Professional Documents

Culture Documents

Caesar II Determines

Caesar II Determines

Uploaded by

Martin VenichCopyright:

Available Formats

You might also like

- Ware House Purlin DesignDocument4 pagesWare House Purlin DesignSuhail Ahamed100% (1)

- An Extension of Newton-Type Algorithms For Nonlinear Process ControlDocument6 pagesAn Extension of Newton-Type Algorithms For Nonlinear Process ControlGustavo Gabriel Jimenez100% (1)

- FRP Vessel Calc Asme RTP 1Document7 pagesFRP Vessel Calc Asme RTP 1GautamNo ratings yet

- 8 CW 5-2Document2 pages8 CW 5-2Kayla IkumaNo ratings yet

- Lug Analysis - MechaniCalcDocument26 pagesLug Analysis - MechaniCalcgbscribd73No ratings yet

- Conductor Sag and Tension CalculatorDocument12 pagesConductor Sag and Tension CalculatorJetn SrisuthumNo ratings yet

- IBR Design Calculations - FinalDocument6 pagesIBR Design Calculations - Finalshazan100% (1)

- Base Plate DesignDocument21 pagesBase Plate Designtitir bagchi100% (1)

- Ejma 2000Document7 pagesEjma 2000jhunkujha11No ratings yet

- DEEP BEAM DesignDocument2 pagesDEEP BEAM DesignmangeshNo ratings yet

- Design of Purlin & Runner-Ro-Final-Rev-0Document8 pagesDesign of Purlin & Runner-Ro-Final-Rev-0Sabrina ImloulNo ratings yet

- Anchore Bolt DesignDocument12 pagesAnchore Bolt DesignPradip NikamNo ratings yet

- Steel ConDocument8 pagesSteel Conkheang mengNo ratings yet

- Base Plate DesignDocument14 pagesBase Plate Designsoumi bhattacharyaNo ratings yet

- Skirt Support Analysis TransportDocument5 pagesSkirt Support Analysis TransportHunnymijie NorNo ratings yet

- 0.0bolt Torque Calculation - R0Document9 pages0.0bolt Torque Calculation - R0Darshan PanchalNo ratings yet

- RIBBED SLAB DESIGN To BS 81101997 Using Table 3.12 CoefficientsDocument8 pagesRIBBED SLAB DESIGN To BS 81101997 Using Table 3.12 CoefficientsShekh Muhsen Uddin AhmedNo ratings yet

- D Concretestruc N20Document8 pagesD Concretestruc N20kuttyNo ratings yet

- RCC92 Ribbed Slabs (Tables)Document8 pagesRCC92 Ribbed Slabs (Tables)lucianduNo ratings yet

- STD01-beam DesignDocument12 pagesSTD01-beam DesignAamir SuhailNo ratings yet

- Calculation Sheet For Slug CatcherDocument12 pagesCalculation Sheet For Slug CatcherchumaNo ratings yet

- Gb1 Pump Room 13nov2013Document3 pagesGb1 Pump Room 13nov2013Erickson MalicsiNo ratings yet

- Rob RCD.3Document3,258 pagesRob RCD.3RobbieNo ratings yet

- Baseplate-Kolom wf250Document79 pagesBaseplate-Kolom wf250Gary JonathanNo ratings yet

- Ibr Stand PipeDocument11 pagesIbr Stand PipeP s JagatheesanNo ratings yet

- Ribbed Slab Design-1Document2 pagesRibbed Slab Design-1HAITHAM ALI100% (2)

- Beam (Flexure & Shear)Document9 pagesBeam (Flexure & Shear)DHYEY PARMARNo ratings yet

- RCC94 Two Way Slabs (Tables) MCY RF CTDocument1 pageRCC94 Two Way Slabs (Tables) MCY RF CTYati ChanNo ratings yet

- RCC92 Ribbed Slabs (Tables)Document7 pagesRCC92 Ribbed Slabs (Tables)Cioabla BogdanNo ratings yet

- HSS Column Base Plate DesignDocument10 pagesHSS Column Base Plate DesignjatinNo ratings yet

- GB2 - Pump Room - 13NOV2013Document3 pagesGB2 - Pump Room - 13NOV2013Erickson MalicsiNo ratings yet

- 05 CalDocument53 pages05 Calnatarajan RavisankarNo ratings yet

- API 650 RF Pad Calculation PDFDocument1 pageAPI 650 RF Pad Calculation PDFRakeshNo ratings yet

- API 650 RF Pad Calculation PDFDocument1 pageAPI 650 RF Pad Calculation PDFBimal DeyNo ratings yet

- Dimensions Materials Status: Spreadsheets To Eurocode 2Document1 pageDimensions Materials Status: Spreadsheets To Eurocode 2jasekan.dcNo ratings yet

