Professional Documents

Culture Documents

Liquid Level Controller EKE 347: Installation Guide

Liquid Level Controller EKE 347: Installation Guide

Uploaded by

jdmurilloa64Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Liquid Level Controller EKE 347: Installation Guide

Liquid Level Controller EKE 347: Installation Guide

Uploaded by

jdmurilloa64Copyright:

Available Formats

Installation guide

Liquid level controller

EKE 347

080R0430

080R0430

80G74_}01-2014

Danfoss

5

110

70 60

080G5000 63

1 2

Liquid Level Regulating principle

AKS 4100/

AKS 4100/ AKS 4100U

AKS 4100U

EKE 347

EKE 347

ICM with

ICAD motor

Danfoss Danfoss

80G75_06-2014 80G76_06-2014

3a 3b

80G77_01-2014

AKS 4100/

AKS 4100U

Danfoss

AKS 4100/

AKS 4100U

EKE 347

EKE 347

80G78_06-2014

Danfoss

Type = AKV / AKVA

3c 3d

© Danfoss A/S (RC-MDP/MWA), 2014-08 DKRCI.PI.RP0.C1.02 / 520H8794 1

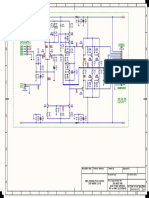

Connection

AKS 41

Connections 24 V DC 24 V AC

L

1

upper level N

2 3

AKS 4100/4100U

ICAD 1st gen

yellow

4-20 mA ICAD/ICM

blue

ICAD 2nd gen

orange

+ blue feedback

–

4-20 mA

DI1 - main switch

24 V+

15 V+

COM

COM

COM

COM

5 V+

DI 2

DI 1

AI 5

AI 4

AI 3

AI 2

AI 1

1 2 3 4 5 6 7 8 9 10 11 12 13 14

15 16 17 18 19 20 21 22 23 24

R GND

CAN H

CAN L

R120

CAN RJ

COM

AO 1

GND

D+

D-

plug for ICAD 1st gen (pre 2010)

remote display yellow green

gray brown 24 V DC

CANbus connection

ModBUS

to other EKE controllers ICAD 2nd gen (2010 +)

orange brown

yellow white 24 V DC

2 DKRCI.PI.RP0.C1.02 / 520H8794 © Danfoss A/S (AC-MCI/MWA), 2014-08

Connection

Connections

lower level

Common High Level Alarm

Normally Open or Normally Open or

Normally Closed Normally Closed

AKV/AKVA

NO 4

NO 3

NO 2

NC 3

NC 2

–/~

C3

C2

NO 2

NC 2

C2

37 36 35 34 33 32 31 30

NO 3

NC 3

C3

29 28 27 26 25

NO 1

NC 1

C1

POWER

SUPPLY

NO 1

NC 1

+/~

C1

-/~

–

+ Low Level Alarm

24 V AC 24 V DC Normally Open or

Normally Closed

+/- 20% 15 VA +/- 20% 10 W

© Danfoss A/S (RC-MDP/MWA), 2014-08 DKRCI.PI.RP0.C1.02 / 520H8794 3

EKE 347 - ON/OFF Application. Connection examples

Open/Close solenoid valve with coil 24V - 230V

NO 4

NO 3

NO 2

NC 3

NC 2

–/~

C3

C2

AKS 4100/ AKS 41/

AKS 4100U AKS 41U

M84H0076_1

M84H0075_1

Danfoss

Danfoss

Voltage: 24 - 230 V a.c.

AKS 4100/ AKS 4100/

AKS 4100U AKS 4100U

M84H0078_1

M84H0077_1

Danfoss

Danfoss

POWER

NO 1

SUPPLY

NC 1

C1

+

–

6 7a

MASTER / SLAVE configuration

MASTER SLAVE 1 SLAVE 2

M84H0080_1

Danfoss

AKVA AKVA AKVA

(ICAD) (ICAD) (ICAD)

15 16 17 18 15 16 17 18 15 16 17 18

AKS 4100/

CAN H

CAN H

CAN H

CAN L

CAN L

CAN L

R120

R120

R120

GND

GND

GND

AKS 4100U

Jumper Jumper

15-16 15-16

7b

I/O configuration

MASTER I/O

NO 2

D02

NC 2

C2

D03

NO 3

NC 3

C3

AKVA

(ICAD)

