Professional Documents

Culture Documents

Vapor Pockets Formation & Column Separation: Design of Pipelines and Pumping Stations (IHD-443)

Vapor Pockets Formation & Column Separation: Design of Pipelines and Pumping Stations (IHD-443)

Uploaded by

mohamed ahmedOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vapor Pockets Formation & Column Separation: Design of Pipelines and Pumping Stations (IHD-443)

Vapor Pockets Formation & Column Separation: Design of Pipelines and Pumping Stations (IHD-443)

Uploaded by

mohamed ahmedCopyright:

Available Formats

Vapor Pockets Formation &

Column Separation

Design of Pipelines and Pumping Stations (IHD-443) Mar 2013

Irrigation and Hydraulics Dept., Cairo University Slide 1

What is the Boiling Point of Water?

• Water Boils at ≈ 100oC

• This is only true if the pressure applied on water is

atmospheric pressure (1013 mm water)

• On Top of Mount Everest (at 8,848m elevation),

the pressure is 260 mbar and water boils at

69oC!!

• Boiling point is function of pressure

• Water can boil (change state from liquid to vapor)

at room temperature if the pressure becomes low

enough.

Design of Pipelines and Pumping Stations (IHD-443) Mar 2013

Irrigation and Hydraulics Dept., Cairo University Slide 2

What is the Boiling Point of Water?

Design of Pipelines and Pumping Stations (IHD-443) Mar 2013

Irrigation and Hydraulics Dept., Cairo University Slide 3

Vapor Pressure

Temperature

(oC)

Vapor Pressure

(g/cm2) Vapor Pressure: is the pressure at

0 6.23 which steam is saturated, at higher

5 8.89 pressure, water would condense..

10 12.51

15 17.38 In other words, if pressure drops

20 23.83

below that value, water will change

25 32.30

30 43.27

state to vapor

35

40

57.34

75.23

Vapor Pressure can be calculated

50 125.83 as a function in Temp.

60 203.19

where P is the

70 317.84

vapor pressure

80 483.01 (mmHg) and T is

90 714.95 temp in Kelvin

100 1013.23

Design of Pipelines and Pumping Stations (IHD-443) Mar 2013

Irrigation and Hydraulics Dept., Cairo University Slide 4

Where can this Happen?

• At locations where negative pressures can be

encountered

• At the eye of the

impeller of a

centrifugal pump

• This is also called

Cavitation

To avoid Cavity Formation:

@NPSH ≥ Required NPSH

Design of Pipelines and Pumping Stations (IHD-443) Mar 2013

Irrigation and Hydraulics Dept., Cairo University Slide 5

Cavitation

• When liquid enters the eye of the impeller,

pressure drops suddenly as the velocity of water

is increased suddenly.

• Cavity

bubbles are

formed if the

pressure of

liquid is

below that of

vapor

pressure

Design of Pipelines and Pumping Stations (IHD-443) Mar 2013

Irrigation and Hydraulics Dept., Cairo University Slide 6

Cavitation

• Vapor bubbles grow in size and travel along the

trailing edge of the impeller.

• Then it reach the

region of high

pressures where it

start collapsing.

• The life cycle of a

cavity bubble is

estimated at 0.003

seconds.

Design of Pipelines and Pumping Stations (IHD-443) Mar 2013

Irrigation and Hydraulics Dept., Cairo University Slide 7

Cavitation

• When pressure increases, the surrounding liquid

rushes to fill the void creating a liquid microjet.

• The microjet

ruptures the bubble

with a force that a

hammering noise is

heard.

• The highly localized

hammering effect

can pit the impeller.

Design of Pipelines and Pumping Stations (IHD-443) Mar 2013

Irrigation and Hydraulics Dept., Cairo University Slide 8

Cavitation

Design of Pipelines and Pumping Stations (IHD-443) Mar 2013

Irrigation and Hydraulics Dept., Cairo University Slide 9

Cavitation

• When Cavitation is encountered at a pump:

– Hammering Noise

and Vibrations

– Reduction in pump

capacity

– Reduction in pumping

head

– Damage to pump

parts

Design of Pipelines and Pumping Stations (IHD-443) Mar 2013

Irrigation and Hydraulics Dept., Cairo University Slide 10

Where else can this Happen?

• Cavitation can also occur at Control Valves:

– Pressure can drop

down to vapor

pressure at the valve

constricted area.

