Professional Documents

Culture Documents

Iss6 - Control Cylinder - ASSISTOR SPRING

Iss6 - Control Cylinder - ASSISTOR SPRING

Uploaded by

LuisaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Iss6 - Control Cylinder - ASSISTOR SPRING

Iss6 - Control Cylinder - ASSISTOR SPRING

Uploaded by

LuisaCopyright:

Available Formats

Instructions for

Pneumatic Swing Phase

Control Cylinder

A pneumatic cylinder used to control the swing in a Trans-femoral or Knee Disarticulation lower limb

external prosthesis during normal locomotion.

To to fitted only as part of an Endolite Modular Limb System.

PSPC Only 239130

SFESK Module 019158

140° SFESK Module 019171

ESK/MKL Module 019161

EUK Module 019152

EUK 4 Bolt Module 019352

All ESK+ Modules

Maximum amputee weight

125 kg

when used during normal walking

PSPC Only for E4BKD 239126

E4BKD Module 019136

Maximum amputee weight

100 kg

when used during normal walking

Fitting Instructions for PSPC For E4BKD refer to Instruction 938012

User/attendant should be aware of potential finger trap hazards at all times.

Fitting Kits: SFESK 019958 , EUK 019952, SFESK+ Full Form Shin 019858, ESK+ Demountable Shin 019758

NOTE:

923700 1mm Chassis Rear Pivot Bearings (923700) are approximately 1mm longer than

the Lower Pivot Bearing (334303) in shin. Identify these correctly before

334303 proceeding with assembly. (not applicable to ESK+)

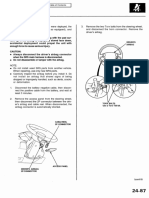

LOWER ATTACHMENTS except ESK+ ( Fig.1)

1. Where sufficient clearance exists, assemble Thrust

Washers onto Bearings, as shown, before inserting

PSPC

Bearings into shin. Ensure the anti-rotation key on each

Bearing is correctly located in the appropriate slot in the

Washer and shin.

*WASHER

SHIM Before the final assembly of the Lower Pivots, put

*WASHER

SHIM

the PSPC into the shin and position between

330134

330134

(optional the Lower Pivot Bearings.

(optional

see note 1) see note 1)

* Ifandthere is insufficient clearance between the bearings

the PSPC then BOTH Shim Washers must be

BEARING removed.

334303

2. Apply a very light smear of STP Oil Treatment

(928105) to each Lower Pivot.

LOCT

IT STPtment

222 E rea

Oil T

LOWER LOWER

PIVOT PIVOT

230050 230050

SHIN

3. Apply Loctite 222 Screw Lock (926001) to

Fig. 1: LOWER ATTACHMENT FOR ALL threads on Lower Pivots and with PSPC positioned

PSPC MODULES with assembly holes aligned with Bearings, insert

Pivots and carefully tighten into the PSPC base.

TRUNNION

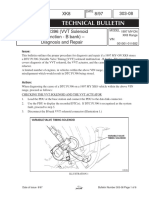

UPPER ATTACHMENT (Figs.2 to 6)

239009 TIGHTEN

LOCKING

SCREW 1. If Spring Assist is required, fit over PSPC piston rod.

IF REQUIRED 2. Apply a small quantity of Loctite 243 to threaded end

FIT SPRING ASSIST

LOCTITE PSPC piston rod, attach Trunnion Assembly and

230313

OVER PISTON ROD 243 tighten locking screw.(Fig. 2)

Fig. 2: FITTING TRUNNION ASSEMBLY

ON ALL MODULES

Blatchford 938057 Page 1 Pneumatic Swing Phase Control

PNEUMATIC SWING PHASE CONTROL

Fitting Instructions for the PSPC (except ESK+)

BEARING

UPPER ATTACHMENT (Figs.2 to 6)

BOLT 923700 (Continued)

233808

NUT 3 Ensure anti-rotation key on each bearing is correctly

233807 located in the appropriate slot.

BEARING

923700 SFESK chassis, outside of lugs.

TRUNNION

239009 EUK and EUK 4 Bolt chassis inside of lugs.

SPRING ASSIST 4. Apply a very light smear of STP Oil Treatment

230313

(928105) to the bearing surfaces only of the Bolt

Fig. 3: SFESK MODULE 019158 and Nut.

