Professional Documents

Culture Documents

List Kompetensi Cylinder Plus

List Kompetensi Cylinder Plus

Uploaded by

meli rizal0 ratings0% found this document useful (0 votes)

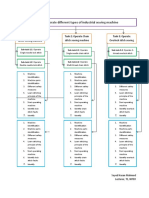

12 views4 pagesThe document outlines training modules for various jobs in a plant cylinder section. It lists 15 modules for each job, covering topics like material handling, common tools, power tools, basic cylinder components, technical drawings, special tools, documents, measurement tools, machine elements, and machining processes. The jobs include washing, disassembly, observation and measurement, assembly, test performance, painting, machining using lathes, milling, and radial drilling. The training modules provide information on structure and function, operating techniques, and maintenance for various tools and machines used in each job.

Original Description:

Original Title

List Kompetensi Cylinder plus

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document outlines training modules for various jobs in a plant cylinder section. It lists 15 modules for each job, covering topics like material handling, common tools, power tools, basic cylinder components, technical drawings, special tools, documents, measurement tools, machine elements, and machining processes. The jobs include washing, disassembly, observation and measurement, assembly, test performance, painting, machining using lathes, milling, and radial drilling. The training modules provide information on structure and function, operating techniques, and maintenance for various tools and machines used in each job.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

Download as xlsx, pdf, or txt

0 ratings0% found this document useful (0 votes)

12 views4 pagesList Kompetensi Cylinder Plus

List Kompetensi Cylinder Plus

Uploaded by

meli rizalThe document outlines training modules for various jobs in a plant cylinder section. It lists 15 modules for each job, covering topics like material handling, common tools, power tools, basic cylinder components, technical drawings, special tools, documents, measurement tools, machine elements, and machining processes. The jobs include washing, disassembly, observation and measurement, assembly, test performance, painting, machining using lathes, milling, and radial drilling. The training modules provide information on structure and function, operating techniques, and maintenance for various tools and machines used in each job.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

