Professional Documents

Culture Documents

Key Skills: S.Thirunavukkarasu

Key Skills: S.Thirunavukkarasu

Uploaded by

Francis DhanarajCopyright:

Available Formats

You might also like

- QAQC Electrical Inspection: A Beginner's GuideFrom EverandQAQC Electrical Inspection: A Beginner's GuideRating: 4 out of 5 stars4/5 (1)

- Quality Assurance Plan For Building ConstructionDocument18 pagesQuality Assurance Plan For Building ConstructionANup GhiMire100% (3)

- Grade 11 Business and Accounting Studies Past Paper 2020 3rd Term Test Western ProvinceDocument25 pagesGrade 11 Business and Accounting Studies Past Paper 2020 3rd Term Test Western Provinceinvictus azmunNo ratings yet

- Sample Electrical Project Manager ResumeDocument4 pagesSample Electrical Project Manager ResumePresanna RajasekaranNo ratings yet

- CV (Sr. QA QC Engineer)Document5 pagesCV (Sr. QA QC Engineer)mansih457100% (1)

- Sample CVDocument8 pagesSample CVyusufal0406No ratings yet

- TORISHIMA - JA - 3542 - MAS Submission - Rev.0 - 20200922Document240 pagesTORISHIMA - JA - 3542 - MAS Submission - Rev.0 - 20200922Francis Dhanaraj100% (1)

- Ra PIDSDocument7 pagesRa PIDSMiko Severa100% (1)

- Consumer MovementDocument16 pagesConsumer MovementJananee Rajagopalan75% (56)

- SAMAYADURAI CV-05-Mar-24Document4 pagesSAMAYADURAI CV-05-Mar-24Vijay Allimuthu AvathipalayamNo ratings yet

- QA QC CIVIL INSPECTOR (1)-compressed (1)Document5 pagesQA QC CIVIL INSPECTOR (1)-compressed (1)Mohamed ArafathNo ratings yet

- ACO 9 2001 055 T7 4 0 SamayaDocument6 pagesACO 9 2001 055 T7 4 0 SamayaVijay Allimuthu AvathipalayamNo ratings yet

- Eepak Axena: Regular Member of Aace, Usa: Constituent Number: 59099 Associate Member of Institution of Engineers, IndiaDocument7 pagesEepak Axena: Regular Member of Aace, Usa: Constituent Number: 59099 Associate Member of Institution of Engineers, IndiadeepaksaxNo ratings yet

- Pravesh Tiwari Resume R-1Document4 pagesPravesh Tiwari Resume R-1pravesh tiwariNo ratings yet

- CVDocument6 pagesCVADNAN REHMATNo ratings yet

- AMIN Consult1Document3 pagesAMIN Consult1aminulhaqNo ratings yet

- Khaja Ghouse Moinuddin - 11 Yrs Experience With Aramco Approved - QC Inspector - CivilDocument5 pagesKhaja Ghouse Moinuddin - 11 Yrs Experience With Aramco Approved - QC Inspector - Civilsyed imranNo ratings yet

- CV Amjad Ahmad KhanDocument15 pagesCV Amjad Ahmad Khannaveedcomsian054No ratings yet

- Ramesh ChaudharyDocument4 pagesRamesh ChaudharyAdesh PatankarNo ratings yet

- Covering Letter: Mukesh Kumar GuptaDocument6 pagesCovering Letter: Mukesh Kumar GuptaTauqeer SalimNo ratings yet

- Krishna Mech EngineerDocument6 pagesKrishna Mech EngineeranjeeNo ratings yet

- Resume-Dec-2023.. (2)Document8 pagesResume-Dec-2023.. (2)Samir Baran BeraNo ratings yet

- Resume Ayaz RevisedDocument4 pagesResume Ayaz RevisedayazeeNo ratings yet

- Aamir Ehsan Detailed CVDocument3 pagesAamir Ehsan Detailed CVnmapeshawarNo ratings yet

- KP Jasim UsmanDocument7 pagesKP Jasim UsmanbobbyNo ratings yet

- Experience: Sulzer Chemtech (JHECO) - Yanbu KSADocument3 pagesExperience: Sulzer Chemtech (JHECO) - Yanbu KSApmkarNo ratings yet

- Career Summary: Ibrahim SopariwalaDocument3 pagesCareer Summary: Ibrahim SopariwalaIbrahim SopariwalaNo ratings yet

- 160308131927Document4 pages160308131927hakrajputNo ratings yet

- Anand CV 2022arDocument6 pagesAnand CV 2022arsanbsahaNo ratings yet

- CV-Engr Muhammad Sohaib Civil QC InspectorDocument3 pagesCV-Engr Muhammad Sohaib Civil QC Inspectorjahangirasim766No ratings yet

- Mohammed Aejaz Ahmed: Personal SummaryDocument3 pagesMohammed Aejaz Ahmed: Personal SummaryAejaz AhmedNo ratings yet

- CV Sample - 2Document20 pagesCV Sample - 2Lateef Ur REhmanNo ratings yet

- Updated CV - Jai Kashyap-1Document6 pagesUpdated CV - Jai Kashyap-1raghavmavenmarketingmediaNo ratings yet

- Cover Letter: Home AddressDocument4 pagesCover Letter: Home AddressVenkates WaranNo ratings yet

- Curriculum VitaeDocument8 pagesCurriculum Vitaeramesh_rhtNo ratings yet

- CV 2023Document5 pagesCV 2023AmitNo ratings yet

- Karim Ali ElAskary Visualcv ResumeDocument3 pagesKarim Ali ElAskary Visualcv ResumeAnonymous a3K3WgNo ratings yet

