Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

8 viewsWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name Date

Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name Date

Uploaded by

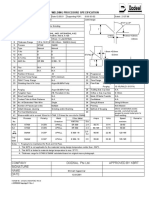

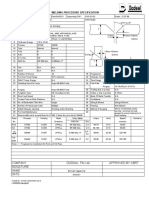

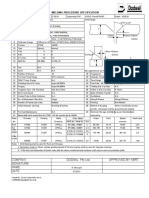

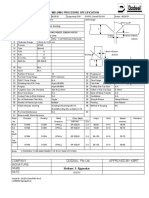

S GoudaDodsal Pte Ltd provides a welding procedure specification for an ethylene project in Doha, Qatar. The specification outlines the materials, processes, parameters and qualifications for welding grade P91 steel pipe ranging from 4.76 to 36.52mm thick using gas tungsten arc welding and shielded metal arc welding. Key details include welding 5B grade P91, F91 and WP91 steel in the uphill position with gas shielding and multiple passes to meet hardness requirements under 241BHN.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You might also like

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document1 pageWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Format No: DOD/Q-Chem/F082 Rev 0 c:/DIR00001/wps/pp20-1Document1 pageWelding Procedure Specification: Format No: DOD/Q-Chem/F082 Rev 0 c:/DIR00001/wps/pp20-1S GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document1 pageWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document2 pagesWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument2 pagesWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document2 pagesWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument2 pagesWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- PP41 Rev.3Document1 pagePP41 Rev.3Ashish ChackoNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument2 pagesWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- PP34. Rev.1xlsDocument1 pagePP34. Rev.1xlsS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Format No: DOD/Q-Chem/F082 Rev 0 c:/DIR00001/wps/pp06Document1 pageFormat No: DOD/Q-Chem/F082 Rev 0 c:/DIR00001/wps/pp06S GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument2 pagesWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- 011 WPS ASME TOP F 2022 - Rev.0Document8 pages011 WPS ASME TOP F 2022 - Rev.0megantara maromNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document1 pageWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (1)

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document1 pageWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed LepdaNo ratings yet

- Form Wps JBL09-2011Document2 pagesForm Wps JBL09-2011fawad aliNo ratings yet

- Asme IxDocument1 pageAsme IxAxel Navarro AlbinesNo ratings yet

- Welding Procedure Specification (WPS) : Asme Sec Ix, 2017 Boiler and Pressure Vessel CodeDocument2 pagesWelding Procedure Specification (WPS) : Asme Sec Ix, 2017 Boiler and Pressure Vessel CodeNuwan RanaweeraNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document2 pagesWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed LepdaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- PP34. Rev.1xlsDocument1 pagePP34. Rev.1xlsS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document2 pagesWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Format No: DOD/Q-Chem/F082 Rev 0 c:/DIR00001/wps/pp20-1Document1 pageWelding Procedure Specification: Format No: DOD/Q-Chem/F082 Rev 0 c:/DIR00001/wps/pp20-1S GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document1 pageWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument2 pagesWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Experiment No 1 Introduction To Hand Tools: HacksawDocument16 pagesExperiment No 1 Introduction To Hand Tools: HacksawTamzid rahmanNo ratings yet

- Catalog-Crimson Oil ToolsDocument23 pagesCatalog-Crimson Oil ToolsTaras ByloNo ratings yet

- Techalloy 55Document1 pageTechalloy 55Muhammad FajriNo ratings yet

- HobartCatalog PDFDocument47 pagesHobartCatalog PDFalisyalalaNo ratings yet

- Steel TH 1Document79 pagesSteel TH 1Fraz AliNo ratings yet

- 3408 AGMWS Vol1 TA2 CleanDocument8 pages3408 AGMWS Vol1 TA2 CleanWong AlexNo ratings yet

- ThreeBond Magnet Bonding Epoxies FlyerDocument2 pagesThreeBond Magnet Bonding Epoxies FlyersuryaNo ratings yet

