Professional Documents

Culture Documents

Stamp Form

Stamp Form

Uploaded by

Gerardo CalleOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Stamp Form

Stamp Form

Uploaded by

Gerardo CalleCopyright:

Available Formats

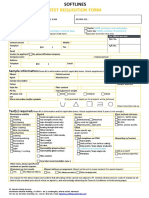

STAMPED FORM

Assistance Request Form

Company: Phone:

Contact: Fax:

Address: Email:

PO#: Terms:

Size I.D. O.D. Overall Length Tolerance

in/mm in/mm ft/in/mm

Temperature Material Conveyed Environmental Temperature

Min. Max. Min. Max.

ºF/ºC ºF/ºC ºF/ºC ºF/ºC

Application

Material Material Conveyed

Media Internal External

Media Environment

Pressure Max. Working Pressure Spikes Vacuum

PSI/kPa PSI/kPa Inches of Hg/kPa

Ends End Style Size Capped Threads/Bolt Orientation Attachment

Material Hole Alignment Mehthods

1 Yes/No

2 Yes/No

Delivery

Quantity Required: Date Required:

Package Type:

Pick Up Date: Ship Via:

Testing Required: Yes/No Type:

Certification Required: Yes/No Type:

STAMPED Form

Application Requirements - Stamped

Purpose

The purpose of this section is to provide a simple to use guide to assist in determin-

ing the correct hose, coupling and attachment method that will satisfy your customers’

needs.

General

The guide uses the STAMPED process. STAMPED is an acronym and stands for the 7

major information areas required to provide a quality hose assembly for your customer,

as follows:

S stands for SIZE; I.D., O.D. and length

T stands for TEMPERATURE of the material conveyed and environmental

A stands for the APPLICATION, the conditions of use

M stands for the MATERIAL being conveyed, type and concentration

P stands for the PRESSURE to which the assembly will be exposed

E stands for ENDS; style, type, orientation, attachment methods, etc.

D stands for DELIVERY; testing, quality, packaging, and delivery requirements

Directions

Using the form:

1. Inform the customer you will be using an application format called STAMPED.

2. Ask your customer the pertinent questions outlined on the form, in sequence.

3. After completing the form, ask your customer to confirm their answers as you repeat

them, insequence.

4. Provide the completed format to your assembly area or order entry as required

The following list of special considerations may help to clarify application parameters:

1. Abrasion

2. Electrical conductivity

3. Environment

4. Flammability

5. Flow rate

Contact Information:

6. Fluid velocity Parker Hannifin Corporation

Parflex Division

1300 North Freedom St.

Ravenna, OH 44266

phone 330 296 2871

fax 330 286 8433

www.parker.com/parflex

© 2011 Parker Hannifin Corporation - All Rights Reserved

You might also like

- Daily Coating Insp ReportDocument2 pagesDaily Coating Insp ReportEhsan KhanNo ratings yet

- Naval Shiphandling 4 Ed PDFDocument188 pagesNaval Shiphandling 4 Ed PDFMateus EckerNo ratings yet

- Paint Inspection:: Daily Coating Inspection ReportDocument1 pagePaint Inspection:: Daily Coating Inspection ReportEhsan KhanNo ratings yet

- PQT and Applicator Qualification Test Report: Report Date: Report NumberDocument10 pagesPQT and Applicator Qualification Test Report: Report Date: Report Numberirwan100% (2)

- Volvo Penta MD6A, MD7A Workshop ManualDocument44 pagesVolvo Penta MD6A, MD7A Workshop ManualChrister Andemark100% (3)

- Dryer Data SheetDocument1 pageDryer Data Sheetacas35100% (1)

- Master Formula CardDocument7 pagesMaster Formula CardTrilochan Ayurveda100% (1)

- OK - EndUserGuideHoseSafetyInstituteDocument8 pagesOK - EndUserGuideHoseSafetyInstituteSunil GhosalkarNo ratings yet

- BET FormDocument2 pagesBET Form74nn4hNo ratings yet

- APEO Free Report (Pre Treat Zip) 68141440341Document3 pagesAPEO Free Report (Pre Treat Zip) 68141440341sy mahNo ratings yet

- UPM Analysis GC-FID FormDocument4 pagesUPM Analysis GC-FID FormIs IskandarNo ratings yet