- Engineer Asif (Civil Engineer)Document4 pagesEngineer Asif (Civil Engineer)Imran AliiiNo ratings yet

- CV Faisal ZAFAR SHAHIDDocument6 pagesCV Faisal ZAFAR SHAHIDAlam MD SazidNo ratings yet

- Curriculum Vitae - Paul Joseph Sebastian..Document4 pagesCurriculum Vitae - Paul Joseph Sebastian..Abdullah AnsariNo ratings yet

- I I I I I: Key Experience and BackgroundDocument4 pagesI I I I I: Key Experience and Backgroundnaveed566No ratings yet

- Engr Bahram Updated CVDocument5 pagesEngr Bahram Updated CVcivilNo ratings yet

- Khalid Civil Qc UpdateDocument3 pagesKhalid Civil Qc UpdateRahimNo ratings yet

- Asim CV Site Engineer QC InspectorDocument15 pagesAsim CV Site Engineer QC InspectorMuhammad ShahidNo ratings yet

- Durocrete Company Profile 2023Document21 pagesDurocrete Company Profile 2023puriganesh1988No ratings yet

- Mohsin Mapari-Mech Engr CVDocument2 pagesMohsin Mapari-Mech Engr CVMohsin MapariNo ratings yet

- Qa/Qc Mechanical Inspection Engineer Resume: Buvanes222@yahoo - Co.inDocument5 pagesQa/Qc Mechanical Inspection Engineer Resume: Buvanes222@yahoo - Co.inpradeep67% (3)

- Bakthiar QC CVDocument3 pagesBakthiar QC CVSyed Bakhtiar HussainNo ratings yet

- Naukri SAMIRJEDHE (21y 0m)Document15 pagesNaukri SAMIRJEDHE (21y 0m)sushil.tripathiNo ratings yet

- QC Engr CV PDFDocument5 pagesQC Engr CV PDFMuthazhagan SaravananNo ratings yet

- Update CV PDFDocument5 pagesUpdate CV PDFAdnan MunirNo ratings yet

- Lva1 App6891Document11 pagesLva1 App6891ganeshram2305No ratings yet

- Lead Structural Engineer Academics: Nimai PurkaitDocument5 pagesLead Structural Engineer Academics: Nimai PurkaitbillNo ratings yet

- CV-K C - ODonnellDocument3 pagesCV-K C - ODonnellSyed Abrar Ul HaqNo ratings yet

- Curriculum Vitae: Ashraf AliDocument4 pagesCurriculum Vitae: Ashraf AliAshraf AliNo ratings yet

- Civil Engineer (B) PDFDocument6 pagesCivil Engineer (B) PDFengrrahman3135No ratings yet

- Vinothkumar-Qaqc CVDocument6 pagesVinothkumar-Qaqc CVsooraj0% (1)

- RVK CVDocument7 pagesRVK CVjithin shankarNo ratings yet

- HIFZUR RAHMAN - OriginalDocument7 pagesHIFZUR RAHMAN - OriginalKshama RaiNo ratings yet

- Coating Inspector ResumeDocument4 pagesCoating Inspector Resumetulasirao.nammiNo ratings yet

- Amritesh - Resume Be Updated-1Document2 pagesAmritesh - Resume Be Updated-1pravesh tiwariNo ratings yet

- Skill Set Profile Summary: Tauqeer SalimDocument3 pagesSkill Set Profile Summary: Tauqeer SalimTauqeer SalimNo ratings yet

- Nilesh Sutradhar - Feb24 2Document5 pagesNilesh Sutradhar - Feb24 2Nilesh SutradharNo ratings yet

- Hand Book For Steel Structure Quality Control on SiteFrom EverandHand Book For Steel Structure Quality Control on SiteNo ratings yet

- Proposed Topic of Research:: BITS ID: 201218TS525Document6 pagesProposed Topic of Research:: BITS ID: 201218TS525Francis DhanarajNo ratings yet

- Strategic Plan For M/s Larsen & Toubro LTD.,: BITS MM ZG611: Project AssignmentDocument22 pagesStrategic Plan For M/s Larsen & Toubro LTD.,: BITS MM ZG611: Project AssignmentFrancis DhanarajNo ratings yet

- Accupocket 150/400: / Solar Energy / Perfect ChargingDocument4 pagesAccupocket 150/400: / Solar Energy / Perfect ChargingFrancis DhanarajNo ratings yet

- Time Study Format 147Document6 pagesTime Study Format 147Francis DhanarajNo ratings yet

- L&T Construction Water & Effluent Treatment Ic Masterlist of Test Eqipments For CalibrationDocument3 pagesL&T Construction Water & Effluent Treatment Ic Masterlist of Test Eqipments For CalibrationFrancis DhanarajNo ratings yet

- Pipe Book - 27-04-2021Document47 pagesPipe Book - 27-04-2021Francis DhanarajNo ratings yet

- Time Study Format 147Document5 pagesTime Study Format 147Francis DhanarajNo ratings yet

- DI Pipe Handling and Storage ProcedureDocument8 pagesDI Pipe Handling and Storage ProcedureFrancis DhanarajNo ratings yet

- PHPL (B) - LTHE-PL-PRO-19 Rev 1-Pipe BookDocument5 pagesPHPL (B) - LTHE-PL-PRO-19 Rev 1-Pipe BookFrancis DhanarajNo ratings yet

- Welding Process Comparision RevisedDocument2 pagesWelding Process Comparision RevisedFrancis DhanarajNo ratings yet

- Welder and Welding Operator Qualification RecordDocument2 pagesWelder and Welding Operator Qualification RecordFrancis DhanarajNo ratings yet

- Guide On Storage, Maintenance and Transportation of Double-Wall Corrugated Polyethylene PipesDocument8 pagesGuide On Storage, Maintenance and Transportation of Double-Wall Corrugated Polyethylene PipesFrancis DhanarajNo ratings yet