&140° SFESK MODULE 019171

ent

P

atm

ST

BEARING

Tre

ent

923700

P

atm

BEARING

Oil

ST

ITE

LOCT2

923700

Tre

NUT

22

Oil

230055

BOLT

230054

THRUST

WASHERS 5. Apply Loctite 222 (926001) to the threads of the

230053

Bolt.

TRUNNION SPRING ASSIST

239009 230313

6. For EUK and EUK 4 Bolt (Fig. 4 and 5) only.

Fig. 4: EUK MODULE 019152 Fit Thrust Washers between Trunnion and inside lugs

of chassis.

BEARING

923700 7. Insert Bolt and Nut through bearings in chassis,

BEARING

923700 ensuring that the Thrust Washers are in line

NUT (EUK and EUK 4 Bolt only) and tighten.

BOLT 230055

230054

THRUST

WASHERS

230053

TRUNNION

239009 SPRING ASSIST

230313

Fig. 5: EUK 4 BOLT MODULE 019352

BEARING

BOLT 923700

233808 NUT

233807

BEARING

923700

TRUNNION

239009

Fig. 6: ESK/MKL MODULE 019161

Pneumatic Swing Phase Control Page 2 Blatchford 938057

Fitting Instructions for the PSPC to ESK+ Shin Modules

ESK+ Full Shin

Oil T

STP

reatm

LOCTIT

222

E

STPtment

Oil T

rea Remove silencing ring

ent

5 and discard prior to

5 Bolt

230079

10Nm

fitting cylinder into

10Nm Nut

230078

Thrust Washer

230080 either ESK+ shin.

Trunnion

239009*

Thrust Washer

230080

Assistor Spring

230313*

Lower Pivot PSPC

230081

LOCTIT STPtment

STP TITE E

Oil T

rea

Oil T LOC 22 222

reatm 2

ent

5

5 10Nm

Lower Pivot

10Nm 230081

Thrust Washer Thrust Washer

231908 231908

ESK+ Demountable Shin

LOCTIT STPtment

E rea

STP 222 Oil T

Oil T

reatm

ent

5

5 Bolt 10Nm

230079

10Nm Nut Thrust Washer

230078 230080

Trunnion

239009*

Thrust Washer

230080

Assistor Spring

230313*

Lower Pivot

230088 PSPC

LOCTIT STPtment

TITE E rea

STP Oil T

Oil T LOC 22 222

reatm 2

ent

6

6 Lower Pivot

10Nm

230088

10Nm

Thrust Washer Thrust Washer

230090 230090

Blatchford 938057 Page 3 Pneumatic Swing Phase Control

PNEUMATIC SWING PHASE CONTROL

SFESK and ESK/MKL with Anterior Extension Stop

Note: When used with SFESK or ESK/MKL with Anterior

Extension Stop, the stop should be adjusted as follows:

SCREW

DOWN FRONT 1. Slacken Trunnion Clamping Screw.

EXTENSION

STOP 2. Using a 6mm Spanner rotate piston rod until Knee

Lock Patella locks into place without rock and with

ease.

3. Retighten the Trunnion Clamping Screw.

4. Remove Patella (except MKL).

5. Using a strip of paper 5mm wide, place on top of the

STRIP OF front buffer. Screw down front extension stop until

PAPER

PULLED OUT paper can be pulled out with a slight resistance. A

WITH A SLIGHT light extension movement should be applied to the

RESISTANCE top of the socket whilst carrying out this adjustment.

6. Replace the Patella(except MKL).

Fig. 7: ESK WITH ANTERIOR EXTENSION STOP

SFESK+ Anterior Extension Stop

When fitted with a PSPC, the ESK+ extension stop should be wound fully home. No adjustment is necessary.

Pneumatic Swing Phase Control Page 4 Blatchford 938057

Length Adjustment for the PSPC

For modules supplied with control cylinder already assembled into the shin, the following

has already been carried out.

