Professional Documents

Culture Documents

2017 05 31 SEAONC Spring Seminar V4

2017 05 31 SEAONC Spring Seminar V4

Uploaded by

Babrak Khan NoorzoiCopyright:

Available Formats

You might also like

- Performance-Based Seismic Design For Tall Building 2nd Edition by CTBUHDocument120 pagesPerformance-Based Seismic Design For Tall Building 2nd Edition by CTBUHbluestacks ers60% (5)

- Finite Element Analysis for Design Engineers, Second EditionFrom EverandFinite Element Analysis for Design Engineers, Second EditionNo ratings yet

- FEA 2014-Course NotesDocument164 pagesFEA 2014-Course NotesVitor Folador GonçalvesNo ratings yet

- PBD of Tall BuilidingsDocument26 pagesPBD of Tall BuilidingsAly Arquillano Jr100% (1)

- A Project Report On Structural Analysis of Hospital Building (C+G+5) Using Etabs. PaperDocument6 pagesA Project Report On Structural Analysis of Hospital Building (C+G+5) Using Etabs. PaperAbdul Razzak100% (2)

- C StrucAnalysis Head Mar161Document3 pagesC StrucAnalysis Head Mar161gulilero_yoNo ratings yet

- Detailed Seismic Assessment Assessment Objectives PrinciplesDocument71 pagesDetailed Seismic Assessment Assessment Objectives Principlesyoshdog@gmail.comNo ratings yet

- CII AWP CBA Engineering Meeting - 2022-05-24 - Meeting SlidesDocument22 pagesCII AWP CBA Engineering Meeting - 2022-05-24 - Meeting SlidesAndrew NgNo ratings yet

- Vibration Analysis and Design - 14 Feb 2005 - AITDocument246 pagesVibration Analysis and Design - 14 Feb 2005 - AITWalid AM100% (1)

- Fyp MDD Writing Seminar - Part 1Document34 pagesFyp MDD Writing Seminar - Part 1Izzuddin FCNo ratings yet

- A Three Cycle View of Design Science ResearchDocument7 pagesA Three Cycle View of Design Science Researchbasil AndreaNo ratings yet

- Unit 22, Group 2 Project ProposalDocument10 pagesUnit 22, Group 2 Project ProposalXiao QiangNo ratings yet

- Lecture 1 Theory of StructuresDocument14 pagesLecture 1 Theory of StructuresShay Patrick CormacNo ratings yet

- The Seismic Assessment of Existing Buildings-July 2017 Version 1Document1,004 pagesThe Seismic Assessment of Existing Buildings-July 2017 Version 1José GomesNo ratings yet

- Finite Element Procedures For Solids and Structures Linear AnalysisDocument11 pagesFinite Element Procedures For Solids and Structures Linear AnalysisRatha ThanNo ratings yet

- ANSYS 14 0 Fluid Dynamics Update Dipankar ChoudhuryDocument87 pagesANSYS 14 0 Fluid Dynamics Update Dipankar ChoudhuryephremNo ratings yet

- 2020-09-07 WITS - MECN 5005A - Systems MGMT - Lecture 5 of 8 - SharedDocument73 pages2020-09-07 WITS - MECN 5005A - Systems MGMT - Lecture 5 of 8 - SharedUnarine MutshinyaloNo ratings yet

- Mechanical Systems I - IntroductionDocument14 pagesMechanical Systems I - IntroductionSayeh Al SayehNo ratings yet

- Research 1Document7 pagesResearch 1Mauricio Osorio G.No ratings yet

- Ce 412 (Uap)Document269 pagesCe 412 (Uap)Abdul MukitNo ratings yet

- Seismic Design - NIST - TN.1863-1Document299 pagesSeismic Design - NIST - TN.1863-1jrobert123321No ratings yet

- Proposal Presentation - Siddiq Khan - 1015831Document35 pagesProposal Presentation - Siddiq Khan - 1015831guyii86No ratings yet

- Introductions: 17-654/17-765 Analysis of Software Artifacts Jonathan AldrichDocument2 pagesIntroductions: 17-654/17-765 Analysis of Software Artifacts Jonathan Aldrichart vandalayNo ratings yet

- Prethesis Final Report Redevelopment of Rythubazar in MehidepatnamDocument40 pagesPrethesis Final Report Redevelopment of Rythubazar in MehidepatnamAkhi Akhila50% (2)

- ATC-114 Next-Generation Hysteretic Relationships For Performance-Based Modeling and AnalysisDocument13 pagesATC-114 Next-Generation Hysteretic Relationships For Performance-Based Modeling and AnalysisJose AlviarNo ratings yet

- 4.design ProcessDocument15 pages4.design Processhuzaimatariq11No ratings yet

- Introduction and Research Approach: 1.1 BackgroundDocument1 pageIntroduction and Research Approach: 1.1 Backgroundanwarali1975No ratings yet

- Intro Cbse Sw-Arch 13Document60 pagesIntro Cbse Sw-Arch 13tsabharwalNo ratings yet

- Hevner, A. R. A Three Cycle View of Design Science ResearchDocument6 pagesHevner, A. R. A Three Cycle View of Design Science ResearchSergio AvilaNo ratings yet

- Architecture Design Course-Brochure RGB 220726-1Document4 pagesArchitecture Design Course-Brochure RGB 220726-1Farah AhmedNo ratings yet

- Machine Design Ashish Agarwal R.V.C.E, Bangalore: DR P R Venkatesh, Mech Dept, RVCE, BangaloreDocument144 pagesMachine Design Ashish Agarwal R.V.C.E, Bangalore: DR P R Venkatesh, Mech Dept, RVCE, BangaloreRajmchzNo ratings yet

- Week2 SystemsScienceAndEngin - Ethics 2021Document91 pagesWeek2 SystemsScienceAndEngin - Ethics 2021Samy OusmanNo ratings yet

- Detailed Seismic Assessment Assessment Procedures Analysis TechniquesDocument111 pagesDetailed Seismic Assessment Assessment Procedures Analysis Techniquesyoshdog@gmail.comNo ratings yet

- NX Nastran Advanced Simulation SolutionsDocument5 pagesNX Nastran Advanced Simulation SolutionsSandeep BhatiaNo ratings yet

- Prestandard and Commentary For The Seismic Rehabilitation of Buildings (TheDocument3 pagesPrestandard and Commentary For The Seismic Rehabilitation of Buildings (Theindah0330No ratings yet

- Iccbss08 (Final)Document32 pagesIccbss08 (Final)JuanNo ratings yet

- PROJ703 - Midterm Presentation - SALMAN Ali - LAMBACHRI AliDocument35 pagesPROJ703 - Midterm Presentation - SALMAN Ali - LAMBACHRI AliGuasslin JoeyNo ratings yet

- Engineering Management Solapur University - SyllabusDocument6 pagesEngineering Management Solapur University - SyllabusMangesh kevadkarNo ratings yet

- Management and OrganizationDocument55 pagesManagement and OrganizationMadhav BhandariNo ratings yet

- An Introduction To Fundamental Architecture Concepts: Warren WeinmeyerDocument60 pagesAn Introduction To Fundamental Architecture Concepts: Warren Weinmeyerlucifer whiteNo ratings yet

- Product Design ProcessDocument14 pagesProduct Design ProcessGooftilaaAniJiraachuunkooYesusiinNo ratings yet

- Presentation SSESL1Document47 pagesPresentation SSESL1Ajith VandebonaNo ratings yet

- The New P-Diagram: U.S. Army Research, Development and Engineering CommandDocument29 pagesThe New P-Diagram: U.S. Army Research, Development and Engineering CommandisolongNo ratings yet

- A3 Instructions (PSO)-updated 21 Jun 2024Document16 pagesA3 Instructions (PSO)-updated 21 Jun 2024Phong ThầnNo ratings yet

- Atc32 1TOCDocument8 pagesAtc32 1TOCer.wasimqadir7654No ratings yet

- Lecture 2 HistoryDocument38 pagesLecture 2 Historyjohnnyferry2No ratings yet

- Specifications For Highway Bridges, V Seismic Design: December 2003Document14 pagesSpecifications For Highway Bridges, V Seismic Design: December 2003vishal kumarNo ratings yet