- Sensitivity: LNT Construction Internal UseDocument10 pagesSensitivity: LNT Construction Internal UseFrancis DhanarajNo ratings yet

- Sop Title: SOP Version No: 01 Date:: Page 1 of 6Document6 pagesSop Title: SOP Version No: 01 Date:: Page 1 of 6Francis DhanarajNo ratings yet

- Smart Glass ProcedureDocument117 pagesSmart Glass ProcedureFrancis DhanarajNo ratings yet

- Method of Statement Natural Gas Pipeline InstallationDocument7 pagesMethod of Statement Natural Gas Pipeline InstallationFrancis DhanarajNo ratings yet

- L&T Hydrocarbon Engineering Limited: Certificate of AppreciationDocument2 pagesL&T Hydrocarbon Engineering Limited: Certificate of AppreciationFrancis DhanarajNo ratings yet

- Part 1-AprilDocument210 pagesPart 1-AprilFrancis DhanarajNo ratings yet

- Geodesic Aluminum Dome & Cover Roof Specification AWWA D108: GeneralDocument4 pagesGeodesic Aluminum Dome & Cover Roof Specification AWWA D108: GeneralFrancis DhanarajNo ratings yet

- FL AWWA Steel Pipelines - 0Document42 pagesFL AWWA Steel Pipelines - 0Francis DhanarajNo ratings yet

- AWWA Manual M11, Steel Pipe-A Guide For Design and InstallationDocument3 pagesAWWA Manual M11, Steel Pipe-A Guide For Design and InstallationFrancis DhanarajNo ratings yet

- Issue: 1.0, Date: 31/5/2020: PDL/GUI/6003Document3 pagesIssue: 1.0, Date: 31/5/2020: PDL/GUI/6003Francis DhanarajNo ratings yet

- Blogging: For Beginners EbookDocument15 pagesBlogging: For Beginners EbookIva JovićNo ratings yet

- EBW docxAAAAAAADocument3 pagesEBW docxAAAAAAASURANA19730% (1)

- PMI Course Catalog-5.17Document19 pagesPMI Course Catalog-5.17meliNo ratings yet

- Revision Test Paper CAP III June 2020Document233 pagesRevision Test Paper CAP III June 2020Roshan PanditNo ratings yet

- The Competition Time JULY 1470844Document65 pagesThe Competition Time JULY 1470844SAT1243No ratings yet

- NSCI Training Calendar 2024 25Document2 pagesNSCI Training Calendar 2024 25paragbhoyar843No ratings yet

- Instructor: FAISAL SARWAR: Ushair Fareed Zahra Sadiq Abdul MoizDocument42 pagesInstructor: FAISAL SARWAR: Ushair Fareed Zahra Sadiq Abdul MoizushairNo ratings yet

- Fiber Glass and AlemuniniumDocument43 pagesFiber Glass and AlemuniniumTesfaye Degefa100% (2)

- RVL 2-05-00 Digital Readiness DiagnosticDocument3 pagesRVL 2-05-00 Digital Readiness DiagnosticGhada NabilNo ratings yet

- 0 - CV Eulalie AnokoiDocument3 pages0 - CV Eulalie AnokoiEulalie AnokoiNo ratings yet

- Better Supply Management With UNSPSC: Says Gary Reiner, Senior VP and CIO of General ElectricDocument23 pagesBetter Supply Management With UNSPSC: Says Gary Reiner, Senior VP and CIO of General ElectricKetsela HailuNo ratings yet

- Bank Account Management in SAP S - 4HANA - SAP BlogsDocument14 pagesBank Account Management in SAP S - 4HANA - SAP BlogsKapadia MritulNo ratings yet

- SME ManualDocument19 pagesSME ManualBojackyNo ratings yet

- ISE 2014 Chapter 2 - Cost Concepts: Fixed/Variable Costs - If Costs Change Appreciably WithDocument15 pagesISE 2014 Chapter 2 - Cost Concepts: Fixed/Variable Costs - If Costs Change Appreciably WithTesfuNo ratings yet

- MSC 1 - MOCK Exam 3 - Answer KeyDocument7 pagesMSC 1 - MOCK Exam 3 - Answer Keytqpkb4xzz8No ratings yet

- Chapter 11-Change and Innovation: True/FalseDocument40 pagesChapter 11-Change and Innovation: True/FalseSufie ImaaniNo ratings yet

- Ashok LeylandDocument16 pagesAshok LeylandSHIVAM AHUJANo ratings yet

- Problems I: P4-5 Eamirrgr)Document1 pageProblems I: P4-5 Eamirrgr)Amel LiaNo ratings yet

- The Financial System: Dr. Andrea LuDocument30 pagesThe Financial System: Dr. Andrea LuMia RenNo ratings yet

- A Leadership Programme For Agricultural Entrepreneurs in SwedenDocument18 pagesA Leadership Programme For Agricultural Entrepreneurs in SwedenAtikah FMNo ratings yet

- Law QDocument7 pagesLaw Qshakhawat HossainNo ratings yet

- University of WestminsterDocument9 pagesUniversity of WestminsterErin BancNo ratings yet

- ESAP FormsDocument17 pagesESAP FormsKa PuringNo ratings yet

- Ss & RQ Model For Inductrial EngineeringDocument25 pagesSs & RQ Model For Inductrial EngineeringPadhai Kar YaarNo ratings yet

- PS-451 Dry Sorbent Injection-B&WDocument4 pagesPS-451 Dry Sorbent Injection-B&WHarun BilirgenNo ratings yet

- Open SourceDocument3 pagesOpen SourcellllNo ratings yet

Key Skills: S.Thirunavukkarasu

Key Skills: S.Thirunavukkarasu

Uploaded by

Francis DhanarajOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Key Skills: S.Thirunavukkarasu

Key Skills: S.Thirunavukkarasu

Uploaded by

Francis DhanarajCopyright:

Available Formats

S.

