Professional Documents

Culture Documents

Skill 3: Program A Honeywell Udi 1700 Process Meter'S Discrete Outputs As Alarms

Skill 3: Program A Honeywell Udi 1700 Process Meter'S Discrete Outputs As Alarms

Uploaded by

jenixson tamondongOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Skill 3: Program A Honeywell Udi 1700 Process Meter'S Discrete Outputs As Alarms

Skill 3: Program A Honeywell Udi 1700 Process Meter'S Discrete Outputs As Alarms

Uploaded by

jenixson tamondongCopyright:

Available Formats

SKILL 3 PROGRAM A HONEYWELL UDI 1700 PROCESS METER’S DISCRETE

OUTPUTS AS ALARMS

Procedure Overview

In this procedure, you will connect and operate a circuit to measure the

level in a process tank. You will also program a process meter to use its relay

contacts as high and low level alarms.

1. Perform a lockout/tagout.

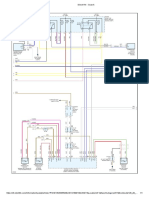

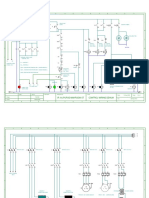

2. Perform the following substeps to set up the T5552, as shown in figure 3-1.

NOTE

The appearance of the electrical outlet will differ based on the electrical

power supplied at your location.

PROCESS CONTROL SYSTEM AMATROL

T5552

ELECTRICAL

PID CONTROLLER FLOW TRANSMITTER

FT1

4-20mA

FLOW SENSORS

FT2

4-20mA TEST

FLOWPVALVE

FV1

4-20mA

PL1 PL2 PL3 PL4

ALM1

ALM2

PROCESS METER

UDI1700

MAX

MIN

OUTLET

SS1 SS2 SS3 SS4 ALM3

ALM4

ALM5

ALM 1234 MAN F

LEVEL SENSORS

0

DI 1234 SET SETUP

PV LT1 LT2

OUT 1234

-sp 0.0

OUTPUT RELAY 1

SP CURRENT INPUT

mA NO COM NC

4-20mA 4-20mA 24VDC

Func. Lower Man SP LS1 LS2 OUTPUT RELAY 2

Loop 1/2 Display Auto Select VOLTAGE INPUT NO COM NC

mV/V

Setup Run

Hold

ENTER

CONTROL RELAYS ALARMPHORN CIRC.PPUMP PLC DISCRETE I/O

24VDC

INPUTS OUTPUTS OUTPUTS AH1 P1

ANALOG ANALOG CR1

ANALOG

AI1 AO1

1 2 3 4 5 6 7 8

CR2

4-20mA

DISCRETE 9 10 11 12 13 14 15 16

DI1 ALARM AUX. POWER

AL1 CR3

DISCRETE

DC POWER SUPPLY PLC ANALOG I/O

DI2 4-20mA

24VDC 24VDC 24VDC

24 VDC 24 VDC

AL2 OPEN COLLECTOR

SOLENOID VALVES

1 2 3 4 5 6 7 8

SV1 SV2 SV3

GND

9 10 11 12 13 14 15 16

HV 100D

HV 100A AIR SUPPLY

(HV2) CONNECTION

(NOT REQUIRED)

MANUAL DRAIN

VALVES

(HV 300 (HV3) &

HV 100C (HV4))

CLOSED

PRESSURE

REGULATOR

SET TO ZERO

HAND VALVES HV 100B (IF CONNECTED)

OPEN (HV1) MANUAL FLOW

CONTROL VALVE

(FV 100 (HFV))

OPEN

Figure 3-1. T5552 Setup

A. Determine if the air supply line is connected to the T5552.

B. If the air supply line is connected, adjust the pressure to 0 psi. If the air supply

line is not connected, do not connect it. You will not need it for this skill.

The diaphragm actuator proportional valve is an air-to-close type, so zero

air pressure will cause it to be fully open.

LB270-XE07AEN-E2-S03, REV. A LIQUID LEVEL CONTROL S03-1

Copyright © 2014 Amatrol, Inc.

