Professional Documents

Culture Documents

Downloaded From Manuals Search Engine

Downloaded From Manuals Search Engine

Uploaded by

David QuispeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Downloaded From Manuals Search Engine

Downloaded From Manuals Search Engine

Uploaded by

David QuispeCopyright:

Available Formats

Downloaded from www.Manualslib.

com manuals search engine

FOREWORD

This supplement has been prepared to provide information

covering general service repairs for the 2L-T and 3 L engines

mounted on the TOYOTA LAND CRUISER, HI LUX, and

4RUNNER.

Applicable models:

LJ70, 72, 73, 77, 79 series

LN 106, 1 11, 130, 135 series

For basic engine service repair, refer to the following repair

manual.

2L, 3 L Engine Repair Manual (Pub. No. RM123E)

Please note that the publications below have also been prepared

as relevant service manuals to the components and systems in

this engine.

All information contained in this manual is the most up-to-date

a t the time of publication. However, specifications and proce-

dures are subject to change without notice.

TOYOTA MOTOR CORPORATION

Downloaded from www.Manualslib.com manuals search engine

TOYOTA

2L-T, 3 L ENGINE *

REPAIR M A N U A L

SUPPLEMENT

INTRODUCTION

ENGINE MECHANICAL mi

TURBOCHARGER SYSTEM

FUEL SYSTEM

COOLING SYSTEM

LUBRICATION SYSTEM la

STARTING SYSTEM

CHARGING SYSTEM

SERVICE SPECIFICATIONS

STANDARD BOLT TORQUE SPECIFICATIONS

SST AND SSM

01994 TOYOTA MOTOR CORPORATION

All rights reserved. This book may not be

reproduced or copied, in whole or in part,

without the written permission of Toyota

Motor Corporation.

Downloaded from www.Manualslib.com manuals search engine

INTRODUCTION

Page

HOW TO USE THIS MANUAL .................................. IN-2

IDENTIFICATION INFORMATION .............................. IN-4

GENERAL REPAIR INSTRUCTIONS ........................... IN-4

ABBREVIATIONS USED IN THIS MANUAL ................. IN-7

Downloaded from www.Manualslib.com manuals search engine

IN-2 INTRODUCTION - How to Use This Manual

HOW TO USE THIS MANUAL

To assist you in finding your way through this manual, the Sec-

tion Title and major heading are given a t the top of every page.

An INDEX is provided on the 1st page of each section to guide

you to the item t o be repaired.

A t the beginning of each section, PRECAUTIONS are given that

pertain to all repair operations contained in that section.

Read these precautions before starting any repair task,

TROUBLESHOOTING tables are included for each system to

help you diagnose the problem and find the cause. The repair

for each possible cause is referenced in the remedy column to

quickly lead you to the solution.

REPAIR PROCEDURES

Most repair operations begin with an overview illustration. I t

identifies the components and shows how the parts fit together.

Example:

kg-cm (ft-lb, ~ . r n ) ]: Specified torque

Non-reusablepart ~ ~ 2 1 1 1

Downloaded from www.Manualslib.com manuals search engine

INTRODUCTION - How to Use This Manual IN-3

The procedures are presented in a step-by-stepformat: &

a The illustration shows what to do and where to do it.

a The task heading tells what to do.

a The detailed text tells how to perform the task and gives

other information such as specifications and warnings.

Example:

Task heading: what to do

REMOVE CRANKSHAFT PULLEY

Using SST, remove the pulley.

SST 09213-60017 (09213-00060)

/'. \

illustration: Set part No. Component part No.

what to do and where

Detailed text: how to do task

/

Install the four injection nozzles.

Torque: 650 kg-cm (47 ft-lb, 64 N-m)

\ Specification

This format provides the experienced technician with a FAST

TRACK to the information needed. The upper case task head-

ing can be read a t a glance when necessary, and the text below

it provides detailed information. Important specifications and

warnings always stand out in bold type.

REFERENCES

References have been kept to a minimum. However; when they

are required, you are given the page to refer to.

SPECIFICATIONS

Specifications are presented in bold type throughout the text

where needed. You never have to leave the procedure to look

up your specifications. They are also found in Appendix A for

quick reference.

