Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

20 viewsMD - CP - Problem Statement

MD - CP - Problem Statement

Uploaded by

Sohan kulalThe document describes the design of a screw jack to lift a 3000kg pickup truck 850mm. It selects materials for each component based on the stresses it will experience and cost considerations. The frame and cup are made of grey cast iron for its compressive strength and ease of forming complex shapes. A steel is chosen for the screw and handle for its strength. A softer phosphor bronze nut is paired with the steel screw to reduce wear.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You might also like

- How TG-X Filler Rods Can Eliminate Back Shielding: Kobelco Welding TodayDocument2 pagesHow TG-X Filler Rods Can Eliminate Back Shielding: Kobelco Welding TodaysatheeshNo ratings yet

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- Utp Cast Iron GBDocument8 pagesUtp Cast Iron GBhrk100No ratings yet

- Technical Information No. 1: Grey Lamellar Graphite Cast IronDocument2 pagesTechnical Information No. 1: Grey Lamellar Graphite Cast IronMOHAMMAD ASIFNo ratings yet

- Wd-Full (Archi+structure)Document42 pagesWd-Full (Archi+structure)Joel Jeffery SarkarNo ratings yet

- Hot-Dip Galvanizing Service: BS 729:1971 Hot-Dip Galvanized Coatings On Iron & Steel ArticlesDocument2 pagesHot-Dip Galvanizing Service: BS 729:1971 Hot-Dip Galvanized Coatings On Iron & Steel ArticleshbookNo ratings yet

- A) Material and B) ConsumablesDocument3 pagesA) Material and B) ConsumablesazaharNo ratings yet

- Seam Strength of Corrugated Plate With High Strength SteelDocument15 pagesSeam Strength of Corrugated Plate With High Strength SteelMariano SalcedoNo ratings yet

- Welding Chart The Complete Reference Guide To WeldingDocument2 pagesWelding Chart The Complete Reference Guide To WeldingJitu JenaNo ratings yet

- 1371755070249-Reinforced Cement ConcreteDocument74 pages1371755070249-Reinforced Cement ConcreteAbdirahman AbukarNo ratings yet

- FT Ros enDocument14 pagesFT Ros enmarjan banooNo ratings yet

- Cast Iron Vs Ductile IronDocument2 pagesCast Iron Vs Ductile IronFekre RaziNo ratings yet

- Investment CastingDocument8 pagesInvestment Castingbandit96No ratings yet

- En GJL 250Document2 pagesEn GJL 250Jitendra BhosaleNo ratings yet

- 1018 Bronze Ferrule Cock (Medium) : Salient FeaturesDocument22 pages1018 Bronze Ferrule Cock (Medium) : Salient FeaturesSanket PhatangareNo ratings yet

- 3 MaterialDocument15 pages3 MaterialRajNo ratings yet

- Dme PDFDocument8 pagesDme PDFAbhishek ChauhanNo ratings yet

- Cold Formed Steel Members and SheetingDocument14 pagesCold Formed Steel Members and SheetingMihai MariusNo ratings yet

- Paperpdf 1597754539Document10 pagesPaperpdf 1597754539Aadarsh SharmaNo ratings yet

- Abrasive Profile Comparator ChartDocument1 pageAbrasive Profile Comparator Chartsflynn79100% (1)

- Notes:: Copy of Electrode Selection ChartDocument2 pagesNotes:: Copy of Electrode Selection Chartmalika_00No ratings yet

- Besi Yuda 231023Document3 pagesBesi Yuda 231023Girah Sakha RamadiansyahNo ratings yet

- YAN Real Estate Floor Modification BOQDocument4 pagesYAN Real Estate Floor Modification BOQDAWITNo ratings yet

- Piping Material DetailsDocument12 pagesPiping Material DetailsJay Vinoth100% (2)

- Besi Uber 2023-03-22Document2 pagesBesi Uber 2023-03-22Gema PutraNo ratings yet

