Professional Documents

Culture Documents

I. Cycle Count Input: Inventory Use Cases

I. Cycle Count Input: Inventory Use Cases

Uploaded by

Derrick Chen0 ratings0% found this document useful (0 votes)

28 views4 pagesThe document describes 13 inventory use cases:

1) Cycle count input allows clerks to enter physical inventory counts.

2) Cycle count reports display count histories.

3) Scrap item reports provide scrap records.

4) Scrap item input logs scrapped parts.

5) Inventory adjustment reports show changes to quantities.

6) Item information lookups display part details.

Original Description:

Original Title

usecases

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document describes 13 inventory use cases:

1) Cycle count input allows clerks to enter physical inventory counts.

2) Cycle count reports display count histories.

3) Scrap item reports provide scrap records.

4) Scrap item input logs scrapped parts.

5) Inventory adjustment reports show changes to quantities.

6) Item information lookups display part details.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

0 ratings0% found this document useful (0 votes)

28 views4 pagesI. Cycle Count Input: Inventory Use Cases

I. Cycle Count Input: Inventory Use Cases

Uploaded by

Derrick ChenThe document describes 13 inventory use cases:

1) Cycle count input allows clerks to enter physical inventory counts.

2) Cycle count reports display count histories.

3) Scrap item reports provide scrap records.

4) Scrap item input logs scrapped parts.

5) Inventory adjustment reports show changes to quantities.

6) Item information lookups display part details.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

You are on page 1of 4

Inventory Use Cases

I. Cycle Count Input

Actor: Inventory clerk

Prerequisite: Cycle counting report is generated

Workflow:

1. Clerk obtains the cycle counting report

2. Clerk physically goes out into the warehouse inventory and counts the parts listed in the

report

3. Clerk returns to a terminal with the actual counts

4. Clerk enters the item ID of the item counted and the quantity counted in the warehouse

and the system automatically uses today’s date for the date stamp.

Post Conditions: Database is updated, Inventory Adjustment Report is updated

II. Cycle Count Report

Actor: Inventory clerk

Prerequisite: None

Workflow:

1. Clerk wants to know about cycle count of a item, items, or the cycle counts on a specific

date.

2. Clerk enters in the item ID(s) or the date and hits the Display button.

3. The system returns all the entries in the database that matches the search parameters.

4. Each entry displays the date of the count, the item ID, the quantity, the date of the last

count, and the date of the next scheduled cycle count.

5. The Clerk may hit the print button to generate a printed report.

Post Conditions: The printer generates a formatted copy of the Cycle Count Report if the Clerk

chose to print the report

III. Scrap Item Report

Precondition: The item is already in inventory database

Actor: Inventory Clerk

Workflow:

1.) Clerk inputs item ID number into text box

2.) Clerk presses search button

3.) System report is created with the item ID, quantity, worth, send to, date, and reason

4.) If the Clerk wishes to, he may print the report.

Post Condition: The printer generates a formatted copy of the Scrap Item Report if the Clerk

chose to print the report.

VI. Scrap Item Input

Precondition: The part is already in the inventory database and all information is available to fill

form out.

Actor: Inventory Clerk

Workflow:

1.) Clerk enters the item ID number, the quantity to scrap, the reason why the item was

damaged, the worth of the item scrapped, who the scrapped items were sent to

2.) The form is submitted with a click of a button, though the Clerk may also cancel the

input as well.

V. Inventory Adjustment Report

Actor: Manager

Prerequisite: None

Workflow:

1. Manager enters ID of the part he/she wishes to see the inventory adjustments for and

click Search

2. The system retrieves the inventory adjustment information from the database

3. The system displays the information reflecting the change in inventory about the part

such as Part ID, Date of Adjustment, Reasons for Adjustment, and Adjusted Quantity.

The system allows the Manager the option to print the report.

4. The Manager repeats the process as needed for different parts.

Post Conditions: A report of adjustment information about a particular part is displayed/printed.

