Professional Documents

Culture Documents

Phase Behavior and Thermodynamic Model Parameters in Simulations of Extractive Distillation For Azeotrope Separation

Phase Behavior and Thermodynamic Model Parameters in Simulations of Extractive Distillation For Azeotrope Separation

Uploaded by

Aeromoon AeroseekOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Phase Behavior and Thermodynamic Model Parameters in Simulations of Extractive Distillation For Azeotrope Separation

Phase Behavior and Thermodynamic Model Parameters in Simulations of Extractive Distillation For Azeotrope Separation

Uploaded by

Aeromoon AeroseekCopyright:

Available Formats

www.nature.

com/scientificreports

OPEN Phase Behavior and

Thermodynamic Model Parameters

in Simulations of Extractive

Received: 4 April 2017

Accepted: 20 July 2017 Distillation for Azeotrope

Separation

Published: xx xx xxxx

Min Li, Xicai Xu, Xin Li, Kang Ma, Bin Qin, Zhaoyou Zhu & Yinglong Wang

Extractive distillation (ED) processes for separating ternary mixtures of benzene-cyclohexane-toluene

with dimethyl formamide (DMF) and N-methyl-2-pyrrolidone (NMP) were studied using Aspen Plus

and PRO/II simulators. The Aspen Plus built-in binary interaction parameters for the toluene-DMF,

benzene-NMP and cyclohexane-NMP systems resulted in inaccurate phase behavior calculations. The

vapor-liquid equilibrium (VLE) for the three binary systems was regressed to illustrate the importance

of using accurate model parameters. The obtained binary interaction parameters described the phase

behavior more accurately compared with the built-in binary interaction parameters in Aspen Plus. In

this study, the effects of the regressed and built-in binary interaction parameters on the ED process

design are presented. The total annual cost (TAC) was calculated to further illustrate the importance of

the regressed binary interaction parameters. The results show that phase behavior and thermodynamic

model parameters should receive more attention during the research and development of ED processes.

Distillation1, which is based on the relative volatility differences between components in a mixture, is one of

the most important separation technologies. However, it is difficult to separate mixtures efficiently using con-

ventional distillation when they have similar boiling points or form azeotropes. To separate azeotropes, several

advanced distillation technologies have been studied, such as pressure-swing distillation2–7, azeotropic distilla-

tion8, 9 and extractive distillation (ED)10–15. ED is achieved by adding an appropriate solvent with a higher boiling

point to enhance the relative volatility of the components.

ED is one of the most economical ways to separate close-boiling mixtures and has been widely used in the

chemical and petroleum industries16. The design and optimization of ED is becoming increasingly attractive

due to its potential economic advantages. The effectiveness of an ED process relies on the proper choice of sol-

vent17. The solvent should be easy to recover and possess a high thermal stability, low toxicity, and high boiling

point18. The key method for solvent selection is to compare the changes in the degree of relative volatility after

adding different solvents. For example, dimethyl sulfoxide is a hydrogen bond breaker that is effective in break-

ing the azeotropes of tetrahydrofuran-water18 and trimethyl borate-methanol19, the solvent butyl propionate can

greatly enlarge the relative volatility of isobutyl acetate and isobutyl alcohol because the solvent forms a homol-

ogous series with isobutyl acetate20, and N-methyl-2-pyrrolidone (NMP) was selected as a suitable solvent for

n-heptane-isobutanol separation21. Residue curve maps (RCMs) can also be used to find suitable solvents for

separation processes. Based on an RCM analysis, water was used as the solvent to separate acetone-methanol22,

and the nontoxic solvent tetraethyleneglycol was used for ethanol-water separation since distillation boundaries

did not appear in the RCM23.

Optimization and process intensification are the two other factors that should be considered when designing

an economic ED process. To reduce the total annual cost (TAC) and achieve further energy saving, methods for

process intensification and integration combined with ED have been published in many papers24–31 using ther-

mally coupled distillation column25, dividing-wall column26 and double-effect distillation31 techniques. Many

College of Chemical Engineering, Qingdao University of Science and Technology, Qingdao, 266042, China.

Correspondence and requests for materials should be addressed to Y.W. (email: yinglongw@126.com)

Scientific Reports | 7: 9497 | DOI:10.1038/s41598-017-09088-2 1

www.nature.com/scientificreports/

Figure 1. T-xy diagram of the Toluene-DMF mixture using the built-in interaction parameters at 1 atm:

NRTL model; UNIQUAC model; and Wilson model.

Figure 2. Optimization algorithm interfaces for the Extractive Distillation Optimization Software.

simulation platforms, such as Aspen Plus, HYSYS, PRO/II and ChemCAD, have been used for the conceptual

design of extractive distillation, and achievements have been made to improve the economics and controllability.

Luyben32 provided a detailed introduction for creating a steady-state design and optimizing and assessing the

controllability of a distillation process using Aspen Plus. Long and Lee33 investigated the ED process with a retro-

fit design using HYSYS to achieve further energy saving and to improve the process capacity. Shirsat et al.34 rig-

orously optimized an ED configuration using ChemCAD, and found that the process of ethanol dehydration was

more economical using a pre-separator column. Timoshenko et al.25 investigated several alternative ED processes

with and without partially thermally coupled columns for different types of ternary mixtures, and a case study

was discussed to select the most energy-saving process using PRO/II software. All of the above studies promoted

the development of ED.

In the separation process, the selection of the thermodynamic model in the simulator software is a primary

issue for performing the phase equilibrium calculation35–38. Dimethyl formamide (DMF) and NMP are widely

used as solvents to design ED processes, and the unusual phase behaviors caused by the different interaction

parameters of toluene-DMF, benzene-NMP and cyclohexane-NMP attracted our interest. Mixtures of DMF

and nonaromatics, such as cyclohexane and heptane, can form minimum boiling point azeotropes39. Luyben40

selected DMF as the solvent to design an ED process using the built-in binary interaction parameters of the NRTL

model. The calculation with the built-in binary interaction parameters for toluene-DMF in Aspen Plus, however,

indicated that the mixture forms a homogeneous minimum boiling azeotrope at atmospheric pressure (Fig. 1).

As seen from the experimental data published in Azeotropic Data41 at different pressures, the binary system of

toluene-DMF does not exhibit azeotropic behavior.

NMP has been chosen as a suitable solvent for separating aromatic and nonaromatic mixtures42–47. Methods for

solvent selection have demonstrated that NMP efficiently alters the relative volatility of benzene-cyclohexane42–44.

Vega et al.43 found that NMP is an efficient solvent for separating benzene-cyclohexane-cyclohexene mixtures

using non-steady-state gas chromatography. However, a few studies40, 48 have shown that NMP is not an efficient

solvent for separating mixtures that contain binary azeotropes of benzene-cyclohexane.

The purpose of this article was to study the effect of various thermodynamic model parameters when design-

ing ED processes for separating mixtures using DMF and NMP solvents. The VLE data that have been reported

in the literature49, 50 were regressed to obtain the binary interaction parameters in order to demonstrate that the

binary system of toluene-DMF does not exhibit azeotropic behavior and that NMP can be used as an appropriate

solvent for separating azeotropic mixtures of benzene-cyclohexane during ED. The detailed separation process

was carried out using the regressed binary interaction parameters to obtain accurate separation results.