- En PP TPS Extended Surface TubesDocument32 pagesEn PP TPS Extended Surface Tubesfah ruNo ratings yet

- 277 - Galvanised Steel SheetsDocument10 pages277 - Galvanised Steel SheetsKaushik SenguptaNo ratings yet

- B 101 - 01 Qjewms1sruqDocument7 pagesB 101 - 01 Qjewms1sruqFadjar ZulkarnainNo ratings yet

- Not For SaleDocument3 pagesNot For SaleSwati SharmaNo ratings yet

- Cast Iron Vs Ductile IronDocument2 pagesCast Iron Vs Ductile IronJayakrishnan RadhakrishnanNo ratings yet

- AZ024 Lecture 7 Steel ConnectionDocument14 pagesAZ024 Lecture 7 Steel ConnectionTong Kin Lun100% (15)

- Tps OHLDocument88 pagesTps OHLNaseem AhmedNo ratings yet

- DIN 17100 ST 37-2 SteelDocument2 pagesDIN 17100 ST 37-2 SteelSiddiqui Abdul KhaliqNo ratings yet

- Indotest Multi LaboratamaDocument3 pagesIndotest Multi LaboratamaRangga Padma NugrahaNo ratings yet

- Design No. D759: October 31, 2003Document9 pagesDesign No. D759: October 31, 2003souravrobinNo ratings yet

- Besi Uber 20230712Document3 pagesBesi Uber 20230712egaNo ratings yet

- Carbon Steel Catalog of SuppliersDocument24 pagesCarbon Steel Catalog of SuppliersRuano Andreola StumpfNo ratings yet

- Special Steel Structures - Courses - 2013Document253 pagesSpecial Steel Structures - Courses - 2013Largu George DanielNo ratings yet

- 1087 Bronze Double Regulating Balancing Valve (Screwed) With NozzleDocument2 pages1087 Bronze Double Regulating Balancing Valve (Screwed) With NozzleSanket PhatangareNo ratings yet

- Shear Load CalculationDocument8 pagesShear Load Calculationvinny1978No ratings yet

- Talja Et Al ENDocument14 pagesTalja Et Al ENStructural TenderNo ratings yet

- Specification Ss-20/5 Steel Structures For Substation and Switching Station MaterialDocument5 pagesSpecification Ss-20/5 Steel Structures For Substation and Switching Station MaterialharrisvasNo ratings yet

- Blind Flange Design For 8", 600#, 15B Service LineDocument2 pagesBlind Flange Design For 8", 600#, 15B Service LineGohar ZamanNo ratings yet

- 1078 Butter y Valve (Wafer Type) PN 16 With S.G Iron Disc: Salient FeaturesDocument17 pages1078 Butter y Valve (Wafer Type) PN 16 With S.G Iron Disc: Salient FeaturesSanket PhatangareNo ratings yet

- Standard Specification For Corrugated Steel Structural Plate, Zinc-Coated, For Field-Bolted Pipe, Pipe-Arches, and ArchesDocument17 pagesStandard Specification For Corrugated Steel Structural Plate, Zinc-Coated, For Field-Bolted Pipe, Pipe-Arches, and Archesjun floresNo ratings yet

- Welding Electrode ChartDocument2 pagesWelding Electrode ChartZaheed Manoo50% (2)

- StrainerDocument2 pagesStrainermayNo ratings yet

- Technical Report: How TGX Filler Rods Can Eliminate Back ShieldingDocument2 pagesTechnical Report: How TGX Filler Rods Can Eliminate Back ShieldingSamuel LatumahinaNo ratings yet

- ZolotoIndustries BSENISO17292Document6 pagesZolotoIndustries BSENISO17292anderson_bicudoNo ratings yet

- General Description of Steel Structure DesignDocument17 pagesGeneral Description of Steel Structure DesignWQC DriveNo ratings yet

