Professional Documents

Culture Documents

Pages From Report Stage 1

Pages From Report Stage 1

Uploaded by

Abdul RahmanCopyright:

Available Formats

You might also like

- Grating Design ReportDocument28 pagesGrating Design ReportnvnagarajuNo ratings yet

- 12 5 16 MVA Power Transformer Data Sheet PDFDocument5 pages12 5 16 MVA Power Transformer Data Sheet PDFajaymannNo ratings yet

- Cable Sizing CalculationDocument72 pagesCable Sizing CalculationHARI my songs100% (3)

- ANALYSIUSDocument2 pagesANALYSIUSLoren ViejayNo ratings yet

- J1237 Asian Paints HAZOP WSDocument98 pagesJ1237 Asian Paints HAZOP WSrohitkushNo ratings yet

- Asian Paints HAZOP WSDocument107 pagesAsian Paints HAZOP WSRaj Kumar100% (1)

- Candidate's Handbook: Iso 50001 Lead AuditorDocument16 pagesCandidate's Handbook: Iso 50001 Lead AuditorAbdul RahmanNo ratings yet

- API Standard 2000 - Venting Atmospheric and Low-Pressure Storage Tanks: Nonrefrigerated and RefrigeratedDocument5 pagesAPI Standard 2000 - Venting Atmospheric and Low-Pressure Storage Tanks: Nonrefrigerated and RefrigeratedNicolas CardonaNo ratings yet

- API Motor Data Sheet Temp LetDocument6 pagesAPI Motor Data Sheet Temp LetkhalidNo ratings yet

- Excel For Etabs Tutorial For RCDocument63 pagesExcel For Etabs Tutorial For RCchbarcenalNo ratings yet

- Concrete Structures For Retaining Aqueous Liquids - Code of PracticeDocument22 pagesConcrete Structures For Retaining Aqueous Liquids - Code of Practicematrix structuresNo ratings yet

- 132KV VT Test Report-Jumsouth Ss by PatrixDocument3 pages132KV VT Test Report-Jumsouth Ss by Patrixharihara_675292894No ratings yet

- 132KV VT Test Report-Jumsouth Ss Updated SIGNEDDocument3 pages132KV VT Test Report-Jumsouth Ss Updated SIGNEDharihara_675292894No ratings yet

- 132KV VT Test Report-Jumsouth Ss by PatrixDocument3 pages132KV VT Test Report-Jumsouth Ss by Patrixharihara_675292894No ratings yet

- 02 Electrical Power SystemsDocument40 pages02 Electrical Power SystemsLA ONDA TROPICAL TV MEXICONo ratings yet

- EDC-DTS-MV001 - Pole Mounted Three-Phase and Two-Phase Outdoor Distribution TransformersDocument69 pagesEDC-DTS-MV001 - Pole Mounted Three-Phase and Two-Phase Outdoor Distribution TransformersJoe bilouteNo ratings yet

- B.O.Q of Electro-Mechanical Works 6Document1 pageB.O.Q of Electro-Mechanical Works 6asdsd dsdaNo ratings yet

- Plumbing Water Supply Pump Head CalculationDocument4 pagesPlumbing Water Supply Pump Head Calculationsyed yaqubNo ratings yet

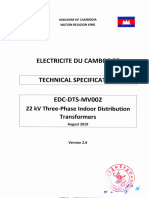

- EDC-DTS-MV002 - 22 KV Three-Phase Indoor Distribution TransformersDocument33 pagesEDC-DTS-MV002 - 22 KV Three-Phase Indoor Distribution TransformersJoe bilouteNo ratings yet

- ELSMT03DDocument4 pagesELSMT03DJhonny RinconesNo ratings yet

- 61404U JI N°x - Process Guidlines For PRV Design - Rev0Document26 pages61404U JI N°x - Process Guidlines For PRV Design - Rev0CristinaNo ratings yet

- Chapter 2 - Rev ADocument29 pagesChapter 2 - Rev AAenur RofiiqNo ratings yet

- NGR Sizing Calculation-MURALIDocument16 pagesNGR Sizing Calculation-MURALIsureshn82960650% (4)

- Pre-Commissioning Test Report of TransformerDocument2 pagesPre-Commissioning Test Report of TransformerBIRANCHINo ratings yet

- CWC Mec DTS P001abcdDocument8 pagesCWC Mec DTS P001abcdAlonso1593No ratings yet

- Pragyan: Uppsc Ae 2021 Civil Engineering Test-07 Detailed SolutionsDocument11 pagesPragyan: Uppsc Ae 2021 Civil Engineering Test-07 Detailed SolutionsThanosh MishraNo ratings yet

- 2SRD AnalysisReport 11132020 PDFDocument25 pages2SRD AnalysisReport 11132020 PDFJuncel BayogoNo ratings yet

- ANZ-DS-E-5017 Power TransformersDocument18 pagesANZ-DS-E-5017 Power Transformersmika cabelloNo ratings yet

- 404 Bus 2 CVT 181021030334Document6 pages404 Bus 2 CVT 181021030334SARAVANAN ANo ratings yet

- Data SheetDocument21 pagesData SheetmizharmuisstNo ratings yet

- 201 - M CVTDocument3 pages201 - M CVTAshutosh KumarNo ratings yet

- Rebound Hammer FormDocument2 pagesRebound Hammer FormAhmad Syauqi Abd RazakNo ratings yet

- DT-Dry Type Data SheetDocument3 pagesDT-Dry Type Data SheetArnold StevenNo ratings yet

- Design Criteria: First FloorDocument2 pagesDesign Criteria: First FloorDave Khyl Josol BosqueNo ratings yet

- Current Transformer Test: Power Supply To Plot P18 at Zayed Military City D108337 SWH38A1Document3 pagesCurrent Transformer Test: Power Supply To Plot P18 at Zayed Military City D108337 SWH38A1Jayaprakash M PNo ratings yet

- HT AppForm - Modified 04092018Document5 pagesHT AppForm - Modified 04092018mayankNo ratings yet

- HT AppForm - Modified 04092018Document5 pagesHT AppForm - Modified 04092018mayankNo ratings yet

- KE3-TBE-ELC-0908-6093 - TBE For TR-REV-ADocument3 pagesKE3-TBE-ELC-0908-6093 - TBE For TR-REV-ASUBAS CHANDRA BEHERANo ratings yet

- ANZ-DS-E-5013 HV IsolatorsDocument17 pagesANZ-DS-E-5013 HV Isolatorsmika cabelloNo ratings yet

- HP22-07-C04-001-02 Sub Structure Power HouseDocument46 pagesHP22-07-C04-001-02 Sub Structure Power HouseZulkifli Basri100% (1)

- Loads List by Spec Equipment Area WWTP3 (Juli 2022)Document3 pagesLoads List by Spec Equipment Area WWTP3 (Juli 2022)Reza SyailendraNo ratings yet

- Notice No.3: Rules and Regulations For TheDocument8 pagesNotice No.3: Rules and Regulations For Thepaparis54gmail.comNo ratings yet

- Anexo 14 ELK-04-GIS - Standard Data Sheet - Rev ADocument10 pagesAnexo 14 ELK-04-GIS - Standard Data Sheet - Rev Apablo.jaraNo ratings yet

- Power Trafo - SAT - T-1Document15 pagesPower Trafo - SAT - T-1imranNo ratings yet

- Renewable Energy Code For The Transmission System, 2015Document22 pagesRenewable Energy Code For The Transmission System, 2015José Miguel Martínez ValerNo ratings yet

- R30 FindingsDocument9 pagesR30 FindingsSARDIFRANC HUTAGALUNGNo ratings yet

- ENI Tubular Goods-BookletDocument46 pagesENI Tubular Goods-BookletWell ControlNo ratings yet

- ML-E Tech ReferenceDocument99 pagesML-E Tech ReferenceSuriya PrakashNo ratings yet

- Inspection Report - Electrical WorkDocument9 pagesInspection Report - Electrical Workpremkumarance_999016No ratings yet

- Acacia Structural AnalysisDocument38 pagesAcacia Structural AnalysisJoshua LopezNo ratings yet

- TKT at 03 DS 2702 A R0 Data Sheet of 13.8 0.4KV, 2000KVA TransformersDocument3 pagesTKT at 03 DS 2702 A R0 Data Sheet of 13.8 0.4KV, 2000KVA TransformersLam Duy TienNo ratings yet

- Anexo 15 PDTG Gis - en 0425Document29 pagesAnexo 15 PDTG Gis - en 0425pablo.jaraNo ratings yet

- FSS 971 40SS 0001 - 1Document34 pagesFSS 971 40SS 0001 - 1Victor Eduardo Gonzalez RojasNo ratings yet

- MM 15-9-2021Document1 pageMM 15-9-2021Fateh Ali KhanNo ratings yet

- Assembly Building D7Document1 pageAssembly Building D7Suthan JoshuaNo ratings yet

- Drg. & GTP - R1 - 11 KV HG Fuse - DiskitDocument4 pagesDrg. & GTP - R1 - 11 KV HG Fuse - DiskitAnand ShekharNo ratings yet

- Annex 6Document2 pagesAnnex 6venkateshbitraNo ratings yet

- Epc Package Gaderwara STPP Stage-Ii (2X800 MW) Ash Handling System & Ash Water Recirculation System Electrical Load ListDocument2 pagesEpc Package Gaderwara STPP Stage-Ii (2X800 MW) Ash Handling System & Ash Water Recirculation System Electrical Load ListvenkateshbitraNo ratings yet

- 2.1. Design ParametersDocument2 pages2.1. Design ParametersFarly VergelNo ratings yet

- HTTPSWWW - Carc.gov - Jositesdefaultfilesinline Filescontrolof Obstacles34gm Obsc PDFDocument63 pagesHTTPSWWW - Carc.gov - Jositesdefaultfilesinline Filescontrolof Obstacles34gm Obsc PDFDipendra ShresthaNo ratings yet

