Professional Documents

Culture Documents

"Guard Touch" Control Panel: Main Features

"Guard Touch" Control Panel: Main Features

Uploaded by

Musharraf KhanCopyright:

Available Formats

You might also like

- Calculation of Short-Circuit IEC 60909Document6 pagesCalculation of Short-Circuit IEC 60909Iuliu Grad88% (8)

- Rotating Equipment Codes and StandardsDocument2 pagesRotating Equipment Codes and StandardsWong Da100% (8)

- Cat Lovato RGAMDocument2 pagesCat Lovato RGAMDavid Martinez100% (2)

- 906-0106 Cummins QSL9-G5 Engine Parts Manual (6-2015) PDFDocument56 pages906-0106 Cummins QSL9-G5 Engine Parts Manual (6-2015) PDFWaqar Ahmed83% (6)

- Switching Power Supply Design: A Concise Practical HandbookFrom EverandSwitching Power Supply Design: A Concise Practical HandbookNo ratings yet

- Lovato Engine and Gen Controllers PDFDocument10 pagesLovato Engine and Gen Controllers PDFMariano Macchi100% (1)

- Specific Relay For The Management of Line Telecommutations and Relief Generator SetsDocument4 pagesSpecific Relay For The Management of Line Telecommutations and Relief Generator SetsKaiser IqbalNo ratings yet

- Etheric Energy Healing ManualDocument6 pagesEtheric Energy Healing ManualDavid Nolan96% (28)

- HT-GC315-Plus-Link DS EN 01.2015 V2.0Document4 pagesHT-GC315-Plus-Link DS EN 01.2015 V2.0shakir tkNo ratings yet

- HT-MC100 DS en 02.2013 V3.2Document3 pagesHT-MC100 DS en 02.2013 V3.2Muhammad UmarNo ratings yet

- Up To 24 Gensets Connected On The Same Bus and Mains Parallel ApplicationDocument20 pagesUp To 24 Gensets Connected On The Same Bus and Mains Parallel ApplicationMohamed Saber100% (1)

- GCP 30Document4 pagesGCP 30wagner_guimarães_10% (1)

- GC315 RENTAL Gensets GC315: Perfect For Groups ofDocument4 pagesGC315 RENTAL Gensets GC315: Perfect For Groups ofWallace FerreiraNo ratings yet

- GC315 RENTAL Gensets GC315: Perfect For Groups ofDocument4 pagesGC315 RENTAL Gensets GC315: Perfect For Groups ofRamon Thales DomeniconiNo ratings yet

- GC315 RENTAL Gensets GC315: Perfect For Groups ofDocument4 pagesGC315 RENTAL Gensets GC315: Perfect For Groups ofRamon Thales DomeniconiNo ratings yet

- GCP-30 Series: Genset Control Package Mains & Generator Protection & ControlDocument4 pagesGCP-30 Series: Genset Control Package Mains & Generator Protection & ControlKukuh WidodoNo ratings yet

- DKG 705Document4 pagesDKG 705taleb 6269No ratings yet

- Dkg-705 Amf, Parallel To Mains and Dual Genset Synchronization Unit With J1939 InterfaceDocument4 pagesDkg-705 Amf, Parallel To Mains and Dual Genset Synchronization Unit With J1939 InterfacerepelindNo ratings yet

- Woodward Synchronizing Module Spec GCP30Document4 pagesWoodward Synchronizing Module Spec GCP30nooruddinkhan1100% (1)

- Planos FTA1300 Submittal (Large HP) (Descargado Internet)Document10 pagesPlanos FTA1300 Submittal (Large HP) (Descargado Internet)Artemio Chata ChambiNo ratings yet

- Modular Parallel Panel (MPP) : 1.1 System DescriptionDocument7 pagesModular Parallel Panel (MPP) : 1.1 System DescriptionRakib HasanNo ratings yet

- B&A Noodstroomsystemen - Woodward Easygen Overview ToepassinDocument56 pagesB&A Noodstroomsystemen - Woodward Easygen Overview ToepassinBojan KitanovskiNo ratings yet

- GCP-30 Series: Genset Control Package Mains & Generator Protection & ControlDocument4 pagesGCP-30 Series: Genset Control Package Mains & Generator Protection & ControlRavi KumarNo ratings yet

- PD24GB07_03Document2 pagesPD24GB07_03Matíi ASNo ratings yet

- Sheet EMCP II+Document4 pagesSheet EMCP II+ANDRE LUIZ RAMOS DE FREITAS100% (1)

- Dkg-209 Automatic Mains Failure UnitDocument53 pagesDkg-209 Automatic Mains Failure UnitAnonymous V9fdC6No ratings yet