- Fire Resistance of Composite Beams Composed of Rolled Steel Profile Concreted Between FlangesDocument15 pagesFire Resistance of Composite Beams Composed of Rolled Steel Profile Concreted Between FlangesNetzoo FlixNo ratings yet

- Brazingofcementedcarbides 1Document10 pagesBrazingofcementedcarbides 1Syed Noman AhmedNo ratings yet

- Blind Flange Design For 8", 600#, 15B Service LineDocument2 pagesBlind Flange Design For 8", 600#, 15B Service LineGohar ZamanNo ratings yet

- Global Marketing For Tube & Pipe: JIS C8305 Rigid Steel ConduitsDocument7 pagesGlobal Marketing For Tube & Pipe: JIS C8305 Rigid Steel ConduitsHoangNo ratings yet

- Shear StudDocument7 pagesShear StudcongtubatdaNo ratings yet

- SG Iron and Cast Iron Material SpecificationsDocument9 pagesSG Iron and Cast Iron Material Specificationsvtsusr fvNo ratings yet

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsFrom EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsNo ratings yet

- S275/ S355: Low/ Medium Yield Strength Structural Steels: Macsteel VRNDocument1 pageS275/ S355: Low/ Medium Yield Strength Structural Steels: Macsteel VRNsorin robertNo ratings yet

- Sample Manufacturing Quality Plan Format: (Logo of Manufacturer)Document12 pagesSample Manufacturing Quality Plan Format: (Logo of Manufacturer)P.Manna100% (1)

- Metal Roofs: Introduction To Steel RoofsDocument31 pagesMetal Roofs: Introduction To Steel RoofsKalsoom RazaNo ratings yet

- Jotun Penguard Express CF TDSDocument5 pagesJotun Penguard Express CF TDSnihad_mNo ratings yet

- Pre-Feasibility Report: Mahalakshmi Profiles Private LimitedDocument30 pagesPre-Feasibility Report: Mahalakshmi Profiles Private LimitedATLAS ScaffoldingNo ratings yet

- General Hot Dip Galvanizing - Schulz Thiele - 2012 - BlickDocument16 pagesGeneral Hot Dip Galvanizing - Schulz Thiele - 2012 - BlickARINDAM SETTNo ratings yet

- CASE STUDY Corrosion of Pump BodyDocument5 pagesCASE STUDY Corrosion of Pump BodyJeevana Sugandha WijerathnaNo ratings yet

- HeliCoil Tapping ChartDocument2 pagesHeliCoil Tapping ChartPurushothama Nanje GowdaNo ratings yet

- Servocut S: Description ApplicationDocument1 pageServocut S: Description ApplicationRAHULGUNDHER25No ratings yet

- Welding of Cast IronDocument10 pagesWelding of Cast IronKrishnendu RouthNo ratings yet

- A 268 Â " A 268M Â " 04 QTI2OC9BMJY4TQDocument6 pagesA 268 Â " A 268M Â " 04 QTI2OC9BMJY4TQCynthia GutierrezNo ratings yet

- Fluxcon Catalogo Monoflange PDFDocument4 pagesFluxcon Catalogo Monoflange PDFlindseyavNo ratings yet

- Portal Frame: Presented By: Ngooi Wan ZheDocument6 pagesPortal Frame: Presented By: Ngooi Wan ZheEmily NgooiNo ratings yet

- 4130 Q+T 75K Min Material Specification (MTR 413075K-14)Document3 pages4130 Q+T 75K Min Material Specification (MTR 413075K-14)Evey HernándezNo ratings yet

- Boric Oxide: Product Data SheetDocument2 pagesBoric Oxide: Product Data SheetVairamuthu SiveshNo ratings yet

- Fitting LabDocument8 pagesFitting LabArun kumar rouniyarNo ratings yet

- Common Valve Casting Materials MetallurgyDocument4 pagesCommon Valve Casting Materials MetallurgyRatnakar PatilNo ratings yet