- Hand Book On Bearing Maintenance PDFDocument182 pagesHand Book On Bearing Maintenance PDFRakesh Jainwal100% (1)

- 2022 - ORG4801 - Examination Question Paper Jan - FebDocument20 pages2022 - ORG4801 - Examination Question Paper Jan - FebpriarlogisticsNo ratings yet

- PTC 072715 Nym Ex DCM 001Document77 pagesPTC 072715 Nym Ex DCM 001LOLA PATRICIA MORALES DE LA CUBANo ratings yet

- Akaki W2 3 by 1 (1st Payment)Document9 pagesAkaki W2 3 by 1 (1st Payment)Hiwot MeleseNo ratings yet

- Welding Metalwork Fabrication Services Sample ProposalDocument10 pagesWelding Metalwork Fabrication Services Sample ProposalDickson PhiriNo ratings yet

- Metal Cutting ToolsDocument12 pagesMetal Cutting ToolsRonald Vincent GonzalesNo ratings yet

- Catalog Jacobs Chuck 02 12Document44 pagesCatalog Jacobs Chuck 02 12alfredohhbNo ratings yet

- Lecture 06 - Types of Permanent Mold Casting ProcessesDocument26 pagesLecture 06 - Types of Permanent Mold Casting ProcessesThe NoobNo ratings yet

- Document: Structural CalculationDocument209 pagesDocument: Structural CalculationStephen Mari CanoNo ratings yet

- Sion Engineering CompressedDocument404 pagesSion Engineering Compressedsagar1689No ratings yet

- 01.00 - CE - Slide Gate 2.0 X 2.0m - MotorizeDocument8 pages01.00 - CE - Slide Gate 2.0 X 2.0m - MotorizeJonesNo ratings yet

- Process That Drastically Decreases The Time Needed To Build A Shell For Investment Casting. Silicate That Is Added To The Stucco. MethodsDocument1 pageProcess That Drastically Decreases The Time Needed To Build A Shell For Investment Casting. Silicate That Is Added To The Stucco. MethodsKamal ThummarNo ratings yet

- AMPCO Metal Welding Materials CatalogueDocument28 pagesAMPCO Metal Welding Materials Cataloguejhax90No ratings yet

- Sabp L 003Document46 pagesSabp L 003Li PengNo ratings yet

- ISSF The Ferritic Solution EnglishDocument68 pagesISSF The Ferritic Solution EnglishdhurushaNo ratings yet

- FP 247 03 Sand Cast BronzesDocument4 pagesFP 247 03 Sand Cast BronzesnfcastingsNo ratings yet

- CSI - 2006-46 Service Tool Case For EVO-2Document1 pageCSI - 2006-46 Service Tool Case For EVO-2Alfonsus Toby PurnomoNo ratings yet

- Lame ItalyDocument48 pagesLame ItalyMohamed RaafatNo ratings yet

- The Best For The Best: Worldwide Corporation Worldwide CustomerDocument68 pagesThe Best For The Best: Worldwide Corporation Worldwide CustomerSAEFUDDIN SAEFUDDINNo ratings yet

- 20 - Reducciones Certificado UL, E19189Document6 pages20 - Reducciones Certificado UL, E19189Jesús David Almario GutiérrezNo ratings yet

- MET410 Fracture Mechanics Question PaperDocument1 pageMET410 Fracture Mechanics Question PaperAshish KumawatNo ratings yet

- Slide Plate Applications by Jerry Godina January 26, 2011: Assembly BasicsDocument2 pagesSlide Plate Applications by Jerry Godina January 26, 2011: Assembly BasicsprathapNo ratings yet

- Welding - Presentation of SPPDocument17 pagesWelding - Presentation of SPPDiego HernándezNo ratings yet

Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name Date

Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name Date

Uploaded by

S Gouda0 ratings0% found this document useful (0 votes)

8 views1 pageDodsal Pte Ltd provides a welding procedure specification for an ethylene project in Doha, Qatar. The specification outlines the materials, processes, parameters and qualifications for welding grade P91 steel pipe ranging from 4.76 to 36.52mm thick using gas tungsten arc welding and shielded metal arc welding. Key details include welding 5B grade P91, F91 and WP91 steel in the uphill position with gas shielding and multiple passes to meet hardness requirements under 241BHN.

