Professional Documents

Culture Documents

JMF

JMF

Uploaded by

Elmo CharlesOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JMF

JMF

Uploaded by

Elmo CharlesCopyright:

Available Formats

12/21/2018 AC 150/5370-10H

the laboratory’s current accreditation and accredited test methods shall be submitted to the Resident

Project Representative (RPR) prior to start of construction.

401-3.3 Job mix formula (JMF). No asphalt mixture shall be placed until an acceptable mix design has

been submitted to the RPR for review and accepted in writing. The RPR’s review shall not relieve the

Contractor of the responsibility to select and proportion the materials to comply with this section.

When the project requires asphalt mixtures of differing aggregate gradations and/or binders, a separate

JMF shall be submitted for each mix. Add anti-stripping agent to meet tensile strength requirements.

The JMF shall be prepared by an accredited laboratory that meets the requirements of paragraph 401-3.2.

The asphalt mixture shall be designed using procedures contained in Asphalt Institute MS-2 Mix Design

Manual, 7th Edition. [ Samples shall be prepared and compacted using a

Marshall compactor in accordance with ASTM D6926. ] [ Samples shall be

prepared and compacted using the gyratory compactor in accordance with

ASTM D6925. ]

Should a change in sources of materials be made, a new JMF must be submitted to the RPR for review

and accepted in writing before the new material is used. After the initial production JMF has been

approved by the RPR and a new or modified JMF is required for whatever reason, the subsequent cost of

the new or modified JMF, including a new control strip when required by the RPR, will be borne by the

Contractor.

The RPR may request samples at any time for testing, prior to and during production, to verify the quality

of the materials and to ensure conformance with the applicable specifications.

************************************************************************************

Select the method for mix design, Marshall Method, ASTM D6926 or Gyratory

Method, ASTM D6925.

The design criteria in Table 1 are target values necessary to meet the acceptance

requirements contained in paragraph 401-6.2. The criteria is based on a production

process which has a material variability with the following standard deviations: Air

Voids = 0.65%.

************************************************************************************

The JMF shall be submitted in writing by the Contractor at least [ 30 ] days prior to the start of paving

operations. The JMF shall be developed within the same construction season using aggregates proposed

for project use.

The JMF shall be dated, and stamped or sealed by the responsible professional Engineer of the laboratory

and shall include the following items as a minimum:

Manufacturer’s Certificate of Analysis (COA) for the asphalt binder used in the JMF in

accordance with paragraph 401-2.3. Certificate of asphalt performance grade is with modifier

already added, if used and must indicate compliance with ASTM D6373. For plant modified

asphalt binder, certified test report indicating grade certification of modified asphalt binder.

Manufacturer’s Certificate of Analysis (COA) for the anti-stripping agent if used in the JMF in

accordance with paragraph 401-2.4.

Certified material test reports for the course and fine aggregate and mineral filler in accordance

with paragraphs 401-2.1.

Item P-401 Asphalt Mix Pavement 268

You might also like

- Warehouse An Overview ProjectDocument48 pagesWarehouse An Overview ProjectHuzaifa Jamnagarwala100% (7)

- BS 594-1 2005 Hot Rolled Asphalt For Roads and Othe Rpaved AreasDocument32 pagesBS 594-1 2005 Hot Rolled Asphalt For Roads and Othe Rpaved Areassallymazeera100% (2)

- Plant Certification ChecklistDocument26 pagesPlant Certification ChecklistAndy Rogers100% (2)

- D4228 Painter QualificationDocument3 pagesD4228 Painter QualificationTanmay Gor0% (2)

- 09 Samss 091Document19 pages09 Samss 091Sohail Tisekar100% (1)

- PIP STS03600 (Nonshrink Cementitous Grout Specification)Document8 pagesPIP STS03600 (Nonshrink Cementitous Grout Specification)Javad Monfared100% (1)

- 150 - 5370 - 10F FaaDocument580 pages150 - 5370 - 10F FaaCiprian ToderascuNo ratings yet

- Do - 253 - s2003 Asphalt and Concrete Batching PlantsDocument12 pagesDo - 253 - s2003 Asphalt and Concrete Batching PlantsrubydelacruzNo ratings yet