- Conductor Sag and Tension CalculatorDocument11 pagesConductor Sag and Tension CalculatorSanjeev KumarNo ratings yet

- Nozzle Reinforcement Calculation Excel SheetDocument3 pagesNozzle Reinforcement Calculation Excel Sheetramesh punjabiNo ratings yet

- Larsen & Toubro Limited: ECC Division - EDRCDocument10 pagesLarsen & Toubro Limited: ECC Division - EDRCNeeraj DubeyNo ratings yet

- Contact Stress Two CylindersDocument3 pagesContact Stress Two CylindersEng-CalculationsNo ratings yet

- Backing Ring CalculationDocument11 pagesBacking Ring CalculationAhmad FaujiNo ratings yet

- TorsionDocument27 pagesTorsioncriscab12345No ratings yet

- Base Plate SizingDocument200 pagesBase Plate SizingNaresh SNo ratings yet

- ACI Section Crack Width ControlDocument6 pagesACI Section Crack Width ControlImaduddin KhajaNo ratings yet

- Base Plate Design ExampleDocument74 pagesBase Plate Design ExampleNiko NištićNo ratings yet

- 30m Anchor and Base Plate MonopoleDocument6 pages30m Anchor and Base Plate MonopoleEhtesham AliNo ratings yet

- Skirt Opening R-201Document9 pagesSkirt Opening R-201Anonymous qUMJ27ITQsNo ratings yet

- Soil Nail ReportDocument9 pagesSoil Nail ReportUtsav ShrivastavaNo ratings yet

- Design Calculation of Shaft/Pin/Axle: 1.0 Basic DataDocument3 pagesDesign Calculation of Shaft/Pin/Axle: 1.0 Basic DatapkvchoudharyNo ratings yet

- Base Slab & Crack Width Check - ACI CodeDocument6 pagesBase Slab & Crack Width Check - ACI CodensureshbabuNo ratings yet

- Base Plate JPDocument2 pagesBase Plate JPNaresh SNo ratings yet

- Trunnion AnalysisDocument45 pagesTrunnion AnalysisChiragJansariNo ratings yet

- H.1 - Gusset Plate - DeckDocument12 pagesH.1 - Gusset Plate - Deckchristi SNo ratings yet

- BS8110 Beam With DeflectionDocument3 pagesBS8110 Beam With DeflectionFrederick TanNo ratings yet

- Design of Base PlateDocument161 pagesDesign of Base PlatemaheshbandhamNo ratings yet

- Superb Doubly Reinforced BEAMDocument3 pagesSuperb Doubly Reinforced BEAMSandeep VarmaNo ratings yet

- Spreader Calculation (ISMC-200)Document4 pagesSpreader Calculation (ISMC-200)mechmohan26No ratings yet

- RC Beam - Singly - NSCP 2015 by RgceDocument4 pagesRC Beam - Singly - NSCP 2015 by RgceJet ToledoNo ratings yet

- SUMMARYCCCCCDocument17 pagesSUMMARYCCCCCShawkat Ali KhanNo ratings yet

- CATENARY SAG-TENSION CALCULATOR (By: Jared Cuchapin, 2018) : 300 DrakeDocument12 pagesCATENARY SAG-TENSION CALCULATOR (By: Jared Cuchapin, 2018) : 300 Drakedursun_yerlikaya100% (2)

- ASME B31.4-Wall Thickness CalDocument2 pagesASME B31.4-Wall Thickness CalBagus Sukoco Koco100% (1)

- Design of Reinforced Concrete Beam Version 2.0 Reference Code: Beam ID: Design Status: Valid Design!Document2 pagesDesign of Reinforced Concrete Beam Version 2.0 Reference Code: Beam ID: Design Status: Valid Design!Raymundo GirayNo ratings yet

- Crack Width BS5400Document3 pagesCrack Width BS5400yuNo ratings yet

- Advanced Uses For Micro Saint Simulation SoftwareDocument4 pagesAdvanced Uses For Micro Saint Simulation SoftwareMartin VenichNo ratings yet

- Data UtilityDocument45 pagesData UtilityMartin VenichNo ratings yet

- MapleNet BrochureDocument4 pagesMapleNet BrochureMartin VenichNo ratings yet

- Sensor Interface Design With Worst Case Analysis - Vol1.flowDocument5 pagesSensor Interface Design With Worst Case Analysis - Vol1.flowMartin VenichNo ratings yet

- hw4 Solution NumericsDocument5 pageshw4 Solution NumericsMartin VenichNo ratings yet

- Computer Simulation of The 7 62mm TT Pistol External Ballistics Using Two Different Air Resistance LawsDocument30 pagesComputer Simulation of The 7 62mm TT Pistol External Ballistics Using Two Different Air Resistance LawsMartin VenichNo ratings yet

