Professional Documents

Culture Documents

3.3.3 Liquid Seal: 3.3 Separating Function 3 Separator Basics

3.3.3 Liquid Seal: 3.3 Separating Function 3 Separator Basics

Uploaded by

Ivan Kawempy0 ratings0% found this document useful (0 votes)

14 views1 pageThis document discusses liquid seals and the position of the interface in a purifier bowl separator. A liquid seal prevents the light liquid phase from flowing over the edge of the top disc, maintaining separation. The sealing liquid must be insoluble in the light phase, have a lower density than the heavy phase, and can be soluble in the heavy phase. In most cases, the heavy phase is used as the sealing liquid. The position of the interface is adjusted for optimal separation by altering the pressure balance between liquid phases using gravity discs of varying diameters to change the outlet size for the heavy phase.

Original Description:

Original Title

Alfa MAB104-26

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document discusses liquid seals and the position of the interface in a purifier bowl separator. A liquid seal prevents the light liquid phase from flowing over the edge of the top disc, maintaining separation. The sealing liquid must be insoluble in the light phase, have a lower density than the heavy phase, and can be soluble in the heavy phase. In most cases, the heavy phase is used as the sealing liquid. The position of the interface is adjusted for optimal separation by altering the pressure balance between liquid phases using gravity discs of varying diameters to change the outlet size for the heavy phase.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

14 views1 page3.3.3 Liquid Seal: 3.3 Separating Function 3 Separator Basics

3.3.3 Liquid Seal: 3.3 Separating Function 3 Separator Basics

Uploaded by

Ivan KawempyThis document discusses liquid seals and the position of the interface in a purifier bowl separator. A liquid seal prevents the light liquid phase from flowing over the edge of the top disc, maintaining separation. The sealing liquid must be insoluble in the light phase, have a lower density than the heavy phase, and can be soluble in the heavy phase. In most cases, the heavy phase is used as the sealing liquid. The position of the interface is adjusted for optimal separation by altering the pressure balance between liquid phases using gravity discs of varying diameters to change the outlet size for the heavy phase.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

3.

3 Separating function 3 Separator Basics

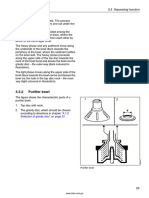

3.3.3 Liquid seal

In a purifier bowl the liquid seal prevents the light

liquid phase from passing the outer edge of the

top disc, thus eliminating flow out through the

outer path. The bowl must therefore be filled with

sealing liquid before the process liquid is

admitted. The sealing liquid will be displaced

slightly by the process liquid into a position that

forms the interface. The location of the interface

will be affected by the relative difference in

density between the phases, but is also

dependent on outer and inner diameters (D1 and

D2 respectively).

The sealing liquid:

• must be insoluble in the light phase.

• must not have higher density than the heavy

phase.

• can be soluble in the heavy phase.

In most cases the heavy phase is used as sealing

G0612011

liquid.

In some cases and only if the process liquid

contains a sufficient quantity of heavy phase

(more than 25%), the process liquid can be

supplied directly as the seal will form

automatically.

3.3.4 Position of interface -

gravity disc

The position of the interface is adjusted for

optimum separation by altering the pressure

balance of the two liquid phases oil and water

inside the separator.

The purifier bowl is adjusted for separation liquid

mixtures with various specific gravity ratios by

altering the diameter of the outlet for the heavy

phase (D2). The heavier or more viscous the light

phase and the larger the liquid feed the smaller

the diameter should be. For this purpose a

number of gravity discs with various hole

diameters is delivered with the separator.

G0600711

Exchange of gravity disc

26

ventas@fdm.com.pe

fdmsac@gmail.com www.fdm.com.pe

whatsapp:959440045

You might also like

- Walid Sabry Very Important Mud Questions, February 2022Document109 pagesWalid Sabry Very Important Mud Questions, February 2022farrog.cryptoNo ratings yet

- Washpipe Assembly Washpipe Assembly: Service ManualDocument60 pagesWashpipe Assembly Washpipe Assembly: Service ManualIvan Kawempy100% (4)

- 3 Separator Basics 3.3 Separating Function: Gravity DiscDocument1 page3 Separator Basics 3.3 Separating Function: Gravity DiscivanNo ratings yet

- Lubrication Testing ProcedureDocument4 pagesLubrication Testing Procedurehunshing1952No ratings yet

- Particle Mech Topic 8Document8 pagesParticle Mech Topic 8Michael Kang'eriNo ratings yet

- PHM - 07-Lecture 07 (Liquid Solid Separation)Document16 pagesPHM - 07-Lecture 07 (Liquid Solid Separation)Ritvi BartiyaNo ratings yet

- Sandaband Material: A Cost Saving Technical Revolution!Document4 pagesSandaband Material: A Cost Saving Technical Revolution!Qaiser HafeezNo ratings yet

- 06-Barite SagDocument9 pages06-Barite SagmarboudNo ratings yet

- Rms Polytechnic: Prepared By: Priyanka PatelDocument35 pagesRms Polytechnic: Prepared By: Priyanka PatelBhaumik ParmarNo ratings yet