- PART II 02 500 MVA 400 220 33 KV R 0 Mar 12 PDFDocument96 pagesPART II 02 500 MVA 400 220 33 KV R 0 Mar 12 PDFGuru Mishra100% (1)

- Tots QuestionsDocument12 pagesTots QuestionsEric Roy GepilanoNo ratings yet

- B-Speech GPS2Document2 pagesB-Speech GPS2tforraiNo ratings yet

- InvoiceDocument3 pagesInvoiceSrinibasNo ratings yet

- Gaslands Vehicle Cards BWDocument3 pagesGaslands Vehicle Cards BWSekcer100% (1)

- Planetary AssaultDocument5 pagesPlanetary AssaultAnonymous tMbueXy100% (1)

- Standard Practice For Certifying Suppliers of Emulsified AsphaltDocument7 pagesStandard Practice For Certifying Suppliers of Emulsified Asphaltjun floresNo ratings yet

- 128-Bituminous Pavements (Series 400)Document72 pages128-Bituminous Pavements (Series 400)MEHDI FARROKHINo ratings yet

- Section 403-A: Warm Mix Asphalt - Open Graded Friction Course (NON-QLA) Page 149Document3 pagesSection 403-A: Warm Mix Asphalt - Open Graded Friction Course (NON-QLA) Page 149Opata OpataNo ratings yet

- WSDOT Standard Practice QC 1Document6 pagesWSDOT Standard Practice QC 1Sheryn Malaya100% (1)

- Item 341 Dense-Graded Hot-Mix Asphalt: 1. DescriptionDocument28 pagesItem 341 Dense-Graded Hot-Mix Asphalt: 1. DescriptionHenok MebrateNo ratings yet

- TXDOT 6260 Reinforced Fabric Joint Underseal PDFDocument4 pagesTXDOT 6260 Reinforced Fabric Joint Underseal PDFthadikkaranNo ratings yet

- 07 - CP 11-14-4 - Hydraulic CementDocument4 pages07 - CP 11-14-4 - Hydraulic CementCarlitos GuerraNo ratings yet

- Mix Design 2021Document137 pagesMix Design 2021Akh RhiNo ratings yet

- Aggregate : Section 403: Open Graded Friction Course (NON-QLA) Page 144Document4 pagesAggregate : Section 403: Open Graded Friction Course (NON-QLA) Page 144Opata OpataNo ratings yet

- Txdot DMS-4640 Chemical Admixtures For ConcreteDocument3 pagesTxdot DMS-4640 Chemical Admixtures For ConcretefiercecatNo ratings yet

- Aggregate SourcesDocument32 pagesAggregate SourcesLuis Carlos Rodrigo DalmauNo ratings yet

- 03 19001part3Document100 pages03 19001part3اسماعيل جودةNo ratings yet

- CS 704Document5 pagesCS 704ZeeshanAliNo ratings yet

- GCPADocument8 pagesGCPAisabellalihuenNo ratings yet

- C3. Paint Specification (WSS-M64J39-A1) v1Document7 pagesC3. Paint Specification (WSS-M64J39-A1) v1Chandrajeet ShelkeNo ratings yet

- MP 401 02 22Document9 pagesMP 401 02 22Red RedNo ratings yet

- EVAHMADocument9 pagesEVAHMAbekimtolajNo ratings yet

- Readymix 2Document6 pagesReadymix 2melatyplamoniaNo ratings yet

- Quality Control ProcedureDocument29 pagesQuality Control Procedurekj_mekanikal33% (3)

- Polymer SpecifcatiionDocument7 pagesPolymer SpecifcatiionSunny RohillaNo ratings yet

- Concrete Repair ClassDocument7 pagesConcrete Repair ClasscikoshrNo ratings yet

- Item P-610 Structural Portland Cement Concrete 105Document11 pagesItem P-610 Structural Portland Cement Concrete 105Anthony McguireNo ratings yet

- Astm C685 C685M 17Document6 pagesAstm C685 C685M 17Alexis MartinezNo ratings yet

- OPSS - PROV 1101 - Nov 2020Document9 pagesOPSS - PROV 1101 - Nov 2020Samantha McLachlinNo ratings yet

- QA Plan Asphalt-602Document31 pagesQA Plan Asphalt-602Radoslava KovackiNo ratings yet