- Euroglass Catalogue June2015 Door and Patch Fittings SectionDocument18 pagesEuroglass Catalogue June2015 Door and Patch Fittings SectionzenitsuNo ratings yet

- Invar: Controlled Expansion AlloysDocument5 pagesInvar: Controlled Expansion AlloyskarthikNo ratings yet

- Catalogue Excel enDocument48 pagesCatalogue Excel enOscar CampoNo ratings yet

- Astm A131 2019 PDFDocument8 pagesAstm A131 2019 PDFazam RazzaqNo ratings yet

- Mechanical Properties For Stainless Steel FastenersDocument3 pagesMechanical Properties For Stainless Steel FastenersGonzalo MazaNo ratings yet

- Esdep Lecture Note (Wg11)Document14 pagesEsdep Lecture Note (Wg11)Tiny Tấn MinhNo ratings yet

- Aalco Metals LTD Stainless Steel 1.4542 17 4 PH 100Document4 pagesAalco Metals LTD Stainless Steel 1.4542 17 4 PH 100Sergio CLNo ratings yet

- GTP and Tech Spec of Polymer Disc Insulator 979Document21 pagesGTP and Tech Spec of Polymer Disc Insulator 979Sourav RanaNo ratings yet

- And AppliedDocument36 pagesAnd AppliedGeorgiana-LuizaNo ratings yet

- 5 Methods To Determine Preheat TemperatureDocument4 pages5 Methods To Determine Preheat TemperatureMohamed AtefNo ratings yet

- CHP 1 - Intro To Material PropertiesDocument33 pagesCHP 1 - Intro To Material PropertiesDũng TrầnNo ratings yet

- Irs Welded Bridge CodeDocument32 pagesIrs Welded Bridge Codeamawauce67% (3)

- Presentation - JOINERY HARDWAREDocument159 pagesPresentation - JOINERY HARDWAREKeya JainNo ratings yet

MD - CP - Problem Statement

MD - CP - Problem Statement

Uploaded by

Sohan kulal0 ratings0% found this document useful (0 votes)

20 views2 pagesThe document describes the design of a screw jack to lift a 3000kg pickup truck 850mm. It selects materials for each component based on the stresses it will experience and cost considerations. The frame and cup are made of grey cast iron for its compressive strength and ease of forming complex shapes. A steel is chosen for the screw and handle for its strength. A softer phosphor bronze nut is paired with the steel screw to reduce wear.

Original Description:

Cp

Original Title

MD_CP_Problem statement

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document describes the design of a screw jack to lift a 3000kg pickup truck 850mm. It selects materials for each component based on the stresses it will experience and cost considerations. The frame and cup are made of grey cast iron for its compressive strength and ease of forming complex shapes. A steel is chosen for the screw and handle for its strength. A softer phosphor bronze nut is paired with the steel screw to reduce wear.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

20 views2 pagesMD - CP - Problem Statement

MD - CP - Problem Statement

Uploaded by

Sohan kulalThe document describes the design of a screw jack to lift a 3000kg pickup truck 850mm. It selects materials for each component based on the stresses it will experience and cost considerations. The frame and cup are made of grey cast iron for its compressive strength and ease of forming complex shapes. A steel is chosen for the screw and handle for its strength. A softer phosphor bronze nut is paired with the steel screw to reduce wear.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 2

Problem statement:-

Design a screw jack to lift 3000kg pickup truck to a height of 850mm.

Material choice and reasons for selection:-

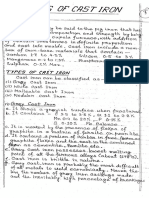

1) The frame of the screw jack has complex shape. It is subjected to compressive stress. Grey

cast iron of grade FG 200 (Sut = 200 N/mm2) is selected as the material for the frame. Cast

iron is cheap and it can be given any complex shape without involving costly machining

operations. Cast iron has higher compressive strength compared with steel. Therefore, it is

technically and economically advantageous to use cast iron for the frame.