- Integrated Circuits, Silicon Monolithic, Hcmos Quad 2-Input Nor Gates With Fully Buffered OutputsDocument24 pagesIntegrated Circuits, Silicon Monolithic, Hcmos Quad 2-Input Nor Gates With Fully Buffered OutputsOMAR MARTINEZNo ratings yet

- Groundwater Hydrology: Conceptual and Computational ModelsFrom EverandGroundwater Hydrology: Conceptual and Computational ModelsRating: 5 out of 5 stars5/5 (1)

- Water Flow Switch: Model: SD-WFD SeriesDocument3 pagesWater Flow Switch: Model: SD-WFD SeriesAbdul RahmanNo ratings yet

- Classification Labelling o EquipmentDocument1 pageClassification Labelling o EquipmentAbdul RahmanNo ratings yet

- Panel Hospital List IGIDocument6 pagesPanel Hospital List IGIAbdul RahmanNo ratings yet

- Dust CloudDocument12 pagesDust CloudAbdul RahmanNo ratings yet

- Risk Analysis and Safety in LPG Storage: The Indexed Method: M. Mariani & M. R. VallerotondaDocument10 pagesRisk Analysis and Safety in LPG Storage: The Indexed Method: M. Mariani & M. R. VallerotondaAbdul RahmanNo ratings yet

- Technical Specifications of Instrumentation and Control Cables 1. Instrumentation Cable: Single PairDocument8 pagesTechnical Specifications of Instrumentation and Control Cables 1. Instrumentation Cable: Single PairAbdul RahmanNo ratings yet

- Specifications Threaded Rod 67030045Document3 pagesSpecifications Threaded Rod 67030045Abdul RahmanNo ratings yet

- Threaded Rod: Product SubmittedDocument1 pageThreaded Rod: Product SubmittedAbdul RahmanNo ratings yet

- Alkaline Earth Metals: General Properties of IIA Group ElementsDocument4 pagesAlkaline Earth Metals: General Properties of IIA Group Elementsswamy ChinthalaNo ratings yet

- 1986 - Arnold First Steps in Symplectic TopologyDocument22 pages1986 - Arnold First Steps in Symplectic TopologyJunjie Luo100% (1)

- Procedimiento de Reemplazo de CojinetesDocument32 pagesProcedimiento de Reemplazo de CojinetesJavier Hector CayaNo ratings yet

- Physical - Chemistry - 3th - Castellan 801 860 32 35Document4 pagesPhysical - Chemistry - 3th - Castellan 801 860 32 35Mira YuliartiNo ratings yet

- Soil NoteDocument13 pagesSoil NoteBhuwan JoshiNo ratings yet

- Making Conductive Ink Using Old Batteries, Pencil Lead, and Activated Charcoal With Glue and PaintDocument11 pagesMaking Conductive Ink Using Old Batteries, Pencil Lead, and Activated Charcoal With Glue and PaintGuian EitoNo ratings yet

- Smart Timer Manual ME 8930Document40 pagesSmart Timer Manual ME 8930Moises JustavinoNo ratings yet

- 06.experimental and Numerical Investigation of Reinforced Concrete Slabs Under Blast LoadingDocument13 pages06.experimental and Numerical Investigation of Reinforced Concrete Slabs Under Blast LoadingPennarasiNo ratings yet

- Impact of Mass and Deformation On The Gearbox of Large Wind TurbinesDocument134 pagesImpact of Mass and Deformation On The Gearbox of Large Wind TurbinesTarek MagdyNo ratings yet

- Work Environment DesignDocument30 pagesWork Environment DesignMoti TadegeNo ratings yet

- Reflection of LightDocument35 pagesReflection of Lightcharlesferrer718No ratings yet

- Data SheetDocument4 pagesData SheetRachel FloresNo ratings yet

- Berekening Van Een CirkelsegmentDocument2 pagesBerekening Van Een Cirkelsegmentuser 54No ratings yet

- 12.5 Meter Technical Data SheetDocument23 pages12.5 Meter Technical Data SheetrituNo ratings yet

- HYW 45 T5 (YANMAR - 4TNV98T GGEH) (Soundproof B10) ENDocument11 pagesHYW 45 T5 (YANMAR - 4TNV98T GGEH) (Soundproof B10) ENRoman ChubaNo ratings yet

- PX Model NomenclatureDocument1 pagePX Model NomenclaturenammarisNo ratings yet

- RS-LiDAR-32 Brochure EN 20200306Document2 pagesRS-LiDAR-32 Brochure EN 20200306nazi1945No ratings yet

- Flow in ConduitsDocument29 pagesFlow in ConduitsEngr Sabiul AlamNo ratings yet

- Assignment 1 ONSDocument4 pagesAssignment 1 ONSVanita ShirsathNo ratings yet

- Nonlinear Modeling of RC Structures Using Opensees: University of Naples Federico IiDocument66 pagesNonlinear Modeling of RC Structures Using Opensees: University of Naples Federico IiJorge Luis Garcia ZuñigaNo ratings yet

- Atoms, Molecules, and IonsDocument54 pagesAtoms, Molecules, and Ionsarsekerci813601No ratings yet

- M Series Product Data Sheet EnglishDocument2 pagesM Series Product Data Sheet EnglishAZMI YAHAYANo ratings yet

- CE Laboratory ApparatusDocument11 pagesCE Laboratory ApparatusMong PhannaNo ratings yet

- Identify Right Triangle 1Document2 pagesIdentify Right Triangle 1MittalNo ratings yet

- L9-Thermal RadiationDocument37 pagesL9-Thermal RadiationskNo ratings yet

- Index of Refraction Lab Lesson Plan E-Portfolio VersionDocument8 pagesIndex of Refraction Lab Lesson Plan E-Portfolio Versionapi-668691050No ratings yet

- Abstract Algebra by Rashid AliDocument274 pagesAbstract Algebra by Rashid Alisaba nazNo ratings yet

- Comparison of Polytropic and Isentropic Efficiency of Natural Gas Compressor Calculated Using Aspen HYSYS & Using Manual CalDocument22 pagesComparison of Polytropic and Isentropic Efficiency of Natural Gas Compressor Calculated Using Aspen HYSYS & Using Manual CaljrfmlNo ratings yet

- Tratos FlexDocument40 pagesTratos FlexSyarief100% (1)

Pages From Report Stage 1

Pages From Report Stage 1

Uploaded by

Abdul RahmanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pages From Report Stage 1

Pages From Report Stage 1

Uploaded by

Abdul RahmanCopyright:

Available Formats

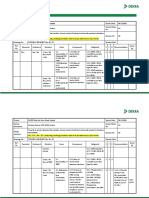

NA - NOT APPLICABLE

CHECKLIST/ SURVEY REPORT SRAP - SEE REMEDIAL

ACTION PLAN

STAGE-I (GAP ANALYSIS OF EXISTING FIRE MR - MEETS REQUIREMENT

NR - NOT REQUIRED

FIGHTING SYSTEM AT PSO HOUSE-CLIFTON)

S.NO. DESCRIPTION EXISTING NFPA REMARKS

REQUIREMENT

2.0 FIRE WATER STORAGE TANK :

(Above Ground)

2.1 Design and Construction Code Not Known NFPA-22 (2003 Ed.) Since this tank is not the

main firewater tank, therfore

2.2 Working Capacity 20000 x 4 -

has not been evaluated for

80,000 US Gallons

2.3 Location of Tank. Yes Away from fire Exposure fire scenarios.

(clause 4.2.1)

2.4 Type of Construction R.C.C. Steel, R.C.C, Wood, etc,. MR

(clause 4.3.1)

2.5 Roof on Tank. Yes Yes MR

(clause 4.14.1)

2.6 Roof Vent Yes Yes MR

(clause 4.15)

2.7 Roof Hatch Yes Dia. 24"-2 Nos. MR

(clause 5.7.3)

2.8 Ladder Interior Exterior and interior Accessable from ground

(clause 5.7.4) MR

2.9 Water Level Gauge / LL/HL Alarm No Yes SRAP

(clause 13.1.11)

2.10 Tank Outlet Nozzle Size 4" 6" <= 25000 USG

SRAP

8" => 30000 to 100000 USG

10" = Greater capacities

(clause 13.2.2.2)

2.11 Controlling Valve Yes Gate with indicator Post MR

or OS&Y

(clause 13.2.12)

2.12 Antivortex Plate Assembly Not Known Yes

(clause 13.2.13)

2.13 Overflow Yes Yes MR

(clause 13.5)

2.14 Shell Manholes N/A 2 nos. in first course

(clause 13.6.2)

2.15 Dual Service Tank Yes May be

(clause 13.7.1)

2.16 Water Quality Good -

2.17 Source of Water Out source -

2.18 Fire Water Tank Condition Satisfactory -

2.19 Notes:

Doc.: 2951-CL-001 Rev.0 Page 20

NA - NOT APPLICABLE

CHECKLIST/ SURVEY REPORT SRAP - SEE REMEDIAL

ACTION PLAN

STAGE-I (GAP ANALYSIS OF EXISTING FIRE MR - MEETS REQUIREMENT

NR - NOT REQUIRED

FIGHTING SYSTEM AT PSO HOUSE-CLIFTON)

S.NO. DESCRIPTION EXISTING NFPA REMARKS

REQUIREMENT

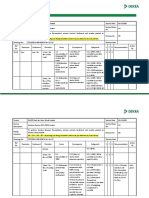

3.0 FIRE PUMP:

(a) (DIESEL ENGINE DRIVEN)

3.1a Design code NFPA 20 NFPA-20 (2003 Ed.)

3.2a UL listed and FM approved Yes -

3.3a. Pump Characteristics

i Clause 7.1.2.1

Pumps shall furnish not less than 150 percent Yes MR

of rated capacity at a total head of not less

than 65 percent of the total rated head.

ii The total shutoff head shall not exceed 140 Clause 7.1.2.2.

Yes MR

percent of the total rated head on vertical

turbine pumps.