- Lehx9590-02 Emcp II+Document4 pagesLehx9590-02 Emcp II+Jorge Luis Tanaka ConchaNo ratings yet

- Datasheet RISH LM 1340Document8 pagesDatasheet RISH LM 1340PT Merapi Trans EnergiNo ratings yet

- TPS6273x Programmable Output Voltage Ultra-Low Power Buck Converter With Up To 50 Ma / 200 Ma Output CurrentDocument37 pagesTPS6273x Programmable Output Voltage Ultra-Low Power Buck Converter With Up To 50 Ma / 200 Ma Output CurrentMyNameNo ratings yet

- DC-DST4601PX Dichron Eng PDFDocument4 pagesDC-DST4601PX Dichron Eng PDFMarco GardinaliNo ratings yet

- GPW SpecificationsDocument2 pagesGPW SpecificationsHectorNo ratings yet

- Film Capacitors - Power Factor CorrectionDocument5 pagesFilm Capacitors - Power Factor CorrectionNisar AhmedNo ratings yet

- Woodward Easy Gen 3200 - 2Document449 pagesWoodward Easy Gen 3200 - 2pabloNo ratings yet

- EM6400 Series Multi-Function MetersDocument6 pagesEM6400 Series Multi-Function MetersAnandSreeNo ratings yet

- Lampiran - Datasheet IC V98xxDocument284 pagesLampiran - Datasheet IC V98xxshaga shaulagaraNo ratings yet

- GC250_ENG_Rev.00Document2 pagesGC250_ENG_Rev.00a.mostafaNo ratings yet

- Taylor Lifts SMSCatalogueDocument18 pagesTaylor Lifts SMSCatalogueMohd Abu AjajNo ratings yet

- Dkg-217 Manual and Remote Start Unit With Synchroscope and Check Synch RelayDocument2 pagesDkg-217 Manual and Remote Start Unit With Synchroscope and Check Synch RelayРинат АхмеровNo ratings yet

- Three-Phase Electronic Meter CST 0420Document2 pagesThree-Phase Electronic Meter CST 0420Sijo JoyNo ratings yet

- Exclusively Distributed By: Montrelec Inc.: Feeder&Lom Protection RelayDocument8 pagesExclusively Distributed By: Montrelec Inc.: Feeder&Lom Protection Relaysajid munirNo ratings yet

- TMP 01Document16 pagesTMP 01flo0909rinNo ratings yet

- GCP 20 Product Specs en ProdSpecDocument4 pagesGCP 20 Product Specs en ProdSpecalbertzhengteeNo ratings yet

- VAMP 300G BrochureDocument20 pagesVAMP 300G BrochureMartin EvdokimovNo ratings yet

- H 0 Rtfa 1807 IV 00Document2 pagesH 0 Rtfa 1807 IV 00Quân BùiNo ratings yet

- Painel de Paralelismo para Moto Geradores Com GCP 22: AplicaçõesDocument2 pagesPainel de Paralelismo para Moto Geradores Com GCP 22: AplicaçõesRicardo NunesNo ratings yet

- Enercon Generator Control SystemsDocument4 pagesEnercon Generator Control Systemsn.schumarnaNo ratings yet

- Automatic Voltage Regulating Relay (Avr-03) : FeaturesDocument1 pageAutomatic Voltage Regulating Relay (Avr-03) : Featuresss subramanyamNo ratings yet

- 28 - Engine and Generator ControllersDocument14 pages28 - Engine and Generator ControllersPatrick Relwendé KonkoboNo ratings yet

- 15.murphy Mpc10 InsertDocument2 pages15.murphy Mpc10 InsertAlfonso RivasNo ratings yet

- Genset Control For Single Unit OperationDocument4 pagesGenset Control For Single Unit Operation8403c36589584aNo ratings yet

- NG 10 Flyer 09 2011 627d145123Document4 pagesNG 10 Flyer 09 2011 627d145123SatheeshNo ratings yet

- NG 10 Flyer 09 2011 627d145122Document8 pagesNG 10 Flyer 09 2011 627d145122SatheeshNo ratings yet

- Reactive Power 12 Steps Regulator BookDocument4 pagesReactive Power 12 Steps Regulator BookAyman ElsayedNo ratings yet

- Dkg-517-J Manual and Remote Start Unit With J1939 Interface: DescriptionDocument2 pagesDkg-517-J Manual and Remote Start Unit With J1939 Interface: DescriptionJorge Omar ToroNo ratings yet