Download as xlsx, pdf, or txt

You are on page 1of 4

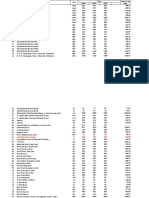

PLANT SECTION JOB SECTION TRAINING MODUL ISI MODUL

Washing 1. Material Handling

CYLINDER DAT

Forklift, Crane

Diassembly 1. Material Handling Forklift, Crane

2. Common Tool

3. Power Tool (Hi Torque) Structure & Function, Teknik pengoperasian, & Maintenance dari

alat-alat : Hi Torque, Hand Grinding, Sander, Buffing, Dynafile,

Dynastraight, Reamer

4. Basic Overhaul

5. Basic Cylinder Structure & Function atas sub komponen cylinder kelas small,

medium, big

6. Special Tool

7. Seal Knowledge Seal Material, Seal Dimension, Seal Profile, Seal Category, Seal

Type

8. Document (WI,QA) Work Instruction, QA Sheet 1-7, QA Memorandum

9. Basic Machine Element

Observation & Measurement 1. Failure Analysis

2. Measurement Tool

3. Diagnostic Tool Thickness Tester, Hardness Tester, Roughness Tester

4. Standard Tolerance

5. Basic NDT NDT Ultrasonic

6. Basic Cylinder Structure & Function atas sub komponen cylinder

7. Document (WI, QA) Work Instruction, QA Sheet 1-7, QA Memorandum

Assembly 1. Material Handling Forklift, Crane

2. Common Tool

3. Power Tool (Hi Torque) Structure & Function, Teknik pengoperasian, & Maintenance dari

alat-alat : Hi Torque, Hand Grinding, Sander, Buffing, Dynafile,

Dynastraight, Reamer

4. Basic Overhaul

5. Basic Cylinder Structure & Function atas sub komponen cylinder kelas small,

medium, big

6. Special Tool

7. Seal Knowledge Seal Material, Seal Dimension, Seal Profile, Seal Category, Seal

Type

8. Document (WI,QA) Work Instruction, QA Sheet 1-7, QA Memorandum

9. Measurement Tool

10. Basic Machine Element

11. Proses Drilling & Tapping Lock Screw Proses drilling pada piston & rod untuk lock screw

Test Performance 1. Material Handling Forklift, Crane

2. Bleeding Air Bleeding air dari dalam cylinder

3. Common Tool

4. Basic Cylinder Structure & Function atas sub komponen cylinder kelas small,

medium, big

5. Basic Hydraulic System

6. Failure Analyst

7. Measurement Tool

8. Test Bench Machine Structure & Function of Machine, Machine Operating,

Maintenance

9. Document (WI,QA) Work Instruction, QA Sheet 1-7, QA Memorandum

Painting 1. Material Handling Forklift, Crane

2. Teknik Pengecatan Komposisi cat, Proses Pengecatan

3. Basic Cylinder Structure & Function atas sub komponen cylinder

Machining I Lathe 1. Material Handling Forklift, Crane

2. Common Tool

3. Power Tool (Gerinda, Mesin Polish, Sander) Structure & Function, Teknik pengoperasian, & Maintenance dari

alat-alat : Hi Torque, Hand Grinding, Sander, Buffing, Dynafile,

Dynastraight, Reamer

4. Basic Cylinder Structure & Function atas sub komponen cylinder kelas small,

medium, big

5. Basic Gambar Teknik & Toleransi Gambar Teknik dan Toleransi

6. Special Tool Latthe

7. Document (WI,QA) Work Instruction, QA Sheet 1-7, QA Memorandum

8. Measurement Tool

11. Basic Machine Element

12. Basic Mesin Bubut Konsep dasar proses pengerjaan bubut, Identifikasi mesin bubut

konvensional, Identifikasi mesin bubut sesuai spesifikasi

pengerjaan, Pemilihan atas jenis pahat

13. Basic Material (Metalurgi)

14. Teknik Pengoperasian Mesin Bubut Parameter proses pengerjaan mesin bubut, Identifikasi macam

proses pembubutan, Merencanakan proses pengerjaan dengan

mesin bubut, Proses pembubutan

15. Material Consumable Good Material pahat, Coolant (dromus), Jenis amplas, Mata gerinda

tangan

Milling 1. Material Handling

2. Common Tool

3. Power Tool (Gerinda, Mesin Polish, Sander)

4. Basic Cylinder

5. Basic Gambar Teknik & Toleransi

6. Special Tool Milling

7. Document (WI,QA)

8. Measurement Tool

11. Basic Machine Element

12. Basic Mesin Milling

13. Basic Material (Metalurgi)

14. Teknik Pengoperasian Mesin Milling

15. Material Consumable Good

Radial Drill 1. Material Handling

2. Common Tool

3. Power Tool (Gerinda, Mesin Polish, Sander)

4. Basic Cylinder

5. Basic Gambar Teknik & Toleransi

6. Special Tool Radial Drill

7. Document (WI,QA)

8. Measurement Tool

11. Basic Machine Element

12. Basic Mesin Drilling

13. Basic Material (Metalurgi)

14. Teknik Pengoperasian Mesin Drilling

15. Material Consumable Good

16. Proses Tapping

Grinding 1. Basic Gambar Teknik & Toleransi Gambar Teknik dan Toleransi

2. Document (WI,QA) Work Instruction, QA Sheet 1-7, QA Memorandum

3. Measurement Tool

4. Basic Machine Element

5. Basic Mesin Grinding Mesin gerinda duduk

6. Basic Material (Metalurgi)

7. Teknik Pengoperasian Mesin Grinding

8. Material Consumable Good Mata gerinda, pendingin

SMAW 1. Material Handling

2. Common Tool

3. Basic Cylinder

4. Basic Gambar Teknik & Toleransi

5. Document (WI,QA)

6. Measurement Tool

7. Basic Machine Element

8. Basic Material (Metalurgi)

9. Basic Mesin Las SMAW

10. Teknik Pengelasan

11. Failure Analysis

12. Material Consumable Good

GMAW 1. Material Handling

2. Common Tool

3. basic cylinder

4. basic gambar teknik & toleransi

5. document (WI,QA)