SKILL 3 PROGRAM A HONEYWELL UDI 1700 PROCESS METER’S DISCRETE OUTPUTS AS ALARMS

C. Fill the reservoir tank with water.

D. Close (fully clockwise) the two process tank manual drain valves, HV 300

(HV3) and HV 100C (HV4).

E. Open (fully counterclockwise) the manual flow control valve, FV 100 (HFV).

F. Open (fully counterclockwise) the flow control hand valves, HV 100B

(HV1) and HV 100A (HV2).

G. Open (fully counterclockwise) the flow control hand valve HV 100D.

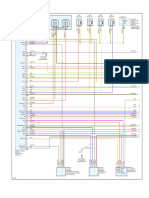

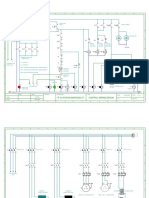

H. Connect the circuit shown in figure 3-2.

This circuit allows you to determine the level of water in the process tank

using the process meter and indicates high and low level alarm conditions

using indicator lamps.

FLOW SENSORS FLOW VALVE DISCRETE I/O PROCESS METER

FT1 FT2 FV1 UDI1700

PL1 PL2 PL3 PL4

1 9 9.0

ALM1 MAX

ALM2 MIN

4-20mA 4-20mA TEST 4-20mA ALM3

SS1 SS2 SS3 SS4 ALM4

ALM5

SET SETUP

LEVEL SENSORS

LT1 LT2

OUTPUT RELAY 1

CURRENT INPUT

mA NO COM NC

4-20mA 4-20mA 24VDC

LS1 LS2 OUTPUT RELAY 2

VOLTAGE INPUT NO COM NC

mV/V

CONTROL RELAYS ALARM HORN CIRC. PUMP PLC DISCRETE I/O

24VDC

AH1 P1

CR1

1 2 3 4 5 6 7 8

CR2

9 10 11 12 13 14 15 16

CR3

DC POWER SUPPLY PLC ANALOG I/O

4-20mA

24VDC 24VDC 24VDC

SOLENOID VALVES

1 2 3 4 5 6 7 8

SV1 SV2 SV3

GND

9 10 11 12 13 14 15 16

Figure 3-2. Level Circuit using Process Meter Alarm Relays

LB270-XE07AEN-E2-S03, REV. A LIQUID LEVEL CONTROL S03-2

Copyright © 2014 Amatrol, Inc.

SKILL 3 PROGRAM A HONEYWELL UDI 1700 PROCESS METER’S DISCRETE OUTPUTS AS ALARMS

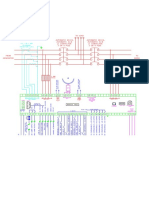

Figure 3-3 shows the wiring diagram for the level circuit.

DC POWER

SUPPLY CIRC. PUMP

SS1 P1

+

-

LT1 PROCESS METER

CURRENT INPUT

PRESSURE SENSOR

+

+ - + -

24 VDC

-

PROCESS METER

OUTPUT RELAY 1 PL3

COM N.O.

+

-

PROCESS METER

OUTPUT RELAY 2 PL4

COM N.O.

+

Figure 3-3. Wiring Diagram for the Level Circuit Using Process Meter Alarm

Relays

3. Remove lockout/tagout.

4. Make sure selector switch SS1 is in the OFF (up) position.

5. Perform the following substeps to enter the Configuration Menu on the

Honeywell UDI 1700 process meter.

A. Turn on the main circuit breaker.

B. Press and hold the SETUP key and then press the up arrow key.

This places the meter in the Select Mode.

C. Use the up and down arrow keys to scroll to the Configuration Menu

(ConF).

The Configuration Menu is locked and requires the unlock code.

D. Use the up and down arrow keys to set the value to 20 and press the

SETUP key to enter the unlock code.

The first parameter in the Configuration Menu (inPt) should appear.

6. Perform the following substeps to verify the Input Type (inPt) and Scale

Range Limits (ruL and rLL).

A. If necessary, use the up and down arrows to change the input type

parameter.

The parameters should be set to “4_20” for 4-20 mA.

If you change the parameter setting, press the SETUP key to bring up the

Yes prompt and press the up arrow key to accept the new value.

