Professional Documents

Culture Documents

BER, Controls Motorized Valve Start-Up Instructions

BER, Controls Motorized Valve Start-Up Instructions

Uploaded by

Joseph YumulOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BER, Controls Motorized Valve Start-Up Instructions

BER, Controls Motorized Valve Start-Up Instructions

Uploaded by

Joseph YumulCopyright:

Available Formats

BERNARD CONTROLS INC.

BEACON Pty ACTUATION & CONTROLS ENGINEER

25 South Street Rydalmere 7, Jalan Bayu 2/5 - Taman Perindustrian.

NSW 2116 AUSTRALIA Tampoi Jaya - 81100 JOHOR BAHRU

Tel: + 61 2 98 41 23 45 Tel: +60 7 23 502 77 / 23 50 281

Fax: + 61 2 96 84 64 39 Fax: +60 7 23 502 80 / 23 50 285

IPU ING PAUL UNGER BERNARD BENELUX NV

Hardtmuthgasse 53 Sophialaan 5

1100 WIEN 3542 AR UTRECHT

Tel: +43 1 602 45 49

Fax: +43 1 603 29 43

Tel: +31 30 24 14 700

Fax: +31 30 24 13 949 START-UP INSTRUCTIONS

BERNARD BENELUX SA

Rue Saint-Denis, 135

G. FAGERBERG NORGE

Postboks 536 - HØDEN

FOR ACTUATORS

1190 BRUXELLES 1522 MOSS

Tel: +32 2 343 41 22 Tel: +47 69 26 50 44

Fax: +32 2 347 28 43 Fax: +47 69 26 73 33 INSTRUCTION DE DEMARRAGE

JCN

Av. Mutinga, 3188 - Pirituba

MARCO

U1. Nowolipki 23/2 DES SERVOMOTEURS

CEP 05110-000 Sao Paulo SP 01-006 WARSZAWA

Tel: +55 11 3 902 2600 Tel: +48 22 63 686 26

Fax: +55 11 3 902 4018 Fax: +48 22 63 635 77

jcn@jcn.com.br 1 - PRECAUTIONS BEFORE BEGINNING INSTALLATION

PINHOL, GOMES & GOMES LDA

TADELLA LIMITED Avenida 24 de Julho, 174 PRECAUTIONS D’UTILISATIONS

5th floor, Ping-an mansion, 1300 LISBOA

23 Financial street Xicheng district Tel: +351 1 39 711 65

BEIJING - CHINA 100032 Fax: +351 1 39 068 58

Tel: +86 10 66 21 03 95 / 03 96 / 03 97 2 - ELECTRICAL CONNECTIONS

Fax: +86 10 66 21 03 99 ACTUATOR TECHNICAL SERVICES

Patrick RD, Jet Park BRANCHEMENT ELECTRIQUE

ARMATEC A/S KEMPTON PARK 1620

Mollevej 15 Tel: +27 11 397 47 56

2990 NIVA Fax: +27 11 397 47 68

Tel: +45 49 14 95 00 actuator@jhbmail.co.za 3 - MECHANICAL STOPS SETTING

Fax: +45 49 14 95 05

www.armatec.dk BERNARD SOUTH-EAST ASIA REGLAGES DES BUTEES MECANIQUES (QUART DE TOUR)

25, soi Sang-Ngen

EGYPTIAN KUWAITI ENGINEER OFFICE Sukhumvit 55, Sukhumvit Road

3 El-Emam Hassan Maamoun 6th Zone Bangkok 10110 Thailand

Naser City - CAIRO Tel: +66 2 391 46 51 4 - TRAVEL LIMIT SWITCH SETTING

Tel: +202 27 40 550 / 559 Fax: +66 2 391 34 90

Fax: + 202 27 40 558 REGLAGE DES FINS DE COURSE

ACTUATION &CONTROLS ENG. (ASIA)

OY SOFFCO AB Block 3029A UBI RD 3

Karapellontie 13 #01-97 SINGAPORE 408661

FIN-02610 ESPOO Tel: +65 74 272 48 5 - POSITION INDICATOR SETTING

Tel: +358 9 59 60 33 Fax: +65 74 298 57

Fax: +358 9 59 67 26 REGLAGE DE L’INDICATEUR DE POSITION

BERNARD SERVOMOTORES

L. BERNARD C/ Valentin Beato, 11 - 1°D

4 rue d’Arsonval - BP 91 28037 MADRID

95505 GONESSE CEDEX Tel: +34 91 304 11 39

Tel: +33 01 34 07 71 00 Fax: +34 91 327 34 42

Fax: +33 01 34 07 71 01 For more information about commissioning instructions or storage,

G. FAGERBERG AB

DEUFRA GMBH Postbox 12105 please consult our << COMMISSIONING INSTRUCTIONS - RANGE SD

Kasinostrasse 22 40241 GOETEBORG

53840 TROISDORF Tel: +46 31 69 37 00 >> or << COMMISSIONING INSTRUCTIONS - RANGE SR/ST >>

Tel: +49 22 41 98 340 Fax: +46 31 69 38 00

Fax: +49 22 41 98 34 44 literature, depending on the type of actuator .