D01

NO 1

NC 1

C1

15 16 17 18 15 16 17 18

AKS 4100/

CAN H

CAN H

CAN L

CAN L

R120

R120

GND

GND

AKS 4100U

M84H0084_1

Jumper Jumper

15-16 15-16

Danfoss

7c

4 DKRCI.PI.RP0.C1.02 / 520H8794 © Danfoss A/S (AC-MCI/MWA), 2014-08

Back

Press and hold = Log Out

Home Image Scroll up

Scroll down

Enter

Press and hold = Log In

Flashing bell = Active alarm

Controller name

Controller mode

Actual liquid level Lower level alarm off (pump on)

Valve opening degree Upper level alarm off

Power on Power on

(1st time)

Setup Wizard

Press and hold Home Image

A guided configuration

of EKE 347 Log in

Short press on

Setup & Service menu Status menu

Reference Setpoint

Alarm setup Active alarms

Control Detailed status

Display Controller info

IO config. QR code

Communication

Service

Setup wizard

IO check

Controller name

Slider indicating position within

the number of submenues

10

© Danfoss A/S (RC-MDP/MWA), 2014-08 DKRCI.PI.RP0.C1.02 / 520H8794 5

ENGLISH Application dependent connections Control Panel (fig. 8)

(fig. 4, 5 and 6) The user interface of the control panel con-

Liquid Level Regulating principle Terminals: sists of a multiline display and 4 individual

Fig. 3a: 33-35 Relay for common alarm. push buttons: Enter button, Page up

LOW Installer can choose between button, Page down button and Back

System configuration ICAD Normally Open (33-34) or Normally button.

Regulating principle Low Closed (34-35) circuits.

Level Signal setup AKS 4100 The relay will switch according to Fig. 8 shows the Home display image,

the programmed setting. which give the actual overview. This is the

Fig. 3b: 25-27 Relay for low level limit. starting point for entering into menus, and

LOW Installer can choose between you will revert to this image by pushing

System configuration AKV/A Normally Open (26-27) or Normally 1 – 3 times (depending on actual position).

Regulating principle Low Closed (25-26) circuits.

Level Signal setup AKS 4100 The relay will switch when the set Display (fig. 9)

value is passed. The display itself show the state of Liquid

Fig. 3c: 30-32 Relay for upper level limit. level, Controller Mode (controller On/

LOW Installer can choose between Off), Valve opening degree, Lower level

System configuration AKV/A Normally Open (30-31) or Normally alarm (on = no alarm present) and Upper

Regulating principle Low Closed (31-32) circuits. level alarm (off = no alarm present).

Level Signal setup AKS 4100 The relay will switch when the set

value is passed. Additional to the external connected alarm

Fig. 3d: 6-10 ICM valve feedback signal from audio/video sources, a Bell symbol will

HIGH ICAD 0/4-20 mA flash in the upper right corner in case of an

System configuration AKV/A alarm.

Regulating principle High Note!

Level Signal setup AKS 4100 If AKV(A) is used, the power supply To see more details on system perfor-

must cover the AKV(A) coil wattage mance and setting of parameters, 2

additionally (see fig. 5). different main menu levels can be reached

Necessary connections (fig. 4, 5 and 6) AKV(A) Coil voltage must be the by operation of the push buttons.

Terminals: same as controller supply voltage

28-29 Supply voltage 24 V a.c. or d.c. AC or DC.

1-7 Signal from level transmitter type

AKS 4100/4100U or MASTER/SLAVE and I/O configuration

7-10 Signal from level transmitter type (fig. 7b and 7c)

AKS 41 When more controllers are connected via

36-37 Expansion valve type AKV or AKVA CAN bus each end of the bus must be ter-

(see note to the right) or minated with a jumper between 15 and 16.

23-24 Expansion valve type: ICM with

ICAD

13-14 Switch function for start/stop of

controller. If a switch is

not connected, terminals 13 and 14

must be shortcircuited.

6 DKRCI.PI.RP0.C1.02 / 520H8794 © Danfoss A/S (RC-MDP/MWA), 2014-08

ENGLISH

Menu’s Status menu Setup & service menu

Entrance to menu’s (see fig. 10) To enter Status menu from Home image: (Requires log-in password assigned in

From Home Image the status menu can be Push once. Commisioning menu)

reached by one push on . From Home

Image the Setup & service menu can be

reached by one push and hold on .

For entrance a Log in is required by the

password given during commisioning.

