Professional Documents

Culture Documents

(E3) Combigrid 40'40 Q1 GRK 4 C Technical Product Data Sheets

(E3) Combigrid 40'40 Q1 GRK 4 C Technical Product Data Sheets

Uploaded by

LaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

(E3) Combigrid 40'40 Q1 GRK 4 C Technical Product Data Sheets

(E3) Combigrid 40'40 Q1 GRK 4 C Technical Product Data Sheets

Uploaded by

LaCopyright:

Available Formats

Geogrid/nonwoven

composite NAUE GmbH & Co. KG

Gewerbestrasse 2

32339 Espelkamp-Fiestel

Germany

Phone:+49 5743 41-0 Fax: :+49 5743 41-240

E-Mail: info@naue.com Internet: www.naue.com

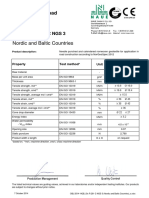

Combigrid® 40/40 Q1 GRK 4 C

(former name: Combigrid® 40/40 Q1 151 GRK 3)

Product description:

Composite of a laid geogrid made of stretched, monolithic polypropylene (PP) flat bars with welded junctions and a

mechanical bonded and calendered filter geotextile welded within the geogrid structure, used for the reinforcement

in many fieids of civil engineering including road construction, landfill and hydraulic engineering

Property Test method* Unit

Geogrid

Raw material polypropylene (PP), white

Mass per unit area EN ISO 9864 g/m2 240

Max. tensile strength, md / cmd** EN ISO 10319 kN/m > 40 / > 40

Elongation at nominal strength,

EN ISO 10319 % <7 1 <7

md / cmd**

Tensile strength at 1% elongation,

EN ISO 10319 kN/m 8/8

md / cmd**

Tensile strength at 2% elongation,

EN ISO 10319 kN/m 16/16

md / cmd**

Tensile strength at 5% elongation,

EN ISO 10319 kN/m 32/32

md / cmd**

Aperture size, md x cmd** mm x mm approx. 31 x 31

Production specific elongation % 0

Geotextile

Raw material polypropylene (PP), white

Mass per unit area EN ISO 9864 g/m2 > 150

Max. tensile strength, md / cmd** EN ISO 10319 kN/m 7.5/11.0

Elongation at max. tensile strength,

EN ISO 10319 % 40/30

md / cmd**

Puncture force EN ISO 12236 N > 1500

Characterstic opening size EN ISO 12956 um 90

Water permeability

- VIH50-Index EN ISO 11058 m/s 9,0 x 10"2

- Flow rateH5o l/(m2 s) 90

Detector tested yes

Roll dimensions, width x length mx m 4.75 x 100

*based on, **md = machine direction, cmd = cross machine direction

The listed technical values are guiding values, achieved in our laboratories and/or independent testing institutes. Our

products are subject to changes without prior notice.

revision date: 17 March 2016 Combigrid Q1 ,xlsx_40'40 Q1 GRK 4 C_e

You might also like

- Mac DrainDocument24 pagesMac Drainsundra0No ratings yet

- Structural Design Against Deflection PDFDocument211 pagesStructural Design Against Deflection PDFLa100% (2)

- Generative Design of Landforms With Dynamo in Civil 3D: Andreas LukaDocument20 pagesGenerative Design of Landforms With Dynamo in Civil 3D: Andreas LukaLaNo ratings yet

- Geogrid: Secugrid® Q (PES/PET)Document1 pageGeogrid: Secugrid® Q (PES/PET)Yassin Abd El AalNo ratings yet

- Acfrogarvoajbomqeijdiaz6ygdx878 W7wb4nrk470csp1k6mdqzrc6rx2q5wdcvgj0j9iqzbnijnfciptb4wkkcs9h5jcczuq-M5pe9nfwydh-Txqnwli1xwju1seuizt OcnzuechhgjywvnwDocument1 pageAcfrogarvoajbomqeijdiaz6ygdx878 W7wb4nrk470csp1k6mdqzrc6rx2q5wdcvgj0j9iqzbnijnfciptb4wkkcs9h5jcczuq-M5pe9nfwydh-Txqnwli1xwju1seuizt OcnzuechhgjywvnwkhoochengmayNo ratings yet

- Fibre-Reinforced Geosynthetic Clay Liner (GBR-C) Bentofix® NSP 4000Document1 pageFibre-Reinforced Geosynthetic Clay Liner (GBR-C) Bentofix® NSP 4000Luis Alberto GutiérrezNo ratings yet

- Geogrid: Secugrid® Q (PP)Document2 pagesGeogrid: Secugrid® Q (PP)SudeepDPoojaryNo ratings yet