INOXLINE

WARIMPEX Binningerstrasse 86

DIOSZEGI UT.37 CH - 4123 ALLSCHWILL

H - 1113 BUDAPEST Tel: +41 61 481 51 00 Pour des renseignements plus complets sur l’entretien ou le stockage, se

Tel: +36 1 16 69 910 Fax: +41 61 481 50 05

Fax: +36 1 20 92 551 reporter, suivant les appareils, à la brochure << INSTRUCTIONS DE MISE

CIMTEK A.S.

INSTRUMENTATION LTD Kenedy Caddesi Yalim Sok N°3 EN SERVICE ET ENTRETIEN - GAMME SD >> ou << INSTRUCTIONS DE

Kanjikode West 678623 KAVAKLIDERE

PALGHAT-KERALA 06660 - ANKARRA MISE EN SERVICE - GAMME SR/ST >>.

el: +91 491 56 61 27 / 56 61 28 Tel: +90 312 41 74 900

Fax: +91 491 56 61 35 / 56 62 40 Fax: +90 312 41 89 716

PECHINEY ITALY S.P.A. EMIRATES HOLDINGS

Viale F. Restelli 5 P.O. Box 984 - Abu Dhabi

20124 MILAN Tel: +9712 773 553

Tel: +39 2 66 89 31 Fax: +9712 725 565

Fax: +39 2 60 81 513 emhold@emirates.net.ae

SEWON INTERNATIONAL CO ZOEDALE FLOW COMPONENTS

1501, Korea Business Center 58 Hurst Grove

1338-32 Seocho Dong, Seocho-ku SEOUL BEDFORD MK40 4DR

Tel: +82 2 581 72 29 / 72 27 Tel: +44 12 34 27 12 81

Fax: +82 2 581 72 28 Fax: +44 12 34 21 42 35

BERNARD CONTROLS INC. U.S.A. BERNARD CONTROLS INC. U.S.A.

15740 Park Row, Suite 100 – Houston, Texas 77084 15740 Park Row, Suite 100 – Houston, Texas 77084

E-mail: bsales@bernardcontrols.com - Tel: (1) 281-578-6666 - Fax: (1) 281-578-2797 E-mail: bsales@bernardcontrols.com - Tel: (1) 281-578-6666 - Fax: (1) 281-578-2797

1. PRECAUTIONS BEFORE 1. PRECAUTIONS

COMMISSIONING D’UTILISATIONS

Warning: Disconnect power before Attention: Débrancher l’alimentation avanat

removing the cover. To insure unit d’ouvirir l’appareil. Pour assurer la meilleure

protection, the cover must be promptly étanchéité, remettre le couvercle de protection OUTPUT SOCKETS & MOUNTING DIMENSIONS

replaced. dès que les opérations de réglage sonte

terminées.

2. ELECTRICAL CONNECTIONS

2. BRANCHEMENT ELECTRIQUE

• Verify the power characteristics.

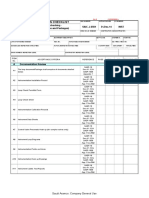

• Check the wiring. • Vérifier la nature et la tension du courant. ACTUATOR OUTPUT SOCKET DIMENSIONS ISO 5211 BOLT CIRCLE MOUNTING BOLT

• Move the valve manually to the half- • Vérifier le câblage*. MODEL (MM) SQUARE (IN) SQUARE FLANGE (INCHES) QTY-SIZExDEPTH

open position. • Amener la vanne en position médiane,

• Connect the travel limits switches and grâce à la commande manuelle. Z3 14 0.551 F05 1.97 4-M6 x .393

the torque limit switches, then check • Brancher les fins de course et les limiteurs

their functioning*. d’effort et vérifier leur fonctionnement par F05 1.97 4-M6 x .59

OA6 & OA8 19 0.748

action manuelle sur les microcontacts. F07 2.76 4-M8 x .79

Briefly start the actuator and check that Donner un ordre bref et vérifier que le sens de

the direction of rotation is in accordance rotation du servomoteur corresopnd bien à OA15 19 0.748 F07 2.76 4-M8 x .79

with the order given. If not, invert the l’ardre donné. Sinon, inverser le sens de F07 2.76 4-M8 x .55

direction. rotation. AT18 & AT25 22 0.866

F10 4.02 4-M10 x .55

F07 2.76 4-M8 x .55

AT50 27 1.063

F10 4.02 4-M10 x .55

AT80 27 1.063 F12 4.92 4-M12 x .71

BT50 27 1.063 F12 4.92 4-M12 x .59

BT100 36 1.417 F14 5.51 4-M16 x .79

BT150 36 1.417 F14 5.51 4-M16 x .79

3. SET MECHANICAL STOPS 3. REGLAGES DES BUTEES

MECANIQUES (QUART DE TOUR)