- 4S-10 01Document27 pages4S-10 01Claudio Hernández PobleteNo ratings yet

- Specifications For Concrete SleepersDocument28 pagesSpecifications For Concrete Sleepersgerfreecalls50% (2)

- Construction Standard Specification SECTION 02512 Paving Asphalt BinderDocument7 pagesConstruction Standard Specification SECTION 02512 Paving Asphalt BinderKulatheepNo ratings yet

- Job Mix Formula ProcessDocument2 pagesJob Mix Formula ProcessKashif MuhammadNo ratings yet

- Quality Management SystemDocument21 pagesQuality Management SystemAugusto M. ReyesNo ratings yet

- Asphalt Binder Quality Program: 1. ScopeDocument7 pagesAsphalt Binder Quality Program: 1. ScopeBander Al–kouhlaniNo ratings yet

- MS-JF-1000 - Rev B - Jan 2018 - Seating and DoorsDocument19 pagesMS-JF-1000 - Rev B - Jan 2018 - Seating and DoorsKnw CalidadNo ratings yet

- Astm D6926 20Document4 pagesAstm D6926 20bimsuriyanNo ratings yet

- 08 - CP 11-16-4 - Hydraulic CementDocument4 pages08 - CP 11-16-4 - Hydraulic CementMed Hédi BANNANINo ratings yet

- Cement Grout AAADocument4 pagesCement Grout AAAabualamalNo ratings yet

- 502.00 Asphalt Pavement 502.10 Asphalt Pavement DescriptionDocument30 pages502.00 Asphalt Pavement 502.10 Asphalt Pavement DescriptionAdjei BaldanNo ratings yet

- Bituminous Pavement Jul 30 2009Document30 pagesBituminous Pavement Jul 30 2009aev65No ratings yet

- QA&QC - Bitumen Design MixDocument8 pagesQA&QC - Bitumen Design MixMuhammadZahirKhanNo ratings yet

- Grade Ordinary Portland Cement - Specification (: Indian Standard 43 Firs-T Revision)Document20 pagesGrade Ordinary Portland Cement - Specification (: Indian Standard 43 Firs-T Revision)kundank_32No ratings yet

- C Add Work Plan 2008Document6 pagesC Add Work Plan 2008T V AnjaneyuluNo ratings yet

- Irs R-48-88Document16 pagesIrs R-48-88sankar.kepro.labNo ratings yet

- Operational Instruction No. 02 / 2011 Particular Specifications For Concrete RepairDocument21 pagesOperational Instruction No. 02 / 2011 Particular Specifications For Concrete RepairMichael LauNo ratings yet

- Practice For Superpave Warm Mix Asphalt (Wma) Mix DesignDocument6 pagesPractice For Superpave Warm Mix Asphalt (Wma) Mix DesignEdil AlmendrasNo ratings yet

- Summary of Decisions of The Structural Engineering Committee SEC 4/2004 Held On 16.9.2004Document5 pagesSummary of Decisions of The Structural Engineering Committee SEC 4/2004 Held On 16.9.2004Cheung LeeNo ratings yet

- Astm C936 C936M 21Document4 pagesAstm C936 C936M 21Dinesh KillariNo ratings yet

- Annual Product Quality Review (APQR) in Pharmaceutical ManufacturingFrom EverandAnnual Product Quality Review (APQR) in Pharmaceutical ManufacturingNo ratings yet

- Department of Transportation Medical Reference for ExaminersFrom EverandDepartment of Transportation Medical Reference for ExaminersNo ratings yet

- Guide to Performance-Based Road Maintenance ContractsFrom EverandGuide to Performance-Based Road Maintenance ContractsNo ratings yet

- Aviation Maintenance Technician Handbook—Powerplant (2024): FAA-H-8083-32BFrom EverandAviation Maintenance Technician Handbook—Powerplant (2024): FAA-H-8083-32BNo ratings yet

- Table 2.3: Arithmetic Operators Operator Mathematical Function ExampleDocument1 pageTable 2.3: Arithmetic Operators Operator Mathematical Function ExampleElmo CharlesNo ratings yet

- Using Message Box and Input Box: 3.1 The Msgbox FunctionDocument1 pageUsing Message Box and Input Box: 3.1 The Msgbox FunctionElmo CharlesNo ratings yet