6. measurement tool

7. basic machine element

8. basic material (metalurgi)

9. basic mesin las GMAW

10. teknik pengelasan

11. failure analysis

12. material consumable good

GTAW 1. material handling

2. common tool

3. basic cylinder

4. basic gambar teknik & toleransi

5. document (WI,QA)

6. measurement tool

7. basic machine element

8. basic material (metalurgi)

9. basic mesin las GMAW

10. teknik pengelasan

11. failure analysis

12. material consumable good

Machining II Polish 1. material handling Forklift, Crane

2. common tool

3. power tool (gerinda, mesin polish, sander) Structure & Function, Teknik pengoperasian, & Maintenance dari

alat-alat : Hi Torque, Hand Grinding, Sander, Buffing, Dynafile,

Dynastraight, Reamer

4. basic cylinder Structure & Function atas sub komponen cylinder kelas small,

medium, big

5. basic gambar teknik & toleransi Gambar teknik dan toleransi

6. special tool polish

7. document (WI,QA) Work Instruction, QA Sheet 1-7, QA Memorandum

8. measurement tool

11. basic machine element

12. basic mesin polish Structure & function,

13. basic material (metalurgi)

14. teknik pengoperasian mesin polish Setting komponen pada mesin, setting mesin, proses

pengoperasian

15. material consumable good

16. diagnostic tool Thickness Tester, Hardness Tester, Roughness Tester

17. failure analysis

Honing 1. material handling Forklift, Crane

2. common tool

3. power tool (gerinda, mesin polish, sander) Structure & Function, Teknik pengoperasian, & Maintenance dari

alat-alat : Hi Torque, Hand Grinding, Sander, Buffing, Dynafile,

Dynastraight, Reamer

4. basic cylinder Structure & Function atas sub komponen cylinder kelas small,

medium, big

5. basic gambar teknik & toleransi Gambar teknik dan toleransi

6. special tool honing

7. document (WI,QA) Work Instruction, QA Sheet 1-7, QA Memorandum

8. measurement tool

11. basic machine element

12. basic mesin honing Structure & function,

13. basic material (metalurgi)

14. teknik pengoperasian mesin honing Setting komponen pada mesin, setting mesin, proses

pengoperasian

15. material consumable good

16. diagnostic tool Thickness Tester, Hardness Tester, Roughness Tester

17. failure analysis

Stripping 1. material handling

2. common tool

3. basic cylinder

4. basic gambar teknik & toleransi

5. document (WI,QA)

6. measurement tool

7. basic machine element

8. diagnostic tool

9. basic chemical

10. basic proses stripping

11. basic electroplating

12. failure analysis

Chrome 1. material handling

2. common tool

3. basic cylinder

4. basic gambar teknik & toleransi

5. document (WI,QA)

6. measurement tool

7. basic machine element

8. diagnostic tool

9. basic chemical

10. basic proses chroming

11. basic electroplating

12. failure analysis

CYLINDER Workshop Washing 1. Material handling Forklift, Crane

Disassembly 1. material handling Forklift, Crane

2. common tool

3. power tool (Hi Torque) Structure & Function, Teknik pengoperasian, & Maintenance dari

alat-alat : Hi Torque, Hand Grinding, Sander, Buffing, Dynafile,

Dynastraight, Reamer

4. basic overhaul

5. basic cylinder Structure & Function atas sub komponen cylinder kelas small,

medium, big

6. special tool

7. seal knowledge Seal Material, Seal Dimension, Seal Profile, Seal Category, Seal

