Professional Documents

Culture Documents

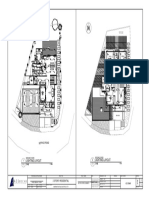

(2.1) Appendix A1 - Schedule of Builders Works (Elev)

(2.1) Appendix A1 - Schedule of Builders Works (Elev)

Uploaded by

edmar jay conchadaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

(2.1) Appendix A1 - Schedule of Builders Works (Elev)

(2.1) Appendix A1 - Schedule of Builders Works (Elev)

Uploaded by

edmar jay conchadaCopyright:

Available Formats

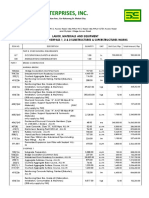

APPENDIX A – “Schedule of Builders' Works and Facilities to

be provided by OTHERS/EMPLOYER/OWNER”

The Main Contractor will undertake or procure that parties other than JSEC carry out the

following works and provide the following facilities free of any charge to JSEC in accordance

(wherever appropriate) with the Delivery and Installation Programme and JSEC’s builders' work

and layout drawings, and the terms and conditions of the Sub-Contract Agreement:

A. SITE FACILITIES Lift shafts and lift motor rooms are to be free of non-lift

related services and other obstructions.

From date of delivery to the Site until installation,

adequate and suitable, dry, illuminated and secure All required structural floors and staircases providing

storage space for all materials, tools and equipment access to the lift shafts and lift motor rooms at each

adjacent to hoist way or other mutually agreed location floor level.

on site.

Lift shafts, lift motor rooms, pit and related or adjoining

Adequate and suitable areas for erection by JSEC of structural concrete works are to be capable of

its offices and other amenities including free use of sustaining without damage or deflection, all loads and

mess room’s latrines, water consumption, canteen, forces generated in both temporary (i.e. during

toilet and other usual facilities of the project site. installation testing and commissioning) and

permanent conditions.

Suitable access routes including all shoring,

strengthening and protection of the structure for All holes, door openings and chases, including any

movement of labor, materials, tools and equipment necessary cutting, and all masonry work related to lift

within the Site in compliance with local regulations. All installations. The door and floor openings for cables

these items shall be provided at no additional cost to and ducts as detailed on JSEC drawings with a

JSEC. 100mm above floor finish line (AFFL) protective curb

about opening to prevent water ingress.

Provide for use at no cost to JSEC all standing

craneage facility on site (tower crane, mobile crane, Datum lines for finished floor levels and alignment of

external passenger hoist) for the purpose of loading wall finishes at each door opening on each floor level

and unloading and relocating of the imported adjacent to each lift shaft.

equipment throughout the installation period, including

the passengers and authorized representatives of Lift shaft separator beams and trimmer beams (if

JSEC. necessary) as required in the approved shop drawings

together with any other structural steelwork (excluding

A centrally located area in which JSEC is able to guide rails and brackets) within lift shafts and machine

deposit rubbish for removal, by others, from site rooms, unless otherwise it is specifically provided in

without charge to JSEC. the Sub-contract.

Any metal ducting requirement (metal sheet or

B. SHAFT REQUIREMENTS expanded metal) shall be supplied and fitted by others

between operating elevators/counterweights located

Dry, clean, watertight lift shafts and pits, properly within the same shaft for ventilation purposes.

framed, enclosed and ventilated, are to be made

available for the exclusive use of JSEC. Shafts are to Note where phased handover is required by the Client,

be of requisite dimensions, square, and vertically temporary internal dividing screens will be required

plumb to be within a tolerance of (plus (+) or minus (- between operating lifts and the work area even if not

) 25mm). Shaft and pit walls shall form a smooth stated on the drawings. Furthermore, for staged

continuous surface and, where necessary in order to installations or phase installations for both elevator

achieve the same finishes, inside the shafts shall be and escalator works, proper installation of water-

provided and built by others. JSEC is obliged to proofed crash deck and hoisting points shall be

immediately check the shaft dimensions once made provided at no additional cost to JSEC.

available to it prior to commencement of lift

installation. Should the dimensions of the lift shafts Safety protection such as fences, kick boards and

and/or pits exceed the tolerance, JSEC reserves the removable barricades at all openings into shafts or

right to reject site possession of the shafts and/or pits pits, including installation and removal together with all

until rectification have been properly executed. JSEC other necessary safety measures and signage.

shall not be subjected to any liquidated damages claim

because of the delay.