The 90º travel must always be limited by

the travel limit switches, so they must be Il est impératif que les butées soient réglées

set to trip prior to contacting the mechanical de sorte qu’à l’issue des manoeuvres

stops. électriques, le secteur en position extreme ne

To modify this position, increase or vienne pas en contact avec les butées

decrease the corresponding stop, then lock mécaniques.

the nut on the screw to prevent a change in Pour modifier cette position, visser ou

position. dévisser la butée corresopndeante, accessible

sur le cote de l’appareil.

The mechanical stops and nuts are located

outside of the actuator housing. * Sur les SM de la gamme SD qui disposent

d’un limiteur d’effort, celui-ci donne un contact

*The torque limit switches of the SD range impulsionel.

actuators only give a short duration contact.

Last printed 9/7/2003 11:55 AM

4. SET TRAVEL LIMIT SWITCHES 4. REGLAGE DES FINS DE COURSE

The cams operating the limit switches are Les cames actionnant les microcontacts

in a cylindrical block which does not require forment un ensemble monobloc don’t les

APPENDIX I

any disassembly or special tools. quatre éléments peuvent être réglés

séparément et independeamment les uns

des autres.

How to proceed: Mode operatoire :

1. Manually operate the actuator to the 1. Amener en manual la vanne dans la

position to be set. position à régler

2. Insert a screwdriver in the slot of the 2. Placer un petit tournevis dans la fente

button encircled by the same color as correspondante à la came à déplacer

the cam to be set. 3. Appuyer pour libérer la came et tourner

3. Push to disengage the lock and turn dans un sens ou l’autre pour amender

clockwise or counter-clockwise la came dans la position recherchee

according to the needed cam position. 4. Relâcher et s’assurer que la tête est

4. Remove the screwdriver and insure remontee en position d’origine, ce qui

the button has returned upward to its verrouille automatiquement la came.

original position, thus locking the cam

in the selected position. Attention: Le fin de course doit couper

l’alimentation moteur avant d’arriver sur la

Caution: Insure that the travel limit butée mécanique.

switches stop the motor before the

quadrant reaches the mechanical stops. 5. REGLAGE DE L’INDICATEUR DE

POSITION

5. POSITION INDICATOR SET

Sur les types sans potentiométre, la fléche

The indicator with arrow can be rotated by peut être tournée à la main sans démontage

hand without removal. Adjust this indicator pour l’amener en face du repère

to its proper position inside the cover correspondant au hublot.

window.

Sur les types avec potentiometre, l’indicateur

Actuators with a potentiometer have an peut etre réglé après desserrage de sa vis

indicator plate held in place by a screw. de fixation.

After loosing this screw, adjustments are

possible.

Last printed 9/7/2003 11:55 AM

INSTRUCTIONS FOR START-UP AND STORAGE 10 - STORAGE

OF SR/ST RANGE ACTUATORS Introduction

INTRODUCTION

The actuator includes electric equipment as well as grease lubricated gears. In spite of the

weatherproof enclosure, oxidation, jamming and other alterations are possible if the actuator

SR/ST range motorized systems are multi-turn actuators resulting from

is not correctly stored.

many years of experience in the field of remote controlled valve systems.

Storage

A number of devices are provided to ensure safety when operating valves.

• Limit switches for closed and open positions

The actuators should be stored under a shelter in a clean, dry place and protected from

• Torque limit switches to protect against accidental overloads constant changes in temperature.

• Visible indicator

• Handwheel for use in the event of a power failure Avoid placing the actuators directly on the floor. For actuators equipped with anti-

condensation heaters, it is recommended that they be connected and voltage applied

Every actuator is tested, adjusted and checked at the factory before especially if the place of storage is humid (standard voltage 120 volts, unless otherwise

delivery. It is lubricated for life and is able to operate in any position or specified).

location.

Check that the temporary sealing plugs in the cable entries are securely in place. In case of

WARNING: The procedure described in this manual must be followed to humidity, metal plugs are used.

prevent damage to the valve or to the mechanism being operated.

Make sure that the covers and the boxes are well closed to insure weatherproof sealing.

1 - START-UP

Control after storage

1-1 ANTI-CONDENSATION HEATER

1. Storage not exceeding one year:

We recommend the use of an anti-condensation heater for all outdoor

installations. • Maintain a visual check of electric equipment.

