Professional Documents

Culture Documents

Ase102:Aerospace Materials and Processes: Session 2019-20 Page:1/1

Ase102:Aerospace Materials and Processes: Session 2019-20 Page:1/1

Uploaded by

Yashwanth Krishna GampaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ase102:Aerospace Materials and Processes: Session 2019-20 Page:1/1

Ase102:Aerospace Materials and Processes: Session 2019-20 Page:1/1

Uploaded by

Yashwanth Krishna GampaCopyright:

Available Formats

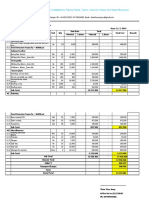

ASE102:AEROSPACE MATERIALS AND PROCESSES

L:3 T:0 P:0 Credits:3

Course Outcomes: Through this course students should be able to

CO1 :: Describe the basics of materials engineering, starting from atoms to crystal lattices and its

final effects on the property of the material.

CO2 :: Analyze and gain knowledge about the fundamentals of phase diagrams, basics of Fe,

Steel, Iron - Iron Carbide diagram.

CO3 :: Classify various heat treatment processes and importance of surface hardening processes.

CO4 :: Identify the materials and manufacturing processes used to fabricate advanced aerospace

structures.

Unit I

The structure of crystalline solids : Fundamental concepts, Unit cells, Metallic crystalline

structures, Density computations, Polymorphism and allotropy, Crystal systems, Crystallographic

directions and planes, Miller indices, Linear and planar atomic densities, Close-packed crystal

structures, Single crystals, Polycrystalline materials, Periodic Table and Classification, Bonding in

Solids - Metallic Bonds, Crystallization of metals, Grain and Grain Boundaries, Effect of Grain

Boundaries on Properties of Metals/ Alloys

Unit II

Imperfection in Solids and Strengthening of Metals : Introduction to Defects and Classification,

Strengthening of Metals by Grain Size reduction, Point Defects, Line Defects, Surface Defects &

Volume Defects, Atomic Vibrations, Strain Hardening, Recovery, Recrystallization and Grain Growth

Unit III

Alloys and Phase Diagrams : Definitions and Basic Concepts, Solubility Limit, Necessity of Alloying

and Types of Solid Solutions, Phases, Unary Phase Diagram,, Lever Rule and Gibbs Phase rule, Binary

Eutectic System, Eutectoid and Peritectic Systems, The Iron - Iron Carbide Phase Diagram, Binary

Isomorphous System, Important Binary Phase Diagrams of Cu-Ni, Ag-Cu, Sn-Pb

Unit IV

Heat Treatment Processes : Process Annealing, Stress relief, Annealing of Ferrous Alloys, Heat

treatment of steels, Normalizing, Quenching and Tempering, Hardenability, Influence of Quenching

Medium, TTT Diagram, Hardening, Surface Hardening Treatments, Age Hardening Treatments

Unit V

Aerospace Materials : Aluminum, Titanium, Magnesium, Beryllium, High strength steels, Super-

alloys, Composites, Metallurgical Considerations Related to Above Stated Materials, Alloys of Al, Mg,

Ti, Mechanical Properties of Materials-Ductility, Strength, Stiffness, Young's Modulus, Hooke's Law,

Resilience, Modulus of Resilience, Fracture Strength, True Stress vs Engineering Stress, True Strain vs

Engineering Strain

Unit VI

Processing of Aerospace Materials : Processing Techniques for Al, Fabrication of Mg and

Beryllium, Melting and Primary Fabrication of Ti, Forging, Forming and Investment Casting,

Fabrication of Medium Carbon Low Alloy Steels, Maraging Steels, Precipitation Hardening Stainless

Steels, Powder Metallurgy, Forging, Forming and Investment Casting of Super-Alloys, Processing of

Polymer Matrix Composites, Processing of Metal Matrix Composites, Fabrication of Ceramic Matrix

Composites

Text Books:

1. CALLISTER'S MATERIALS SCIENCE AND ENGINEERING, 2ED, W/CD by R.

BALASUBRAMANIAM, WILEY

References:

1. MANUFACTURING TECHNOLOGY FOR AEROSPACE STRUCTURAL MATERIALS by F.C.

CAMPBELL, ELSEVIER

Session 2019-20 Page:1/1

You might also like

- Material Science & MetallurgyDocument2 pagesMaterial Science & MetallurgyBhavesh Pipaliya0% (1)

- Lesson Plan: Page 1 of 6 Unit: I Branch: B.E. Mechanical Engg. Semester: IVDocument6 pagesLesson Plan: Page 1 of 6 Unit: I Branch: B.E. Mechanical Engg. Semester: IVDinesh Kumar RNo ratings yet

- Mett.7th SemDocument9 pagesMett.7th SemLokesh DahiyaNo ratings yet

- Material SciencesDocument2 pagesMaterial SciencesSaikiran Bobde KshatriyaNo ratings yet

- Gujarat Technological University Automobile Engineering (02) /mechanical EngineeringDocument4 pagesGujarat Technological University Automobile Engineering (02) /mechanical EngineeringJay RajguruNo ratings yet

- ME3392 SyllabusDocument2 pagesME3392 Syllabusmanoj1316kumar_63152No ratings yet

- Engineering Materials (Me - 213)Document2 pagesEngineering Materials (Me - 213)Umar ChNo ratings yet

- Mms Syllabus r10Document1 pageMms Syllabus r10sureshbabuchallariNo ratings yet

- Mangalore Institute of Technology and Engineering: Material Science and MetallurgyDocument203 pagesMangalore Institute of Technology and Engineering: Material Science and MetallurgyNISHAANTH S 1861462No ratings yet

- Me209 Mechanical Properties of Structural Materials PDFDocument4 pagesMe209 Mechanical Properties of Structural Materials PDFjishnuNo ratings yet

- ME3392Document2 pagesME3392pityraj2003No ratings yet

- Emr 2201 Engineering Materials I Year 2 Bsc. Marine EngineeringDocument29 pagesEmr 2201 Engineering Materials I Year 2 Bsc. Marine EngineeringAhmed O MohamedNo ratings yet

- M&MSDocument2 pagesM&MSASIST MechNo ratings yet

- Engg Metallurgy Study MaterialDocument178 pagesEngg Metallurgy Study Material7 D24 ANSHUMAN PATILNo ratings yet

- Metallurgy SyllabusDocument1 pageMetallurgy SyllabusSathrudhan ChoudharyNo ratings yet

- PHRE 415 - Metallurgy and Workshop PracticesDocument2 pagesPHRE 415 - Metallurgy and Workshop Practicesasphaltnoob8No ratings yet

- MT 010 601 Non Ferrous Physical MetallurgyDocument2 pagesMT 010 601 Non Ferrous Physical Metallurgyവിഷ്ണു സിNo ratings yet

- Regarding The Syllabus of The Written Test For PHD Admission (In The Department of Metallurgical and Materials Engineering)Document2 pagesRegarding The Syllabus of The Written Test For PHD Admission (In The Department of Metallurgical and Materials Engineering)chauhan100% (1)

- Engineering MaterialDocument2 pagesEngineering Materialultimatestatus2279No ratings yet

- Cruystal Structure CHP 1Document23 pagesCruystal Structure CHP 1pavanvasanth kommineniNo ratings yet

- Bmee209l Materials-science-And-Engineering TH 1.0 67 Bmee209lDocument3 pagesBmee209l Materials-science-And-Engineering TH 1.0 67 Bmee209lKrijayNo ratings yet

- B. TECH. (4 Semester) Mechanical Engineering Material Science (Me - 204 E)Document2 pagesB. TECH. (4 Semester) Mechanical Engineering Material Science (Me - 204 E)Jai SheokandNo ratings yet

- 7 MetallurgyDocument2 pages7 MetallurgyNarasimha Murthy InampudiNo ratings yet

- ME309 Metallurgy and Material Science PDFDocument4 pagesME309 Metallurgy and Material Science PDFPremnath G100% (1)