2) The screw is subjected to torsional moment, compressive force and bending

moment. From strength consideration, plain carbon steel of grade 30C8 (Syt = 400

N/mm2 and E = 207 000 N/mm2) is selected as material for the screw.

3) There is relative motion between the screw and the nut, which results in friction.

The friction causes wear at the contacting surfaces. When the same material is used

for these two components, the surfaces of both components get worn out, requiring

replacement. This is undesirable. The size and shape of the screw make it costly

compared with the nut. Therefore, if at all a component is to be replaced due to

wear, it should be the nut, which is less costly compared with the screw. The wear is

always restricted to a softer surface. Therefore, the nut should be made of softer

material. This protects the screw against wear. Cast variety of phosphor bronze of

Grade-1 (Sut = 190 N/mm2 ) is selected as the material for the nut. Phosphor bronze

is soft compared with hardened steel screw. In addition to this consideration,

phosphor bronze has low coefficient of friction, which reduces the torque to

overcome friction at the thread surface. It has excellent conformability and

machinability. Conformability is the ability of the material to yield and adopt its

shape to that of the screw. Cost is the main limitation of phosphor bronze. For steel

screw and phosphor bronze nut, the permissible bearing pressure (Sb) and

coefficient of friction (m) are taken as 10 N/mm2 and 0.1 respectively.

4) The handle is subjected to bending moment. The yield strength is the criterion for

the selection of material. Plain carbon steel of grade 30C8 (Syt = 400 N/mm2) is

selected as the material for the handle.

5) The shape and dimensions of the cup are such that it is easier and economical to

make it by the casting process. Grey cast iron of Grade FG 200 is used for the cup.

The complete part list of the screw jack is given in the following table.

Sr. No. Name of component Quantity Material

1 Frame 1 Grey cast iron FG 200 (IS: 210 – 1978)

2 Screw 1 Steel 30C8 (IS: 1570 – 1978)

3 Nut 1 Phosphor bronze Grade-1 (IS: 28 – 1975)

4 Handle 1 Steel 30C8 (IS: 1570 – 1978)

5 Cup 1 Grey cast iron FG 200 (IS: 210 – 1978)

6 Set Screw 1 Commercial steel

7 Washer 1 Commercial steel

You might also like

- How TG-X Filler Rods Can Eliminate Back Shielding: Kobelco Welding TodayDocument2 pagesHow TG-X Filler Rods Can Eliminate Back Shielding: Kobelco Welding TodaysatheeshNo ratings yet

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- Utp Cast Iron GBDocument8 pagesUtp Cast Iron GBhrk100No ratings yet

- Technical Information No. 1: Grey Lamellar Graphite Cast IronDocument2 pagesTechnical Information No. 1: Grey Lamellar Graphite Cast IronMOHAMMAD ASIFNo ratings yet

- Wd-Full (Archi+structure)Document42 pagesWd-Full (Archi+structure)Joel Jeffery SarkarNo ratings yet

- Hot-Dip Galvanizing Service: BS 729:1971 Hot-Dip Galvanized Coatings On Iron & Steel ArticlesDocument2 pagesHot-Dip Galvanizing Service: BS 729:1971 Hot-Dip Galvanized Coatings On Iron & Steel ArticleshbookNo ratings yet

- A) Material and B) ConsumablesDocument3 pagesA) Material and B) ConsumablesazaharNo ratings yet

- Seam Strength of Corrugated Plate With High Strength SteelDocument15 pagesSeam Strength of Corrugated Plate With High Strength SteelMariano SalcedoNo ratings yet

- Welding Chart The Complete Reference Guide To WeldingDocument2 pagesWelding Chart The Complete Reference Guide To WeldingJitu JenaNo ratings yet