VI. Look Up Item Information

Actor: Inventory Clerk

Prerequisite: None

Workflow:

1. Inventory Clerk enters ID of the items he/she wants to look up and click Search.

2. The system retrieves the inventory information from the database

3. The system displays the information about the part such as Item ID, Description, Status,

Quantity, Cost, Weight, Size, and Cycle Count. The system allows the Clerk to print out

the report.

4. The Inventory Clerk repeats the process as needed for different items.

Post Conditions: A report of information about a particular item is displayed/printed.

VII. Update Item Information

Actor: Inventory Clerk

Prerequisite: Part to be updated already exists in the database

Workflow:

1. Clerk enters an item ID and hits the Go button.

2. The system retrieves item information from the database and displays it in user ediable

fields.

3. Clerk changes any information in any of the fields.

4. Clerk hits the Update button to commit the change or Cancel to discard the changes.

Post Conditions: Database is updated

VIII. Failed Item Look Up

Actor: Inventory Clerk

Prerequisite: Item does not exist in the database

Workflow:

1. Clerk tries to look up a single invalid item during a look up in any UI window

2. The system reports an error looking up the item and asks if the clerk wishes to enter a

new item or to try a new search

3. If the Clerk wishes to add a new item, go to Add a New Item, otherwise, return to

previous window

Post Conditions: Change UI window to either Add a New Item or the previous window, and

retain the item ID from the failed look up

IX. Item Status Report

Precondition: The item is already in inventory database

Actor: Inventory Clerk

Work Flow:

1.) Clerk inputs item ID number into search box

2.) Presses search button

3.) System will return with whether the item is in warehouse are being stocked.

Postcondition: None

X. Inventory Valuation Report

Precondition: Name/ID of item are entered in the inventory database.

Actor: Inventory Clerk

Work Flow:

1. Inventory Clerk enters ID of the item and clicks the Search button.

2. If the Inventory Clerk wants to see the valuation reports for all the items in the

database, he/she does not fill in the ID of the item and just clicks Search button.

3. The system matches up this ID with the item ID from the database and retrieves

information about that part from the database.

4. The system display to the screen these following fields for each of the item: Item ID,

Description of the item, Status, Quantity, Unit cost, and Total cost. The system

allows the Clerk to print out the report.

5. The Inventory Clerk repeats the process as needed for different items.

Post Condition: A valuation report for items is displayed/printed. The Inventory Clerk knows

about the value of all items in the database.

XI. Delete Part

Precondition: Item already exists in inventory database

Actor: Inventory Clerk

Work Flow:

1.) Clerk enters an item ID, then clicks the Search button.

2.) Screen displays the item ID, description, quantity in inventory, the cost of the

item, and the total cost of all the items.

3.) Clerk clicks on the Delete button.

4.) System brings up confirmation on the deletion of the part.

5.) Clerk verifies the deletion by clicking on Ok or he can Cancel the deletion.

Post Condition: If verified, the data associated with the item is deleted from system .

Notification will appear on the next inventory status report.

XII. Add Item

Precondition: Item is not already in database and unknown part is received

Actor: Inventory Clerk

Workflow:

1.) Enters the ID for the item

2.) ID number is entered into the system and verified to make sure ID number

does not already exist

3.) If ID number is not being used ID number is added to system

4.) Clerk enters information about the item such as weight, cost, size (length,

height, width), description, and the period between cycle counts.

5.) The system sets the quantity to zero and the last cycle count to this date.

6.) Clerk clicks the OK button to submit the information.

Post Condition: Item is added to database and notification of addition with description will

appear on the next inventory status report.

XIII. Add Item on Order

Precondition: Item is not already in database and part is being ordered for first time

Actor: Clerk

Workflow:

1.) Clerk orders a new item not in database

2.) System displays the Add Item screen

3.) After entering and confirming the data, the system returns the Clerk to the previous

screen.

Post Condition: Item is added to database and notification of addition with description will

appear on the next inventory status report, and the system returns the user to the previous screen.