Scientific Reports | 7: 9497 | DOI:10.1038/s41598-017-09088-2 2

www.nature.com/scientificreports/

Model aij aji bij/K bji/K αij RMSDa (P/kPa) RMSDa (yi)

Toluene (i) + DMF (j)

NRTLb 0 0 332.814 −28.501 0.10 0.140 0.0119

UNIQUACc −7.297 7.608 2683.662 −2884.069 0.168 0.0118

Wilsond 0 0 −125.353 −200.774 0.145 0.0117

Benzene (i) + NMP (j)

NRTLb 0 0 3776.060 −2904.104 0.03 0.026 0.0004

UNIQUACc −1.510 1.088 666.906 −528.010 0.089 0.0010

Wilsond 2.386 −2.442 −1103.648 1121.244 0.076 0.0007

Cyclohexane (i) + NMP (j)

NRTLb 0 0 1085.790 −270.811 0.14 0.027 0.0002

UNIQUACc 9.229 21.900 −3414.744 −7217.892 0.066 0.0001

Wilsond 0 0 −181.280 −769.390 0.045 0.0004

Table 1. Correlated model parameters and average absolute deviations for the systems.

1

RMSD = n ∑ ni =1(Mexp 22

a 1

i − Mcal

i ) , where n is the total number of data points and M

exp

and Mcal represent the

experimental and calculated values, respectively. NRTL model: τij = aij + bij/T. UNIQUAC model:

b c

τij = exp(aij + bij/T). dWilson model: In Aij = aij + bij/T.

Figure 3. Comparison between the experimental data, correlated results and default results for the system of

Toluene-DMF at T = 373.15 K: experimental data; correlated results from the NRTL model; correlated

results from the UNIQUAC model; correlated results from the Wilson model; and the default results from

the NRTL model.

Methods

Data regression. Experimental data were obtained using the function from the National Institute of

Standards and Technology ThermoData Engine (NIST TDE) in Aspen Plus V8.8. The NRTL, UNIQUAC, and

Wilson models were used to correlate the experimental data for this binary system. Area consistency tests were

used to check the thermodynamic consistency. Experimental data49, 50 for the systems of toluene-DMF, ben-

zene-NMP and cyclohexane-NMP, which passed the thermodynamic area consistency test, were regressed

to obtain binary interaction parameters. The root mean square deviation51, 52 (RMSD) values were calculated

between the experimental and calculated results to select the appropriate thermodynamic model. The non-ran-

domness parameter (α) of the NRTL model was set at different values. Renon and Prausnitz53 recommended

setting α between 0.2 and 0.5. In many examples in the literature54, 55, the values of αij were smaller than 0.2 to

achieve better regression results. A wider interval for α was considered to correlate the experimental data with

high accuracy, and the value of α was optimized by minimizing the RMSD.

Economics. The TAC is the sum of the annualized operating costs and capital costs, and the relevant approx-

imation methods were taken from Douglas56. The total capital investments refer to the cost of the column ves-

sels and heat exchangers. The investments required for the valves, reflux drums, pipes, and pumps are usually

neglected. The columns and sieve plate parameters are determined using the “Tray Sizing” function. And the

first stage is the reflux drum and the last stage is the reboiler. The total heat transfer coefficients of reboilers and

condensers are 0.568 kW/(Km2) and 0.852 kW/(Km2), respectively. Detailed information for calculating the TAC

was described in our previous paper57.

Scientific Reports | 7: 9497 | DOI:10.1038/s41598-017-09088-2 3

www.nature.com/scientificreports/

Figure 4. Experimental data and calculated results using the built-in binary interaction parameters for the

system of Benzene-Cyclohexane-Toluene-DMF: experimental data; NRTL model; UNIQUAC model;

and Wilson model.

Process optimization. In previous work, we developed software to optimize pressure-swing distilla-

tion processes based on simulated annealing algorithms58 and sequential iterative optimization procedures59.

In this study, the influence of the solvent-to-feed ratio was considered during ED, and Extractive Distillation

Optimization Software (EDOS)60 software was developed to implement program optimization on the basis of a

sequential iterative optimization procedure. The EDOS was programmed using a simulation-optimization tech-

nique implemented by the Visual Basic interface with Aspen Plus and the optimization algorithm, as shown in

Fig. 2. The design variables including the solvent amount, the total number of stages in columns, the feed tray

location and the solvent feed stage were optimized to obtain the minimal total annual cost. All the optimization

data were saved in Microsoft Excel for further verification and analysis.

Scientific Reports | 7: 9497 | DOI:10.1038/s41598-017-09088-2 4

www.nature.com/scientificreports/

Figure 5. Process flowsheet of TCEDRBIP with details.

Results and Discussion

Benzene-cyclohexane-toluene separation using DMF as the solvent. Thermodynamic models

such as NRTL, UNIQUAC and Wilson were used to analyze the properties of a ternary mixture with and without

DMF. The simulation results showed that DMF and toluene formed a homogeneous minimum boiling azeo-

trope at atmospheric pressure using different models with the built-in binary interaction parameters of Aspen

Plus. The azeotropic composition and temperature were 0.42 mol% DMF and 383.83 K for the NRTL model,

1.54 mol% DMF and 383.78 K for the UNIQUAC model, and 1.87 mol% DMF and 383.72 K for the Wilson model,

respectively. For the three models, the azeotropes disappeared at 0.9 atm, 0.7 atm and 0.5 atm, respectively. The

azeotropic data were inconsistent with the actual data. Hence, the selection of the thermodynamic model and the

determination of the exact binary interaction parameters require more attention to describe the phase behavior

of toluene-DMF accurately. Figure 1 shows the T-xy diagram for the system of toluene-DMF at 1 atm using the

built-in binary interaction parameters of the NRTL, UNIQUAC and Wilson models. However, the experimental

data published in Azeotropic Data41 indicate that the binary system of toluene-DMF does not exhibit azeotropic

behavior under different pressures. Therefore, the built-in binary interaction parameters should be modified.

Experimental data for the binary system of toluene-DMF were taken from the work of Yu et al.49. The obtained

binary interaction parameters and RMSD values are shown in Table 1. The average deviations in the pressure

and vapor phases using the NRTL model were 0.140 and 0.0119, respectively. The small deviations indicated

that the NRTL model with the regressed binary parameters could be used to describe the phase behavior of the

toluene-DMF mixture. Figure 2 shows the comparison among the experimental data, correlated results, and

default results. The figure shows that the built-in binary interaction parameters produced large deviations in the

VLE phase behavior, and the regressed binary interaction parameters described the phase behavior accurately.

As shown in Fig. 3, the xy curves calculated using the regressed binary interaction parameters did not exhibit

azeotropic behavior for the toluene-DMF binary system.

For the binary systems of benzene-cyclohexane, benzene-toluene, cyclohexane-toluene, benzene-DMF and

cyclohexane-DMF, the VLE predicted using the built-in binary interaction parameters was compared with the

experimental data41 to verify the suitability of the thermodynamic model. Figure 4 indicates that the NRTL model

with the built-in binary interaction parameters fit the experimental data well. Hence, the parameters can be

used to simulate the VLE for benzene-cyclohexane, benzene-toluene, cyclohexane-toluene, benzene-DMF and

cyclohexane-DMF systems.