- 1371755070249-Reinforced Cement ConcreteDocument74 pages1371755070249-Reinforced Cement ConcreteAbdirahman AbukarNo ratings yet

- FT Ros enDocument14 pagesFT Ros enmarjan banooNo ratings yet

- Cast Iron Vs Ductile IronDocument2 pagesCast Iron Vs Ductile IronFekre RaziNo ratings yet

- Investment CastingDocument8 pagesInvestment Castingbandit96No ratings yet

- En GJL 250Document2 pagesEn GJL 250Jitendra BhosaleNo ratings yet

- 1018 Bronze Ferrule Cock (Medium) : Salient FeaturesDocument22 pages1018 Bronze Ferrule Cock (Medium) : Salient FeaturesSanket PhatangareNo ratings yet

- 3 MaterialDocument15 pages3 MaterialRajNo ratings yet

- Dme PDFDocument8 pagesDme PDFAbhishek ChauhanNo ratings yet

- Cold Formed Steel Members and SheetingDocument14 pagesCold Formed Steel Members and SheetingMihai MariusNo ratings yet

- Paperpdf 1597754539Document10 pagesPaperpdf 1597754539Aadarsh SharmaNo ratings yet

- Abrasive Profile Comparator ChartDocument1 pageAbrasive Profile Comparator Chartsflynn79100% (1)

- Notes:: Copy of Electrode Selection ChartDocument2 pagesNotes:: Copy of Electrode Selection Chartmalika_00No ratings yet

- Besi Yuda 231023Document3 pagesBesi Yuda 231023Girah Sakha RamadiansyahNo ratings yet

- YAN Real Estate Floor Modification BOQDocument4 pagesYAN Real Estate Floor Modification BOQDAWITNo ratings yet

- Piping Material DetailsDocument12 pagesPiping Material DetailsJay Vinoth100% (2)

- Besi Uber 2023-03-22Document2 pagesBesi Uber 2023-03-22Gema PutraNo ratings yet

- En PP TPS Extended Surface TubesDocument32 pagesEn PP TPS Extended Surface Tubesfah ruNo ratings yet

- 277 - Galvanised Steel SheetsDocument10 pages277 - Galvanised Steel SheetsKaushik SenguptaNo ratings yet

- B 101 - 01 Qjewms1sruqDocument7 pagesB 101 - 01 Qjewms1sruqFadjar ZulkarnainNo ratings yet

- Not For SaleDocument3 pagesNot For SaleSwati SharmaNo ratings yet

- Cast Iron Vs Ductile IronDocument2 pagesCast Iron Vs Ductile IronJayakrishnan RadhakrishnanNo ratings yet

- AZ024 Lecture 7 Steel ConnectionDocument14 pagesAZ024 Lecture 7 Steel ConnectionTong Kin Lun100% (15)

- Tps OHLDocument88 pagesTps OHLNaseem AhmedNo ratings yet

- DIN 17100 ST 37-2 SteelDocument2 pagesDIN 17100 ST 37-2 SteelSiddiqui Abdul KhaliqNo ratings yet

- Indotest Multi LaboratamaDocument3 pagesIndotest Multi LaboratamaRangga Padma NugrahaNo ratings yet

- Design No. D759: October 31, 2003Document9 pagesDesign No. D759: October 31, 2003souravrobinNo ratings yet

- Besi Uber 20230712Document3 pagesBesi Uber 20230712egaNo ratings yet

- Carbon Steel Catalog of SuppliersDocument24 pagesCarbon Steel Catalog of SuppliersRuano Andreola StumpfNo ratings yet

- Special Steel Structures - Courses - 2013Document253 pagesSpecial Steel Structures - Courses - 2013Largu George DanielNo ratings yet

- 1087 Bronze Double Regulating Balancing Valve (Screwed) With NozzleDocument2 pages1087 Bronze Double Regulating Balancing Valve (Screwed) With NozzleSanket PhatangareNo ratings yet