THIRUNAVUKKARASU

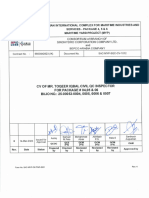

Profile Summary : A Highly motivated, Dedicated and Adaptable, Civil Engineering Profession ,Specialized and

Skilled in Construction Quality Management system, worked 13 years as QA/QC Engineer ( Employer’s role)

in Oman, Perform best professionalisms in Quality Management System, accomplished Prestigious projects in

Oman . Acquired versatile knowledge from past diversified Constructions industries, Enthusiast of Record proof,

with continual improvements in career.

Address Al Hambar , Sohar, Sultanate of Oman . Mobile: +968 95236150, email.id: arasu0015@yahoo.co.in

KEY SKILLS

Graduate Civil Engineer with 25 years Experiences Construction field

Specialized in Construction QA/QC works

ISO 9001: 2000 QMS , Certified Lead Auditor

Working 10+ years as Client’s QA/QC Engineer in Royal Court Affair (Govt. of

Oman). Oman.

Worked 3 years as QA/QC Engineer in MNC company ( LTEM , OMAN)

Skilled in Site Quality Inspection ,documentation for the civil construction

activities

Possess Professional knowledge, Interpersonal, Effective communications skills

Address: Keen, Enforcing & Accomplishing Team works at ON& OFF site

Al Hambar , Sohar , Soutanate of

Oman. Managerial Skills for site Coordination, Trouble shooting.

Mobile Number: +96895236150

Email id : arasu0015@yahoo.co.in

1. Current Organizations Royal Estates, Royal Court Affairs, Oman, (Govt. of

Oman )

Position QA /QC Engineer from Employer side.

Durations From 2009 to till Date

Current Project Expansion of Sohar Hospital , Sohar , Sultanate of Oman from 2017 till date.

Project handled Sultan Qaboos Mosque , Bukha from 2013 to 2017

Majlis Oman, Oman Parliamentary House , form 2009 to 2013

Restoration of Sohar fort.

Clients Royal Estates, Royal Court Affairs, Muscat, Sultanate of Oman.( An Entity

of Oman Government for Design , construction & maintenance of

Buildings, Infrastructures for Royal offices , palaces , sultanate of Oman )

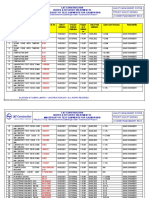

Features, and Area involved of Handled Projects

Construction of Mega RCC concrete structure like Retaining wall of 400 mm thick Basement structures, Piling structures, Under

Ground water tank, Pumping stations, Electrical sub stations, cooling tower, Tunnel works.

HVAC Chiller compound with Related Chill water Pipeline works of 600 – 100 mm dia D.I pipes for 20000 meter length.

Fire water line from 300 -100 dia M.S pile line works 10000 mtrs lengths

Domestic Hot water & Cold water line of various dia of copper line 50000 mts.

External Storm water Pipe line 600 -150 mm dia 10000 mts

Road, boundary, podium wall structures.

Responsibilities:

Reviewing the submissions of Contractors QA/QC Documents PQP, ITP , works Method statements and approving

Reviewing Contractor’s submission of All MAS of Civil materials as per BOQ , Specifications, accompanied compliance statements

and Approving / Approving with comments .

Sensitivity: LNT Construction Internal Use

Reviewing the Delivered Materials As per above Approved MAS and Clearing Site MIR

Ensuring the Effective implementations of Contractor’s QA/QC operations at site

Monitoring the Contractor’s QA/QC works, Reviewing Contractor CONQUAS submission as per Approved PQP.

Day to Day site inspection along with Contractor QC team, to clear the IR for site Activities.

Witnessing concrete trial mix, field quality tests of structures, finishing works and giving comments /approvals.

Witnessing concrete Pouring , ensuring the Quality parameter of fresh concrete for the structural casting

Witnessing the Concrete Cube strength at Lab.

Identify the Non Quality conformances , Issuing the NCR , Observations

Conduction Bi weekly meeting, Reviewing Site QA/QC works, Documentations addressing the Site issues with the immediate

boss.

Qualitative Recoding Reporting & Updating to concerned the Status of Project QA/QC functional

Reviewing the Monthly Project QA/QC Reports and Commenting, Time to Time instruction to contractor to improve the site

QA/QC system & Activities.

Enacting the correction , corrective action , Preventive actions

Reviewing, Coordination the Project Testing, commissioning, ending Qualitative documents & Approving toward project closing.

Previous Employer Details

2. Company Larsen & Toubro Eelectromech LLC Oman.

Position Held QA & QC Engineer

Durations Jan 2007 to Dec 2009

Project handled Construction of oil storage tanks ,associated tank civil foundations , pipe

line sleepers, culverts , bund wall ,RCC retaining walls, roads , pile

foundations

Clients Oil tanking Terminals & Co. Llc, Oman, PDO , Oman

Project Features & Area Handled:

Constructions on shore Elevated Oil Storage Tanks of range of 10 m -20m dia with 20 m ht. Rolled M.S steel tankages

Associated Pipe line of 36 k.m all around and interconnections pipeline works of various dia ranging from 900 mm to 300 mm.

Massive Onshore concrete structure like RCC bund wall, underground Retaining walls, Piling structures, Pipe sleepers, Under

Ground Oil Pumping Stations with continuous Dewatering method.