- SECUTEX R 201 Ficha TécnicaDocument1 pageSECUTEX R 201 Ficha TécnicaMax FerrolNo ratings yet

- Teranap 431 TP 4m (En)Document2 pagesTeranap 431 TP 4m (En)Franco Saenz SolisNo ratings yet

- Secutex RS 1201Document1 pageSecutex RS 1201Yusuf Rendra PratamaNo ratings yet

- TS1000 (4.51) en 180607Document1 pageTS1000 (4.51) en 180607kabiru isahNo ratings yet

- R - May - Secutex MR 301, MR 401, MR 501 - eDocument1 pageR - May - Secutex MR 301, MR 401, MR 501 - eEngineering IndramasNo ratings yet

- TN 160RE10ceDocument1 pageTN 160RE10ceAna AnaNo ratings yet

- VTD08-PLUS - Complete Waterproofing - MTC-1185 - 20-06-23Document1 pageVTD08-PLUS - Complete Waterproofing - MTC-1185 - 20-06-23Pritpal SinghNo ratings yet

- 03 - Data-Sheet-GCL-5000-NDocument1 page03 - Data-Sheet-GCL-5000-Nreshan champikaNo ratings yet

- Fta377 Rev2 GBDocument1 pageFta377 Rev2 GBCatalin FilipNo ratings yet

- Technical Data Sheet Uk MacdrainDocument1 pageTechnical Data Sheet Uk MacdrainMe Kang He Kodos We Kang And KodosNo ratings yet

- Maktex Py 300: Product DescriptionDocument1 pageMaktex Py 300: Product DescriptionHatem ElGabryNo ratings yet

- Cordaflex (SMK) (N) ShtoeuDocument4 pagesCordaflex (SMK) (N) ShtoeurachidNo ratings yet

- Ds - TECHDRAIN GTG 720 - enDocument1 pageDs - TECHDRAIN GTG 720 - enThameem SharaafNo ratings yet

- TDS of GRIDTEXTILE 5050FG.14-SP1Document1 pageTDS of GRIDTEXTILE 5050FG.14-SP1reshan champikaNo ratings yet

- Benfelt 48 140820182 Extended Version 09 2022Document2 pagesBenfelt 48 140820182 Extended Version 09 2022MarijaRRRRNo ratings yet

- TN 120RE10ceDocument1 pageTN 120RE10ceAna AnaNo ratings yet

- Deckdrain S1200NW8 Data SheetDocument1 pageDeckdrain S1200NW8 Data SheetsdvsdvdsaNo ratings yet

- Composite HosesDocument19 pagesComposite Hosesaravindkumar arunagiriNo ratings yet

- Isostud Geo P-EngDocument1 pageIsostud Geo P-EngPiulitza88No ratings yet

- Alfgrid G30-301Document1 pageAlfgrid G30-301Aladin Abrash0% (1)

- Ds - INTERDRAIN GMG 620 - enDocument1 pageDs - INTERDRAIN GMG 620 - enThameem SharaafNo ratings yet

- The Geotextile Protection Layer For The Geomembrane Shall Be Made by A Needle Punching Process Using Staple Fibres and Should Have The Following Physical PropertiesDocument3 pagesThe Geotextile Protection Layer For The Geomembrane Shall Be Made by A Needle Punching Process Using Staple Fibres and Should Have The Following Physical PropertiesIr Ahmad AfiqNo ratings yet

- K 80010691Document2 pagesK 80010691Виталий ХебибулинNo ratings yet

- TECNOLEN 25 Bs1d0 - 42234 - 42344 - V5 - ENDocument2 pagesTECNOLEN 25 Bs1d0 - 42234 - 42344 - V5 - ENKarima ABOUALINo ratings yet

- Ply Wood DATASheetDocument2 pagesPly Wood DATASheetmohammed mustafaNo ratings yet

- Quality Product Certification ReinforcementDocument3 pagesQuality Product Certification ReinforcementsamiNo ratings yet

- Sefar Spécification: SEFAR TETEX MONO 03-1010-K 050 225 CM Numéro D' Article: 3B03-0420-225-00Document1 pageSefar Spécification: SEFAR TETEX MONO 03-1010-K 050 225 CM Numéro D' Article: 3B03-0420-225-00Bkiri AbderrahimNo ratings yet

- Alyaf - A401 XL - MDSDocument1 pageAlyaf - A401 XL - MDSfarha zoheb imranNo ratings yet

- Hdpe TR 144 Film Polymer SMDocument2 pagesHdpe TR 144 Film Polymer SMAkram.yishakNo ratings yet