You might also like

- Inventory Management System For CollegeDocument9 pagesInventory Management System For CollegeNishtha Garg100% (4)

- 302CEM Coursework - April2021 + Rubricv1Document11 pages302CEM Coursework - April2021 + Rubricv1renz testNo ratings yet

- PDF Download Baby Treatment Based On NDT PrinciplesDocument2 pagesPDF Download Baby Treatment Based On NDT PrinciplesHiten J Thakker0% (2)

- B. (DR - Robert - Mellor) - Entrepreneurship - For - Everyone PDFDocument257 pagesB. (DR - Robert - Mellor) - Entrepreneurship - For - Everyone PDFWaleed Amir100% (1)

- About The ProjectDocument4 pagesAbout The ProjectAnonymous PHCzwD8eAONo ratings yet

- Understanding Item Import and Debugging Problems With Item Import Doc ID 268968 1Document20 pagesUnderstanding Item Import and Debugging Problems With Item Import Doc ID 268968 1kriole13No ratings yet

- 1.1. Background: Chapter OneDocument55 pages1.1. Background: Chapter OneMan Tade100% (1)

- II. Use Case ModelDocument30 pagesII. Use Case Modelfirebolt_gxNo ratings yet

- Mecaninprec Sas Information SystemDocument13 pagesMecaninprec Sas Information SystemLina Vanessa BermudezNo ratings yet

- Writing Use Cases: Course Instructor: Idrees Ahmad Course Code: SE321Document24 pagesWriting Use Cases: Course Instructor: Idrees Ahmad Course Code: SE321Wahab KhanNo ratings yet

- Invotery MangementDocument9 pagesInvotery MangementSeshu naiduNo ratings yet

- Jan.21 With Page Number and Table of ContentsDocument34 pagesJan.21 With Page Number and Table of Contentsfirebolt_gxNo ratings yet

- Oracle Fixed Assets User ManualDocument60 pagesOracle Fixed Assets User ManualVenu Gopal ChallaNo ratings yet

- SRS AssDocument17 pagesSRS AssMuhammad HarisNo ratings yet

- Physical InventoryDocument8 pagesPhysical Inventorytumpak bennyNo ratings yet

- Class DiagramDocument7 pagesClass Diagrammanognamanu802_10982No ratings yet

- CP 4Document23 pagesCP 4Soll HaileNo ratings yet

- Sap Cin ConfigDocument40 pagesSap Cin ConfigNaveen KumarNo ratings yet

- Physical InventoryDocument7 pagesPhysical InventoryJagadish JaganNo ratings yet

- Medical ERP System: Functional RequirementsDocument3 pagesMedical ERP System: Functional RequirementsajilnathNo ratings yet

- Usecase Diagram For Point of Sale Machine: CustomerDocument17 pagesUsecase Diagram For Point of Sale Machine: CustomerAadil SafiNo ratings yet

- Use Case Specifications For Stock Maintenance SystemDocument10 pagesUse Case Specifications For Stock Maintenance SystemAnup PatwariNo ratings yet

- DIA Processes DocumentsDocument52 pagesDIA Processes DocumentsPuneetNo ratings yet

- Stock Management SystemDocument29 pagesStock Management SystemBharat Ane NenuNo ratings yet

- IT Asset Management Process DescriptionDocument8 pagesIT Asset Management Process DescriptionlozinioNo ratings yet

- Project Use CasesDocument6 pagesProject Use CasesFrank Opare AnnorNo ratings yet

- Software ConstructionDocument18 pagesSoftware ConstructionAadil SafiNo ratings yet

- Customer Return Process in SAP SDDocument14 pagesCustomer Return Process in SAP SDBalaji_SAP100% (4)

- Spring 2012 Allen Briscoe-SmithDocument4 pagesSpring 2012 Allen Briscoe-SmithtestacctlolNo ratings yet

- Step by Step MM CIN Excise InvoiceDocument51 pagesStep by Step MM CIN Excise InvoiceshravaninathreddyNo ratings yet

- Reservation - Goods Issue For AssetsDocument10 pagesReservation - Goods Issue For AssetsmeddebyounesNo ratings yet

- PHysical Inventory in SAPDocument16 pagesPHysical Inventory in SAPVishnu Kumar SNo ratings yet

