Professional Documents

Culture Documents

DOC021

DOC021

Uploaded by

Kumara Subramanian0 ratings0% found this document useful (0 votes)

11 views7 pages1143 aaa

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1143 aaa

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

11 views7 pagesDOC021

DOC021

Uploaded by

Kumara Subramanian1143 aaa

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 7

| yaw (An IATF 18949:2016 Certified Company) pees

Boh KALARIA FORGE PVT. LTD. (01/15.10.2012)

PRE-DISPATCH INSPECTION Report - DIMENTIONAL

art Name : Anchor Shackle - Forging Date: 1@ltel as

Cust. Part No. AS-10-2F (REV.00) KLE Part No. :KLF-S401 Invoice No.: G -713

[Customer Name : IAC ELECTRICAL PVT.LTD. ToralQty: 2662 Now

no.| Parameter |insrumentuses | Specetion -——-—C™Oaon oneness

a DIAMETER Venier 9450+10/10 lus> lucalasalaculnsal ob

a WIDTH P/L Venier 16005/05 lsc lisa liszlis.¢lis.al ok

3_|_Insibe Gar en. Venier 24001.0/10 leno lane lon tel ees et)

4 WIDTH Venier 200+05/05 [on loo ees (eee ee

5 CENTER weicHTGauce | 760x010 [oo 262] acai ac.2l on

6 "ANGLE severprorecron] 12°83 ak lok lak lok a es

7 RADIUS RADIUS GAUGE RG < lee lee lee [e im

8 RADIUS RADIUS GAUGE Ro feo eal| Perea | eta (esters eT

9 “THICKNESS Venier 1805/05 hee [rea [ree | rea [p66 | oly

to | nanoness | Hardnesstester | 175-2108" |io~ [yo [rea fro lias late

Fr MARKING Visual AsPer Requirment [TAG GF AS-10-2 120 ok

2 WEIGHT weight Balance | 0.750K8 Approx |g.aa|g.a2e|6. 910] 0.23/60. 920] 0k

No Crack, Laps,

a , Laps, ok Jok |ok Jo ok

aa | — visuat end & Dent wana] SP [OK Jo ‘

4

15

16

17

18

19

20

21

22

23

24

25

26 th

2 we

* Marked dimensios are critical

All Dimensios are in mm.

checked By Quality inch : reviewed By DrectorTech.: ff Perrah

pena Kalaria

Senet Forge Pvl. Ltd.

Swe, -Seeclane

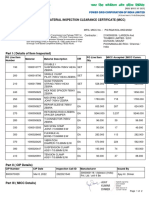

(CHEMICAL & METALLURGICAL TEST REPORT FB 03(047480648)

WS. JAC ELECTRIGALS PVT.LTD. frone, incor Date, ToD

ISANKRAIL INDUSTRIAL PARK, PLOTNO.53 fone: oGzoezzact Dae: 72082020

INH-6 JALA DHULAGORI, HOWRAH 711302 __|nvoice No:_G-713 bate: 18102000

PartName KEFORG No | _Cuslomer Part Nob Ne ay.

[TANGHOR SHACKLE - FORGING AIFS 7AS-10F REVO 7562 Noe

TATERIAL SPECIFICATION

= Ss vitae | cet ara

cow ARIS STEELPUTLID. TSE Daan | aU al

CHEMICAL ANLYSIS

Eiemet | ¢ [wo] © [| 8 | P | G@ [NW] Mm | Vv aL

wn [040 [060] 016 | — | > — =m

wax | om0 |_| 035 | om | ooo | —- | - | - | — :

movuat_| oa | oa | oe | com | oom | — | — | — | — =

TWETALLURGIOAL RESULTS

INCLUSION RATING 1S:4169/ ASTM ESA acum] Soconoipon)

x ; z see | eee

TL* |] >a }]r]«f[ry>«|™” fol-

fre 20 | 20 [20 | 20 | 20 | 20 | 20 | 20 | oo] nw, —

facrua_ 100| os | oso | oo | ooo | 000 | 100 | oso fobs

THEGHANICAL PROPERTIES (ASTI ASTOIS-1628)

TEA wacko |wertest] mxupTest

UIs] Ys Impact] vardness | _ vATER IW

wnt) |qumma | EL% | PA% | value | seen | ces SPARK &

rcTuaL_| es7.70 | 4284s | 3148 776169 |_ ASHER

WARDENABILITY (HRO) As periS3648

He | wane] ane Wie | IE | ae | OT

PS | isnm | mm | som [65 mm] 9 | oom | Yim | 5mm | sn

EC.