- Shear Load CalculationDocument8 pagesShear Load Calculationvinny1978No ratings yet

- Talja Et Al ENDocument14 pagesTalja Et Al ENStructural TenderNo ratings yet

- Specification Ss-20/5 Steel Structures For Substation and Switching Station MaterialDocument5 pagesSpecification Ss-20/5 Steel Structures For Substation and Switching Station MaterialharrisvasNo ratings yet

- Blind Flange Design For 8", 600#, 15B Service LineDocument2 pagesBlind Flange Design For 8", 600#, 15B Service LineGohar ZamanNo ratings yet

- 1078 Butter y Valve (Wafer Type) PN 16 With S.G Iron Disc: Salient FeaturesDocument17 pages1078 Butter y Valve (Wafer Type) PN 16 With S.G Iron Disc: Salient FeaturesSanket PhatangareNo ratings yet

- Standard Specification For Corrugated Steel Structural Plate, Zinc-Coated, For Field-Bolted Pipe, Pipe-Arches, and ArchesDocument17 pagesStandard Specification For Corrugated Steel Structural Plate, Zinc-Coated, For Field-Bolted Pipe, Pipe-Arches, and Archesjun floresNo ratings yet

- Welding Electrode ChartDocument2 pagesWelding Electrode ChartZaheed Manoo50% (2)

- StrainerDocument2 pagesStrainermayNo ratings yet

- Technical Report: How TGX Filler Rods Can Eliminate Back ShieldingDocument2 pagesTechnical Report: How TGX Filler Rods Can Eliminate Back ShieldingSamuel LatumahinaNo ratings yet

- ZolotoIndustries BSENISO17292Document6 pagesZolotoIndustries BSENISO17292anderson_bicudoNo ratings yet

- General Description of Steel Structure DesignDocument17 pagesGeneral Description of Steel Structure DesignWQC DriveNo ratings yet

- Fire Resistance of Composite Beams Composed of Rolled Steel Profile Concreted Between FlangesDocument15 pagesFire Resistance of Composite Beams Composed of Rolled Steel Profile Concreted Between FlangesNetzoo FlixNo ratings yet

- Brazingofcementedcarbides 1Document10 pagesBrazingofcementedcarbides 1Syed Noman AhmedNo ratings yet

- Blind Flange Design For 8", 600#, 15B Service LineDocument2 pagesBlind Flange Design For 8", 600#, 15B Service LineGohar ZamanNo ratings yet

- Global Marketing For Tube & Pipe: JIS C8305 Rigid Steel ConduitsDocument7 pagesGlobal Marketing For Tube & Pipe: JIS C8305 Rigid Steel ConduitsHoangNo ratings yet

- Shear StudDocument7 pagesShear StudcongtubatdaNo ratings yet

- SG Iron and Cast Iron Material SpecificationsDocument9 pagesSG Iron and Cast Iron Material Specificationsvtsusr fvNo ratings yet

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsFrom EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsNo ratings yet

- S275/ S355: Low/ Medium Yield Strength Structural Steels: Macsteel VRNDocument1 pageS275/ S355: Low/ Medium Yield Strength Structural Steels: Macsteel VRNsorin robertNo ratings yet

- Sample Manufacturing Quality Plan Format: (Logo of Manufacturer)Document12 pagesSample Manufacturing Quality Plan Format: (Logo of Manufacturer)P.Manna100% (1)

- Metal Roofs: Introduction To Steel RoofsDocument31 pagesMetal Roofs: Introduction To Steel RoofsKalsoom RazaNo ratings yet

- Jotun Penguard Express CF TDSDocument5 pagesJotun Penguard Express CF TDSnihad_mNo ratings yet

- Pre-Feasibility Report: Mahalakshmi Profiles Private LimitedDocument30 pagesPre-Feasibility Report: Mahalakshmi Profiles Private LimitedATLAS ScaffoldingNo ratings yet

