Professional Documents

Culture Documents

Chlorinated Rubber High-Build Marine Coating (Topcoat)

Chlorinated Rubber High-Build Marine Coating (Topcoat)

Uploaded by

Fabio Samir Cuzinsky0 ratings0% found this document useful (0 votes)

27 views1 page1. The document describes a chlorinated rubber high-build marine coating called Top Coat that is intended as a protective and decorative coating for ship hulls and other marine surfaces.

2. The product meets various technical standards including having a solid content of 70%, drying within 2 hours, and passing tests for impact resistance, flexibility, adhesion, salt water resistance, and salt spray resistance up to 400 hours.

3. The coating is produced by mixing chlorinated rubber resin with other ingredients like epoxidized soybean oil, chlorinated paraffin, and titanium dioxide, then thinning the mixture and adjusting properties before packaging.

Original Description:

Original Title

Chlorinated rubber high-build marine coating(topcoat)

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1. The document describes a chlorinated rubber high-build marine coating called Top Coat that is intended as a protective and decorative coating for ship hulls and other marine surfaces.

2. The product meets various technical standards including having a solid content of 70%, drying within 2 hours, and passing tests for impact resistance, flexibility, adhesion, salt water resistance, and salt spray resistance up to 400 hours.

3. The coating is produced by mixing chlorinated rubber resin with other ingredients like epoxidized soybean oil, chlorinated paraffin, and titanium dioxide, then thinning the mixture and adjusting properties before packaging.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

27 views1 pageChlorinated Rubber High-Build Marine Coating (Topcoat)

Chlorinated Rubber High-Build Marine Coating (Topcoat)

Uploaded by

Fabio Samir Cuzinsky1. The document describes a chlorinated rubber high-build marine coating called Top Coat that is intended as a protective and decorative coating for ship hulls and other marine surfaces.

2. The product meets various technical standards including having a solid content of 70%, drying within 2 hours, and passing tests for impact resistance, flexibility, adhesion, salt water resistance, and salt spray resistance up to 400 hours.

3. The coating is produced by mixing chlorinated rubber resin with other ingredients like epoxidized soybean oil, chlorinated paraffin, and titanium dioxide, then thinning the mixture and adjusting properties before packaging.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

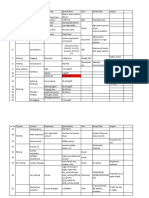

Chlorinated rubber high-build marine coating (Top Coat) Technical data

Product Standard: Marine paint for hull GB/T-6748-2008

Product Topcoat Quantity Color Peacock blue

Test items Test index Test result

Solid content ≥50 70

1 Chlorinated rubber resin 18 Fineness ≤40 35

Surface dry≤4 Surface dry≤2

2 Epoxidized soybean oil 1 Drying time

hard dry≤24 hard dry≤20

Impact resistance ≥50 50

3 70°chlorinated paraffin 10 Production Procedure: Flexibility (mm) ≤ 1 1

Mix 1, 2, 3, 4 together and Adhesion (Circle)≤ 1 1

4 Xylene 20 fully dissolve them in high- Salt water resistance h ≥ 48h 96h

speed stirring, and then add

5 Dispersant 0.3 5, 6, 7, 8, 9, 10, 11, 12 in Salt spray resistance The film does not wrinkle, fall

400h

sequence, following by (400h) off or rust

6 Polyamide wax 0.5 high-speed stirring for 30-40

minutes. Add 14 to adjust Dipping treatment≤4

Artificial ageing resistance UVB-313::300h

7 Anti-settling agent 1 the viscosity when grinding. Chalking≤2 no cracks

While fineness is below 40, Marine atmospheric exposure Dipping treatment≤4

Weather resistance

8 Defoamer 0.2 add 13 with high-speed for 12 months Chalking≤2 no cracks

stirring for 20-30 minutes. 15W-40 diesel engine

Oil resistance 48h pass

9 Titanium dioxide 4 Add 14 to adjust the lubricating oil

viscosity, finished with Product Application: Used as protection and decoration on the hull, ship

10 Titanium blue 2 filtering and packaging at superstructure, freeboard, and other construction surface. This product has

the end. excellent weather resistance, durability and water resistance. Matching

11 Barium sulfate 26 primer is aqueous phase chlorinated rubber primer or aqueous phase

chlorinated rubber aluminum primer.