Parameter mode (read/write mode)

When maneuvering in Setup & service

menu or Status menu there is an overall The Status menu is an open menu acces-

logic of showing possible actions for each sible for all. Therefore only 1 parameter

parameter. can be changed from here. A selection of

other parameters can be seen from the

Plain text: status menu:

Read only

Status menu ( Open menu )

Options

Setpoint

To enter Setup and service menu from

Liquid level setpoint 0 - 100%

Home image:

Active alarms

Example of alarm content. The list will be empty in Push and hold .

normal operation as no alarm is active.

Level signal out of range hours minutes Maneuvering in the Status menu and the

Standby mode hours minutes Setup and service menu’s are done by use

Detailed status of the 4 push buttons shown in fig. 8.

Framed text: Controller state Stop, Manual, Auto,

Parameter can be changed - push to Slave, IO

The Setup & service menu is divided into

highlight. Actual level 0.0 - 100%

3 access levels, where personnel have

Actual reference 0.0 - 100%

individual authority.

Actual OD 0.0 - 100%

Digital input status On / Off

Most advanced level is Commissioning,

Actual level signal current mA

where you have access to change all

Oscillation amplitude 0.0 - 100%

allowable parameters, including password

Oscillation period sec

issuing and re-run of Setup wizard. Default

Controller Info

password for commissioning is 300.

Type

Name (Controller name) Service level is for service personnel and

Highlighted text: SW (Software version)

Scroll with / to the desired selection has fewer rights than commissioning.

Bios (Bios version) Default password is 200.

and push to enter the selection. Adr (Controller address)

Once entered the parameter is valid and SN (Serial Number)

the text changes to framed text. The lowest level is for Daily use, and allows

PV (Product version) only a few changes. Default password is

Site (Production site) 100.

QR code

Code Below table shows authority given to the

3 levels.

Read & Write

Read only

© Danfoss A/S (RC-MDP/MWA), 2014-08 DKRCI.PI.RP0.C1.02 / 520H8794 7

Setup & service menu (Requires Log-In. Password to be assigned in Commisioning menu)

User level - access Default

Parameter Options

Daily Service Commissioning values

Reference Main switch On, Off RW RW RW Off

Liquid level setpoint 0 - 100% RW RW RW 50.0%

Operation mode Master, IO, Slave R R RW (L) Master

Alarm setup Lower level limit 0 - 100% RW RW RW 15%

Upper level limit 0 - 100% RW RW RW 85%

Level alarm mode Time, Hysteresis R R RW Time

Lower delay 0 - 999 sec R RW RW (D) 10 sec

Upper delay 0 - 999 sec R RW RW (D) 50 sec

Lower level hysteresis 0-20 % R RW RW (D) 3%

Upper level hysteresis 0-20 % R RW RW (D) 5%

Function common alarm Not follow; Follow up; Follow low; Follow all R R RW Not follow

Oscillation detect band 0 - 100% R RW RW (D) 100%

Oscillation detect timeout 2 - 30 min R RW RW (D) 20 min

IO Lower level limit 0 - 100% RW RW RW (D) 5%

IO Upper level limit 0 - 100% RW RW RW (D) 95%

IO Lower level hysteresis 0-20 % R RW RW (D) 3%

IO Upper level hysteresis 0-20 % R RW RW (D) 3%

IO Lower delay 0 - 999 sec R RW RW (D) 10 sec

IO Upper delay 0 - 999 sec R RW RW (D) 50 sec

IO Level limit 0 - 100% R RW RW (D) 50%

IO Level delay 0 - 999 sec R RW RW (D) 10 sec

IO Level hysteresis 0-20 % R RW RW (D) 3%

IO Level action Falling,Rising R RW RW (D) Falling

Control Control Method On/Off ,P, PI R RW RW PI

Regulating principle Low, High R RW RW Low

P-band 5 - 200% R RW RW (D) 30.0%

Integration time Tn 60 - 600 sec R RW RW (D) 400 sec

Neutral zone 0 - 25% R RW RW (D) 2.0%

Difference 0,5-25% R RW RW (D) 2%

Period time for AKV/AKVA 3-15 sec R RW RW (D) 6 sec

Minimum OD 0 - 99% R RW RW (D) 0%

Maximum OD 1 - 100% R RW RW (D) 100%

Display Language EN,CN,PT,RU,SP,FR,IT, GER, ARAB R RW (L) RW (L) (D) EN

Output indication level, OD R RW RW (D) Level

Login timeout 0 - 120 min R RW RW 10 min

Backlight timeout 0 - 120 min RW RW RW 2 min

Password daily 3 -digit, 0 - 999 N/A N/A RW 100

Password service 3 -digit, 0 - 999 N/A N/A RW 200

Password commission 3 -digit, 0 - 999 N/A N/A RW 300

IO config System configuration ICAD+NC, ICAD, AKV/A+NC, AKV/A, NC only R R RW (L) ICAD + NC