Process design. The triple column extractive distillation process using built-in binary interaction parame-

ters (TCEDBBIP) was reported previously for separating the ternary mixture of benzene-cyclohexane-toluene

using DMF as the solvent40. In this study, triple column extractive distillation using regressed binary interaction

parameters (TCEDRBIP) was designed using the same feeding conditions to design the modified separation pro-

cess. The mixture flow rate was 100 kmol/h with a composition of 30 mol% benzene, 30 mol% cyclohexane and

40 mol% toluene at 323 K. The operating pressure of the first column (C1) was set at 0.6 atm to achieve high-purity

cyclohexane because the azeotrope of cyclohexane-DMF disappeared under this pressure. The operating pressure

of the second column (C2) was set at 1 atm, and the product of benzene was recovered at the top of the column.

The operating pressure of the third column (C3) was set at 0.5 atm to avoid using the medium-pressure stream

in the reboiler. The stage pressure drop was set at 0.0068 atm. Three specifications, 0.005 mol% cyclohexane in

C1, 99 mol% benzene in C2, and 0.1 mol% toluene in C3, were achieved by varying the reflux ratios of the corre-

sponding columns.

Scientific Reports | 7: 9497 | DOI:10.1038/s41598-017-09088-2 5

www.nature.com/scientificreports/

Figure 6. Composition and temperature profiles of TCEDRBIP: (a) Composition profiles in C1; (b) temperature

profile in C1; (c) composition profiles in C2; (d) temperature profile in C2; (e) composition profiles in C3; and

(f) temperature profile in C3.

Process Column NT NE/NF RR FE kmol/h Qreb MW Qcond MW Pressure atm

Column 1 58 19/37 2.91 1.636 1.019 0.60

TCEDRBIP Column 2 54 −/12 4.02 114.00 1.398 1.300 1.00

Column 3 30 -/23 1.71 0.894 1.046 0.50

Column 1 80 20/40 3.88 1.731 1.251 0.69

TCEDBBIP Column 2 41 −/20 5.26 89.74 1.820 1.608 1.08

Column 3 21 −/15 1.80 0.679 1.137 0.12

Table 2. Optimal operation parameters and energy consumption of the two processes.

Scientific Reports | 7: 9497 | DOI:10.1038/s41598-017-09088-2 6

www.nature.com/scientificreports/

Figure 7. Comparison between the experimental data, correlated results and default results for two systems of

(a) Benzene-NMP and (b) Cyclohexane-NMP at T = 333.25 K: experimental data; correlated results from

the NRTL model; correlated results from the UNIQUAC model; correlated results from the Wilson model;

and the default results from the NRTL model.

Figure 8. Comparison between the correlated results and default results from the Aspen Plus and PRO/II

simulators using the NRTL model for the system of Benzene-Cyclohexane at P = 101.33 kPa: default

parameters from PRO/II; correlated results from Aspen Plus; and default results from Aspen Plus.

The detailed optimization results are shown in Fig. 5 with the operating conditions, heat duties, stream infor-

mation and equipment sizes. Figure 6 shows the liquid composition and temperature profiles of the three col-

umns. The total reboiler and condenser duties of the columns were 3.928 and 3.365 MW, respectively. The TAC

calculated for TCEDRBIP was 1.430 × 106 $/y. The annual operating cost and total capital cost were 9.095 × 105

$/y and 1.562 × 106 $/y, respectively.

Process comparison. The data in Table 2 show the optimal parameters of TCEDRBIP and TCEDBBIP. The

obtained operating pressure was different in TCEDBBIP40. In TCEDBBIP, C1 and C3 were operated at 0.69 atm

and 0.12 atm, respectively, due to the existence of azeotropic behavior in the binary system of toluene-DMF. In

fact, in TCEDRBIP, azeotropic behavior was not observed for toluene-DMF, and the system of toluene-DMF was

effectively separated without requiring very high vacuum.

TCEDRBIP, which was optimized on the basis of the minimal TAC, required larger amounts of solvent

(114.362 kmol/h) than TCEDBBIP, which was designed based on the total energy consumption in the reboilers of

the columns. The total energy consumption in the reboilers of TCEDRBIP was 3.928 MW and was lower than that

of TCEDBBIP. Stages of 58, 54 and 30 in the three columns of TCEDRBIP needed to reach the specification purity

of the products with the lowest TAC. The annual operating cost and the total capital cost of TCEDBBIP were

1.007 × 106 $/y and 1.689 × 106 $/y, respectively. TCEDRBIP incurred 7.13% energy consumption and reduced

the TAC by 8.92% compared with TCEDBBIP.

Scientific Reports | 7: 9497 | DOI:10.1038/s41598-017-09088-2 7

www.nature.com/scientificreports/

Figure 9. Process flowsheet of DCEDRBIP with details.

Figure 10. Composition and temperature profiles of TCEDRBIP: (a) Composition profiles in C1; (b)

temperature profile in C1; (c) composition profiles in C2; and (d) temperature profile in C2.

Scientific Reports | 7: 9497 | DOI:10.1038/s41598-017-09088-2 8

www.nature.com/scientificreports/

Figure 11. Process flowsheet of DCEDBBIP with details.

Benzene-cyclohexane separation with NMP as the solvent. NMP has been used as an efficient

solvent for separating the azeotropes of benzene-cyclohexane mixtures. Timoshenko et al.25 employed NMP

to separate the ternary mixture of benzene-cyclohexane-toluene and designed the separation process using

PRO/II software with the NRTL thermodynamic model. The ternary mixture contained a binary azeotrope of

benzene-cyclohexane, and the important role of adding NMP was to break the azeotrope to improve the relative

volatility of benzene and cyclohexane. Timoshenko’s designs were carried out in steady state using the Aspen

Plus platform, and the results of the simulation with the built-in binary interaction parameters showed that the

separation process was not duplicated using the same optimized parameters. To obtain accurate parameters for

the separation process using Aspen Plus, binary interaction parameters of benzene-NMP and cyclohexane-NMP

were regressed using VLE data from the literature50.

Experimental data for the binary systems of benzene-NMP and cyclohexane-NMP, which passed the thermo-

dynamic area consistency test, were taken from the work of Gierycz et al.50. The binary interaction parameters

and RMSD values are shown in Table 1. The average deviations in the pressure using the NRTL model for the two

systems were 0.0263 and 0.0271, respectively. The average deviations in the vapor phase using the NRTL model

for both systems were 0.000374 and 0.000156, respectively. The small deviations show that the NRTL model can

be used to describe the phase behaviors of the two systems. Figure 7a and b show the comparison among the

experimental data, correlated results, and default parameter results. As shown in Fig. 7a and b, the vapor behavior

curves of the systems calculated with the regressed binary interaction parameters were more satisfied compared

with those using the built-in binary interaction parameters in Aspen Plus.