3.4a Design Flow Rate 500 US gpm -

3.5a Design Head 104 Psi - SRAP

3.6a Type of pump Centrifugal Centrifugal

(clause 5.2.1)

- Horizontal, in line fire pump OR Horizontal For +ve suction head

(clause 6.1.2)

- Vertical turbine pump N/A For Suction Lift MR

(clause 7.1.1)

3.7a Pressure Gauges No At discharge & suction SRAP

(clause 5.10)

3.8a Pressure Relief Valve No if Static head + Pump shut off SRAP

> system design pressure

(clause 5.18)

3.9a Circulation Relief Valve Not Applicable For recirculation

(clause 5.11)

(Not applicable for Engine Pump)

3.10a Valves at Suction Piping Yes OS&Y Gate MR

(clause 5.14.5)

3.11a Valves at Discharge Piping Yes Check & OS&Y Gate MR

(clause 5.15)

3.12a Water Flow Test Device No To test the pump SRAP

(clause 5.19)

3.13a Automatic Air Release Valve Yes For vertical turbine and for side MR

suction/side discharge pumps

(clause 6.3.3)

3.14a Suction strainer Yes Basket strainer on suction MR

manifold of each pump

(clause 7.3.4)

Doc.: 2951-CL-001 Rev.0 Page 21

NA - NOT APPLICABLE

CHECKLIST/ SURVEY REPORT SRAP - SEE REMEDIAL

ACTION PLAN

STAGE-I (GAP ANALYSIS OF EXISTING FIRE MR - MEETS REQUIREMENT

NR - NOT REQUIRED

FIGHTING SYSTEM AT PSO HOUSE-CLIFTON)

S.NO. DESCRIPTION EXISTING NFPA REMARKS

REQUIREMENT

3.15a Starting and Control Manual Automatic / Manual MR

(clause 10.5)

Each pump shall have

individual pressure sensing line

3.16a - Diesel Engine Drive Yes Listed by Testing Lab. MR

(clause 11.2.1)

I - Instrumentation & Control Yes Governor MR

Yes Over speed shut down device MR

Yes Tachometer MR

Yes Oil pressure gauge MR

Yes Temperature Gauge MR

Yes Instrument panel MR

Yes (clause 11.2.4.1 to 11.2.4.7) MR

ii - Starting Method Yes 2 storage battery units MR

Yes 2 means for recharging - MR

storage batteries

(clause 11.2.5.2.1 & 11.2.5.3)

iii - Engine Cooling Heat Exchanger Heat exchanger / radiator MR

(clause 11.2.6)

iv - Fuel Tank Capacity Min. 8-hours (clause 11.4.3) MR

v - Fuel Tank Construction SRAP

Single wall Without containment

vi - Fuel Tank Level Gauge No - SRAP

3.17a Pump Condition Not Good -

Shaft Packing is leaked

3.18a Service Sweet Water -

3.19a Pump Controller UL Listed Listed by Testing Lab.

Not connected with Fire

(clause 12.1.3) water Pump

I Locked cabinet for switches with Yes All switches required to keep MR

break glass panel controller in automatic position

shall be in locked cabinet with

break glass panels(clause 12.3.4)

ii Automatic position indicator Yes clause 12.4.1.2 MR

iii Low oil pressure indicator Yes Visible indication critically low MR

oil pressure in the lubrication

system (clause 12.4.1.3(1))

iv clause 12.4.1.3 (2) MR

High eng. Jacket coolant temperature Yes

v Engine start failure indication Yes clause 12.4.1.3 (3) MR

Doc.: 2951-CL-001 Rev.0 Page 22

NA - NOT APPLICABLE

CHECKLIST/ SURVEY REPORT SRAP - SEE REMEDIAL

ACTION PLAN

STAGE-I (GAP ANALYSIS OF EXISTING FIRE MR - MEETS REQUIREMENT

NR - NOT REQUIRED

FIGHTING SYSTEM AT PSO HOUSE-CLIFTON)

S.NO. DESCRIPTION EXISTING NFPA REMARKS

REQUIREMENT

vi Shutdown from over speed indicator Yes clause 12.4.1.3 (4) MR

vii Battery failure indicator for each Yes clause 12.4.1.3 (5) MR

battery

viii Low hydraulic pressure indicator Yes clause 12.4.1.3 (7) MR

ix Battery charger failure indicator for Yes clause 12.4.1.3 (6) MR

each controller.

x Common audible alarm Yes clause 12.4.1.3 MR

xi Alarm silencing switch Yes Not allowed, clause 12.4.1.4 MR

xii Pressure switch Yes clause 12.5.2.1 MR

xiii Pressure recorder device or Yes clause 12.4.4 (Not reqd. for non- MR

pressure sensing line pressure actuated controller.

xiv Voltmeter for each battery bank Yes Accuracy +/- 5% MR

clause 12.4.5

xv Shutdown Manual clause 12.5.5 MR

xvi Weekly program timer Yes clause 12.5.2.7 MR

Doc.: 2951-CL-001 Rev.0 Page 23

NA - NOT APPLICABLE

CHECKLIST/ SURVEY REPORT SRAP - SEE REMEDIAL

ACTION PLAN

STAGE-I (GAP ANALYSIS OF EXISTING FIRE MR - MEETS REQUIREMENT

NR - NOT REQUIRED

FIGHTING SYSTEM AT PSO HOUSE-CLIFTON)

S.NO. DESCRIPTION EXISTING NFPA REMARKS

REQUIREMENT

3.0 PRESSURE MAINTENANCE

(b) (JOCKEY PUMP) Not Available

3.1b Design Code

3.2b UL listed and FM approved -

3.3b Type of pump -

3.4b Pressure Gauges -

3.5b Valves at Suction Piping -

3.6b Valves at Discharge Piping -

3.7b Rated Flow Rate -

3.8b Maximum Head -

3.9b Service -

3.10b Pump Condition -

3.11b Pressure Switch -

3.12b Pressure Safety Valve

Doc.: 2951-CL-001 Rev.0 Page 24

NA - NOT APPLICABLE

CHECKLIST/ SURVEY REPORT SRAP - SEE REMEDIAL

ACTION PLAN

STAGE-I (GAP ANALYSIS OF EXISTING FIRE MR - MEETS REQUIREMENT

NR - NOT REQUIRED

FIGHTING SYSTEM AT PSO HOUSE-CLIFTON)

S.NO. DESCRIPTION EXISTING NFPA REMARKS

REQUIREMENT

4.0 FIRE WATER NETWORK:

(a) FLOOR Ist (divided into two portions i.e., half at east and half at west side)

4.1a Design code Not known NFPA-14 (1996 Ed.)

4.2a Controlling valves N/A Indicating type listed

(Clause 2-6)

4.3a (i) Hose Station - Cabinets Easily accessible in case MR

East side Cabinet is accessible of fire

West side Cabinet is inside (Clause 2-7.1.1) SRAP

Toilet and not accessible.

4.3a (ii) Dedicated for fire equipement

Yes and conspicuously identified MR

(Clause 2-7.1.1)

4.3a (iii) Break Glass Device is not For break glass type cabinet SRAP

available device break the glass panel

shall be attached securely

(Clause 2-7.1.2)

4.4a Hose Station - Hose Yes UL listed Hose MR

(Clause 2-7.2)

100 - 150 ft. Maximum length of hose MR

100 ft and Dia.1 1/2" attached

for ready use

(Clause 2-7.2)

4.5a Hose Station - Hose rack Yes Each 1 1/2" hose station with MR

1 1/2" hose shall be equiped

with listed rack or approved

facility

(Clause 2-7.3)

N/A Each 1 1/2" hose station with

less than 1 1/2" hose shall be

equiped with listed continous

flow reel

(Clause 2-7.3)

4.6a Hose Station - Nozzle Yes Listed for class II MR

(Clause 2-7.4)

4.7a Hose Station - Label No label " fire hose for use by SRAP

occupants" and operating

instructions shall be available

on each rack

(Clause 2-7.5)

Doc.: 2951-CL-001 Rev.0 Page 25

NA - NOT APPLICABLE

CHECKLIST/ SURVEY REPORT SRAP - SEE REMEDIAL

ACTION PLAN

STAGE-I (GAP ANALYSIS OF EXISTING FIRE MR - MEETS REQUIREMENT

NR - NOT REQUIRED

FIGHTING SYSTEM AT PSO HOUSE-CLIFTON)

S.NO. DESCRIPTION EXISTING NFPA REMARKS

REQUIREMENT

4.8a Hose Connection Yes Hose connection externally MR

threaded per NFPA 1963 shall

be equiped wuth cap

(Clause 2-8)

4.9a Type of Standpipe System Automatic Wet Automatic Dry, Automatic Wet MR

Semi-Automatic Dry,

Manual Dry & Manual Wet

(Clause 3-2)

4.10a Class of Standpipe System Class II Class I, Class II & Class III

(Clause 3-3)

Doc.: 2951-CL-001 Rev.0 Page 26

NA - NOT APPLICABLE

CHECKLIST/ SURVEY REPORT SRAP - SEE REMEDIAL

ACTION PLAN

STAGE-I (GAP ANALYSIS OF EXISTING FIRE MR - MEETS REQUIREMENT

NR - NOT REQUIRED

FIGHTING SYSTEM AT PSO HOUSE-CLIFTON)

S.NO. DESCRIPTION EXISTING NFPA REMARKS

REQUIREMENT

4.0 FIRE WATER NETWORK:

(b) FLOOR 2nd (divided into two portions i.e., half at east and half at west side)

4.1 b Design code Not known NFPA-14 (1996 Ed.)

4.2 b (i) Controlling valves N/A Indicating type listed

(Clause 2-6)

4.3 b (i) Hose Station - Cabinets Easily accessible in case MR

East side Cabinet is accessible of fire

(Clause 2-7.1.1) SRAP

West side Cabinet is inside

Server Room and not accessible.