B. Scroll to the next parameter, Scale Range Upper Limit (ruL).

LB270-XE07AEN-E2-S03, REV. A LIQUID LEVEL CONTROL S03-3

Copyright © 2014 Amatrol, Inc.

SKILL 3 PROGRAM A HONEYWELL UDI 1700 PROCESS METER’S DISCRETE OUTPUTS AS ALARMS

C. If necessary, use the up and down arrows to change the parameter.

The parameter should be set to 27.7.

If you change the parameter setting, press the SETUP key to bring up the

Yes prompt and press the up arrow key to accept the new value.

D. Scroll to the next parameter, Scale Range Lower Limit (rLL).

E. If necessary, use the up and down arrows to change the parameter.

The parameter should be set to 0.0.

If you change the parameter setting, press the SETUP key to bring up the

Yes prompt and press the up arrow key to accept the new value.

7. Perform the following substeps to set the Alarm 1 parameters. These

parameters are located in the Configuration Menu.

A. Scroll to the Alarm 1 Type parameter (ALA1).

B. Use the up and down arrow keys to set the parameter to P_Lo.

This sets Alarm 1 as a Process Low Alarm.

C. Press the SETUP key to bring up the Yes prompt.

D. Press the up arrow key to accept the setting.

E. Scroll to the next parameter (PLA1).

This is the Process Low Alarm 1 parameter.

F. Use the up and down arrow keys to set the value to 2.0.

This sets the low alarm value as 2.0 inches.

G. Press the SETUP key to bring up the Yes prompt and then press the up

arrow key to accept the setting.

H. Scroll to the next parameter (AHY1).

This is the Hysteresis setting for alarm 1.

I. Use the up and down arrow keys to set the value to 0.1.

This sets the hysteresis to 0.1 inch.

J. Press the SETUP key to bring up the Yes prompt and then press the up

arrow key to accept the setting.

8. Perform the following substeps to set the Alarm 2 parameters.

A. Scroll to the Alarm 2 Type parameter (ALA2).

B. Use the up and down arrow keys to set the parameter to P_Hi.

This sets Alarm 2 as a Process High Alarm.

C. Press the SETUP key to bring up the Yes prompt.

D. Press the up arrow key to accept the setting.

E. Scroll to the next parameter (PhA2).

This is the Process High Alarm 2 parameter.

F. Use the up and down arrow keys to set the value to 8.0.

G. Press the SETUP key to bring up the Yes prompt and then press the up

arrow key to accept the setting.

LB270-XE07AEN-E2-S03, REV. A LIQUID LEVEL CONTROL S03-4

Copyright © 2014 Amatrol, Inc.

SKILL 3 PROGRAM A HONEYWELL UDI 1700 PROCESS METER’S DISCRETE OUTPUTS AS ALARMS

H. Scroll to the next parameter (AHY2).

This is the Hysteresis setting for Alarm 2.

I. Use the up and down arrow keys to set the value to 0.1.

This set the hysteresis to 0.1 inch.

J. Press the SETUP key to bring up the Yes prompt and then press the

arrow key to accept the setting.

9. Perform the following substeps to set the Output Usage parameter for the

Alarms.

These parameters are also located in the Configuration Menu.

A. Scroll to the Output 1 Usage parameter (USE 1).

This parameter sets the relay action for alarm 1.

B. Use the up and down arrow keys to set the parameter to A1nd.

This sets Alarm Relay 1 as direct acting, non-latching. That means that

when the process variable value is below the low alarm value (2.0), the

NO contact of Alarm Relay 1 is closed and the NC contact is open. Since

non-latching is also selected, the contacts will return to their normal states

when the process variable exceeds 2.0.

C. Press the SETUP key to bring up the Yes prompt and then press the up

arrow key to accept the setting.

D. Repeat substeps A-C to set the Output Usage 2 parameter (USE 2) to

A2nd.

10. Perform the following substeps to exit the Configuration Menu and the Select

Mode.

A. Press and hold the SETUP key and then press the up arrow key.

This exits the Configuration Menu and returns to the Select Mode.

B. Use the up and down arrow keys to scroll until “OPtr” appears on

the display.