Level signal setup AKS 4100, AKS 41, Current, Voltage R R RW (L) AKS4100

Voltage at low liquid level 0-10V R RW RW (D) 0V

Voltage at high liquid level 0-10V R RW RW (D) 10 V

Current at low liquid level 0-20 mA R RW RW (D) 4 mA

Current at high liquid level 0-20 mA R RW RW (D) 20 mA

Valve position setup Not used, Current, Voltage R R RW (L) Not used

Voltage at closed valve 0-10V R RW RW (D) 0V

position

Voltage at open valve 0-10V R RW RW (D) 10 V

position

Current at closed valve 0-20 mA R RW RW (D) 4 mA

position

Current at open valve 0-20 mA R RW RW (D) 20 mA

position

Common alarm setup D04, High alarm, D03, Disp only R R RW (L) High alarm

Multiple valve setup Not used, 2 same cap, 2 dif cap, 3 same cap, 3 dif cap R R RW (L) Not used

Multiple valve pattern Parallel,Sequence R R RW (D) Parallel

Valve A capacity 0-100 % R R RW (L) (D) 50%

Valve B capacity 0-100 % R R RW (L) (D) 50%

Valve C capacity 0-100 % R R RW (L) (D) 30%

ICAD takeover OD 0-100% R RW RW (D) 80%

IO module setup Used, Not used R R RW (L) (D) Not used

Communication CAN ID 1 - 127 R R RW 1

CAN baudrate 20k, 50k, 125k, 250k, 500k, 1M R R RW 500k

Modbus ID 0 - 120 R R RW 1

Modbus baudrate 0, 1200, 2400, 4800, 9600, 14400, 19200, 28800, 38400 R R RW 19200

Modbus mode 8N1, 8E1, 8N2 R R RW 8N1

Modbus mapping Operation, Setup R R RW Operation

Valve B CAN ID 1 - 127 R R RW (D) 2

Valve C CAN ID 1 - 127 R R RW (D) 3

IO Mod. CAN ID 1 - 127 R R RW (D) 4

RW = Read & Write R = Read only N/A = Not shown (L) = Locked by Mainswitch ( Switch OFF Mainswitch for change of setting)

(D) = Parameter is hidden if not active in the selected application

8 DKRCI.PI.RP0.C1.02 / 520H8794 © Danfoss A/S (RC-MDP/MWA), 2014-08

Setup & service menu (Requires Log-In. Password to be assigned in Commisioning menu) - Continued

User level - access Default

Parameter Options

Daily Service Commissioning values

Service Controller state R R R -

Actual level R R R (D) -

Actual referrence R R R (D) -

Actual OD R R R (D) -

Actual valve position R R R (D)

Digital input status R R R (D) -

Actual level signal voltage R R R (D)

Actual level signal current R R R (D) -

Actual position signal R R R (D)

voltage

Actual position signal R R R (D)

current

Actual OD A R R R (D)

Actual OD B R R R (D)

Actual OD C R R R (D)

Manual Mode On, Off R RW RW (D) Off

Manual OD 0 - 100% R RW RW (D) 50.0%

Manual low alarm Off-On R RW RW (D) Off

Manual high alarm Off-On R RW RW (D) Off

Manual common alarm Off-On R RW RW (D) On

Apply defaults None, Factory N/A N/A RW (D) None

Setup wizard Setup wizard Re-run Setup wizard N/A N/A RW -

I/O check Main switch EKE act: Off - On R R R Off

AKS 4100 EKE act: 0 - 20 mA R R R (D) -

ICAD EKE act: 4 - 20 mA R R R (D) -

Nor. Close (NC) EKE act: Off - On R R R (D) -

Upper lvl (alarm) EKE act: Off - On R R R (D) -

Lower lvl (alarm) EKE act: Off - On R R R (D) -

Controller Controller name Type in controller name RW RW RW -

name

RW = Read & Write R = Read only N/A = Not shown (L) = Locked by Mainswitch ( Switch OFF Mainswitch for change of setting)

(D) = Parameter is hidden if not active in the selected application

© Danfoss A/S (RC-MDP/MWA), 2014-08 DKRCI.PI.RP0.C1.02 / 520H8794 9

First time start-up 7. Upper level limit Alarm and error codes:

(Setup wizard) Type in any limit from 0% to 100% When detecting an alarm from external

When all connections to the controller (default is 85%) sources or the flashing bell in the display,

have been made, the first time start-up can the alarm description can be found as a text

be performed. 85% message in the Status menu under Active

alarms.