LOCTITE

243

F Blatchford E F Blatchford E F Blatchford E

Pneumatic Swing Phase Pneumatic Swing Phase Pneumatic Swing Phase

Control Cylinder Control Cylinder Control Cylinder

SN SN SN

Chas. A. Blatchford & Sons Ltd Chas. A. Blatchford & Sons Ltd Chas. A. Blatchford & Sons Ltd

Basingstoke Hampshire RG22 4AH Basingstoke Hampshire RG22 4AH Basingstoke Hampshire RG22 4AH

United Kingdom United Kingdom United Kingdom

A B C

o

90

LO

CT

222 ITE

WITNESS

LINE

WITNESS LINE

MUST NOT BE VISIBLE

BELOW TRUNNION

D E F AFTER ADJUSTMENT

Blatchford 938057 Page 5 Pneumatic Swing Phase Control

PNEUMATIC SWING PHASE CONTROL

Adjustment Instructions for the PSPC

The adjustment at the fitting stage should be carried out to suit the individual wearer

SETTING THE FLEXION AND EXTENSION VALVE

The Flexion and Extension Valves should be adjusted

to suit the individual wearers gait characteristics.

Turn each adjuster within the range specified below,

clockwise to increase resistance and anti-clockwise to

reduce resistance.

APPROXIMATE RANGE OF ADJUSTMENT

EXTENSION: MAX. - NO RINGS SHOWING

MIN. - 3 RINGS SHOWING

FLEXION: MAX. - NO RINGS SHOWING

FLEXION EXTENSION MIN. - 3 RINGS SHOWING

ADJUSTER ADJUSTER

WARNING: The Red Ring on each adjuster should

never be visible after adjustment.

THE RED

RING

SHOULD

NEVER

BE VISIBLE

AFTER

ADJUSTMENT

F Blatchford E

Pneumatic Swing Phase

Control Cylinder

SN

Chas. A. Blatchford & Sons Ltd

Basingstoke Hampshire RG22 4AH

United Kingdom

Fig. 7: ADJUSTMENTS OF THE PSPC

Pneumatic Swing Phase Control Page 6 Blatchford 938057

Functional Checks for the PSPC

THE FOLLOWING MANUAL CHECKS MAY BE MADE TO ENSURE CORRECT FUNCTION OF THE CYLINDER

NON RETURN VALVES AND SEALS

VALVE POSITIONS OUTSTOKE INSTROKE

Extension Resistance Minimum

Free Cushioned

Flexion Resistance Maximum

Extension Resistance Maximum

Cushioned Free

Flexion Resistance Minimum

Maintenance Instructions for PSPC

No specific maintenance is required of this device; however in normal service an Endolite

limb should be inspected annually to check for correct function, lubrication and security of

assembly.

The wearer should be advised that any change in performance of the device must be reported

to the practitioner.

STORAGE AND HANDLING

No special storage or handling requirements are associated with this device.

Use product packaging supplied.

Blatchford Products Ltd

Lis t e r R o a d , B a s i n g s t o k e , H a m p s h i r e , R G 2 2 4 AH, United Kingdom

Te l e p h o n e : + 4 4 ( 0 ) 1 2 5 6 3 1 6 6 0 0 F a c s i m i l e : + 4 4 ( 0 ) 1 2 5 6 4 7 9 7 0 5

Email: sales@blatchford.co.uk www.blatchford.co.uk

938057/06-1105

You might also like

- AWTF80SC ManualDocument2 pagesAWTF80SC ManualАанатолий СлободянNo ratings yet

- Install Cruise Control On Toyota Corolla AltisDocument7 pagesInstall Cruise Control On Toyota Corolla AltisFrank JosephNo ratings yet

- Switching Power Supply Design: A Concise Practical HandbookFrom EverandSwitching Power Supply Design: A Concise Practical HandbookNo ratings yet

- 5vz-Fe Timing Belt InstallationDocument6 pages5vz-Fe Timing Belt InstallationJorge RisquezNo ratings yet

- Installation Manual: Model T455B/C Engine BrakesDocument10 pagesInstallation Manual: Model T455B/C Engine BrakesemmanuelNo ratings yet

- Sap Co ResumeDocument7 pagesSap Co ResumeSri KanthNo ratings yet

- 2zzge Valve Clearance PDFDocument6 pages2zzge Valve Clearance PDFGullwing Motor ServiceNo ratings yet

- Reassembly: See Page SR 1 0Document4 pagesReassembly: See Page SR 1 0Moh DeBrNo ratings yet