CAUTIONS, NOTICES, HINTS:

a CAUTIONS are presented in bold type, and indicate there i s

a possibility of injury to you or other people.

NOTICES are also presented in bold type, and indicate the

possibility of damage to the components being repaired.

HINTS are separated from the text but do not appear in bold.

They provide additional information to help you efficiently

perform the repair.

Downloaded from www.Manualslib.com manuals search engine

IN-4 INTRODUCTION - Identification Information. General R e ~ a i Instructions

r

IDENTIFICATION INFORMATION

ENGINE SERIAL NUMBER

The engine serial number is stamped on the left side of the

cylinder block.

GENERAL REPAIR INSTRUCTIONS

Use fender, seat and floor covers to keep the vehicle clean

and prevent damage.

During disassembly, keep parts in order to facilitate reas-

sembly.

Observe the following.

(a) Before performing electrical work, disconnect the

negative (-) cable from the battery terminal.

(b) I f it is necessary to disconnect the battery for inspec-

tion or repair, always disconnect the cable from the

negative (-) terminal which is grounded to the vehi-

cle body.

(c) To prevent damage to the battery terminal post, loos-

en the terminal nut and raise the cable straight up

without twisting or prying it.

(d) Clean the battery terminal posts and cable terminals

with a shop rag. Do not scrape them with a file or

other abrasive object.

(e) Install the cable terminal to the battery post with the

nut loose, and tighten the nut after installation. Do

not use a hammer to tap the terminal onto the post.

(f) Be sure the cover for the positive (+) terminal is pro-

perly in place.

Check hose and wiring connectors to make sure that they

are.secure and correct.

Non-reusable parts

(a) Always replace cotter pins, gaskets, O-rings, oil seals,

etc. with new ones.

(b) Non-reusable parts are indicated in the component

illustrations by the " 4 " symbol.

Precoated parts

Precoated parts are bolts and nuts, etc. These are coated

with a seal lock adhesive a t the factory.

(a) I f a precoated part is retightened, loosened or caused

to move in any way, it must be recoated with the

specified adhesive.

Seal Lock Adhesive

IN0036

Downloaded from www.Manualslib.com manuals search engine

INTRODUCTION - General Repair Instructions IN-5

(b) Recoating of Precoated Parts c

(1) Clean off the old adhesive from the part's

threads.

(2) Dry with compressed air.

(3) Apply the specified seal lock adhesive to the

part's threads.

(c) Precoated parts are indicated in the component illus-

trations by the " *" symbol.

7. When necessary, use a sealer on gaskets to prevent leaks.

8. Carefully observe all specifications for bolt torques.

Always use a torque wrench.

9. Use of special service tools (SST) and special service

materials (SSM) may be required, depending on the nature

of the repair. Be sure to use SST and SSM where specified

and follow the proper work procedure. A l i s t of SST and

SSM can be found at the back of this manual.

10. When replacing fuses, be sure the new fuse is the correct

amperage. DO NOT exceed the rating or use one of a

lower rating.

11. Care must be taken when jacking up and supporting the

vehicle. Be sure to lift and support the vehicle a t the

proper locations.

( a ) I f the vehicle is to be jacked up only a t the front or

rear end, be sure to block the wheels in order to en-

sure safety.

(b) After the vehicle is jacked up, be sure to support it on

stands. It is extremely dangerous to do any work on

the vehicle raised on a jack alone, even for a small job

that can be finished quickly.

12. Observe the following precautions to avoid damaging the

parts:

(a) Be careful not to drop electrical components, such as

sensors or relays. I f they are dropped on a hard floor,

they should be replaced and not reused.

(b) When separating electrical connectors, pull on the

connector itself, not the wires.

(c) When disconnecting vacuum hoses, pull on the end

of the hose, not the middle.

WRONG CORRECT

Downloaded from www.Manualslib.com manuals search engine

IN-6 INTRODUCTION - General R e ~ a i Instructions

r

Example (d) When steam cleaning an engine, protect the distribu-

// tor, coil, air filter, and injection pump from water.