11 kva Electrical substations & Transformer

Internal Road & Storm water , Oil Drainage pipe line works

Responsibilities:

Preparing the Project’s QA/QC Plan , Getting management Prior Review, Approval and Getting Final Approval from Client

Preparing ITP , Working Methodology for all activities, obtaining management review, Prior approval and Getting final approval

from the client

Preparation of Material Compliance statements , collecting all data, catalogue submission of MAS for all civil materials as per

Project scopes , specifications and obtaining Approval from Clients for all MAS .

Establishing site QA/QC Laboratory with necessary standard requirements and ensuring proper functional

Witnessing the Concrete Trial Mix and Obtaining the Concrete Mix Design

Witnessing the concrete pouring and offering for Client final inspections and approvals.

Witnessing the Concrete Cube strength , Recording , Reporting regularly and submitting statistical cube reports for actual concrete

characteristics strength

Implementing CONQUAS and assess the Product quality rating.

Promoting and creating awareness about risk based thinking

Preparing of Risk & Opportunities and reviewing the same time to time.

Conducting training and awareness programme to construction team to get final product within time and low cost

Day to Day witnessing of all civil activities as Per Approved ITP and offering IR for Client’s witnessing, inspecting and obtaining Final

Approvals.

Sensitivity: LNT Construction Internal Use

Maintaining Day to Day Quality Documents , Reporting Project QA/QC Status Reports to QA/QC Head

Recording, Reporting the Site Day to Day inspections, Status of QA/QC to QA/QC Manager.

Identifying the Non conformances to the site activities issuing the NCR and Coordination with the concerned Engineer to close out

the NCR

Enacting correction, corrective action, and Preventive action for the Non conformances.

Calibrating the site QA/QC controlling mechanism along with QA/QC manager , Internal Auditor and Preparing for External QA/QC

Audit

Establishing and controlling the QA/QC documentations.

Reporting , Recording the Quality Non conformances , finding the Root causes , Adopting the Preventive, corrective actions .

Getting involved for the Project’s testing, commissioning & close out documentations.

3. Company M/s. Dawood contracting L.L.C, Sultanate of Oman

Position Held Project Engineer

Durations 2003 to 2007

Project handled Construction of Junood Mess, RAFO, Ministry of Defense, Oman

Client Ministry of Defense, Sultanate of Oman.

Responsibilities:

Project Planning , Reviewing , Submitting and Getting approval

Executing the Project as per Approved Programme

Preparing , submitting , obtaining the Bi-weekly micro programme

Implementing. Monitoring, the Macro and Micro level Project Progress against Programme.

Controlling the Project progress against the Programme

Timey notifying , recording to client about the designs , ambiguities

Coordination with the clients and others for technical & commercial matters

Carrying out the Site Inspections, All activities, assessing the works as per the Contracts qualitatively, Quantitatively.

Involving / Coordination for Project’s Material Procurements , Sub contractors , ensuring the material delivery and sub-

contractors works as per the Programme

Involving Final Inspections, Pre commissioning for works civil. MEP with prior submission , approval of pre commissioning , final

testing commissioning documents

Substantial Physical completion of whole works and documented completions and handing over the project with justifiable time,

cost overrun.

4. Company M/s. Al Moram Contracting Co. LLC

Position Held Project Engineer

Durations 2001 to 2003

Project handled Facility Management of Sultan Qaboos Hospital, Salalah , Oman. And

Construction Engineer

Project Planning , Reviewing , Submitting and Getting approval

Executing the Project as per Approved Programme

Preparing , submitting , obtaining the Bi-weekly micro programme

Implementing. Monitoring, the Macro and Micro level Project Progress against Programme.

Controlling the Project progress against the Programme

Timey notifying , recording to client about the designs , ambiguities

Coordination with the clients and others for technical & commercial matters

Carrying out the Site Inspections, All activities, assessing the works as per the Contracts qualitatively, Quantitatively.

Involving / Coordination for Project’s Material Procurements , Sub contractors , ensuring the material delivery and sub-

contractors works as per the Programme

Involving Final Inspections, Pre commissioning for works civil. MEP with prior submission , approval of pre commissioning , final

testing commissioning documents

3

Sensitivity: LNT Construction Internal Use

Substantial Physical completion of whole works and Documented completions and handing over the project with justifiable time,

cost ,and quality .

5. Company Holsman Videocon India Ltd. Other Pvt .company &

Ministries.

Position Held Project Engineer

Durations 1996 to 2000

Project handled Construction of Ford Car, Distillery factories in Chennai , Other Pvt,&

Govt. Organization in India.

Review IFC drawings , Establish the constructions Elements as per Approved IFC,

Coordinate with concerned to Prepare the Shop drg. And Get it approved from the Client

Weekly Micro work plan as per Project Plant , Arrange Resource to get establish at site

Get involved in Site QC and Ensure the works as per the Required quality, Productivity norms.

Get involved in the QS to raise monthly invoice.

Educations Details : Bachelor Of Civil Engineering , Passed in April 1994 ,

University: Manonmaniyam Sundaranar University , Tirunelveli , Tamil Nadu, India .