Original Description:

Original Title

PP22 Rev.1

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentDodsal Pte Ltd provides a welding procedure specification for an ethylene project in Doha, Qatar. The specification outlines the materials, processes, parameters and qualifications for welding grade P91 steel pipe ranging from 4.76 to 36.52mm thick using gas tungsten arc welding and shielded metal arc welding. Key details include welding 5B grade P91, F91 and WP91 steel in the uphill position with gas shielding and multiple passes to meet hardness requirements under 241BHN.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

Download as xls, pdf, or txt

0 ratings0% found this document useful (0 votes)

8 views1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name Date

Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name Date

Uploaded by

S GoudaDodsal Pte Ltd provides a welding procedure specification for an ethylene project in Doha, Qatar. The specification outlines the materials, processes, parameters and qualifications for welding grade P91 steel pipe ranging from 4.76 to 36.52mm thick using gas tungsten arc welding and shielded metal arc welding. Key details include welding 5B grade P91, F91 and WP91 steel in the uphill position with gas shielding and multiple passes to meet hardness requirements under 241BHN.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

Download as xls, pdf, or txt

You are on page 1of 1

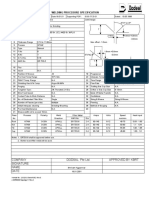

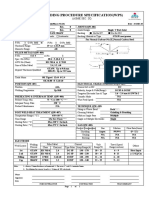

Dodsal Pte Ltd

Q-Chem Ethylene Project

Doha, Qatar

Job No : 7979/G2/010 WELDING PROCEDURE SPECIFICATION

1 7979/WPS/PP/22 Rev.1 Date:21.01.01 Supporting PQR : 0505-2B Dated : 30.04.00

2 Joint Design Refer Attachment Joint Design

3 Backing None

4 Joint Prep. Machining and/or Grinding

5 Base Metal Spec. 5B Gr.2

6 Base Metal A335 Gr P91, A182 F91, A234 WP91

Refer Attachment - 1

7 Pipe Dia Range All

8 Thickness Range 4.76 to 36.52mm (GTAW-8mm, SMAW-28.52mm)

9 Process GTAW SMAW

10 Type Manual Manual

11 F.No 6 4

12 A.No 5 5

13 S.F.A No. 5.28 5.5

14 AWS No. ER 90S-B9 E9015-B9 SMAW

14.26

GTAW

15 Flux N.A. N.A. 4.0

16 Insert N.A. N.A.

17 Position Of Groove All 18 Progression Uphill

19 Pre Heat Temp Range 200°C 20 Interpass Temp. 300°C

21 PWHT Temp. Range 732°C ± 28°C 22 Time Range 2.4 minutes/mm (2hrs minimum)

23 Shielding Gas & % Comp Argon 99.99% purity 24 Flow Rate Shielding 7-12 LPM (15-25 CFH)

Purging 10-15 LPM (21-31 CFH)