12 Talcum powder 2

Surface Treatment: It is recommended to remove any grease, debris and

13 52°chlorinated paraffin 6 moisture on paint film after base primer is fully dry out in order to achieve

the best performance. Substrate’s temperature must be 3℃ higher than the

14 Trimethylbenzene 9

dew point and steel plate temperature is less than 55℃, when coating.

You might also like

- Araldite 2015: Advanced MaterialsDocument6 pagesAraldite 2015: Advanced MaterialsFilipe Alberto MagalhaesNo ratings yet

- Drilling ProcessDocument15 pagesDrilling ProcessAl Fredo95% (21)

- Chlorinated Rubber High-Build Marine CoatingDocument1 pageChlorinated Rubber High-Build Marine CoatingNawarNo ratings yet

- Nitocote HT120: Constructive SolutionsDocument3 pagesNitocote HT120: Constructive SolutionsSHAIK ASIMUDDINNo ratings yet

- Multipurpose Binder, Primer & Laminating Resin Epigen 0402: Potable Water SuitabilityDocument2 pagesMultipurpose Binder, Primer & Laminating Resin Epigen 0402: Potable Water Suitabilityjulius hasan33No ratings yet

- En 5830 Rubber Crimb Binder 4000Document2 pagesEn 5830 Rubber Crimb Binder 4000recep kablanNo ratings yet

- 21 - Resins For Road Marking PaintsDocument4 pages21 - Resins For Road Marking Paintsraj jangid100% (1)

- s2 Tampur 150 V1au 10Document2 pagess2 Tampur 150 V1au 10ABCNo ratings yet

- Fosroc Nitocote HT120: Constructive SolutionsDocument4 pagesFosroc Nitocote HT120: Constructive SolutionsVincent JavateNo ratings yet

- Ar 250Document1 pageAr 250Yoo KyungsikNo ratings yet

- TDS Durazane® 1800Document3 pagesTDS Durazane® 1800siaoling.bioNo ratings yet

- Lead Free Paints, Lead Free Paint, Manufacturer, Supplier, India PlasmaDocument3 pagesLead Free Paints, Lead Free Paint, Manufacturer, Supplier, India PlasmaKrishna PandeyNo ratings yet

- High Build Epoxy Coating Epigen 1311: Potable Water SuitabilityDocument2 pagesHigh Build Epoxy Coating Epigen 1311: Potable Water Suitabilityjulius hasan33No ratings yet

- Synthetic Enamel - Matt FinishDocument3 pagesSynthetic Enamel - Matt FinishSameer HyderNo ratings yet

- Epilux 8: Product DescriptionDocument2 pagesEpilux 8: Product DescriptionMoin AltafNo ratings yet

- TDS of TITANE R6628 HUGODocument1 pageTDS of TITANE R6628 HUGOMokrane HamaidiNo ratings yet

- Renolin Hi Temp Chain LubeDocument2 pagesRenolin Hi Temp Chain Lubempe.mohamed2010No ratings yet

- Sika Poxitar MyDocument3 pagesSika Poxitar Myhijur ChenNo ratings yet

- Abe Construction Chemicals Ds Epidermix365Document3 pagesAbe Construction Chemicals Ds Epidermix365Brendon BNo ratings yet

- Ra22 ArmourZinc 120 PrimerDocument2 pagesRa22 ArmourZinc 120 PrimerDenis MNo ratings yet

- Araldite 2047-1: Advanced MaterialsDocument6 pagesAraldite 2047-1: Advanced MaterialsLiberio AragaoNo ratings yet

- EF 097 - WB DIY Floor Coating - AD 3805Document4 pagesEF 097 - WB DIY Floor Coating - AD 3805nanoNo ratings yet

- En 581 Aliphatic Rubber BinderDocument2 pagesEn 581 Aliphatic Rubber Binderrecep kablanNo ratings yet

- Bipigard Coaltar Finish PDFDocument2 pagesBipigard Coaltar Finish PDFKhirod KroutNo ratings yet

- CarbolineDocument18 pagesCarbolineimaduddinshaNo ratings yet

- Durepox 2K Primer TDSDocument4 pagesDurepox 2K Primer TDSOswaldo Manuel Ramirez MarinNo ratings yet

- Engine Enamel: Technical Data ATO-65Document2 pagesEngine Enamel: Technical Data ATO-65v8chargeNo ratings yet

- Epilux 155Document2 pagesEpilux 155Allana100% (1)

- Araldit-STANDARD Datasheet PDFDocument3 pagesAraldit-STANDARD Datasheet PDFsiva shanmugamNo ratings yet