- Application Pack 2:: PWM Based H-Bridge Power ControlDocument6 pagesApplication Pack 2:: PWM Based H-Bridge Power ControlMartin VenichNo ratings yet

- Piping Solutions MathcadDocument20 pagesPiping Solutions MathcadMartin Venich100% (1)

- Vissim/Fixed P Vissim/Fixed P Vissim/Fixed P Vissim/Fixed P Vissim/Fixed Point Oint Oint Oint OintDocument1 pageVissim/Fixed P Vissim/Fixed P Vissim/Fixed P Vissim/Fixed P Vissim/Fixed Point Oint Oint Oint OintMartin VenichNo ratings yet

- Optimizing The Design of A Helical SpringDocument4 pagesOptimizing The Design of A Helical SpringMartin VenichNo ratings yet

- Robot Arm Writing MaplesoftDocument12 pagesRobot Arm Writing MaplesoftMartin VenichNo ratings yet

- Application Pack 6:: Automatic OptimisationDocument5 pagesApplication Pack 6:: Automatic OptimisationMartin VenichNo ratings yet

- Vissim/C-Vissim/C - Vissim/C - Vissim/C - Vissim/C-Code Code Code Code CodeDocument1 pageVissim/C-Vissim/C - Vissim/C - Vissim/C - Vissim/C-Code Code Code Code CodeMartin VenichNo ratings yet

- Advances in Engineering Software: Gürol Yıldırım, Vijay P. SinghDocument8 pagesAdvances in Engineering Software: Gürol Yıldırım, Vijay P. SinghMartin VenichNo ratings yet

- Professional Vissim: Dynamic Modeling and Simulation SoftwareDocument2 pagesProfessional Vissim: Dynamic Modeling and Simulation SoftwareMartin VenichNo ratings yet

- Application Pack 4:: Real-Time Simulation With Data Acquisition CardsDocument8 pagesApplication Pack 4:: Real-Time Simulation With Data Acquisition CardsMartin VenichNo ratings yet

- Application Pack 3:: Visual Programming For Low-Cost Industrial DspsDocument8 pagesApplication Pack 3:: Visual Programming For Low-Cost Industrial DspsMartin VenichNo ratings yet

- United Kingdom Standard Perpetual: Matlab SimulinkDocument9 pagesUnited Kingdom Standard Perpetual: Matlab SimulinkMartin VenichNo ratings yet

- Braking Distance of A Skidding CarDocument3 pagesBraking Distance of A Skidding CarMartin VenichNo ratings yet

- For Ideal Beam in Socket: 7250.0 Lb/in - 12250.0 Lb/inDocument7 pagesFor Ideal Beam in Socket: 7250.0 Lb/in - 12250.0 Lb/inMartin VenichNo ratings yet

- Angle Fitting - Niu Method: Element X y X y (In) (In) (In) (In) yDocument5 pagesAngle Fitting - Niu Method: Element X y X y (In) (In) (In) (In) yMartin VenichNo ratings yet

- WIND LOADING ANALYSIS - Wall Components and Cladding: Input DataDocument15 pagesWIND LOADING ANALYSIS - Wall Components and Cladding: Input DataMartin VenichNo ratings yet

- Example J.7 Base Plate Bearing On Concrete: = P / (Φ · 0.85f') = Bn = B D = Φ · 0.85f' A min (2, (A / A) )Document2 pagesExample J.7 Base Plate Bearing On Concrete: = P / (Φ · 0.85f') = Bn = B D = Φ · 0.85f' A min (2, (A / A) )Martin VenichNo ratings yet

- Free Vibration of LTMDocument18 pagesFree Vibration of LTMSourabhYadavNo ratings yet

- GATE Thermodynamics Questions - Mechanical Engineering TutorialsDocument16 pagesGATE Thermodynamics Questions - Mechanical Engineering Tutorialsmahendra shakyaNo ratings yet

- May 21 U4 QPDocument32 pagesMay 21 U4 QPHasin RahmanNo ratings yet

- Chapter Two: Synthesis, Characterization of Semicarbazide and Thiosemicarbazide Based Ligands and Their ComplexesDocument38 pagesChapter Two: Synthesis, Characterization of Semicarbazide and Thiosemicarbazide Based Ligands and Their ComplexesJallow KowlyNo ratings yet

- A MODIFIED PENG ROBINSON EQUATION OF STATE FOR ELV 20519 FTP PDFDocument16 pagesA MODIFIED PENG ROBINSON EQUATION OF STATE FOR ELV 20519 FTP PDFalex rene cardonaNo ratings yet