– This can happen at

very small valve

openings if the

manufacturers sizing

recommendations are

not followed

Design of Pipelines and Pumping Stations (IHD-443) Mar 2013

Irrigation and Hydraulics Dept., Cairo University Slide 11

Where else can this Happen?

Design of Pipelines and Pumping Stations (IHD-443) Mar 2013

Irrigation and Hydraulics Dept., Cairo University Slide 12

Where else can this Happen?

• Cavitation can also occur at Control Valves:

Design of Pipelines and Pumping Stations (IHD-443) Mar 2013

Irrigation and Hydraulics Dept., Cairo University Slide 13

Where else can this Happen?

• During a hydraulic transient event:

– Pressures may drop down to vapor pressure and

sometimes to full vacuum.

– Water will flush from liquid to vapor resulting in a

temporary column separation

Design of Pipelines and Pumping Stations (IHD-443) Mar 2013

Irrigation and Hydraulics Dept., Cairo University Slide 14

Column Separation

• During a hydraulic transient event:

– When system pressure is increased again, vapor

condenses to liquid as the two columns accelerate

towards each other

– Extreme transient pressures will form when the two

column collide.

This is considered the

most violent and

damaging water hammer

phenomenon possible

Design of Pipelines and Pumping Stations (IHD-443) Mar 2013

Irrigation and Hydraulics Dept., Cairo University Slide 15

Column Separation

• We can also have column separation without

having water to boil

– When we have an Air Valve located at a high point and

suddenly pressure drops below zero at the valve

location.

– Some types of Air Valves will limit subatmospheric

pressures by letting Air into the pipeline (and not Vapor)

Design of Pipelines and Pumping Stations (IHD-443) Mar 2013

Irrigation and Hydraulics Dept., Cairo University Slide 16

Column Separation

• We can also have column separation without

having water to boil

– Air valves can ingress HUGE volumes of air.

– When pressure rises again, the water columns

accelerate towards each other and the air valve should

expel air out of the system (double acting)

What will happen when the two

columns join Highly depends on

the rate by which the Air Valve

expels air

Design of Pipelines and Pumping Stations (IHD-443) Mar 2013

Irrigation and Hydraulics Dept., Cairo University Slide 17

Column Separation

This is the case of

Fast air exhaust

rate

Extreme transient

pressures are

formed as the two

columns collapse

Design of Pipelines and Pumping Stations (IHD-443) Mar 2013

Irrigation and Hydraulics Dept., Cairo University Slide 18

Column Separation

This is the case of

Slow air exhausting

rate

The air outflow

through the valve is

throttled and thus

air inside the

pipeline is

compressed

This acts as a

cushion slowing

down both columns

before collapse and

acceptable

transient pressures

are formed

Design of Pipelines and Pumping Stations (IHD-443) Mar 2013

Irrigation and Hydraulics Dept., Cairo University Slide 19

You might also like

- Oil and Gas Artificial Fluid Lifting TechniquesFrom EverandOil and Gas Artificial Fluid Lifting TechniquesRating: 5 out of 5 stars5/5 (1)

- Water Hammer in HRSGDocument11 pagesWater Hammer in HRSGEduardoNo ratings yet

- Lab 5 Thermo FluidsDocument13 pagesLab 5 Thermo FluidsAimiWaniNo ratings yet

- Chilled Water PipingDocument34 pagesChilled Water Pipingapi-2599951798% (50)

- Steam EjectorsDocument6 pagesSteam EjectorsmayurjannuNo ratings yet

- Understanding EjectorDocument6 pagesUnderstanding Ejectormrazamudinishak100% (1)

- LBYCVW2 - Experiment 2Document11 pagesLBYCVW2 - Experiment 2Shean Berwin GonzalesNo ratings yet

- 3.0 Water Lines Preface: Bechtel ConfidentialDocument6 pages3.0 Water Lines Preface: Bechtel ConfidentialCristhianNo ratings yet

- Proper Sizing of Steam Header Drains Prevents Water InductionDocument7 pagesProper Sizing of Steam Header Drains Prevents Water InductionmhdsolehNo ratings yet

- 2 12 Power GenMiddleEast 2004Document17 pages2 12 Power GenMiddleEast 2004Satrio HaryoNo ratings yet