- Requirement AnalysisDocument11 pagesRequirement AnalysisAnteneh bezahNo ratings yet

- Goods Receipt With Purchase Order: Step 2)Document4 pagesGoods Receipt With Purchase Order: Step 2)Nbhaskar BhaskarNo ratings yet

- Use Case Number: 1 Use Case Name: Maintain Employee Information Actor: AdministratorDocument9 pagesUse Case Number: 1 Use Case Name: Maintain Employee Information Actor: AdministratorAmberShahNo ratings yet

- SRS Documentation For Personnel Management SystemDocument22 pagesSRS Documentation For Personnel Management SystemVarun SrinivasanNo ratings yet

- Material Transactions - SAP PSDocument14 pagesMaterial Transactions - SAP PSanilNo ratings yet

- User Manual - InventoryDocument84 pagesUser Manual - InventoryMohammad AnasNo ratings yet

- Chapter Two PropasalDocument12 pagesChapter Two PropasalTolosa TafeseNo ratings yet

- Migo Good ReceiptDocument6 pagesMigo Good ReceiptFasihNo ratings yet

- Session 3 - 23.12.2023Document17 pagesSession 3 - 23.12.2023khaoulahourirNo ratings yet

- Create An ItemDocument28 pagesCreate An ItemSuteu Cristina MariaNo ratings yet

- P2P - Procure To Pay CycleDocument38 pagesP2P - Procure To Pay CycleAnonymous U1c56EcgZ0% (1)

- Stock Maintenance SystemDocument28 pagesStock Maintenance SystemVinodNo ratings yet

- ITC Assignment 4Document2 pagesITC Assignment 4hashaam dogarNo ratings yet

- Direct Material Request and CGR Process Flow 0.2Document25 pagesDirect Material Request and CGR Process Flow 0.2dinu mauryaNo ratings yet

- 25346-Procure To Pay CycleDocument34 pages25346-Procure To Pay CycleSAlah MOhammedNo ratings yet

- Process Sale Use CaseDocument8 pagesProcess Sale Use CaseEminOzNo ratings yet

- Hotel Project DocumentationDocument59 pagesHotel Project DocumentationAmol KambleNo ratings yet

- Console Base POS Assignment 4Document11 pagesConsole Base POS Assignment 4Zunair AliNo ratings yet

- SASE Project ReportDocument16 pagesSASE Project ReportSyed Abdul SaboorNo ratings yet

- SAP MM Without WM Physical InventoryDocument12 pagesSAP MM Without WM Physical InventoryNuman DeğirmenciNo ratings yet

- SRS - F1802BF18B (MC180204630, MC170402017)Document22 pagesSRS - F1802BF18B (MC180204630, MC170402017)munawarzareef4541No ratings yet

- SAP MM - Inventory Management ProcessDocument50 pagesSAP MM - Inventory Management Processjuventus fans club indonesia100% (1)

- Unit 1 - Assignment 2 FrontsheetDocument32 pagesUnit 1 - Assignment 2 FrontsheetToàn Đỗ KhánhNo ratings yet

- Use Case Narratives For Inventory Management System: Dr. Kasi Periyasamy February 2009Document9 pagesUse Case Narratives For Inventory Management System: Dr. Kasi Periyasamy February 2009Julio Navarro CadezaNo ratings yet

- Assignment 1 Summer 2011Document3 pagesAssignment 1 Summer 2011Karthik SrinivasNo ratings yet

- Test Plan - Real EstateDocument5 pagesTest Plan - Real Estatedevid mandefroNo ratings yet

- Tickets SAP SDDocument5 pagesTickets SAP SDtanushitcetNo ratings yet

- IDeliverable - Writing An Orchard Webshop Module From Scratch - Part 5Document23 pagesIDeliverable - Writing An Orchard Webshop Module From Scratch - Part 5Active88No ratings yet

- Journal of Marketing Communications Call For PapersDocument3 pagesJournal of Marketing Communications Call For PapersAj KimmelNo ratings yet