- General Hot Dip Galvanizing - Schulz Thiele - 2012 - BlickDocument16 pagesGeneral Hot Dip Galvanizing - Schulz Thiele - 2012 - BlickARINDAM SETTNo ratings yet

- CASE STUDY Corrosion of Pump BodyDocument5 pagesCASE STUDY Corrosion of Pump BodyJeevana Sugandha WijerathnaNo ratings yet

- HeliCoil Tapping ChartDocument2 pagesHeliCoil Tapping ChartPurushothama Nanje GowdaNo ratings yet

- Servocut S: Description ApplicationDocument1 pageServocut S: Description ApplicationRAHULGUNDHER25No ratings yet

- Welding of Cast IronDocument10 pagesWelding of Cast IronKrishnendu RouthNo ratings yet

- A 268 Â " A 268M Â " 04 QTI2OC9BMJY4TQDocument6 pagesA 268 Â " A 268M Â " 04 QTI2OC9BMJY4TQCynthia GutierrezNo ratings yet

- Fluxcon Catalogo Monoflange PDFDocument4 pagesFluxcon Catalogo Monoflange PDFlindseyavNo ratings yet

- Portal Frame: Presented By: Ngooi Wan ZheDocument6 pagesPortal Frame: Presented By: Ngooi Wan ZheEmily NgooiNo ratings yet

- 4130 Q+T 75K Min Material Specification (MTR 413075K-14)Document3 pages4130 Q+T 75K Min Material Specification (MTR 413075K-14)Evey HernándezNo ratings yet

- Boric Oxide: Product Data SheetDocument2 pagesBoric Oxide: Product Data SheetVairamuthu SiveshNo ratings yet

- Fitting LabDocument8 pagesFitting LabArun kumar rouniyarNo ratings yet

- Common Valve Casting Materials MetallurgyDocument4 pagesCommon Valve Casting Materials MetallurgyRatnakar PatilNo ratings yet

- Euroglass Catalogue June2015 Door and Patch Fittings SectionDocument18 pagesEuroglass Catalogue June2015 Door and Patch Fittings SectionzenitsuNo ratings yet

- Invar: Controlled Expansion AlloysDocument5 pagesInvar: Controlled Expansion AlloyskarthikNo ratings yet

- Catalogue Excel enDocument48 pagesCatalogue Excel enOscar CampoNo ratings yet

- Astm A131 2019 PDFDocument8 pagesAstm A131 2019 PDFazam RazzaqNo ratings yet

- Mechanical Properties For Stainless Steel FastenersDocument3 pagesMechanical Properties For Stainless Steel FastenersGonzalo MazaNo ratings yet

- Esdep Lecture Note (Wg11)Document14 pagesEsdep Lecture Note (Wg11)Tiny Tấn MinhNo ratings yet

- Aalco Metals LTD Stainless Steel 1.4542 17 4 PH 100Document4 pagesAalco Metals LTD Stainless Steel 1.4542 17 4 PH 100Sergio CLNo ratings yet

- GTP and Tech Spec of Polymer Disc Insulator 979Document21 pagesGTP and Tech Spec of Polymer Disc Insulator 979Sourav RanaNo ratings yet

- And AppliedDocument36 pagesAnd AppliedGeorgiana-LuizaNo ratings yet

- 5 Methods To Determine Preheat TemperatureDocument4 pages5 Methods To Determine Preheat TemperatureMohamed AtefNo ratings yet

- CHP 1 - Intro To Material PropertiesDocument33 pagesCHP 1 - Intro To Material PropertiesDũng TrầnNo ratings yet

- Irs Welded Bridge CodeDocument32 pagesIrs Welded Bridge Codeamawauce67% (3)

- Presentation - JOINERY HARDWAREDocument159 pagesPresentation - JOINERY HARDWAREKeya JainNo ratings yet