- A1369 DatasheetDocument22 pagesA1369 Datasheetconaco.tecnologiaNo ratings yet

- DSE8610 PDocument9 pagesDSE8610 PMohammad KhodadadNo ratings yet

- Data Sheet: RISH LM 1350 / LM 1360Document10 pagesData Sheet: RISH LM 1350 / LM 1360Erik Marcelo BarrenecheaNo ratings yet

- Automatic / Manual Start Unit For Gen-Sets: Provides Flexible Start and Control Functions For Diesel GeneratorsDocument2 pagesAutomatic / Manual Start Unit For Gen-Sets: Provides Flexible Start and Control Functions For Diesel GeneratorsSiding BarroNo ratings yet

- GC315 Datasheet en REV. 1.8Document9 pagesGC315 Datasheet en REV. 1.8shakir tkNo ratings yet

- Genset Control For Multiple Unit Operation: Easygen-2200/2300/2500Document4 pagesGenset Control For Multiple Unit Operation: Easygen-2200/2300/2500brayan pedro collazos sanchezNo ratings yet

- DC Dst2700Document2 pagesDC Dst2700muhammad arifNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Technical Data Sheet: CR220-HDDocument2 pagesTechnical Data Sheet: CR220-HDWaqar AhmedNo ratings yet

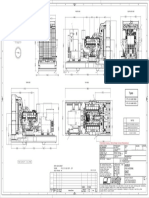

- Preliminary Drawing - Before Design Contact ManufacturerDocument1 pagePreliminary Drawing - Before Design Contact ManufacturerWaqar AhmedNo ratings yet

- Auto Start & Auto Mains Failure Control Modules: GensetDocument3 pagesAuto Start & Auto Mains Failure Control Modules: GensetWaqar AhmedNo ratings yet

- Preliminary Drawing - Before Design Contact ManufacturerDocument1 pagePreliminary Drawing - Before Design Contact ManufacturerWaqar AhmedNo ratings yet

- Advanced Search Tips PDFDocument3 pagesAdvanced Search Tips PDFWaqar AhmedNo ratings yet

- Cummins InPower Pro v11.0 English + ActivationDocument1 pageCummins InPower Pro v11.0 English + ActivationWaqar Ahmed50% (2)

- Owner Owner Manual Manual: Remote Monitoring SystemDocument120 pagesOwner Owner Manual Manual: Remote Monitoring SystemWaqar Ahmed100% (1)

- Generator SpecificationDocument6 pagesGenerator SpecificationWaqar AhmedNo ratings yet

- MR Mohd Hafiz .: 520008477400 10-Jan-20 Jan-20Document2 pagesMR Mohd Hafiz .: 520008477400 10-Jan-20 Jan-20Waqar AhmedNo ratings yet

- DC20DDocument4 pagesDC20DWaqar AhmedNo ratings yet

- 3b33b4017d851ab6400e0ef34d6d51ffDocument119 pages3b33b4017d851ab6400e0ef34d6d51ffWaqar AhmedNo ratings yet

- Sistem Otomasi Di BoilerDocument43 pagesSistem Otomasi Di BoilerRinto Saputra100% (1)

- Energy Skate Park Pre-Lab: SmallerDocument7 pagesEnergy Skate Park Pre-Lab: SmallerJaderson Ana PaulaNo ratings yet

- Kolayat Rays PowerDocument6 pagesKolayat Rays PowerJP GuptaNo ratings yet

- WindpowerDocument24 pagesWindpowerDouglasNo ratings yet

- IGBC Net Zero Energy Buildings Rating System - Pilot - Nov - 2018Document42 pagesIGBC Net Zero Energy Buildings Rating System - Pilot - Nov - 2018Shatakshi AgnihotriNo ratings yet

- Challenges in Integrating Renewable EnerDocument2 pagesChallenges in Integrating Renewable EnerAngamuthu AnanthNo ratings yet

- FOOD PREPARATION AREA (KITCHEN) Although The Food Preparation Area, or Kitchen, Is Listed in The SupportDocument1 pageFOOD PREPARATION AREA (KITCHEN) Although The Food Preparation Area, or Kitchen, Is Listed in The SupportĐức ToànNo ratings yet

- Brochure Super Pump II 11Document2 pagesBrochure Super Pump II 11kend starNo ratings yet

- Module 1 Introduction To Energy ScienceDocument19 pagesModule 1 Introduction To Energy Scienceaadityapawar210138No ratings yet

- Emergency SwitchboardDocument132 pagesEmergency SwitchboardDalmatius GonsalvesNo ratings yet

- Kpi Manual - Final220509Document66 pagesKpi Manual - Final220509Júnior Nonato AraujoNo ratings yet