- Four Best Uncensored AI Art Generators - Nazmul Rumi PDFDocument16 pagesFour Best Uncensored AI Art Generators - Nazmul Rumi PDFmoneygain4everNo ratings yet

- How To Set Up Digicast Digital Satellite Receiver White PaperDocument7 pagesHow To Set Up Digicast Digital Satellite Receiver White PaperFEMIZZ12No ratings yet

- ROS Cheat Sheet v1.01 1Document1 pageROS Cheat Sheet v1.01 1hbuddyNo ratings yet

- 2021-2022 M1 EtechDocument49 pages2021-2022 M1 EtechMarshiela AbdulaNo ratings yet

- Week 2 - VLANsDocument24 pagesWeek 2 - VLANsQiu LeNo ratings yet

- Code To Activate Windows 10Document2 pagesCode To Activate Windows 10MohanrajNo ratings yet

- HomeLYnk Remote ServicesDocument2 pagesHomeLYnk Remote ServicesVictor Raul Iturrieta MadridNo ratings yet

- List of Countries by Average Elevation - WikipediaDocument8 pagesList of Countries by Average Elevation - Wikipediamalaparte127No ratings yet

- Notice: Environmental Statements Notice of Intent: Florida Gas Transmission Co.Document2 pagesNotice: Environmental Statements Notice of Intent: Florida Gas Transmission Co.Justia.comNo ratings yet

- Incorporate Custom LayoutDocument6 pagesIncorporate Custom LayoutvaidehiapawarNo ratings yet

- AirPrime EM75XX AT Command Reference r2 PDFDocument140 pagesAirPrime EM75XX AT Command Reference r2 PDFjacobbowserNo ratings yet

- GW3900 Series - v2.4Document5 pagesGW3900 Series - v2.4Hubert Chang EscalanteNo ratings yet

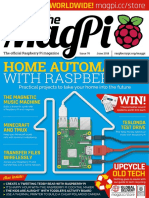

- Mag Pi 70Document100 pagesMag Pi 70Benjamin DoverNo ratings yet

- ETI - PPT (Application Hacking) (Autosaved)Document7 pagesETI - PPT (Application Hacking) (Autosaved)ShivaniNo ratings yet

- 6kW FMDocument25 pages6kW FMParvathala Thulasi RamNo ratings yet

- An Oracle 10g Upgrade Case Study: Looking at System Performance Before and After The UpgradeDocument86 pagesAn Oracle 10g Upgrade Case Study: Looking at System Performance Before and After The Upgradeapi-27472162No ratings yet

- 6.4.3.3 Packet Tracer - Connect A Router To A LANDocument5 pages6.4.3.3 Packet Tracer - Connect A Router To A LANSergio MonteNo ratings yet

- Social Media QuestionaireDocument7 pagesSocial Media QuestionaireMBRMDRNo ratings yet

- FLipkart-Mi-TV ReviewsDocument309 pagesFLipkart-Mi-TV Reviewsgg712No ratings yet

- PacketFence PaloAlto Quick Install GuideDocument8 pagesPacketFence PaloAlto Quick Install GuideChandru BlueEyesNo ratings yet

- X32 Compact Digital Mixer: Quick Start GuideDocument33 pagesX32 Compact Digital Mixer: Quick Start GuidelesoundNo ratings yet

- Summary Works NEW 2 RevitionDocument41 pagesSummary Works NEW 2 RevitionnaconnetNo ratings yet

- How Encryption Enables Crucial Data Control: Focuses Role of Information Systems Department On Managing and PlanningDocument4 pagesHow Encryption Enables Crucial Data Control: Focuses Role of Information Systems Department On Managing and PlanningSiegfred LaborteNo ratings yet

- DRIVES-FT-CC-004 - Altivar Process ATV6x0 Update - 250116 - Rev 2Document32 pagesDRIVES-FT-CC-004 - Altivar Process ATV6x0 Update - 250116 - Rev 2Edwin RamírezNo ratings yet

- Listening, Use of English and Reading: Focus 5 PhotocopiableDocument6 pagesListening, Use of English and Reading: Focus 5 Photocopiableleandro lozanoNo ratings yet