4.3b (ii) Dedicated for fire equipement

Yes and conspicuously identified MR

(Clause 2-7.1.1)

4.3b (iii) Break Glass Device is not For break glass type cabinet SRAP

available device break the glass panel

shall be attached securely

(Clause 2-7.1.2)

4.4b Hose Station - Hose Yes UL listed Hose MR

(Clause 2-7.2)

100 - 150 ft. Maximum length of hose MR

100 ft and Dia.1 1/2" attached

for ready use

(Clause 2-7.2)

4.5 b Hose Station - Hose rack Yes Each 1 1/2" hose station with MR

1 1/2" hose shall be equiped

with listed rack or approved

facility

(Clause 2-7.3)

N/A Each 1 1/2" hose station with

less than 1 1/2" hose shall be

equiped with listed continous

flow reel

(Clause 2-7.3)

4.6 b Hose Station - Nozzle Yes Listed for class II MR

(Clause 2-7.4)

4.7 b Hose Station - Label No label " fire hose for use by SRAP

occupants" and operating

instructions shall be available

on each rack

(Clause 2-7.5)

Doc.: 2951-CL-001 Rev.0 Page 27

NA - NOT APPLICABLE

CHECKLIST/ SURVEY REPORT SRAP - SEE REMEDIAL

ACTION PLAN

STAGE-I (GAP ANALYSIS OF EXISTING FIRE MR - MEETS REQUIREMENT

NR - NOT REQUIRED

FIGHTING SYSTEM AT PSO HOUSE-CLIFTON)

S.NO. DESCRIPTION EXISTING NFPA REMARKS

REQUIREMENT

4.8 b Hose Connection Yes Hose connection externally MR

threaded per NFPA 1963 shall

be equiped wuth cap

(Clause 2-8)

4.9 b Type of Standpipe System Automatic Wet Automatic Dry, Automatic Wet

Semi-Automatic Dry,

Manual Dry & Manual Wet

(Clause 3-2)

4.10 b Class of Standpipe System Class II Class I, Class II & Class III

(Clause 3-3)

Doc.: 2951-CL-001 Rev.0 Page 28

NA - NOT APPLICABLE

CHECKLIST/ SURVEY REPORT SRAP - SEE REMEDIAL

ACTION PLAN

STAGE-I (GAP ANALYSIS OF EXISTING FIRE MR - MEETS REQUIREMENT

NR - NOT REQUIRED

FIGHTING SYSTEM AT PSO HOUSE-CLIFTON)

S.NO. DESCRIPTION EXISTING NFPA REMARKS

REQUIREMENT

4.0 FIRE WATER NETWORK:

(c) FLOOR 3rd (divided into two portions i.e., half at east and half at west side)

4.1 c Design code Not known NFPA-14 (1996 Ed.)

4.2 c Controlling valves N/A Indicating type listed

(Clause 2-6)

4.3c (i) Hose Station - Cabinets Both East and West Sides are Easily accessible in case MR

accessible of fire

(Clause 2-7.1.1)

4.3c (ii) Dedicated for fire equipement

Yes and conspicuously identified MR

(Clause 2-7.1.1)

4.3c (iii) Break Glass Device is not For break glass type cabinet SRAP

available device break the glass panel

shall be attached securely

(Clause 2-7.1.2)

4.4 c Hose Station - Hose Yes UL listed Hose MR

(Clause 2-7.2)

100 - 150 ft. Maximum length of hose MR

100 ft and Dia.1 1/2" attached

for ready use

(Clause 2-7.2)

4.5 c Hose Station - Hose rack Yes Each 1 1/2" hose station with MR

1 1/2" hose shall be equiped

with listed rack or approved

facility

(Clause 2-7.3)

N/A Each 1 1/2" hose station with

less than 1 1/2" hose shall be

equiped with listed continous

flow reel

(Clause 2-7.3)

4.6 c Hose Station - Nozzle Yes Listed for class II MR

(Clause 2-7.4)

4.7 c Hose Station - Label No label " fire hose for use by MR

occupants" and operating

instructions shall be available

on each rack

(Clause 2-7.5)

Doc.: 2951-CL-001 Rev.0 Page 29

NA - NOT APPLICABLE

CHECKLIST/ SURVEY REPORT SRAP - SEE REMEDIAL

ACTION PLAN

STAGE-I (GAP ANALYSIS OF EXISTING FIRE MR - MEETS REQUIREMENT

NR - NOT REQUIRED

FIGHTING SYSTEM AT PSO HOUSE-CLIFTON)

S.NO. DESCRIPTION EXISTING NFPA REMARKS

REQUIREMENT

4.8 c Hose Connection Yes Hose connection externally MR

threaded per NFPA 1963 shall

be equiped wuth cap

(Clause 2-8)

4.9 c Type of Standpipe System Automatic Wet Automatic Dry, Automatic Wet

Semi-Automatic Dry,

Manual Dry & Manual Wet

(Clause 3-2)

4.10 c Class of Standpipe System Class II Class I, Class II & Class III

(Clause 3-3)

Doc.: 2951-CL-001 Rev.0 Page 30

NA - NOT APPLICABLE

CHECKLIST/ SURVEY REPORT SRAP - SEE REMEDIAL

ACTION PLAN

STAGE-I (GAP ANALYSIS OF EXISTING FIRE MR - MEETS REQUIREMENT

NR - NOT REQUIRED

FIGHTING SYSTEM AT PSO HOUSE-CLIFTON)

S.NO. DESCRIPTION EXISTING NFPA REMARKS

REQUIREMENT

4.0 FIRE WATER NETWORK:

(d) FLOOR 4th (divided into two portions i.e., half at east and half at west side)

4.1 d Design code Not known NFPA-14 (1996 Ed.)

4.2 d Controlling valves N/A Indicating type listed MR

(Clause 2-6)

4.3d (i) Hose Station - Cabinets Both East and West Sides are Easily accessible in case MR

accessible of fire

(Clause 2-7.1.1)

4.3d (ii) Dedicated for fire equipement

Yes and conspicuously identified MR

(Clause 2-7.1.1)

4.3d (iii) Break Glass Device is not For break glass type cabinet SRAP

available device break the glass panel

shall be attached securely

(Clause 2-7.1.2)

4.4 d Hose Station - Hose Yes UL listed Hose MR

(Clause 2-7.2)

100 - 150 ft. Maximum length of hose MR

100 ft and Dia.1 1/2" attached

for ready use

(Clause 2-7.2)

4.5 d Hose Station - Hose rack Yes Each 1 1/2" hose station with MR

1 1/2" hose shall be equiped

with listed rack or approved

facility

(Clause 2-7.3)

N/A Each 1 1/2" hose station with

less than 1 1/2" hose shall be

equiped with listed continous

flow reel

(Clause 2-7.3)

4.6 d Hose Station - Nozzle Yes Listed for class II MR

(Clause 2-7.4)

4.7 d Hose Station - Label No label " fire hose for use by SRAP

occupants" and operating

instructions shall be available

on each rack

(Clause 2-7.5)

Doc.: 2951-CL-001 Rev.0 Page 31

NA - NOT APPLICABLE

CHECKLIST/ SURVEY REPORT SRAP - SEE REMEDIAL

ACTION PLAN

STAGE-I (GAP ANALYSIS OF EXISTING FIRE MR - MEETS REQUIREMENT

NR - NOT REQUIRED

FIGHTING SYSTEM AT PSO HOUSE-CLIFTON)

S.NO. DESCRIPTION EXISTING NFPA REMARKS

REQUIREMENT

4.8 d Hose Connection Yes Hose connection externally MR

threaded per NFPA 1963 shall

be equiped wuth cap

(Clause 2-8)

4.9 d Type of Standpipe System Automatic Wet Automatic Dry, Automatic Wet

Semi-Automatic Dry,

Manual Dry & Manual Wet

(Clause 3-2)

4.10 d Class of Standpipe System Class II Class I, Class II & Class III

(Clause 3-3)

Doc.: 2951-CL-001 Rev.0 Page 32

NA - NOT APPLICABLE

CHECKLIST/ SURVEY REPORT SRAP - SEE REMEDIAL

ACTION PLAN

STAGE-I (GAP ANALYSIS OF EXISTING FIRE MR - MEETS REQUIREMENT

NR - NOT REQUIRED

FIGHTING SYSTEM AT PSO HOUSE-CLIFTON)

S.NO. DESCRIPTION EXISTING NFPA REMARKS

REQUIREMENT

4.0 FIRE WATER NETWORK:

(e) FLOOR 5th (divided into two portions i.e., half at east and half at west side)

4.1e Design code Not known NFPA-14 (1996 Ed.)

4.2e Controlling valves N/A Indicating type listed

(Clause 2-6)

4.3e (i) Hose Station - Cabinets Easily accessible in case MR

West side Cabinet is accessible of fire

East side Cabinet is not (Clause 2-7.1.1) SRAP

accessable.

4.3e (ii) Dedicated for fire equipement

Yes and conspicuously identified MR

(Clause 2-7.1.1)

4.3e (iii) Break Glass Device is not For break glass type cabinet SRAP

available device break the glass panel

shall be attached securely

(Clause 2-7.1.2)

4.4e Hose Station - Hose Yes UL listed Hose MR

(Clause 2-7.2)

100 - 150 ft. Maximum length of hose MR

100 ft and Dia.1 1/2" attached

for ready use

(Clause 2-7.2)

4.5e Hose Station - Hose rack Yes Each 1 1/2" hose station with MR

1 1/2" hose shall be equiped

with listed rack or approved

facility

(Clause 2-7.3)

N/A Each 1 1/2" hose station with

less than 1 1/2" hose shall be

equiped with listed continous

flow reel

(Clause 2-7.3)

4.6e Hose Station - Nozzle Yes Listed for class II MR

(Clause 2-7.4)

4.7e Hose Station - Label No label " fire hose for use by SRAP

occupants" and operating

instructions shall be available

on each rack

(Clause 2-7.5)

Doc.: 2951-CL-001 Rev.0 Page 33

NA - NOT APPLICABLE

CHECKLIST/ SURVEY REPORT SRAP - SEE REMEDIAL

ACTION PLAN

STAGE-I (GAP ANALYSIS OF EXISTING FIRE MR - MEETS REQUIREMENT

NR - NOT REQUIRED

FIGHTING SYSTEM AT PSO HOUSE-CLIFTON)

S.NO. DESCRIPTION EXISTING NFPA REMARKS

REQUIREMENT

4.8e Hose Connection Yes Hose connection externally MR

threaded per NFPA 1963 shall

be equiped wuth cap

(Clause 2-8)

4.9e Type of Standpipe System Automatic Wet Automatic Dry, Automatic Wet

Semi-Automatic Dry,

Manual Dry & Manual Wet

(Clause 3-2)

4.10e Class of Standpipe System Class II Class I, Class II & Class III

(Clause 3-3)

Doc.: 2951-CL-001 Rev.0 Page 34

NA - NOT APPLICABLE

CHECKLIST/ SURVEY REPORT SRAP - SEE REMEDIAL

ACTION PLAN

STAGE-I (GAP ANALYSIS OF EXISTING FIRE MR - MEETS REQUIREMENT

NR - NOT REQUIRED

FIGHTING SYSTEM AT PSO HOUSE-CLIFTON)

S.NO. DESCRIPTION EXISTING NFPA REMARKS

REQUIREMENT

4.0 FIRE WATER NETWORK:

(f) FLOOR 6th (divided into two portions i.e., half at east and half at west side)

4.1f Design code Not known NFPA-14 (1996 Ed.)