- Power System Stability:: The Hong Kong Polytechnic UniversityDocument32 pagesPower System Stability:: The Hong Kong Polytechnic Universitybenson215No ratings yet

- Pelton TurbineDocument28 pagesPelton TurbineHendro CahyonoNo ratings yet

- Sustainable Building MaterialsDocument13 pagesSustainable Building Materialssmishra2222No ratings yet

- Ee04 801 - Jun11Document1 pageEe04 801 - Jun11Angamuthu AnanthNo ratings yet

- DUIT2012-Teaching and Learning The Physics Energy ConceptDocument17 pagesDUIT2012-Teaching and Learning The Physics Energy ConceptMárlon PessanhaNo ratings yet

- HPCL Mumbai - RUF Consideration - 31 - Aug - 2018Document2 pagesHPCL Mumbai - RUF Consideration - 31 - Aug - 2018kumar.arunk6784No ratings yet

- Energy Storage Systems For Advanced Power ApplicationsDocument41 pagesEnergy Storage Systems For Advanced Power ApplicationsJr ManiNo ratings yet

- Q4 Energy Accounting Formats For Fy 2022-23Document787 pagesQ4 Energy Accounting Formats For Fy 2022-23shamasultana46364No ratings yet

- EFS KitDocument13 pagesEFS KitAmalia PrassNo ratings yet

- IS 1180 Revisionmodified - 04122014Document4 pagesIS 1180 Revisionmodified - 04122014Sudhakar JoshiNo ratings yet

- Module-3 - ELECTRIC TRACTIONDocument66 pagesModule-3 - ELECTRIC TRACTIONSandeep GowdaNo ratings yet

- EconomizerDocument7 pagesEconomizernsralmasiNo ratings yet

- Project Ice MakerDocument15 pagesProject Ice Makerhiren_mistry55No ratings yet

- R5220205 Electrical Machines-IIDocument1 pageR5220205 Electrical Machines-IIsivabharathamurthyNo ratings yet

- Aeroleaves PPT 16-9-22Document14 pagesAeroleaves PPT 16-9-22A48Rayan PereiraNo ratings yet

- ME-IE-103T ELEMENTS OF MECHANICAL ENGINEERING (2) PdpuDocument1 pageME-IE-103T ELEMENTS OF MECHANICAL ENGINEERING (2) Pdpushubham toshniwalNo ratings yet

"Guard Touch" Control Panel: Main Features

"Guard Touch" Control Panel: Main Features

Uploaded by

Musharraf KhanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

"Guard Touch" Control Panel: Main Features

"Guard Touch" Control Panel: Main Features

Uploaded by

Musharraf KhanCopyright:

Available Formats

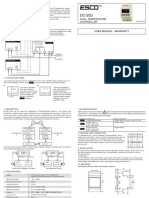

"GUARD TOUCH" CONTROL PANEL

MAIN FEATURES

Guard Touch is the new revolutionary controller with touch screen, researched

and developed by Visa S.p.A., which will be standard supply on our gensets.

From a technical and operational viewpoint, the new device is different from its

predecessors, but still maintains Visa’s main characteristic: MODULARITY!

Guard Touch is a versatile controller able to satisfy all the requests of the end-

user. From manual to automatic (AMF), up to complete synchronisation in

parallel. GUARD TOUCH is much more then a simple controller, it’s the evolution

of perfection.

FUNCTIONS MEASUREMENTS AND PROTECTION

COMMANDS AND FUNCTIONS: MAINS measurements:

-Genset status: OFF, MAN, AUTO, TEST; Voltage VAC mains: L1-L2, L2-L3, L3-L1, L1-N, L2-N, L3-N; Lx-N <= 300V

-Fuel refilling pump status: OFF, MAN, AUTO; (RMS); Lx-N <= 300V (RMS).

-Start; GENSET measurements:

-Stop; Voltage VAC genset: L1-L2, L2-L3, L3-L1, L1-N, L2-N, L3-N; Lx-N <= 300V

-Remote start; (RMS); Lx-N <= 300V (RMS); Currents: L1, L2, L3, - L4 (RMS); Active

-Manual command opening / closing GCB and MCB; power: sum and per each phase; Apparent power: sum and per each phase;

-Manual command START ON; Reactive power: sum and per each phase; Power factor: average and per

-Manual command STOP ON; each phase; Active energy produced: sum and per each phase; Battery

-16 programmable time-out (or countdown) for maintenance (per hour and voltage VDC; Battery charger current (up to max 2 bc); Speed; Working

months); hours; Rental hours (for rent applications); Starting attempts counter;

-Monitoring output of coil relay continuity outputs; Successful starts in % ; ACB MCB manoeuvres counter ; Coolant liquid

-GCB and MCB feedback monitoring; temperature ; Oil pressure; Oil temperature; Engine exhaust temperature

-CANbus SAE J1939 communication monitoring main bearings 1; Engine exhaust temperature main bearings 2; Fuel level in

-BLACK BOX: 2500 events; % ; Engine power used in %; Air turbo pressure ; Air turbo temperature ;

-4 graphic TREND (choose among 40 measurements); Immediate fuel consumption; Fuel consumption from the last start up; Total

-HELP with descriptions and solutions for recorded problems; fuel consumption (calculated on engine lifespan); Alternator windings

-Acoustic alarm ; temperature.