- Spring Adjuster Kit: Aisin AW TF-60SN, TF-80SC, TF-81SCDocument2 pagesSpring Adjuster Kit: Aisin AW TF-60SN, TF-80SC, TF-81SCrodolfo paucaraNo ratings yet

- Reassembly: 1. Install Spring Bumper To Piston RodDocument1 pageReassembly: 1. Install Spring Bumper To Piston RodsalusfrankNo ratings yet

- E32 Autobox DismantlingDocument23 pagesE32 Autobox DismantlingSteven J Baynes100% (1)

- LTM1080 PT1Document14 pagesLTM1080 PT1William VillanuevaNo ratings yet

- Brakes (2.4L)Document2 pagesBrakes (2.4L)Ruhu royNo ratings yet

- Assembly Procedure 24MDocument21 pagesAssembly Procedure 24Misaias.simaoNo ratings yet

- (TM) Chrysler Manual de Taller Chrysler PT Cruiser 2001 PDFDocument413 pages(TM) Chrysler Manual de Taller Chrysler PT Cruiser 2001 PDFJihr Hernandez100% (1)

- Product End of Life Instructions: Okken 115, 70-F and 70-2 PCC and MCC Low VoltageDocument6 pagesProduct End of Life Instructions: Okken 115, 70-F and 70-2 PCC and MCC Low VoltageAdel MaacheNo ratings yet

- SKF CouplingDocument16 pagesSKF CouplingThomas JoseNo ratings yet

- Bell430 MM CH07Document10 pagesBell430 MM CH07ame.venkyNo ratings yet

- Assembly Procedure: Reverse ShaftDocument28 pagesAssembly Procedure: Reverse ShaftedI_restrepo_1No ratings yet

- Reassembly: 1. Assemble Piston and Connecting RodDocument7 pagesReassembly: 1. Assemble Piston and Connecting Roddolphi_742078No ratings yet

- Reensamble de Caja de Transferencia Hilux Vf2cmDocument27 pagesReensamble de Caja de Transferencia Hilux Vf2cmromuloNo ratings yet

- 070-251 SM - 2007 - 01 Service Manual TDSH & GDSHDocument12 pages070-251 SM - 2007 - 01 Service Manual TDSH & GDSHAlexNo ratings yet

- Instruction Manual Dodge Torque-Arm™ II Speed Reducers Ratios 5, 9, 15, 25, and 40:1Document29 pagesInstruction Manual Dodge Torque-Arm™ II Speed Reducers Ratios 5, 9, 15, 25, and 40:1DavidNo ratings yet

- 10 - Timing Chain - Installation PDFDocument11 pages10 - Timing Chain - Installation PDFbakriramzi100% (2)

- 11 Trans ReassemDocument44 pages11 Trans ReassemAnangtri WahyudiNo ratings yet

- Cople Jse1-0237aea-03-16Document15 pagesCople Jse1-0237aea-03-16Jorge GascaNo ratings yet

- !!!WARNING!!!: 2R-Series 2R2500 & 2R3500 Double Acting & Spring Return Scotch Yoke ActuatorsDocument7 pages!!!WARNING!!!: 2R-Series 2R2500 & 2R3500 Double Acting & Spring Return Scotch Yoke ActuatorsAmaury FreireNo ratings yet

- MKA-55 Stabilizer Kit Instruction Sheet 2374952rcDocument16 pagesMKA-55 Stabilizer Kit Instruction Sheet 2374952rcCoryNo ratings yet

- 12165-70 - 1 Sundry Instr.Document328 pages12165-70 - 1 Sundry Instr.kodrysNo ratings yet

- Dodge MTA 4207 H PDFDocument28 pagesDodge MTA 4207 H PDFJhonathan AlejandroNo ratings yet

- Pneumatic Actuators Firesafe: Type and Design The Principle and Application of The Scotch Yoke ConstructionDocument4 pagesPneumatic Actuators Firesafe: Type and Design The Principle and Application of The Scotch Yoke ConstructionreliableplacementNo ratings yet

- Engine Removal and InstallationDocument8 pagesEngine Removal and InstallationEj GonzalezNo ratings yet

- Minolta Maxxum Dynax 7 Repair Guide - OCRDocument66 pagesMinolta Maxxum Dynax 7 Repair Guide - OCRRui FonsecaNo ratings yet