- Bipigard Coaltar FinishDocument2 pagesBipigard Coaltar FinishKhirod Krout100% (1)

- TDS Kan HB Epoxy ZP Primer 290119Document3 pagesTDS Kan HB Epoxy ZP Primer 290119oliviaNo ratings yet

- Pds Zincanode 690 VocDocument2 pagesPds Zincanode 690 VocmuthukumarNo ratings yet

- 3500-00 Simathane Gloss (Finish Coat)Document3 pages3500-00 Simathane Gloss (Finish Coat)Hendri Dwi cahyonoNo ratings yet

- TDS RovalDocument4 pagesTDS RovalSyahril Fira86No ratings yet

- Epilux 58 M.I.O.: Product DescriptionDocument2 pagesEpilux 58 M.I.O.: Product DescriptionMoin AltafNo ratings yet

- Bipigard ST Cte Black PDFDocument2 pagesBipigard ST Cte Black PDFKhirod KroutNo ratings yet

- Masteremaco 2525: Solvent Free Epoxy Binder, Structural Adhesive and General Purpose PrimerDocument2 pagesMasteremaco 2525: Solvent Free Epoxy Binder, Structural Adhesive and General Purpose PrimerSetyo poernomoNo ratings yet

- Evonik Ancamine2811Document2 pagesEvonik Ancamine2811kishanptlNo ratings yet

- Automotive High Heat Paint: Technical Data ATO-15Document2 pagesAutomotive High Heat Paint: Technical Data ATO-15HillNo ratings yet

- Chapter 3 - Drilling Fluid Prepration: 3.1 Oil Based Mud CompositionDocument7 pagesChapter 3 - Drilling Fluid Prepration: 3.1 Oil Based Mud CompositionImranKabirNo ratings yet

- CR Metal PrimerDocument3 pagesCR Metal PrimerSameer HyderNo ratings yet

- PCM - TDS - 2023 XZDocument2 pagesPCM - TDS - 2023 XZEngr. Imran Hasan PathanNo ratings yet

- ZINKY-14 - Epoxy Zinc Rich Primer - 80% Zinc On Dry FilmDocument5 pagesZINKY-14 - Epoxy Zinc Rich Primer - 80% Zinc On Dry FilmppglNo ratings yet

- Two Component Clear Epoxy Adhesive: Araldite CrystalDocument3 pagesTwo Component Clear Epoxy Adhesive: Araldite CrystalreinpolyNo ratings yet

- Euclid Chemical TDS Tremco CPG DURALKOTE 240Document2 pagesEuclid Chemical TDS Tremco CPG DURALKOTE 240Lim Yong SiangNo ratings yet

- Nitobond TMDocument2 pagesNitobond TMVincent JavateNo ratings yet

- 3500-00 Simathane GlossDocument3 pages3500-00 Simathane GlossSAEFUDDIN SAEFUDDINNo ratings yet

- Muehlmeier en Resins Vinylester ResinDocument11 pagesMuehlmeier en Resins Vinylester Resinuzzy2No ratings yet

- Green Rebar EpoxyDocument1 pageGreen Rebar EpoxyአንዋርጀማልNo ratings yet

- Carboguard 1209: Selection & Specification DataDocument4 pagesCarboguard 1209: Selection & Specification DataQuy Dom100% (2)

- SHER-WOOD® CAB-Acrylic Lacquer: Product FinishesDocument2 pagesSHER-WOOD® CAB-Acrylic Lacquer: Product Finishesdavid hallNo ratings yet

- Renolit H 443-HD 88Document2 pagesRenolit H 443-HD 88miguelfpintoNo ratings yet

- Darina RL GR 2Document2 pagesDarina RL GR 2nutchai2538No ratings yet

- Nax Premila 7000 TDS ANZDocument4 pagesNax Premila 7000 TDS ANZjanakaNo ratings yet

- Devcon Flexane-High-Performance-Putty - 15330Document2 pagesDevcon Flexane-High-Performance-Putty - 15330Yajaira ValdezNo ratings yet

- Cloverdale Tds EF16174 eDocument4 pagesCloverdale Tds EF16174 eenaron777No ratings yet

- BNT 2Document3 pagesBNT 2ahetesham marufNo ratings yet

- Ecosurf SA-7Document2 pagesEcosurf SA-7Saepul Indra MulyanaNo ratings yet

- Poliuretano Inyección Hidrofobico 10L Catalizador FichaDocument5 pagesPoliuretano Inyección Hidrofobico 10L Catalizador FichaVictor Hugo Opazo CarreñoNo ratings yet