- For An Analysis of Your Application and Our Engineering Recommendation, Please Complete and Return This FormDocument4 pagesFor An Analysis of Your Application and Our Engineering Recommendation, Please Complete and Return This FormPierTavaraNo ratings yet

- MANUF PROCESS - Troubleshooting App. Defects in Automotive Plastic Injection Molding DCC 2007Document54 pagesMANUF PROCESS - Troubleshooting App. Defects in Automotive Plastic Injection Molding DCC 2007dcajr687253No ratings yet

- : ﺔﻘﻴﺛﻮﻟا ناﻮﻨﻋ: ﺔﻴﻤﻴﻈﻨﺘﻟا ةﺪﺣﻮﻟا Work Instructions title: Organization Unit: Doc Ref.: ﺔﻘﻴﺛﻮﻟا ﻢﻗرDocument1 page: ﺔﻘﻴﺛﻮﻟا ناﻮﻨﻋ: ﺔﻴﻤﻴﻈﻨﺘﻟا ةﺪﺣﻮﻟا Work Instructions title: Organization Unit: Doc Ref.: ﺔﻘﻴﺛﻮﻟا ﻢﻗرDavidNo ratings yet

- Purchase ProcedureDocument13 pagesPurchase ProcedureHarsh KachhawaNo ratings yet

- Item Code Quantity UOM Description Stock / Non Stock Item Estimated Unit Cost ($) Total Cost ($)Document3 pagesItem Code Quantity UOM Description Stock / Non Stock Item Estimated Unit Cost ($) Total Cost ($)DILNo ratings yet

- Report PaintDocument1 pageReport PaintEhsan KhanNo ratings yet

- 2021 - PCO Accreditation Application Form and Establishment CategorizationDocument4 pages2021 - PCO Accreditation Application Form and Establishment CategorizationAlfa PoligNo ratings yet

- GP Topcoat: Technical Data SheetDocument3 pagesGP Topcoat: Technical Data SheetZhiyong ZhuNo ratings yet

- DRI CertificateDocument9 pagesDRI CertificateakloioNo ratings yet

- 06-PPFA v2.3 SelectingDocument12 pages06-PPFA v2.3 Selectingsneh222No ratings yet

- Tank Calibration AlllDocument8 pagesTank Calibration AlllMahmoud GaberNo ratings yet

- Tank Calibration Survey - Report DetailsDocument8 pagesTank Calibration Survey - Report DetailsMahmoud GaberNo ratings yet

- (AYSA19-27074) (AYSA19-191899) HYUNDAI TECH CO., LTD - WolverineDocument9 pages(AYSA19-27074) (AYSA19-191899) HYUNDAI TECH CO., LTD - WolverineharidatarciNo ratings yet

- Training Program Lumut BalaiDocument4 pagesTraining Program Lumut BalaiSales OrigroupNo ratings yet

- Itma Tga PVC & AbsDocument4 pagesItma Tga PVC & AbsSetiausaha JKTN SelangorNo ratings yet

- Job Number Client Name Job Description Client Address Grade Date Received Sample Description Date CompletedDocument4 pagesJob Number Client Name Job Description Client Address Grade Date Received Sample Description Date CompletedakloioNo ratings yet

- Softlines General TRF (Indonesia) 2022 - UnlockedDocument5 pagesSoftlines General TRF (Indonesia) 2022 - UnlockedVimalNo ratings yet

- Selecting The Proper Plastic Piping Material: ©2003, 2004, 2005 - Plastics Pipe and Fittings AssociationDocument12 pagesSelecting The Proper Plastic Piping Material: ©2003, 2004, 2005 - Plastics Pipe and Fittings AssociationAshfaq AnwerNo ratings yet

- Application QuestionnaireDocument1 pageApplication QuestionnaireBalesh NidhankarNo ratings yet

- Questionaire For Drum Flaker - NEWDocument2 pagesQuestionaire For Drum Flaker - NEWBhavin TalatiNo ratings yet

- Hazwaste Generator HWG ID Registration FormDocument5 pagesHazwaste Generator HWG ID Registration FormMeggy TayaoNo ratings yet