25 Purging Argon 99.99% purity 26 Trailling Gas Cup Size N.A.

27 Tungsten Type : 2% Thoriated Size Dia 2.4mm 28 Orifice or Gas Cup Size 8-13mm

29 Wire Feed Speed N.A. 30 Mode Of Metal Transfer N.A.

31 Contact Tube to Work Distance N.A. 32 Oscillations N.A.

33 No. of Electrodes/ Filler Wire Single 34 String & Weave String & Weave

35 Number of Passes (per side) Multiple 36 Peening Not Allowed

37 Initial/ interpass cleaning Grinding and or Brushing 38 Method of Gouging where unristricted access permits

roots shall be ground to sound

39 Pre Heat Maintenance Yes 40 metal & back welded

41 Weave width not to exceed 10mm for GTAW & 3.0 core wire dia for SMAW

Pass Process Polarity Weld Filler Metal Amps Volts Speed Remarks

No. Direction Trade Name Dia mm/min H. Input

Root GTAW DCEN UPHILL Bohler C9MV-1G 2.4 60-100 9-15 45-100 0.7 to 2.1

Hot GTAW DCEN UPHILL Bohler C9MV-1G 2.4 70-100 10-15 70-120 0.6 to 1.5

Fill 2.5/

(Multi) SMAW DCEP UPHILL Bohler Fox C9MV 3.2 60-160 20-25 60-120 1.1 to 2.1

Cap 2.5/

(Multi) SMAW DCEP UPHILL Bohler Fox C9MV 3.2 75-160 20-25 70-120 1 to 2.2

Notes 1,Purging to be maintained for Root and Hot pass.

2. PQR shows the thk. Deposited by GTAW is 4.0mm & 14.26mm by SMAW process.

3. Hardness shall not exceed 241BHN .

COMPANY DODSAL Pte Ltd. APPROVED BY KBRT

SIGNATURE

NAME Shrikant Ajgaonkar

DATE 21.01.2001

Format No : DOD/Q-Chem/F082 Rev 0

c:\DIR00001\wps\pp22 Rev.1.xls

You might also like

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document1 pageWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Format No: DOD/Q-Chem/F082 Rev 0 c:/DIR00001/wps/pp20-1Document1 pageWelding Procedure Specification: Format No: DOD/Q-Chem/F082 Rev 0 c:/DIR00001/wps/pp20-1S GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document1 pageWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document2 pagesWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument2 pagesWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document2 pagesWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument2 pagesWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- PP41 Rev.3Document1 pagePP41 Rev.3Ashish ChackoNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument2 pagesWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- PP34. Rev.1xlsDocument1 pagePP34. Rev.1xlsS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Format No: DOD/Q-Chem/F082 Rev 0 c:/DIR00001/wps/pp06Document1 pageFormat No: DOD/Q-Chem/F082 Rev 0 c:/DIR00001/wps/pp06S GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument2 pagesWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- 011 WPS ASME TOP F 2022 - Rev.0Document8 pages011 WPS ASME TOP F 2022 - Rev.0megantara maromNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document1 pageWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (1)

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document1 pageWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed LepdaNo ratings yet

- Form Wps JBL09-2011Document2 pagesForm Wps JBL09-2011fawad aliNo ratings yet

- Asme IxDocument1 pageAsme IxAxel Navarro AlbinesNo ratings yet

- Welding Procedure Specification (WPS) : Asme Sec Ix, 2017 Boiler and Pressure Vessel CodeDocument2 pagesWelding Procedure Specification (WPS) : Asme Sec Ix, 2017 Boiler and Pressure Vessel CodeNuwan RanaweeraNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document2 pagesWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed LepdaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- PP34. Rev.1xlsDocument1 pagePP34. Rev.1xlsS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document2 pagesWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Format No: DOD/Q-Chem/F082 Rev 0 c:/DIR00001/wps/pp20-1Document1 pageWelding Procedure Specification: Format No: DOD/Q-Chem/F082 Rev 0 c:/DIR00001/wps/pp20-1S GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document1 pageWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument2 pagesWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Experiment No 1 Introduction To Hand Tools: HacksawDocument16 pagesExperiment No 1 Introduction To Hand Tools: HacksawTamzid rahmanNo ratings yet

- Catalog-Crimson Oil ToolsDocument23 pagesCatalog-Crimson Oil ToolsTaras ByloNo ratings yet

- Techalloy 55Document1 pageTechalloy 55Muhammad FajriNo ratings yet

- HobartCatalog PDFDocument47 pagesHobartCatalog PDFalisyalalaNo ratings yet

- Steel TH 1Document79 pagesSteel TH 1Fraz AliNo ratings yet

- 3408 AGMWS Vol1 TA2 CleanDocument8 pages3408 AGMWS Vol1 TA2 CleanWong AlexNo ratings yet