(e) Never use an impact wrench to remove or install

temp. switches or temp. sensors.

(f) When checking continuity a t the wire connector, in-

sert the tester probe carefully to prevent terminals

from bending.

(g) When using a vacuum gauge, never force the hose on-

to a connector that is too large. Use a step-down

adapter instead. Once the hose has been stretched, it

may leak.

13. Tag hoses before disconnecting them:

(a) When disconnecting vacuum hoses, use tags to iden-

tify how they should be reconnected.

(b) After completing a job, double check that the vacu-

um hoses are properly connected. A label under the

hood shows the proper layout.

Downloaded from www.Manualslib.com manuals search engine

INTRODUCTION - Abbreviations Used in This Manual IN-7

ABBREVIATIONS USED IN THIS MANUAL,

AIC Air Conditioner

ACSD Automatic Cold Start Device

Approx. Approximately

EGR Exhaust Gas Recirculation

EVRV Electronic Vacuum Regulating Valve

EX Exhaust (manifold, valve)

Ex. Except

F l PG Formed i n Place Gasket

FL Fusible Link

HAC High Altitude Compensation

IN Intake (manifold, valve)

LH Left-Hand

01s Oversized

PIJ Pilot Injection Device

RH Right-Hand

SSM Special Service Materials

SST Special Service Tools

ST D Standard

TDC Top Dead Center

UIS Undersize

VSV Vacuum Switching Valve

w/ With

wlo. Without

Downloaded from www.Manualslib.com manuals search engine

You might also like

- Toyota 1PZ 1HZ 1HD T Engine Repair Manual Rm172e PDFDocument348 pagesToyota 1PZ 1HZ 1HD T Engine Repair Manual Rm172e PDFSalim Abdulrahim100% (7)

- Ford Fiesta Mk7 Routine Maintenance Guide (2013 To 2017 Models) - Haynes PublishingDocument7 pagesFord Fiesta Mk7 Routine Maintenance Guide (2013 To 2017 Models) - Haynes PublishinggregNo ratings yet

- Installation of Cylinder Head: Downloaded From Manuals Search EngineDocument6 pagesInstallation of Cylinder Head: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Installation of Cylinder Head: Downloaded From Manuals Search EngineDocument6 pagesInstallation of Cylinder Head: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Toyota 2azfe Valve Clearance PDFDocument9 pagesToyota 2azfe Valve Clearance PDFMarcos EmmanuelNo ratings yet

- Light Vehicle Engine Mechanical, Lubrication & Cooling System Units & ComponentsDocument56 pagesLight Vehicle Engine Mechanical, Lubrication & Cooling System Units & Componentsgeorge_zouridisNo ratings yet

- FT 70 - 80 DT Dual Transmission PDFDocument78 pagesFT 70 - 80 DT Dual Transmission PDFAntnhe BayuNo ratings yet

- Palava Case Study FinalDocument24 pagesPalava Case Study Finalanon_66961994100% (1)

- 13C PDFDocument81 pages13C PDFKyaw Kyaw LinnNo ratings yet

- Em2008 PDFDocument407 pagesEm2008 PDFBeto GarciaNo ratings yet

- LR4 2010 5.0LDocument832 pagesLR4 2010 5.0LLuis Ramon Arguello RealNo ratings yet

- Almera N16 TechDocument4 pagesAlmera N16 TechSpiros FousasNo ratings yet

- Adjustment of Valve Clearance: No. 1 No. 3 EX EXDocument11 pagesAdjustment of Valve Clearance: No. 1 No. 3 EX EXDavid QuispeNo ratings yet

- Customer Experience Center 1-800-331-4331: Quick Reference GuideDocument30 pagesCustomer Experience Center 1-800-331-4331: Quick Reference GuideNaveed Gondal100% (1)

- MGA Workshop ManualDocument296 pagesMGA Workshop ManualTony CapuanoNo ratings yet

- 1hd T PDFDocument2 pages1hd T PDFAnonymous wpUyixsjNo ratings yet

- Engine MechanicalDocument17 pagesEngine MechanicalAdrian Marian GafincuNo ratings yet