4.2f Controlling valves N/A Indicating type listed

(Clause 2-6)

4.3f (i) Hose Station - Cabinets Easily accessible in case MR

West side Cabinet is accessible of fire

East side Cabinet is not (Clause 2-7.1.1) SRAP

accessable.

4.3f (ii) Dedicated for fire equipement

Yes and conspicuously identified MR

(Clause 2-7.1.1)

4.3f (iii) Break Glass Device is not For break glass type cabinet SRAP

available device break the glass panel

shall be attached securely

(Clause 2-7.1.2)

4.4f Hose Station - Hose Yes UL listed Hose MR

(Clause 2-7.2)

100 - 150 ft. Maximum length of hose MR

100 ft and Dia.1 1/2" attached

for ready use

(Clause 2-7.2)

4.5f Hose Station - Hose rack Yes Each 1 1/2" hose station with MR

1 1/2" hose shall be equiped

with listed rack or approved

facility

(Clause 2-7.3)

N/A Each 1 1/2" hose station with

less than 1 1/2" hose shall be

equiped with listed continous

flow reel

(Clause 2-7.3)

4.6f Hose Station - Nozzle Yes Listed for class II MR

(Clause 2-7.4)

4.7f Hose Station - Label No label " fire hose for use by MR

occupants" and operating

instructions shall be available

on each rack

(Clause 2-7.5)

Doc.: 2951-CL-001 Rev.0 Page 35

NA - NOT APPLICABLE

CHECKLIST/ SURVEY REPORT SRAP - SEE REMEDIAL

ACTION PLAN

STAGE-I (GAP ANALYSIS OF EXISTING FIRE MR - MEETS REQUIREMENT

NR - NOT REQUIRED

FIGHTING SYSTEM AT PSO HOUSE-CLIFTON)

S.NO. DESCRIPTION EXISTING NFPA REMARKS

REQUIREMENT

4.8f Hose Connection Yes Hose connection externally MR

threaded per NFPA 1963 shall

be equiped wuth cap

(Clause 2-8)

4.9f Type of Standpipe System Automatic Wet Automatic Dry, Automatic Wet

Semi-Automatic Dry,

Manual Dry & Manual Wet

(Clause 3-2)

4.10f Class of Standpipe System Class II Class I, Class II & Class III

(Clause 3-3)

Doc.: 2951-CL-001 Rev.0 Page 36

NA - NOT APPLICABLE

CHECKLIST/ SURVEY REPORT SRAP - SEE REMEDIAL

ACTION PLAN

STAGE-I (GAP ANALYSIS OF EXISTING FIRE MR - MEETS REQUIREMENT

NR - NOT REQUIRED

FIGHTING SYSTEM AT PSO HOUSE-CLIFTON)

S.NO. DESCRIPTION EXISTING NFPA REMARKS

REQUIREMENT

4.0 FIRE WATER NETWORK:

(g) FLOOR 7th (divided into two portions i.e., half at east and half at west side)

4.1g Design code Not known NFPA-14 (1996 Ed.)

4.2 g Controlling valves N/A Indicating type listed

(Clause 2-6)

4.3g (i) Hose Station - Cabinets Easily accessible in case MR

West side Cabinet is accessible of fire

East side Cabinet is not (Clause 2-7.1.1) SRAP

accessable.

4.3g (ii) Dedicated for fire equipement

Yes and conspicuously identified MR

(Clause 2-7.1.1)

4.3g (iii) Break Glass Device is not For break glass type cabinet SRAP

available device break the glass panel

shall be attached securely

(Clause 2-7.1.2)

4.4 g Hose Station - Hose Yes UL listed Hose MR

(Clause 2-7.2)

100 - 150 ft. Maximum length of hose MR

100 ft and Dia.1 1/2" attached

for ready use

(Clause 2-7.2)

4.5 g Hose Station - Hose rack Yes Each 1 1/2" hose station with MR

1 1/2" hose shall be equiped

with listed rack or approved

facility

(Clause 2-7.3)

N/A Each 1 1/2" hose station with

less than 1 1/2" hose shall be

equiped with listed continous

flow reel

(Clause 2-7.3)

4.6 g Hose Station - Nozzle Yes Listed for class II MR

(Clause 2-7.4)

4.7 g Hose Station - Label No label " fire hose for use by MR

occupants" and operating

instructions shall be available

on each rack

(Clause 2-7.5)

Doc.: 2951-CL-001 Rev.0 Page 37

NA - NOT APPLICABLE

CHECKLIST/ SURVEY REPORT SRAP - SEE REMEDIAL

ACTION PLAN

STAGE-I (GAP ANALYSIS OF EXISTING FIRE MR - MEETS REQUIREMENT

NR - NOT REQUIRED

FIGHTING SYSTEM AT PSO HOUSE-CLIFTON)

S.NO. DESCRIPTION EXISTING NFPA REMARKS

REQUIREMENT

4.8 g Hose Connection Yes Hose connection externally MR

threaded per NFPA 1963 shall

be equiped wuth cap

(Clause 2-8)

4.9 g Type of Standpipe System Automatic Wet Automatic Dry, Automatic Wet

Semi-Automatic Dry,

Manual Dry & Manual Wet

(Clause 3-2)

4.10 g Class of Standpipe System Class II Class I, Class II & Class III

(Clause 3-3)

Doc.: 2951-CL-001 Rev.0 Page 38

NA - NOT APPLICABLE

CHECKLIST/ SURVEY REPORT SRAP - SEE REMEDIAL

ACTION PLAN

STAGE-I (GAP ANALYSIS OF EXISTING FIRE MR - MEETS REQUIREMENT

NR - NOT REQUIRED

FIGHTING SYSTEM AT PSO HOUSE-CLIFTON)

S.NO. DESCRIPTION EXISTING NFPA REMARKS

REQUIREMENT

4.0 FIRE WATER NETWORK:

(h) FLOOR 8th (divided into two portions i.e., half at east and half at west side)

4.1h Design code Not known NFPA-14 (1996 Ed.)

4.2h Controlling valves N/A Indicating type listed

(Clause 2-6)

4.3h (i) Hose Station - Cabinets Easily accessible in case MR

West side Cabinet is accessible of fire

East side Cabinet is not (Clause 2-7.1.1) SRAP

accessable.

4.3h (ii) Dedicated for fire equipement

Yes and conspicuously identified MR

(Clause 2-7.1.1)

4.3h (iii) Break Glass Device is not For break glass type cabinet SRAP

available device break the glass panel

shall be attached securely

(Clause 2-7.1.2)

4.4h Hose Station - Hose Yes UL listed Hose MR

(Clause 2-7.2)

100 - 150 ft. Maximum length of hose MR

100 ft and Dia.1 1/2" attached

for ready use

(Clause 2-7.2)

4.5h Hose Station - Hose rack Yes Each 1 1/2" hose station with MR

1 1/2" hose shall be equiped

with listed rack or approved

facility

(Clause 2-7.3)

N/A Each 1 1/2" hose station with

less than 1 1/2" hose shall be

equiped with listed continous

flow reel

(Clause 2-7.3)

4.6h Hose Station - Nozzle Yes Listed for class II MR

(Clause 2-7.4)

4.7h Hose Station - Label No label " fire hose for use by MR

occupants" and operating

instructions shall be available

on each rack

(Clause 2-7.5)

Doc.: 2951-CL-001 Rev.0 Page 39

NA - NOT APPLICABLE

CHECKLIST/ SURVEY REPORT SRAP - SEE REMEDIAL

ACTION PLAN

STAGE-I (GAP ANALYSIS OF EXISTING FIRE MR - MEETS REQUIREMENT

NR - NOT REQUIRED

FIGHTING SYSTEM AT PSO HOUSE-CLIFTON)

S.NO. DESCRIPTION EXISTING NFPA REMARKS

REQUIREMENT

4.8h Hose Connection Yes Hose connection externally MR

threaded per NFPA 1963 shall

be equiped wuth cap

(Clause 2-8)

4.9h Type of Standpipe System Automatic Wet Automatic Dry, Automatic Wet

Semi-Automatic Dry,

Manual Dry & Manual Wet

(Clause 3-2)

4.10h Class of Standpipe System Class II Class I, Class II & Class III

(Clause 3-3)

Doc.: 2951-CL-001 Rev.0 Page 40

NA - NOT APPLICABLE

CHECKLIST/ SURVEY REPORT SRAP - SEE REMEDIAL

ACTION PLAN

STAGE-I (GAP ANALYSIS OF EXISTING FIRE MR - MEETS REQUIREMENT

NR - NOT REQUIRED

FIGHTING SYSTEM AT PSO HOUSE-CLIFTON)

S.NO. DESCRIPTION EXISTING NFPA REMARKS

REQUIREMENT

4.0 FIRE WATER NETWORK:

(i) FLOOR 9th (divided into two portions i.e., half at east and half at west side)

4.1i Design code Not known NFPA-14 (1996 Ed.)