- (AYSA19-27073) (AYSA19-191898) HYUNDAI TECH CO., LTD - WolverineDocument9 pages(AYSA19-27073) (AYSA19-191898) HYUNDAI TECH CO., LTD - WolverineharidatarciNo ratings yet

- Painting & Inspection FormatDocument1 pagePainting & Inspection FormatABEC Trombay siteNo ratings yet

- 01 2nd Fda - Pqri Ecevit Bilgili Slides For Posting 2 PDFDocument18 pages01 2nd Fda - Pqri Ecevit Bilgili Slides For Posting 2 PDFMahesh PatilNo ratings yet

- Questionnaire For Wet Grinding System: Customer Plant Contact AddressDocument5 pagesQuestionnaire For Wet Grinding System: Customer Plant Contact AddressTecnoExpress CHILENo ratings yet

- Discharge Permit Presentation - CalumbaDocument53 pagesDischarge Permit Presentation - CalumbaTimoty James PaulinNo ratings yet

- Explosion Testing Order Form: Special InstructionsDocument2 pagesExplosion Testing Order Form: Special Instructionsdwidjo atmodjoNo ratings yet

- Consultancy Form 2015Document1 pageConsultancy Form 2015madhu77No ratings yet

- Backfill Compond Test ReportDocument15 pagesBackfill Compond Test ReportTarunNo ratings yet

- eSUN PETG-Filament TDS V4.0Document2 pageseSUN PETG-Filament TDS V4.0AlbertNo ratings yet

- 940534Q - Par Fit Replacement Elements - DIN Series - Parker NADocument3 pages940534Q - Par Fit Replacement Elements - DIN Series - Parker NAGBB FUTSAL - SJCNo ratings yet

- F23Document2 pagesF23aravindanNo ratings yet

- Ppap:: Requirements:: Sign-Off Sheet: PO #: DateDocument1 pagePpap:: Requirements:: Sign-Off Sheet: PO #: DateJoshua CuellarNo ratings yet

- Test Report: Plastometal Engg. (I) PVT LTDDocument4 pagesTest Report: Plastometal Engg. (I) PVT LTDSandeep MalhotraNo ratings yet

- Seepex Pumps Application Work Sheet: Your DetailsDocument1 pageSeepex Pumps Application Work Sheet: Your DetailseduinNo ratings yet

- PERMULAB SDN BHD (392059-X) : Form 1Document2 pagesPERMULAB SDN BHD (392059-X) : Form 1Andrew TanNo ratings yet

- Bio-Fertilizer Data SheetDocument1 pageBio-Fertilizer Data SheetOnyekachi MacaulayNo ratings yet

- 11MM Cord Sample Test Report - 17.02.2017Document1 page11MM Cord Sample Test Report - 17.02.2017quality3No ratings yet

- Test Report: Sample DescriptionDocument7 pagesTest Report: Sample DescriptionAtharv KanetkarNo ratings yet

- HW Generator Denr FormDocument4 pagesHW Generator Denr FormDonna Liza FajardoNo ratings yet

- ETP Query Sheet: General InformationDocument2 pagesETP Query Sheet: General InformationJahid AbedinNo ratings yet

- Plastic PipesDocument12 pagesPlastic PipesitaiNo ratings yet

- Combustion Application Data SheetDocument1 pageCombustion Application Data SheetsendutdutNo ratings yet

- New India Fire Risk Inspection FormatDocument4 pagesNew India Fire Risk Inspection Formatsahu.aashish03No ratings yet

- RWT Ro229. (250 LPH) PDFDocument5 pagesRWT Ro229. (250 LPH) PDFRinse Water TechnologyNo ratings yet

- SOP For Calibration of FT-IR SpectrometerDocument8 pagesSOP For Calibration of FT-IR SpectrometerSolomon Gamanuel100% (1)

- Liquid Application Data SheetDocument1 pageLiquid Application Data SheetYhoj VillanuevaNo ratings yet

- Lab Services - Trac - ORACLEDocument2 pagesLab Services - Trac - ORACLErnd labNo ratings yet

- 45-D00502-enDocument4 pages45-D00502-endegrsacNo ratings yet

- M Tech Thesis Award ProformaDocument1 pageM Tech Thesis Award ProformaSachin BagadNo ratings yet