- 4th Semester SyllabusDocument8 pages4th Semester Syllabus006KAbhishek KumarNo ratings yet

- EMMDocument159 pagesEMMDaniel DasNo ratings yet

- ME 210 Metallurgy and Materials EngineeringDocument5 pagesME 210 Metallurgy and Materials EngineeringkannanNo ratings yet

- EME Module 2Document31 pagesEME Module 2Yashaswini AnandNo ratings yet

- ME 210 Metallurgy and Materials EngineeringDocument5 pagesME 210 Metallurgy and Materials Engineeringnandan144No ratings yet

- ME511-Advanced Materials and Processes-CourseplanDocument2 pagesME511-Advanced Materials and Processes-CourseplananandandmeenaNo ratings yet

- B Tech Aeronautical Syllabus PDFDocument45 pagesB Tech Aeronautical Syllabus PDFNizam muddinNo ratings yet

- Sixth Semester: Teaching Scheme Credits 4 ObjectivesDocument15 pagesSixth Semester: Teaching Scheme Credits 4 ObjectivesNitin RautNo ratings yet

- Introduction To Materials Science - HistoryDocument5 pagesIntroduction To Materials Science - HistoryBhaskara P AcharNo ratings yet

- Elements of Matallurgy & Materials ScienceDocument2 pagesElements of Matallurgy & Materials Sciencebhati_mukesh89No ratings yet

- ME6403 Emm SyllabusDocument1 pageME6403 Emm SyllabusdsathiyaNo ratings yet

- B.tech Automobile (III VIII Sem) W.e.f2012 13Document48 pagesB.tech Automobile (III VIII Sem) W.e.f2012 13Kuldeep BhattacharjeeNo ratings yet

- Material Science SyllabusDocument2 pagesMaterial Science Syllabus1DA20ME023 Girish M BNo ratings yet

- .NG Mec 224 Properties of Mat TheoryDocument73 pages.NG Mec 224 Properties of Mat TheoryYusuf taiwoNo ratings yet

- Applied Metallurgy by WMDocument162 pagesApplied Metallurgy by WMwilson moNo ratings yet

- EmmDocument1 pageEmmBalaji KingNo ratings yet

- Material Science and Engineering: (Common To Mechanical Engineering and Mechanical Engineering (Robotics) )Document2 pagesMaterial Science and Engineering: (Common To Mechanical Engineering and Mechanical Engineering (Robotics) )suneethaNo ratings yet

- Engineering MaterialsDocument2 pagesEngineering MaterialsRïtämPäl100% (1)

- Material Science & MetallurgyDocument2 pagesMaterial Science & Metallurgysameer_m_daniNo ratings yet

- 1 THDocument2 pages1 THAditya TNo ratings yet

- ME 2203 Engineering Materials: Dr. Kazi MD ShorowordiDocument5 pagesME 2203 Engineering Materials: Dr. Kazi MD ShorowordiTahmim AlamNo ratings yet

- 12M304Document2 pages12M304vinaysammNo ratings yet

- Unit 1Document280 pagesUnit 1Abhishek ChavanNo ratings yet

- Introduction To Engineering Materials Subject Code: Che-302: Instructor: Engr. Shazia Naz MalikDocument5 pagesIntroduction To Engineering Materials Subject Code: Che-302: Instructor: Engr. Shazia Naz MalikZarar SaleemNo ratings yet

- The Effects of Alloying Elements On Steels 1Document36 pagesThe Effects of Alloying Elements On Steels 1Common ManNo ratings yet

- Mf5103 Advances in Casting and Welding: For Syllabus, Question Papers, Notes & Many MoreDocument2 pagesMf5103 Advances in Casting and Welding: For Syllabus, Question Papers, Notes & Many MoreNandha Gopal SenthilnathanNo ratings yet