- A301 - EN MethodDocument1 pageA301 - EN MethodAhmad ElghazolyNo ratings yet

- Ficha Tecnica MaxDocument1 pageFicha Tecnica MaxFernando Daga JanampaNo ratings yet

- KXNEDocument2 pagesKXNEJan GawełNo ratings yet

- Crgo MTCDocument4 pagesCrgo MTCGupta Gupta100% (1)

- TDS ThermaSmartPRO Sheet v2.2EU 20200928Document2 pagesTDS ThermaSmartPRO Sheet v2.2EU 20200928Lorenzo Antonio ConcepciónNo ratings yet

- Cordaflex (SMK) (N) ShtoeuDocument3 pagesCordaflex (SMK) (N) Shtoeufikri abu kassimNo ratings yet

- Spesifikasi Non Woven BCIPDocument2 pagesSpesifikasi Non Woven BCIPmaizar yudhaNo ratings yet

- Betacavi 75ohm CatalogueDocument24 pagesBetacavi 75ohm CatalogueAnderson EvangelistaNo ratings yet

- Polifelt CatalogDocument28 pagesPolifelt CatalogCreanga CristinaNo ratings yet

- Qdrain C15 65 14F Eng 1Document1 pageQdrain C15 65 14F Eng 1Thameem SharaafNo ratings yet

- Waterproofing Membrane, CharacteristicsDocument4 pagesWaterproofing Membrane, CharacteristicsyamegNo ratings yet

- Engel macPET 320-150 Technical Specifications - ENDocument3 pagesEngel macPET 320-150 Technical Specifications - ENDawn UnderNo ratings yet

- StrataDrain SD 60.15.2 Datasheet - Jan 24Document1 pageStrataDrain SD 60.15.2 Datasheet - Jan 24TYRONENo ratings yet

- Technical Data Sheet SIMONA® ECTFE-GKDocument2 pagesTechnical Data Sheet SIMONA® ECTFE-GKjdiaz87No ratings yet

- TDS of Energy C3N-6004B120-BL 13sDocument1 pageTDS of Energy C3N-6004B120-BL 13sCesar PereiraNo ratings yet

- Elastocoat C 6335-101Document4 pagesElastocoat C 6335-101Cristina AndronescuNo ratings yet

- Non Woven Geotextile Membrane T1000Document1 pageNon Woven Geotextile Membrane T1000Gelila TadesseNo ratings yet

- Hi-Tech Bush SpecsDocument4 pagesHi-Tech Bush SpecsRony MartínezNo ratings yet

- Qdrain C15 65 10F Eng 1Document1 pageQdrain C15 65 10F Eng 1Thameem SharaafNo ratings yet

- Dual-Band Panel Dual Polarization Half-Power Beam WidthDocument2 pagesDual-Band Panel Dual Polarization Half-Power Beam WidthFatbardh DragushaNo ratings yet

- A401 - EN MethodDocument1 pageA401 - EN MethodAhmad SamyNo ratings yet

- Silicate Fabric JT1200HT: Vermiculite-Based Coating FabricDocument1 pageSilicate Fabric JT1200HT: Vermiculite-Based Coating FabricMahmoudNo ratings yet

- Epd Huesker StabilenkaDocument11 pagesEpd Huesker StabilenkaPeteris SkelsNo ratings yet

- (E2) Design Option 2 - AASHTO'93Document2 pages(E2) Design Option 2 - AASHTO'93LaNo ratings yet

- 50 Years of Lincoln Agritech: A Celebration of New Zealand Agricultural Engineering and InnovationDocument45 pages50 Years of Lincoln Agritech: A Celebration of New Zealand Agricultural Engineering and InnovationLaNo ratings yet

- That CAD Girl: Jennifer DibonaDocument2 pagesThat CAD Girl: Jennifer DibonaLaNo ratings yet

- TS ANA 2020 en Analyze Models 1Document148 pagesTS ANA 2020 en Analyze Models 1La100% (1)

- 3tq3f Basic Knowledge in Civil Engineering Book of 59 Topics Including History of Civil Engineering NR 1Document148 pages3tq3f Basic Knowledge in Civil Engineering Book of 59 Topics Including History of Civil Engineering NR 1La0% (1)

- 27 FTP PDFDocument7 pages27 FTP PDFLaNo ratings yet

- (E1) Design Option 1 - AASHTO'93Document2 pages(E1) Design Option 1 - AASHTO'93LaNo ratings yet

- June 2023 (v1) MS - Paper 6 CAIE Biology IGCSEDocument7 pagesJune 2023 (v1) MS - Paper 6 CAIE Biology IGCSEiayesha899No ratings yet

- L1 Discussion - Introduction To First Order Differential EquationsDocument7 pagesL1 Discussion - Introduction To First Order Differential EquationsCarlo EdolmoNo ratings yet