4.2i Controlling valves N/A Indicating type listed

(Clause 2-6)

4.3i (i) Hose Station - Cabinets Easily accessible in case MR

West side Cabinet is accessible of fire

(Clause 2-7.1.1)

4.3i (ii) Dedicated for fire equipement

Yes and conspicuously identified MR

(Clause 2-7.1.1)

4.3i (iii) Break Glass Device is not For break glass type cabinet SRAP

available device break the glass panel

shall be attached securely

(Clause 2-7.1.2)

4.4i Hose Station - Hose Yes UL listed Hose MR

(Clause 2-7.2)

100 - 150 ft. Maximum length of hose MR

100 ft and Dia.1 1/2" attached

for ready use

(Clause 2-7.2)

4.5i Hose Station - Hose rack Yes Each 1 1/2" hose station with MR

1 1/2" hose shall be equiped

with listed rack or approved

facility

(Clause 2-7.3)

N/A Each 1 1/2" hose station with

less than 1 1/2" hose shall be

equiped with listed continous

flow reel

(Clause 2-7.3)

4.6i Hose Station - Nozzle Yes Listed for class II MR

(Clause 2-7.4)

4.7i Hose Station - Label No label " fire hose for use by MR

occupants" and operating

instructions shall be available

on each rack

(Clause 2-7.5)

Doc.: 2951-CL-001 Rev.0 Page 41

NA - NOT APPLICABLE

CHECKLIST/ SURVEY REPORT SRAP - SEE REMEDIAL

ACTION PLAN

STAGE-I (GAP ANALYSIS OF EXISTING FIRE MR - MEETS REQUIREMENT

NR - NOT REQUIRED

FIGHTING SYSTEM AT PSO HOUSE-CLIFTON)

S.NO. DESCRIPTION EXISTING NFPA REMARKS

REQUIREMENT

4.8i Hose Connection Yes Hose connection externally MR

threaded per NFPA 1963 shall

be equiped wuth cap

(Clause 2-8)

4.9i Type of Standpipe System Automatic Wet Automatic Dry, Automatic Wet

Semi-Automatic Dry,

Manual Dry & Manual Wet

(Clause 3-2)

4.10i Class of Standpipe System Class II Class I, Class II & Class III

(Clause 3-3)

Doc.: 2951-CL-001 Rev.0 Page 42

NA - NOT APPLICABLE

CHECKLIST/ SURVEY REPORT SRAP - SEE REMEDIAL

ACTION PLAN

STAGE-I (GAP ANALYSIS OF EXISTING FIRE MR - MEETS REQUIREMENT

NR - NOT REQUIRED

FIGHTING SYSTEM AT PSO HOUSE-CLIFTON)

S.NO. DESCRIPTION EXISTING NFPA REMARKS

REQUIREMENT

4.0 FIRE WATER NETWORK:

(j) FLOOR Ground

4.1j Design code Not known NFPA-14 (1996 Ed.)

4.2j Controlling valves N.A. Indicating type listed

(Clause 2-6)

4.3j (i) Hose Station - Cabinets Not Available Easily accessible in case SRAP

of fire

(Clause 2-7.1.1)

4.3j (ii) Dedicated for fire equipement

N.A. and conspicuously identified

(Clause 2-7.1.1)

4.3j (iii) For break glass type cabinet

N.A. device break the glass panel

shall be attached securely

(Clause 2-7.1.2)

4.4j Hose Station - Hose No UL listed Hose SRAP

(Clause 2-7.2)

- Maximum length of hose

100 ft and Dia.1 1/2" attached

for ready use

(Clause 2-7.2)

4.5j Hose Station - Hose rack No Each 1 1/2" hose station with SRAP

1 1/2" hose shall be equiped

with listed rack or approved

facility

(Clause 2-7.3)

N/A Each 1 1/2" hose station with

less than 1 1/2" hose shall be

equiped with listed continous

flow reel

(Clause 2-7.3)

4.6j Hose Station - Nozzle No Listed for class II SRAP

(Clause 2-7.4)

4.7j Hose Station - Label No label " fire hose for use by SRAP

occupants" and operating

instructions shall be available

on each rack

(Clause 2-7.5)

Doc.: 2951-CL-001 Rev.0 Page 43

NA - NOT APPLICABLE

CHECKLIST/ SURVEY REPORT SRAP - SEE REMEDIAL

ACTION PLAN

STAGE-I (GAP ANALYSIS OF EXISTING FIRE MR - MEETS REQUIREMENT

NR - NOT REQUIRED

FIGHTING SYSTEM AT PSO HOUSE-CLIFTON)

S.NO. DESCRIPTION EXISTING NFPA REMARKS

REQUIREMENT

4.8j Hose Connection N.A. Hose connection externally MR

threaded per NFPA 1963 shall

be equiped wuth cap

(Clause 2-8)

4.9j Type of Standpipe System Automatic Wet Automatic Dry, Automatic Wet

Semi-Automatic Dry,

Manual Dry & Manual Wet

(Clause 3-2)

4.10j Class of Standpipe System Class II Class I, Class II & Class III

(Clause 3-3)

4.11j Fire Department Connection Yes No Shut-off valve b/w fire MR

department Connection and the

system

(Clause 4-3.1)

Yes Listed Check valve b/w fire MR

department Connection and the

system

(Clause 4-3.2)

No Location shall be on street side of Coupling is not connected

buildings, fully visible and SRAP

accessable.

(Clause 4-3.5.1)

1 No. 2 Nos. remotely located for High SRAP

rise buildings.

(Clause 5-12.2)

Doc.: 2951-CL-001 Rev.0 Page 44

NA - NOT APPLICABLE

CHECKLIST/ SURVEY REPORT SRAP - SEE REMEDIAL

ACTION PLAN

STAGE-I (GAP ANALYSIS OF EXISTING FIRE MR - MEETS REQUIREMENT

NR - NOT REQUIRED

FIGHTING SYSTEM AT PSO HOUSE-CLIFTON)

S.NO. DESCRIPTION EXISTING NFPA REMARKS

REQUIREMENT

4.0 FIRE WATER NETWORK:

(k) FLOOR Basement

4.1k Design code Not known NFPA-14 (1996 Ed.)

4.2k Controlling valves Yes Indicating type listed

(Clause 2-6)

4.3k (i) Hose Station - Cabinets 2 Nos. Available Easily accessible in case MR

of fire

(Clause 2-7.1.1)

4.3k (ii) Dedicated for fire equipement

Yes and conspicuously identified MR

(Clause 2-7.1.1)

4.3k (iii) Break Glass Device is not For break glass type cabinet SRAP

available device break the glass panel

shall be attached securely

(Clause 2-7.1.2)

4.4k Hose Station - Hose Yes UL listed Hose MR

(Clause 2-7.2)

100 - 150 ft. Maximum length of hose MR

100 ft and Dia.1 1/2" attached

for ready use

(Clause 2-7.2)

4.5k Hose Station - Hose rack Yes Each 1 1/2" hose station with MR

1 1/2" hose shall be equiped

with listed rack or approved

facility

(Clause 2-7.3)

N/A Each 1 1/2" hose station with

less than 1 1/2" hose shall be

equiped with listed continous

flow reel

(Clause 2-7.3)

4.6k Hose Station - Nozzle Yes Listed for class II MR

(Clause 2-7.4)

4.7k Hose Station - Label No label " fire hose for use by SRAP

occupants" and operating

instructions shall be available

on each rack

(Clause 2-7.5)

Doc.: 2951-CL-001 Rev.0 Page 45

NA - NOT APPLICABLE

CHECKLIST/ SURVEY REPORT SRAP - SEE REMEDIAL

ACTION PLAN

STAGE-I (GAP ANALYSIS OF EXISTING FIRE MR - MEETS REQUIREMENT

NR - NOT REQUIRED

FIGHTING SYSTEM AT PSO HOUSE-CLIFTON)

S.NO. DESCRIPTION EXISTING NFPA REMARKS

REQUIREMENT

4.8k Hose Connection Yes Hose connection externally MR

threaded per NFPA 1963 shall

be equiped wuth cap

(Clause 2-8)

4.9k Type of Standpipe System Automatic Wet Automatic Dry, Automatic Wet

Semi-Automatic Dry,

Manual Dry & Manual Wet

(Clause 3-2)

4.10k Class of Standpipe System Class II Class I, Class II & Class III

(Clause 3-3)

4.11k Isolation Valves No Isolation Valve should be SRAP

provided at each standpipe.

(Clause 4-2.2)

4.12 k (i) Drains No Each standpipe shall have

draining system at downstream of SRAP

isolation valve

(Clause 5-11.1)

4.12 k (ii) No Sizes as per Standpipe : SRAP

Upto 2" : 3/4" or lrager

2 1/2" to 3 1/2" : 1 1/4" or lrager

4" or > : 2" only

(Clause 5-11.2)

Doc.: 2951-CL-001 Rev.0 Page 46

NA - NOT APPLICABLE

CHECKLIST/ SURVEY REPORT SRAP - SEE REMEDIAL

ACTION PLAN

STAGE-I (GAP ANALYSIS OF EXISTING FIRE MR - MEETS REQUIREMENT

NR - NOT REQUIRED

FIGHTING SYSTEM AT PSO HOUSE-CLIFTON)

S.NO. DESCRIPTION EXISTING NFPA REMARKS

REQUIREMENT

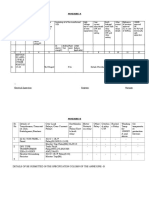

5.0 OTHER REQUIREMENTS

(a) FLOOR Ist

5.1a Fire Extinguisher

Type: DCP- 6 Kg Yes DCP- 6Kg (6 Nos.)

- MR

CO2 - 6 Kg CO2 - 6 Kg (4 Nos.)

5.2a Inergen System / CO2 System - - -

5.3a FM 200 System - - -

5.0 OTHER REQUIREMENTS

(b) FLOOR 2nd

5.1b Fire Extinguisher

Type: DCP- 6 Kg Yes DCP- 6Kg (5 Nos.)