- Tech k0 Structural Bolt Installation 210520Document2 pagesTech k0 Structural Bolt Installation 210520sadiaajmal09No ratings yet

- Ohlins - DTC - Einbauanleitung Oehlins Motorrad DMX 0301Document4 pagesOhlins - DTC - Einbauanleitung Oehlins Motorrad DMX 0301AlbertoNo ratings yet

- Murphy.70 Press - SendDocument1 pageMurphy.70 Press - SendAndres CelyNo ratings yet

- Overload Clutches For Index Drives (Type D-Sa, Adjustable) : Operating PrincipleDocument4 pagesOverload Clutches For Index Drives (Type D-Sa, Adjustable) : Operating PrincipleSuhas KODRENo ratings yet

- Sps Siot Installation Instructions GLL Limit 50012101 5 Ciid 52168Document7 pagesSps Siot Installation Instructions GLL Limit 50012101 5 Ciid 52168Zahira Yadira Arévalo MéndezNo ratings yet

- Pump ManualDocument16 pagesPump ManualHussein_ipsNo ratings yet

- Disassembling and Reassembling Diesel Engine Turbocharger Based On The Manufacturer's ManualDocument21 pagesDisassembling and Reassembling Diesel Engine Turbocharger Based On The Manufacturer's ManualChriscarl De LimaNo ratings yet

- Grua Hidraulica Rt880e PDFDocument967 pagesGrua Hidraulica Rt880e PDFGustavo100% (1)

- 60 - RT-flex - Crank Angle SensorDocument18 pages60 - RT-flex - Crank Angle SensorSumit ChauhanNo ratings yet

- 01 Drivers Air BagDocument2 pages01 Drivers Air BagF MNo ratings yet

- pvq10pvq13 10designDocument4 pagespvq10pvq13 10designJosueNo ratings yet

- Piston & Motors: PumpsDocument4 pagesPiston & Motors: PumpshoiNo ratings yet

- ATV 2015 OUTLANDER L (Continuously Variable Transmission (CVT) - 450) - Shop Manual - 04cE60AAE - SM51Y015S01 - enDocument22 pagesATV 2015 OUTLANDER L (Continuously Variable Transmission (CVT) - 450) - Shop Manual - 04cE60AAE - SM51Y015S01 - enfe100% (1)

- Fujitec BrakesDocument10 pagesFujitec Brakesjeferson_camiloNo ratings yet

- M SR 0022 PDFDocument1 pageM SR 0022 PDFMoh DeBrNo ratings yet

- MHEV Damper Bolt RD StrategyDocument1 pageMHEV Damper Bolt RD StrategyManea AurelianNo ratings yet

- Kalmar Montacargas DCE 90-180, DCE 70-32E3-70-35E Workshop Manual (PDF - Io)Document151 pagesKalmar Montacargas DCE 90-180, DCE 70-32E3-70-35E Workshop Manual (PDF - Io)ValeriNo ratings yet

- md0000001178202007 PM 221650 RT760E 002 PARTSDocument899 pagesmd0000001178202007 PM 221650 RT760E 002 PARTSDecomaderas SanchezNo ratings yet

- XR700 and XR3000: Ignition InspectionDocument20 pagesXR700 and XR3000: Ignition InspectionDevine LightNo ratings yet

- MECANISME JVC (DVC, VHS, VHS-C) - SERVICE MANUAL (No.86700)Document44 pagesMECANISME JVC (DVC, VHS, VHS-C) - SERVICE MANUAL (No.86700)Delcu MarinicaNo ratings yet

- Sincronizacion de Motor Toyota 2rz-FeDocument5 pagesSincronizacion de Motor Toyota 2rz-Femarran almarrany100% (1)

- SIS 2.0 1Document7 pagesSIS 2.0 1rw593767No ratings yet

- Toyota TercelDocument29 pagesToyota TercelAbdon Reyes100% (1)

- 303-08 P1396 RepairDocument6 pages303-08 P1396 Repairmarcelo ustarezNo ratings yet

- Es7370 Br10lyDocument24 pagesEs7370 Br10lyJacksonNo ratings yet

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationFrom EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Navigator: Instructions For UseDocument84 pagesNavigator: Instructions For UseLuisaNo ratings yet