- 096 09247 03 - TDSDocument2 pages096 09247 03 - TDSMuhamad Samsul BahriNo ratings yet

- Chapter 2 Force and Motion (Answer)Document108 pagesChapter 2 Force and Motion (Answer)Nadia SaidonNo ratings yet

- Schedule - JEE Advanced Crash Course 2024Document2 pagesSchedule - JEE Advanced Crash Course 2024saurav.saha1984No ratings yet

- FYP PresentationDocument19 pagesFYP PresentationAsad TararNo ratings yet

- General Relativity - Tom MarshDocument104 pagesGeneral Relativity - Tom MarshMemo SaucedoNo ratings yet

- Flow ChartDocument2 pagesFlow ChartJames PerriamNo ratings yet

- Mechanics of Fluids Si Edition 5th Edition Potter Test BankDocument3 pagesMechanics of Fluids Si Edition 5th Edition Potter Test Bankwalleyeemploye2g100% (28)

- Design Report: HAWT Graduation ProjectDocument30 pagesDesign Report: HAWT Graduation ProjectMohamed MedhatNo ratings yet

- Angular Momentum: Reading: Chapter 11 (11-7 To 11-12)Document11 pagesAngular Momentum: Reading: Chapter 11 (11-7 To 11-12)Arafat AnikNo ratings yet

- We Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsDocument21 pagesWe Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsAllan PaoloNo ratings yet

- CH - 2 p1 DynaDocument11 pagesCH - 2 p1 DynaFikadu BelaynehNo ratings yet

- Me6411 Manufacturing Technology-II Lab ManualDocument35 pagesMe6411 Manufacturing Technology-II Lab ManualdibyenindusNo ratings yet

- Turk Indutive Speed Sensor PDFDocument3 pagesTurk Indutive Speed Sensor PDFAhmad DagamsehNo ratings yet

- Arches Vaults and Dome FinalDocument39 pagesArches Vaults and Dome FinalPratima Mahesh0% (1)

- Waveguides: The Symmetric Slab WaveguideDocument26 pagesWaveguides: The Symmetric Slab WaveguidemstefaneNo ratings yet

- tp2 Systc3a8mes Asservis Numc3a9riquesDocument1 pagetp2 Systc3a8mes Asservis Numc3a9riquesomarNo ratings yet

- 10th Class Past Papers BISE Sahiwal G 2 Previous Papers NOTESPK CompressedDocument16 pages10th Class Past Papers BISE Sahiwal G 2 Previous Papers NOTESPK CompressedFaisal RasheedNo ratings yet

- Waste Glass: Table 5.1 Types of Glass and Their Main UsesDocument2 pagesWaste Glass: Table 5.1 Types of Glass and Their Main UsesGowri J BabuNo ratings yet

- 04 ECE405Tut 2013 Solution PDFDocument8 pages04 ECE405Tut 2013 Solution PDFDavy MardamootooNo ratings yet

- Ntse Phy Che MaterialDocument68 pagesNtse Phy Che Materialabirami.narayanan857100% (1)

- Physical Geodesy100Document23 pagesPhysical Geodesy100EfrenNo ratings yet

- Keele (1983-10 AES Preprint) - Horn Covers Flat Rectangular AreaDocument22 pagesKeele (1983-10 AES Preprint) - Horn Covers Flat Rectangular AreaBob BeduneauNo ratings yet

Caesar II Determines

Caesar II Determines

Uploaded by

Martin VenichOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Caesar II Determines

Caesar II Determines

Uploaded by

Martin VenichCopyright:

Available Formats

Caesar II Determines

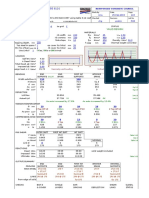

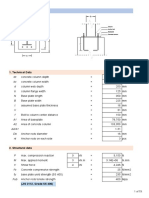

Design Code ASME B31.4 Pipeline Material API 5L Gr. X60

Design Pressure P 4.75MPa Design Temperature T max 50 °C

Outside Diameter Do 914.4mm Wall Thickness tn 13.7mm

Young Modulus E 201790MPa Poisson's Ratio ν 0.3

1

Coefficient of Thermal Expansion α 0.000340 Δ°C Axial Force (from C II file) Fa 3760.735kN

Installation Temperature T i 21 °C

Thermal Force

π

Do Di

2 2 2

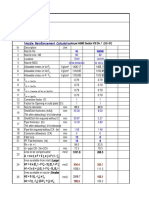

Inside Diameter Di Do 2 tn 887 mm Area1

4 38765.97 mm

Thermal_Force E α T max T i Area1 Thermal_Force 77130.68 kN

Bourdon Force

π 2 2

Area2 Di 617926.93 mm

4

Bourdon_Force ( 1 2 ν) P Area2 Bourdon_Force 1174.06 kN

Determines the stress equation based on

Limiting_Force Thermal_Force Bourdon_Force 78304.74 kN

Delta = Limiting Force + Local Axial Force Delta Limiting_Force Fa 82065.48 kN

Delta

1.048

Limiting_Force

Delta

Stress_Equation "Fully Restrained" if 0.025

Limiting_Force

"Unrestrained" otherwise

Stress_Equation "Unrestrained"