- Screening Reactor For Water HammerDocument49 pagesScreening Reactor For Water HammerYu GanNo ratings yet

- Minor Losses & Pressure Requirements: V H K 2gDocument0 pagesMinor Losses & Pressure Requirements: V H K 2gAnastasia Monica KhunniegalshottestNo ratings yet

- Cooling Tower Pump Intake Design Tech PaperDocument8 pagesCooling Tower Pump Intake Design Tech PaperMark ChongNo ratings yet

- Piping System RevDocument32 pagesPiping System Revapi-25999517100% (9)

- Energy Conservation and Management - Lecturer - 03-ADocument53 pagesEnergy Conservation and Management - Lecturer - 03-AAbdullah MobeenNo ratings yet

- Nuclear Engineering and Design: R.K. Bagul, D.S. Pilkhwal, P.K. Vijayan, J.B. JoshiDocument16 pagesNuclear Engineering and Design: R.K. Bagul, D.S. Pilkhwal, P.K. Vijayan, J.B. JoshiRABIUL ISLAMNo ratings yet

- Water Hammer Arresters - Engineer Report PDFDocument48 pagesWater Hammer Arresters - Engineer Report PDFPhillip_vaziri1832No ratings yet

- What Is Definition of The SurgeDocument11 pagesWhat Is Definition of The Surgehosam aliNo ratings yet

- Hydraulic SprinklerDocument26 pagesHydraulic SprinklerHaya MandoNo ratings yet

- PenstockDocument22 pagesPenstockAbiued EjigueNo ratings yet

- CSHS 2003 GajicDocument16 pagesCSHS 2003 GajicMircea BolovedeaNo ratings yet

- Example 4-6 Water Flow in Pipe System: Le, Le, 3.5Document17 pagesExample 4-6 Water Flow in Pipe System: Le, Le, 3.5pierre-françois Le BouilleNo ratings yet

- Engineering & Expertise Transient Analysis: Water HammerDocument16 pagesEngineering & Expertise Transient Analysis: Water HammerArmando Emilio PoujolNo ratings yet

- Engineering & Expertise: Transient AnalysisDocument16 pagesEngineering & Expertise: Transient Analysislimin zhangNo ratings yet

- Water HammerDocument20 pagesWater HammerAJITKp90No ratings yet

- Water Vapor Migration and Condensation Control in BuildingsDocument11 pagesWater Vapor Migration and Condensation Control in BuildingsQuora EarningNo ratings yet

- Computational Fluid Dynamics (CFD) Simulation of Liquid Column Separation in Pipe TransientsDocument12 pagesComputational Fluid Dynamics (CFD) Simulation of Liquid Column Separation in Pipe TransientsDario Andres Serrano FlorezNo ratings yet

- Power Plant: CondensersDocument7 pagesPower Plant: CondensersMustafam98No ratings yet

- Cooling Tower DesignDocument11 pagesCooling Tower DesignSmrutiNo ratings yet

- Strainer Guide - Part24Document1 pageStrainer Guide - Part24Sri SubektiNo ratings yet

- Cold Front - Vol. 9 No. 1, 2009 NewsletterDocument10 pagesCold Front - Vol. 9 No. 1, 2009 NewsletterCaptain hopiNo ratings yet

- Cooling Tower AssignmentDocument11 pagesCooling Tower AssignmentSaad khan100% (2)

- WatsonDocument6 pagesWatsonLanang Delonix Regia SugiartoNo ratings yet

- Reverse WaterhammerDocument10 pagesReverse WaterhammerjygomezNo ratings yet

- Piping System in Building: Asst. Prof. Channarong AsavatesanupapDocument59 pagesPiping System in Building: Asst. Prof. Channarong AsavatesanupapIatan AlexandruNo ratings yet

- Hydraulic Design of Stepped SpillwaysDocument12 pagesHydraulic Design of Stepped SpillwaysCristian Hadad100% (1)

- Steam Mains and Drainage: Piping LayoutDocument11 pagesSteam Mains and Drainage: Piping Layouthej hejNo ratings yet

- Achi3 (Spray, Incline)Document15 pagesAchi3 (Spray, Incline)Avadhesh SharmaNo ratings yet

- Yawmc 0442 Us YarwayDocument20 pagesYawmc 0442 Us YarwayGUZMANNo ratings yet

- Lecture On SurgeDocument42 pagesLecture On SurgeJaspal SinghNo ratings yet

- Design of Water Supply System-High Rise BLDGDocument108 pagesDesign of Water Supply System-High Rise BLDGJolo ManiagoNo ratings yet