Process design. In this study, double-column extractive distillation using the regressed interaction parame-

ters (DCEDRBIP) and using the built-in binary interaction parameters (DCEDBBIP) were explored to separate

benzene-cyclohexane using NMP as a solvent. A Flash 2 model in Aspen Plus was employed to calculate the

relative volatility of the benzene and cyclohexane to illustrate the effect of NMP on the azeotrope. The relative

volatility values calculated using the regressed and built-in binary interaction parameters were 3.96 and 2.21,

respectively. Figure 8 shows the accuracy of the binary interaction parameters for describing the influence of the

NMP solvent on the VLE with a solvent to feed mole ratio of 1. The results show that the addition of NMP could

enlarge the relative volatility of benzene and cyclohexane. The relative volatility calculated using the built-in

binary interaction parameters deviated from the experimental data to a large extent. Furthermore, the relative

volatility calculated using the regressed binary interaction parameters was close to the value that was calculated

using the built-in binary interaction parameters in the PRO/II software.

The mixture flow rate was 100 kmol/h with a composition of 75 mol% benzene and 25 mol% cyclohexane. Both

columns were operated at atmospheric pressure, and the tray drop pressure between two adjacent stages was set

at 0.0068 atm. The cyclohexane product of the extractive column was specified as 99.5 mol%. For the recovery

column, the bottom purity was set at 99.99 mol% NMP. The detailed optimization results for DCEDRBIP are

shown in Fig. 9, and the liquid composition and temperature profiles for the DCEDRBIP process with the min-

imal TAC are shown in Fig. 10. The detailed process of DCEDBBIP is shown in Fig. 11, and Fig. 12 shows the

liquid composition and temperature profiles. The reboiler duties of the processes with the regressed and built-in

Scientific Reports | 7: 9497 | DOI:10.1038/s41598-017-09088-2 9

www.nature.com/scientificreports/

Figure 12. Composition and temperature profiles of DCEDBBIP: (a) Composition profiles in C1; (b)

temperature profile in C1; (c) composition profiles in C2; and (d) temperature profile in C2.

binary interaction parameters were 2.442 and 4.195 MW, respectively, and condenser duties of the two processes

were 1.396 and 2.334 MW, respectively. The TAC values calculated for both processes were 7.659 × 105 $/y and

1.402 × 106 $/y, respectively.

Process comparison. Although the differences in the relative volatility for the two processes were small, the

optimal parameters and energy consumption of the two processes were significantly different, which has a great

impact on practical applications. The total number of stages in DCEDRBIP and DCEDBBIP were 52 and 100,

respectively. The solvent amount of DCEDRBIP was lower than that of DCEDBBIP. Therefore, the column vessel

cost of DCEDRBIP was lower. DCEDRBIP and DCEDBBIP required 2.594 and 4.195 MW of energy in the reboil-

ers, respectively. The difference between the energy consumption of the two processes was large. DCEDRBIP

incurred 38.16% energy consumption and reduced the TAC by 45.37% compared with DCEDBBIP.

Conclusion

Extractive distillation processes using regressed and built-in binary interaction parameters for separating mix-

tures were investigated. The simulation results using the regressed binary interaction parameters did not indicate

azeotropic behavior for the system of toluene-DMF, and the VLE was consistent with the experimental data. The

total energy consumption of TCEDRBIP was lower and accounted for 9.70% of the annual operating cost and

reduced the TAC by 8.92% compared with TCEDBBIP.

The effect of the amount of NMP on the relative volatility of benzene and cyclohexane was calculated. The

relative volatility calculated using the regressed binary interaction parameters was 3.96, which was 1.84 times

the value calculated using the built-in binary interaction parameters. The solvent requirements of DCEDRBIP

were lower than those of DCEDBBIP. The TAC had large deviations between the two processes. The DCEDRBIP

reduced the TAC and energy consumption by 45.37% and 38.16%, respectively.

For some systems, the built-in binary interaction parameters were more accurate for describing the phase

behaviors. However, the phase behaviors of some systems described by the built-in binary interaction parameters

were obviously different from the experimental data in determining the azeotropic phenomenon or the rela-

tive volatility of the components. There were great deviations between the simulated results obtained using the

regressed and built-in binary interaction parameters. For systems in which the built-in binary interaction param-

eters cannot describe the phase behavior accurately, it is more appropriate to use binary interaction parameters

regressed by experimental data to design and optimize the separation process. It is important for researchers to

Scientific Reports | 7: 9497 | DOI:10.1038/s41598-017-09088-2 10

www.nature.com/scientificreports/

carefully study the VLE data and determine the suitable binary interaction parameters when designing distillation

processes for azeotrope separation.

References

1. Asano, M. et al. Distillation of photon entanglement using a plasmonic metamaterial. Sci. Rep. 5, 18313, doi:10.1038/srep18313

(2015).

2. Luyben, W. L. Pressure-Swing Distillation for Minimum- and Maximum-Boiling Homogeneous Azeotropes. Ind. Eng. Chem. Res.

51, 10881–10886 (2012).

3. Yu, B., Wang, Q. & Xu, C. Design and Control of Distillation System for Methylal/Methanol Separation. Part 2: Pressure Swing

Distillation with Full Heat Integration. Ind. Eng. Chem. Res. 51, 1293–1310 (2012).

4. Repke, J. U., Forner, F. & Klein, A. Separation of homogeneous azeotropic mixtures by pressure swing distillation–analysis of the

operation performance. Chem. Eng. Technol. 28, 1151–1157 (2005).

5. Liang, S. et al. Insight into pressure-swing distillation from azeotropic phenomenon to dynamic control. Chem. Eng. Res. Des. 117,

318–335 (2017).

6. Huang, K., Shan, L., Zhu, Q. & Qian, J. Adding rectifying/stripping section type heat integration to a pressure-swing distillation

(PSD) process. Appl. Therm. Eng. 28, 923–932 (2008).

7. Modla, G. & Lang, P. Feasibility of new pressure swing batch distillation methods. Chem. Eng. Sci. 63, 2856–2874 (2008).

8. Luyben, W. L. Control of a multiunit heterogeneous azeotropic distillation process. AlChE J. 52, 623–637 (2006).

9. Li, W. et al. Multiple Steady-States Analysis and Unstable Operating Point Stabilization in Homogeneous Azeotropic Distillation

with Intermediate Entrainer. Ind. Eng. Chem. Res. 54, 7668–7686 (2015).

10. An, Y. et al. Design/optimization of energy-saving extractive distillation process by combining preconcentration column and

extractive distillation column. Chem. Eng. Sci. 135, 166–178 (2015).

11. Wang, Y., Cui, P., Ma, Y. & Zhang, Z. Extractive distillation and pressure-swing distillation for THF/ethanol separation. J. Chem.

Technol. Biotechnol. 90, 1463–1472 (2015).

12. You, X., Rodriguez-Donis, I. & Gerbaud, V. Low pressure design for reducing energy cost of extractive distillation for separating

diisopropyl ether and isopropyl alcohol. Chem. Eng. Res. Des. 109, 540–552 (2016).

13. Yuan, S., Yang, W., Yin, H. & Chen, Z. Separation of acetone–tetrahydrofuran azeotropic mixture by continuous extractive

distillation. J. Chem. Technol. Biotechnol. 88, 1523–1528 (2013).

14. Ebrahimzadeh, E., Matagi, J., Fazlollahi, F. & Baxter, L. L. Alternative extractive distillation system for CO2–ethane azeotrope

separation in enhanced oil recovery processes. Appl. Therm. Eng. 96, 39–47 (2016).