Type

8. document (WI,QA) Work Instruction, QA Sheet 1-7, QA Memorandum

9. basic machine element

Observation & Measurement 1. Failure analysis

2. Measurement tool

3. Diagnostic tool Thickness Tester, Hardness Tester, Roughness Tester

4. Standard tolerance

5. Basic NDT NDT Ultrasonic

6. Basic Cylinder Structure & Function atas sub komponen cylinder kelas small,

medium, big

7. Document (WI, QA) Work Instruction, QA Sheet 1-7, QA Memorandum

Assembly 1. material handling Forklift, Crane

2. common tool

3. power tool (Hi Torque) Structure & Function, Teknik pengoperasian, & Maintenance dari

alat-alat : Hi Torque, Hand Grinding, Sander, Buffing, Dynafile,

Dynastraight, Reamer

4. basic overhaul

5. basic cylinder Structure & Function atas sub komponen cylinder kelas small,

medium, big

6. special tool

7. seal knowledge Seal Material, Seal Dimension, Seal Profile, Seal Category, Seal

Type

8. document (WI,QA) Work Instruction, QA Sheet 1-7, QA Memorandum

9. measurement tool

10. basic machine element

11. Proses drilling & tapping lock screw Proses drilling pada piston & rod untuk lock screw

Test Performance 1. material handling Forklift, Crane

2. Bleeding air Bleeding air dari dalam cylinder

3. common tool

4. basic cylinder Structure & Function atas sub komponen cylinder kelas small,

medium, big

5. basic hydraulic system

6. failure analyst

7. measurement tool

8. test bench machine Structure & Function of Machine, Machine Operating,

Maintenance

9. document (WI,QA) Work Instruction, QA Sheet 1-7, QA Memorandum

Painting 1. material handling Forklift, Crane

2. teknik pengecatan Komposisi cat, Proses Pengecatan

3. basic cylinder Structure & Function atas sub komponen cylinder

Field Maintenance 1. Cylinder maintenance Maintenance hydraulic cylinder

Trobleshooting 2. Troubleshooting hydraiulic cylinder Troubleshooting pada unit (hydraulic system)

Remove & Install 3. Reusable parts

4. Failure analysis

5. Hydraulic cylinder Structure & Function atas sub komponen cylinder kelas small,

medium, big

6. Hydraulic systems

7. Basic machine element

8. OMM unit

9. Basic R & I

10. Common tools

11. Material handling Forklift, Crane

12. Basic overhaul

You might also like

- Homebase Air Conditioner 253797 ManualDocument14 pagesHomebase Air Conditioner 253797 Manualbmmanuals75% (16)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Zesto Corp. Maintenance GuidelinesDocument6 pagesZesto Corp. Maintenance GuidelinesRaymond CanieteNo ratings yet

- Introduction To Rotating Equipment MaintenanceDocument456 pagesIntroduction To Rotating Equipment MaintenanceJShearer97% (61)

- Centrifugal Pump Repair Data Form: Performed By: DateDocument2 pagesCentrifugal Pump Repair Data Form: Performed By: DateGerardo Hg100% (4)

- GT 7001 As30Document28 pagesGT 7001 As30Aviv Al RasyidNo ratings yet

- 2012 Basic Engine Analysis BookDocument114 pages2012 Basic Engine Analysis BookDiego RomeroNo ratings yet

- 4 Types of ProblemsDocument72 pages4 Types of Problemsmagudeesh100% (1)

- Jishu Hozen - AM PDFDocument48 pagesJishu Hozen - AM PDFDicky Hartanto100% (1)

- Is My Machine OK?: A Field Guide to Assessing Process MachineryFrom EverandIs My Machine OK?: A Field Guide to Assessing Process MachineryNo ratings yet

- ME131 wk4B Wk5a PDFDocument33 pagesME131 wk4B Wk5a PDFLance IanNo ratings yet

- Ignition SystemDocument37 pagesIgnition SystemdwcdiscoNo ratings yet

- Allowable Ampacities of Insulated ConductorsDocument2 pagesAllowable Ampacities of Insulated ConductorsJohn Paks100% (2)

- PM - G - 2 - Indentification of Plant & MachineryDocument4 pagesPM - G - 2 - Indentification of Plant & MachinerySanjay PatelNo ratings yet

- MC CON-Q0305 Scaffolder-System 30.10.2017Document17 pagesMC CON-Q0305 Scaffolder-System 30.10.2017abhijit shindeNo ratings yet