As soon as the actuator is on site, apply power to the heater to prevent • Operate manually the microswitches, buttons, selectors, etc. to insure their correct

any condensation from forming. mechanical function.

• Operate apparatus manually.

1-2 MANUAL HANDWHEEL

• Verify the correct grease consistency.

• Follow all instructions included in these commissioning instructions.

All SR/ST range actuators are provided with an automatic declutching

handwheel, with motor drive priority. Normal operating direction is

2. Storage exceeding one year:

indicated on the handwheel.

The SRA6 actuator has a handwheel clutch knob. In order to manually • Long time stocking changes grease consistency. The grease thinly applied on the stem

operate the actuator, align the arrow of the knob with the front triangular dries up.

sign (Fig. 1) on the housing (it may be necessary to slightly turn the • Remove all the old grease from the actuator mechanical parts and replace it with new

handwheel a few degrees for engagement). When power is applied to the grease.

motor, the knob automatically returns to its declutched position. • Maintain a visual check of electric equipment.

• Operate manually the microswitches, buttons, selectors, etc., to insure their correct

2 - ELECTRICAL CONNECTIONS mechanical function.

• Follow all instructions included in these commissioning instructions.

a) Verify the power characteristics.

b) Check wiring (Fig. 2).

c) Move the valve manually to the half-open position.

d) Connect the travel limits switches and the torque limit switches, then

check their functioning.

e) Briefly start briefly the actuator and check that the direction of rotation

is in accordance with the order given. If not, invert the direction.

Before refitting the cover, verify the position of the visual indicator.

Last printed 9/7/2003 11:55 AM

7 - PROPORTIONAL VISIBLE INDICATOR (Fig. 10) 3 - SETTING THE TRAVEL LIMIT SWITCHES

The indicator disc is rotated by the cam block system. The cams operating the limit switches are in a cylindrical block, which

Turn electrically the valve to the completely open position and rotate the does not require any disassembly or special tools. Each cam can be set

disc until the symbol appears in the sight opening. independently of each other. There are 4 cams included in the camblock,

Turn electrically the valve to the completely closed position to check that each marked with a different color and number:

the symbol is visible in the sight opening. a) 1 = white and 2 = black for end of travel limits

Adjust as required. b) 3 = beige and 4 = gray for additional limit switches and are optional.

8 - REMOTE TRANSMISSION (FIG. 10 and 11)

3-1 HOW TO SET THE CAMS

This is optional.

Transmission is performed in the standard model by a potentiometer of 1. Insert a screwdriver in the slot of the button encircled by the same

total resistance 1000 ohms, 3 W. color as the cam to be set (Fig. 3).

Gears drive the potentiometer slide from the cam block system. The 2. Press lightly to disengage the cam from its locked position.

effective maximum resistance of the potentiometer is 750 ohms. 3. Turning the screwdriver rotates the cam to the position that trips the

limit switch.

8-1 SETTING 4. Remove the screwdriver and insure that the button has returned to its

original position, thus locking the cam in its selected position.

Example of setting with an 8v indicator (0-100%) and stabilized settable

supply AL6-12.

• Turn electrically the valve to the closed position.

• Unlock the 2 screws << a >> (Fig. 8). 3-2 TO STOP WHEN VALVES ARE IN THE CLOSED POSITION USING

• Turn the potentiometer until the indicator needle is on 0%. THE TORQUE LIMITER DEVICE

• Lock the 2 screws << a >>.

• Verify there is a rise in indication as soon as the opening starts. Shunt the << Closing >> limit switch at the connection plate (Fig. 5) as per

• Turn electrically the valve to the fully open position. the instructions given in the provided diagram.

• Adjust the indicator needle to 100% by adjusting the supply voltage. Proceed in the same way as in §3.1, making sure when closing under

power that limit switch << F >> is correctly activated a little before stopping

9 - MAINTENANCE by opening of the torque limiter contact << F >> (Fig. 7). When limit switch

<< F >> is reversed, it serves to shunt the << Opening >> limiter contact to

All SR actuators are lubricated for life and therefore require no specific insure at the start of a reverse movement that an unblocking torque is

maintenance. applied greater than the seating torque.

The condition of the valve stem and its nut must nevertheless be checked

periodically to insure they are clean and well lubricated.

4 - CHECKING AND ADJUSTING LIMIT SWITCHES USING THE

We recommend that a program of periodic maintenance be drawn up for PROPORTIONAL REV-COUNTER (fig. 4).

actuators that are operated infrequently.

This device is optional.

It replaces the standard cam block for special purposes.