After switching power on, the Danfoss logo

will appear for 5 seconds 8. Control method Both alarms and errors will be shown here.

Select one of these 3 predefined methods: If more alarms/errors occur simultaneously,

The setup wizard will start. PI - ctrl they will be shown as subsequent text lines.

P - ctrl

During the setup wizard following se- On/Off Alarms:

Upper level

quence must be repeated for all parameter Lower level

settings: 9. Level signal setup Standby mode

Select one of these 4 predefined signal Valve B CAN ID conflict

Valve C CAN ID conflict

a) Parameter name + 1st option setup:

IO module CAN ID conflict

b) Press to highlight 1st option AKS 4100 IO module communication

c) Scroll with / to your desired Voltage Communication to master lost

option. Current Min/max OD conflict

Common alarm HW conflict

d) Press to set your choice xxxxxx AKS 41 Control method conflict

e) Scroll with to next parameter (repeat Multiple valve setup conflict

sequence a to e) 10. Valve feedback setup Valve C alarm

Select one of these 3 predefined feedback Valve B alarm

Oscillation in level signal

1. Language setup (valve feedback is only possible with Valve position

You can select any of these 9 languages: ICAD): Multiple valve capacity

English, Chinese, Portuguese, Russian, Not used Valve C communication

Valve B communication

Spanish, French, Italian, German, Arabic Voltage

Current Errors:

2. System configuration Internal error

Select any of these 5 predefined configura- 11. Common alarm setup Level signal out of range

Valve position signal out of range

tions: Select one of these 4 predefined methods: Sensor supply overload

ICAD + NC(solenoid) High Alarm AKS 4100 error

NC(solenoid) D04 Too much current AI3

Too much current AI4

AKV/A Disp only (only Bell symbol flashing)

DO4 overload

AKV/A + NC(solenoid) D03

ICAD

12. Apply wizard settings

3. Operation mode Press to confirm all inputs

Select any of these 3 predefined modes: or

Master (EKE 347 as Master controller) Press to return to last menu

IO (EKE 347 as In/Out module)

Slave (EKE 347 as slave for another Once data entry has been confirmed, the

Master controller has sufficient data to do a

qualified regulation of your system.

4. Regulating principle

Select one of these 2 principles

Low You are now asked to select one of these

High menus.

Main menu

5. Liquid level setpoint Main switch

Type in any level setpoint from 0% to 100% I/O check

(default is 50.0%)

Press for reaching the Setup & service

50.0% menu or press 2 times for reaching the

Home display image.

6. Lower level limit If for some reason it is needed to run the

Type in any limit from 0% to 100% setup wizard again, this is possible by log

(default is 15%) in to the setup & service menu with

commissioning authority.

15%

10 DKRCI.PI.RP0.C1.02 / 520H8794 © Danfoss A/S (RC-MDP/MWA), 2014-08

© Danfoss A/S (RC-MDP/MWA), 2014-08 DKRCI.PI.RP0.C1.02 / 520H8794 11

www.danfoss.com/ir

12 DKRCI.PI.RP0.C1.02 / 520H8794 © Danfoss A/S (RC-MDP/MWA), 2014-08

You might also like

- Esquema Fonte Comunic 16, 46, CP 112Document2 pagesEsquema Fonte Comunic 16, 46, CP 112PB1808100% (2)

- E-7 CE MANUAL Rev.1Issue.2 PDFDocument155 pagesE-7 CE MANUAL Rev.1Issue.2 PDFnylsk8100% (5)

- LV5-1510-20-UL-SLR 1MW/ GFDI/6input/Insul - Monitor: Verdrahtungshinweise Wiring InstructionsDocument113 pagesLV5-1510-20-UL-SLR 1MW/ GFDI/6input/Insul - Monitor: Verdrahtungshinweise Wiring Instructionsedvaldo alves pintoNo ratings yet

- JeppView - SBCT - CURITIBA (22 Charts)Document22 pagesJeppView - SBCT - CURITIBA (22 Charts)WalterRodriguesNo ratings yet