- TPM Text Book CompleteDocument261 pagesTPM Text Book Completeivan platiniNo ratings yet

- 3.1 Project Design ExecutionDocument12 pages3.1 Project Design ExecutionAlif SyahnandaNo ratings yet

- Pilani Campus: Practice, EDD, BITS PilaniDocument3 pagesPilani Campus: Practice, EDD, BITS PilaniRitik GuptaNo ratings yet

- Curriculum Alignment - Machine Operator Blow Moulding - L4Document5 pagesCurriculum Alignment - Machine Operator Blow Moulding - L4ZakNo ratings yet

- ME Lab DetailsDocument4 pagesME Lab Detailsabhilash sharanNo ratings yet

- Skill Required Skill Required Skill Required Skill Required Skill Required Skill RequiredDocument2 pagesSkill Required Skill Required Skill Required Skill Required Skill Required Skill RequiredRavi YadavNo ratings yet

- Osa SH25Document58 pagesOsa SH25EvowithducadosNo ratings yet

- Chart PDFDocument1 pageChart PDFmihuteelNo ratings yet

- MMVDocument42 pagesMMVHardik PatelNo ratings yet

- Section 2: Bench Metal Works: (Type Text)Document2 pagesSection 2: Bench Metal Works: (Type Text)Alleah LuciaNo ratings yet

- Autonomous Ship Industrie 4Document18 pagesAutonomous Ship Industrie 4IdhamtanahbaruNo ratings yet

- 14 - Introduction To Rotating Equipment Maintenance PDFDocument456 pages14 - Introduction To Rotating Equipment Maintenance PDFShubhamShukla100% (1)

- Roles & ResponsibilitiesDocument12 pagesRoles & ResponsibilitiesPavan SamudralaNo ratings yet

- Abap Project Demo On Wednesday 11.30 Am: BASICS (1 Day)Document2 pagesAbap Project Demo On Wednesday 11.30 Am: BASICS (1 Day)anup kumarNo ratings yet

- 1.1 Process Equipment - An OverviewDocument45 pages1.1 Process Equipment - An Overviewrodrigoperezsimone100% (1)

- New Staff Training Mech. Eng - DanielDocument2 pagesNew Staff Training Mech. Eng - DanielDaniel Garnando KristianNo ratings yet

- WFT SOW - For Wellbore Clean Up Tools (WBCU) - Sept 16th.Document1 pageWFT SOW - For Wellbore Clean Up Tools (WBCU) - Sept 16th.EduardNo ratings yet

- Module Details Gravity and Low Pressure Die Casting Technology C - Casting and Following ProcessesDocument5 pagesModule Details Gravity and Low Pressure Die Casting Technology C - Casting and Following ProcessessalimmalmaliNo ratings yet

- TLE Carpentry7-8 Weeks2-3Document5 pagesTLE Carpentry7-8 Weeks2-3Ric Jhon LoraNo ratings yet

- Std-203-Operation and Maintenance of Hoisting EquipmentDocument18 pagesStd-203-Operation and Maintenance of Hoisting EquipmentamitNo ratings yet

- Welder SMAW MAG MIG SAWDocument88 pagesWelder SMAW MAG MIG SAWjayson acunaNo ratings yet

- WFT SOW - 7'' Liner Hanger - 08082021Document1 pageWFT SOW - 7'' Liner Hanger - 08082021EduardNo ratings yet

- Week - 1 - Assingment Module 1 PDFDocument9 pagesWeek - 1 - Assingment Module 1 PDFsathish kumarNo ratings yet

- SOP For Maintenance & Testing of 6.6KV BET-CETDocument2 pagesSOP For Maintenance & Testing of 6.6KV BET-CETArbind NathNo ratings yet

- RCA FormatDocument293 pagesRCA FormatONMPlanning EngineerPT. GPOSKPSiteNo ratings yet

- TCF GuideDocument25 pagesTCF GuideAlicia ForbesNo ratings yet

- Training Need IdentificationDocument58 pagesTraining Need Identificationrohitbagga100% (1)