- Land Cruiser 2009Document296 pagesLand Cruiser 2009anaNo ratings yet

- TATA Minibus 407 MaintainanceDocument13 pagesTATA Minibus 407 MaintainancePraveen Kumar ReddyNo ratings yet

- Catalog Isuzu Elf Euro 2 NKR 55Document5 pagesCatalog Isuzu Elf Euro 2 NKR 55excelmin338No ratings yet

- Peugeot Jetforce ManualDocument43 pagesPeugeot Jetforce ManualLukas Jar100% (1)

- Toyota 5l Valve ClearanceDocument5 pagesToyota 5l Valve ClearancedennoNo ratings yet

- Lombardini LDW 442 CRS - GBDocument144 pagesLombardini LDW 442 CRS - GBAndrej ŠtirnNo ratings yet

- Nissan Zd30 Ddti Em2 IngDocument9 pagesNissan Zd30 Ddti Em2 IngJose Luis Jimenez HuashuayoNo ratings yet

- EM Nissan Yd 2008 PDFDocument211 pagesEM Nissan Yd 2008 PDFAlex Polo LuisNo ratings yet

- Navara Owner Manual en 2017Document336 pagesNavara Owner Manual en 2017Mary Ann UsaragaNo ratings yet

- Mitsubishi Engine F9Q Series Workshop ManualDocument48 pagesMitsubishi Engine F9Q Series Workshop ManualAlexandru sNo ratings yet

- How To Set or Cancel Service ReminderDocument3 pagesHow To Set or Cancel Service Reminderbubuyat0% (1)

- 2000 Nissan Frontier KA24DE LCDocument16 pages2000 Nissan Frontier KA24DE LCDavid CervantesNo ratings yet

- Charging For Toyota Land CruiserDocument16 pagesCharging For Toyota Land CruiserAbu AliNo ratings yet

- Mitsubishi FTODocument14 pagesMitsubishi FTOJhonatan JalluranaNo ratings yet

- Sds Toyota vx100Document8 pagesSds Toyota vx100Ferry DarmawanNo ratings yet

- Cylinder Head Bolt Tightening SequenceDocument2 pagesCylinder Head Bolt Tightening Sequenceອູ່ ໄຊ ອິນເຕີNo ratings yet

- 017 - Automatic Transmission - 6T70 (M7U M7W) - Repair Instructions - On VehicleDocument98 pages017 - Automatic Transmission - 6T70 (M7U M7W) - Repair Instructions - On VehicleGedas GvildysNo ratings yet

- Кардан Передний Задний Мосты LGPRO-WE-0554 - 1st - WSMW - 05 - N - G.Exp - 729Document188 pagesКардан Передний Задний Мосты LGPRO-WE-0554 - 1st - WSMW - 05 - N - G.Exp - 729Dmitry BondarNo ratings yet

- Frontier d22 - Sist DireccionDocument43 pagesFrontier d22 - Sist DireccionrubenNo ratings yet

- Y61 CRD X Sm7e-Y61kg1 emDocument22 pagesY61 CRD X Sm7e-Y61kg1 emDaniel BruceNo ratings yet

- Engine 2 0 103 KW TDI PD 2 0 100 KW TDI PDDocument262 pagesEngine 2 0 103 KW TDI PD 2 0 100 KW TDI PD19crystiNo ratings yet

- 2002 Subaru ImprezaDocument3,337 pages2002 Subaru Imprezagigabyte3235840No ratings yet

- Atc Sistema XtrailDocument164 pagesAtc Sistema XtrailOscarPeredaNo ratings yet

- G10 Maintanence Manual-Gasoline-20211027Document56 pagesG10 Maintanence Manual-Gasoline-20211027Toby MijaresNo ratings yet

- Ford Ranger Spare PartsDocument2 pagesFord Ranger Spare PartsNgila João AndréNo ratings yet

- Engine - VQ25DE and VQ35DE Cooling System PDFDocument27 pagesEngine - VQ25DE and VQ35DE Cooling System PDFscott glackenNo ratings yet

- Trailblazer 28288123 PDFDocument300 pagesTrailblazer 28288123 PDFkamote ka0% (1)