- Phonic Nexus 540Document6 pagesPhonic Nexus 540Jim50% (2)

- Specific Relay For The Management of Line Telecommutations and Relief Generator SetsDocument4 pagesSpecific Relay For The Management of Line Telecommutations and Relief Generator SetsKaiser IqbalNo ratings yet

- Sicoma Mao 9000-6000 Uso y Manual de MantenimientoDocument112 pagesSicoma Mao 9000-6000 Uso y Manual de MantenimientoLeonel Intriago100% (4)

- Jtec PDFDocument9 pagesJtec PDFcesar Miranda100% (1)

- TR-5-C 1650x550 Manual 2010 Rev A PDFDocument244 pagesTR-5-C 1650x550 Manual 2010 Rev A PDFArmandoOlivares100% (1)

- EKE Installation GuideDocument32 pagesEKE Installation GuideHenryNo ratings yet

- A6V10424583 - 2 - and 3-Port Valves With - BR - Flanged Connections - enDocument14 pagesA6V10424583 - 2 - and 3-Port Valves With - BR - Flanged Connections - enAjdin BuljubasicNo ratings yet

- A6V10424583 - 2 - and 3-Port Valves With - BR - Flanged Connections - enDocument20 pagesA6V10424583 - 2 - and 3-Port Valves With - BR - Flanged Connections - enBen ZithaNo ratings yet

- Matrix 1.4 Vi Ab300w4l Power AmpDocument1 pageMatrix 1.4 Vi Ab300w4l Power Ampbahattin147No ratings yet

- Www.Fineprint.Cn: Pdf 文件使用 "Pdffactory Pro" 试用版本创建Document1 pageWww.Fineprint.Cn: Pdf 文件使用 "Pdffactory Pro" 试用版本创建Ivan Lopez FacerNo ratings yet

- Power KSC-570Document1 pagePower KSC-570Lucie Pavlíčková100% (1)

- Instruction: Type AKS 4100/4100U Coaxial D14 VersionDocument12 pagesInstruction: Type AKS 4100/4100U Coaxial D14 VersionVasti Diaz AguilarNo ratings yet

- Switchgrear - Pricelist - Feb 2024Document7 pagesSwitchgrear - Pricelist - Feb 2024rahulNo ratings yet

- A6V13343014 enDocument16 pagesA6V13343014 enMohamad RagabNo ratings yet

- E&MTraction Items Spares ListDocument45 pagesE&MTraction Items Spares ListDEVI PRASAD GREENSECURENo ratings yet

- Accessories AH2342-CA Ȝ: SpecificationDocument1 pageAccessories AH2342-CA Ȝ: SpecificationhoiNo ratings yet

- Sema Atx SmpsDocument1 pageSema Atx SmpsDeepak AnandNo ratings yet

- 300B PPDocument1 page300B PPAndree W. KurniawanNo ratings yet

- SDSC RNP Z Rwy 20Document1 pageSDSC RNP Z Rwy 20azx72No ratings yet

- Dol Rev and FWDDocument1 pageDol Rev and FWDAthul ANo ratings yet

- İlave Özellikler: ECC731 Eccc Ecvc Ecsc EctcDocument6 pagesİlave Özellikler: ECC731 Eccc Ecvc Ecsc EctcAsk ienNo ratings yet

- PIC16F72: LM393 C1815 PC817 5K 5K 5K Transformer Bilal Electronics KarachiDocument1 pagePIC16F72: LM393 C1815 PC817 5K 5K 5K Transformer Bilal Electronics KarachiMian Fahim100% (1)

- Ad 2 Eddf 3-1-27Document1 pageAd 2 Eddf 3-1-27NewmasterNo ratings yet

- SBRF - Rnav Gnss Rwy 18 - Iac - 20200813Document1 pageSBRF - Rnav Gnss Rwy 18 - Iac - 20200813Ricardo PalermoNo ratings yet

- ECSP28 Tech BrochureDocument3 pagesECSP28 Tech BrochuresalesadminNo ratings yet

- Apecs 0250 Series Actuators: Spring ChartDocument2 pagesApecs 0250 Series Actuators: Spring Chartpan - panNo ratings yet

- 16bis0091 VL2017181003417 Ast03Document4 pages16bis0091 VL2017181003417 Ast03MassSomeshNo ratings yet