- Qualitative Data Analysis: (Version 0.5, 1/4/05) Daniel K. Schneider, TECFA, University of GenevaDocument22 pagesQualitative Data Analysis: (Version 0.5, 1/4/05) Daniel K. Schneider, TECFA, University of Genevashafee kayNo ratings yet

- Ejemplo de Aplicacion Asce Sei 41 13Document17 pagesEjemplo de Aplicacion Asce Sei 41 13Marvin DouglasNo ratings yet

- Design Research DesignDocument13 pagesDesign Research DesignJyothsna Priya KattakindaNo ratings yet

- Exam Guide: Structural SystemsDocument21 pagesExam Guide: Structural SystemsPaolo PaoitNo ratings yet

- Eng Des ConceptsDocument41 pagesEng Des ConceptsAmali LakmaliNo ratings yet

- Review of Conventional Seismic Design Intro To Performance-Based DesignDocument43 pagesReview of Conventional Seismic Design Intro To Performance-Based DesignmamandaweNo ratings yet

- Hexagon PPM GT STRUDL Product Sheet USDocument2 pagesHexagon PPM GT STRUDL Product Sheet USTimothy HoNo ratings yet

- Pre-Doctorate of Architecture: Prof. Mohamed Shawky Abou-LeilaDocument27 pagesPre-Doctorate of Architecture: Prof. Mohamed Shawky Abou-Leilasomaiaarafa93No ratings yet

- Product Design ProcessDocument14 pagesProduct Design ProcessProf Dr Kathirrvelu SubramanianNo ratings yet

- 6.6 Job Description Directory (To-Be) : Reliance Industries LimitedDocument6 pages6.6 Job Description Directory (To-Be) : Reliance Industries Limitedsatyamech1_395565923No ratings yet

- Slides9 Analysis&DesignDocument21 pagesSlides9 Analysis&DesignAI WarlockNo ratings yet

- Pages from CSA A23 (1) .3-04 - 加拿大标准协会 Design of Concrete Structures-3Document1 pagePages from CSA A23 (1) .3-04 - 加拿大标准协会 Design of Concrete Structures-3Babrak Khan NoorzoiNo ratings yet

- Pages from CSA A23 (1) .3-04 - 加拿大标准协会 Design of Concrete Structures-2Document1 pagePages from CSA A23 (1) .3-04 - 加拿大标准协会 Design of Concrete Structures-2Babrak Khan NoorzoiNo ratings yet

- Assembling by Fusion Welding - ETN M 9 16Document4 pagesAssembling by Fusion Welding - ETN M 9 16Babrak Khan NoorzoiNo ratings yet

- Benefits of Steel RC Shear Walls in Building Structures - ETN-D-8-21Document4 pagesBenefits of Steel RC Shear Walls in Building Structures - ETN-D-8-21Babrak Khan NoorzoiNo ratings yet

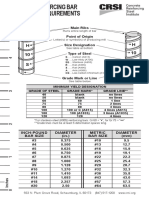

- Astm Reinforcing Bar Marking Requirements: (Inch-Pound)Document2 pagesAstm Reinforcing Bar Marking Requirements: (Inch-Pound)Babrak Khan NoorzoiNo ratings yet

- 2020 14 Mazzoni GroundmotionselectionDocument139 pages2020 14 Mazzoni GroundmotionselectionBabrak Khan NoorzoiNo ratings yet

- E1586522786733 PDFDocument1 pageE1586522786733 PDFBabrak Khan NoorzoiNo ratings yet

- Pacific Earthquake Engineering Research CenterDocument143 pagesPacific Earthquake Engineering Research CenterBabrak Khan NoorzoiNo ratings yet

- Chapter 9 Conflict and NegotiationDocument9 pagesChapter 9 Conflict and NegotiationCharles CabarlesNo ratings yet

- Assignment Brief - BTEC (RQF) Higher National Diploma in Business (Business Management)Document9 pagesAssignment Brief - BTEC (RQF) Higher National Diploma in Business (Business Management)Lee DucNo ratings yet

- 4A~5A 1학기 영어 (10학년)Document25 pages4A~5A 1학기 영어 (10학년)이동민No ratings yet

- 4.1 What Is SuccessDocument7 pages4.1 What Is SuccessGanita NarnawreNo ratings yet

- For Advertisement of Diploma Working ProfessionalDocument6 pagesFor Advertisement of Diploma Working Professionalhem956546No ratings yet

- On DP Vessel ClassificationDocument20 pagesOn DP Vessel ClassificationDaniloNo ratings yet

- Modeling and Mapping The Spatial-Temporal Changes in Land Use and Land Cover in Lagos: A Dynamics For Building A Sustainable Urban CityDocument17 pagesModeling and Mapping The Spatial-Temporal Changes in Land Use and Land Cover in Lagos: A Dynamics For Building A Sustainable Urban CityAhmed RagabNo ratings yet

- TMR1302 Datasheet EN V1.1Document5 pagesTMR1302 Datasheet EN V1.1shreyas dasNo ratings yet

- Final SOP of RajDocument3 pagesFinal SOP of RajRikhil NairNo ratings yet

- TDP 2023-2040 Consultation Report-2023-06-15-07-54-06Document203 pagesTDP 2023-2040 Consultation Report-2023-06-15-07-54-06evhbartoloNo ratings yet

- Uea Dissertation ExtensionDocument4 pagesUea Dissertation ExtensionBuySchoolPapersOnlineCanada100% (1)

- Short Circuit of Inverter BasedDocument11 pagesShort Circuit of Inverter Basedoliver voltaNo ratings yet

- Lesson 1 Conceptual Framework of Mathematics From K 3Document34 pagesLesson 1 Conceptual Framework of Mathematics From K 3Godwin Jerome Reyes100% (2)

- SDS Natve Tapioca Starch Food GradeDocument1 pageSDS Natve Tapioca Starch Food GradesinarkanakajayaNo ratings yet

- Samuelson UnderstandingMarxianNotion 1971Document34 pagesSamuelson UnderstandingMarxianNotion 1971Kaio DanielNo ratings yet

- Control of Underground CorrosionDocument24 pagesControl of Underground CorrosionCarlos Rafael Lizarraga ArreolaNo ratings yet

- Final Examination SEMESTER I, SESSION 2015/2016: SAB 2722 / SKAA 2722 1Document9 pagesFinal Examination SEMESTER I, SESSION 2015/2016: SAB 2722 / SKAA 2722 1Hanis SyafiqNo ratings yet

- Decision Making DecentralizationDocument73 pagesDecision Making DecentralizationAnju MargaretNo ratings yet

- Cvpr2022 Glip Grounded Language Image Pre TrainingDocument20 pagesCvpr2022 Glip Grounded Language Image Pre Training郭妙恬No ratings yet

- Essay On ObamaDocument2 pagesEssay On Obamamywofod1nud2100% (2)

- G11 EnglishDocument15 pagesG11 EnglishSay the name seventeenNo ratings yet

- Bme 9 and 10Document16 pagesBme 9 and 10Unnecessary BuyingNo ratings yet

- Measurement - Using Basic Precision Dimensional InstrumentsDocument49 pagesMeasurement - Using Basic Precision Dimensional InstrumentskrishnaNo ratings yet

- Library Room 5: Tribhuvanuniversity Institute of Engineering, Pulchowk CampusDocument8 pagesLibrary Room 5: Tribhuvanuniversity Institute of Engineering, Pulchowk CampusBreaking DieNo ratings yet

- 1 s2.0 S0160412020319292 MainDocument23 pages1 s2.0 S0160412020319292 MainCitra CesiliaNo ratings yet

- Study Guide:: Ricks P. Ortiz Principles of Soil Science - DedeDocument4 pagesStudy Guide:: Ricks P. Ortiz Principles of Soil Science - DedeRicks P. OrtizNo ratings yet

- Waker WatwerDocument31 pagesWaker WatweraeliasgNo ratings yet

- 2.sample Question 03 Agri SystemsDocument19 pages2.sample Question 03 Agri Systemsvendetta021199No ratings yet

- B2 First Practice Test Writing Answer KeyDocument2 pagesB2 First Practice Test Writing Answer KeyRocio FernandezNo ratings yet

- Dunne - Resurgence in Quantum Field Theory and Quantum MechanicsDocument58 pagesDunne - Resurgence in Quantum Field Theory and Quantum MechanicsL VNo ratings yet

2017 05 31 SEAONC Spring Seminar V4

2017 05 31 SEAONC Spring Seminar V4

Uploaded by

Babrak Khan NoorzoiOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2017 05 31 SEAONC Spring Seminar V4

2017 05 31 SEAONC Spring Seminar V4

Uploaded by

Babrak Khan NoorzoiCopyright:

Available Formats

ATC 114 – Nonlinear Analysis Guidelines May 31, 2017

Guidelines for Nonlinear Structural

Analysis and Design of Buildings

Curt Haselton, PhD, PE

Greg Deierlein, PhD, PE

and the ATC 114 Team

SEAONC Spring Seminar

San Francisco, May 31, 2017

Presentation Outline

• Scope and background

• Organization of the Guidelines

• Part I: General Modeling Requirements

(including approach to modeling cyclic damage)

• Part IIa: Steel Frame Building Modeling

• Part IIb: RC Frame Building Modeling

• Illustrative Example

SEAONC Spring Seminar 1

ATC 114 – Nonlinear Analysis Guidelines May 31, 2017

Scope/Focus for Modeling Guidelines

• Support primarily nonlinear dynamic analyses

(monotonic backbone curve and then cyclic

deterioration).