-Date and clock with battery. ALTERNATOR protections:

APPLICATIONS: Max voltage (59); Min voltage (27); Max frequency (81U); Min frequency

-SPM: single prime mover; (81O); Phase sequence error; Voltage asymmetry; Currents asymmetry ;

-SSB: single stand-by. Energy reversal (32); Short circuit (50); Max temperature alternator windings;

COMMUNICATION with external hardware: Alternator capability: Max kW (51), Max kVAr inductive and capacitive.

-1 CANbus for SAE J1939 opto-isolated for engine communication; MAINS protection:

-1 proprietary CANbus opto-isolated for Guard Touch communications; Max voltage (59); Min voltage (27); Max frequency (81U); Min frequency

-1 RS485 for GSM communications, PC monitoring, MODbus, Ethernet (81O); Phase sequence error ; Voltage asymmetry.

connection; ENGINE protections:

-1 RS485 for external connection, battery charger, remote alarm card, Coolant liquid temperature; Oil pressure; Oil temperature; Oil level; Low fuel

expansion board I/O. level; Max power; Over-speed (12); Broken belt; Missed start; Missed stop;

Min coolant level; Visualisation of engine error codes via CANbus SAE

DISPLAY J1939.

- Display black and white with 16 grey tones

-Touch screen

-320 (W) x 240 (H) pixels

-Range of operation -20°C +70°C

N.A.= not available; O.R. = on request. Reference conditions standard ISO8528-1: temperature 25 °C, altitude 1-1000 m. A.M.S.L., 30% relative humidity, 100 kPa atmospheric pressure (1 bar), 0.8

delayed power factor, load applied balanced not distorting. The data provided is subject to variation without prior notice.

Visa S.p.A. via I° Maggio, 55 31043 Fontanelle (TV) Italy Tel: +39 0422 5091 Fax: +39 0422 509350

Mail: visa@visa.it Web: www.visa.it SAP 109000000041-001-00 19-03-2015

1.1

Powered by TCPDF (www.tcpdf.org)

You might also like

- Calculation of Short-Circuit IEC 60909Document6 pagesCalculation of Short-Circuit IEC 60909Iuliu Grad88% (8)

- Rotating Equipment Codes and StandardsDocument2 pagesRotating Equipment Codes and StandardsWong Da100% (8)

- Cat Lovato RGAMDocument2 pagesCat Lovato RGAMDavid Martinez100% (2)

- 906-0106 Cummins QSL9-G5 Engine Parts Manual (6-2015) PDFDocument56 pages906-0106 Cummins QSL9-G5 Engine Parts Manual (6-2015) PDFWaqar Ahmed83% (6)

- Switching Power Supply Design: A Concise Practical HandbookFrom EverandSwitching Power Supply Design: A Concise Practical HandbookNo ratings yet

- Lovato Engine and Gen Controllers PDFDocument10 pagesLovato Engine and Gen Controllers PDFMariano Macchi100% (1)

- Specific Relay For The Management of Line Telecommutations and Relief Generator SetsDocument4 pagesSpecific Relay For The Management of Line Telecommutations and Relief Generator SetsKaiser IqbalNo ratings yet

- Etheric Energy Healing ManualDocument6 pagesEtheric Energy Healing ManualDavid Nolan96% (28)

- HT-GC315-Plus-Link DS EN 01.2015 V2.0Document4 pagesHT-GC315-Plus-Link DS EN 01.2015 V2.0shakir tkNo ratings yet

- HT-MC100 DS en 02.2013 V3.2Document3 pagesHT-MC100 DS en 02.2013 V3.2Muhammad UmarNo ratings yet

- Up To 24 Gensets Connected On The Same Bus and Mains Parallel ApplicationDocument20 pagesUp To 24 Gensets Connected On The Same Bus and Mains Parallel ApplicationMohamed Saber100% (1)

- GCP 30Document4 pagesGCP 30wagner_guimarães_10% (1)