But the C-II output report shows Fully-Restrained Stress Equation

Node Axial Bending Torsion Hoop OCTAHEDRA SIF/Ind SIF/Ind Code Allow abl Ratio % Piping

Stress Stress Stress Stress L Stress ex In- ex Out- Stress e Stress Code

N./sq.m m . N./sq.m N./sq.m m . N./sq.m N./sq.m m . Plane Plane N./sq.m N./sq.m

m. m. m. m.

2210 -21.3 12.54 0 158.52 196.98 1 1 158.52 297.85 53.22 B31.4/R

2211 -21.3 4.14 0 158.52 191.04 1 1 158.52 297.85 53.22 B31.4/R

Node Axial Shear Bending Torsion FX N. FY N. FZ N. MX N.m . MY N.m . MZ N.m . Elem ent

Force N. Force N. Mom ent Mom ent Nam e

N.m . N.m .

2210 3760735 17002 107846 -36 3760346 54304 -16405 -506 -8 -107845

2211 -3760735 17002 35633 36 -3760346 -54304 16405 191 -6 35633

Page 1 of 1

You might also like

- Ware House Purlin DesignDocument4 pagesWare House Purlin DesignSuhail Ahamed100% (1)

- An Extension of Newton-Type Algorithms For Nonlinear Process ControlDocument6 pagesAn Extension of Newton-Type Algorithms For Nonlinear Process ControlGustavo Gabriel Jimenez100% (1)

- FRP Vessel Calc Asme RTP 1Document7 pagesFRP Vessel Calc Asme RTP 1GautamNo ratings yet

- 8 CW 5-2Document2 pages8 CW 5-2Kayla IkumaNo ratings yet

- Lug Analysis - MechaniCalcDocument26 pagesLug Analysis - MechaniCalcgbscribd73No ratings yet

- Conductor Sag and Tension CalculatorDocument12 pagesConductor Sag and Tension CalculatorJetn SrisuthumNo ratings yet

- IBR Design Calculations - FinalDocument6 pagesIBR Design Calculations - Finalshazan100% (1)

- Base Plate DesignDocument21 pagesBase Plate Designtitir bagchi100% (1)

- Ejma 2000Document7 pagesEjma 2000jhunkujha11No ratings yet

- DEEP BEAM DesignDocument2 pagesDEEP BEAM DesignmangeshNo ratings yet

- Design of Purlin & Runner-Ro-Final-Rev-0Document8 pagesDesign of Purlin & Runner-Ro-Final-Rev-0Sabrina ImloulNo ratings yet

- Anchore Bolt DesignDocument12 pagesAnchore Bolt DesignPradip NikamNo ratings yet

- Steel ConDocument8 pagesSteel Conkheang mengNo ratings yet

- Base Plate DesignDocument14 pagesBase Plate Designsoumi bhattacharyaNo ratings yet

- Skirt Support Analysis TransportDocument5 pagesSkirt Support Analysis TransportHunnymijie NorNo ratings yet

- 0.0bolt Torque Calculation - R0Document9 pages0.0bolt Torque Calculation - R0Darshan PanchalNo ratings yet

- RIBBED SLAB DESIGN To BS 81101997 Using Table 3.12 CoefficientsDocument8 pagesRIBBED SLAB DESIGN To BS 81101997 Using Table 3.12 CoefficientsShekh Muhsen Uddin AhmedNo ratings yet

- D Concretestruc N20Document8 pagesD Concretestruc N20kuttyNo ratings yet

- RCC92 Ribbed Slabs (Tables)Document8 pagesRCC92 Ribbed Slabs (Tables)lucianduNo ratings yet

- STD01-beam DesignDocument12 pagesSTD01-beam DesignAamir SuhailNo ratings yet

- Calculation Sheet For Slug CatcherDocument12 pagesCalculation Sheet For Slug CatcherchumaNo ratings yet

- Gb1 Pump Room 13nov2013Document3 pagesGb1 Pump Room 13nov2013Erickson MalicsiNo ratings yet

- Rob RCD.3Document3,258 pagesRob RCD.3RobbieNo ratings yet

- Baseplate-Kolom wf250Document79 pagesBaseplate-Kolom wf250Gary JonathanNo ratings yet