ACTUAL

SURPLY CONDITION WICROSTRUCTURE HEAT TREATHENT

7s forged, dy Nomaizd & Shot Basta Peat Forte Nomaling

FERS

lccrreeo-wxr Te Tr FroNs ARE CORRECT A RE BASED ON Fast ma v

fcturesescosarencnstrss PREPARED ay AUTHORISED stonarony

[ase contact ene of auery eal qualia org cam & mr@lalrTorgecom

| Rept ice & Works

Survey NoSO/t, Plot a6,

National High 27 Shapar (rave.

Dit: kt (uy) NDIA tw,

49120725407 pase eween ee

Ssh leon

oaceenere Forge Pvt. Ltd.

www kalarla-forge.com An ISO/TS 16949:2009 Certified Company

NORMALIZING PROCESS REPORT

ITEM NAME : ANCHOR SHACKLE-20MM

DRG.NO. | PART NO. : AS-10-2F REV.00

REPORT NO. & DATE: 4010 / 29.09.20

CUSTOMER NAME: IAC ELECTRICAL PVT.LTD.

CHARGE QTY & WEIGHT.: 1500 NOS. 1044 KG.

PROCESS: NORMALIZING / ANNEALING : NORMALIZING.

MATERIAL: CL-4

HEAT CHARGE NO.: 29121 20

SOAKING TEMP.: 840°C

KLF ALLOTED MATERIAL HEAT NO.: Bld

HARDNESS SPECIFIED : 175-210 BHN

HARDNESS OBSERVED (BHN): 179 TO 187 BHN

KLF BATCH CARD NO.: 150920-3

COOLING MEDIA (AIRIFURNACEIFAN) : FAN

FURNACE TYPE: BELL TYPE ELECTRIC FURNACE

LOADING TIME : 02:08

LOADING TEMP: 363°C

SOAKING START TIME : 13:03

BATCH NO. : 1/20

‘SOAKING END TIME : 15:03 |

|

J

100

°

02:08:24 3—-—

02:28:26 5

PREPARED BY : fe af

Forging mirs. for Automoti

ey AUTHORISED BY: 5

‘ole line transmission, Oil & gas, General Engineering & CNC Turned components

ee Kalaria

Natasa ties, Satan Forge Put. Ltd.

‘Dist; Rakot (Gu,) INDIA. ‘BWeb. — : www kalaria-forge.com An ISO/TS 16949:2009 Certified Compan

NORMALIZING PROCESS REPORT

ITEM NAME : ANCHOR SHACKLE-20MM DRG.NO. / PART NO. : AS-10-2F REV.00

REPORT NO. & DATE: 4011 /29.09.20 CUSTOMER NAME: IAC ELECTRICAL PVT.LTD,

CHARGE QTY & WEIGHT.: 1182 NOS, 823 KG. PROCESS: NORMALIZING / ANNEALING : NORMALIZING

MATERIAL: CL-4 SOAKING TEMP.: 840°C _|

HEAT CHARGE NO.: 29121 20 KLF ALLOTED MATERIAL HEAT NO: BU |

HARDNESS SPECIFIED : 175-210 BHN KLF BATCH CARD NO.: 150920:3

HARDNESS OBSERVED (BHN): 179 TO 187 BHN

COOLING MEDIA (AIRIFURNACEIFAN) : FAN FURNACE TYPE: BELL TYPE ELECTRIC FURNACE

LOADING TIME : 15:25 LOADING TEMP: 556°C

‘SOAKING START TIME : 21:35 SOAKING END TIME : 23:35

BATCH NO. :/20

(0 RS

ERGPPTSSSSSTSSSSSSESSSSSSSS SSS SSS

RERSRSHSRSHSHSRSRSRSESRSASHSESHES

aaag8 SSRSRRRSSRAAARRRRRANAARAAAR

PREPARED BY: }e=i¥ / AUTHORISED BY peas

Forging mits. for Automotive, Pole line transmission, Oil & gas, General Engineering & CNC Turned components

MICROSTRUCTURE REPORT - IN HOUSE LAB FLB0S (00 /01.02.14)

Name Of Customer __; IACELECTRICALS LTD. Test Report No: KLFM-

CULCUTTA Date +: 29.09.20

Part Name/No. +: AS-25X102 (BATCH NO: 1/20)

Material Specification: CLASS-IV

Batch Card No. + 10920-3

Condition of Sample —_: Normalized forge cut piece

Heat Charge Number: 2912120

Type Of Test : Micro Evaluation

Test Method +: ASTM E-3, ASM Vol-9, ASTM E-112

Magnification:

Etchant = 2% Nital

Remarks: The Microstructure shows Ferrite and Pearlite in Normalizing condition having 7 to 8 ASTM

grain size number.