- Araldite 2014-2: Advanced MaterialsDocument6 pagesAraldite 2014-2: Advanced MaterialsAnonymous r3MoX2ZMTNo ratings yet

- DFMA DFM DFA Design For Manufacturing and AssemblyDocument15 pagesDFMA DFM DFA Design For Manufacturing and AssemblyNuria VarelaNo ratings yet

- Ball Valves Floating OmbDocument24 pagesBall Valves Floating OmbMASOUDNo ratings yet

- NCL Blocks and RendersDocument10 pagesNCL Blocks and Rendersarups27No ratings yet

- Deck - Calistoga Spa SurroundDocument4 pagesDeck - Calistoga Spa SurroundHelicon1No ratings yet

- Fabrication ProcessDocument6 pagesFabrication ProcessSounak ChakrabortyNo ratings yet

- Coatin &ring FormationDocument6 pagesCoatin &ring FormationMustafa RamadanNo ratings yet

- Basic Welding Filler Metal Technology: Lesson Ix Estimating and Comparing Weld Metal CostsDocument1 pageBasic Welding Filler Metal Technology: Lesson Ix Estimating and Comparing Weld Metal CostsRené Andrade MuñozNo ratings yet

- BackDocument55 pagesBackRoni HanafiyahNo ratings yet

- Catalog Accesorii AEGDocument116 pagesCatalog Accesorii AEGGhiuli Aptisa100% (2)

- 1.0 Title: Shield Metal Arc Welding (SMAW)Document13 pages1.0 Title: Shield Metal Arc Welding (SMAW)Exo NadiNo ratings yet

- Lethal Service - Quick Guide - Pressure Vessel EngineeringDocument8 pagesLethal Service - Quick Guide - Pressure Vessel EngineeringIara NascimentoNo ratings yet

- RSA-A4-PR-WI-02 (Metalizing) - Rev 0Document1 pageRSA-A4-PR-WI-02 (Metalizing) - Rev 0Abhishek KadamNo ratings yet

- q3. Summative Smaw 1st and 2ndDocument4 pagesq3. Summative Smaw 1st and 2ndHERNAN JAY BUYOKNo ratings yet

- Common G-Codes For CNC Machining CentersDocument2 pagesCommon G-Codes For CNC Machining CentersivtrubeljaNo ratings yet

- Shim SpacerDocument24 pagesShim Spacerrasalkeshav4563No ratings yet

- Wiac - Info PDF Din en 12953 2 2012 05 PRDocument19 pagesWiac - Info PDF Din en 12953 2 2012 05 PRWael MaatougNo ratings yet

- Cast Iron Basic Training and ApplicatonsDocument34 pagesCast Iron Basic Training and ApplicatonsKeerthivasan NNo ratings yet

- Bentone 34 TDSDocument2 pagesBentone 34 TDSAmir OsossNo ratings yet

- CNC WirecutDocument6 pagesCNC WirecutUmair RaisNo ratings yet

- Ok ProjrctDocument172 pagesOk Projrctmithinlucky46No ratings yet

- Application Manual Chapter 7 - Process GeneralDocument102 pagesApplication Manual Chapter 7 - Process GeneralVishal MaliNo ratings yet

- Wrought Washers FlyerDocument2 pagesWrought Washers FlyerG.L. HuyettNo ratings yet

- A7734a enDocument2 pagesA7734a enAbhineet ShrivastavaNo ratings yet

- White Semi-Hard Natural Rubber: Technical Data SheetDocument2 pagesWhite Semi-Hard Natural Rubber: Technical Data SheetSantosh JayasavalNo ratings yet

- WDHearn PresentationDocument26 pagesWDHearn PresentationMarrakech TaiwanNo ratings yet

- Jet-Lube 550 Nonmetallic AntiSeize CompoundDocument1 pageJet-Lube 550 Nonmetallic AntiSeize CompoundDon HowardNo ratings yet

- Hbe Oil Tanks Weldless Steel en 0220Document8 pagesHbe Oil Tanks Weldless Steel en 0220Emir EsimNo ratings yet

- Hitachi skd61 PDFDocument12 pagesHitachi skd61 PDFHieu Nguyen MinhNo ratings yet

- Method Statement For CoringDocument4 pagesMethod Statement For CoringNasir Nagoor PitchaiNo ratings yet