- Corrosion-Resistant Component For PEM Fuel Cells: Shuo-Jen Lee, Ching-Han Huang, Jian-Jang Lai, Yu-Pang ChenDocument7 pagesCorrosion-Resistant Component For PEM Fuel Cells: Shuo-Jen Lee, Ching-Han Huang, Jian-Jang Lai, Yu-Pang ChenSoh Ming LunNo ratings yet

- Engineering MetallurgyDocument2 pagesEngineering MetallurgyROOSSVELT PRABHU K A VNo ratings yet

- Mmse Apj KtuDocument5 pagesMmse Apj KtuSherwinNo ratings yet

- Course Plan: Department of Mechanical EngineeringDocument12 pagesCourse Plan: Department of Mechanical EngineeringMalagouda PatilNo ratings yet

- Metallurgy 5th Ed 1977 PDFDocument483 pagesMetallurgy 5th Ed 1977 PDFanon_435115635No ratings yet

- ESDEP Vol0302Document124 pagesESDEP Vol0302aladinmf1No ratings yet

- Note For Introduction To Materials MST 510Document147 pagesNote For Introduction To Materials MST 510Khairul BarsriNo ratings yet

- Module 8Document19 pagesModule 8Sundresh NNo ratings yet

- High Temperature Corrosion: Fundamentals and EngineeringFrom EverandHigh Temperature Corrosion: Fundamentals and EngineeringNo ratings yet

- Course Code Course Title Course Planner: Through This Course Students Should Be Able ToDocument6 pagesCourse Code Course Title Course Planner: Through This Course Students Should Be Able ToYashwanth Krishna GampaNo ratings yet

- Course Code Course Title Course Planner: Through This Course Students Should Be Able ToDocument7 pagesCourse Code Course Title Course Planner: Through This Course Students Should Be Able ToYashwanth Krishna GampaNo ratings yet

- Course Code Course Title Course Planner: Through This Course Students Should Be Able ToDocument8 pagesCourse Code Course Title Course Planner: Through This Course Students Should Be Able ToYashwanth Krishna GampaNo ratings yet

- Course Code Course Title Course Planner: Through This Course Students Should Be Able ToDocument2 pagesCourse Code Course Title Course Planner: Through This Course Students Should Be Able ToYashwanth Krishna GampaNo ratings yet

- Course Code Course Title Course Planner: Through This Course Students Should Be Able ToDocument5 pagesCourse Code Course Title Course Planner: Through This Course Students Should Be Able ToYashwanth Krishna GampaNo ratings yet

- Smec 216Document1 pageSmec 216Yashwanth Krishna GampaNo ratings yet

- SpythonDocument1 pageSpythonYashwanth Krishna GampaNo ratings yet

- MTH167Document1 pageMTH167Yashwanth Krishna GampaNo ratings yet

- RPT Ip Print NewDocument10 pagesRPT Ip Print NewYashwanth Krishna GampaNo ratings yet

- FRM Course Syllabus IPDownloadDocument1 pageFRM Course Syllabus IPDownloadYashwanth Krishna GampaNo ratings yet

- SET-A (Test - 2 Even Numbers) : Ase344 - Helicopter Theory and AerodynamicsDocument1 pageSET-A (Test - 2 Even Numbers) : Ase344 - Helicopter Theory and AerodynamicsYashwanth Krishna GampaNo ratings yet

- Ase317: Space Dynamics Answer All The Question: 3 X 10 30Document9 pagesAse317: Space Dynamics Answer All The Question: 3 X 10 30Yashwanth Krishna GampaNo ratings yet

- ASTM A194-A194M 2010 (Carbon and Alloy Steek Nuts For Bolts)Document11 pagesASTM A194-A194M 2010 (Carbon and Alloy Steek Nuts For Bolts)Acricia PereiraNo ratings yet

- GP 09-04-01Document31 pagesGP 09-04-01Anbarasan Perumal100% (1)

- Tsurumi: Submersible EjectorsDocument8 pagesTsurumi: Submersible EjectorsDio MiNo ratings yet