- ThreeBond Magnet Bonding Epoxies FlyerDocument2 pagesThreeBond Magnet Bonding Epoxies FlyersuryaNo ratings yet

- Hand Book On Bearing Maintenance PDFDocument182 pagesHand Book On Bearing Maintenance PDFRakesh Jainwal100% (1)

- 2022 - ORG4801 - Examination Question Paper Jan - FebDocument20 pages2022 - ORG4801 - Examination Question Paper Jan - FebpriarlogisticsNo ratings yet

- PTC 072715 Nym Ex DCM 001Document77 pagesPTC 072715 Nym Ex DCM 001LOLA PATRICIA MORALES DE LA CUBANo ratings yet

- Akaki W2 3 by 1 (1st Payment)Document9 pagesAkaki W2 3 by 1 (1st Payment)Hiwot MeleseNo ratings yet

- Welding Metalwork Fabrication Services Sample ProposalDocument10 pagesWelding Metalwork Fabrication Services Sample ProposalDickson PhiriNo ratings yet

- Metal Cutting ToolsDocument12 pagesMetal Cutting ToolsRonald Vincent GonzalesNo ratings yet

- Catalog Jacobs Chuck 02 12Document44 pagesCatalog Jacobs Chuck 02 12alfredohhbNo ratings yet

- Lecture 06 - Types of Permanent Mold Casting ProcessesDocument26 pagesLecture 06 - Types of Permanent Mold Casting ProcessesThe NoobNo ratings yet

- Document: Structural CalculationDocument209 pagesDocument: Structural CalculationStephen Mari CanoNo ratings yet

- Sion Engineering CompressedDocument404 pagesSion Engineering Compressedsagar1689No ratings yet

- 01.00 - CE - Slide Gate 2.0 X 2.0m - MotorizeDocument8 pages01.00 - CE - Slide Gate 2.0 X 2.0m - MotorizeJonesNo ratings yet

- Process That Drastically Decreases The Time Needed To Build A Shell For Investment Casting. Silicate That Is Added To The Stucco. MethodsDocument1 pageProcess That Drastically Decreases The Time Needed To Build A Shell For Investment Casting. Silicate That Is Added To The Stucco. MethodsKamal ThummarNo ratings yet

- AMPCO Metal Welding Materials CatalogueDocument28 pagesAMPCO Metal Welding Materials Cataloguejhax90No ratings yet

- Sabp L 003Document46 pagesSabp L 003Li PengNo ratings yet

- ISSF The Ferritic Solution EnglishDocument68 pagesISSF The Ferritic Solution EnglishdhurushaNo ratings yet

- FP 247 03 Sand Cast BronzesDocument4 pagesFP 247 03 Sand Cast BronzesnfcastingsNo ratings yet

- CSI - 2006-46 Service Tool Case For EVO-2Document1 pageCSI - 2006-46 Service Tool Case For EVO-2Alfonsus Toby PurnomoNo ratings yet

- Lame ItalyDocument48 pagesLame ItalyMohamed RaafatNo ratings yet

- The Best For The Best: Worldwide Corporation Worldwide CustomerDocument68 pagesThe Best For The Best: Worldwide Corporation Worldwide CustomerSAEFUDDIN SAEFUDDINNo ratings yet

- 20 - Reducciones Certificado UL, E19189Document6 pages20 - Reducciones Certificado UL, E19189Jesús David Almario GutiérrezNo ratings yet

- MET410 Fracture Mechanics Question PaperDocument1 pageMET410 Fracture Mechanics Question PaperAshish KumawatNo ratings yet

- Slide Plate Applications by Jerry Godina January 26, 2011: Assembly BasicsDocument2 pagesSlide Plate Applications by Jerry Godina January 26, 2011: Assembly BasicsprathapNo ratings yet

- Welding - Presentation of SPPDocument17 pagesWelding - Presentation of SPPDiego HernándezNo ratings yet