C. Press the SETUP key to exit the Select Mode and return the meter to the

normal operating mode.

11. Perform the following substeps to set the Process Variable Offset parameter

(OFFS).

The Process Variable Offset Parameter is located in the Set Up Menu. Since

the level sensor is mounted beneath the process tank, the offset value is used

to make the process variable value read 0.0 when the level is at the zero inch

mark on the tank.

A. Press and hold the SETUP key and then press the up arrow key to enter

the Select Mode.

B. Use the up and down arrow keys to scroll to the Set Up Menu

(SEtP).

The Set Up Menu is locked and requires the unlock code.

LB270-XE07AEN-E2-S03, REV. A LIQUID LEVEL CONTROL S03-5

Copyright © 2014 Amatrol, Inc.

SKILL 3 PROGRAM A HONEYWELL UDI 1700 PROCESS METER’S DISCRETE OUTPUTS AS ALARMS

C. Use the up and down arrow keys to set the value to 10 and press the

SETUP key to enter the unlock code.

The first parameter in the Set Up Menu is the Input Filter Time Constant

(FILt) parameter.

D. Scroll to the Process Variable Offset (OFFS) parameter.

E. Use the up and down keys to change the value to -4.1.

The sensing element for the level sensor is located approximately 4.1

inches below the zero inch mark in the tank. A setting of -4.1 offsets the

zero reading so that the meter displays 0.0 when the water is at the zero

inch mark on the tank.

F. Press the Setup key to accept the value.

G. Press and hold the Setup key and press the up arrow key to exit the Set

Up Menu.

H. Scroll until “OPtr” appears on the display and press the Setup key to exit

the Select Mode and return the meter to normal operation.

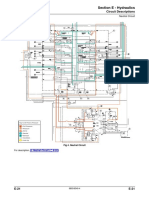

The process meter is now programmed and should return to the normal

operating mode. When the process meter returns to the operating mode,

the process variable's value on the display should indicate 0.0, as shown

in figure 3-4. If it does not indicate 0.0, adjust the Process Variable Offset

parameter (OFFS) value until the displayed process variable value is 0.

UDI1700

ALM1 MAX

ALM2 MIN

ALM3

ALM4

ALM5

SET SETUP

Figure 3-4. Process Meter Display PV Value of 0.0

LB270-XE07AEN-E2-S03, REV. A LIQUID LEVEL CONTROL S03-6

Copyright © 2014 Amatrol, Inc.

SKILL 3 PROGRAM A HONEYWELL UDI 1700 PROCESS METER’S DISCRETE OUTPUTS AS ALARMS

12. Start the circulation pump by placing selector switch SS1 in the ON position.

Does an alarm condition exist? ___________________________ (Yes/No)

You should find that the low-level alarm indicator lamp (PL3) is on because

the level is below the low level alarm value (2 inches).

13. When the level reaches the 3-inch (7.5-cm) mark, turn off selector switch

SS1 to stop the pump.

Does an alarm condition exist? ___________________________ (Yes/No)

You should find that the low (PL3) and high-level (PL4) alarm indicator lamps

are off because the level is within the acceptable range (2.0-8.0 inches).

14. Turn on selector switch SS1 to start the pump.

15. When the level reaches the 9-inch (23-cm) mark, turn off selector switch SS1

to stop the pump.

Does an alarm condition exist? ___________________________ (Yes/No)

You should find that the high-level alarm indicator lamp (PL4) is on because

the level is above the high alarm value (8 inches).

As long as the level stays between the low and high level settings (low =

2.0, high = 8.0), neither alarm is active. If the level falls below the low level

setting, the low level alarm (alarm 1) is active. If the level exceeds the high

level setting, the high level alarm (alarm 2) is active.

16. Perform the following substeps to shut down the T5552.

A. Open (fully counterclockwise) both of the process tank manual drain

valves, HV 300 (HV3) and HV 100C (HV4), to drain the tank. When the

tank is empty, close (fully clockwise) the valves.

B. Turn off the main circuit breaker.

C. Disconnect the circuit.

LB270-XE07AEN-E2-S03, REV. A LIQUID LEVEL CONTROL S03-7

Copyright © 2014 Amatrol, Inc.