If the motorized valve has been supplied by a valve manufacturer, a

simple closing and opening movement must be carried out to check that

the limit switches operate correctly, thus verifying the factory setting.

A step-down gearing is provided for the repeater system so that the cams

turn through 270º rotation.

If settings need to be adjusted, proceed as follows:

Last printed 9/7/2003 11:55 AM

4-1 SETTING 5-2 TORQUE LIMITER SET BY MOVING OF CAM (FIG. 7)

(type SR6 to SR50)

• Turn the valve manually to halfway position.

• Unlock the cams from their drive spindle << a >> by partially The torque limiter must be at rest when adjusting settings (Fig. 8).

unscrewing screws << b >> (Fig. 4).

• Bring the valve manually to the closed position, then adjust limit cam Depending on the direction of movement for the valve of which the torque

<< F >> so that the correct switch is operated (Fig. 5). is being adjusted, unlock nut << a >> of the cam to be adjusted.

• Tighten locking screw << b >>.

• Turn valve manually to the open position and then adjust limit cam << Moving the cam away from the contact switch increases torque.

0 >> so that the correct switch is activated (Fig. 4).

• Tighten up locking screw << b >>. Lock nut << a >> after the adjustment is accomplished.

• Adjust the cams that trip the auxiliary switches in the same way as the

limit switches, but bear in mind that they must be tripped a little before REMARK: THE TORQUE LIMIT DEVICE GIVES A MAINTAINED

the travel limit switches. CONTACT.

5 - TORQUE LIMITER

The actuator is delivered with the torque limit system calibrated at the 5-3 TORQUE LIMITER ADJUSTED BY MICROMETER SCREW (FIG. 8)

factory to the torque required on the customers order.

This device is optional for the SR6 to SR50 actuators.

If the torque limiter is activated during operation, check:

The torque limiter must be at rest when adjusting settings.

• that the valve stem is clean and well-lubricated,

• that the valve stem does not jam in the nut,

Depending on the direction of movement for the valve of which the torque

• that the valve stuffing box is not too tight. is to be modified, turn the micrometer screw << a >> of the cam to be

adjusted. This modifies the angle of deflection of the cam within the

If Torque has to be increased, consult the valve manufacturer and follow provided limit.

the procedures indicated in § 5-1, 5-2 or 5-3.

The figure required for the adjustment torque is obtained from the

5-1 TORQUE LIMITER SET BY SPRING COMPRESSION equivalence table for the reference number given on the bottom of the

(type SRA6 - Fig. 6) casing and depends on the position given by the cam reference mark.

To gain access to the torque limit system, remove the cover plate between

the handwheel clutch knob and the motor.

To change the torque setting, turn nuts << a >> that compress the springs 6 - PRECAUTIONS

of the torque limit device. The torque can be increased or decreased by

tightening or loosening nuts << a >>. Lock the nuts in place after Replace covers immediately after start-up, making sure their seals are

adjustment (see setting charts Appendix I). clean (Fig. 9).

Never fail to replace the protection covers.

REMARK: THE TORQUE LIMIT DEVICE PROVIDES A SHORT If water ever enters, thoroughly dry before replacing covers.

DURATION CONTACT (NOT MAINTAINED ON SRA6.1 ACTUATORS

AND MAINTAINED ON THE SRA6.2 ACTUATORS).

Last printed 9/7/2003 11:55 AM

You might also like

- Fundamentals of Steam System Design - I-PDocument236 pagesFundamentals of Steam System Design - I-PJesus Andres SuarezNo ratings yet

- lcr-t4 Transistor Tester ManualDocument2 pageslcr-t4 Transistor Tester ManualJoseph YumulNo ratings yet

- Byspeed 3015 BA V010 enDocument524 pagesByspeed 3015 BA V010 enΈλσαΟγκρένιNo ratings yet

- BELL B40D B35D Parts CatalogDocument982 pagesBELL B40D B35D Parts CatalogWere Wolf33% (3)

- Shipmate Rs8100Document38 pagesShipmate Rs8100George MecseryNo ratings yet

- MO 13 Provision Refeer PlantDocument124 pagesMO 13 Provision Refeer PlantjakeyateslaxNo ratings yet

- Enraf Tanksystem - Gtex - WorldwideDocument2 pagesEnraf Tanksystem - Gtex - WorldwideShanmugamoorthyNo ratings yet

- Qingdao Beihai Davit PDFDocument12 pagesQingdao Beihai Davit PDFMg PhyoNo ratings yet

- Qingdao Beihai DavitDocument12 pagesQingdao Beihai DavitZdravko Eta LovicNo ratings yet

- Catalogo Tec Container ENV WEBDocument24 pagesCatalogo Tec Container ENV WEBFederico BabichNo ratings yet

- Grundfosliterature 5092Document20 pagesGrundfosliterature 5092GamberiniNo ratings yet