- Machinery Diagnostics - L2 2024Document43 pagesMachinery Diagnostics - L2 2024raisulatik73No ratings yet

- Equipment Initial Production Control SystemDocument1 pageEquipment Initial Production Control Systemsrmohapatra5086No ratings yet

- Self Employed Tailor PDFDocument272 pagesSelf Employed Tailor PDFeragonindia100% (2)

- Machine Shop Practice - Volume II, Industrial Press, New York, 1971Document2 pagesMachine Shop Practice - Volume II, Industrial Press, New York, 1971HeroNo ratings yet

- Goverment 2. University 3. Stackholder 4. Industry 5. BankingDocument1 pageGoverment 2. University 3. Stackholder 4. Industry 5. Bankingbrema riskyNo ratings yet

- FG AMHQ0102 Inline Checker 29.06.2018 PDFDocument239 pagesFG AMHQ0102 Inline Checker 29.06.2018 PDFAbhilasha Rajeev Singh BaghelNo ratings yet

- Checksheet Pergantian MoldDocument2 pagesChecksheet Pergantian MoldZacky Al Mubaroq100% (2)

- GRA2092 Projection Weld Nut EP WorkbookDocument69 pagesGRA2092 Projection Weld Nut EP WorkbookJOECOOL67No ratings yet

- 77R00Document2 pages77R00SanjayNo ratings yet

- Standard Operating Procedures SOP and Emegency Response by Mr. Mohan GharadDocument5 pagesStandard Operating Procedures SOP and Emegency Response by Mr. Mohan GharadPukar AdhikariNo ratings yet

- Q Concepts: Training Material ONDocument11 pagesQ Concepts: Training Material ONVinod SaleNo ratings yet

- Curriculum MOA-BMDocument5 pagesCurriculum MOA-BMabhigoodboy3No ratings yet

- Syllabus For Craft-Instructor CBT 2 FitterDocument23 pagesSyllabus For Craft-Instructor CBT 2 FitterpradeeNo ratings yet

- Manufacturing & Production ProcessesDocument2 pagesManufacturing & Production ProcessesPrashant GautamNo ratings yet

- Design of Machine NotesDocument19 pagesDesign of Machine NotesAnonymous 886Teo76tzNo ratings yet

- CMRP Practice QuestionsDocument4 pagesCMRP Practice Questionslinbaba123No ratings yet

- Production Management Op KannaDocument18 pagesProduction Management Op Kannasam_swamynathanNo ratings yet

- JSA Rebar Cutting & BendingDocument2 pagesJSA Rebar Cutting & BendingGunjan Sinha AdityaNo ratings yet

- B1-7b Maintenance Practices General SR 2016-06!18!220131 101112Document342 pagesB1-7b Maintenance Practices General SR 2016-06!18!220131 101112Pratik GhumatkarNo ratings yet

- Pedagogy AssignmentDocument1 pagePedagogy AssignmentRtr Hasan MahmudNo ratings yet

- Identify - Components of A Project Charter - CourseraDocument1 pageIdentify - Components of A Project Charter - CourseraSaptarshi BhattacharjeeNo ratings yet

- Ir5000 6000smDocument839 pagesIr5000 6000smoleg-spb85% (13)

- Ensuring Quality to Gain Access to Global Markets: A Reform ToolkitFrom EverandEnsuring Quality to Gain Access to Global Markets: A Reform ToolkitNo ratings yet

- BrakeDocument1 pageBrakemeli rizalNo ratings yet

- Consumable Parts ListDocument1 pageConsumable Parts Listmeli rizalNo ratings yet

- Elc ShecmaticDocument1 pageElc Shecmaticmeli rizalNo ratings yet

- 41P09NE0108Document8 pages41P09NE0108meli rizalNo ratings yet

- Daily MonitorDocument132 pagesDaily Monitormeli rizalNo ratings yet

- Diesel EngineDocument3 pagesDiesel Enginemeli rizalNo ratings yet

- Cajas Condulet C-LB-LL-TDocument4 pagesCajas Condulet C-LB-LL-TWashington MazziniNo ratings yet