Training Course Certificate: Successfully completed QUALITY MANAGEMENT SYSTEM (QMS), LEAD AUDITTOR

(ISO 9001: 2000) Training course No; A 18021 certified by IRCA, certificate number ; A18021/695/2008

Driving License: Valid Driving license from Sultanate of Oman L.No: 62575893, issued at Muscat, Expire on 10/10/2023

Personal Details:

D.O.B : 16-05-1972 Indian Married , email id : arasu0015@yahoo.co.in

References: Eng. Khalid Al Bulushi , Assit. HEREA, Royal Estate , Muscat . Ph Number : 24088841

Eng. Saif Zahran Ali Al jabri, Project Director , BBAA, Sohar , Ph number : 99419191

Signature

Place :

Date :

Sensitivity: LNT Construction Internal Use

You might also like

- QAQC Electrical Inspection: A Beginner's GuideFrom EverandQAQC Electrical Inspection: A Beginner's GuideRating: 4 out of 5 stars4/5 (1)

- Quality Assurance Plan For Building ConstructionDocument18 pagesQuality Assurance Plan For Building ConstructionANup GhiMire100% (3)

- Grade 11 Business and Accounting Studies Past Paper 2020 3rd Term Test Western ProvinceDocument25 pagesGrade 11 Business and Accounting Studies Past Paper 2020 3rd Term Test Western Provinceinvictus azmunNo ratings yet

- Sample Electrical Project Manager ResumeDocument4 pagesSample Electrical Project Manager ResumePresanna RajasekaranNo ratings yet

- CV (Sr. QA QC Engineer)Document5 pagesCV (Sr. QA QC Engineer)mansih457100% (1)

- Sample CVDocument8 pagesSample CVyusufal0406No ratings yet

- TORISHIMA - JA - 3542 - MAS Submission - Rev.0 - 20200922Document240 pagesTORISHIMA - JA - 3542 - MAS Submission - Rev.0 - 20200922Francis Dhanaraj100% (1)

- Ra PIDSDocument7 pagesRa PIDSMiko Severa100% (1)

- Consumer MovementDocument16 pagesConsumer MovementJananee Rajagopalan75% (56)

- SAMAYADURAI CV-05-Mar-24Document4 pagesSAMAYADURAI CV-05-Mar-24Vijay Allimuthu AvathipalayamNo ratings yet

- QA QC CIVIL INSPECTOR (1)-compressed (1)Document5 pagesQA QC CIVIL INSPECTOR (1)-compressed (1)Mohamed ArafathNo ratings yet

- ACO 9 2001 055 T7 4 0 SamayaDocument6 pagesACO 9 2001 055 T7 4 0 SamayaVijay Allimuthu AvathipalayamNo ratings yet

- Eepak Axena: Regular Member of Aace, Usa: Constituent Number: 59099 Associate Member of Institution of Engineers, IndiaDocument7 pagesEepak Axena: Regular Member of Aace, Usa: Constituent Number: 59099 Associate Member of Institution of Engineers, IndiadeepaksaxNo ratings yet

- Pravesh Tiwari Resume R-1Document4 pagesPravesh Tiwari Resume R-1pravesh tiwariNo ratings yet

- CVDocument6 pagesCVADNAN REHMATNo ratings yet

- AMIN Consult1Document3 pagesAMIN Consult1aminulhaqNo ratings yet

- Khaja Ghouse Moinuddin - 11 Yrs Experience With Aramco Approved - QC Inspector - CivilDocument5 pagesKhaja Ghouse Moinuddin - 11 Yrs Experience With Aramco Approved - QC Inspector - Civilsyed imranNo ratings yet

- CV Amjad Ahmad KhanDocument15 pagesCV Amjad Ahmad Khannaveedcomsian054No ratings yet

- Ramesh ChaudharyDocument4 pagesRamesh ChaudharyAdesh PatankarNo ratings yet

- Covering Letter: Mukesh Kumar GuptaDocument6 pagesCovering Letter: Mukesh Kumar GuptaTauqeer SalimNo ratings yet

- Krishna Mech EngineerDocument6 pagesKrishna Mech EngineeranjeeNo ratings yet

- Resume-Dec-2023.. (2)Document8 pagesResume-Dec-2023.. (2)Samir Baran BeraNo ratings yet

- Resume Ayaz RevisedDocument4 pagesResume Ayaz RevisedayazeeNo ratings yet

- Aamir Ehsan Detailed CVDocument3 pagesAamir Ehsan Detailed CVnmapeshawarNo ratings yet

- KP Jasim UsmanDocument7 pagesKP Jasim UsmanbobbyNo ratings yet

- Experience: Sulzer Chemtech (JHECO) - Yanbu KSADocument3 pagesExperience: Sulzer Chemtech (JHECO) - Yanbu KSApmkarNo ratings yet

- Career Summary: Ibrahim SopariwalaDocument3 pagesCareer Summary: Ibrahim SopariwalaIbrahim SopariwalaNo ratings yet

- 160308131927Document4 pages160308131927hakrajputNo ratings yet

- Anand CV 2022arDocument6 pagesAnand CV 2022arsanbsahaNo ratings yet

- CV-Engr Muhammad Sohaib Civil QC InspectorDocument3 pagesCV-Engr Muhammad Sohaib Civil QC Inspectorjahangirasim766No ratings yet

- Mohammed Aejaz Ahmed: Personal SummaryDocument3 pagesMohammed Aejaz Ahmed: Personal SummaryAejaz AhmedNo ratings yet

- CV Sample - 2Document20 pagesCV Sample - 2Lateef Ur REhmanNo ratings yet

- Updated CV - Jai Kashyap-1Document6 pagesUpdated CV - Jai Kashyap-1raghavmavenmarketingmediaNo ratings yet

- Cover Letter: Home AddressDocument4 pagesCover Letter: Home AddressVenkates WaranNo ratings yet

- Curriculum VitaeDocument8 pagesCurriculum Vitaeramesh_rhtNo ratings yet

- CV 2023Document5 pagesCV 2023AmitNo ratings yet

- Karim Ali ElAskary Visualcv ResumeDocument3 pagesKarim Ali ElAskary Visualcv ResumeAnonymous a3K3WgNo ratings yet

- Engineer Asif (Civil Engineer)Document4 pagesEngineer Asif (Civil Engineer)Imran AliiiNo ratings yet