- Water Hammer and Other Hydraulic PhenomenaDocument7 pagesWater Hammer and Other Hydraulic Phenomenamariel3943No ratings yet

- Draft Tube and CavitationDocument8 pagesDraft Tube and Cavitationasn90100% (1)

- A Numerical Analysis of Hydrodynamic and Heat Transfer Effects of Shell-and-Tube Heat Exchanger For Different Baf e Space and CutDocument21 pagesA Numerical Analysis of Hydrodynamic and Heat Transfer Effects of Shell-and-Tube Heat Exchanger For Different Baf e Space and CutememNo ratings yet

- Desired Circulation Ratio For Natural CirculationDocument7 pagesDesired Circulation Ratio For Natural Circulationolivegarden1900No ratings yet

- Desuperheaters BasicsDocument16 pagesDesuperheaters Basicsaamer6789100% (1)

- Computers & Fluids: Lanchang Xing, Hoi Yeung, Yanfeng Geng, Yi Cao, Joseph ShenDocument12 pagesComputers & Fluids: Lanchang Xing, Hoi Yeung, Yanfeng Geng, Yi Cao, Joseph Shenbedhief ahmedNo ratings yet

- Condensate Induced Water HammeringDocument26 pagesCondensate Induced Water Hammeringparag14No ratings yet

- KOSO DSH General Catalog - Ver08Document20 pagesKOSO DSH General Catalog - Ver08निखिल बायवारNo ratings yet

- GJTI Surge Analysis 15.11.2019Document68 pagesGJTI Surge Analysis 15.11.2019divyaent91No ratings yet

- Recirculating Domestic Hot Water Systems JulyAug10Document15 pagesRecirculating Domestic Hot Water Systems JulyAug10Peter LiNo ratings yet

- WEIR - Technical Bulletin - Hazards of Blocked PipesDocument6 pagesWEIR - Technical Bulletin - Hazards of Blocked PipesWesley MendesNo ratings yet

- Aspects Regarding Fouling of Steam Condenser - A Case StudyDocument8 pagesAspects Regarding Fouling of Steam Condenser - A Case Study10 000 de cartiNo ratings yet

- Hydraulic Tables; The Elements Of Gagings And The Friction Of Water Flowing In Pipes, Aqueducts, Sewers, Etc., As Determined By The Hazen And Williams Formula And The Flow Of Water Over The Sharp-Edged And Irregular Weirs, And The Quantity DischargedFrom EverandHydraulic Tables; The Elements Of Gagings And The Friction Of Water Flowing In Pipes, Aqueducts, Sewers, Etc., As Determined By The Hazen And Williams Formula And The Flow Of Water Over The Sharp-Edged And Irregular Weirs, And The Quantity DischargedNo ratings yet

- Hydrostatic and Hydro-Testing in the Oil and Gas FieldFrom EverandHydrostatic and Hydro-Testing in the Oil and Gas FieldRating: 3 out of 5 stars3/5 (2)

- Pneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshFrom EverandPneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshNo ratings yet

- Heating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsFrom EverandHeating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsNo ratings yet

- Case Studies in Fluid Mechanics with Sensitivities to Governing VariablesFrom EverandCase Studies in Fluid Mechanics with Sensitivities to Governing VariablesNo ratings yet

- C.V.talat Mostafa949516Document9 pagesC.V.talat Mostafa949516mohamed ahmedNo ratings yet

- CVS-English Brief-2018925024Document6 pagesCVS-English Brief-2018925024mohamed ahmedNo ratings yet

- CVEN4308 Structural Dynamics: School of Civil and Environmental EngineeringDocument10 pagesCVEN4308 Structural Dynamics: School of Civil and Environmental Engineeringmohamed ahmedNo ratings yet

- CVEN9511: Geotechnical Models and Site InvestigationDocument13 pagesCVEN9511: Geotechnical Models and Site Investigationmohamed ahmedNo ratings yet

- Cven9809 Reinforced Concrete Structures: School of Civil and Environmental EngineeringDocument9 pagesCven9809 Reinforced Concrete Structures: School of Civil and Environmental Engineeringmohamed ahmedNo ratings yet

