Rev (1!11!11)Document62 pagesPCI Sandwich Wall Panels SOA Guide Rev (1!11!11)Nuno FerreiraNo ratings yet

- Preliminary Design Rules of ThumbDocument11 pagesPreliminary Design Rules of Thumbnimal1234No ratings yet

- Bridge Column Design Based On AASHTO 17th & ACI 318-14: Input Data & Design SummaryDocument5 pagesBridge Column Design Based On AASHTO 17th & ACI 318-14: Input Data & Design SummaryPn EkanayakaNo ratings yet

- Dramix® Steel Fibre Reinforcement For Concrete Tunnel LiningsDocument24 pagesDramix® Steel Fibre Reinforcement For Concrete Tunnel LiningsHeri SiswantoNo ratings yet

- Catalogo FischerDocument52 pagesCatalogo FischerVictor Manuel BonettoNo ratings yet

- Prokon FootingDocument58 pagesProkon Footingmbhanusagar.keynesNo ratings yet

- Typical Stair DetailsDocument1 pageTypical Stair DetailsM IQbalNo ratings yet

- QCS 2010 Section 4 Part 10 Static Load Testing of Piles PDFDocument14 pagesQCS 2010 Section 4 Part 10 Static Load Testing of Piles PDFbryanpastor106No ratings yet

- Construction of Multi-Purpose Building (MPB) in Datu Mamintal National High School, Bubong, Lanao Del SurDocument31 pagesConstruction of Multi-Purpose Building (MPB) in Datu Mamintal National High School, Bubong, Lanao Del SurSalaman II Bongcarawan MangcaNo ratings yet

- A TowerDocument4 pagesA Towerriz2010No ratings yet

- Bbs Pot. Besi RS MTDocument8 pagesBbs Pot. Besi RS MTAmudNo ratings yet

- What Is Precast ConcreteDocument27 pagesWhat Is Precast ConcreteMarrielle BalagotNo ratings yet

- UB 203x102x23: Cross-Section PropertiesDocument2 pagesUB 203x102x23: Cross-Section PropertiesRanjit S KashyapNo ratings yet

- Excavation Design in Stratified RockDocument14 pagesExcavation Design in Stratified RockRobert PrinceNo ratings yet

- 05-05 Vikarabad Shops V Venkatesh - 001Document55 pages05-05 Vikarabad Shops V Venkatesh - 001deerangareddyofficeNo ratings yet

- Number:: 2045 Placentia Avenue Costa Mesa, California 92627Document12 pagesNumber:: 2045 Placentia Avenue Costa Mesa, California 92627CarsonBakerNo ratings yet

- 2933 Tencent Seafront Tower Practice On Binding BuildingsDocument8 pages2933 Tencent Seafront Tower Practice On Binding BuildingskhatribharatNo ratings yet

- Behavior of Cantilever SlabsDocument1 pageBehavior of Cantilever Slabsatoz2033No ratings yet