- Manual Sistem Analiza Clor RezidualDocument108 pagesManual Sistem Analiza Clor RezidualCatalin CNo ratings yet

- Especificação Melservo-J2-C-S100 - Servo - SpindleDocument71 pagesEspecificação Melservo-J2-C-S100 - Servo - SpindlemiltonrighettoNo ratings yet

- AJ71UC24 R2 (4) S2 User's ManualDocument120 pagesAJ71UC24 R2 (4) S2 User's ManualGilberto GuerreroNo ratings yet

- Ero Cla 2004Document54 pagesEro Cla 2004Дима СелютинNo ratings yet

- Ax07c UgbDocument120 pagesAx07c Ugbapi-3728789No ratings yet

- Cegedim Contacts WorldDocument5 pagesCegedim Contacts Worlddushy1986No ratings yet

- Grundfosliterature-413755 1940674Document112 pagesGrundfosliterature-413755 1940674Martin MeynersNo ratings yet

- BURGMANN Manual 15.4Document153 pagesBURGMANN Manual 15.4EmmanuelNo ratings yet

- ValvDocument12 pagesValvWilliams MedinaNo ratings yet

- Bytube en PDFDocument386 pagesBytube en PDFGarry HatteyNo ratings yet

- E Rev2 SF-SGDocument4 pagesE Rev2 SF-SGoleg7962No ratings yet

- Installing & Adjusting of PTFE Seat For MTV & VSS Valves (New Edition)Document8 pagesInstalling & Adjusting of PTFE Seat For MTV & VSS Valves (New Edition)Deepesh MerchantNo ratings yet

- SC-manual-R8 (EN+SMOKE) - 2013.06.14Document30 pagesSC-manual-R8 (EN+SMOKE) - 2013.06.14TharinSiriwardanaNo ratings yet

- Grundfosliterature 3279256Document12 pagesGrundfosliterature 3279256Rossana CRNo ratings yet

- Cod - Quick Guide E.sybox Mini 3Document2 pagesCod - Quick Guide E.sybox Mini 3sumbertop orbitNo ratings yet

- Your Solution Network: North East AsiaDocument20 pagesYour Solution Network: North East AsiamasterumNo ratings yet

- Mechanical Seal - Eagle BurgmanDocument149 pagesMechanical Seal - Eagle BurgmanAmol Patki71% (7)

- Service Network - 20211007Document14 pagesService Network - 20211007Antonis IsidorouNo ratings yet

- Miniature Drive Systems: Dr. Fritz Faulhaber GMBH & Co. KGDocument440 pagesMiniature Drive Systems: Dr. Fritz Faulhaber GMBH & Co. KGVic MayAlNo ratings yet

- Service Around The WorldDocument44 pagesService Around The WorldViliame D RoqicaNo ratings yet

- Sadiguard Torque Limiters (DB)Document23 pagesSadiguard Torque Limiters (DB)purushothamNo ratings yet

- Ophthalmic Ultrasound Authorized Distributors Albania: Gen - AlbfarmaDocument12 pagesOphthalmic Ultrasound Authorized Distributors Albania: Gen - AlbfarmaAbiNo ratings yet

- PM - B40D - B35D - ADT - PIN 7.2 IT4 - RevA - Feb2013Document804 pagesPM - B40D - B35D - ADT - PIN 7.2 IT4 - RevA - Feb2013Pieter BothaNo ratings yet

- K - Aquatherm-Climatherm Katalog (ENG)Document20 pagesK - Aquatherm-Climatherm Katalog (ENG)Arthur DiependalNo ratings yet

- 130 2 02 2 30 Przekaźnik 24V Dcac Kuhnke ManualDocument133 pages130 2 02 2 30 Przekaźnik 24V Dcac Kuhnke ManualChawki DerouicheNo ratings yet

- 130 2 02 2 30 Przekaźnik 24V Dcac Kuhnke Manual PDFDocument133 pages130 2 02 2 30 Przekaźnik 24V Dcac Kuhnke Manual PDFChawki DerouicheNo ratings yet

- 117 12 02 1 10 Przekaźnik 24V Dcac Kuhnke ManualDocument133 pages117 12 02 1 10 Przekaźnik 24V Dcac Kuhnke Manualfilisan mirceaNo ratings yet

- UG - Speaker - 6l - GB - 180315 7Document1 pageUG - Speaker - 6l - GB - 180315 7cheng yifangNo ratings yet

- Service StationsDocument59 pagesService StationsIswahyudi AprilyastonoNo ratings yet

- PM b30d Mk7.2 Adt Rev ADocument796 pagesPM b30d Mk7.2 Adt Rev ABassieNo ratings yet