- 938280S Iss2Document74 pages938280S Iss2LuisaNo ratings yet

- Elitevt: Instructions For UseDocument64 pagesElitevt: Instructions For UseLuisaNo ratings yet

- 938280S Iss4Document84 pages938280S Iss4LuisaNo ratings yet

- Iss7Document48 pagesIss7LuisaNo ratings yet

- LESER India Catalogue Type 526 IC API Series PDFDocument12 pagesLESER India Catalogue Type 526 IC API Series PDFyg89No ratings yet

- 16271A0334. SeminarDocument13 pages16271A0334. SeminaranilbabuNo ratings yet

- RTPDocument16 pagesRTPsamyu83No ratings yet

- F3 - Checklist - HDPE Butt Fusion WeldingDocument1 pageF3 - Checklist - HDPE Butt Fusion WeldingQasim Saeed KhanNo ratings yet

- 2012-14 Revised Improvement PlanDocument7 pages2012-14 Revised Improvement Planapi-250619894No ratings yet

- Bd9470xxx eDocument38 pagesBd9470xxx eJose GargaglioneNo ratings yet

- Danfoss Cpce SeriesDocument7 pagesDanfoss Cpce SeriesLigan Budi PNo ratings yet

- 1200 10 Ceiling & LiningDocument7 pages1200 10 Ceiling & Liningmangeshshinde124No ratings yet

- Individual Assignments of EmergingDocument4 pagesIndividual Assignments of EmergingM.CedrickNo ratings yet

- CP SanitaryDocument2 pagesCP SanitaryMuthu ManiNo ratings yet

- Lecure-4 Biopotential Amplifiers & FiltersDocument87 pagesLecure-4 Biopotential Amplifiers & FiltersNoor Ahmed75% (4)

- Edtpa Lesson Plan 1Document2 pagesEdtpa Lesson Plan 1api-480117695No ratings yet

- Class XI Practical Assignment MysqlDocument6 pagesClass XI Practical Assignment Mysqlharsh0% (2)

- n6316 NVR User Manual v1.0 20130814 EnglishDocument114 pagesn6316 NVR User Manual v1.0 20130814 EnglishVũ ĐặngNo ratings yet

- Implementation and Monitoring:: Assessing Performance in Contract RelationshipsDocument49 pagesImplementation and Monitoring:: Assessing Performance in Contract RelationshipsReddy SumanthNo ratings yet

- 48 Tips For Active Inspire & PrometheanDocument12 pages48 Tips For Active Inspire & PrometheanPCHSbearsNo ratings yet

- MXT9000 enDocument2 pagesMXT9000 enntt_121987No ratings yet

- I0qm BalunDocument2 pagesI0qm BalunDundo SakićNo ratings yet

- DB-01 01 02 05-Pump-M189Document2 pagesDB-01 01 02 05-Pump-M189Miguel Jiménez FloresNo ratings yet

- 7SG18 Solkor N Catalogue Sheet PDFDocument16 pages7SG18 Solkor N Catalogue Sheet PDFEBENo ratings yet

- POC Panel ListDocument6 pagesPOC Panel ListPRETHISH G A 21ADR035No ratings yet

- Onboard Me M CFG Ref ProjDocument28 pagesOnboard Me M CFG Ref ProjWali AhsanNo ratings yet

- Scorereport 2Document3 pagesScorereport 2api-455855848No ratings yet

- Hire Charges of EquipmentDocument1 pageHire Charges of EquipmentDEEPAK100% (1)

- Novel Commercial Arrangements For Smart PDFDocument76 pagesNovel Commercial Arrangements For Smart PDFDEVULAL BNo ratings yet

- Stock+List 6ct8.3g2 Esn#30549237 Cpl#2218 GeneradorDocument34 pagesStock+List 6ct8.3g2 Esn#30549237 Cpl#2218 GeneradorAlexis SanchezNo ratings yet

- IPC-TM-650 Test Methods ManualDocument1 pageIPC-TM-650 Test Methods ManualWim Op 't VeldNo ratings yet

- Simple and Fractional DistillationDocument10 pagesSimple and Fractional DistillationJoana Bless PereyNo ratings yet

- 02AdvancedThinkAhead2 FinalExam1 AKDocument2 pages02AdvancedThinkAhead2 FinalExam1 AKmariasanztiNo ratings yet