Professional Documents

Culture Documents

DTS Que Paper

DTS Que Paper

Uploaded by

NagsOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DTS Que Paper

DTS Que Paper

Uploaded by

NagsCopyright:

Available Formats

Register No:

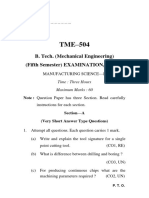

PSG Institute of Technology and Applied Research, Coimbatore - 641 061

(Affiliated to Anna University, Chennai)

III - B.E (MECH) Sixth Semester

Internal Assessment I - March 2021

ME8651 – Design of Transmission Systems

(PSG Design Data Book is permitted)

Date: 22.03.2021 Session: FN

Time: 1 hour 30 minutes. Maximum: 50Marks

CO1 Enumerate and explain the different modes of transmission systems, Understanding

their nomenclature and its suitable applications.

CO3 Determine the gear tooth parameters and assess the bending and wear Applying

strength in spur, helical, bevel, worm and crossed helical gears

Cognition CO1 CO3 Total Marks

Level

Q. No. Max. Marks Q. No. Max. Marks

Remembering 3,7,8,10 8 8

Understanding 1,2,4,5,6,9 12 12

Applying 11,12 30 30

Total Marks 20 30 50

Answer ALL questions

PART A – (10 × 2 = 20 marks)

1. Why most of the electric vehicle uses only one gear set? (Understanding) CO1

2. In general racing cars use straight cut gears instead of helical (Understanding) CO1

gears. Why?

3. What is Lewis form factor? (Remembering) CO1

4. Explain the phenomenon of interference in gears. (Understanding) CO1

5. Differentiate double helical and herringbone gears. (Understanding) CO1

6. How to counteract the axial force generated in the helical gears? (Understanding) CO1

7. What is virtual number of teeth in Helical gears? (Remembering) CO1

8. List down the types of failure in gears? Highlight the failure type (Remembering) CO1

that causes small cavities on the gear material

9. What are the conditions required for interchangeability in gears? (Understanding) CO1

10. What is pressure angle? Mention the ideal pressure angle. (Remembering) CO1

PART B – (1 × 15 = 30 marks)

11 a) Design a straight spur gear drive to transmit 8 kW. The pinion (Applying) CO3

speed is 720 rpm and the speed ratio is 2. Both the gears are

made of the same surface hardened carbon steel with 55 RC and

core hardness less than 350 BHN. Ultimate strength is 720

N/mm2 and the yield strength is 360 N/mm2.

(OR)

11 b) Design a pair of helical gears for the turbine that has the (Applying) CO3

transmission ratio of 10:1. The pinion rotates at 5000 rpm and

made of carbon steel and the gear wheel is made of high-grade

cast iron. Power transmitted = 90 kW. The gear pair is required

to last for at least 11000 hrs. Select suitable gear material.

11 a) Deduce the expression for the forces acting on a gear tooth of a (Applying) CO3

helical gear with the aid of a schematic diagram.

(OR)

11 b) The gear pair is made of C40 steel. The pinion is transmitting (Applying) CO3

30 kW at 1200 rpm. The gear ratio is 3. Gear is to work for 8

hours per day, 6 days a week and for 3 years. Design the drive.

You might also like

- Astm A370 2020Document50 pagesAstm A370 2020امين100% (1)

- Instant Download Ebook PDF Aircraft Propulsion 2nd Edition by Saeed Farokhi PDF ScribdDocument41 pagesInstant Download Ebook PDF Aircraft Propulsion 2nd Edition by Saeed Farokhi PDF Scribdcynthia.sutton629100% (52)

- Spesifikasjoner Kubota U10 3 PDFDocument390 pagesSpesifikasjoner Kubota U10 3 PDFEdwin Beltran100% (2)