- Introduction To HVAC&R Systems: Ir. Dr. Sam C. M. HuiDocument48 pagesIntroduction To HVAC&R Systems: Ir. Dr. Sam C. M. HuiJerry ChanNo ratings yet

- All Stainless Steel Pressure Gauges With Bourdon TubeDocument2 pagesAll Stainless Steel Pressure Gauges With Bourdon TubetitiNo ratings yet

- Evaluation of The Particle Sizes of Four Clay Minerals Tan2016Document12 pagesEvaluation of The Particle Sizes of Four Clay Minerals Tan2016Laura Ximena Giraldo100% (1)

- C 1279-00Document6 pagesC 1279-00Tenson LauNo ratings yet

- Set 100Document11 pagesSet 100lelon81No ratings yet

- I E B Q S: Ch.3 Foundation SettlementDocument8 pagesI E B Q S: Ch.3 Foundation SettlementAhmed2No ratings yet

- Conceptual Energy Hewitt-2Document21 pagesConceptual Energy Hewitt-2nosferatu123456No ratings yet

- Miscellaneous Friction LossesDocument9 pagesMiscellaneous Friction LossesunlimitedpsxNo ratings yet

- Nozzle Loads - Part 1 - Piping Engineering - Knowledge BaseDocument6 pagesNozzle Loads - Part 1 - Piping Engineering - Knowledge BaseNitinNo ratings yet

- Activity 6 Product Disassembly ChartDocument5 pagesActivity 6 Product Disassembly Chartapi-504977947No ratings yet

- Ray Optics and Optical Instruments: Very Short Answer Type QuestionsDocument5 pagesRay Optics and Optical Instruments: Very Short Answer Type QuestionsAvni RaghavNo ratings yet

- Belirsizlik ICP OESDocument11 pagesBelirsizlik ICP OESDeniz ErsoyNo ratings yet

- Determination of Moisture ContentDocument24 pagesDetermination of Moisture ContentBliss Eye50% (6)

- Conservation of Energy Problems Worksheet 3Document15 pagesConservation of Energy Problems Worksheet 3Balkis MungurNo ratings yet

- Circuit Theory: Report BigprojectDocument10 pagesCircuit Theory: Report BigprojectVũ Hoàng LongNo ratings yet

- Exponential and Logarithmic Function (Q)Document29 pagesExponential and Logarithmic Function (Q)Belladonna LeeNo ratings yet

- Turning Away From Philosophy of BeingDocument152 pagesTurning Away From Philosophy of BeingEve AthanasekouNo ratings yet

- Logarithmic Decrement: Consider Eq.8A For Underdamped SystemDocument6 pagesLogarithmic Decrement: Consider Eq.8A For Underdamped SystemFahad ChaudharyNo ratings yet

- 4.3 Examples of Beam Analysis Using The Direct Stiffness Method DDocument1 page4.3 Examples of Beam Analysis Using The Direct Stiffness Method DAHMED SHAKERNo ratings yet

- Lamina PropertiesDocument7 pagesLamina PropertiesMohd ShahrizanNo ratings yet

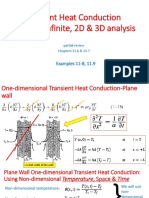

- Lecture 21 - Transient (Semiinfinite, 2D&3D)Document27 pagesLecture 21 - Transient (Semiinfinite, 2D&3D)nickNo ratings yet

- 1219 - Offshore Foundation Design - 2 Pile - A1Document138 pages1219 - Offshore Foundation Design - 2 Pile - A1naseebNo ratings yet

- ML Lab ManualDocument41 pagesML Lab ManualAnna BhosadikeNo ratings yet

- It Is Given That The Line: y Ax BXC DX Xe A B D eDocument5 pagesIt Is Given That The Line: y Ax BXC DX Xe A B D eChan RicNo ratings yet

- Dr. Awani Bhushan Assistant Professor SMEC, VIT ChennaiDocument21 pagesDr. Awani Bhushan Assistant Professor SMEC, VIT ChennaiAyush AgrawalNo ratings yet

- Homework-Assignment-4-Ceng2311 - EDM & Total Station ApplicationsDocument4 pagesHomework-Assignment-4-Ceng2311 - EDM & Total Station ApplicationsEhab2001No ratings yet

- Students' Notes Yr 1o (Physics)Document51 pagesStudents' Notes Yr 1o (Physics)Engr. Douglas IdieseruNo ratings yet

- Strengthening Mechanisms: MET246E Materials PhysicsDocument10 pagesStrengthening Mechanisms: MET246E Materials PhysicsbazingaNo ratings yet