- GC315 RENTAL Gensets GC315: Perfect For Groups ofDocument4 pagesGC315 RENTAL Gensets GC315: Perfect For Groups ofWallace FerreiraNo ratings yet

- GC315 RENTAL Gensets GC315: Perfect For Groups ofDocument4 pagesGC315 RENTAL Gensets GC315: Perfect For Groups ofRamon Thales DomeniconiNo ratings yet

- GC315 RENTAL Gensets GC315: Perfect For Groups ofDocument4 pagesGC315 RENTAL Gensets GC315: Perfect For Groups ofRamon Thales DomeniconiNo ratings yet

- GCP-30 Series: Genset Control Package Mains & Generator Protection & ControlDocument4 pagesGCP-30 Series: Genset Control Package Mains & Generator Protection & ControlKukuh WidodoNo ratings yet

- DKG 705Document4 pagesDKG 705taleb 6269No ratings yet

- Dkg-705 Amf, Parallel To Mains and Dual Genset Synchronization Unit With J1939 InterfaceDocument4 pagesDkg-705 Amf, Parallel To Mains and Dual Genset Synchronization Unit With J1939 InterfacerepelindNo ratings yet

- Woodward Synchronizing Module Spec GCP30Document4 pagesWoodward Synchronizing Module Spec GCP30nooruddinkhan1100% (1)

- Planos FTA1300 Submittal (Large HP) (Descargado Internet)Document10 pagesPlanos FTA1300 Submittal (Large HP) (Descargado Internet)Artemio Chata ChambiNo ratings yet

- Modular Parallel Panel (MPP) : 1.1 System DescriptionDocument7 pagesModular Parallel Panel (MPP) : 1.1 System DescriptionRakib HasanNo ratings yet

- B&A Noodstroomsystemen - Woodward Easygen Overview ToepassinDocument56 pagesB&A Noodstroomsystemen - Woodward Easygen Overview ToepassinBojan KitanovskiNo ratings yet

- GCP-30 Series: Genset Control Package Mains & Generator Protection & ControlDocument4 pagesGCP-30 Series: Genset Control Package Mains & Generator Protection & ControlRavi KumarNo ratings yet

- PD24GB07_03Document2 pagesPD24GB07_03Matíi ASNo ratings yet

- Sheet EMCP II+Document4 pagesSheet EMCP II+ANDRE LUIZ RAMOS DE FREITAS100% (1)

- Dkg-209 Automatic Mains Failure UnitDocument53 pagesDkg-209 Automatic Mains Failure UnitAnonymous V9fdC6No ratings yet

- Lehx9590-02 Emcp II+Document4 pagesLehx9590-02 Emcp II+Jorge Luis Tanaka ConchaNo ratings yet

- Datasheet RISH LM 1340Document8 pagesDatasheet RISH LM 1340PT Merapi Trans EnergiNo ratings yet

- TPS6273x Programmable Output Voltage Ultra-Low Power Buck Converter With Up To 50 Ma / 200 Ma Output CurrentDocument37 pagesTPS6273x Programmable Output Voltage Ultra-Low Power Buck Converter With Up To 50 Ma / 200 Ma Output CurrentMyNameNo ratings yet

- DC-DST4601PX Dichron Eng PDFDocument4 pagesDC-DST4601PX Dichron Eng PDFMarco GardinaliNo ratings yet

- GPW SpecificationsDocument2 pagesGPW SpecificationsHectorNo ratings yet

- Film Capacitors - Power Factor CorrectionDocument5 pagesFilm Capacitors - Power Factor CorrectionNisar AhmedNo ratings yet

- Woodward Easy Gen 3200 - 2Document449 pagesWoodward Easy Gen 3200 - 2pabloNo ratings yet

- EM6400 Series Multi-Function MetersDocument6 pagesEM6400 Series Multi-Function MetersAnandSreeNo ratings yet

- Lampiran - Datasheet IC V98xxDocument284 pagesLampiran - Datasheet IC V98xxshaga shaulagaraNo ratings yet

- GC250_ENG_Rev.00Document2 pagesGC250_ENG_Rev.00a.mostafaNo ratings yet

- Taylor Lifts SMSCatalogueDocument18 pagesTaylor Lifts SMSCatalogueMohd Abu AjajNo ratings yet

- Dkg-217 Manual and Remote Start Unit With Synchroscope and Check Synch RelayDocument2 pagesDkg-217 Manual and Remote Start Unit With Synchroscope and Check Synch RelayРинат АхмеровNo ratings yet

- Three-Phase Electronic Meter CST 0420Document2 pagesThree-Phase Electronic Meter CST 0420Sijo JoyNo ratings yet