- MR

CO2 - 6 Kg CO2 - 6 Kg (3 Nos.)

5.2b Inergen System / CO2 System - - -

5.3b FM 200 System Yes (Server Room) - MR

5.0 OTHER REQUIREMENTS

(c) FLOOR 3rd

5.1c Fire Extinguisher

Type: DCP- 6 Kg Yes DCP- 6Kg (5 Nos.)

- SRAP

CO2 - 6 Kg CO2 - 6 Kg (5 Nos.)

5.2c Inergen System / CO2 System - - -

5.3c FM 200 System - - -

5.0 OTHER REQUIREMENTS

(d) FLOOR 4th

5.1d Fire Extinguisher

Type: DCP- 6 Kg Yes DCP- 6Kg (5 Nos.)

- MR

CO2 - 6 Kg CO2 - 6 Kg (2 Nos.)

5.2d Inergen System / CO2 System - - -

5.3d FM 200 System - - -

5.0 OTHER REQUIREMENTS

(e) FLOOR 5th

5.1e Fire Extinguisher

Type: DCP- 6 Kg Yes DCP- 6Kg (5 Nos.)

- MR

CO2 - 6 Kg CO2 - 6 Kg (3 Nos.)

5.2e Inergen System / CO2 System - - -

5.3e FM 200 System - - -

5.0 OTHER REQUIREMENTS

(f) FLOOR 6th

5.1f Fire Extinguisher

Type: DCP- 6 Kg Yes DCP- 6Kg (5 Nos.)

- MR

CO2 - 6 Kg CO2 - 6 Kg (3 Nos.)

5.2f Inergen System / CO2 System - - -

5.3f FM 200 System - - -

Doc.: 2951-CL-001 Rev.0 Page 47

NA - NOT APPLICABLE

CHECKLIST/ SURVEY REPORT SRAP - SEE REMEDIAL

ACTION PLAN

STAGE-I (GAP ANALYSIS OF EXISTING FIRE MR - MEETS REQUIREMENT

NR - NOT REQUIRED

FIGHTING SYSTEM AT PSO HOUSE-CLIFTON)

S.NO. DESCRIPTION EXISTING NFPA REMARKS

REQUIREMENT

5.0 OTHER REQUIREMENTS

(g) FLOOR 7th

5.1g Fire Extinguisher

Type: DCP- 6 Kg Yes DCP- 6Kg (5 Nos.)

- MR

CO2 - 6 Kg CO2 - 6 Kg (3 Nos.)

5.2g Inergen System / CO2 System - - -

5.3g FM 200 System - - -

5.0 OTHER REQUIREMENTS

(h) FLOOR 8th

5.1h Fire Extinguisher

Type: DCP- 6 Kg Yes DCP- 6Kg (5 Nos.)

- MR

CO2 - 6 Kg CO2 - 6 Kg (3 Nos.)

5.2h Inergen System / CO2 System - - -

5.3h FM 200 System Yes (IT Room) - MR

5.0 OTHER REQUIREMENTS

(i) FLOOR 9th

5.1i Fire Extinguisher

Type: DCP- 6 Kg Yes DCP- 6Kg (4 Nos.) - SRAP

5.2i Inergen System / CO2 System - - -

5.3i FM 200 System - - -

5.0 OTHER REQUIREMENTS

(j) FLOOR Ground

5.1j Fire Extinguisher

Type: DCP- 6 Kg Yes DCP- 6Kg (6 Nos.)

- SRAP

CO2 - 6 Kg CO2 - 6 Kg (3 Nos.)

5.2j Inergen System / CO2 System No (Generator Room) - SRAP

5.3j FM 200 System - - -

5.0 OTHER REQUIREMENTS

(k) FLOOR Basement

5.1k Fire Extinguisher

Type: DCP- 6 Kg Yes DCP- 6Kg (8 Nos.)

- SRAP

CO2 - 6 Kg CO2 - 50 Kg (2 Nos.)

5.2k Inergen System / CO2 System No (Generator Room) - SRAP

No (K.E.S.C. Room)

No (A.C. Plant Room)

5.3k FM 200 System - - -

Doc.: 2951-CL-001 Rev.0 Page 48

You might also like

- Grating Design ReportDocument28 pagesGrating Design ReportnvnagarajuNo ratings yet

- 12 5 16 MVA Power Transformer Data Sheet PDFDocument5 pages12 5 16 MVA Power Transformer Data Sheet PDFajaymannNo ratings yet

- Cable Sizing CalculationDocument72 pagesCable Sizing CalculationHARI my songs100% (3)

- ANALYSIUSDocument2 pagesANALYSIUSLoren ViejayNo ratings yet

- J1237 Asian Paints HAZOP WSDocument98 pagesJ1237 Asian Paints HAZOP WSrohitkushNo ratings yet

- Asian Paints HAZOP WSDocument107 pagesAsian Paints HAZOP WSRaj Kumar100% (1)

- Candidate's Handbook: Iso 50001 Lead AuditorDocument16 pagesCandidate's Handbook: Iso 50001 Lead AuditorAbdul RahmanNo ratings yet

- API Standard 2000 - Venting Atmospheric and Low-Pressure Storage Tanks: Nonrefrigerated and RefrigeratedDocument5 pagesAPI Standard 2000 - Venting Atmospheric and Low-Pressure Storage Tanks: Nonrefrigerated and RefrigeratedNicolas CardonaNo ratings yet

- API Motor Data Sheet Temp LetDocument6 pagesAPI Motor Data Sheet Temp LetkhalidNo ratings yet

- Excel For Etabs Tutorial For RCDocument63 pagesExcel For Etabs Tutorial For RCchbarcenalNo ratings yet

- Concrete Structures For Retaining Aqueous Liquids - Code of PracticeDocument22 pagesConcrete Structures For Retaining Aqueous Liquids - Code of Practicematrix structuresNo ratings yet

- 132KV VT Test Report-Jumsouth Ss by PatrixDocument3 pages132KV VT Test Report-Jumsouth Ss by Patrixharihara_675292894No ratings yet

- 132KV VT Test Report-Jumsouth Ss Updated SIGNEDDocument3 pages132KV VT Test Report-Jumsouth Ss Updated SIGNEDharihara_675292894No ratings yet

- 132KV VT Test Report-Jumsouth Ss by PatrixDocument3 pages132KV VT Test Report-Jumsouth Ss by Patrixharihara_675292894No ratings yet

- 02 Electrical Power SystemsDocument40 pages02 Electrical Power SystemsLA ONDA TROPICAL TV MEXICONo ratings yet

- EDC-DTS-MV001 - Pole Mounted Three-Phase and Two-Phase Outdoor Distribution TransformersDocument69 pagesEDC-DTS-MV001 - Pole Mounted Three-Phase and Two-Phase Outdoor Distribution TransformersJoe bilouteNo ratings yet

- B.O.Q of Electro-Mechanical Works 6Document1 pageB.O.Q of Electro-Mechanical Works 6asdsd dsdaNo ratings yet

- Plumbing Water Supply Pump Head CalculationDocument4 pagesPlumbing Water Supply Pump Head Calculationsyed yaqubNo ratings yet

- EDC-DTS-MV002 - 22 KV Three-Phase Indoor Distribution TransformersDocument33 pagesEDC-DTS-MV002 - 22 KV Three-Phase Indoor Distribution TransformersJoe bilouteNo ratings yet

- ELSMT03DDocument4 pagesELSMT03DJhonny RinconesNo ratings yet

- 61404U JI N°x - Process Guidlines For PRV Design - Rev0Document26 pages61404U JI N°x - Process Guidlines For PRV Design - Rev0CristinaNo ratings yet

- Chapter 2 - Rev ADocument29 pagesChapter 2 - Rev AAenur RofiiqNo ratings yet

- NGR Sizing Calculation-MURALIDocument16 pagesNGR Sizing Calculation-MURALIsureshn82960650% (4)

- Pre-Commissioning Test Report of TransformerDocument2 pagesPre-Commissioning Test Report of TransformerBIRANCHINo ratings yet

- CWC Mec DTS P001abcdDocument8 pagesCWC Mec DTS P001abcdAlonso1593No ratings yet

- Pragyan: Uppsc Ae 2021 Civil Engineering Test-07 Detailed SolutionsDocument11 pagesPragyan: Uppsc Ae 2021 Civil Engineering Test-07 Detailed SolutionsThanosh MishraNo ratings yet

- 2SRD AnalysisReport 11132020 PDFDocument25 pages2SRD AnalysisReport 11132020 PDFJuncel BayogoNo ratings yet

- ANZ-DS-E-5017 Power TransformersDocument18 pagesANZ-DS-E-5017 Power Transformersmika cabelloNo ratings yet

- 404 Bus 2 CVT 181021030334Document6 pages404 Bus 2 CVT 181021030334SARAVANAN ANo ratings yet

- Data SheetDocument21 pagesData SheetmizharmuisstNo ratings yet

- 201 - M CVTDocument3 pages201 - M CVTAshutosh KumarNo ratings yet

- Rebound Hammer FormDocument2 pagesRebound Hammer FormAhmad Syauqi Abd RazakNo ratings yet

- DT-Dry Type Data SheetDocument3 pagesDT-Dry Type Data SheetArnold StevenNo ratings yet

- Design Criteria: First FloorDocument2 pagesDesign Criteria: First FloorDave Khyl Josol BosqueNo ratings yet

- Current Transformer Test: Power Supply To Plot P18 at Zayed Military City D108337 SWH38A1Document3 pagesCurrent Transformer Test: Power Supply To Plot P18 at Zayed Military City D108337 SWH38A1Jayaprakash M PNo ratings yet

- HT AppForm - Modified 04092018Document5 pagesHT AppForm - Modified 04092018mayankNo ratings yet

- HT AppForm - Modified 04092018Document5 pagesHT AppForm - Modified 04092018mayankNo ratings yet