- Table 3.2: Returned Values and Command ButtonsDocument1 pageTable 3.2: Returned Values and Command ButtonsElmo CharlesNo ratings yet

- A Preliminaries/Genera Conditions: Information Provided Measurement Rules Rules CoverageDocument1 pageA Preliminaries/Genera Conditions: Information Provided Measurement Rules Rules CoverageElmo CharlesNo ratings yet

- Core Principles: 1. Programme and RecordsDocument1 pageCore Principles: 1. Programme and RecordsElmo CharlesNo ratings yet

- Table 3.1: Style Values and Command Buttons Style Value Named Constant Button DisplayedDocument1 pageTable 3.1: Style Values and Command Buttons Style Value Named Constant Button DisplayedElmo CharlesNo ratings yet

- Example 2.5: Figure 2.3: Concatenation of StringsDocument1 pageExample 2.5: Figure 2.3: Concatenation of StringsElmo CharlesNo ratings yet

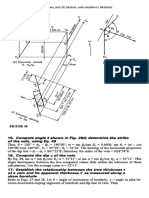

- (D) Plan Plan (B) Elevation Normal Toh H: 15. Compute Angle O Shown in Fig. 2Bd Determine The StrikeDocument1 page(D) Plan Plan (B) Elevation Normal Toh H: 15. Compute Angle O Shown in Fig. 2Bd Determine The StrikeElmo CharlesNo ratings yet

- Of The Intersection Points and Point G: H H F FDocument1 pageOf The Intersection Points and Point G: H H F FElmo CharlesNo ratings yet

- Guidance Part A: Delay, Disruption and Acceleration ConceptsDocument1 pageGuidance Part A: Delay, Disruption and Acceleration ConceptsElmo CharlesNo ratings yet

- Civilengenhandbook 440Document1 pageCivilengenhandbook 440Elmo CharlesNo ratings yet

- Preliminaries/General Conditions: A ContinuedDocument1 pagePreliminaries/General Conditions: A ContinuedElmo CharlesNo ratings yet

- In Terms of The Known Angles) S P and BDocument1 pageIn Terms of The Known Angles) S P and BElmo CharlesNo ratings yet

- Global Claims: SCL Delay and Disruption Protocol 2 Edition: February 2017 8Document1 pageGlobal Claims: SCL Delay and Disruption Protocol 2 Edition: February 2017 8Elmo CharlesNo ratings yet

- SCL Delay and Disruption Protocol 2 Edition: February 2017 7Document1 pageSCL Delay and Disruption Protocol 2 Edition: February 2017 7Elmo CharlesNo ratings yet

- Procedure For Granting EOT: SCL Delay and Disruption Protocol 2 Edition: February 2017 6Document1 pageProcedure For Granting EOT: SCL Delay and Disruption Protocol 2 Edition: February 2017 6Elmo CharlesNo ratings yet

- Pre I Aries/ Ene Al Itions Co N Ed: 3 Lo e S Q I Eme TS: Pec L Itations T Od/se Uence/t I G/ SeDocument1 pagePre I Aries/ Ene Al Itions Co N Ed: 3 Lo e S Q I Eme TS: Pec L Itations T Od/se Uence/t I G/ SeElmo CharlesNo ratings yet

- General Definitions: I I R L V I L IDocument1 pageGeneral Definitions: I I R L V I L IElmo CharlesNo ratings yet

- SMM7 21Document1 pageSMM7 21Elmo CharlesNo ratings yet

- SMM7 23Document1 pageSMM7 23Elmo CharlesNo ratings yet

- 1.3.1 General AASHTO LRFD Design EquationDocument1 page1.3.1 General AASHTO LRFD Design EquationElmo CharlesNo ratings yet

- 2020-04-Lockdown-Rollback-Checklist-Research-Note 4Document1 page2020-04-Lockdown-Rollback-Checklist-Research-Note 4Elmo CharlesNo ratings yet

- 2020-04-Lockdown-Rollback-Checklist-Research-Note 2Document1 page2020-04-Lockdown-Rollback-Checklist-Research-Note 2Elmo CharlesNo ratings yet

- 2020-04-Lockdown-Rollback-Checklist-Research-Note 3Document1 page2020-04-Lockdown-Rollback-Checklist-Research-Note 3Elmo CharlesNo ratings yet