- Live You : Technical Data: Fluids & CapacitiesDocument3 pagesLive You : Technical Data: Fluids & CapacitiesАндрей УгляницаNo ratings yet

- Diagnose Timing Chain Fault: How To Diagnose A Timing Chain Fault in The YD25 D40, D22 Navara & R51 Pathfinder EngineDocument4 pagesDiagnose Timing Chain Fault: How To Diagnose A Timing Chain Fault in The YD25 D40, D22 Navara & R51 Pathfinder EngineJuan VarelaNo ratings yet

- Nissan Livina L11 - Engine Control SystemDocument629 pagesNissan Livina L11 - Engine Control SystemH. Yusmira (Kang Otto)No ratings yet

- Mivec: MIVEC (Mitsubishi Innovative Valve Timing Electronic Control System)Document5 pagesMivec: MIVEC (Mitsubishi Innovative Valve Timing Electronic Control System)alibababujanglapokNo ratings yet

- Manual Patrol Y61Document54 pagesManual Patrol Y61linda5healNo ratings yet

- Engine Lubrication System: SectionDocument23 pagesEngine Lubrication System: Sectiontomallor101No ratings yet

- p5 5S-FE+ENGINE+REPAIR+MANUALDocument23 pagesp5 5S-FE+ENGINE+REPAIR+MANUALkavindaNo ratings yet

- Ford Ecosport Trend 1.5L Ti-VCT Owners ManualDocument236 pagesFord Ecosport Trend 1.5L Ti-VCT Owners ManualJoeDabid100% (1)

- Volkswagen 6 Speed Dual Clutch Gearbox 02e Workshop Manual Edition 072010 Mex5r006620Document105 pagesVolkswagen 6 Speed Dual Clutch Gearbox 02e Workshop Manual Edition 072010 Mex5r006620strobo333No ratings yet

- Engine Management OverviewDocument73 pagesEngine Management OverviewZM Ohn100% (3)

- Sec 05 BRAKES For Isuzu PantherDocument52 pagesSec 05 BRAKES For Isuzu PantherAsep Ahmad SaepulohNo ratings yet

- Engine Specifications: February 2001 ES-TOY07R1Document2 pagesEngine Specifications: February 2001 ES-TOY07R1Pencil neck100% (1)

- Kia Sedona Grand Carnival Owner's ManualDocument593 pagesKia Sedona Grand Carnival Owner's Manualraza514No ratings yet

- Toyota Landcruiser: (Kinetic Dynamic Suspension System)Document1 pageToyota Landcruiser: (Kinetic Dynamic Suspension System)george_mudura1No ratings yet

- Automatic Air Conditioner: SectionDocument136 pagesAutomatic Air Conditioner: SectiondaltonNo ratings yet

- Toyota Tester 2 Scanner ManualDocument136 pagesToyota Tester 2 Scanner ManualMohammed Alhaddad100% (1)

- 03 ClutchDocument23 pages03 Clutcheko sulistyo utomoNo ratings yet

- Toyota 1hd FT Engine Repair ManualDocument20 pagesToyota 1hd FT Engine Repair Manualjohn100% (59)

- Atmega16 (L) : Table 106. Pin Name Mapping (Continued)Document6 pagesAtmega16 (L) : Table 106. Pin Name Mapping (Continued)David QuispeNo ratings yet

- Atmega16 (L) : Programming The EepromDocument6 pagesAtmega16 (L) : Programming The EepromDavid QuispeNo ratings yet

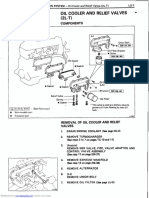

- !3imzy: Oil Cooler and Relief ValvesDocument6 pages!3imzy: Oil Cooler and Relief ValvesDavid QuispeNo ratings yet

- Fuel System FU-11 11. Remove Governor Cover: Downloaded From Manuals Search EngineDocument6 pagesFuel System FU-11 11. Remove Governor Cover: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Troubleshooting: Downloaded From Manuals Search EngineDocument6 pagesTroubleshooting: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Installation of Injection Pump: Downloaded From Manuals Search EngineDocument6 pagesInstallation of Injection Pump: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Starting System: Differ From The Above Listed ManualDocument6 pagesStarting System: Differ From The Above Listed ManualDavid QuispeNo ratings yet