- CV Faisal ZAFAR SHAHIDDocument6 pagesCV Faisal ZAFAR SHAHIDAlam MD SazidNo ratings yet

- Curriculum Vitae - Paul Joseph Sebastian..Document4 pagesCurriculum Vitae - Paul Joseph Sebastian..Abdullah AnsariNo ratings yet

- I I I I I: Key Experience and BackgroundDocument4 pagesI I I I I: Key Experience and Backgroundnaveed566No ratings yet

- Engr Bahram Updated CVDocument5 pagesEngr Bahram Updated CVcivilNo ratings yet

- Khalid Civil Qc UpdateDocument3 pagesKhalid Civil Qc UpdateRahimNo ratings yet

- Asim CV Site Engineer QC InspectorDocument15 pagesAsim CV Site Engineer QC InspectorMuhammad ShahidNo ratings yet

- Durocrete Company Profile 2023Document21 pagesDurocrete Company Profile 2023puriganesh1988No ratings yet

- Mohsin Mapari-Mech Engr CVDocument2 pagesMohsin Mapari-Mech Engr CVMohsin MapariNo ratings yet

- Qa/Qc Mechanical Inspection Engineer Resume: Buvanes222@yahoo - Co.inDocument5 pagesQa/Qc Mechanical Inspection Engineer Resume: Buvanes222@yahoo - Co.inpradeep67% (3)

- Bakthiar QC CVDocument3 pagesBakthiar QC CVSyed Bakhtiar HussainNo ratings yet

- Naukri SAMIRJEDHE (21y 0m)Document15 pagesNaukri SAMIRJEDHE (21y 0m)sushil.tripathiNo ratings yet

- QC Engr CV PDFDocument5 pagesQC Engr CV PDFMuthazhagan SaravananNo ratings yet

- Update CV PDFDocument5 pagesUpdate CV PDFAdnan MunirNo ratings yet

- Lva1 App6891Document11 pagesLva1 App6891ganeshram2305No ratings yet

- Lead Structural Engineer Academics: Nimai PurkaitDocument5 pagesLead Structural Engineer Academics: Nimai PurkaitbillNo ratings yet

- CV-K C - ODonnellDocument3 pagesCV-K C - ODonnellSyed Abrar Ul HaqNo ratings yet

- Curriculum Vitae: Ashraf AliDocument4 pagesCurriculum Vitae: Ashraf AliAshraf AliNo ratings yet

- Civil Engineer (B) PDFDocument6 pagesCivil Engineer (B) PDFengrrahman3135No ratings yet

- Vinothkumar-Qaqc CVDocument6 pagesVinothkumar-Qaqc CVsooraj0% (1)

- RVK CVDocument7 pagesRVK CVjithin shankarNo ratings yet

- HIFZUR RAHMAN - OriginalDocument7 pagesHIFZUR RAHMAN - OriginalKshama RaiNo ratings yet

- Coating Inspector ResumeDocument4 pagesCoating Inspector Resumetulasirao.nammiNo ratings yet

- Amritesh - Resume Be Updated-1Document2 pagesAmritesh - Resume Be Updated-1pravesh tiwariNo ratings yet

- Skill Set Profile Summary: Tauqeer SalimDocument3 pagesSkill Set Profile Summary: Tauqeer SalimTauqeer SalimNo ratings yet

- Nilesh Sutradhar - Feb24 2Document5 pagesNilesh Sutradhar - Feb24 2Nilesh SutradharNo ratings yet

- Hand Book For Steel Structure Quality Control on SiteFrom EverandHand Book For Steel Structure Quality Control on SiteNo ratings yet

- Proposed Topic of Research:: BITS ID: 201218TS525Document6 pagesProposed Topic of Research:: BITS ID: 201218TS525Francis DhanarajNo ratings yet

- Strategic Plan For M/s Larsen & Toubro LTD.,: BITS MM ZG611: Project AssignmentDocument22 pagesStrategic Plan For M/s Larsen & Toubro LTD.,: BITS MM ZG611: Project AssignmentFrancis DhanarajNo ratings yet

- Accupocket 150/400: / Solar Energy / Perfect ChargingDocument4 pagesAccupocket 150/400: / Solar Energy / Perfect ChargingFrancis DhanarajNo ratings yet

- Time Study Format 147Document6 pagesTime Study Format 147Francis DhanarajNo ratings yet

- L&T Construction Water & Effluent Treatment Ic Masterlist of Test Eqipments For CalibrationDocument3 pagesL&T Construction Water & Effluent Treatment Ic Masterlist of Test Eqipments For CalibrationFrancis DhanarajNo ratings yet

- Pipe Book - 27-04-2021Document47 pagesPipe Book - 27-04-2021Francis DhanarajNo ratings yet

- Time Study Format 147Document5 pagesTime Study Format 147Francis DhanarajNo ratings yet

- DI Pipe Handling and Storage ProcedureDocument8 pagesDI Pipe Handling and Storage ProcedureFrancis DhanarajNo ratings yet

- PHPL (B) - LTHE-PL-PRO-19 Rev 1-Pipe BookDocument5 pagesPHPL (B) - LTHE-PL-PRO-19 Rev 1-Pipe BookFrancis DhanarajNo ratings yet

- Welding Process Comparision RevisedDocument2 pagesWelding Process Comparision RevisedFrancis DhanarajNo ratings yet

- Welder and Welding Operator Qualification RecordDocument2 pagesWelder and Welding Operator Qualification RecordFrancis DhanarajNo ratings yet

- Guide On Storage, Maintenance and Transportation of Double-Wall Corrugated Polyethylene PipesDocument8 pagesGuide On Storage, Maintenance and Transportation of Double-Wall Corrugated Polyethylene PipesFrancis DhanarajNo ratings yet