- KE3-TBE-ELC-0908-6093 - TBE For TR-REV-ADocument3 pagesKE3-TBE-ELC-0908-6093 - TBE For TR-REV-ASUBAS CHANDRA BEHERANo ratings yet

- ANZ-DS-E-5013 HV IsolatorsDocument17 pagesANZ-DS-E-5013 HV Isolatorsmika cabelloNo ratings yet

- HP22-07-C04-001-02 Sub Structure Power HouseDocument46 pagesHP22-07-C04-001-02 Sub Structure Power HouseZulkifli Basri100% (1)

- Loads List by Spec Equipment Area WWTP3 (Juli 2022)Document3 pagesLoads List by Spec Equipment Area WWTP3 (Juli 2022)Reza SyailendraNo ratings yet

- Notice No.3: Rules and Regulations For TheDocument8 pagesNotice No.3: Rules and Regulations For Thepaparis54gmail.comNo ratings yet

- Anexo 14 ELK-04-GIS - Standard Data Sheet - Rev ADocument10 pagesAnexo 14 ELK-04-GIS - Standard Data Sheet - Rev Apablo.jaraNo ratings yet

- Power Trafo - SAT - T-1Document15 pagesPower Trafo - SAT - T-1imranNo ratings yet

- Renewable Energy Code For The Transmission System, 2015Document22 pagesRenewable Energy Code For The Transmission System, 2015José Miguel Martínez ValerNo ratings yet

- R30 FindingsDocument9 pagesR30 FindingsSARDIFRANC HUTAGALUNGNo ratings yet

- ENI Tubular Goods-BookletDocument46 pagesENI Tubular Goods-BookletWell ControlNo ratings yet

- ML-E Tech ReferenceDocument99 pagesML-E Tech ReferenceSuriya PrakashNo ratings yet

- Inspection Report - Electrical WorkDocument9 pagesInspection Report - Electrical Workpremkumarance_999016No ratings yet

- Acacia Structural AnalysisDocument38 pagesAcacia Structural AnalysisJoshua LopezNo ratings yet

- TKT at 03 DS 2702 A R0 Data Sheet of 13.8 0.4KV, 2000KVA TransformersDocument3 pagesTKT at 03 DS 2702 A R0 Data Sheet of 13.8 0.4KV, 2000KVA TransformersLam Duy TienNo ratings yet

- Anexo 15 PDTG Gis - en 0425Document29 pagesAnexo 15 PDTG Gis - en 0425pablo.jaraNo ratings yet

- FSS 971 40SS 0001 - 1Document34 pagesFSS 971 40SS 0001 - 1Victor Eduardo Gonzalez RojasNo ratings yet

- MM 15-9-2021Document1 pageMM 15-9-2021Fateh Ali KhanNo ratings yet

- Assembly Building D7Document1 pageAssembly Building D7Suthan JoshuaNo ratings yet

- Drg. & GTP - R1 - 11 KV HG Fuse - DiskitDocument4 pagesDrg. & GTP - R1 - 11 KV HG Fuse - DiskitAnand ShekharNo ratings yet

- Annex 6Document2 pagesAnnex 6venkateshbitraNo ratings yet

- Epc Package Gaderwara STPP Stage-Ii (2X800 MW) Ash Handling System & Ash Water Recirculation System Electrical Load ListDocument2 pagesEpc Package Gaderwara STPP Stage-Ii (2X800 MW) Ash Handling System & Ash Water Recirculation System Electrical Load ListvenkateshbitraNo ratings yet

- 2.1. Design ParametersDocument2 pages2.1. Design ParametersFarly VergelNo ratings yet

- HTTPSWWW - Carc.gov - Jositesdefaultfilesinline Filescontrolof Obstacles34gm Obsc PDFDocument63 pagesHTTPSWWW - Carc.gov - Jositesdefaultfilesinline Filescontrolof Obstacles34gm Obsc PDFDipendra ShresthaNo ratings yet

- Integrated Circuits, Silicon Monolithic, Hcmos Quad 2-Input Nor Gates With Fully Buffered OutputsDocument24 pagesIntegrated Circuits, Silicon Monolithic, Hcmos Quad 2-Input Nor Gates With Fully Buffered OutputsOMAR MARTINEZNo ratings yet

- Groundwater Hydrology: Conceptual and Computational ModelsFrom EverandGroundwater Hydrology: Conceptual and Computational ModelsRating: 5 out of 5 stars5/5 (1)

- Water Flow Switch: Model: SD-WFD SeriesDocument3 pagesWater Flow Switch: Model: SD-WFD SeriesAbdul RahmanNo ratings yet

- Classification Labelling o EquipmentDocument1 pageClassification Labelling o EquipmentAbdul RahmanNo ratings yet

- Panel Hospital List IGIDocument6 pagesPanel Hospital List IGIAbdul RahmanNo ratings yet

- Dust CloudDocument12 pagesDust CloudAbdul RahmanNo ratings yet

- Risk Analysis and Safety in LPG Storage: The Indexed Method: M. Mariani & M. R. VallerotondaDocument10 pagesRisk Analysis and Safety in LPG Storage: The Indexed Method: M. Mariani & M. R. VallerotondaAbdul RahmanNo ratings yet

- Technical Specifications of Instrumentation and Control Cables 1. Instrumentation Cable: Single PairDocument8 pagesTechnical Specifications of Instrumentation and Control Cables 1. Instrumentation Cable: Single PairAbdul RahmanNo ratings yet

- Specifications Threaded Rod 67030045Document3 pagesSpecifications Threaded Rod 67030045Abdul RahmanNo ratings yet

- Threaded Rod: Product SubmittedDocument1 pageThreaded Rod: Product SubmittedAbdul RahmanNo ratings yet

- Alkaline Earth Metals: General Properties of IIA Group ElementsDocument4 pagesAlkaline Earth Metals: General Properties of IIA Group Elementsswamy ChinthalaNo ratings yet

- 1986 - Arnold First Steps in Symplectic TopologyDocument22 pages1986 - Arnold First Steps in Symplectic TopologyJunjie Luo100% (1)

- Procedimiento de Reemplazo de CojinetesDocument32 pagesProcedimiento de Reemplazo de CojinetesJavier Hector CayaNo ratings yet

- Physical - Chemistry - 3th - Castellan 801 860 32 35Document4 pagesPhysical - Chemistry - 3th - Castellan 801 860 32 35Mira YuliartiNo ratings yet

- Soil NoteDocument13 pagesSoil NoteBhuwan JoshiNo ratings yet

- Making Conductive Ink Using Old Batteries, Pencil Lead, and Activated Charcoal With Glue and PaintDocument11 pagesMaking Conductive Ink Using Old Batteries, Pencil Lead, and Activated Charcoal With Glue and PaintGuian EitoNo ratings yet

- Smart Timer Manual ME 8930Document40 pagesSmart Timer Manual ME 8930Moises JustavinoNo ratings yet

- 06.experimental and Numerical Investigation of Reinforced Concrete Slabs Under Blast LoadingDocument13 pages06.experimental and Numerical Investigation of Reinforced Concrete Slabs Under Blast LoadingPennarasiNo ratings yet

- Impact of Mass and Deformation On The Gearbox of Large Wind TurbinesDocument134 pagesImpact of Mass and Deformation On The Gearbox of Large Wind TurbinesTarek MagdyNo ratings yet

- Work Environment DesignDocument30 pagesWork Environment DesignMoti TadegeNo ratings yet

- Reflection of LightDocument35 pagesReflection of Lightcharlesferrer718No ratings yet

- Data SheetDocument4 pagesData SheetRachel FloresNo ratings yet

- Berekening Van Een CirkelsegmentDocument2 pagesBerekening Van Een Cirkelsegmentuser 54No ratings yet

- 12.5 Meter Technical Data SheetDocument23 pages12.5 Meter Technical Data SheetrituNo ratings yet

- HYW 45 T5 (YANMAR - 4TNV98T GGEH) (Soundproof B10) ENDocument11 pagesHYW 45 T5 (YANMAR - 4TNV98T GGEH) (Soundproof B10) ENRoman ChubaNo ratings yet

- PX Model NomenclatureDocument1 pagePX Model NomenclaturenammarisNo ratings yet

- RS-LiDAR-32 Brochure EN 20200306Document2 pagesRS-LiDAR-32 Brochure EN 20200306nazi1945No ratings yet

- Flow in ConduitsDocument29 pagesFlow in ConduitsEngr Sabiul AlamNo ratings yet

- Assignment 1 ONSDocument4 pagesAssignment 1 ONSVanita ShirsathNo ratings yet

- Nonlinear Modeling of RC Structures Using Opensees: University of Naples Federico IiDocument66 pagesNonlinear Modeling of RC Structures Using Opensees: University of Naples Federico IiJorge Luis Garcia ZuñigaNo ratings yet

- Atoms, Molecules, and IonsDocument54 pagesAtoms, Molecules, and Ionsarsekerci813601No ratings yet

- M Series Product Data Sheet EnglishDocument2 pagesM Series Product Data Sheet EnglishAZMI YAHAYANo ratings yet

- CE Laboratory ApparatusDocument11 pagesCE Laboratory ApparatusMong PhannaNo ratings yet

- Identify Right Triangle 1Document2 pagesIdentify Right Triangle 1MittalNo ratings yet

- L9-Thermal RadiationDocument37 pagesL9-Thermal RadiationskNo ratings yet

- Index of Refraction Lab Lesson Plan E-Portfolio VersionDocument8 pagesIndex of Refraction Lab Lesson Plan E-Portfolio Versionapi-668691050No ratings yet

- Abstract Algebra by Rashid AliDocument274 pagesAbstract Algebra by Rashid Alisaba nazNo ratings yet

- Comparison of Polytropic and Isentropic Efficiency of Natural Gas Compressor Calculated Using Aspen HYSYS & Using Manual CalDocument22 pagesComparison of Polytropic and Isentropic Efficiency of Natural Gas Compressor Calculated Using Aspen HYSYS & Using Manual CaljrfmlNo ratings yet

- Tratos FlexDocument40 pagesTratos FlexSyarief100% (1)