15. Shen, W. et al. Systematic design of an extractive distillation for maximum-boiling azeotropes with heavy entrainers. AlChE J. 61,

3898–3910 (2015).

16. Lei, Z., Li, C. & Chen, B. Extractive Distillation: A Review. Sep. Purif. Rev. 32, 121–213 (2007).

17. Lei, Z., Chen, B. & Ding, Z. Special Distillation Processes (Elsevier, 2005).

18. Zhang, Z. G. et al. Entrainer selection for separating tetrahydrofuran/water azeotropic mixture by extractive distillation. Sep. Purif.

Technol. 122, 73–77 (2014).

19. Bao, Z., Zhang, W., Cui, X. & Xu, J. Design, Optimization and Control of Extractive Distillation for the Separation of Trimethyl

Borate–Methanol. Ind. Eng. Chem. Res. 53, 14802–14814 (2014).

20. Muñoz, R., Montón, J. B., Burguet, M. C. & De La Torre, J. Separation of isobutyl alcohol and isobutyl acetate by extractive

distillation and pressure-swing distillation: Simulation and optimization. Sep. Purif. Technol. 50, 175–183 (2006).

21. Wang, Y. et al. Effect of solvent flow rates on controllability of extractive distillation for separating binary azeotropic mixture. Ind.

Eng. Chem. Res. 54, 12908–12919 (2015).

22. Luyben, W. L. Comparison of extractive distillation and pressure-swing distillation for acetone−methanol separation. Ind. Eng.

Chem. Res. 47, 2696–2707 (2008).

23. Ravagnani, M. A. S. S., Reis, M. H. M., Filho, R. M. & Wolf-Maciel, M. R. Anhydrous ethanol production by extractive distillation:

A solvent case study. Process Saf. Environ. Prot. 88, 67–73 (2010).

24. Chen, Y. C., Hung, S. K., Lee, H. Y. & Chien, I. Energy-Saving Designs for Separation of a Close-Boiling 1,2-Propanediol and

Ethylene Glycol Mixture. Ind. Eng. Chem. Res. 54, 3828–3843 (2015).

25. Timoshenko, A. V., Anokhina, E. A., Morgunov, A. V. & Rudakov, D. G. Application of the partially thermally coupled distillation

flowsheets for the extractive distillation of ternary azeotropic mixtures. Chem. Eng. Res. Des. 104, 139–155 (2015).

26. Yu, J. et al. Improving the performance of extractive dividing-wall columns with intermediate heating. Ind. Eng. Chem. Res. 54,

2709–2723 (2015).

27. Wang, X., Xie, L., Tian, P. & Tian, G. Design and control of extractive dividing wall column and pressure-swing distillation for

separating azeotropic mixture of acetonitrile/N-propanol. Chem. Eng. Process. 110, 172–187 (2016).

28. García-Ventura, U. M., Barroso-Muñoz, F. O., Hernández, S. & Castro-Montoya, A. J. Experimental study of the production of high

purity ethanol using a semi-continuous extractive batch dividing wall distillation column. Chem. Eng. Process. 108, 74–77 (2016).

29. Dai, X. et al. Energy-saving dividing-wall column design and control for benzene extraction distillation via mixed entrainer. Chem.

Eng. Process. 100, 49–64 (2016).

30. Kim, Y. H. Energy saving of benzene separation process for environmentally friendly gasoline using an extended DWC (divided wall

column). Energy. 100, 58–65 (2016).

31. You, X., Rodriguez-Donis, I. & Gerbaud, V. Reducing process cost and CO2 emissions for extractive distillation by double-effect heat

integration and mechanical heat pump. Appl. Energy. 166, 128–140 (2016).

32. Luyben, W. L. Distillation design and control using Aspen simulation (John Wiley & Sons, 2013).

33. Duc Long, N. & Lee, M. Optimal retrofit design of extractive distillation to energy efficient thermally coupled distillation scheme.

AlChE J. 59, 1175–1182 (2013).

34. Shirsat, S. P., Dawande, S. D. & Kakade, S. S. Simulation and optimization of extractive distillation sequence with pre-separator for

the ethanol dehydration using n-butyl propionate. Korean J. Chem. Eng. 30, 2163–2169 (2013).

35. Cadoret, L., Yu, C. C., Huang, H. P. & Lee, M. J. Effects of physical properties estimation on process design: a case study using

AspenPlus. Asia-Pac. J. Chem. Eng. 4, 729–734 (2009).

36. Li, W. et al. New pressure-swing distillation for separating pressure-insensitive maximum boiling azeotrope via introducing a heavy

entrainer: design and control. Ind. Eng. Chem. Res. 52, 7836–7853 (2013).

37. Chen, Y. C., Yu, B. Y., Hsu, C. C. & Chien, I. L. Comparison of Heteroazeotropic and Extractive Distillation for the Dehydration of

Propylene Glycol Methyl Ether. Chem. Eng. Res. Des. 111, 184–195 (2016).

38. Arifin, S. & Chien, I. L. Design and control of an isopropyl alcohol dehydration process via extractive distillation using dimethyl

sulfoxide as an entrainer. Ind. Eng. Chem. Res. 47, 790–803 (2008).

39. Ruiz, C., Coca, J., Vega, A. & Díez, F. V. Extractive distillation of hydrocarbons with dimethylformamide: experimental and

simulation data. Ind. Eng. Chem. Res. 36, 4934–4939 (1997).

40. Luyben, W. L. Control comparison of conventional and thermally coupled ternary extractive distillation processes. Chem. Eng. Res.

Des. 106, 253–262 (2015).

41. Gmehling, J. Azeotropic data (Wiley-VCH, 2004).

Scientific Reports | 7: 9497 | DOI:10.1038/s41598-017-09088-2 11

www.nature.com/scientificreports/

42. Wenwei, D. & Jiquan, F. Solvents selection by using of computer in extractive distillation separation for the system of benzene-

cyclohexane. Computers & Applied Chemistry. 6, 757–760 (2011).

43. Vega, A., Díez, F., Esteban, R. & Coca, J. Solvent selection for cyclohexane−cyclohexene−benzene separation by extractive

distillation using non-steady-state gas chromatography. Ind. Eng. Chem. Res. 36, 803–807 (1997).

44. Peng, B., Hui-Xing, W. U., Zhu, S. Q., Jing-Song, L. & Hun-Yang, L. Study on the solvent for the recovery of benzene and cyclohexane

by extractive distillation. Tianjin Chemical Industry (2001).

45. Chen, B., Lei, Z. & Li, J. Separation on Aromatics and Non-aromatics by Extractive Distillation with NMP. J. Chem. Eng. Jpn. 36,

20–24 (2003).

46. Yang, Z. S., Li, C. L. & Wu, J. Y. A Novel Method for Selection of Solvent for Extractive Distillation for Separating Cyclohexane-

Cyclohexene-Benzene. Petroche. Technol. 30, 285–288 (2001).

47. Yu, K., Uchibori, T., Ishikawa, T. & Tsuboi, A. Method for separating cyclohexene. US. 5865958 A (1999).

48. Zhang, Z. G., Shi-Min, X. U. & Zhang, W. J. Binary Mixed Solvents for Separating Benzene-Cyclohexane by Extractive Distillation.