- Is As: &sleeve PlugDocument6 pagesIs As: &sleeve PlugDavid QuispeNo ratings yet

- Datasheet (3) (254-284) - 1-5Document5 pagesDatasheet (3) (254-284) - 1-5David QuispeNo ratings yet

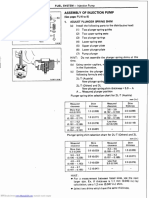

- Assembly of Injection Pump: FU-16 Fuel SystemDocument6 pagesAssembly of Injection Pump: FU-16 Fuel SystemDavid QuispeNo ratings yet

- Downloaded From Manuals Search EngineDocument6 pagesDownloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Downloaded From Manuals Search EngineDocument6 pagesDownloaded From Manuals Search EngineDavid QuispeNo ratings yet

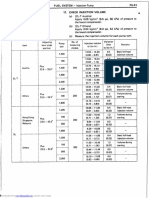

- Fuel System FU-31 2. Pre-Set Full Load Injection VolumeDocument6 pagesFuel System FU-31 2. Pre-Set Full Load Injection VolumeDavid QuispeNo ratings yet

- I Removal of TurbochargerDocument6 pagesI Removal of TurbochargerDavid QuispeNo ratings yet

- 2L-T W/ Hac: Downloaded From Manuals Search EngineDocument6 pages2L-T W/ Hac: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- System: Differ From The Above Listed ManualDocument6 pagesSystem: Differ From The Above Listed ManualDavid QuispeNo ratings yet

- Adjustment of Valve Clearance: No. 1 No. 3 EX EXDocument11 pagesAdjustment of Valve Clearance: No. 1 No. 3 EX EXDavid QuispeNo ratings yet

- Troubleshooting: Insufficient Acceleration, Lack of Power or Excessive Fuel ConsumptionDocument6 pagesTroubleshooting: Insufficient Acceleration, Lack of Power or Excessive Fuel ConsumptionDavid QuispeNo ratings yet

- Components: Downloaded From Manuals Search EngineDocument6 pagesComponents: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Intake Venturi System (LN 2L-T: Only)Document11 pagesIntake Venturi System (LN 2L-T: Only)David QuispeNo ratings yet

- (Others) : Downloaded From Manuals Search EngineDocument10 pages(Others) : Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Inspection and Repair of Crankshaft: Crank Journal DiameterDocument6 pagesInspection and Repair of Crankshaft: Crank Journal DiameterDavid QuispeNo ratings yet

- 4Y Engine: TOYOTA Material Handling CompanyDocument10 pages4Y Engine: TOYOTA Material Handling CompanyDavid QuispeNo ratings yet

- Excessive Fuel Consumption: Downloaded From Manuals Search EngineDocument10 pagesExcessive Fuel Consumption: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Excessive Exhaust S M O K E: Downloaded From Manuals Search EngineDocument11 pagesExcessive Exhaust S M O K E: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Cutout: Downloaded From Manuals Search EngineDocument10 pagesCutout: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Trouble Diagnosis Trouble Diagnosis Trouble Diagnosis IntroductionDocument66 pagesTrouble Diagnosis Trouble Diagnosis Trouble Diagnosis IntroductionDavid QuispeNo ratings yet

- Abbreviations Used in Manual,: Downloaded From Manuals Search EngineDocument11 pagesAbbreviations Used in Manual,: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Ascd Brake Switch Ascd Brake Switch Component Description: Ec-29, "Automatic Speed Control Device (Ascd) "Document12 pagesAscd Brake Switch Ascd Brake Switch Component Description: Ec-29, "Automatic Speed Control Device (Ascd) "David QuispeNo ratings yet

- Hydrogen 11th Chemistry MCQDocument18 pagesHydrogen 11th Chemistry MCQsameer devidasNo ratings yet

- PHA7/W: Physics (Specification A) PHA7/W Unit 7 Nuclear Instability: Applied Physics OptionDocument12 pagesPHA7/W: Physics (Specification A) PHA7/W Unit 7 Nuclear Instability: Applied Physics OptionAli WanNo ratings yet