• Modeling vs. acceptance criteria:

• ATC-114 focuses on modeling guidelines.

• Rely on parent document (e.g., ASCE 7 Chp. 16) for the needed

acceptance criteria checks and associated hazard levels.

• Adopt a reliability framework. Write the approach around

the ASCE 7-16 draft Chapter 16, provide guidance on

variability numbers.

• Audience: Practicing engineers with ~Master’s education

ATC-114 Project Team

• Project Technical Committee – Steel: • Applied Technology Council

Greg Deierlein (Project Director) Jon A. Heintz (Program Manager)

Stephen Bono Ayse Hortacsu (Associate

James Malley Program Manager)

Silvia Mazzoni Veronica Cedillos (Associate

Chia-Ming Uang Project Manager)

plus Dimitrios Lignos & Amit Kanvinde

• National Institute of Standards

and Technology (NIST)

• Project Technical Committee – RC: Project Funding & Review

Curt Haselton (Project Director) Steven McCabe

Wassim Ghannoum Jay Harris

Mahmoud Hachem Siamak Sattar

John Hooper Matthew Speicher

Santiago Pujol Kevin Wong

Plus - project review panel and other contributors listed in reports

SEAONC Spring Seminar 2

ATC 114 – Nonlinear Analysis Guidelines May 31, 2017

5

Reference Documents

NIST Seismic Design Tech Brief 4: Nonlinear

Structural Analysis for Seismic Design

• General guidance on using nonlinear analysis for

design

• Focus on high-level goals and objectives

• Overview of key concepts and assumptions

• Summary of modeling capabilities and resources

• Guidance on NL static & dynamic analysis

PEER/ATC 72-1: Modeling and Acceptance Criteria for

Seismic Design and Analysis (2010)

• General Nonlinear Modeling

• Steel and RC Moment Frame Components

• Shear Walls and Slab-Column Frames

• Podium Diaphragms and Collectors

6

Reference Documents

PEER Tall Building Initiative:

• 2010 (2017) guidelines

• Supporting documents - http://peer.berkeley.edu/tbi/

LA Tall Buildings Structural Design Council:

• 2011 guidelines

• Annual conference

• Special provisions for RC structures

Guideline Documents

• Performance Objectives

• Design Process and Documentation

• Seismic Input and Modeling Criteria

• Service Level Evaluation

• MCE Level Evaluation

• Documentation and Peer Review

SEAONC Spring Seminar 3

ATC 114 – Nonlinear Analysis Guidelines May 31, 2017

7

Reference Documents

ASCE 7-16 Minimum Design Loads for Buildings

• Chapter 16 – Seismic Response History Procedures

• Emphasis on nonlinear dynamic analysis

• Analyses and checks for MCE levels

• Selection and scaling ground motions (UHS or CMS)

• Risk/probabilistic basis for demand and acceptance criteria:

- Deformation-controlled components

- Force-controlled components

ASCE 41-13 (17) Seismic Evaluation & Retrofit of Existing Buildings

• General performance assessment framework (IO, LS, CP)

• Requirements for assessing properties of existing buildings

• Structural component modeling parameters and acceptance

criteria

• Nonlinear static (pushover) analysis procedure

ATC 114: How it is Expected to be Used

ATC-114 provides guidelines for nonlinear modeling

to support design in accordance with other standards

SEAONC Spring Seminar 4

ATC 114 – Nonlinear Analysis Guidelines May 31, 2017

ATC 114: Organization of Guidelines

Part I: General Guidelines

Part IIa: Part IIb: Part IIc: Part IId:

Guidelines Guidelines Guidelines Guidelines

Specific to

Steel

Specific to

RC

Specific to Specific to

Steel Braced

…

RC

Moment Moment Shear Walls Frames

Frames Frames

10

ATC 114: Organization of Guidelines

Part I: General Part II: System Specific

1. Introduction and Scope 1. Introduction and Scope

2. Overview of NL Modeling and 2. Structural Behavior and

Analysis Procedure Failure Modes

3. General Modeling 3. NL Modeling of Frames &

Requirements Components

4. Nonlinear Static (Pushover) 4. Concentrated Hinge Models

5. Nonlinear Response-History 5. Fiber-Type Beam-Column

6. Performance Assessment and Models

Acceptance Criteria 6. Continuum FE Component

Appendices Models

A: Overview of Methods for RHA Appendices

B: Consideration of Uncertainties A: Non-ductile frames

C: Calibration of Nonlinear B: Illustrative Examples

Component Models

SEAONC Spring Seminar 5

ATC 114 – Nonlinear Analysis Guidelines May 31, 2017

11

Types of Nonlinear Analysis Models

12

Types of Nonlinear Analysis Models

Concentrated Hinge

Fiber-Type Elements

SEAONC Spring Seminar 6

ATC 114 – Nonlinear Analysis Guidelines May 31, 2017

13

Basic Requirements

• Expected Properties

• materials

• model parameters

• mass

• gravity loads (1.0D + 0.5L)

• Geometric Nonlinear (P-D) Effects

• Structural Behavior and Failure Modes

• “simulated” vs “non-simulated” effects

• influence of non-structural components

14

Modeling Approach for Cyclic Loading

𝑄

Typical Approach: ASCE 41

type curve that implicitly

incorporates cyclic deterioration

D or Q

SEAONC Spring Seminar 7

ATC 114 – Nonlinear Analysis Guidelines May 31, 2017

15

Modeling Approach for Cyclic Loading

Continue the same cyclic pattern

15

(see Table 2) until lateral

resistance of the specimen

degrades to 20% or less of the

10 peak resistance exhibited during

the test in both directions

Drift Ratio *102

5 1/3 of 0.2% = 0.067%

0

Cycles

0 10

-5

-10

-15

Pause for telepresence digital still images

Additional images upon large drifts

Continue the same cyclic pattern

(see Table 2) until complete the

4.375% and subsequent 1.458%

Collapse-Level Protocol

drift ratios then start monotonic

loading in both directions. 9

1/3 of 0.2% = 0.067%

8

7 Start monotonic loading in both

6

directions.

Column Drift Ratio (%)

Continue the same cyclic pattern

(see Table 2) until complete the

2.75% and subsequent 0.917% 5

drift ratios then start monotonic

loading in both directions. 4

Pause for telepresence digital still images

1/3 of 0.2% = 0.067%

3

Additional images upon large drifts

2

1 Starting from this point on taking

0 pictures every one inch.