- Trane Parts Catalogue 2015Document202 pagesTrane Parts Catalogue 2015Said ZubizaNo ratings yet

- DAB Booster & Transfer Pumps Set PDFDocument127 pagesDAB Booster & Transfer Pumps Set PDFFILID MADNo ratings yet

- 90685ve WDG 1200 1210 Insitu User ManualDocument100 pages90685ve WDG 1200 1210 Insitu User ManualasepNo ratings yet

- Zodiac Authorized Sales & Service:: AngolaDocument44 pagesZodiac Authorized Sales & Service:: AngolaMubeen NavazNo ratings yet

- Inmarsat ServiceDocument28 pagesInmarsat ServiceAntonis IsidorouNo ratings yet

- User Manual Thermox WDG-1200/1210/Insitu AMETEKDocument100 pagesUser Manual Thermox WDG-1200/1210/Insitu AMETEKkotrex3No ratings yet

- TODAY Tourism & Business Magazine, Volume 23, February, 2016From EverandTODAY Tourism & Business Magazine, Volume 23, February, 2016No ratings yet

- TODAY Tourism & Business Magazine, Volume 22, October , 2015From EverandTODAY Tourism & Business Magazine, Volume 22, October , 2015No ratings yet

- TODAY Tourism & Business Magazine, Volume 22, September, 2015From EverandTODAY Tourism & Business Magazine, Volume 22, September, 2015Rating: 5 out of 5 stars5/5 (1)

- TODAY Tourism & Business Magazine, Volume 21, November, 2014From EverandTODAY Tourism & Business Magazine, Volume 21, November, 2014No ratings yet

- TODAY Tourism & Business Magazine, Volume 22, December, 2015From EverandTODAY Tourism & Business Magazine, Volume 22, December, 2015No ratings yet

- TODAY Tourism & Business Magazine, Volume 21, September 2014From EverandTODAY Tourism & Business Magazine, Volume 21, September 2014No ratings yet

- TODAY Tourism & Business Magazine, Volume 21, December, 2014From EverandTODAY Tourism & Business Magazine, Volume 21, December, 2014No ratings yet

- CI-132 Series User's Manual: Industrial 2-Port RS-422/485 Serial BoardDocument71 pagesCI-132 Series User's Manual: Industrial 2-Port RS-422/485 Serial BoardJoseph YumulNo ratings yet

- Programmer User Manual CF800PROG: Cooper Safety LTDDocument8 pagesProgrammer User Manual CF800PROG: Cooper Safety LTDJoseph YumulNo ratings yet

- NF1002 - NF1004 - NF2000: Conventional / Addressable Microprocessor-Based Fire PanelsDocument72 pagesNF1002 - NF1004 - NF2000: Conventional / Addressable Microprocessor-Based Fire PanelsJoseph YumulNo ratings yet

- 1990 - Miata Wiring DiagramsDocument7 pages1990 - Miata Wiring DiagramsJoseph YumulNo ratings yet

- Migration of Wincc Projects From V4 To V7Document55 pagesMigration of Wincc Projects From V4 To V7Joseph YumulNo ratings yet

- Series 9470/32: Digital Input Output Module For Zone 1Document6 pagesSeries 9470/32: Digital Input Output Module For Zone 1Joseph YumulNo ratings yet

- Channel For Deif System: TopicDocument26 pagesChannel For Deif System: TopicJoseph YumulNo ratings yet

- drv11873 Yamaha Mio IcDocument24 pagesdrv11873 Yamaha Mio IcJoseph YumulNo ratings yet

- Upac Analog DC Ultra Slimpak Analogue Transmitter DCDocument2 pagesUpac Analog DC Ultra Slimpak Analogue Transmitter DCJoseph YumulNo ratings yet

- MTU, E531960 00E Screen Saver MCS-5 (08-23-10)Document1 pageMTU, E531960 00E Screen Saver MCS-5 (08-23-10)Joseph YumulNo ratings yet

- Firenet Graphix Software Package: Product Overview Standard FeaturesDocument2 pagesFirenet Graphix Software Package: Product Overview Standard FeaturesJoseph YumulNo ratings yet

- BAT54 / BAT54A / BAT54C / BAT54S: Schottky DiodesDocument6 pagesBAT54 / BAT54A / BAT54C / BAT54S: Schottky DiodesJoseph YumulNo ratings yet

- Lista Canales Config - 900PL - C1-Mod 06-02-03 para CMRDocument50 pagesLista Canales Config - 900PL - C1-Mod 06-02-03 para CMRJoseph YumulNo ratings yet

- Axiom NW, 32628-EN Tank Level Indicators Vegaconnect 4Document24 pagesAxiom NW, 32628-EN Tank Level Indicators Vegaconnect 4Joseph YumulNo ratings yet