- 2021-X1 CVEN2303x1570 2Document9 pages2021-X1 CVEN2303x1570 2mohamed ahmedNo ratings yet

- Presentation 1Document36 pagesPresentation 1mohamed ahmedNo ratings yet

- 1.3 Objectives and ScopeDocument10 pages1.3 Objectives and Scopemohamed ahmedNo ratings yet

- Presentation 1Document3 pagesPresentation 1mohamed ahmedNo ratings yet

- Prof. Dr. Aly I. MetwallyDocument22 pagesProf. Dr. Aly I. Metwallymohamed ahmedNo ratings yet

- Sheet3 Draft 2020Document3 pagesSheet3 Draft 2020mohamed ahmedNo ratings yet

- Chapter 10 - Structural DesignDocument56 pagesChapter 10 - Structural Designmohamed ahmedNo ratings yet

- Application Form: Personal DataDocument3 pagesApplication Form: Personal Datamohamed ahmedNo ratings yet

- CSI Solution Demonstrates Use of These FeaturesDocument11 pagesCSI Solution Demonstrates Use of These Featuresmohamed ahmedNo ratings yet

- Behavior of RC Members Subjected To Shear With Background To Provisions of The New Edition of Ecp 203 by Ahmed Abd Elmoniem Saleh BayomeDocument15 pagesBehavior of RC Members Subjected To Shear With Background To Provisions of The New Edition of Ecp 203 by Ahmed Abd Elmoniem Saleh Bayomemohamed ahmedNo ratings yet

- قسم التشييدDocument41 pagesقسم التشييدmohamed ahmedNo ratings yet

- Preliminary Design Outline: 3.1 ObjectiveDocument10 pagesPreliminary Design Outline: 3.1 Objectivemohamed ahmedNo ratings yet

- Sheet 2: Modeling of Beams Using Computer Software and Comparing Results With Manual CalculationsDocument7 pagesSheet 2: Modeling of Beams Using Computer Software and Comparing Results With Manual Calculationsmohamed ahmedNo ratings yet

- 1.4.4 Prepare Phase 1 Research ReportDocument8 pages1.4.4 Prepare Phase 1 Research Reportmohamed ahmedNo ratings yet

- Department of Roads, Project Number SPR-PL-1 (038), 514 PagesDocument9 pagesDepartment of Roads, Project Number SPR-PL-1 (038), 514 Pagesmohamed ahmedNo ratings yet

- FIGURE P7.30: (A) Use Dimensional Analysis With The Assumption That The WingbeatDocument6 pagesFIGURE P7.30: (A) Use Dimensional Analysis With The Assumption That The Wingbeatmohamed ahmedNo ratings yet

- Mary Beth D. Hueste, John B. Mander, and Anagha S. Parkar: Technical Report Documentation PageDocument8 pagesMary Beth D. Hueste, John B. Mander, and Anagha S. Parkar: Technical Report Documentation Pagemohamed ahmedNo ratings yet

- Section 8.4.2: Minor Losses (Also See Lab Problem 8.131.)Document7 pagesSection 8.4.2: Minor Losses (Also See Lab Problem 8.131.)mohamed ahmedNo ratings yet

- قسم الإنشاءاتDocument44 pagesقسم الإنشاءاتmohamed ahmedNo ratings yet

- Reports: Engineers and Social ResponsibilityDocument12 pagesReports: Engineers and Social Responsibilitymohamed ahmedNo ratings yet

- Spherical BearingDocument2 pagesSpherical Bearingmohamed ahmedNo ratings yet

- Groundwater: (Phreatic and Confined Aquifers) : Aquifer BDocument11 pagesGroundwater: (Phreatic and Confined Aquifers) : Aquifer Bmohamed ahmedNo ratings yet

- Rainfed Versus Irrigated Agriculture:: Regions P (Mm/yr) Irrigation DrainageDocument4 pagesRainfed Versus Irrigated Agriculture:: Regions P (Mm/yr) Irrigation Drainagemohamed ahmedNo ratings yet

- Meyerfire - Hydraulic Calculation Tipsheet February 2021Document1 pageMeyerfire - Hydraulic Calculation Tipsheet February 2021Eugene BeangkeNo ratings yet

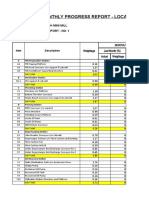

- Monthly Progress Report - Local PortionDocument4 pagesMonthly Progress Report - Local PortionShureendran Muniandy RajanNo ratings yet