- DTS Iat-1Document2 pagesDTS Iat-1Ajay KumarNo ratings yet

- Em-1 Model Set-ADocument4 pagesEm-1 Model Set-AarunNo ratings yet

- DTS Ciat 2Document1 pageDTS Ciat 2MECHANICAL SMCETNo ratings yet

- Em-1 Cia-1 Set-ADocument3 pagesEm-1 Cia-1 Set-AarunNo ratings yet

- Dme KtuDocument9 pagesDme Ktuhyy5u6No ratings yet

- Em-1 Model Set-BDocument4 pagesEm-1 Model Set-BarunNo ratings yet

- Mechanical Engineering s7 & s8Document330 pagesMechanical Engineering s7 & s8The OpenstudioNo ratings yet

- Em-1 Cia-2 Set-ADocument3 pagesEm-1 Cia-2 Set-AarunNo ratings yet

- Em-1 Cia-I Set-BDocument3 pagesEm-1 Cia-I Set-BarunNo ratings yet

- PH8151 - Engineering PhysicsDocument3 pagesPH8151 - Engineering PhysicsK.GAYATHRINo ratings yet

- Dynamics of MachineryDocument2 pagesDynamics of MachineryGopi TNo ratings yet

- Mee641 June2021Document3 pagesMee641 June2021yathishyathi84958058No ratings yet

- Me 8073 - Unconventional Machining Processes: Kothandaraman Nagar, Dindigul - 624 622Document2 pagesMe 8073 - Unconventional Machining Processes: Kothandaraman Nagar, Dindigul - 624 622balajimeieNo ratings yet

- MO CIA 1 Set 1 23-24Document2 pagesMO CIA 1 Set 1 23-24arumugam gopalNo ratings yet

- Question Paper For MeDocument4 pagesQuestion Paper For MeVishal JhaNo ratings yet

- Met304 DDM SyllabusDocument10 pagesMet304 DDM SyllabuselsonpaulNo ratings yet

- Em I CIA 2 Set BDocument4 pagesEm I CIA 2 Set BarunNo ratings yet

- Thiagarajar College of Engineering, Madurai 625 015 Department of Mechanical EngineeringDocument1 pageThiagarajar College of Engineering, Madurai 625 015 Department of Mechanical EngineeringHALO MC NOBLE ACTUALNo ratings yet

- ME8492 ModelDocument3 pagesME8492 ModelBala AbimanyuNo ratings yet

- Tribology QP & Syllabus Vtu PRASHANTHDocument21 pagesTribology QP & Syllabus Vtu PRASHANTHpachieduNo ratings yet

- Low - Power - VLSI - JUNE 2023Document2 pagesLow - Power - VLSI - JUNE 20231ms21ec132No ratings yet

- Name: Admission NoDocument3 pagesName: Admission NoSHISHIRNo ratings yet

- 3c) Question Paper (End Term Exam) Mechanics ME 101Document2 pages3c) Question Paper (End Term Exam) Mechanics ME 101Hashua WarNo ratings yet

- Ramaiah: MSEE02Document2 pagesRamaiah: MSEE02hari krishnaNo ratings yet

- CE 8601 Internal 2 Answerkey 2021Document10 pagesCE 8601 Internal 2 Answerkey 2021ci_balaNo ratings yet

- Ramaiah: Semester End Examinations - January 2020Document2 pagesRamaiah: Semester End Examinations - January 2020hari krishnaNo ratings yet

- Ce 451 Te Ii ('09-'13) PDFDocument36 pagesCe 451 Te Ii ('09-'13) PDFSakibNo ratings yet

- r05310802 Mechanical Unit Operations IDocument7 pagesr05310802 Mechanical Unit Operations ISrinivasa Rao GNo ratings yet

- 20me652 - Tribology MQPDocument2 pages20me652 - Tribology MQPranjithkrajNo ratings yet

- Manufacturing Science-IiDocument5 pagesManufacturing Science-Iiayansiddiqui7700No ratings yet

- Assignment 1 - Introduction To EM and TrussDocument5 pagesAssignment 1 - Introduction To EM and TrussAshok Ashok100% (1)

- Affiliated To Anna University Chennai, Approved by Aicte-NewdelhiDocument1 pageAffiliated To Anna University Chennai, Approved by Aicte-NewdelhiRamNo ratings yet

- Machine Design Model PaperDocument2 pagesMachine Design Model Paperlalamramesh78No ratings yet