- Eddm08r Engm01lDocument8 pagesEddm08r Engm01lMark ChangNo ratings yet

- AC1240 Jan 2012Document169 pagesAC1240 Jan 2012taoistpengNo ratings yet

- ZWWWDocument16 pagesZWWWGio GNo ratings yet

- Balanced Mains Filter: Schematic DiagramDocument2 pagesBalanced Mains Filter: Schematic DiagramkosarobNo ratings yet

- International - Rectifier 92 0065 DatasheetDocument85 pagesInternational - Rectifier 92 0065 DatasheetDomenico ScorranoNo ratings yet

- Electronically Operated Valves PDFDocument28 pagesElectronically Operated Valves PDFlarafernandoNo ratings yet

- Omega Acb User ManualDocument149 pagesOmega Acb User ManualPriyanshu SainiNo ratings yet

- ALD810026Document6 pagesALD810026Juan GaleanoNo ratings yet

- From Pdp-Acx1 From Ups Panel Pdp-Atsx3: Fhi 1 2W 110V-60HzDocument11 pagesFrom Pdp-Acx1 From Ups Panel Pdp-Atsx3: Fhi 1 2W 110V-60Hzpepenapao1217No ratings yet

- (IAC) Rnpxrwy34: Alt, Elev, HGT: FT Dist: NM BRG: Mag VA/CHG: 05'W 8000'Document1 page(IAC) Rnpxrwy34: Alt, Elev, HGT: FT Dist: NM BRG: Mag VA/CHG: 05'W 8000'Davi Greuel HochapfelNo ratings yet

- SBSJ Rnp-X-Rwy-34 Iac 20210520Document1 pageSBSJ Rnp-X-Rwy-34 Iac 20210520Ricardo PalermoNo ratings yet

- Onyx 24-4 - Schematics - Power Supply (0015989-XX REVB02)Document1 pageOnyx 24-4 - Schematics - Power Supply (0015989-XX REVB02)Cristian MassuelNo ratings yet

- GENERAL Schematic FOR ARC-160Document1 pageGENERAL Schematic FOR ARC-160Chulipa Motores0% (1)

- (SID) RWY 24 Rnav Epdar 1B - Mided 1B: Gnss Req. Rnav 1. or RNP 1Document1 page(SID) RWY 24 Rnav Epdar 1B - Mided 1B: Gnss Req. Rnav 1. or RNP 1Bruno MartinsNo ratings yet

- Block Diagram InitialDocument1 pageBlock Diagram InitialDeepak AgrawalNo ratings yet

- TV Sony Kv-21t5kDocument6 pagesTV Sony Kv-21t5keduardskNo ratings yet

- 22 08 09 Nord 18556010Document5 pages22 08 09 Nord 18556010Sebastián Felipe Argüello LópezNo ratings yet

- A6V10338690 enDocument8 pagesA6V10338690 enOmair FarooqNo ratings yet

- 38 10 00 sc2Document28 pages38 10 00 sc2Lena BatboldNo ratings yet

- Changes: OPS: This Chart Is A Part of Navigraph Charts and Is Intended For Flight Simulation Use OnlyDocument12 pagesChanges: OPS: This Chart Is A Part of Navigraph Charts and Is Intended For Flight Simulation Use Onlyİ. Çağlar YILDIRIMNo ratings yet

- Cineral Tc1433nuDocument4 pagesCineral Tc1433nuMundodoRadioNo ratings yet

- Solenoid Coils Esc Series Technical Information en GB 7988770Document4 pagesSolenoid Coils Esc Series Technical Information en GB 7988770mohamed ghareebNo ratings yet

- 250A, 600VAC Electronic Trip Type: General UL/CSA Interrupting Capacity (Ka RMS)Document4 pages250A, 600VAC Electronic Trip Type: General UL/CSA Interrupting Capacity (Ka RMS)A. SajadiNo ratings yet

- 2 Fets - 3 IcsDocument1 page2 Fets - 3 IcsDiego Villa LuzuriagaNo ratings yet

- 02 Sensor KarşılıklarıDocument4 pages02 Sensor KarşılıklarıMehmet ÇakırNo ratings yet

- Phinma Power Generation Corporation: Presented By: University of PangasinanDocument16 pagesPhinma Power Generation Corporation: Presented By: University of PangasinanJohn Kenneth SegundoNo ratings yet