You might also like

- Caterpillar 3412D MARINE ENGINE Workshop Repair Service Manual PDF DownloadDocument405 pagesCaterpillar 3412D MARINE ENGINE Workshop Repair Service Manual PDF Downloadben threadwell75% (4)

- 320D, 321D, 323D, 324D, 325D, Hydraulic System - Attachment 329D, 330D, and 336D ExcavatorDocument2 pages320D, 321D, 323D, 324D, 325D, Hydraulic System - Attachment 329D, 330D, and 336D Excavatorxuan80% (5)

- Allen Heath Ag8700 1 Qu16 PsuDocument7 pagesAllen Heath Ag8700 1 Qu16 PsuSugeng HariadiNo ratings yet

- Skill 7: Connect and Operate Discrete Inputs On A Honeywell Udc 3500 ControllerDocument8 pagesSkill 7: Connect and Operate Discrete Inputs On A Honeywell Udc 3500 Controllerjenixson tamondongNo ratings yet

- Skill 6: Connect and Operate Alarms On A Honeywell Udc 3500 ControllerDocument7 pagesSkill 6: Connect and Operate Alarms On A Honeywell Udc 3500 Controllerjenixson tamondongNo ratings yet

- Zed R16 003-849 PsuDocument2 pagesZed R16 003-849 Psuosman saraçNo ratings yet

- 1000SR 07 - Can - MK6Document11 pages1000SR 07 - Can - MK6marceloaav1100% (1)

- Scan 1200 XT Service Manual V 1Document22 pagesScan 1200 XT Service Manual V 1Silverio SogorbNo ratings yet

- Search - AMM - A320 - IAC - 34 - 34-10-00Document1 pageSearch - AMM - A320 - IAC - 34 - 34-10-00ashmigeorgeNo ratings yet

- Air Conditioning - Manual A - C Circuit (Heating and Air Conditioning) - ALLDATA RepairDocument2 pagesAir Conditioning - Manual A - C Circuit (Heating and Air Conditioning) - ALLDATA RepairAlejandro Quiñones VelazquezNo ratings yet

- 01Document1 page01cristianNo ratings yet

- Onkyo+Txsr 805+schematicsDocument36 pagesOnkyo+Txsr 805+schematicsJuarez Mesquita Leite JuniorNo ratings yet

- Diagram 1 A/C AMPLIFIER ASSEM..Document2 pagesDiagram 1 A/C AMPLIFIER ASSEM..Jose HuescaNo ratings yet

- GLC300 en ManualDocument16 pagesGLC300 en ManualMihai Iavorschi86% (7)

- Ibanez LF7 - Lo-Fi Filter - SchematicDocument1 pageIbanez LF7 - Lo-Fi Filter - SchematicDavid Brown100% (1)

- NHT11 1284 - 1 SalidaDocument1 pageNHT11 1284 - 1 Salidaloro100No ratings yet

- Tx01 004 4141 0 Profibus 7relay ModulatingDocument1 pageTx01 004 4141 0 Profibus 7relay ModulatingZarcancel RufusNo ratings yet

- Lexus 2Document1 pageLexus 2Rosa SozaNo ratings yet

- H2-02 - BMS Point Schedule (MV)Document1 pageH2-02 - BMS Point Schedule (MV)Aldhi PriambudiNo ratings yet

- Headphone Mute Speaker Amp: Near MST - IC Ground in The Middle of The L/RDocument7 pagesHeadphone Mute Speaker Amp: Near MST - IC Ground in The Middle of The L/Rgarcia5No ratings yet

- Diagram 1Document5 pagesDiagram 1Cristofer2No ratings yet

- TIIDA SánchezDocument6 pagesTIIDA SánchezJesus SanchezNo ratings yet

- KH X-Band Mk4 Block DiagramDocument1 pageKH X-Band Mk4 Block DiagramGlobal Ship SparesNo ratings yet

- Hyundai h-cmd4004 dv7891Document12 pagesHyundai h-cmd4004 dv7891MantasPuskoriusNo ratings yet