- Ibr Stand PipeDocument11 pagesIbr Stand PipeP s JagatheesanNo ratings yet

- Ribbed Slab Design-1Document2 pagesRibbed Slab Design-1HAITHAM ALI100% (2)

- Beam (Flexure & Shear)Document9 pagesBeam (Flexure & Shear)DHYEY PARMARNo ratings yet

- RCC94 Two Way Slabs (Tables) MCY RF CTDocument1 pageRCC94 Two Way Slabs (Tables) MCY RF CTYati ChanNo ratings yet

- RCC92 Ribbed Slabs (Tables)Document7 pagesRCC92 Ribbed Slabs (Tables)Cioabla BogdanNo ratings yet

- HSS Column Base Plate DesignDocument10 pagesHSS Column Base Plate DesignjatinNo ratings yet

- GB2 - Pump Room - 13NOV2013Document3 pagesGB2 - Pump Room - 13NOV2013Erickson MalicsiNo ratings yet

- 05 CalDocument53 pages05 Calnatarajan RavisankarNo ratings yet

- API 650 RF Pad Calculation PDFDocument1 pageAPI 650 RF Pad Calculation PDFRakeshNo ratings yet

- API 650 RF Pad Calculation PDFDocument1 pageAPI 650 RF Pad Calculation PDFBimal DeyNo ratings yet

- Dimensions Materials Status: Spreadsheets To Eurocode 2Document1 pageDimensions Materials Status: Spreadsheets To Eurocode 2jasekan.dcNo ratings yet

- Conductor Sag and Tension CalculatorDocument11 pagesConductor Sag and Tension CalculatorSanjeev KumarNo ratings yet

- Nozzle Reinforcement Calculation Excel SheetDocument3 pagesNozzle Reinforcement Calculation Excel Sheetramesh punjabiNo ratings yet

- Larsen & Toubro Limited: ECC Division - EDRCDocument10 pagesLarsen & Toubro Limited: ECC Division - EDRCNeeraj DubeyNo ratings yet

- Contact Stress Two CylindersDocument3 pagesContact Stress Two CylindersEng-CalculationsNo ratings yet

- Backing Ring CalculationDocument11 pagesBacking Ring CalculationAhmad FaujiNo ratings yet

- TorsionDocument27 pagesTorsioncriscab12345No ratings yet

- Base Plate SizingDocument200 pagesBase Plate SizingNaresh SNo ratings yet

- ACI Section Crack Width ControlDocument6 pagesACI Section Crack Width ControlImaduddin KhajaNo ratings yet

- Base Plate Design ExampleDocument74 pagesBase Plate Design ExampleNiko NištićNo ratings yet

- 30m Anchor and Base Plate MonopoleDocument6 pages30m Anchor and Base Plate MonopoleEhtesham AliNo ratings yet

- Skirt Opening R-201Document9 pagesSkirt Opening R-201Anonymous qUMJ27ITQsNo ratings yet

- Soil Nail ReportDocument9 pagesSoil Nail ReportUtsav ShrivastavaNo ratings yet

- Design Calculation of Shaft/Pin/Axle: 1.0 Basic DataDocument3 pagesDesign Calculation of Shaft/Pin/Axle: 1.0 Basic DatapkvchoudharyNo ratings yet

- Base Slab & Crack Width Check - ACI CodeDocument6 pagesBase Slab & Crack Width Check - ACI CodensureshbabuNo ratings yet

- Base Plate JPDocument2 pagesBase Plate JPNaresh SNo ratings yet

- Trunnion AnalysisDocument45 pagesTrunnion AnalysisChiragJansariNo ratings yet

- H.1 - Gusset Plate - DeckDocument12 pagesH.1 - Gusset Plate - Deckchristi SNo ratings yet

- BS8110 Beam With DeflectionDocument3 pagesBS8110 Beam With DeflectionFrederick TanNo ratings yet

- Design of Base PlateDocument161 pagesDesign of Base PlatemaheshbandhamNo ratings yet

- Superb Doubly Reinforced BEAMDocument3 pagesSuperb Doubly Reinforced BEAMSandeep VarmaNo ratings yet

- Spreader Calculation (ISMC-200)Document4 pagesSpreader Calculation (ISMC-200)mechmohan26No ratings yet

- RC Beam - Singly - NSCP 2015 by RgceDocument4 pagesRC Beam - Singly - NSCP 2015 by RgceJet ToledoNo ratings yet

- SUMMARYCCCCCDocument17 pagesSUMMARYCCCCCShawkat Ali KhanNo ratings yet

- CATENARY SAG-TENSION CALCULATOR (By: Jared Cuchapin, 2018) : 300 DrakeDocument12 pagesCATENARY SAG-TENSION CALCULATOR (By: Jared Cuchapin, 2018) : 300 Drakedursun_yerlikaya100% (2)