Journal of Tianjin University. 39, 424–427 (2006).

49. Yu, S. Isothermal Vapor-Liquid Equilibrium of Binary System DMF-Toluene. Journal of Nanchang University. 3 (1999).

50. Gierycz, P., Rogalski, M. & Malanowski, S. Vapour—liquid equilibria in binary systems formed by N-Methylpyrrolidone with

hydrocarbons and hydroxyl derivatives. Fluid Phase Equilib. 22, 107–122 (1985).

51. Zhang, L. et al. Measurements and correlations of density, viscosity, and vapour-liquid equilibrium for fluoro alcohols. J. Chem.

Thermodyn. 102, 155–163 (2016).

52. Gao, J. et al. Isobaric Vapor–Liquid Equilibrium for Binary Systems of Thioglycolic Acid with Water, Butyl Acetate, Butyl Formate,

and Isobutyl Acetate at 101.3 kPa. J. Chem. Eng. Data. 62, 355–361 (2017).

53. Renon, H. & Prausnitz, J. M. Local compositions in thermodynamic excess functions for liquid mixtures. AlChE J. 14, 135–144

(1968).

54. Luo, H. P., Zhou, J. H., Xiao, W. D. & Zhu, K. H. Isobaric vapor-liquid equilibria of binary mixtures containing dimethyl carbonate

under atmospheric pressure. J. Chem. Eng. Data. 46, 842–845 (2001).

55. Orchillés, A. V., Miguel, P. J., Vercher, E. & Martí nez-Andreu, A. Isobaric vapor−liquid and liquid−liquid equilibria for

chloroform + methanol + 1-ethyl-3-methylimidazolium trifluoromethanesulfonate at 100 kPa. J. Chem. Eng. Data. 55, 1209–1214

(2009).

56. Douglas, J. M. Conceptual Design of Chemical Processes (McGraw-Hill Science/Engineering/Math, 1988).

57. Cao, Y. et al. Effect of feed temperature on economics and controllability of pressure-swing distillation for separating binary

azeotrope. Chem. Eng. Process. 110, 160–171 (2016).

58. Wang, Y. et al. Application of a simulated annealing algorithm to design and optimize a pressure-swing distillation process. Comput.

Chem. Eng. 95, 97–107 (2016).

59. Zhu, Z., Xu, D., Liu, X., Zhang, Z. & Wang, Y. Separation of acetonitrile/methanol/benzene ternary azeotrope via triple column

pressure-swing distillation. Sep. Purif. Technol. 169, 66–77 (2016).

60. Qingdao University of Science & Technology. Extractive Distillation Optimization Software: porpoise V1.0. NO. 2015SR214466.

Acknowledgements

Financial support from the National Natural Science Foundation of China (Project 21676152) is gratefully

acknowledged.

Author Contributions

M.L., Z.Y.Z. and Y.L.W. conceived the idea. M.L., K.M. and B.Q. designed the separation process. M.L., X.L. and

Y.L.W. analyzed the simulation results, M.L., X.C.L., X.L. and Y.L.W. wrote the manuscript. All authors reviewed

the manuscript.

Additional Information

Competing Interests: The authors declare that they have no competing interests.

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and

institutional affiliations.

Open Access This article is licensed under a Creative Commons Attribution 4.0 International

License, which permits use, sharing, adaptation, distribution and reproduction in any medium or

format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Cre-

ative Commons license, and indicate if changes were made. The images or other third party material in this

article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the

material. If material is not included in the article’s Creative Commons license and your intended use is not per-

mitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the

copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

© The Author(s) 2017

Scientific Reports | 7: 9497 | DOI:10.1038/s41598-017-09088-2 12

You might also like

- UCTM2017Document13 pagesUCTM2017Medha HebbarNo ratings yet

- aCinChE PDFDocument432 pagesaCinChE PDFAeromoon AeroseekNo ratings yet

- Energy-Efficient Recovery of Tetrahydrofuran and Ethyl Acetate by Triple-Column Extractive DistillationpdfDocument13 pagesEnergy-Efficient Recovery of Tetrahydrofuran and Ethyl Acetate by Triple-Column Extractive DistillationpdfLEXELNo ratings yet

- Isobaric Vapour-Liquid Equilibrium Data Estimation of CPME/Methanol System Using Modified UNIFAC Dortmund MethodDocument17 pagesIsobaric Vapour-Liquid Equilibrium Data Estimation of CPME/Methanol System Using Modified UNIFAC Dortmund MethodBrijeshNo ratings yet

- (Polish Journal of Chemical Technology) Process Simulation of Dimethyl Ether Synthesis Via Methanol Vapor Phase DehydrationDocument6 pages(Polish Journal of Chemical Technology) Process Simulation of Dimethyl Ether Synthesis Via Methanol Vapor Phase DehydrationKaramYassNo ratings yet

- (18994741 - Polish Journal of Chemical Technology) Process Simulation of Dimethyl Ether Synthesis Via Methanol Vapor Phase DehydrationDocument6 pages(18994741 - Polish Journal of Chemical Technology) Process Simulation of Dimethyl Ether Synthesis Via Methanol Vapor Phase DehydrationGlacier RamkissoonNo ratings yet

- Process Simulation of Dimethyl Ether Synthesis Via Methanol Vapor PhaseDocument6 pagesProcess Simulation of Dimethyl Ether Synthesis Via Methanol Vapor PhaseDavid Alemán SánchezNo ratings yet

- Aspenhysys Simulation of Methanol To Dimethylether (Dme) : Hassan Babiker, Babiker.A.Karma, Adil. A.MohammedDocument7 pagesAspenhysys Simulation of Methanol To Dimethylether (Dme) : Hassan Babiker, Babiker.A.Karma, Adil. A.MohammedFernadez Ramos CarolayNo ratings yet

- Direct synthesis of dimethyl ether from syngas over mechanical mixtures of CuO - ZnO - Al2O3 and γ-Al2O3 - Process optimization and kinetic modellingDocument10 pagesDirect synthesis of dimethyl ether from syngas over mechanical mixtures of CuO - ZnO - Al2O3 and γ-Al2O3 - Process optimization and kinetic modellingAngie Paola AcostaNo ratings yet

- Energy Efficient Solvents For CO Absorption From Flue Gas: Vapor Liquid Equilibrium and Pilot Plant StudyDocument26 pagesEnergy Efficient Solvents For CO Absorption From Flue Gas: Vapor Liquid Equilibrium and Pilot Plant StudyEr Mayur PatilNo ratings yet

- Selective Extraction of Benzene From Benzene-Cyclohexane Mixture Using 1-Ethyl-3-Methylimidazolium Tetrafluoroborate Ionic LiquidDocument8 pagesSelective Extraction of Benzene From Benzene-Cyclohexane Mixture Using 1-Ethyl-3-Methylimidazolium Tetrafluoroborate Ionic LiquidBüşraNo ratings yet

- Destilacion Por MembranaDocument11 pagesDestilacion Por MembranaRobert MarleyNo ratings yet