- Engine Controls (Powertrain Management) - ALLDATA RepairDocument5 pagesEngine Controls (Powertrain Management) - ALLDATA RepairRonald FerminNo ratings yet

- Deepsea 7420 CAD DrawingDocument2 pagesDeepsea 7420 CAD Drawingsnipie renz100% (1)

- ALC Geared Application Electrical DiagramDocument20 pagesALC Geared Application Electrical Diagramمحمد حسينNo ratings yet

- en - E2 Control Panel Technical ManualDocument16 pagesen - E2 Control Panel Technical ManualChrisanto MangubatNo ratings yet

- SD313 3 MFI Control System (G4HE/G4HG: EPSILON 1.0L/1.1L M/T)Document1 pageSD313 3 MFI Control System (G4HE/G4HG: EPSILON 1.0L/1.1L M/T)Huy Trần QuốcNo ratings yet

- KG-UV920R Service ManualDocument38 pagesKG-UV920R Service ManualErik JirikNo ratings yet

- 科瑞康心电监护血氧模块线路图Document1 page科瑞康心电监护血氧模块线路图wendongNo ratings yet

- Color Schematics Engine Controls 1 6l 1 of 4Document1 pageColor Schematics Engine Controls 1 6l 1 of 4fernandoNo ratings yet

- Maestro 81 20 Gearless Eng 1Document18 pagesMaestro 81 20 Gearless Eng 1Mohammed AldaffaieNo ratings yet

- Kakamanana PDFDocument1 pageKakamanana PDFAnonymous BZQOJwWIh6No ratings yet

- Uvls.2 Uqair-A.12Document1 pageUvls.2 Uqair-A.12Anonymous BZQOJwWIh6No ratings yet

- FLUKE 27 Schematic DiagramDocument4 pagesFLUKE 27 Schematic Diagrambudi0251No ratings yet

- 2015 Creta D 1.6 Tci-U2-DiagramDocument1 page2015 Creta D 1.6 Tci-U2-DiagramJimmy Durand LunaNo ratings yet

- Gecko ControllerDocument1 pageGecko ControllerBruce CollverNo ratings yet

- SLD Layout1Document1 pageSLD Layout1Robert TiinNo ratings yet

- Customer's Installation: Table of Components Mark Description GridDocument1 pageCustomer's Installation: Table of Components Mark Description GridcristianNo ratings yet

- Dak Drinh HPP Control and Monitoring System ArchitectureDocument1 pageDak Drinh HPP Control and Monitoring System ArchitectureNông Dân Anh HùngNo ratings yet

- Engine Controls Cruze 2012 1.8ltsDocument5 pagesEngine Controls Cruze 2012 1.8ltsRogelio ArenasNo ratings yet

- Circuit Descriptions: Section E - HydraulicsDocument1 pageCircuit Descriptions: Section E - HydraulicsNikNo ratings yet

- 6SE709x xxx84Document1 page6SE709x xxx84qwasawsewNo ratings yet

- JSS 2150 Service Manual (1) Trang 3Document1 pageJSS 2150 Service Manual (1) Trang 3quangtiendt05No ratings yet

- Ir .HJ - Pupud Mahpudin ST Control Wiring Dehum: A B C D E F G HDocument6 pagesIr .HJ - Pupud Mahpudin ST Control Wiring Dehum: A B C D E F G HindraNo ratings yet

- Ir .HJ - Pupud Mahpudin ST Control Wiring Dehum: A B C D E F G HDocument5 pagesIr .HJ - Pupud Mahpudin ST Control Wiring Dehum: A B C D E F G HindraNo ratings yet

- Control Wiring DEHUM Dan AhuDocument7 pagesControl Wiring DEHUM Dan AhuindraNo ratings yet

- Gitet Pedan SLDDocument1 pageGitet Pedan SLDSidiq PermonoNo ratings yet

- SPC 324A 14 Asbuilt DGRDocument4 pagesSPC 324A 14 Asbuilt DGRapsNo ratings yet

- Cat Dcs Sis ControllerDocument2 pagesCat Dcs Sis ControllerSiding BarroNo ratings yet

- 2015 Creta G 1.6 Mpi A-T-DiagramDocument1 page2015 Creta G 1.6 Mpi A-T-DiagramJimmy Durand LunaNo ratings yet