- Cy0u10a R Engineering Chemistry Sept 2022Document2 pagesCy0u10a R Engineering Chemistry Sept 2022kangirene9705No ratings yet

- 6501civsl Ihd 1Document5 pages6501civsl Ihd 1anushkakrajasinghaNo ratings yet

- Mae - Mait.ac - In: B. Tech (MAE) - VI Sem ETAT 302 (Machine Design)Document3 pagesMae - Mait.ac - In: B. Tech (MAE) - VI Sem ETAT 302 (Machine Design)Shivanant BhagatNo ratings yet

- 20PSE204 - Finite Element AnalysisDocument4 pages20PSE204 - Finite Element AnalysisJithin K SunilNo ratings yet

- Cia I QP DomDocument2 pagesCia I QP DomThiyagu SundaramNo ratings yet

- Dynamics of MachinesDocument6 pagesDynamics of Machinesayansiddiqui7700No ratings yet

- Internal Assessment Test II, Odd Semester (2016-2017) : Year/Sem: II/III Duration: 1 Hour Max. Marks: 50Document3 pagesInternal Assessment Test II, Odd Semester (2016-2017) : Year/Sem: II/III Duration: 1 Hour Max. Marks: 50Muthukrishnan biherNo ratings yet

- Subjective Questions (Any Three) :-: Univ. Roll NoDocument3 pagesSubjective Questions (Any Three) :-: Univ. Roll NoSonukNo ratings yet

- Physics Handwritten NotesDocument2 pagesPhysics Handwritten NotesChalla SaiNo ratings yet

- Dynamics and Design of MachineryDocument10 pagesDynamics and Design of MachineryBen JoeNo ratings yet

- Me62o June2021Document3 pagesMe62o June2021Rambo 420No ratings yet

- IS, S, EXAM - (M) 2018: Mechanical Engineering Paper - IDocument8 pagesIS, S, EXAM - (M) 2018: Mechanical Engineering Paper - IAbhishek KumarNo ratings yet

- Me8593 - Dme - Model QPDocument3 pagesMe8593 - Dme - Model QPChandrasekhar PrabhakaranNo ratings yet

- 신소재과학 시험문제모음Document9 pages신소재과학 시험문제모음Hanjin SeoNo ratings yet

- ModelQp 18ME53 TM 2022-23Document3 pagesModelQp 18ME53 TM 2022-23varshitha srinivasNo ratings yet

- Engineering Academy: ESE Conventional Revision TEST - IIIDocument8 pagesEngineering Academy: ESE Conventional Revision TEST - IIIvidya chakitwarNo ratings yet

- PART-A Answer ALL Questions (5x2 10 Marks) : Reg - NoDocument6 pagesPART-A Answer ALL Questions (5x2 10 Marks) : Reg - NoMEHALA SNo ratings yet

- BTMC503TheoryOfMachineIIpdfDocument2 pagesBTMC503TheoryOfMachineIIpdfAmar KoliNo ratings yet

- L-4ff-lIME Date: 07/12/2014: Section-ADocument25 pagesL-4ff-lIME Date: 07/12/2014: Section-AAdnan Shahariar AnikNo ratings yet

- 2021 IIDocument2 pages2021 II1ms20ei002No ratings yet

- An Autonomous Institution, Affiliated To Anna University, ChennaiDocument1 pageAn Autonomous Institution, Affiliated To Anna University, ChennaiRAMESH KUMAR ANo ratings yet

- Me8651 DTS 1Document2 pagesMe8651 DTS 1Ramaswamy SubbiahNo ratings yet

- Sensors and Transducers - Internal Test 3 - QPDocument3 pagesSensors and Transducers - Internal Test 3 - QPMukesh ManideepNo ratings yet

- CVR College of Engineering: B.Tech. III Year IIDocument1 pageCVR College of Engineering: B.Tech. III Year IIRambabuDaraNo ratings yet

- DME Unit Test 4 - 2018Document3 pagesDME Unit Test 4 - 2018hodmech tjsec.inNo ratings yet