- Thickener vs. ClarifierDocument2 pagesThickener vs. ClarifierBhaski Madhappan100% (1)

- Draft - Sludge ManipulationDocument9 pagesDraft - Sludge ManipulationAndrea Gilang FauziNo ratings yet

- Dispersion Know HowDocument24 pagesDispersion Know HowQuimicosgenericosgaffaro GaffaroNo ratings yet

- Measures Affects Desirable Limits Control Flow PropertiesDocument1 pageMeasures Affects Desirable Limits Control Flow PropertiesAndrei CazacuNo ratings yet

- Article - Mixing Process ClassificationsDocument5 pagesArticle - Mixing Process ClassificationsraritylimNo ratings yet

- Spraying and Atomizing of Liquids: TU, Dortmund, GermanyDocument30 pagesSpraying and Atomizing of Liquids: TU, Dortmund, GermanyAndrea BoriNo ratings yet

- 3.1 Basic Principles of SeparationDocument1 page3.1 Basic Principles of SeparationIvan KawempyNo ratings yet

- Leaching EquipmentsDocument32 pagesLeaching EquipmentsArun Kumar80% (5)

- BOSTIK Flowfill NonShrinkGroutGP Rev1Document3 pagesBOSTIK Flowfill NonShrinkGroutGP Rev1Antonette Marie ElgarioNo ratings yet

- DS 730 HS-Super GroutDocument2 pagesDS 730 HS-Super GroutJignessh JoshiNo ratings yet

- Pre CleanerDocument8 pagesPre CleanerKhairi MohammadNo ratings yet

- Brines and Other Workover FluidsDocument90 pagesBrines and Other Workover Fluidsqazim786100% (4)

- SuspensionsDocument21 pagesSuspensionsFatimaalzahraa KazomNo ratings yet

- Rotary Pre CoatDocument5 pagesRotary Pre Coatagrocel_bhv5591No ratings yet

- Liquid Liquid Separation TechnologyDocument16 pagesLiquid Liquid Separation TechnologyMurrali Raj JeyagapalNo ratings yet

- Gravity Thickeners and Clarifiers - ReportDocument14 pagesGravity Thickeners and Clarifiers - ReportKristine Kaye TomimbangNo ratings yet

- What Is Gravity Disc of Purifier - Selection and Fuctions of Purifier Gravity Disc - MarinesiteDocument1 pageWhat Is Gravity Disc of Purifier - Selection and Fuctions of Purifier Gravity Disc - Marinesitedesign murahNo ratings yet

- Lanko 702 Durabed Data Sheet April 2006Document4 pagesLanko 702 Durabed Data Sheet April 2006Lenard BuenaventuraNo ratings yet

- Filtration and Cake Thickness: Fluid TestingDocument8 pagesFiltration and Cake Thickness: Fluid TestingLawson IdukuNo ratings yet

- Mud NotesDocument56 pagesMud Notesrainaldy sebastianNo ratings yet

- Chapter 3Document67 pagesChapter 3TaytoNo ratings yet

- Liquid Liquid Separation TechnologyDocument16 pagesLiquid Liquid Separation TechnologyaravindNo ratings yet

- Spin Coating Sythesis of Films: Lab ManualDocument20 pagesSpin Coating Sythesis of Films: Lab Manualtarun yadavNo ratings yet

- W2b SlidesTekstDocument7 pagesW2b SlidesTekstAlvaro Torres AravenaNo ratings yet

- A Review of Lime SlakersDocument18 pagesA Review of Lime SlakerspuracsintesesNo ratings yet

- Decantation: Presented By: Harshit Patwa Mahendra Pratap SinghDocument9 pagesDecantation: Presented By: Harshit Patwa Mahendra Pratap SinghmotilalNo ratings yet

- Mud 1Document5 pagesMud 1MohamedElAbbasyNo ratings yet

- Walid Questions, 2020Document69 pagesWalid Questions, 2020MoNo ratings yet

- Tech Sheet Ar L SDocument2 pagesTech Sheet Ar L Sjhonny tintin barrosNo ratings yet

- CompletionDocument62 pagesCompletionavanishNo ratings yet

- Thickening StaticDocument5 pagesThickening Staticzamburitti100% (1)

- Rupture Disc 1Document12 pagesRupture Disc 1venkeekuNo ratings yet

- The Pusher CentrifugeDocument4 pagesThe Pusher CentrifugetafakorNo ratings yet

- Lecture Notes - Module 2 - Contact Angle Phenomena-1Document16 pagesLecture Notes - Module 2 - Contact Angle Phenomena-1Archa UnniNo ratings yet

- Principle of SedimentationDocument13 pagesPrinciple of SedimentationKataiTaiNo ratings yet

- Separation Process in Oil and Gas - Part-2 by Anand PatelDocument10 pagesSeparation Process in Oil and Gas - Part-2 by Anand PatelAbderrahmane AbderrahmaniNo ratings yet