- Liquatec Products: Automatic Shutoff Valves (ASOV)Document14 pagesLiquatec Products: Automatic Shutoff Valves (ASOV)cangussubrNo ratings yet

- RFI-3410 - Daily Fit Up Inspection Report (Pipe Support) - OKDocument76 pagesRFI-3410 - Daily Fit Up Inspection Report (Pipe Support) - OKnguyennamxmNo ratings yet

- D-155 D-179 D-206 D-239 D-246 D-268 D-310 D-358 DT-239 DT-358 DT-402 Fuel System & Turbochargers & Injectors.Document100 pagesD-155 D-179 D-206 D-239 D-246 D-268 D-310 D-358 DT-239 DT-358 DT-402 Fuel System & Turbochargers & Injectors.moiNo ratings yet

- AlarmDocument3 pagesAlarmOMiD QahqaieNo ratings yet

- FHC-Hydraulic CalculationDocument4 pagesFHC-Hydraulic CalculationKiên Nguyễn Hữu100% (1)

- Motoniveladora 16M PDFDocument2 pagesMotoniveladora 16M PDFJose Carlos Annicchiarico BritoNo ratings yet

- Material Borrow From F&DDocument1 pageMaterial Borrow From F&DRizkiHusniNo ratings yet

- Hydac RVE Check ValvesDocument4 pagesHydac RVE Check ValvesDragan LazicNo ratings yet

- SE Lecture 6Document8 pagesSE Lecture 6666667No ratings yet

- Tubulacao Dimensioes Globais Valvulas e ConexoesDocument3 pagesTubulacao Dimensioes Globais Valvulas e ConexoesDouglas Fernandes Dos SantosNo ratings yet

- Multiport 8574GDocument1 pageMultiport 8574GFranz Huanay MartínezNo ratings yet

- Tosaca-Manual Engelsk 01Document9 pagesTosaca-Manual Engelsk 01jajakaNo ratings yet

- Control Panel STD Design PDFDocument71 pagesControl Panel STD Design PDFDuy ThaiNo ratings yet

- Pump Starup ProcedureDocument23 pagesPump Starup ProcedureKrishnan ManiNo ratings yet

- Unit 3 - Control Components in Hydraulic SystemDocument10 pagesUnit 3 - Control Components in Hydraulic SystemDagnachee TeguNo ratings yet

- German Malaysian Institute: Matrix of Course Learning Outcomes & Course ContentDocument6 pagesGerman Malaysian Institute: Matrix of Course Learning Outcomes & Course ContentAnonymous 5YMOxVQNo ratings yet

- YT Hydraulic Service Manual TD1413-01EDocument26 pagesYT Hydraulic Service Manual TD1413-01ENgoc Nguyen100% (2)

- PrayerDocument50 pagesPrayerKristine ValenzuelaNo ratings yet

- Well Head, ValvesDocument58 pagesWell Head, ValvesAhmed Ousama100% (1)

- MTR's SO# 1009605Document20 pagesMTR's SO# 1009605ksi meritosNo ratings yet

- Ep 61450Document9 pagesEp 61450Maura ApostolacheNo ratings yet

- AccumulatorDocument6 pagesAccumulatorgopinathsampathNo ratings yet

- Industry Valves - Solenoid Valves LUCIFER - FLUIDTECHNIK (PDFDrive)Document110 pagesIndustry Valves - Solenoid Valves LUCIFER - FLUIDTECHNIK (PDFDrive)engvaithyNo ratings yet

- Alberta Pressure TankDocument2 pagesAlberta Pressure Tankrusli bahtiarNo ratings yet

- Sainitary Drainage SystemDocument10 pagesSainitary Drainage Systemajaydce05No ratings yet

- BVA Remote Valves CatalogDocument1 pageBVA Remote Valves CatalogTitanplyNo ratings yet

- PZV Orifice TypeDocument2 pagesPZV Orifice TypeHajarath AliNo ratings yet

- Riksa Uji K3 Hydrant PLN UP3 Palopo (Gudang Dan ULP Palopo Kota)Document21 pagesRiksa Uji K3 Hydrant PLN UP3 Palopo (Gudang Dan ULP Palopo Kota)Nire'one ZainyNo ratings yet