- ASME B31.4-Wall Thickness CalDocument2 pagesASME B31.4-Wall Thickness CalBagus Sukoco Koco100% (1)

- Design of Reinforced Concrete Beam Version 2.0 Reference Code: Beam ID: Design Status: Valid Design!Document2 pagesDesign of Reinforced Concrete Beam Version 2.0 Reference Code: Beam ID: Design Status: Valid Design!Raymundo GirayNo ratings yet

- Crack Width BS5400Document3 pagesCrack Width BS5400yuNo ratings yet

- Advanced Uses For Micro Saint Simulation SoftwareDocument4 pagesAdvanced Uses For Micro Saint Simulation SoftwareMartin VenichNo ratings yet

- Data UtilityDocument45 pagesData UtilityMartin VenichNo ratings yet

- MapleNet BrochureDocument4 pagesMapleNet BrochureMartin VenichNo ratings yet

- Sensor Interface Design With Worst Case Analysis - Vol1.flowDocument5 pagesSensor Interface Design With Worst Case Analysis - Vol1.flowMartin VenichNo ratings yet

- hw4 Solution NumericsDocument5 pageshw4 Solution NumericsMartin VenichNo ratings yet

- Computer Simulation of The 7 62mm TT Pistol External Ballistics Using Two Different Air Resistance LawsDocument30 pagesComputer Simulation of The 7 62mm TT Pistol External Ballistics Using Two Different Air Resistance LawsMartin VenichNo ratings yet

- Application Pack 2:: PWM Based H-Bridge Power ControlDocument6 pagesApplication Pack 2:: PWM Based H-Bridge Power ControlMartin VenichNo ratings yet

- Piping Solutions MathcadDocument20 pagesPiping Solutions MathcadMartin Venich100% (1)

- Vissim/Fixed P Vissim/Fixed P Vissim/Fixed P Vissim/Fixed P Vissim/Fixed Point Oint Oint Oint OintDocument1 pageVissim/Fixed P Vissim/Fixed P Vissim/Fixed P Vissim/Fixed P Vissim/Fixed Point Oint Oint Oint OintMartin VenichNo ratings yet

- Optimizing The Design of A Helical SpringDocument4 pagesOptimizing The Design of A Helical SpringMartin VenichNo ratings yet

- Robot Arm Writing MaplesoftDocument12 pagesRobot Arm Writing MaplesoftMartin VenichNo ratings yet

- Application Pack 6:: Automatic OptimisationDocument5 pagesApplication Pack 6:: Automatic OptimisationMartin VenichNo ratings yet

- Vissim/C-Vissim/C - Vissim/C - Vissim/C - Vissim/C-Code Code Code Code CodeDocument1 pageVissim/C-Vissim/C - Vissim/C - Vissim/C - Vissim/C-Code Code Code Code CodeMartin VenichNo ratings yet

- Advances in Engineering Software: Gürol Yıldırım, Vijay P. SinghDocument8 pagesAdvances in Engineering Software: Gürol Yıldırım, Vijay P. SinghMartin VenichNo ratings yet

- Professional Vissim: Dynamic Modeling and Simulation SoftwareDocument2 pagesProfessional Vissim: Dynamic Modeling and Simulation SoftwareMartin VenichNo ratings yet

- Application Pack 4:: Real-Time Simulation With Data Acquisition CardsDocument8 pagesApplication Pack 4:: Real-Time Simulation With Data Acquisition CardsMartin VenichNo ratings yet

- Application Pack 3:: Visual Programming For Low-Cost Industrial DspsDocument8 pagesApplication Pack 3:: Visual Programming For Low-Cost Industrial DspsMartin VenichNo ratings yet

- United Kingdom Standard Perpetual: Matlab SimulinkDocument9 pagesUnited Kingdom Standard Perpetual: Matlab SimulinkMartin VenichNo ratings yet

- Braking Distance of A Skidding CarDocument3 pagesBraking Distance of A Skidding CarMartin VenichNo ratings yet

- For Ideal Beam in Socket: 7250.0 Lb/in - 12250.0 Lb/inDocument7 pagesFor Ideal Beam in Socket: 7250.0 Lb/in - 12250.0 Lb/inMartin VenichNo ratings yet

- Angle Fitting - Niu Method: Element X y X y (In) (In) (In) (In) yDocument5 pagesAngle Fitting - Niu Method: Element X y X y (In) (In) (In) (In) yMartin VenichNo ratings yet

- WIND LOADING ANALYSIS - Wall Components and Cladding: Input DataDocument15 pagesWIND LOADING ANALYSIS - Wall Components and Cladding: Input DataMartin VenichNo ratings yet