- CMR 900 Particular Operation For The 900-70 Supervisor UnitDocument14 pagesCMR 900 Particular Operation For The 900-70 Supervisor UnitJoseph YumulNo ratings yet

- B 813 FCBDFDocument110 pagesB 813 FCBDFJoseph YumulNo ratings yet

- RS220 Spare PartsDocument33 pagesRS220 Spare PartsRonak MotaNo ratings yet

- FPD DetroitDiesel Series 60 CatalogDocument18 pagesFPD DetroitDiesel Series 60 CatalogRamyaChaudryNo ratings yet

- Fill Stop Fill ValveDocument1 pageFill Stop Fill ValveDenier RubianoNo ratings yet

- Whitehall Built-In SwivetteDocument2 pagesWhitehall Built-In Swivettecvl1983No ratings yet

- Ranger 700: 1. ContentsDocument8 pagesRanger 700: 1. ContentsIgnacio Alejandro Jose Helo Varela100% (1)

- Phoenix USA, Inc. 2013 CatalogDocument25 pagesPhoenix USA, Inc. 2013 CatalogLeigh Ann Proffitt NethertonNo ratings yet

- Chapter 3 - Ball Valves and Drain CocksDocument32 pagesChapter 3 - Ball Valves and Drain CocksFeras BatarsehNo ratings yet

- Service Station Manual: SMT RCRDocument118 pagesService Station Manual: SMT RCRRudolf PaalNo ratings yet

- MSS SP-53 1999Document9 pagesMSS SP-53 1999ISRAEL PORTILLONo ratings yet

- Fuel Gas System PDFDocument11 pagesFuel Gas System PDFChandra Elia Agustin TariganNo ratings yet

- Actuators For Three Point Control Amv 56K: Data SheetDocument4 pagesActuators For Three Point Control Amv 56K: Data SheetandreiterenteNo ratings yet

- Sequencing of CylindresDocument5 pagesSequencing of CylindreschtganduNo ratings yet

- Calculation and Specification of Bilge System: Design Iv Machinery System Department of Marine EngineeringDocument36 pagesCalculation and Specification of Bilge System: Design Iv Machinery System Department of Marine EngineeringAfanda Dwi R RNo ratings yet

- Thai 4a Gen P02a 15-01-0011 - Rev.1 Cameron b4d Instructions ManualDocument18 pagesThai 4a Gen P02a 15-01-0011 - Rev.1 Cameron b4d Instructions Manualkid6232863No ratings yet

- 2-Way Oil Shutoff Valve: General DescriptionDocument4 pages2-Way Oil Shutoff Valve: General Descriptionmacaco logoNo ratings yet

- 1976-77 Koomey General CatalogDocument152 pages1976-77 Koomey General CatalogNicasio AlonzoNo ratings yet

- Carver: Operation, Installation and Maintenance ManualDocument38 pagesCarver: Operation, Installation and Maintenance ManualzsmithNo ratings yet

- Pick Up 1500 2012 6.7LDocument297 pagesPick Up 1500 2012 6.7LShingeki Hong LeeNo ratings yet

- Ammonia COP2011Document75 pagesAmmonia COP2011sauroNo ratings yet

- ST-125™ Control System For Stanadyne DB-4 Series Pumps: Product Manual 04169 (Revision D)Document24 pagesST-125™ Control System For Stanadyne DB-4 Series Pumps: Product Manual 04169 (Revision D)Arc HieNo ratings yet

- 304 Hvac Presentation With Notes v4.1 Rev 2-26-16 SpsDocument339 pages304 Hvac Presentation With Notes v4.1 Rev 2-26-16 SpsPepe Al100% (3)

- 05 - B - RTA 8 Series RTA 2 Series Fuel Pump UpdateDocument16 pages05 - B - RTA 8 Series RTA 2 Series Fuel Pump UpdateGiovanniJara100% (1)

- PmsDocument94 pagesPmssdk1978100% (1)

- 237-Feedback 38 005-Feedback 38 005 PH Process ControlDocument4 pages237-Feedback 38 005-Feedback 38 005 PH Process ControlJunaid AhmadNo ratings yet

- SAIC-J-6501 Rev 8Document12 pagesSAIC-J-6501 Rev 8Rashid ArshadNo ratings yet

- MVP Cone April 2007Document44 pagesMVP Cone April 2007Jose Luis DiazNo ratings yet

- Viking Air Relief ValveDocument2 pagesViking Air Relief ValveSyed AsimNo ratings yet

- Floating EquipmentDocument9 pagesFloating Equipmentkaveh-bahiraeeNo ratings yet

- Injection Pump Specification ©Document4 pagesInjection Pump Specification ©murillo_rodriguez8382No ratings yet