- Jurnal Kuc 4Document8 pagesJurnal Kuc 4kamunaya1720No ratings yet

- Monteiro 2013Document9 pagesMonteiro 2013mppatilmayurNo ratings yet

- Extraction of Aromatics From Petroleum Naphtha Reformate by Solvent PDFDocument6 pagesExtraction of Aromatics From Petroleum Naphtha Reformate by Solvent PDFmehul10941100% (1)

- Separation of Isobutyl Alcohol and Isobutyl Acetate by Extractive Distillation and Pressure-Swing DistillationDocument9 pagesSeparation of Isobutyl Alcohol and Isobutyl Acetate by Extractive Distillation and Pressure-Swing DistillationMiguel SantosNo ratings yet

- Experimental Data and Theoretical ConsidDocument21 pagesExperimental Data and Theoretical Considmarco_ravelo_10No ratings yet

- Continuouspharmaceuticalprocess Engineering and Economics - BR - Investigating Technical Efficiency, Environmental Impact and EconomicviabilityDocument4 pagesContinuouspharmaceuticalprocess Engineering and Economics - BR - Investigating Technical Efficiency, Environmental Impact and EconomicviabilitySwastik Reddy PingaliNo ratings yet

- J. Chem. Thermodynamics: Hui Guo, Xiaoqin Shi, Shufeng ShenDocument10 pagesJ. Chem. Thermodynamics: Hui Guo, Xiaoqin Shi, Shufeng ShenJuan Fernando Cano LarrotaNo ratings yet

- Simulation and Process Integration For Tert-Amyl-Methyl EtherDocument18 pagesSimulation and Process Integration For Tert-Amyl-Methyl EtherJessica CehNo ratings yet

- 1999 XD PengDocument8 pages1999 XD PengLeonard SaftaNo ratings yet

- Journal of Chromatography A: Franziska Bezold, Maria E. Weinberger, Mirjana MincevaDocument6 pagesJournal of Chromatography A: Franziska Bezold, Maria E. Weinberger, Mirjana MincevaSimonaNo ratings yet

- Simulation and Process Integration For Tert-Amyl-methyl EtherDocument18 pagesSimulation and Process Integration For Tert-Amyl-methyl EtherjinmgNo ratings yet

- SolventExtraction OfAromaticComponents FromLube-OilCut ByN-methylpyrrolidoneDocument8 pagesSolventExtraction OfAromaticComponents FromLube-OilCut ByN-methylpyrrolidonebelizondohNo ratings yet

- eNRTL Parameter Fitting Procedure For BLDocument8 pageseNRTL Parameter Fitting Procedure For BLBinay AkhuriNo ratings yet

- 1 s2.0 S1383586619340894 MainDocument18 pages1 s2.0 S1383586619340894 MainPriyam NayakNo ratings yet

- Evaluation of Amine-Blend Solvent Systems For CO Post-Combustion Capture ApplicationsDocument8 pagesEvaluation of Amine-Blend Solvent Systems For CO Post-Combustion Capture ApplicationsaziziNo ratings yet

- 1 s2.0 S0255270117310590 MainDocument16 pages1 s2.0 S0255270117310590 MainOktaviani KusumaNo ratings yet

- Alhseinat Icorporating 2014Document9 pagesAlhseinat Icorporating 2014Ehsan BozorgwarNo ratings yet

- N HeptaneDocument7 pagesN HeptaneFranciscoBarrancoLopezNo ratings yet

- Siklohekzan PDFDocument9 pagesSiklohekzan PDFebrarNo ratings yet

- DEEA - MAPA eNRTL PaperDocument18 pagesDEEA - MAPA eNRTL PaperMaythee SaisriyootNo ratings yet

- Httpsmdpi Res - Comd Attachmentprocessesprocesses 06 00020article Deployprocesses 06 00020.pdfversion 1519544708Document20 pagesHttpsmdpi Res - Comd Attachmentprocessesprocesses 06 00020article Deployprocesses 06 00020.pdfversion 1519544708anwarabdullah960No ratings yet

- Separation of Di-N-Propyl Ether and N-Propyl Alcohol by Extractive DistillationDocument9 pagesSeparation of Di-N-Propyl Ether and N-Propyl Alcohol by Extractive DistillationsaraNo ratings yet

- Antecedentes 14Document6 pagesAntecedentes 14Carlos Mario Ortiz MuñozNo ratings yet

- Journal of Chromatography A:, Mahmoud Ebrahimi, Mohammad-Saeid HosseiniDocument7 pagesJournal of Chromatography A:, Mahmoud Ebrahimi, Mohammad-Saeid HosseinijubuhlerNo ratings yet

- Some Guidelines For Choosing A Characterization Method For Petroleum Fractions in Process SimulatorsDocument7 pagesSome Guidelines For Choosing A Characterization Method For Petroleum Fractions in Process SimulatorsBahar MeschiNo ratings yet

- Yadollah Tavan, Reza Hasanvandian: SciencedirectDocument7 pagesYadollah Tavan, Reza Hasanvandian: SciencedirectdanaosajoNo ratings yet

- Full Bioethylene Process - 2019-07-04 - Revised - UnmarkedDocument54 pagesFull Bioethylene Process - 2019-07-04 - Revised - UnmarkedKashaf TehreemNo ratings yet

- Bildea, 2017Document10 pagesBildea, 2017AnaNo ratings yet

- 2020 IOP Conf. Ser. - Overcometheequilibriumlimitationinpara-XyleneproductionDocument12 pages2020 IOP Conf. Ser. - Overcometheequilibriumlimitationinpara-XyleneproductionWilly DinataNo ratings yet

- Optimization of Solvent For The Determination of Polybrominated Diphenyl Ethers in High-Impact Polystyrene by GC/ECDDocument4 pagesOptimization of Solvent For The Determination of Polybrominated Diphenyl Ethers in High-Impact Polystyrene by GC/ECDMuaz HaziqNo ratings yet

- Byproduct Analysis of PO XLPEDocument1 pageByproduct Analysis of PO XLPETANMAY NAYAKNo ratings yet

- Nhien 2016Document10 pagesNhien 2016Syed Ejaz HaiderNo ratings yet

- Hyperbranched Polymers: New Selective Solvents For Extractive Distillation and Solvent ExtractionDocument19 pagesHyperbranched Polymers: New Selective Solvents For Extractive Distillation and Solvent ExtractionRaja Maizatulakmal0% (1)

- Extracive DistillationDocument13 pagesExtracive DistillationJoel OkohNo ratings yet

- Processes: Methanol Synthesis: Optimal Solution For A Better Efficiency of The ProcessDocument20 pagesProcesses: Methanol Synthesis: Optimal Solution For A Better Efficiency of The ProcessNguyen Dang Binh ThanhNo ratings yet

- Assessment of Solvent Degradation Within A Global Process Model of Post-Combustion CO CaptureDocument6 pagesAssessment of Solvent Degradation Within A Global Process Model of Post-Combustion CO Capturecosmicbabe_2000No ratings yet

- Thermodynamic Behavior of Hydrogen NaturDocument6 pagesThermodynamic Behavior of Hydrogen NaturisvpNo ratings yet

- Extractive Distillation of Acetone/Methanol Mixture Using Water As EntrainerDocument8 pagesExtractive Distillation of Acetone/Methanol Mixture Using Water As EntrainernataliaNo ratings yet