Schedule of Builder’s Works (Elevators) Page 1 of 2

Grouting-up of openings including the space between commissioning stages as set out in the Delivery and

the edge of the slab and landing door sill, channels Installation Programme). Such permanent power

and chases, including making good around push- supply capacity is to satisfy the electrical power

button boxes, indicators, architraves, brackets and the loading requirement provided by JSEC in respect of

other embeds must be carried out in accordance with the installation and to permit the simultaneous

JSEC Installation Programe. operation of all lift and escalator units). The circuit

should be tested and labeled correctly. These facilities

Reinforced Pit to support buffer and rail loads including all cabling, accessories, termination and the

transmitted to pit slabs. Provide structural supports in consumption supply shall be provided at no cost to

pit floor for car and/or counterweight buffers and rail JSEC.

impact loads. The pit must be cleared of rubbish and

must be water-proofed in order to avoid and prevent 1. The permanent power supply is to include fused

water ingress. disconnect switches (for both three-phase and single-

phase supply) for each elevator, together with all cut-

Provide wall pockets and/or structural beams for outs, circuit breakers, lightning arrestors and other

adequate support of the elevator equipment. devices necessary to satisfy all applicable codes and

regulations. Any power factor correction is to be

Provide structural up-thrust tie down beams in elevator undertaken by others.

pit floor for compensation sheave assembly, when

required. Verify load and reaction on JSEC shop 2. As a minimum requirement, there should be one (1)

drawings. 40 watts fluorescent fixture over each machine, as

applicable. Shaft lighting shall span the full-height of

The Main Contractor shall be responsible for the cost each lift shaft (with light points at not more than 6

for the replacement of lift equipments that will be meter intervals) with accessible switching adjacent to

damaged or contaminated by or as a result of the lift pit ladder, and machine room. A separate three-

operations of other trades, such as but not limited to way switch for individual pit lighting together with a

water ingress and material damage. 220-volt socket outlet with cover (weather and water-

proofed) shall be provided. All permanent lighting must

C. POWER SUPPLY AND ELECTRICAL WORKS be completed prior to our commissioning activities. All

light fittings shall be protected by guarded fittings.

Permanent power supply (in accordance with our

electrical requirements and approved JSEC contract Single phase 220V temporary electric power for

shop drawings), 3-phase power including earth wire hand-tools provided at earthed outlets in machine

and neutral (400V / 60Hz), terminating at each circuit rooms and in each lift shaft at intervals of not more

breaker in the lift machine room/machine-room-less than 3 floors, together with adequate temporary

control panel (unless otherwise stated, the permanent lighting for safe working in each such area.

power is required during the testing and

Schedule of Builder’s Works (Elevators) Page 2 of 2

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Chapter 17 Light-Gauge Steel ConstructionDocument16 pagesChapter 17 Light-Gauge Steel ConstructionFrancis AncoNo ratings yet

- Substation Bldg. and Site Dev't. TES-P-119-19-R1Document44 pagesSubstation Bldg. and Site Dev't. TES-P-119-19-R1Pageduesca Rouel33% (3)

- ISD Assignment 2 - Group 27Document51 pagesISD Assignment 2 - Group 27Nelson LeeNo ratings yet

- Calawis Water Treatment Plant Tayabasan Weir 2Document1 pageCalawis Water Treatment Plant Tayabasan Weir 2edmar jay conchadaNo ratings yet

- 00 Samaco Residence ELEC Rev 00-20x30Document1 page00 Samaco Residence ELEC Rev 00-20x30edmar jay conchadaNo ratings yet

- Gate Valve Resilient Seat: Rev.: D Ref.: VOC4241C-00.pasDocument1 pageGate Valve Resilient Seat: Rev.: D Ref.: VOC4241C-00.pasedmar jay conchadaNo ratings yet

- Calawis Water Treatment Plant Tayabasan Weir 2Document1 pageCalawis Water Treatment Plant Tayabasan Weir 2edmar jay conchadaNo ratings yet

- HV - Engineered - Induction - Motors - Tech - Catalog - 9AKK103508 - RevL - EN052021 - LowresDocument160 pagesHV - Engineered - Induction - Motors - Tech - Catalog - 9AKK103508 - RevL - EN052021 - Lowresedmar jay conchadaNo ratings yet

- Check Valve Pn16 Flanged Type Swing: Ref.: CB 3240PN16.pasDocument1 pageCheck Valve Pn16 Flanged Type Swing: Ref.: CB 3240PN16.pasedmar jay conchadaNo ratings yet

- PN16 Joints Dismantling: Ref.: JT4243 .Pas Rev.: Initial Date: 30/05/2016 Page: 1/1Document1 pagePN16 Joints Dismantling: Ref.: JT4243 .Pas Rev.: Initial Date: 30/05/2016 Page: 1/1edmar jay conchadaNo ratings yet

- Gauge With Abs Box Dry Dial PressureDocument1 pageGauge With Abs Box Dry Dial Pressureedmar jay conchadaNo ratings yet

- CP S07 Work Package Procurement Plan UpdateDocument1 pageCP S07 Work Package Procurement Plan Updateedmar jay conchadaNo ratings yet

- CP S04 Work Package Procurement Plan UpdateDocument1 pageCP S04 Work Package Procurement Plan Updateedmar jay conchadaNo ratings yet

- Marimla Bridge & Overpass Final OfferDocument3 pagesMarimla Bridge & Overpass Final Offeredmar jay conchadaNo ratings yet

- Cash Acknowledgement Receipt - 1st InvoiceDocument1 pageCash Acknowledgement Receipt - 1st Invoiceedmar jay conchadaNo ratings yet