Tested By: feist Authorized Signature »_-~, Jn

re soos rrov.-=Ssts00 Sz zavn= su onto» «zak os

ves e000 =o e000 «selon wz et0'0 «asco = zeo €

9s yoo =—«sho00 «e000 -—«=«oloG>©rooD «eB otco> «za z

ve 120000 trove sooo | prio sszo0«=s sad »=nivc> =o’ L

_ % is: ae % - =

[ as € Tus ad A iL aN :

coso'o + ooove cosa xenm

revo zc00 e100 sro se srzo0——cwz0'0 7080 >

coro onan

e000 sreoo sooo = uso reo s200 20v0 €

e000 seo woo uso zz hz0 e090 z

se000 oreo wooo = oueoo ase sev 1510 t

a ts _% th _|

oO ow 19 eT =

asa aauis

___evsunoieo _eogsu9 _ovse0s_wwzrvio _gena___wuSvMS vg ee ests

L aa

—_ _ Ls ee eee

Surey o1duids 1005 30K adh, BEN PONSA eu aIeG eINsEO

“prT ad 6104

Bneyey

V13SNOH NI- LYOd3y 1831 TWOINSHO

"ARIAS STEEL PRIVATE LIMITED

4 ARJAS STEEL {romney Onn stl nda Pot th

at Oma TAMA APT

TEST CERTIFICATE TSR RECHOET

[sxe _ moots —vocona rnin fan [eat ens ac

Eisner: Inaieae sone _| 76h Toa [road

posses nowre: —apsaorm accu ee 2pm frntne roe r

Ft ens fae os A

oan rome Tae

ee ate lee [enaioes fore fsbo heae [aa

[Chemieal Composition 5

Jorwen [vo [ste [a [ae [es [a we [ee ae [ee eo

TECHNICAL PROPERTIES INGLUSIONRATING AS PER ASTER METHOD A

Foe | cm faites] et |e] me Lo

bx [ae =m

aco [0 IE

TORN HARDENABILTY RG)

METALLURGICAL PROPERTIES Ears Jordy Vas

‘Deca | MSS Train Sze Inclusion Rating Distance

eee eon (ater ews arom

peowiadis wore oo

Lechter apna pan enemas cba Ta8 TU apa pape =

sgn tron ay eS a nel cron ween he ane poe

[Sime reSipemnatn ics te Gansan ta tomer Sesh oan ne wae etek .

= iene ear Text Sevier sees

crs rsd wn Tad Carr Btn avy Compo Wawa Wan Dango RA nd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 18 1Document1 page18 1Kumara SubramanianNo ratings yet

- HIRKO MELKAMU @taj City Centre KolkataDocument1 pageHIRKO MELKAMU @taj City Centre KolkataKumara SubramanianNo ratings yet

- Bird Guard MQP RGTLDocument3 pagesBird Guard MQP RGTLKumara SubramanianNo ratings yet

- NFC 33 041 Anchoring Clamps CompressDocument25 pagesNFC 33 041 Anchoring Clamps CompressKumara SubramanianNo ratings yet

- Final Newtown Brochure SoftDocument8 pagesFinal Newtown Brochure SoftKumara SubramanianNo ratings yet

- 21 09 01Document1 page21 09 01Kumara SubramanianNo ratings yet

- Catalogue TESORAX - en v2023Document23 pagesCatalogue TESORAX - en v2023Kumara SubramanianNo ratings yet

- DrawingDocument1 pageDrawingKumara SubramanianNo ratings yet

- MICC NO: 1200056606: Part I (Details of Item Inspected)Document2 pagesMICC NO: 1200056606: Part I (Details of Item Inspected)Kumara SubramanianNo ratings yet

- Bms HB 3000-b Brinell-HardheidstesterDocument20 pagesBms HB 3000-b Brinell-HardheidstesterKumara SubramanianNo ratings yet

- Ride Details Bill DetailsDocument3 pagesRide Details Bill DetailsKumara SubramanianNo ratings yet

- TS Part01Document366 pagesTS Part01Kumara SubramanianNo ratings yet

- CY2023Document1 pageCY2023Kumara SubramanianNo ratings yet

- QQQDocument1 pageQQQKumara SubramanianNo ratings yet

- BSI Fire Standards Brochure UK enDocument4 pagesBSI Fire Standards Brochure UK enuttam boseNo ratings yet

- L&T Construction Power Transmission & Distribution Transmission Line Business Units Quality Management SystemDocument3 pagesL&T Construction Power Transmission & Distribution Transmission Line Business Units Quality Management SystemKumara SubramanianNo ratings yet

- 04.0099.72.00.02 Training Cum Competence RecordDocument1 page04.0099.72.00.02 Training Cum Competence RecordKumara SubramanianNo ratings yet