- IOM R&P-Rev3Document22 pagesIOM R&P-Rev3Nam Nguyễn ĐứcNo ratings yet

- Iwm-160 V1.0 2Document1 pageIwm-160 V1.0 2andreasmonNo ratings yet

- HX-1200 - SCHEMA - RE - PDF Version 1Document1 pageHX-1200 - SCHEMA - RE - PDF Version 1Muhammad AzamNo ratings yet

- Lc1d18e7 Datasheet Us En-UsDocument7 pagesLc1d18e7 Datasheet Us En-UsnusaNo ratings yet

- Belimo R2..Xx-S.. AP Datasheet En-GbDocument4 pagesBelimo R2..Xx-S.. AP Datasheet En-GbQAQC PAGSINCNo ratings yet

- GMC LSSCR Scroll Saw User's ManualDocument16 pagesGMC LSSCR Scroll Saw User's ManualAntonio Alan Lopez100% (3)

- Recloser Cooper PDFDocument48 pagesRecloser Cooper PDFJuan ArriazaNo ratings yet

- Sesorize Switch Room LightsDocument7 pagesSesorize Switch Room Lightsemil feguroNo ratings yet

- Driver's Cab 4Document42 pagesDriver's Cab 4M RefaiNo ratings yet

- UX B160WG TecnicoDocument106 pagesUX B160WG TecnicoJonatán AscenNo ratings yet

- Helpful Information: 8178 E 44th Street Tulsa, OK. 74145 Voice +1.918.622.5600 Fax +1.918.628.2853Document18 pagesHelpful Information: 8178 E 44th Street Tulsa, OK. 74145 Voice +1.918.622.5600 Fax +1.918.628.2853Mike CahuanaNo ratings yet

- FIX MICROSWITCH - Electronic Service Information System (ERWIN - ERWIN) PDFDocument18 pagesFIX MICROSWITCH - Electronic Service Information System (ERWIN - ERWIN) PDFOleksiy OsiychukNo ratings yet

- Analyser Shelter ATEC Italy - WWW - AtecsrlDocument3 pagesAnalyser Shelter ATEC Italy - WWW - AtecsrlMalyshAVNo ratings yet

- MD (BD) - Lst-Cep-In-1001 Control System Io List Rev0 PDFDocument17 pagesMD (BD) - Lst-Cep-In-1001 Control System Io List Rev0 PDFKook PengNo ratings yet

- Addressable Emergency Lighting With Central Battery SystemDocument10 pagesAddressable Emergency Lighting With Central Battery Systemskywalker_handsomeNo ratings yet

- S&C 115 KV LBSDocument9 pagesS&C 115 KV LBSสมชาย ภูพงศ์ไพบูลย์No ratings yet

- Electric Load Current Sensor On-Vehicle InspectionDocument4 pagesElectric Load Current Sensor On-Vehicle Inspectioncork_ieNo ratings yet

- Foxboro Modelo 43 ApDocument8 pagesFoxboro Modelo 43 ApRubenjarabacolonNo ratings yet

- Parts Manual: Hydraulic Power Supply UnitsDocument41 pagesParts Manual: Hydraulic Power Supply UnitsAnonymous hKGD6RT82No ratings yet

- BHB Sicam Emic Eng PDFDocument318 pagesBHB Sicam Emic Eng PDFtoseruNo ratings yet

- Murphy.40 ASM150.instDocument4 pagesMurphy.40 ASM150.instS M NaveedNo ratings yet

- sbp1100j (B)Document10 pagessbp1100j (B)PVelozoNo ratings yet

- EM34-3 & EM34-3XL Operating Instructions: (For Model With Two Digital Meters)Document24 pagesEM34-3 & EM34-3XL Operating Instructions: (For Model With Two Digital Meters)Asigri Mahfouz JohnNo ratings yet

- Joventa DMDocument2 pagesJoventa DMsandiatru88No ratings yet

- Manual de Mini Cooper ErroresDocument9 pagesManual de Mini Cooper Erroresjk100% (1)

- Pressure Reducing ValveDocument28 pagesPressure Reducing ValveSreenubabu Kandru50% (2)

- Asco Dust Collector System BrochureDocument2 pagesAsco Dust Collector System BrochureWalid AhmedNo ratings yet

- MIDTERM-EXAM UtilitiesDocument3 pagesMIDTERM-EXAM Utilitiescristineangeljasmin04No ratings yet

- Failure Codes HD 325-7RDocument8 pagesFailure Codes HD 325-7Rgire_3pich2005No ratings yet

- Autometer Sport Comp 3904Document3 pagesAutometer Sport Comp 3904Eaky Chiengpradit100% (1)