- Panel Circuitbreaker Tech - Data Sheets PDFDocument76 pagesPanel Circuitbreaker Tech - Data Sheets PDFedmar jay conchadaNo ratings yet

- Delta Star Transformer BrochureDocument12 pagesDelta Star Transformer Brochureedmar jay conchadaNo ratings yet

- Building Construction - Iii: Waterproofing in BuildingsDocument30 pagesBuilding Construction - Iii: Waterproofing in BuildingsPulkit SainiNo ratings yet

- Floor Installation of The Agru Sure Grip Concrete Protective Liner Floor Standard MethodDocument6 pagesFloor Installation of The Agru Sure Grip Concrete Protective Liner Floor Standard MethodManriquez AndresNo ratings yet

- TriMast Mount For 75cm-1m AntennasDocument4 pagesTriMast Mount For 75cm-1m AntennasCarlosAgustoPinedaSanchezNo ratings yet

- Technical Specification: 20' X 8' X 8'6" ISO 1CC TYPE Steel Dry Cargo ContainerDocument23 pagesTechnical Specification: 20' X 8' X 8'6" ISO 1CC TYPE Steel Dry Cargo ContainerMAYMODERN STEELNo ratings yet

- The Standard Pricing List Tower D2Document6 pagesThe Standard Pricing List Tower D2Gurgaon propertiesNo ratings yet

- 8 - Design and Construction of The New NLB BuildingDocument15 pages8 - Design and Construction of The New NLB Buildinglim kang haiNo ratings yet

- Staad Example NewDocument58 pagesStaad Example Newsusarlasaicharan100% (1)

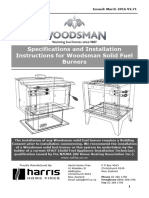

- Woodsman Installation InstructionsDocument14 pagesWoodsman Installation Instructionskimba worthNo ratings yet

- Concrete TechnologyDocument186 pagesConcrete Technologysmg26thmayNo ratings yet

- Ce013 Cruz, Mark-Kiolo Final-SubmissionDocument61 pagesCe013 Cruz, Mark-Kiolo Final-SubmissionKiolo CruzNo ratings yet

- Electric Radiant Floor Heating: Installation GuideDocument14 pagesElectric Radiant Floor Heating: Installation GuideLucian CiudinNo ratings yet

- Week Seven Class: Jss Two Week: 7 Topic: Site Preparation (I) Tools For Site Preparation (Ii) Techniques For Site PreparationDocument11 pagesWeek Seven Class: Jss Two Week: 7 Topic: Site Preparation (I) Tools For Site Preparation (Ii) Techniques For Site PreparationAdio Babatunde Abiodun Cabax100% (2)

- Bill of Quantities TemplateDocument6 pagesBill of Quantities TemplateDiaszNo ratings yet

- Repair of Joint SpallingDocument2 pagesRepair of Joint SpallingHuaman Chavez Jesus AngelNo ratings yet

- CLH Lacson L'Fisher Existing & Proposed LayoutDocument1 pageCLH Lacson L'Fisher Existing & Proposed LayoutLimar SetatraNo ratings yet

- Gold Star: High Polymer Modified, Cementitious, Tile/stone AdhesiveDocument3 pagesGold Star: High Polymer Modified, Cementitious, Tile/stone AdhesiveGaganNo ratings yet

- 3.2.2.1 Dead LoadDocument10 pages3.2.2.1 Dead LoadNeølie Abello LatúrnasNo ratings yet

- Comflor 210: Composite Floor DeckingDocument24 pagesComflor 210: Composite Floor DeckingJing CaoNo ratings yet

- 1.03 Sanitary Plumbing Floor Waste GulliesDocument3 pages1.03 Sanitary Plumbing Floor Waste GulliesRanmal AbhaNo ratings yet

- Buildable Solutions For High Rise Residential Development LowresDocument109 pagesBuildable Solutions For High Rise Residential Development LowresWei Yuen100% (1)

- Westlake 20: Bedrooms Bathrooms GarageDocument6 pagesWestlake 20: Bedrooms Bathrooms GarageindyanexpressNo ratings yet

- January 2022 Ale Exam Day 01-Am Subjects: 5 Questions About DICTUMSDocument7 pagesJanuary 2022 Ale Exam Day 01-Am Subjects: 5 Questions About DICTUMSBevs Rivera100% (1)

- Facility Hygienic Design ChecklistDocument6 pagesFacility Hygienic Design ChecklistEyad Al-Jeezani100% (1)

- Uniform Mechanical Code - 2009 Chapter 6Document14 pagesUniform Mechanical Code - 2009 Chapter 6memosplumbing100% (1)

- De JOYA Villanueva Residence Schedule of Construction ActualDocument1 pageDe JOYA Villanueva Residence Schedule of Construction ActualAdrian Marasigan ReyesNo ratings yet

- LG Masina SpalatDocument325 pagesLG Masina Spalatbugy costyNo ratings yet