- Example J.7 Base Plate Bearing On Concrete: = P / (Φ · 0.85f') = Bn = B D = Φ · 0.85f' A min (2, (A / A) )Document2 pagesExample J.7 Base Plate Bearing On Concrete: = P / (Φ · 0.85f') = Bn = B D = Φ · 0.85f' A min (2, (A / A) )Martin VenichNo ratings yet

- Free Vibration of LTMDocument18 pagesFree Vibration of LTMSourabhYadavNo ratings yet

- GATE Thermodynamics Questions - Mechanical Engineering TutorialsDocument16 pagesGATE Thermodynamics Questions - Mechanical Engineering Tutorialsmahendra shakyaNo ratings yet

- May 21 U4 QPDocument32 pagesMay 21 U4 QPHasin RahmanNo ratings yet

- Chapter Two: Synthesis, Characterization of Semicarbazide and Thiosemicarbazide Based Ligands and Their ComplexesDocument38 pagesChapter Two: Synthesis, Characterization of Semicarbazide and Thiosemicarbazide Based Ligands and Their ComplexesJallow KowlyNo ratings yet

- A MODIFIED PENG ROBINSON EQUATION OF STATE FOR ELV 20519 FTP PDFDocument16 pagesA MODIFIED PENG ROBINSON EQUATION OF STATE FOR ELV 20519 FTP PDFalex rene cardonaNo ratings yet

- 096 09247 03 - TDSDocument2 pages096 09247 03 - TDSMuhamad Samsul BahriNo ratings yet

- Chapter 2 Force and Motion (Answer)Document108 pagesChapter 2 Force and Motion (Answer)Nadia SaidonNo ratings yet

- Schedule - JEE Advanced Crash Course 2024Document2 pagesSchedule - JEE Advanced Crash Course 2024saurav.saha1984No ratings yet

- FYP PresentationDocument19 pagesFYP PresentationAsad TararNo ratings yet

- General Relativity - Tom MarshDocument104 pagesGeneral Relativity - Tom MarshMemo SaucedoNo ratings yet

- Flow ChartDocument2 pagesFlow ChartJames PerriamNo ratings yet

- Mechanics of Fluids Si Edition 5th Edition Potter Test BankDocument3 pagesMechanics of Fluids Si Edition 5th Edition Potter Test Bankwalleyeemploye2g100% (28)

- Design Report: HAWT Graduation ProjectDocument30 pagesDesign Report: HAWT Graduation ProjectMohamed MedhatNo ratings yet

- Angular Momentum: Reading: Chapter 11 (11-7 To 11-12)Document11 pagesAngular Momentum: Reading: Chapter 11 (11-7 To 11-12)Arafat AnikNo ratings yet

- We Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsDocument21 pagesWe Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsAllan PaoloNo ratings yet

- CH - 2 p1 DynaDocument11 pagesCH - 2 p1 DynaFikadu BelaynehNo ratings yet

- Me6411 Manufacturing Technology-II Lab ManualDocument35 pagesMe6411 Manufacturing Technology-II Lab ManualdibyenindusNo ratings yet

- Turk Indutive Speed Sensor PDFDocument3 pagesTurk Indutive Speed Sensor PDFAhmad DagamsehNo ratings yet

- Arches Vaults and Dome FinalDocument39 pagesArches Vaults and Dome FinalPratima Mahesh0% (1)

- Waveguides: The Symmetric Slab WaveguideDocument26 pagesWaveguides: The Symmetric Slab WaveguidemstefaneNo ratings yet

- tp2 Systc3a8mes Asservis Numc3a9riquesDocument1 pagetp2 Systc3a8mes Asservis Numc3a9riquesomarNo ratings yet

- 10th Class Past Papers BISE Sahiwal G 2 Previous Papers NOTESPK CompressedDocument16 pages10th Class Past Papers BISE Sahiwal G 2 Previous Papers NOTESPK CompressedFaisal RasheedNo ratings yet

- Waste Glass: Table 5.1 Types of Glass and Their Main UsesDocument2 pagesWaste Glass: Table 5.1 Types of Glass and Their Main UsesGowri J BabuNo ratings yet

- 04 ECE405Tut 2013 Solution PDFDocument8 pages04 ECE405Tut 2013 Solution PDFDavy MardamootooNo ratings yet

- Ntse Phy Che MaterialDocument68 pagesNtse Phy Che Materialabirami.narayanan857100% (1)

- Physical Geodesy100Document23 pagesPhysical Geodesy100EfrenNo ratings yet

- Keele (1983-10 AES Preprint) - Horn Covers Flat Rectangular AreaDocument22 pagesKeele (1983-10 AES Preprint) - Horn Covers Flat Rectangular AreaBob BeduneauNo ratings yet