- Molecular Modeling of Geochemical Reactions: An IntroductionFrom EverandMolecular Modeling of Geochemical Reactions: An IntroductionJames D. KubickiNo ratings yet

- Level Switches-CatalougeDocument4 pagesLevel Switches-CatalougeharishupretiNo ratings yet

- Asce 7 Seismic ExampleDocument7 pagesAsce 7 Seismic ExampleKatherine Prado100% (1)

- Spraymec 6050 WPCDocument3 pagesSpraymec 6050 WPCPatop CofréNo ratings yet

- COP 1240 Drifter Parts For Atlas Copco: No Crawler Drill Drfter Part Number Part Name Q'ty RemarksDocument6 pagesCOP 1240 Drifter Parts For Atlas Copco: No Crawler Drill Drfter Part Number Part Name Q'ty RemarksDaniel Ricardo Páez AlvarezNo ratings yet

- Some Aerodynamic Problems of Satellite Launch VehiclesDocument37 pagesSome Aerodynamic Problems of Satellite Launch VehiclesFatima IrfanNo ratings yet

- BNBC 2012 Part 6 Chapter 6 and 7 PDFDocument160 pagesBNBC 2012 Part 6 Chapter 6 and 7 PDFAifam RawNo ratings yet

- Thermal BowingDocument8 pagesThermal BowingA. VenugopalNo ratings yet

- Throttle Body Presentation 1Document7 pagesThrottle Body Presentation 1Krishna MandalNo ratings yet

- Online QuizDocument16 pagesOnline QuizPhyo Marn Hone LinNo ratings yet

- 2019 Metal Cutting Metal Forming Metrology PDFDocument203 pages2019 Metal Cutting Metal Forming Metrology PDFZia Ur Rehman100% (1)

- Case Studies On VibrationsDocument36 pagesCase Studies On VibrationslubangjarumNo ratings yet

- Forces and MatterDocument9 pagesForces and MatterAbdur RahmanNo ratings yet

- Fabcor 86 RDocument2 pagesFabcor 86 RAnonymous fj4iRr1No ratings yet

- Steel Piping System A106Document1 pageSteel Piping System A106NoorudheenEVNo ratings yet

- For Gear, Spline & Rack ManufacturingDocument24 pagesFor Gear, Spline & Rack ManufacturingDANIEL MANRIQUEZ FAVILANo ratings yet

- Fisher ES Sliding-Stem Control ValveDocument20 pagesFisher ES Sliding-Stem Control ValveAmiroucheBenlakehalNo ratings yet

- CPCQD Operation ManualDocument44 pagesCPCQD Operation ManualZii RamNo ratings yet

- Chapter One: Edge-Supported Two-Way Slabs: Reinforced Concrete II Design For Water Supply EngineeringDocument11 pagesChapter One: Edge-Supported Two-Way Slabs: Reinforced Concrete II Design For Water Supply Engineeringjebril yusufNo ratings yet

- Boiler Safety ChecklistDocument2 pagesBoiler Safety ChecklistAnand Pal Singh100% (1)

- REE - Question Bank-2Document1 pageREE - Question Bank-2Arc ReactorNo ratings yet

- Renault 19 Belt TensionDocument23 pagesRenault 19 Belt TensionIvan AlilovicNo ratings yet

- Installation, Operation and Maintenance Manual FOR De-Watering PumpDocument18 pagesInstallation, Operation and Maintenance Manual FOR De-Watering PumpsatfasNo ratings yet

- V08-DC32e INSTRUCTION MANUAL (OPERATION)Document103 pagesV08-DC32e INSTRUCTION MANUAL (OPERATION)Data IBTNo ratings yet

- SPC Pulsar NS 200 - AS 200 (2019 08 22)Document106 pagesSPC Pulsar NS 200 - AS 200 (2019 08 22)Willy Mansilla A100% (1)

- Bs Motor EngDocument36 pagesBs Motor Engjroyal692974No ratings yet

- York Water-Cooled Chillers: Capacity Model and DescriptionDocument2 pagesYork Water-Cooled Chillers: Capacity Model and DescriptionDee RajaNo ratings yet

- N 1Document42 pagesN 1nadaf2No ratings yet