- Biomass-Derived Oxymethylene Ethers As Diesel Additives A Thermodynamic AnalysisDocument4 pagesBiomass-Derived Oxymethylene Ethers As Diesel Additives A Thermodynamic AnalysisMarcelo TavaresNo ratings yet

- 1 s2.0 S016773221732127X MainDocument11 pages1 s2.0 S016773221732127X Mainsweety vermaNo ratings yet

- 6 Chilev 463-474Document12 pages6 Chilev 463-474emad hayekNo ratings yet

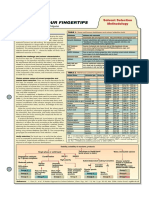

- Facts at Your Fingertips-200706-Solvent SelectionDocument1 pageFacts at Your Fingertips-200706-Solvent Selectiononizuka-t2263No ratings yet

- 12A7DDocument10 pages12A7DSulthon Nur JamilNo ratings yet

- Batch Extractive Distillation of Mixture Methanol-Acetonitrile Using Aniline As A AsolventDocument6 pagesBatch Extractive Distillation of Mixture Methanol-Acetonitrile Using Aniline As A AsolventBharat SharmaNo ratings yet

- Hou 2021Document16 pagesHou 2021¡SrDanecMxNo ratings yet

- SSRN Id3874836Document10 pagesSSRN Id3874836Anirban BhowalNo ratings yet

- Lit VLEUNIFAC1979Document10 pagesLit VLEUNIFAC1979andcerv23No ratings yet

- Thermochemical Processing of Biomass: Conversion into Fuels, Chemicals and PowerFrom EverandThermochemical Processing of Biomass: Conversion into Fuels, Chemicals and PowerNo ratings yet

- Part 3 Chapter 11Document9 pagesPart 3 Chapter 11Aeromoon AeroseekNo ratings yet

- Chapter 16Document15 pagesChapter 16Aeromoon AeroseekNo ratings yet

- Chemical Process Simulation and The Aspen HYSYS v10.0 Software © 2020Document3 pagesChemical Process Simulation and The Aspen HYSYS v10.0 Software © 2020Aeromoon AeroseekNo ratings yet

- MSDS - Calcium Octoate 5Document4 pagesMSDS - Calcium Octoate 5Future InnovationsNo ratings yet

- Sci 10. BiomoleDocument2 pagesSci 10. BiomoleJuan AnthonioNo ratings yet

- Proses Pembuatan LPG: Extraction Plant Dan Fractionation Plant PT. Perta Samtan GasDocument23 pagesProses Pembuatan LPG: Extraction Plant Dan Fractionation Plant PT. Perta Samtan GasBagas JuniarNo ratings yet

- Flexible Glucose SensorDocument7 pagesFlexible Glucose SensorSAYYID HAMEEM N 20MTS0018No ratings yet

- Research Article Removal of 3-MCPD Esters and Related Substances After Refining by Adsorbent MaterialDocument6 pagesResearch Article Removal of 3-MCPD Esters and Related Substances After Refining by Adsorbent MaterialAlexNo ratings yet

- F3 Chem Et3 QNDocument7 pagesF3 Chem Et3 QNBenjamin mwanikiNo ratings yet

- December 27, 2021 Finals Lab ActivityDocument3 pagesDecember 27, 2021 Finals Lab ActivityDahn MoycoNo ratings yet

- 2.0 Group I - Alkali MetalsDocument6 pages2.0 Group I - Alkali MetalsBrian NyagaNo ratings yet

- Modules - MidtermDocument39 pagesModules - MidtermGahnzelle Eidref FerreriaNo ratings yet

- Bredel Heavy Duty Hose PumpsDocument11 pagesBredel Heavy Duty Hose PumpsSourav GhoshNo ratings yet

- Kinetic Molecular Model of Liquids and SolidsDocument12 pagesKinetic Molecular Model of Liquids and Solidsdavid jenil nabuaNo ratings yet

- 2019 Book Carbon-ContainingPolymerComposDocument582 pages2019 Book Carbon-ContainingPolymerComposAna SilvaNo ratings yet

- Polyseal PU PF: 2 Part Pitch Free Polyurethane SealantDocument2 pagesPolyseal PU PF: 2 Part Pitch Free Polyurethane SealantAlexi ALfred H. TagoNo ratings yet

- Garlock Style 9900 Spec Sheet - (NA) 2021-09 ENDocument1 pageGarlock Style 9900 Spec Sheet - (NA) 2021-09 ENDrojanle MezbraNo ratings yet

- Unit 1 Lesson 2: Use of Nail Care Tools and EquipmentDocument56 pagesUnit 1 Lesson 2: Use of Nail Care Tools and EquipmentRheovien Joy BagoodNo ratings yet

- Fire/Explosion Capabilities of Aloha 5.4.1.2: A Facility Siting Case StudyDocument24 pagesFire/Explosion Capabilities of Aloha 5.4.1.2: A Facility Siting Case StudyHemanidhi GuptaNo ratings yet

- Falta SEZDocument22 pagesFalta SEZ9831681327No ratings yet

- Combustion of Agricultural ResiduesDocument27 pagesCombustion of Agricultural ResiduesAsmita AtreNo ratings yet

- Burns Et Al 2018 Dark Classics in Chemical Neuroscience FentanylDocument10 pagesBurns Et Al 2018 Dark Classics in Chemical Neuroscience Fentanyldavidbarrera220315231No ratings yet

- Fajan's RulesDocument19 pagesFajan's RulesRicky LawNo ratings yet

- F 8.5.1.2 - 6 7073 PS Fripsy Flips Ketchup Sticks 40g 2023Document1 pageF 8.5.1.2 - 6 7073 PS Fripsy Flips Ketchup Sticks 40g 2023soteris demetriouNo ratings yet

- Analysis - e-RoHS Analysis Method Guidelines-v3-Sharp Corp PDFDocument43 pagesAnalysis - e-RoHS Analysis Method Guidelines-v3-Sharp Corp PDF楊宗棠No ratings yet

- Omar - BuildingDNASEDocument4 pagesOmar - BuildingDNASEOMAR ID-AGRAMNo ratings yet

- Asm-35-2000 Aluminum Sheet Metal Work in Building ConstructionDocument31 pagesAsm-35-2000 Aluminum Sheet Metal Work in Building ConstructionSamuel Yu LiuNo ratings yet

- INOVOL F3600 Polyether Polyol TDSDocument1 pageINOVOL F3600 Polyether Polyol TDSvikashNo ratings yet

- Course Syllabus - : Chem 1Document2 pagesCourse Syllabus - : Chem 1Janea PelpinosasNo ratings yet

- Conradson Carbon Residue - Wikipedia PDFDocument8 pagesConradson Carbon Residue - Wikipedia PDFAbdul Jabbar AL-RashdiNo ratings yet

- Bulk BOQUpload TemplateDocument12 pagesBulk BOQUpload TemplatemargamvivekkumarNo ratings yet

- C32 TitrationDocument12 pagesC32 TitrationManushka ThomasNo ratings yet

- Measurement: - Simple MachinesDocument5 pagesMeasurement: - Simple Machinesakhilesh sahooNo ratings yet