- 4650 and 4850 Section 90Document74 pages4650 and 4850 Section 90josephmw0308No ratings yet

- HANSY PART LIST - To Be Updated - 20180808 PDFDocument5 pagesHANSY PART LIST - To Be Updated - 20180808 PDFJose Martinez MillaNo ratings yet

- Motor and Gear 3kW, 4kW - Parts List - 2020Document1 pageMotor and Gear 3kW, 4kW - Parts List - 2020Centrifugal SeparatorNo ratings yet

- Demolition Hammer: GSH 11 E - 3 611 C16 8K0Document8 pagesDemolition Hammer: GSH 11 E - 3 611 C16 8K0sanjoy PaulNo ratings yet

- Material Spare PartDocument4 pagesMaterial Spare PartAgus WinNo ratings yet

- Price ListDocument11 pagesPrice ListJacy Maricor Reabad100% (1)

- Parts List: TMCE-600Document45 pagesParts List: TMCE-600newtonNo ratings yet

- LeyendaDocument5 pagesLeyendaRaimundo GuevaraNo ratings yet

- Ground Floor Power Layout Ground Floor Lighting Layout: A A' B B' C C' D D' E A A' B B' C C' D D' EDocument1 pageGround Floor Power Layout Ground Floor Lighting Layout: A A' B B' C C' D D' E A A' B B' C C' D D' EHassan AlaskaNo ratings yet

- Price List 2020 & 2021 From HardwareDocument48 pagesPrice List 2020 & 2021 From HardwareChinangNo ratings yet

- Puffer Riscaldamento Scheda TecDocument3 pagesPuffer Riscaldamento Scheda TecAlexander CiutiNo ratings yet

- Arranjo Geral - Vitoria Recycle Grinder and BlowerDocument1 pageArranjo Geral - Vitoria Recycle Grinder and BlowerAndré Andrade RamosNo ratings yet

- Service Parts List: M12™ Brushless 1/2" (13Mm) Driver-DrillDocument2 pagesService Parts List: M12™ Brushless 1/2" (13Mm) Driver-DrillAmjad AlQasrawiNo ratings yet

- ISCAR Cutting Tools - Metal Working Tools - Milling - Shouldering - EPNI-FDocument2 pagesISCAR Cutting Tools - Metal Working Tools - Milling - Shouldering - EPNI-FHumberto MontañoNo ratings yet

- Operating Manual: Focuspro Th5000 SeriesDocument60 pagesOperating Manual: Focuspro Th5000 SeriesAnonymous bJlN5IhUNo ratings yet

- Allen Bradley 1485 PowertapDocument2 pagesAllen Bradley 1485 PowertapRAFAEL CARDOSONo ratings yet

- Part List CPA 7, CPA 10, CPA 15, CPA 20 & IVR AIR CompressorDocument32 pagesPart List CPA 7, CPA 10, CPA 15, CPA 20 & IVR AIR Compressorsuresh avhad100% (1)

- MW3 - Delta - User Guide PDFDocument52 pagesMW3 - Delta - User Guide PDFHarry James BoundenNo ratings yet

- 712 Series Pilot Ignition Systems (Flame Rectification) : Installation DataDocument16 pages712 Series Pilot Ignition Systems (Flame Rectification) : Installation Datasalquintero74No ratings yet

- D65EX-12 SN 60942-UP (S6D125E-2 (Emission) Eng. Installed)Document843 pagesD65EX-12 SN 60942-UP (S6D125E-2 (Emission) Eng. Installed)Ednaldo nabucoNo ratings yet

- Heavy Equipmenet Register No 1 (Autorecovered)Document364 pagesHeavy Equipmenet Register No 1 (Autorecovered)islamhse10No ratings yet

- Pipes & Fittings: PricelistDocument18 pagesPipes & Fittings: PricelistMitrasNo ratings yet

- Industrial Duty Commercial Door Operator: Owner'S ManualDocument36 pagesIndustrial Duty Commercial Door Operator: Owner'S ManualMagdi FarhanNo ratings yet