- Spot Welding PDFDocument6 pagesSpot Welding PDFjames.anitNo ratings yet

- Cold Forming Glossary of Terms PDFDocument17 pagesCold Forming Glossary of Terms PDFLuis LujanoNo ratings yet

- Is 2486 1 1993Document18 pagesIs 2486 1 1993SatyaNo ratings yet

- QCR W 2001Document4 pagesQCR W 2001Madhan KannanNo ratings yet

- Building Materials and Construction Techniques: Traction Elevator-Group3Document47 pagesBuilding Materials and Construction Techniques: Traction Elevator-Group3Gayathri kalkiNo ratings yet

- Steel Surfaces A Guide To Alloys Finishes Fabrication and Maintenance in Architecture and Art 1St Edition L William Zahner All ChapterDocument68 pagesSteel Surfaces A Guide To Alloys Finishes Fabrication and Maintenance in Architecture and Art 1St Edition L William Zahner All Chaptercharlotte.nichols292100% (6)

- Car Truss PDFDocument2 pagesCar Truss PDFThein Than AungNo ratings yet

- Compact Stainless Steel Water Regulators Specification SheetDocument2 pagesCompact Stainless Steel Water Regulators Specification SheetWattsNo ratings yet

- CSF-71T Technical Report EN - V2Document7 pagesCSF-71T Technical Report EN - V2Miroslav ThôngNo ratings yet

- Welded ConnectionsDocument8 pagesWelded ConnectionsALONSO GOMEZNo ratings yet

- Simboluri SudareDocument8 pagesSimboluri SudarecornelutsNo ratings yet

- DR - 011123 - Project Fujimaki - EDKDocument2 pagesDR - 011123 - Project Fujimaki - EDKMuhammad RozaqNo ratings yet

- JSW Steel Full 2010Document106 pagesJSW Steel Full 2010Nishant SharmaNo ratings yet

- Internal Linings: NIOEC-SP-80-05Document11 pagesInternal Linings: NIOEC-SP-80-05aminNo ratings yet

- Approved 06 01 2014Document12 pagesApproved 06 01 2014DukeNo ratings yet

- Wearplate en 09v5Document3 pagesWearplate en 09v5BepdjNo ratings yet

- Heat Treatment - NewDocument67 pagesHeat Treatment - Newsyamimi balkhisNo ratings yet

- Aisi 4140 SteelDocument3 pagesAisi 4140 SteelduhkacttusNo ratings yet

- SAE J403 Grade 1055: Matmatch Is Trusted by 2 Million+ Engineers and Product Developers Each YearDocument4 pagesSAE J403 Grade 1055: Matmatch Is Trusted by 2 Million+ Engineers and Product Developers Each YearALEX MURPHYNo ratings yet

- Cov Fast Stainless Steel Cat - 3rd Ed - Jun 09Document116 pagesCov Fast Stainless Steel Cat - 3rd Ed - Jun 09jaffliangNo ratings yet

- Lime in Iron OreDocument14 pagesLime in Iron Oreranjeet_nismNo ratings yet

- En19 Steel - 4140 - 1.7225 - Scm440 - 42crmo4: Related Specifications Astm A29/A29M Din en 10083/3 Jis G4053 GB GB/TDocument7 pagesEn19 Steel - 4140 - 1.7225 - Scm440 - 42crmo4: Related Specifications Astm A29/A29M Din en 10083/3 Jis G4053 GB GB/THugh O'Brien GwazeNo ratings yet

- Astm G 35 PDFDocument3 pagesAstm G 35 PDFJORGE ARTURO TORIBIO HUERTANo ratings yet

- Aws SWPS B2.1-1-003Document18 pagesAws SWPS B2.1-1-003wknuttzenNo ratings yet

- Steel Grades Equivalence TableDocument16 pagesSteel Grades Equivalence Tabletwintwinkai100% (3)

- Actuador Serie 92Document6 pagesActuador Serie 92Jorge Henostroza IntiNo ratings yet

- Basketball Equipment SpecificationDocument11 pagesBasketball Equipment Specificationsumit potdarNo ratings yet