- Schematik Disjaya SPK100 - Update SiteDocument1 pageSchematik Disjaya SPK100 - Update SiteArra JanrafSasihNo ratings yet

- 33207te SCHDocument1 page33207te SCHDany GuitNo ratings yet

- Solar Mars Gas Turbine Generator Drive Application Control PackageDocument3 pagesSolar Mars Gas Turbine Generator Drive Application Control PackagePrsNo ratings yet

- Schematic Hxhd200a8 - PipDocument1 pageSchematic Hxhd200a8 - PipPaulKajzerNo ratings yet

- Constant Current Regulator MicroprocessoDocument8 pagesConstant Current Regulator MicroprocessoEng-Waleed MohamadNo ratings yet

- Emr 4000 Instructions Im02602009eDocument1,010 pagesEmr 4000 Instructions Im02602009eAgus SuwardonoNo ratings yet

- E2Document1 pageE2Aila P. TabrillaNo ratings yet

- EE9AL EE5D Celestial Mendoza PDF File 2Document3 pagesEE9AL EE5D Celestial Mendoza PDF File 2jenixson tamondongNo ratings yet

- Salinas Corporation DTRDocument3 pagesSalinas Corporation DTRjenixson tamondongNo ratings yet

- Optimizing The Palinpinon-2 Geothermal Reservoir, Southern Negros Geothermal Production Field, PhilippinesDocument7 pagesOptimizing The Palinpinon-2 Geothermal Reservoir, Southern Negros Geothermal Production Field, Philippinesjenixson tamondongNo ratings yet

- EE9AL EE5D Celestial Mendoza PDF File 1Document8 pagesEE9AL EE5D Celestial Mendoza PDF File 1jenixson tamondongNo ratings yet

- Optimum Selection of Steam Turbine and Condenser For Geothermal Power PlantDocument6 pagesOptimum Selection of Steam Turbine and Condenser For Geothermal Power Plantjenixson tamondongNo ratings yet

- Philippine Wind Farm Analysis and Site Selection Analysis: January 1, 2000 - December 31, 2000Document88 pagesPhilippine Wind Farm Analysis and Site Selection Analysis: January 1, 2000 - December 31, 2000jenixson tamondongNo ratings yet

- Report DocumentationDocument37 pagesReport Documentationjenixson tamondongNo ratings yet

- Ee9al Ee5d Pedro Dalino PDF File 1Document11 pagesEe9al Ee5d Pedro Dalino PDF File 1jenixson tamondongNo ratings yet

- Solar Powerplant Design (6!14!2020)Document99 pagesSolar Powerplant Design (6!14!2020)jenixson tamondong100% (1)

- 5cis 35 P 41,667.00Document15 pages5cis 35 P 41,667.00jenixson tamondongNo ratings yet

- Katelyn Rose B. NavarroDocument1 pageKatelyn Rose B. Navarrojenixson tamondongNo ratings yet

- Selbijan Albert C. EE14 Problem Set 4Document5 pagesSelbijan Albert C. EE14 Problem Set 4jenixson tamondongNo ratings yet

- Protection Devices and Systems For High-Voltage APDocument2 pagesProtection Devices and Systems For High-Voltage APjenixson tamondongNo ratings yet

- Geothermal 20 Power 20 TechnologyDocument10 pagesGeothermal 20 Power 20 Technologyjenixson tamondongNo ratings yet

- Ee9al Ee5d Pedro Dalino PDF File 3Document8 pagesEe9al Ee5d Pedro Dalino PDF File 3jenixson tamondongNo ratings yet

- Iloilo A Bs3 03 Geothermal RoadmapDocument12 pagesIloilo A Bs3 03 Geothermal Roadmapjenixson tamondongNo ratings yet

- UCS617Document1 pageUCS617Devanshi GudsariyaNo ratings yet

- Attributional Style and The Generality of Learned HelplessnessDocument7 pagesAttributional Style and The Generality of Learned HelplessnessWan-yi ChenNo ratings yet

- 7.NS EOG Review Packet PDFDocument28 pages7.NS EOG Review Packet PDFNatalie ShadiNo ratings yet