- .Design and Development of Motorized Multipurpose MachineDocument3 pages.Design and Development of Motorized Multipurpose MachineANKITA MORENo ratings yet

- 988GDocument24 pages988GCao Hao NguyenNo ratings yet

- Joint Efficiency and Quality FactorDocument2 pagesJoint Efficiency and Quality FactorVioleta&Florin GasparNo ratings yet

- Indonesia Energy Outlook 2021 enDocument120 pagesIndonesia Energy Outlook 2021 enrully prayogaNo ratings yet

- SWP-Confined Space EntryDocument11 pagesSWP-Confined Space EntryMainrajNo ratings yet

- VT-pro 525-625 Service Manual PDFDocument13 pagesVT-pro 525-625 Service Manual PDFMario A. RojoNo ratings yet

- Physical Science 3Document6 pagesPhysical Science 3Morelei FernandezNo ratings yet

- CMT 555 - EXPERIMENT 4 - Determination of AvogadroDocument12 pagesCMT 555 - EXPERIMENT 4 - Determination of AvogadroafifiNo ratings yet

- 2013-2 Reactions and Properties of Lewis Acids and BasesDocument42 pages2013-2 Reactions and Properties of Lewis Acids and BasesTsabita AfaaninNo ratings yet

- Origin of The Universe PDFDocument3 pagesOrigin of The Universe PDFReynante SantosNo ratings yet

- Transformer XII B Physics Shivam Beda InvestigatoryDocument14 pagesTransformer XII B Physics Shivam Beda InvestigatoryJohn SamuelNo ratings yet

- 66 KV Substation Getco RanasanDocument7 pages66 KV Substation Getco RanasanDivyanshu Agarwal100% (1)

- S o L U T I o N o F U P S C P A P e R S O F B A S I C A N D A P P L I e D T H e R M o D y N A M I C S F I R S T L A W o F T H e R M o D y N A M I C SDocument18 pagesS o L U T I o N o F U P S C P A P e R S O F B A S I C A N D A P P L I e D T H e R M o D y N A M I C S F I R S T L A W o F T H e R M o D y N A M I C SHimanshu Chauhan50% (2)

- CrystalDocument22 pagesCrystalAshok PradhanNo ratings yet

- Effects On Transmission LinesDocument4 pagesEffects On Transmission Linesscripduser1533No ratings yet

- 962gii PDFDocument28 pages962gii PDFMA TotalforkliftNo ratings yet

- JS750 Concrete MixerDocument5 pagesJS750 Concrete MixerErikNo ratings yet

- Hoja de Datos Motor de Inducción CEM31112 0.75HPDocument10 pagesHoja de Datos Motor de Inducción CEM31112 0.75HPSergio VargasNo ratings yet

- SB E082qbebiconDocument8 pagesSB E082qbebiconMAZENNo ratings yet

- Enel Sustainability-Report 2022Document593 pagesEnel Sustainability-Report 2022muhammad farisNo ratings yet

- Annexure-III Chimney Spec (1) .Document31 pagesAnnexure-III Chimney Spec (1) .oundhakar100% (1)

- Session 23 Local Climate Change Expenditure TaggingDocument72 pagesSession 23 Local Climate Change Expenditure TaggingMDRRMC Response1855No ratings yet

- Manual Zaf-Zdaf EngDocument20 pagesManual Zaf-Zdaf EngIulian TitaNo ratings yet

- Metro ClarkDocument21 pagesMetro ClarkRowelito Talawan67% (6)

- Open Circuit Current Transformer Characteristics - Voltage DisturbanceDocument4 pagesOpen Circuit Current Transformer Characteristics - Voltage DisturbanceAdam AbrahamNo ratings yet

- Oilfield IndexDocument56 pagesOilfield IndexEmad AliNo ratings yet

- EN380 Naval Materials Science and Engineering Course Notes, U.S. Naval AcademyDocument11 pagesEN380 Naval Materials Science and Engineering Course Notes, U.S. Naval AcademyTheophilus Oduro-NyarkoNo ratings yet