-1

Pause for telepresence digital still images -2

Additional images upon large drifts

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

Pause for telepresence digital still images

Nojavan et al., 2014

16

Modeling Approach for Cyclic Loading

Nojavan et al., 2014

SEAONC Spring Seminar 8

ATC 114 – Nonlinear Analysis Guidelines May 31, 2017

17

Modeling Approach for Cyclic Loading

Nojavan et al., 2014

18

Modeling Approach for Cyclic Loading

Nojavan et al., 2014

SEAONC Spring Seminar 9

ATC 114 – Nonlinear Analysis Guidelines May 31, 2017

19

Modeling Approach for Cyclic Loading

150

100

50

Force (kN)

-50

-100 Monotonic

Cyclic Loading

Cyclic Envelope

-150

-100 0 100 200

Displacement (mm)

Ingham et al., 2001

20

Modeling Approach for Cyclic Loading

Suzuki and Lignos, 2015

SEAONC Spring Seminar 10

ATC 114 – Nonlinear Analysis Guidelines May 31, 2017

21

Modeling Approach for Cyclic Loading

Suzuki and Lignos, 2015

22

Modeling Approach for Cyclic Loading

6000 Monotonic

Curve

Beam End Moment [kips-in]

4000

First-Cycle

Envelope

2000

Extrapolation

0

Extrapolation

-2000

-4000

-6000

-0.1 -0.05 0 0.05 0.1

Chord Rotation θ [rad]

(Tremblay et al. 1997, ATC-72-1)

SEAONC Spring Seminar 11

ATC 114 – Nonlinear Analysis Guidelines May 31, 2017

23

Modeling Approach for Cyclic Loading

𝑄 Δ#%

Δ#

Δ∗# Δ∗#%

𝑄&

𝑄&∗

𝑄*

response is

typically monotonic

between and envelope

depends on

𝐾( ASCE 41 loading-history

𝑄)∗

first-cycle

envelope

D or Q

24

Modeling Approach for Cyclic Loading

300

Experimental Results cyclic (between cycles)

Model Prediction

200

Shear Force (kN)

100

in-cycle

0

Test 170 (kN, mm, rad):

-100 θy = 0.0131

θstf 40 = 0.0012

My = 3.462725e+005 kN-mm

Mc /My = 1.21

-200 θcap,pl = 0.060 (LB = 0)

θpc = 0.225

λ = 81, c = 1.00

isPDeltaRemoved = 1

-300

-0.1 -0.05 0 0.05 0.1

Column Drift (displacement/height)

!

SEAONC Spring Seminar 12

ATC 114 – Nonlinear Analysis Guidelines May 31, 2017

25

Modeling Approach for Cyclic Loading

26

Modeling Approach for Cyclic Loading

Type A – DIRECT SIMULATION :

Cyclic and in-cycle degradation explicitly modeled

during analysis; backbone curve hardens/softens as a

function of damage (e.g., Ibarra-Krawinkler)

Type B – DEGRADED BACKBONE:

Post-peak capping and cyclic degradation modeled with

fixed backbone curve that remains fixed during analysis;

backbone curve is defined based on measured (data) or

assumed cyclic softening (e.g., ASCE 41)

Type C – ELASTIC-PLASTIC:

Model captures cyclic degradation, but post-peak

softening is not modeled; an ultimate limit state is

imposed to avoid unconservative analyses in post-peak

realm.

SEAONC Spring Seminar 13

ATC 114 – Nonlinear Analysis Guidelines May 31, 2017

27

ATC 114: Organization of Guidelines

Part I: General

1. Introduction and Scope

2. Overview of NL Modeling and

Analysis Procedure

3. General Modeling

Requirements

4. Nonlinear Static (Pushover)

5. Nonlinear Response-History

6. Performance Assessment and

Acceptance Criteria

Appendices

A: Overview of Methods for RHA

B: Consideration of Uncertainties

C: Calibration of Nonlinear

Component Models

28

ATC 114: Organization of Guidelines

Part I: General - Chapter 3

1. General Guidelines

2. Seismic Mass

3. Gravity Loads

4. Geometric Nonlinearities

5. Material Properties

6. Floor Diaphragms and Collectors

7. Equivalent Viscous Damping

8. Torsion

9. Foundation Modeling

10. Soil-Structure Interaction

11. Gravity Framing Systems

12. Non-Modeled Building Stiffness

13. Residual Drifts

SEAONC Spring Seminar 14

ATC 114 – Nonlinear Analysis Guidelines May 31, 2017

29

Diaphragms, Collectors & Distributors

Discontinuous Shear

Wall (Lateral System)

30

Energy Dissipation and Damping

Is energy dissipation explicitly modeled or approximated by

equivalent viscous damping?

SEAONC Spring Seminar 15

ATC 114 – Nonlinear Analysis Guidelines May 31, 2017

31

Energy Dissipation and Damping

32

Energy Dissipation and Damping

PEER TBI v.2: 2.5% for MCE

Ref: Cruz & Miranda, 2016; Bernal et al., 2015

SEAONC Spring Seminar 16

ATC 114 – Nonlinear Analysis Guidelines May 31, 2017

33

ATC 114: Organization of Guidelines

Part I: General

1. Introduction and Scope

2. Overview of NL Modeling and

Analysis Procedure

3. General Modeling

Requirements

4. Nonlinear Static (Pushover)

5. Nonlinear Response-History

6. Performance Assessment and

Acceptance Criteria

Appendices

A: Overview of Methods for RHA

B: Consideration of Uncertainties

C: Calibration of Nonlinear

Component Models

34

Part I: Acceptance Criteria

§ So far, we have talked about doing a lot of detailed

nonlinear modeling.

§ Structural responses do not tell us about performance

until to compare with the acceptance criteria.

§ The acceptance criteria will depend on what document

is being used to govern the design.

SEAONC Spring Seminar 17

ATC 114 – Nonlinear Analysis Guidelines May 31, 2017

35

Part I: Acceptance Criteria

Will give examples

from ASCE7-16

here.

36

Part I: Acceptance Criteria

§ Big Focus of ASCE 7-16 Chapter 16 Revision:

Develop acceptance criteria more clearly tied to the

ASCE7 safety goals.

§ Explicit Goal: Acceptable collapse probability.

§ Implicit Verification Approach: Use average structural

responses (with 11 motions) to show compliance.

SEAONC Spring Seminar 18

ATC 114 – Nonlinear Analysis Guidelines May 31, 2017

37

Part I: Acceptance Criteria

38

Part I: Acceptance Criteria

ASCE 7-16: Uncertainties considered in specified acceptance

criteria, including demand & capacity factors

SEAONC Spring Seminar 19

ATC 114 – Nonlinear Analysis Guidelines May 31, 2017

39

Part I: Acceptance Criteria

§ Force-controlled (brittle) components:

2.0 𝐼( 𝐹& ≤ 𝐹( for “critical” (comparable to PEER-TBI-v1)

1.5 𝐼( 𝐹& ≤ 𝐹( for “ordinary” Contrast: Much more

1.0 𝐼( 𝐹& ≤ 𝐹( for “non-critical” (judgment) that the average-

stringent

based approach that could be

F = mean demand (from 11 motions) used in ASCE 41.

u

Fe = expected strength

Critical = failure causes immediate global collapse

Ordinary = failure causes local collapse (one bay)

Non-critical = failure does not cause collapse

40

Part I: Acceptance Criteria

§ Deformation-controlled (ductile) components:

1) Limits applied to mean demands:

ü ASCE 41 Limit: CP / Ie

ü Loss in Vertical Load Carrying Capacity:

fs DLVCC where fs is equal to

0.3 / Ie critical

0.5 / Ie ordinary

2) Limits of analysis model for peak demands

from individual ground motions

SEAONC Spring Seminar 20

ATC 114 – Nonlinear Analysis Guidelines May 31, 2017

41

Part I: Acceptance Criteria

§ Drift limits:

• Mean drift ≤ 2.0*(normal limit)

• The factor of two comes from:

ü 1.5 = MCE / DBE

ü 1.25 = Approx. ratio of R / Cd

ü 1.1 = A little extra because we trust NL RHA

more

42

Part I: Acceptance Criteria

§ Treatment of “collapses” and “unacceptable responses”:

• Past Treatment in ASCE7-10: Nothing but silence….

• ASCE7-16 Criteria:

ü Basic Case: Allow up to 1/11 “collapses” but not 2/11.

ü With Spectral Matching: Require 0/11 collapses.

ü For Risk Categories III-IV: Require 0/11 collapses.

§ “Collapses” are more generally called “unacceptable

responses” and include:

• True dynamic instability,

• Analytical solution fails to converge,

• Deformation-controlled demands exceed valid modeling range,

• Critical/ordinary force-controlled demands exceed capacity,

• Predicted deformation demands on elements not modeled

exceed the deformations at gravity load failure.