- Hermetic Type CAM CAMR EN 12 2019Document28 pagesHermetic Type CAM CAMR EN 12 2019SamanNo ratings yet

- Engine Oil Pump - Disassemble: Shutdown SISDocument4 pagesEngine Oil Pump - Disassemble: Shutdown SISOecox Cah DjadoelNo ratings yet

- Deformation (Physics) - WikipediaDocument17 pagesDeformation (Physics) - Wikipediaismail adeizaNo ratings yet

- Chapter 12. Analysis of Consolidation Under EmbankmentDocument9 pagesChapter 12. Analysis of Consolidation Under EmbankmentDEBASISNo ratings yet

- Icm-En-1600 - Field Instrument InstallationDocument22 pagesIcm-En-1600 - Field Instrument Installationnghiemta18No ratings yet

- Gas Tungsten-Arc Welding GTAW - Welding TechnologyDocument2 pagesGas Tungsten-Arc Welding GTAW - Welding TechnologyMuhammadNo ratings yet

- Fundamentals of Induction HeatingDocument3 pagesFundamentals of Induction HeatingautomuthuNo ratings yet

- Thermodynamics 03Document4 pagesThermodynamics 03Cullen MoralesNo ratings yet

- TCAEMM EmptyvaluesdocumentDocument241 pagesTCAEMM EmptyvaluesdocumentJithinNo ratings yet

- Approximate Analysis For Frames Subjected To Lateral Loads: Portal Frame MethodDocument27 pagesApproximate Analysis For Frames Subjected To Lateral Loads: Portal Frame MethodAlaine SobredoNo ratings yet

- Blince OMR Hydraulic MotorDocument10 pagesBlince OMR Hydraulic MotorJoaquin CarvajalNo ratings yet

- Mathcad - BASEPLATE DESIGN - 10 PDFDocument6 pagesMathcad - BASEPLATE DESIGN - 10 PDFMonotobo X MakinaNo ratings yet

- Compresor VMY para RefrigeracionDocument4 pagesCompresor VMY para RefrigeracionSantiago WasingerNo ratings yet

- Sop Sample AerospaceDocument2 pagesSop Sample AerospaceSURAJ100% (1)

- Lattice DynamicsDocument23 pagesLattice DynamicsFrankNo ratings yet

- Penggunaan High Damping Rubber Bearing System Pada Struktur Bangunan Gedung Dengan Analisis Time HistoryDocument10 pagesPenggunaan High Damping Rubber Bearing System Pada Struktur Bangunan Gedung Dengan Analisis Time HistoryC O L H O F V C KNo ratings yet

- XZC710Document3 pagesXZC710ZubairAhmedSiddiquiNo ratings yet

- MmawDocument1 pageMmawVishal JoshiNo ratings yet

- Calculation of Aluminum FrameDocument12 pagesCalculation of Aluminum FrameT Yong ChiamNo ratings yet

- Field Testing of CompressorsDocument12 pagesField Testing of CompressorsmishraenggNo ratings yet

- Mobil Grease GuideDocument2 pagesMobil Grease GuideMohamed ShabanNo ratings yet

- HC-74 NormaDocument2 pagesHC-74 Normargi178No ratings yet

- Stainless Steel Flanges Price List India Stainless Steel Flanges Price List India, ss304 Flange Price List, ss316 Flange Price ListDocument18 pagesStainless Steel Flanges Price List India Stainless Steel Flanges Price List India, ss304 Flange Price List, ss316 Flange Price ListAbhishek BaneNo ratings yet

- Lecture 1Document13 pagesLecture 1bennimenNo ratings yet

- Finite Element Analysis of Foundation On Layered and Homogeneous Soil Deposit Under Dynamic LoadingDocument10 pagesFinite Element Analysis of Foundation On Layered and Homogeneous Soil Deposit Under Dynamic Loadingsujan95No ratings yet

- Yanbu Ii Power & Water Project: Package: 3Document7 pagesYanbu Ii Power & Water Project: Package: 3mohd as shahiddin jafriNo ratings yet

- Advanced Structural Dynamic: Subject of PresentationDocument27 pagesAdvanced Structural Dynamic: Subject of PresentationSaurabh PednekarNo ratings yet

- Astm E164 13Document25 pagesAstm E164 13OteloElMoro67% (3)