- 2020-04-Lockdown-Rollback-Checklist-Research-Note 1Document1 page2020-04-Lockdown-Rollback-Checklist-Research-Note 1Elmo CharlesNo ratings yet

- Nice Classification - 11 Edition, Version 2017Document1 pageNice Classification - 11 Edition, Version 2017Elmo CharlesNo ratings yet

- Recommended Criteria For Single Samples: Table 1 Table 1Document1 pageRecommended Criteria For Single Samples: Table 1 Table 1Elmo CharlesNo ratings yet

- VMA in HMADocument1 pageVMA in HMAElmo CharlesNo ratings yet

- Truck LoadingDocument1 pageTruck LoadingElmo CharlesNo ratings yet

- GR Yaris Brochure - TCM 3060 2009643Document40 pagesGR Yaris Brochure - TCM 3060 2009643udayippu idNo ratings yet

- Death March Kara Hajimaru Isekai Kyusoukyoku Book 07 - Volume 07Document491 pagesDeath March Kara Hajimaru Isekai Kyusoukyoku Book 07 - Volume 07Ale DragutNo ratings yet

- EN81-28 Risk of Trapping FlowChart v3Document1 pageEN81-28 Risk of Trapping FlowChart v3Ashraful ShohagNo ratings yet

- Technical Description of WY-130 - Vagão de Rejeito de LastroDocument12 pagesTechnical Description of WY-130 - Vagão de Rejeito de LastroReinaldo SantiagoNo ratings yet

- ARINC Meteorological Data Collection and Reporting System (MDCRS)Document16 pagesARINC Meteorological Data Collection and Reporting System (MDCRS)SHERIEFNo ratings yet

- HARGA PLUS ONGKIR - KAB ENDE Reverensi MEGALDocument15 pagesHARGA PLUS ONGKIR - KAB ENDE Reverensi MEGALario miguelNo ratings yet

- Risk Assessment MV Power Cables & Accessories InstallationDocument10 pagesRisk Assessment MV Power Cables & Accessories InstallationAdil HasanovNo ratings yet

- Standards INDEXDocument8 pagesStandards INDEXZohair AftabNo ratings yet

- Ryanair 09 Adrian DunneDocument33 pagesRyanair 09 Adrian Dunneballes84No ratings yet

- ER LogbookDocument19 pagesER LogbookmyzuraNo ratings yet

- Stock Transfer Plant To PlantDocument36 pagesStock Transfer Plant To Plantbalu4indians100% (1)

- Car Buying Project XLS 95 Excel Version 1Document13 pagesCar Buying Project XLS 95 Excel Version 1rolfwillNo ratings yet

- BSP Hammer JCBDocument14 pagesBSP Hammer JCBashish sahaNo ratings yet

- British Progress in Pumps and Pumping EnginesDocument204 pagesBritish Progress in Pumps and Pumping EnginesVictor MartinezNo ratings yet

- Go FL DMT and Ee A 40164421357Document3 pagesGo FL DMT and Ee A 40164421357कुँ. विकास सिंह राजावतNo ratings yet

- Fce TestDocument8 pagesFce TestLorgia Calixto CastillejoNo ratings yet

- C1803 04 PDFDocument3 pagesC1803 04 PDFMaiChiVuNo ratings yet

- Block 08 Dasholi - ResourceRate - LabourDocument2 pagesBlock 08 Dasholi - ResourceRate - LabourManojNo ratings yet

- WIII ChartDocument44 pagesWIII ChartSangwang Singwing MbaheNo ratings yet

- Attachment - 6 Termination Letter of Driver and OperatorDocument2 pagesAttachment - 6 Termination Letter of Driver and OperatorAmeerHamzaWarraich100% (1)

- Steve Schmidt City of Northfield Mr. Dan Olson, PlannerDocument25 pagesSteve Schmidt City of Northfield Mr. Dan Olson, Plannerapi-27444268No ratings yet

- VIP RECEPTION & GENERAL RECEPTION For Nick LeibhamDocument2 pagesVIP RECEPTION & GENERAL RECEPTION For Nick LeibhamSunlight FoundationNo ratings yet

- 02Document117 pages02Netzoo FlixNo ratings yet

- Cat 980L: Wheel LoaderDocument2 pagesCat 980L: Wheel LoaderEstrella AnguianoNo ratings yet