- Dry-Jet-Wet SpinningDocument16 pagesDry-Jet-Wet SpinningaadishNo ratings yet

- Sedimentation CE4305Document117 pagesSedimentation CE4305Jeezan AzikNo ratings yet

- 2020.02.19 3 Phase Disc SeparatorDocument12 pages2020.02.19 3 Phase Disc SeparatorGeorgeNo ratings yet

- RCT-ConGrout GPDocument3 pagesRCT-ConGrout GPfahadNo ratings yet

- Jigging: Mineral ProcessingDocument16 pagesJigging: Mineral ProcessingnitinrnnnNo ratings yet

- Sedimentation: Thus, Sedimentor Has Two-Fold FunctionDocument5 pagesSedimentation: Thus, Sedimentor Has Two-Fold FunctionSunday AugustineNo ratings yet

- 012 Water Control-Abbas RadhiDocument16 pages012 Water Control-Abbas RadhiNasih Noori100% (1)

- Cera Grout 40Document2 pagesCera Grout 40Anwar Hussain100% (1)

- MasterFlow 526Document3 pagesMasterFlow 526ashraf komiNo ratings yet

- 2022.10.28 3 Phase Decanter CentrifugeDocument14 pages2022.10.28 3 Phase Decanter CentrifugeGeorgeNo ratings yet

- Wetting and Dispersing Additives: TEGO® DispersDocument12 pagesWetting and Dispersing Additives: TEGO® DispersChinmoy DholeNo ratings yet

- Drip-Off Effect ManualDocument16 pagesDrip-Off Effect Manualpro6339No ratings yet

- Volute Dewatering PressDocument4 pagesVolute Dewatering PressPj EboraNo ratings yet

- LJ Dosing Technology Seminar enDocument80 pagesLJ Dosing Technology Seminar enafoliveiraNo ratings yet

- 3.3.1 Purification: 3.3 Separating Function 3 Separator BasicsDocument1 page3.3.1 Purification: 3.3 Separating Function 3 Separator BasicsIvan KawempyNo ratings yet

- 3 Separator Basics 3.3 Separating Function: 3.3.2 Purifier BowlDocument1 page3 Separator Basics 3.3 Separating Function: 3.3.2 Purifier BowlIvan KawempyNo ratings yet

- 3 Separator Basics 3.3 Separating FunctionDocument1 page3 Separator Basics 3.3 Separating FunctionIvan KawempyNo ratings yet

- 3.1.1 Factors Influencing The Separation Result: 3 Separator Basics 3.1 Basic Principles of SeparationDocument1 page3.1.1 Factors Influencing The Separation Result: 3 Separator Basics 3.1 Basic Principles of SeparationIvan KawempyNo ratings yet

- 3 Separator Basics 3.1 Basic Principles of Separation: Disc StackDocument1 page3 Separator Basics 3.1 Basic Principles of Separation: Disc StackIvan KawempyNo ratings yet

- 3.1 Basic Principles of SeparationDocument1 page3.1 Basic Principles of SeparationIvan KawempyNo ratings yet

- Shell Cyprina Grease Ra: High Quality Lithium Soap GreaseDocument2 pagesShell Cyprina Grease Ra: High Quality Lithium Soap GreaseIvan KawempyNo ratings yet

- Cyprina 3Document1 pageCyprina 3Ivan KawempyNo ratings yet

- 1 Read This First: Safety InstructionsDocument1 page1 Read This First: Safety InstructionsIvan KawempyNo ratings yet

- Issue 1 Document No: VSM300-OM-0006 Contents Index Page 4 of 5Document1 pageIssue 1 Document No: VSM300-OM-0006 Contents Index Page 4 of 5Ivan KawempyNo ratings yet

- BOP Control Air Pump Type 80 - Parts ManualDocument5 pagesBOP Control Air Pump Type 80 - Parts ManualIvan KawempyNo ratings yet

- Issue 1 Document No: VSM300-OM-0006 Contents Index Page 3 of 5Document1 pageIssue 1 Document No: VSM300-OM-0006 Contents Index Page 3 of 5Ivan KawempyNo ratings yet

- Issue 1 Document No: VSM300-OM-0006 Contents Index Page 2 of 5Document1 pageIssue 1 Document No: VSM300-OM-0006 Contents Index Page 2 of 5Ivan KawempyNo ratings yet

- Overhaul DC Motor 1000HP: PT. ABB Sakti IndustriDocument16 pagesOverhaul DC Motor 1000HP: PT. ABB Sakti IndustriIvan KawempyNo ratings yet

- Issue 1 Document No: VSM300-OM-0006 Contents Index Page 1 of 5Document1 pageIssue 1 Document No: VSM300-OM-0006 Contents Index Page 1 of 5Ivan KawempyNo ratings yet

- Overhaul DC Motor 1000HP: PT. ABB Sakti IndustriDocument13 pagesOverhaul DC Motor 1000HP: PT. ABB Sakti IndustriIvan KawempyNo ratings yet

- WPS 002 ASME Section IXDocument4 pagesWPS 002 ASME Section IXIvan KawempyNo ratings yet