SEAONC Spring Seminar 21

ATC 114 – Nonlinear Analysis Guidelines May 31, 2017

43

Presentation Outline

• Scope and background

• Organization of the Guidelines

• Part I: General Modeling Requirements

(including approach to modeling cyclic damage)

• Part IIa: Steel Frame Building Modeling

• Part IIb: RC Frame Building Modeling

• Illustrative Example

44

Part IIa – Steel SMF

1. Introduction and Scope

2. Structural Behavior and

Failure Modes

3. NL Modeling of Frames &

Components

4. Concentrated Hinge Models

5. Fiber-Type Beam-Column

Models

6. Continuum FE Component

Models

Appendices

A: Pre-Northridge Steel SMF

B: Illustrative Example

Photo: D. Lignos

SEAONC Spring Seminar 22

ATC 114 – Nonlinear Analysis Guidelines May 31, 2017

45

Part IIa: Steel

Expected Behavior:

• Deterioration modes

• Likelihood of occurence

46

Part IIa: Steel

Concentrated Hinge

Continuum FEM Fiber-Type Elements

SEAONC Spring Seminar 23

ATC 114 – Nonlinear Analysis Guidelines May 31, 2017

47

Connection Panel Zone

Panel Zone Shear Demand

48

Connection Panel Zone

ANSI/AISC 360 Section J10.6

Initial Yield Strength

Panel Zone Shear Response

SEAONC Spring Seminar 24

ATC 114 – Nonlinear Analysis Guidelines May 31, 2017

49

Connection Panel Zone

Panel Zone – NL Models

< Vy

Vy =

Panel Zone – Elastic Models

50

Beam Hinge Model

Type A – Direct Simulation

Idealized Envelope Curve Parameters

Monotonic vs. Cyclic Backbone

Type B – Degraded Backbone

SEAONC Spring Seminar 25

ATC 114 – Nonlinear Analysis Guidelines May 31, 2017

51

Deteriorating Beam Hinge Model

Qcap

200

Experimental Results

Model Prediction

K-

150

100

50

Shear Force (kN)

0

-50 Test 19 (kN, mm, rad):

K = 3.1779e+007

e

K = 7.4024e+007

init

-100 as = 0.02

ac = -0.04 (ND = 1)

qy = 0.0091

qcap,pl = 0.069 (LB = 1)

q = 0.116 (LB = 1)

-150 u,mono,pl

l = 85, c = 1.20

isPDeltaRemoved = 1

-200

-100 -50 0 50 100 150

Column Top Horizontal Deflection (mm)

Semi-Empirical -- calibrated from Empirical - calibrated from tests:

tests, fiber analyses, and

mechanics: • Capping (peak) point

• Secant Stiffness (EIeff) • Post-peak unloading (strain

softening) stiffness

• Yield Strength (My)

• Hysteretic stiffness/strength

• Hardening Stiffness degradation

52

Deteriorating Beam Hinge Model

Monotonic Backbone

• measured from monotonic tests

• inferred from cyclic data

(e.g., calibration with Ibarra-

Krawinkler model in OpenSees)

4

x10

2

MMax

Beam End Moment, M [kip-in]

90%MMax

1.5 80%MMax

1 First-Cycle Envelope

0.5

Δ ‘’cap,pl Δ ‘’pc

• measured from symmetric cyclic

0

Data

tests

-0.5

-1

First-Cycle Envelope

M

• tri-linear envelope parameters

Max

-1.5

90%M

Max based on Mmax

80%M

Max

-2

-0.05 0 0.05 0.1

Chord Rotation, θ [rad]

SEAONC Spring Seminar 26

ATC 114 – Nonlinear Analysis Guidelines May 31, 2017

53

Deteriorating Beam Hinge Model

Strength Parameters Mu

M*y

M y* = 1.1⋅ Ry ⋅ Z RBS ⋅ Fy,n Cyclic skeleton

(RBS Connection)

u COVs = 0.1

Ke

Mr

Deformation Parameters

θu

θcap,pl’ θpc'

COV = 0.4

COV = 0.3

COV = 0.3 (Suzuki and Lignos 2015)

54

Deteriorating Beam Hinge Model

qp

monotonic

Pre-Peak Plastic Rotation, qp

cyclic

skeleton

Statistically fit to ~ 50 tests

SEAONC Spring Seminar 27

ATC 114 – Nonlinear Analysis Guidelines May 31, 2017

55

Deteriorating Beam Hinge Model

W30x108 W27x147 (stocky)

Illustrative Examples of New Model Calibrations

(Suzuki and Lignos 2015)

56

Composite Beam Effects

SEAONC Spring Seminar 28

ATC 114 – Nonlinear Analysis Guidelines May 31, 2017

57

Composite Beam Effects

Bare Steel Beam

Composite Beam Action

• detailing considerations (studs, bearing

strength, slab reinforcement)

• increased strength

• reduced deterioration Composite Beam

58

Steel Columns: Test Data

Elkady and Lignos, 2015

Ozkula and Uang, 2015

SEAONC Spring Seminar 29

ATC 114 – Nonlinear Analysis Guidelines May 31, 2017

59

Columns: Effects of Loading Protocol

600

Monotonic

Column End Moment [kN-m]

400 Curve

200

First-Cycle

0

Envelope

-200

-400

-600

-0.2 -0.1 0 0.1 0.2

Chord Rotation θ [rad]

(Suzuki and Lignos 2015)

60

Steel Columns: FEM Analyses

S. Mises

S4R Shell Element [ksi]

bf /150

thickness

Local d /150

0.15Fy

15’ sesiM .S

0.3F

]isk[ ASTM (2003)

y

0.073Fy bf

bf /150

1”x1” Global

H /1000

Measured d d /150

AISC 360-10

Meshing Residual Stresses Imperfections

Source: Elkady and Lignos (2015)

SEAONC Spring Seminar 30

ATC 114 – Nonlinear Analysis Guidelines May 31, 2017

61

Steel Columns: FEM Analyses

0

2000

Axial Displacement [mm]

1000 -50

M x [kN.m]

0 -100

-1000

Expr. Data -150

-2000 FEA

Expr. Data

FEA

-0.03 -0.02 -0.01 0 0.01 0.02 0.03 -200

True Rotation 3 x [rad] -0.05 0 0.05

True Rotation, 3 [rad]

x

Source: Elkady and Lignos (2015)

62

Columns:

SYM-20

Hinge Model Calibration

3.5%

Plastic Rotation θp [rad]

3.0%

2.5%

2.0%

7.0%

Plastic Rotation θp [rad]

1.5% 6.0%

1.0%

5.0%

0.5%

0.0% 4.0%

0 20 40 60 80

3.0%

Web Local Slenderness, h/tw

SYM-20 2.0%

3.5%

1.0%

Plastic Rotation θp [rad]

3.0%

2.5% 0.0%

0.00 0.20 0.40 0.60

2.0%

1.5% Compressive Axial Load Ratio, P/Py

1.0%

0.5%

0.0%

0 2 4 6 8 10

Flange Local Slenderness, bf/2tf

Elkady and Lignos (2015)

Ozkula and Uang (2015)

SEAONC Spring Seminar 31

ATC 114 – Nonlinear Analysis Guidelines May 31, 2017

63

Columns: Hinge Model Calibration

Mu*

M*y

Ke

M*r

Θu*

Θp* Θpc*

Elkady and Lignos (2015); calibrated to 50 tests & 400 FE analyses

64

Gravity Beam (Shear Tab) Connections

Based on Liu and Astaneh-Asl (2004)

SEAONC Spring Seminar 32

ATC 114 – Nonlinear Analysis Guidelines May 31, 2017

65

Gravity Beam (Shear Tab) Connections

Based on Liu and Astaneh-Asl (2004)

66

Steel: Appendix on PN Connections

Fracture Mechanics Based Stress Limits for Fiber Cross Section Model

(bottom)

(top)

SEAONC Spring Seminar 33

ATC 114 – Nonlinear Analysis Guidelines May 31, 2017

67

Steel: Appendix on PN Connections

Strain limit for fracture critical (pre-Northridge) connections that

pass the stress check:

= 1 (bottom flange); 2 (top flange)

= beam depth

Plastic Rotation (rad)

Calibration of fiber hinge

model to test data

Beam depth (inch)