- Exclusively Distributed By: Montrelec Inc.: Feeder&Lom Protection RelayDocument8 pagesExclusively Distributed By: Montrelec Inc.: Feeder&Lom Protection Relaysajid munirNo ratings yet

- TMP 01Document16 pagesTMP 01flo0909rinNo ratings yet

- GCP 20 Product Specs en ProdSpecDocument4 pagesGCP 20 Product Specs en ProdSpecalbertzhengteeNo ratings yet

- VAMP 300G BrochureDocument20 pagesVAMP 300G BrochureMartin EvdokimovNo ratings yet

- H 0 Rtfa 1807 IV 00Document2 pagesH 0 Rtfa 1807 IV 00Quân BùiNo ratings yet

- Painel de Paralelismo para Moto Geradores Com GCP 22: AplicaçõesDocument2 pagesPainel de Paralelismo para Moto Geradores Com GCP 22: AplicaçõesRicardo NunesNo ratings yet

- Enercon Generator Control SystemsDocument4 pagesEnercon Generator Control Systemsn.schumarnaNo ratings yet

- Automatic Voltage Regulating Relay (Avr-03) : FeaturesDocument1 pageAutomatic Voltage Regulating Relay (Avr-03) : Featuresss subramanyamNo ratings yet

- 28 - Engine and Generator ControllersDocument14 pages28 - Engine and Generator ControllersPatrick Relwendé KonkoboNo ratings yet

- 15.murphy Mpc10 InsertDocument2 pages15.murphy Mpc10 InsertAlfonso RivasNo ratings yet

- Genset Control For Single Unit OperationDocument4 pagesGenset Control For Single Unit Operation8403c36589584aNo ratings yet

- NG 10 Flyer 09 2011 627d145123Document4 pagesNG 10 Flyer 09 2011 627d145123SatheeshNo ratings yet

- NG 10 Flyer 09 2011 627d145122Document8 pagesNG 10 Flyer 09 2011 627d145122SatheeshNo ratings yet

- Reactive Power 12 Steps Regulator BookDocument4 pagesReactive Power 12 Steps Regulator BookAyman ElsayedNo ratings yet

- Dkg-517-J Manual and Remote Start Unit With J1939 Interface: DescriptionDocument2 pagesDkg-517-J Manual and Remote Start Unit With J1939 Interface: DescriptionJorge Omar ToroNo ratings yet

- A1369 DatasheetDocument22 pagesA1369 Datasheetconaco.tecnologiaNo ratings yet

- DSE8610 PDocument9 pagesDSE8610 PMohammad KhodadadNo ratings yet

- Data Sheet: RISH LM 1350 / LM 1360Document10 pagesData Sheet: RISH LM 1350 / LM 1360Erik Marcelo BarrenecheaNo ratings yet

- Automatic / Manual Start Unit For Gen-Sets: Provides Flexible Start and Control Functions For Diesel GeneratorsDocument2 pagesAutomatic / Manual Start Unit For Gen-Sets: Provides Flexible Start and Control Functions For Diesel GeneratorsSiding BarroNo ratings yet

- GC315 Datasheet en REV. 1.8Document9 pagesGC315 Datasheet en REV. 1.8shakir tkNo ratings yet

- Genset Control For Multiple Unit Operation: Easygen-2200/2300/2500Document4 pagesGenset Control For Multiple Unit Operation: Easygen-2200/2300/2500brayan pedro collazos sanchezNo ratings yet

- DC Dst2700Document2 pagesDC Dst2700muhammad arifNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Technical Data Sheet: CR220-HDDocument2 pagesTechnical Data Sheet: CR220-HDWaqar AhmedNo ratings yet

- Preliminary Drawing - Before Design Contact ManufacturerDocument1 pagePreliminary Drawing - Before Design Contact ManufacturerWaqar AhmedNo ratings yet

- Auto Start & Auto Mains Failure Control Modules: GensetDocument3 pagesAuto Start & Auto Mains Failure Control Modules: GensetWaqar AhmedNo ratings yet

- Preliminary Drawing - Before Design Contact ManufacturerDocument1 pagePreliminary Drawing - Before Design Contact ManufacturerWaqar AhmedNo ratings yet

- Advanced Search Tips PDFDocument3 pagesAdvanced Search Tips PDFWaqar AhmedNo ratings yet

- Cummins InPower Pro v11.0 English + ActivationDocument1 pageCummins InPower Pro v11.0 English + ActivationWaqar Ahmed50% (2)

- Owner Owner Manual Manual: Remote Monitoring SystemDocument120 pagesOwner Owner Manual Manual: Remote Monitoring SystemWaqar Ahmed100% (1)