- NG300 ESales Spec SheetDocument2 pagesNG300 ESales Spec SheetSamrandNo ratings yet

- CSMSP11 Lecture03 EMWaves2Document46 pagesCSMSP11 Lecture03 EMWaves2ErosDNo ratings yet

- Learning To Prompt For Continual LearningDocument13 pagesLearning To Prompt For Continual Learningchristinechenpp04No ratings yet

- Quarter 2 Countless and Active Particles of Matter: Learner's Activity SheetDocument8 pagesQuarter 2 Countless and Active Particles of Matter: Learner's Activity SheetHersheyNo ratings yet

- Digitax ST User Guide Issue 6 (0475-0001-06) - Approved PDFDocument210 pagesDigitax ST User Guide Issue 6 (0475-0001-06) - Approved PDFMazarel AurelNo ratings yet

- Transition Metal 4Document4 pagesTransition Metal 4Sushant ShahNo ratings yet

- Rel Series KolarcDocument4 pagesRel Series KolarcDarko NikolovskiNo ratings yet

- Configuration Manual: AR-SERIES ControllerDocument28 pagesConfiguration Manual: AR-SERIES ControllerJam AnjumNo ratings yet

- Iso 15809Document15 pagesIso 15809Manoj KumarNo ratings yet

- All PastPapersDocument320 pagesAll PastPapersDsquaredNo ratings yet

- K V Rao Adv Java PDFDocument151 pagesK V Rao Adv Java PDFFeleke AfeworkNo ratings yet

- Product Specifications Product Specifications: Cellmax Cellmax - Ext Ext - Cpu CPUDocument2 pagesProduct Specifications Product Specifications: Cellmax Cellmax - Ext Ext - Cpu CPUNataša Mihić BoskovićNo ratings yet

- Create The Project: Castro Valley Castro Valley Urban StudyDocument5 pagesCreate The Project: Castro Valley Castro Valley Urban StudyVicces P. EstradaNo ratings yet

- Yoshitake Kawaki KYDocument19 pagesYoshitake Kawaki KYAkif DinçNo ratings yet

- Gamry The Basics of EIS Part 2Document13 pagesGamry The Basics of EIS Part 2Mobasher KhanNo ratings yet

- dl100 UmDocument88 pagesdl100 UmTammam KorkmasNo ratings yet

- MWD - Annular Pressure BasicsDocument4 pagesMWD - Annular Pressure BasicskhalidmkarajagiNo ratings yet

- Caption TextDocument9 pagesCaption TextRenal Abdillah AmurtiNo ratings yet

- 1SCA022400R9910 Otp16t3mDocument4 pages1SCA022400R9910 Otp16t3mmuhammad ihsanNo ratings yet

- Seismic Analysis - Specifying Seismic Weight Through Reference Load CasesDocument4 pagesSeismic Analysis - Specifying Seismic Weight Through Reference Load CasesapirakqNo ratings yet

- Disclosure To Promote The Right To InformationDocument15 pagesDisclosure To Promote The Right To InformationIndira BanerjeeNo ratings yet

- Week 3: Product Development: E-Yantra, IIT BombayDocument9 pagesWeek 3: Product Development: E-Yantra, IIT BombayArnav SinghNo ratings yet

- Downloading The User's Guide Scope: EnglishDocument10 pagesDownloading The User's Guide Scope: EnglishCesar Oseguera CabreraNo ratings yet

- GS-4500 Instrumentation Design and Installation SpecificationDocument76 pagesGS-4500 Instrumentation Design and Installation SpecificationSmart LauNo ratings yet

- ABB - 12 - E - 16 Materials and Semi-Finished Products For Switchgear InstallationsDocument24 pagesABB - 12 - E - 16 Materials and Semi-Finished Products For Switchgear InstallationsHan HuangNo ratings yet

- Magsino, Christian N Bsais 2A - ADocument24 pagesMagsino, Christian N Bsais 2A - AChristian N MagsinoNo ratings yet

- AD8561Document11 pagesAD8561ΠΑΝΑΓΙΩΤΗΣΠΑΝΑΓΟΣNo ratings yet