Data from Ramirez, Lignos, Miranda, Kolios 2012

68

Presentation Outline

• Scope and background

• Organization of the Guidelines

• Part I: General Modeling Requirements

(including approach to modeling cyclic damage)

• Part IIa: Steel Frame Building Modeling

• Part IIb: RC Frame Building Modeling

• Illustrative Example

SEAONC Spring Seminar 34

ATC 114 – Nonlinear Analysis Guidelines May 31, 2017

69

Part IIb: Concrete

Concentrated Hinge

Fiber-Type Elements

70

RC Beam-Column Hinge Models

SEAONC Spring Seminar 35

ATC 114 – Nonlinear Analysis Guidelines May 31, 2017

71

RC Beam-Column Hinge Models

Key Response Parameters:

• strength

• initial stiffness

• post-yield stiffness

• plastic rotation (capping) capacity

• post-capping slope

• cyclic deterioration rate

Calibration Process:

• 250+ columns (PEER database)

• flexure & flexure-shear dominant

• calibrated to expected values

72

RC Beam-Column Hinge Models

120

Kstf Ky

100

Fy

80

Force (kN)

60

40

0.4Fy

20

θstf_40 θy

0

0 0.002 0.004 0.006 0.008 0.01 0.012 0.014

Chord Rotation (rad)

SEAONC Spring Seminar 36

ATC 114 – Nonlinear Analysis Guidelines May 31, 2017

73

RC Beam-Column Hinge Models

Qcap

Key Design/Detailing Variables:

rsh – amount of steel stirrups

n – axial load ratio (P/Ag f’c)

sn – tie spacing

asl – joint bond slip

ATC-114: Guidelines for Nonlinear Structural

Analysis and Design of Buildings

Dispersion:

74

RC Beam-Column Hinge Models

q pc = (0.76)(0.031)v (0.02 + 40rsh )1.02 £ 0.10

Haselton, et al. (2008)

SEAONC Spring Seminar 37

ATC 114 – Nonlinear Analysis Guidelines May 31, 2017

75

RC Beam-Column Hinge Models

ATC-114

Comparison of qp,cyclic and ”a”

ASCE 41 (2008, 2013)

76

RC Beam-Column Hinge Models

ATC-114

Comparison of (qp+ qpc)cyclic and ”b”

ASCE 41 (2008, 2013)

SEAONC Spring Seminar 38

ATC 114 – Nonlinear Analysis Guidelines May 31, 2017

77

RC Fiber Models

78

RC Fiber Models

SEAONC Spring Seminar 39

ATC 114 – Nonlinear Analysis Guidelines May 31, 2017

79

RC Fiber Models

80

RC Fiber Models

Adapted from Ghannoum

and Moehle, 2012

SEAONC Spring Seminar 40

ATC 114 – Nonlinear Analysis Guidelines May 31, 2017

81

Presentation Outline

• Scope and background

• Organization of the Guidelines

• Part I: General Modeling Requirements

(including approach to modeling cyclic damage)

• Part IIa: Steel Frame Building Modeling

• Part IIb: RC Frame Building Modeling

• Illustrative Example

82

Illustrative Example - Steel SMF

5-Story Steel Frame Building

• SMF with RBS connections

• Seismic Design Category D

SM1 = 1g; T1 = 1.1s (1.6s)

R=8; Cs = 0.07

MRSA design (ASCE 7-10)

SDRmax = 1.6%

• Irregularity

setback at 4-th floor

vertical irregularity in mass,

stiffness & strength

1-bay offset of SMF

1 discontinuous column

• NLRHA with PERFORM 3D

SEAONC Spring Seminar 41

ATC 114 – Nonlinear Analysis Guidelines May 31, 2017

83

Flowchart of

Analysis Approach

84

PERFORM 3D Model

Gravity Framing

SMF Framing Lines

5% is used where V exceeds 0.5Vn

Diaphragm Model

SEAONC Spring Seminar 42

ATC 114 – Nonlinear Analysis Guidelines May 31, 2017

85

Illustrative Example - Steel SMF

Input Ground Motions

• ASCE 7-16

• MCEr (UHS) Target

• 11 pairs of GM, representing

characteristic earthquakes

(causal features)

• Period Range 0.2T1 to 2T1

(T1 = 1.6s)

86

Acceptance Criteria – Deformation Controlled

SEAONC Spring Seminar 43

ATC 114 – Nonlinear Analysis Guidelines May 31, 2017

87

Acceptance Criteria – Force Controlled

88

Story Drifts - MCEr

SEAONC Spring Seminar 44

ATC 114 – Nonlinear Analysis Guidelines May 31, 2017

89

Story Drifts – Influence of Gravity Framing

+0.2 (+6%)

-0.2 (-13%)

PR Gravity Connections Pin-Connected Connections

90

Hinge Rotations - MCEr

Beam Hinge, q Column Base Hinge, q

SEAONC Spring Seminar 45

ATC 114 – Nonlinear Analysis Guidelines May 31, 2017

91

PZ Rotations - MCEr

Fifth Floor GL 3A PZ

Panel Zones

0.022

• Design intentionally violated AISC

341 PZ strength requirements

• 10% of non-conforming PZ

exceeded the fracture control limit

gPZ, limit & gPZ, Alt

gCP ASCE/SEI 41-17 Mean

of gp,z < 0.015 rad

Elevation (ft)

TH11

Floor

TH10 52

5

TH9

TH8 • Conforming PZ all had minimal

deformations

TH7

TH6

TH5

TH4

TH3

TH2

TH1

0.0% 1.0% 2.0% 3.0% 4.0% 5.0% 6.0% 7.0%

PZ Shear Strain (radians)

PZ at Critical Location, g

kink

92

Frame Overstrength

North South Story Shear North South Overturning Moment

896 65 11,638

65

5 5

52 52

947 21,339

4

4 1.7x larger than W/R 2.2x larger than W/R

39 39

1,180 71,538

Elevation (ft)

Mean

Elevation (ft)

TH11

(R=8, W=3)

Story

Story

(R=8)

DBE

TH10 3

DBE

3

TH9

TH8

TH7

26 26

1,293 TH6

83,352

TH5

(R=8)

DBE

2

TH4

2

TH3

TH2

TH1

13 13

1,690 97,687

(R=8, W=3)

DBE

1 1

0 0

0 1000 2000 3000 4000 0 25000 50000 75000 100000 125000 150000

Story Shear (kips) Story Moment (k-ft)

Shear in Frames Overturning Moment in Frames

SEAONC Spring Seminar 46

ATC 114 – Nonlinear Analysis Guidelines May 31, 2017

93

Influence of Diaphragm Stiffness

Frame Layout Shear in Frames

• Diaphragm at floor 4 considered critical, so force demand is

multiplied by 2. Load factor of 1.5 used at other floors.

• Transfer level: Vu = 7.4 and 7.6 klf (for 5% and 30% stiffness)

• Other levels Vu = 7.5 klf to 2.6 klf

• Even rigid diaphragm did not make much difference in this case.

94

Illustrative Example - Summary

1) Prescriptive SMF Design (R=8) evaluated by NLRHA

2) Story Drift: mean 3.3%<4%; peak 6.2% okay

3) Deformation Limits

• RBS hinge okay

• PZ – exceed limits, but would be okay for AISC conforming

design

4) Other Limit States

• Gravity Connection Rotations (0.037 < 0.10 to 0.09)

• Force checks not presented, but should be confirmed,

especially given the high overstrength

5) ASCE 7-16 deformation limits (with f-factors) are more

conservative of ASCE 41 CP limits

6) Results are not overly sensitive to diaphragm stiffness,

gravity framing, composite beam action

SEAONC Spring Seminar 47

ATC 114 – Nonlinear Analysis Guidelines May 31, 2017

95

Concluding Remarks

1) Nonlinear response history analysis is an effective tool to

inform design, but it should not replace good design

• reliable load paths and details

• capacity design

• well-behaved response

2) Develop clear objectives for the analysis (basis of design)

• acceptance criteria

• demand parameters

3) Quality assurance

• utilization of elastic and nonlinear static analyses

• selective plots of response quantities

• sensitivity analyses

• selected validation with test data

4) Effective presentation of results

96

More to come …

Part I: General Guidelines

Part IIa: Part IIb: Part IIc: Part IId:

Guidelines Guidelines Guidelines Guidelines

Specific to

Steel

Specific to

RC

Specific to Specific to

Steel Braced

…

RC

Moment Moment Shear Walls Frames

Frames Frames

ATC-114: Guidelines for Nonlinear Structural

Analysis and Design of Buildings

SEAONC Spring Seminar 48

You might also like

- Performance-Based Seismic Design For Tall Building 2nd Edition by CTBUHDocument120 pagesPerformance-Based Seismic Design For Tall Building 2nd Edition by CTBUHbluestacks ers60% (5)

- Finite Element Analysis for Design Engineers, Second EditionFrom EverandFinite Element Analysis for Design Engineers, Second EditionNo ratings yet

- FEA 2014-Course NotesDocument164 pagesFEA 2014-Course NotesVitor Folador GonçalvesNo ratings yet

- PBD of Tall BuilidingsDocument26 pagesPBD of Tall BuilidingsAly Arquillano Jr100% (1)

- A Project Report On Structural Analysis of Hospital Building (C+G+5) Using Etabs. PaperDocument6 pagesA Project Report On Structural Analysis of Hospital Building (C+G+5) Using Etabs. PaperAbdul Razzak100% (2)

- C StrucAnalysis Head Mar161Document3 pagesC StrucAnalysis Head Mar161gulilero_yoNo ratings yet

- Detailed Seismic Assessment Assessment Objectives PrinciplesDocument71 pagesDetailed Seismic Assessment Assessment Objectives Principlesyoshdog@gmail.comNo ratings yet

- CII AWP CBA Engineering Meeting - 2022-05-24 - Meeting SlidesDocument22 pagesCII AWP CBA Engineering Meeting - 2022-05-24 - Meeting SlidesAndrew NgNo ratings yet

- Vibration Analysis and Design - 14 Feb 2005 - AITDocument246 pagesVibration Analysis and Design - 14 Feb 2005 - AITWalid AM100% (1)

- Fyp MDD Writing Seminar - Part 1Document34 pagesFyp MDD Writing Seminar - Part 1Izzuddin FCNo ratings yet

- A Three Cycle View of Design Science ResearchDocument7 pagesA Three Cycle View of Design Science Researchbasil AndreaNo ratings yet

- Unit 22, Group 2 Project ProposalDocument10 pagesUnit 22, Group 2 Project ProposalXiao QiangNo ratings yet

- Lecture 1 Theory of StructuresDocument14 pagesLecture 1 Theory of StructuresShay Patrick CormacNo ratings yet

- The Seismic Assessment of Existing Buildings-July 2017 Version 1Document1,004 pagesThe Seismic Assessment of Existing Buildings-July 2017 Version 1José GomesNo ratings yet

- Finite Element Procedures For Solids and Structures Linear AnalysisDocument11 pagesFinite Element Procedures For Solids and Structures Linear AnalysisRatha ThanNo ratings yet

- ANSYS 14 0 Fluid Dynamics Update Dipankar ChoudhuryDocument87 pagesANSYS 14 0 Fluid Dynamics Update Dipankar ChoudhuryephremNo ratings yet

- 2020-09-07 WITS - MECN 5005A - Systems MGMT - Lecture 5 of 8 - SharedDocument73 pages2020-09-07 WITS - MECN 5005A - Systems MGMT - Lecture 5 of 8 - SharedUnarine MutshinyaloNo ratings yet

- Mechanical Systems I - IntroductionDocument14 pagesMechanical Systems I - IntroductionSayeh Al SayehNo ratings yet

- Research 1Document7 pagesResearch 1Mauricio Osorio G.No ratings yet

- Ce 412 (Uap)Document269 pagesCe 412 (Uap)Abdul MukitNo ratings yet

- Seismic Design - NIST - TN.1863-1Document299 pagesSeismic Design - NIST - TN.1863-1jrobert123321No ratings yet

- Proposal Presentation - Siddiq Khan - 1015831Document35 pagesProposal Presentation - Siddiq Khan - 1015831guyii86No ratings yet

- Introductions: 17-654/17-765 Analysis of Software Artifacts Jonathan AldrichDocument2 pagesIntroductions: 17-654/17-765 Analysis of Software Artifacts Jonathan Aldrichart vandalayNo ratings yet

- Prethesis Final Report Redevelopment of Rythubazar in MehidepatnamDocument40 pagesPrethesis Final Report Redevelopment of Rythubazar in MehidepatnamAkhi Akhila50% (2)

- ATC-114 Next-Generation Hysteretic Relationships For Performance-Based Modeling and AnalysisDocument13 pagesATC-114 Next-Generation Hysteretic Relationships For Performance-Based Modeling and AnalysisJose AlviarNo ratings yet

- 4.design ProcessDocument15 pages4.design Processhuzaimatariq11No ratings yet

- Introduction and Research Approach: 1.1 BackgroundDocument1 pageIntroduction and Research Approach: 1.1 Backgroundanwarali1975No ratings yet

- Intro Cbse Sw-Arch 13Document60 pagesIntro Cbse Sw-Arch 13tsabharwalNo ratings yet

- Hevner, A. R. A Three Cycle View of Design Science ResearchDocument6 pagesHevner, A. R. A Three Cycle View of Design Science ResearchSergio AvilaNo ratings yet

- Architecture Design Course-Brochure RGB 220726-1Document4 pagesArchitecture Design Course-Brochure RGB 220726-1Farah AhmedNo ratings yet

- Machine Design Ashish Agarwal R.V.C.E, Bangalore: DR P R Venkatesh, Mech Dept, RVCE, BangaloreDocument144 pagesMachine Design Ashish Agarwal R.V.C.E, Bangalore: DR P R Venkatesh, Mech Dept, RVCE, BangaloreRajmchzNo ratings yet

- Week2 SystemsScienceAndEngin - Ethics 2021Document91 pagesWeek2 SystemsScienceAndEngin - Ethics 2021Samy OusmanNo ratings yet

- Detailed Seismic Assessment Assessment Procedures Analysis TechniquesDocument111 pagesDetailed Seismic Assessment Assessment Procedures Analysis Techniquesyoshdog@gmail.comNo ratings yet

- NX Nastran Advanced Simulation SolutionsDocument5 pagesNX Nastran Advanced Simulation SolutionsSandeep BhatiaNo ratings yet

- Prestandard and Commentary For The Seismic Rehabilitation of Buildings (TheDocument3 pagesPrestandard and Commentary For The Seismic Rehabilitation of Buildings (Theindah0330No ratings yet

- Iccbss08 (Final)Document32 pagesIccbss08 (Final)JuanNo ratings yet

- PROJ703 - Midterm Presentation - SALMAN Ali - LAMBACHRI AliDocument35 pagesPROJ703 - Midterm Presentation - SALMAN Ali - LAMBACHRI AliGuasslin JoeyNo ratings yet

- Engineering Management Solapur University - SyllabusDocument6 pagesEngineering Management Solapur University - SyllabusMangesh kevadkarNo ratings yet

- Management and OrganizationDocument55 pagesManagement and OrganizationMadhav BhandariNo ratings yet

- An Introduction To Fundamental Architecture Concepts: Warren WeinmeyerDocument60 pagesAn Introduction To Fundamental Architecture Concepts: Warren Weinmeyerlucifer whiteNo ratings yet

- Product Design ProcessDocument14 pagesProduct Design ProcessGooftilaaAniJiraachuunkooYesusiinNo ratings yet

- Presentation SSESL1Document47 pagesPresentation SSESL1Ajith VandebonaNo ratings yet

- The New P-Diagram: U.S. Army Research, Development and Engineering CommandDocument29 pagesThe New P-Diagram: U.S. Army Research, Development and Engineering CommandisolongNo ratings yet

- A3 Instructions (PSO)-updated 21 Jun 2024Document16 pagesA3 Instructions (PSO)-updated 21 Jun 2024Phong ThầnNo ratings yet

- Atc32 1TOCDocument8 pagesAtc32 1TOCer.wasimqadir7654No ratings yet

- Lecture 2 HistoryDocument38 pagesLecture 2 Historyjohnnyferry2No ratings yet

- Specifications For Highway Bridges, V Seismic Design: December 2003Document14 pagesSpecifications For Highway Bridges, V Seismic Design: December 2003vishal kumarNo ratings yet