- Generator SpecificationDocument6 pagesGenerator SpecificationWaqar AhmedNo ratings yet

- MR Mohd Hafiz .: 520008477400 10-Jan-20 Jan-20Document2 pagesMR Mohd Hafiz .: 520008477400 10-Jan-20 Jan-20Waqar AhmedNo ratings yet

- DC20DDocument4 pagesDC20DWaqar AhmedNo ratings yet

- 3b33b4017d851ab6400e0ef34d6d51ffDocument119 pages3b33b4017d851ab6400e0ef34d6d51ffWaqar AhmedNo ratings yet

- Sistem Otomasi Di BoilerDocument43 pagesSistem Otomasi Di BoilerRinto Saputra100% (1)

- Energy Skate Park Pre-Lab: SmallerDocument7 pagesEnergy Skate Park Pre-Lab: SmallerJaderson Ana PaulaNo ratings yet

- Kolayat Rays PowerDocument6 pagesKolayat Rays PowerJP GuptaNo ratings yet

- WindpowerDocument24 pagesWindpowerDouglasNo ratings yet

- IGBC Net Zero Energy Buildings Rating System - Pilot - Nov - 2018Document42 pagesIGBC Net Zero Energy Buildings Rating System - Pilot - Nov - 2018Shatakshi AgnihotriNo ratings yet

- Challenges in Integrating Renewable EnerDocument2 pagesChallenges in Integrating Renewable EnerAngamuthu AnanthNo ratings yet

- FOOD PREPARATION AREA (KITCHEN) Although The Food Preparation Area, or Kitchen, Is Listed in The SupportDocument1 pageFOOD PREPARATION AREA (KITCHEN) Although The Food Preparation Area, or Kitchen, Is Listed in The SupportĐức ToànNo ratings yet

- Brochure Super Pump II 11Document2 pagesBrochure Super Pump II 11kend starNo ratings yet

- Module 1 Introduction To Energy ScienceDocument19 pagesModule 1 Introduction To Energy Scienceaadityapawar210138No ratings yet

- Emergency SwitchboardDocument132 pagesEmergency SwitchboardDalmatius GonsalvesNo ratings yet

- Kpi Manual - Final220509Document66 pagesKpi Manual - Final220509Júnior Nonato AraujoNo ratings yet

- Power System Stability:: The Hong Kong Polytechnic UniversityDocument32 pagesPower System Stability:: The Hong Kong Polytechnic Universitybenson215No ratings yet

- Pelton TurbineDocument28 pagesPelton TurbineHendro CahyonoNo ratings yet

- Sustainable Building MaterialsDocument13 pagesSustainable Building Materialssmishra2222No ratings yet

- Ee04 801 - Jun11Document1 pageEe04 801 - Jun11Angamuthu AnanthNo ratings yet

- DUIT2012-Teaching and Learning The Physics Energy ConceptDocument17 pagesDUIT2012-Teaching and Learning The Physics Energy ConceptMárlon PessanhaNo ratings yet

- HPCL Mumbai - RUF Consideration - 31 - Aug - 2018Document2 pagesHPCL Mumbai - RUF Consideration - 31 - Aug - 2018kumar.arunk6784No ratings yet

- Energy Storage Systems For Advanced Power ApplicationsDocument41 pagesEnergy Storage Systems For Advanced Power ApplicationsJr ManiNo ratings yet

- Q4 Energy Accounting Formats For Fy 2022-23Document787 pagesQ4 Energy Accounting Formats For Fy 2022-23shamasultana46364No ratings yet

- EFS KitDocument13 pagesEFS KitAmalia PrassNo ratings yet

- IS 1180 Revisionmodified - 04122014Document4 pagesIS 1180 Revisionmodified - 04122014Sudhakar JoshiNo ratings yet

- Module-3 - ELECTRIC TRACTIONDocument66 pagesModule-3 - ELECTRIC TRACTIONSandeep GowdaNo ratings yet

- EconomizerDocument7 pagesEconomizernsralmasiNo ratings yet

- Project Ice MakerDocument15 pagesProject Ice Makerhiren_mistry55No ratings yet

- R5220205 Electrical Machines-IIDocument1 pageR5220205 Electrical Machines-IIsivabharathamurthyNo ratings yet

- Aeroleaves PPT 16-9-22Document14 pagesAeroleaves PPT 16-9-22A48Rayan PereiraNo ratings yet

- ME-IE-103T ELEMENTS OF MECHANICAL ENGINEERING (2) PdpuDocument1 pageME-IE-103T ELEMENTS OF MECHANICAL ENGINEERING (2) Pdpushubham toshniwalNo ratings yet