- Sensitivity: LNT Construction Internal UseDocument10 pagesSensitivity: LNT Construction Internal UseFrancis DhanarajNo ratings yet

- Sop Title: SOP Version No: 01 Date:: Page 1 of 6Document6 pagesSop Title: SOP Version No: 01 Date:: Page 1 of 6Francis DhanarajNo ratings yet

- Smart Glass ProcedureDocument117 pagesSmart Glass ProcedureFrancis DhanarajNo ratings yet

- Method of Statement Natural Gas Pipeline InstallationDocument7 pagesMethod of Statement Natural Gas Pipeline InstallationFrancis DhanarajNo ratings yet

- L&T Hydrocarbon Engineering Limited: Certificate of AppreciationDocument2 pagesL&T Hydrocarbon Engineering Limited: Certificate of AppreciationFrancis DhanarajNo ratings yet

- Part 1-AprilDocument210 pagesPart 1-AprilFrancis DhanarajNo ratings yet

- Geodesic Aluminum Dome & Cover Roof Specification AWWA D108: GeneralDocument4 pagesGeodesic Aluminum Dome & Cover Roof Specification AWWA D108: GeneralFrancis DhanarajNo ratings yet

- FL AWWA Steel Pipelines - 0Document42 pagesFL AWWA Steel Pipelines - 0Francis DhanarajNo ratings yet

- AWWA Manual M11, Steel Pipe-A Guide For Design and InstallationDocument3 pagesAWWA Manual M11, Steel Pipe-A Guide For Design and InstallationFrancis DhanarajNo ratings yet

- Issue: 1.0, Date: 31/5/2020: PDL/GUI/6003Document3 pagesIssue: 1.0, Date: 31/5/2020: PDL/GUI/6003Francis DhanarajNo ratings yet

- Blogging: For Beginners EbookDocument15 pagesBlogging: For Beginners EbookIva JovićNo ratings yet

- EBW docxAAAAAAADocument3 pagesEBW docxAAAAAAASURANA19730% (1)

- PMI Course Catalog-5.17Document19 pagesPMI Course Catalog-5.17meliNo ratings yet

- Revision Test Paper CAP III June 2020Document233 pagesRevision Test Paper CAP III June 2020Roshan PanditNo ratings yet

- The Competition Time JULY 1470844Document65 pagesThe Competition Time JULY 1470844SAT1243No ratings yet

- NSCI Training Calendar 2024 25Document2 pagesNSCI Training Calendar 2024 25paragbhoyar843No ratings yet

- Instructor: FAISAL SARWAR: Ushair Fareed Zahra Sadiq Abdul MoizDocument42 pagesInstructor: FAISAL SARWAR: Ushair Fareed Zahra Sadiq Abdul MoizushairNo ratings yet

- Fiber Glass and AlemuniniumDocument43 pagesFiber Glass and AlemuniniumTesfaye Degefa100% (2)

- RVL 2-05-00 Digital Readiness DiagnosticDocument3 pagesRVL 2-05-00 Digital Readiness DiagnosticGhada NabilNo ratings yet

- 0 - CV Eulalie AnokoiDocument3 pages0 - CV Eulalie AnokoiEulalie AnokoiNo ratings yet

- Better Supply Management With UNSPSC: Says Gary Reiner, Senior VP and CIO of General ElectricDocument23 pagesBetter Supply Management With UNSPSC: Says Gary Reiner, Senior VP and CIO of General ElectricKetsela HailuNo ratings yet

- Bank Account Management in SAP S - 4HANA - SAP BlogsDocument14 pagesBank Account Management in SAP S - 4HANA - SAP BlogsKapadia MritulNo ratings yet

- SME ManualDocument19 pagesSME ManualBojackyNo ratings yet

- ISE 2014 Chapter 2 - Cost Concepts: Fixed/Variable Costs - If Costs Change Appreciably WithDocument15 pagesISE 2014 Chapter 2 - Cost Concepts: Fixed/Variable Costs - If Costs Change Appreciably WithTesfuNo ratings yet

- MSC 1 - MOCK Exam 3 - Answer KeyDocument7 pagesMSC 1 - MOCK Exam 3 - Answer Keytqpkb4xzz8No ratings yet

- Chapter 11-Change and Innovation: True/FalseDocument40 pagesChapter 11-Change and Innovation: True/FalseSufie ImaaniNo ratings yet

- Ashok LeylandDocument16 pagesAshok LeylandSHIVAM AHUJANo ratings yet

- Problems I: P4-5 Eamirrgr)Document1 pageProblems I: P4-5 Eamirrgr)Amel LiaNo ratings yet

- The Financial System: Dr. Andrea LuDocument30 pagesThe Financial System: Dr. Andrea LuMia RenNo ratings yet

- A Leadership Programme For Agricultural Entrepreneurs in SwedenDocument18 pagesA Leadership Programme For Agricultural Entrepreneurs in SwedenAtikah FMNo ratings yet

- Law QDocument7 pagesLaw Qshakhawat HossainNo ratings yet

- University of WestminsterDocument9 pagesUniversity of WestminsterErin BancNo ratings yet

- ESAP FormsDocument17 pagesESAP FormsKa PuringNo ratings yet

- Ss & RQ Model For Inductrial EngineeringDocument25 pagesSs & RQ Model For Inductrial EngineeringPadhai Kar YaarNo ratings yet

- PS-451 Dry Sorbent Injection-B&WDocument4 pagesPS-451 Dry Sorbent Injection-B&WHarun BilirgenNo ratings yet

- Open SourceDocument3 pagesOpen SourcellllNo ratings yet