- Qualitative Data Analysis: (Version 0.5, 1/4/05) Daniel K. Schneider, TECFA, University of GenevaDocument22 pagesQualitative Data Analysis: (Version 0.5, 1/4/05) Daniel K. Schneider, TECFA, University of Genevashafee kayNo ratings yet

- Ejemplo de Aplicacion Asce Sei 41 13Document17 pagesEjemplo de Aplicacion Asce Sei 41 13Marvin DouglasNo ratings yet

- Design Research DesignDocument13 pagesDesign Research DesignJyothsna Priya KattakindaNo ratings yet

- Exam Guide: Structural SystemsDocument21 pagesExam Guide: Structural SystemsPaolo PaoitNo ratings yet

- Eng Des ConceptsDocument41 pagesEng Des ConceptsAmali LakmaliNo ratings yet

- Review of Conventional Seismic Design Intro To Performance-Based DesignDocument43 pagesReview of Conventional Seismic Design Intro To Performance-Based DesignmamandaweNo ratings yet

- Hexagon PPM GT STRUDL Product Sheet USDocument2 pagesHexagon PPM GT STRUDL Product Sheet USTimothy HoNo ratings yet

- Pre-Doctorate of Architecture: Prof. Mohamed Shawky Abou-LeilaDocument27 pagesPre-Doctorate of Architecture: Prof. Mohamed Shawky Abou-Leilasomaiaarafa93No ratings yet

- Product Design ProcessDocument14 pagesProduct Design ProcessProf Dr Kathirrvelu SubramanianNo ratings yet

- 6.6 Job Description Directory (To-Be) : Reliance Industries LimitedDocument6 pages6.6 Job Description Directory (To-Be) : Reliance Industries Limitedsatyamech1_395565923No ratings yet

- Slides9 Analysis&DesignDocument21 pagesSlides9 Analysis&DesignAI WarlockNo ratings yet

- Pages from CSA A23 (1) .3-04 - 加拿大标准协会 Design of Concrete Structures-3Document1 pagePages from CSA A23 (1) .3-04 - 加拿大标准协会 Design of Concrete Structures-3Babrak Khan NoorzoiNo ratings yet

- Pages from CSA A23 (1) .3-04 - 加拿大标准协会 Design of Concrete Structures-2Document1 pagePages from CSA A23 (1) .3-04 - 加拿大标准协会 Design of Concrete Structures-2Babrak Khan NoorzoiNo ratings yet

- Assembling by Fusion Welding - ETN M 9 16Document4 pagesAssembling by Fusion Welding - ETN M 9 16Babrak Khan NoorzoiNo ratings yet

- Benefits of Steel RC Shear Walls in Building Structures - ETN-D-8-21Document4 pagesBenefits of Steel RC Shear Walls in Building Structures - ETN-D-8-21Babrak Khan NoorzoiNo ratings yet

- Astm Reinforcing Bar Marking Requirements: (Inch-Pound)Document2 pagesAstm Reinforcing Bar Marking Requirements: (Inch-Pound)Babrak Khan NoorzoiNo ratings yet

- 2020 14 Mazzoni GroundmotionselectionDocument139 pages2020 14 Mazzoni GroundmotionselectionBabrak Khan NoorzoiNo ratings yet

- E1586522786733 PDFDocument1 pageE1586522786733 PDFBabrak Khan NoorzoiNo ratings yet

- Pacific Earthquake Engineering Research CenterDocument143 pagesPacific Earthquake Engineering Research CenterBabrak Khan NoorzoiNo ratings yet

- Chapter 9 Conflict and NegotiationDocument9 pagesChapter 9 Conflict and NegotiationCharles CabarlesNo ratings yet

- Assignment Brief - BTEC (RQF) Higher National Diploma in Business (Business Management)Document9 pagesAssignment Brief - BTEC (RQF) Higher National Diploma in Business (Business Management)Lee DucNo ratings yet

- 4A~5A 1학기 영어 (10학년)Document25 pages4A~5A 1학기 영어 (10학년)이동민No ratings yet

- 4.1 What Is SuccessDocument7 pages4.1 What Is SuccessGanita NarnawreNo ratings yet

- For Advertisement of Diploma Working ProfessionalDocument6 pagesFor Advertisement of Diploma Working Professionalhem956546No ratings yet

- On DP Vessel ClassificationDocument20 pagesOn DP Vessel ClassificationDaniloNo ratings yet

- Modeling and Mapping The Spatial-Temporal Changes in Land Use and Land Cover in Lagos: A Dynamics For Building A Sustainable Urban CityDocument17 pagesModeling and Mapping The Spatial-Temporal Changes in Land Use and Land Cover in Lagos: A Dynamics For Building A Sustainable Urban CityAhmed RagabNo ratings yet

- TMR1302 Datasheet EN V1.1Document5 pagesTMR1302 Datasheet EN V1.1shreyas dasNo ratings yet

- Final SOP of RajDocument3 pagesFinal SOP of RajRikhil NairNo ratings yet

- TDP 2023-2040 Consultation Report-2023-06-15-07-54-06Document203 pagesTDP 2023-2040 Consultation Report-2023-06-15-07-54-06evhbartoloNo ratings yet

- Uea Dissertation ExtensionDocument4 pagesUea Dissertation ExtensionBuySchoolPapersOnlineCanada100% (1)

- Short Circuit of Inverter BasedDocument11 pagesShort Circuit of Inverter Basedoliver voltaNo ratings yet

- Lesson 1 Conceptual Framework of Mathematics From K 3Document34 pagesLesson 1 Conceptual Framework of Mathematics From K 3Godwin Jerome Reyes100% (2)

- SDS Natve Tapioca Starch Food GradeDocument1 pageSDS Natve Tapioca Starch Food GradesinarkanakajayaNo ratings yet

- Samuelson UnderstandingMarxianNotion 1971Document34 pagesSamuelson UnderstandingMarxianNotion 1971Kaio DanielNo ratings yet

- Control of Underground CorrosionDocument24 pagesControl of Underground CorrosionCarlos Rafael Lizarraga ArreolaNo ratings yet

- Final Examination SEMESTER I, SESSION 2015/2016: SAB 2722 / SKAA 2722 1Document9 pagesFinal Examination SEMESTER I, SESSION 2015/2016: SAB 2722 / SKAA 2722 1Hanis SyafiqNo ratings yet

- Decision Making DecentralizationDocument73 pagesDecision Making DecentralizationAnju MargaretNo ratings yet

- Cvpr2022 Glip Grounded Language Image Pre TrainingDocument20 pagesCvpr2022 Glip Grounded Language Image Pre Training郭妙恬No ratings yet

- Essay On ObamaDocument2 pagesEssay On Obamamywofod1nud2100% (2)

- G11 EnglishDocument15 pagesG11 EnglishSay the name seventeenNo ratings yet

- Bme 9 and 10Document16 pagesBme 9 and 10Unnecessary BuyingNo ratings yet

- Measurement - Using Basic Precision Dimensional InstrumentsDocument49 pagesMeasurement - Using Basic Precision Dimensional InstrumentskrishnaNo ratings yet

- Library Room 5: Tribhuvanuniversity Institute of Engineering, Pulchowk CampusDocument8 pagesLibrary Room 5: Tribhuvanuniversity Institute of Engineering, Pulchowk CampusBreaking DieNo ratings yet

- 1 s2.0 S0160412020319292 MainDocument23 pages1 s2.0 S0160412020319292 MainCitra CesiliaNo ratings yet

- Study Guide:: Ricks P. Ortiz Principles of Soil Science - DedeDocument4 pagesStudy Guide:: Ricks P. Ortiz Principles of Soil Science - DedeRicks P. OrtizNo ratings yet

- Waker WatwerDocument31 pagesWaker WatweraeliasgNo ratings yet

- 2.sample Question 03 Agri SystemsDocument19 pages2.sample Question 03 Agri Systemsvendetta021199No ratings yet

- B2 First Practice Test Writing Answer KeyDocument2 pagesB2 First Practice Test Writing Answer KeyRocio FernandezNo ratings yet

- Dunne - Resurgence in Quantum Field Theory and Quantum MechanicsDocument58 pagesDunne - Resurgence in Quantum Field Theory and Quantum MechanicsL VNo ratings yet